Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Maintaining and repairing dies interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Maintaining and repairing dies Interview

Q 1. Explain the process of sharpening a worn die.

Sharpening a worn die is a crucial maintenance task that extends its lifespan and maintains product quality. The process depends heavily on the type of die and the nature of the wear. Generally, it involves using specialized grinding equipment to carefully remove small amounts of material from the working surfaces.

For example, with a progressive die used for stamping metal parts, we might use a surface grinder to restore the sharpness of punches and dies. This requires precision to avoid altering the die’s geometry. The process often involves multiple passes, with frequent inspections under magnification to ensure even material removal and avoid over-grinding. Before sharpening, it’s essential to thoroughly clean the die to remove any debris that could damage the grinding wheel or lead to uneven sharpening. After sharpening, the die undergoes a rigorous inspection to check for any irregularities.

Another example involves using electro-discharge machining (EDM) for intricate dies where traditional grinding might be too aggressive or risk damaging delicate features. EDM uses electrical sparks to erode material precisely, ideal for fine adjustments.

Q 2. Describe different types of die failures and their causes.

Die failures can stem from various issues, broadly categorized into:

- Fractures/Cracks: These often result from excessive stress, fatigue from repeated cycles, or inherent flaws in the material. For instance, a sudden impact or overloading can lead to cracking, while repeated bending stress can cause fatigue fractures.

- Wear and Tear: This is the most common type and involves gradual erosion of the die’s working surfaces due to friction and material removal. This often occurs on punches and the die cavity surfaces, leading to dimensional inaccuracies and decreased part quality. The severity depends on the material being worked, lubrication, and the die material itself.

- Deformation: This could involve bending, distortion, or even chipping of the die, usually due to impact, improper clamping, or excessive pressure during operation. Picture a punch bending slightly under excessive force, leading to part defects.

- Erosion/Corrosion: Certain die materials can be susceptible to chemical attack from the materials being processed, or from environmental factors. This leads to pitting and overall reduction in the die’s performance.

Understanding the cause of failure allows for preventive measures like selecting appropriate die materials, using better lubrication, or optimizing the stamping process.

Q 3. How do you identify and address die misalignment?

Die misalignment leads to parts with dimensional inconsistencies and potential damage to the die itself. Identification and correction requires a methodical approach.

We typically start with a visual inspection, checking for any obvious signs of misalignment. For instance, if a punch isn’t centered within the die cavity, it’ll be apparent. More precise methods involve using precision measuring instruments such as dial indicators or optical comparators. We carefully measure the distances and angles to identify the degree of misalignment.

Addressing misalignment can involve adjusting the die’s mounting system. This may require loosening and precisely repositioning the die within its holder using shims or adjusting bolts. If the misalignment is due to wear, then repair or replacement of worn components is necessary. For example, worn bushings might need to be replaced or adjusted to restore proper alignment. Finally, post-adjustment inspection is crucial to ensure the problem has been successfully resolved and the die operates correctly.

Q 4. What are the common methods for repairing cracked dies?

Repairing cracked dies is challenging and often requires specialized techniques. The approach depends on the severity and location of the crack.

- Welding: For smaller cracks in certain die materials (like steel), specialized welding techniques (e.g., TIG welding) might be used to close the crack. This requires great skill to avoid warping the die or creating further damage.

- Brazing: Similar to welding, but uses a filler metal with a lower melting point. It can be useful for repairing less severe cracks.

- Epoxy Repair: For smaller cracks in less critical areas, epoxy resin can be applied to fill the crack and strengthen the affected region. This isn’t a permanent solution and may require more frequent monitoring.

- Replacement: If the crack is severe or located in a critical area, replacing the damaged section or the entire die might be the most economical and reliable solution.

The choice of repair method depends on multiple factors including the severity of the crack, the type of die material, and the cost-benefit analysis of repair versus replacement.

Q 5. How do you inspect a die for wear and tear?

Regular die inspection is essential for preventing catastrophic failures. The process involves both visual and dimensional checks.

Visual inspection involves carefully examining the die’s surfaces under magnification to check for cracks, chipping, wear, and signs of erosion or corrosion. We often use magnifying glasses and sometimes even microscopes for detailed assessment. Dimensional checks use various precision measurement instruments such as micrometers, calipers, and optical comparators. This allows us to check for dimensional changes in punches and dies, ensuring they still conform to specifications.

During inspection, we create a detailed record of the findings, noting the type and location of any wear or damage. This information is crucial for scheduling maintenance and making decisions about repair or replacement.

Q 6. Explain the importance of proper die lubrication.

Proper die lubrication is paramount for extending die life and improving the quality of the finished parts. Lubrication reduces friction between the die and the workpiece, minimizing wear and tear. It also helps dissipate heat generated during the stamping process, preventing excessive wear or even die failure due to overheating.

Lubricants must be carefully chosen based on the materials being processed and the die material. For example, a water-soluble lubricant might be used for processing certain metals, while a more specialized oil-based lubricant is necessary for others. Lubricant application methods also matter. Some dies utilize centralized lubrication systems, while others require manual application. Inconsistent lubrication can lead to uneven wear and die damage. Proper lubrication practices significantly improve efficiency and reduce downtime associated with die failure and maintenance.

Q 7. Describe your experience with different die materials (e.g., steel, carbide).

My experience spans a variety of die materials, with a strong focus on steel and carbide.

Steel dies are widely used due to their relatively low cost and good machinability. However, they’re susceptible to wear, especially when working with harder materials. The type of steel chosen – tool steels like A2, D2, or even high-speed steel – heavily influences its performance and lifespan. Regular sharpening and maintenance are crucial for steel dies.

Carbide dies are significantly harder and more wear-resistant than steel dies. They provide longer lifespan and better surface finish for demanding applications, but are more expensive and challenging to machine. Carbide dies are particularly useful when processing very hard or abrasive materials. I’ve worked extensively with both materials, selecting the optimal choice based on application requirements and cost-benefit analysis. The choice often involves considering factors such as material hardness, desired precision, production volume, and overall cost of ownership.

Q 8. How do you troubleshoot a die that is producing defective parts?

Troubleshooting a die producing defective parts is a systematic process. It begins with careful observation of the defects themselves. What type of defect is it? Is it consistent across all parts, or sporadic? Knowing the nature of the defect – a burr, a crack, a mis-shape, an incomplete feature – narrows down the possible causes.

Next, I’d meticulously examine the die itself. This involves checking for wear and tear on punches and dies, looking for signs of damage like chipping, cracking, or bending. I’d also inspect the stripper plates, guides, and bushings for any misalignment or excessive wear. Sometimes, a seemingly minor issue like a slightly bent punch can cause significant defects. I might use measuring instruments like micrometers or calipers to ensure dimensions are within tolerance.

Then, I consider the material being used. Changes in material hardness or consistency can impact the outcome. If everything seems mechanically sound, I’d check the press settings, including the tonnage and speed. Incorrect settings can lead to part defects. Finally, I’d carefully document all findings, the steps taken to troubleshoot, and the ultimate solution implemented, to avoid repeating the same issue.

For example, once I was troubleshooting a progressive die producing parts with a consistent burr. After thorough inspection, I discovered that the punch’s cutting edge was slightly dull. A simple sharpening solved the problem immediately.

Q 9. What safety precautions do you take when maintaining and repairing dies?

Safety is paramount when maintaining and repairing dies. I always begin by ensuring the press is completely locked out and tagged out – this means the power is off, and the press is physically secured to prevent accidental operation. I use appropriate personal protective equipment (PPE), including safety glasses, gloves, and hearing protection. When handling sharp tools or heavy components, extra care is essential.

I also work in a well-lit and organized area to prevent accidents caused by slips, trips, or falls. I regularly inspect tools and equipment for damage before using them, and report any hazardous conditions immediately. Dies themselves can be heavy, so I use proper lifting techniques and equipment when necessary. If there are any concerns about specific die components such as high-pressure hydraulic systems, I work with other certified maintenance personnel following all applicable safety protocols.

Training is an integral part of safety. I keep up to date on all safety guidelines and participate in regular safety training programs.

Q 10. Describe your experience with preventative maintenance on dies.

Preventative maintenance is key to extending the lifespan of dies and preventing costly downtime. My preventative maintenance routine typically involves regular inspections of the die for wear and tear. I pay close attention to critical areas such as cutting edges, bushings, and guide pins. I use precision measuring tools to check for dimensional accuracy and ensure components are within tolerance.

Lubrication is a crucial part of my preventative maintenance. Proper lubrication reduces friction and wear, extending the life of moving parts. I use the appropriate lubricants for each component and ensure they’re applied correctly. I also regularly clean the die to remove chips, debris, and lubricants that have accumulated. This prevents buildup from interfering with the die’s operation and causing damage.

I keep detailed records of all preventative maintenance tasks, including the date, the work performed, and the condition of the die. This data helps me identify patterns and trends and make informed decisions about maintenance scheduling. In one instance, implementing a more frequent lubrication schedule on a progressive die significantly reduced wear and extended its life by several months.

Q 11. How do you document die maintenance procedures?

I document die maintenance procedures meticulously. My documentation includes detailed drawings and schematics of the die, showing all components and their specifications. I maintain a comprehensive log of all maintenance activities. This log includes the date, type of maintenance performed (e.g., preventative maintenance, repair), the parts replaced or repaired, and the time spent on each task.

The documentation also captures any issues or challenges encountered during maintenance, along with the solutions implemented. Photos and videos are frequently included to illustrate critical elements and repair procedures. I use a combination of digital and hard copy documentation, depending on the specific needs. This ensures that maintenance history is readily available and allows for easy analysis and troubleshooting in the future. This detailed documentation is crucial for training new personnel and ensures consistency in maintenance procedures.

Q 12. How do you handle emergency die repairs during production?

Emergency die repairs during production require a quick and efficient response. My first step is to assess the situation and determine the severity of the problem. If the defect is minor and can be corrected quickly without major disassembly, I might perform a temporary repair to keep production running. This might involve using a hand-held grinder to remove a small burr or adjusting the die slightly to correct misalignment.

However, if the damage is extensive, I might prioritize safety and temporarily shut down the press to perform the necessary repairs. This is where having detailed documentation and a readily available supply of spare parts is very important. I work quickly and efficiently, using all available resources to restore the die to full functionality as soon as possible. Communicating effectively with production staff is critical, keeping them updated on progress and estimated downtime.

Following the emergency repair, I would conduct a more thorough inspection and make any permanent repairs needed to avoid recurrence of the failure. I also review the incident to identify the root cause and implement preventative measures to reduce the risk of future emergencies.

Q 13. What software or tools do you use to maintain and repair dies?

I utilize various software and tools in my work. Computer-aided design (CAD) software helps me understand the die’s design and identify potential problem areas. I also use Computer-aided manufacturing (CAM) software for creating numerical control (NC) programs for machining die components. Measurement tools, such as micrometers, calipers, and optical comparators are essential for precise measurements and ensuring accuracy.

Specialized equipment such as grinders, milling machines, and lathes are used for machining and repairing die components. I frequently use a variety of hand tools such as wrenches, screwdrivers, and punches for assembly and disassembly. Software for managing preventative maintenance schedules and storing die maintenance records assists in tracking performance and facilitating timely interventions.

The specific software and tools used depend on the type of die and the complexity of the repair, but meticulous record-keeping ensures consistency and efficiency.

Q 14. Explain your experience with different types of die sets (e.g., progressive, compound).

I have extensive experience working with different types of die sets, including progressive, compound, and single-stage dies. Progressive dies are highly efficient for mass production, as they perform multiple operations in a single stroke of the press. Understanding their intricate sequences and timing is critical for maintenance. Compound dies perform multiple operations within a single die set, but unlike progressive dies, they don’t use a progressive feed mechanism. Their design often requires careful attention to the precise alignment of punches and dies.

Single-stage dies, on the other hand, perform a single operation per stroke. Although simpler in design, maintaining their accuracy and sharpness is still crucial. My experience encompasses repairing and maintaining all of these types of die sets, including troubleshooting and resolving problems related to their unique mechanisms. I am proficient in identifying and repairing issues specific to each type of die, such as ensuring proper feed mechanisms for progressive dies or precise alignment for compound dies.

This experience has allowed me to develop a strong understanding of the strengths and limitations of each die type, leading to informed decisions regarding maintenance and repair strategies, extending the operational life and optimizing production efficiency.

Q 15. How do you measure die dimensions accurately?

Accurately measuring die dimensions is crucial for ensuring consistent product quality and preventing costly downtime. We employ a variety of precision instruments depending on the die’s size and complexity. For example, calipers are used for measuring smaller features, while coordinate measuring machines (CMMs) provide highly accurate measurements of larger and more intricate components. CMMs offer 3D measurement capabilities, providing a complete dimensional picture.

The process involves several steps: first, we carefully clean the die to remove any debris that might interfere with accurate measurements. Then, we select the appropriate measuring instrument based on the die’s features. We always take multiple measurements at different points and orientations to account for potential variations. The data is then analyzed to identify any discrepancies and compare it to the original design specifications. If deviations exceed acceptable tolerances, corrective actions are taken, which might include die repair or replacement. For instance, if we find a progressive die punch is slightly out of alignment, we may use a die grinding machine to correct its position.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with die cleaning and storage procedures?

Die cleaning and storage are paramount to extending the lifespan of the tooling and maintaining precision. Our cleaning procedures involve carefully removing all debris, including metal chips, lubricants, and other contaminants. We use appropriate solvents and cleaning agents, always ensuring compatibility with the die material. For example, we use specialized brushes and compressed air to avoid scratching the die surface. Following cleaning, we apply a corrosion inhibitor to protect the die from rust and oxidation.

Storage is equally important. We store dies in controlled environments, typically climate-controlled rooms to minimize temperature and humidity fluctuations. Dies are individually wrapped or stored in protective cases to prevent damage or contamination. Larger dies are often stored on specially designed racks to facilitate easy retrieval and prevent damage from stacking. Proper labeling and documentation ensure easy identification and tracking of each die.

Q 17. Describe your experience with hydraulic press die maintenance.

My experience with hydraulic press die maintenance involves both preventative maintenance and addressing failures. Preventative maintenance includes regular lubrication of moving parts, checking for wear and tear, and ensuring proper alignment. We monitor hydraulic fluid levels and quality, and conduct regular inspections of the press itself to ensure it’s functioning correctly. This preventative approach reduces unexpected breakdowns and costly repairs.

When dealing with failures, I have experience troubleshooting a wide range of issues, such as hydraulic leaks, binding mechanisms, and broken components. Diagnosing the problem requires a systematic approach, starting with visual inspections and moving to more in-depth analyses as needed. For instance, a sudden drop in hydraulic pressure could indicate a leak in a hydraulic line, which requires immediate attention to prevent further damage. We frequently utilize pressure gauges and flow meters to pinpoint the source of these issues. Repair involves replacing faulty parts and ensuring proper reassembly and alignment. We also perform rigorous testing after any repair to ensure the die is functioning correctly before returning it to production.

Q 18. How do you determine the root cause of a recurring die problem?

Troubleshooting recurring die problems demands a methodical approach. I begin by gathering data on the frequency, nature, and circumstances of the problem. This usually involves reviewing production records, interviewing operators, and conducting thorough visual inspections of the die. I use a root cause analysis (RCA) method, such as the 5 Whys, to systematically drill down to the underlying cause.

For example, if a progressive die is repeatedly producing parts with burrs, I would investigate various possibilities: Is the punch dull? Is the die misaligned? Are the materials consistent? By repeatedly asking ‘why’ (Why are there burrs? Why is the punch dull? Why are the materials inconsistent?), I can trace the issue back to its root cause. This helps in developing effective solutions, such as sharpening the punch, realigning the die components, or investigating the materials supplier for inconsistencies. Implementing corrective actions and closely monitoring the die’s performance afterwards is crucial to prevent the problem from recurring.

Q 19. Explain your experience with different types of die coatings.

Various die coatings are used to enhance die performance and extend their lifespan. My experience encompasses several types, including chrome plating, titanium nitride (TiN), and diamond-like carbon (DLC) coatings. Chrome plating provides excellent wear resistance and corrosion protection, making it ideal for high-volume production. However, it can be brittle and susceptible to chipping under certain conditions.

TiN coatings offer excellent hardness and wear resistance, along with improved lubricity. They’re particularly useful in applications involving abrasive materials. DLC coatings, on the other hand, provide exceptional hardness, low friction, and chemical inertness. They’re a more advanced option, suitable for demanding applications requiring very high precision and extended tool life. The choice of coating depends on the specific application, the material being processed, and the desired performance characteristics. For example, a die used to stamp a high-strength steel would benefit from a durable coating like DLC or TiN, whereas a die used for softer materials might only require chrome plating.

Q 20. Describe your experience with using specialized tools for die repair (e.g., EDM, grinding).

I have extensive experience using specialized tools for die repair. Electrical Discharge Machining (EDM) is invaluable for creating complex shapes and modifying die components with high precision. EDM allows for precise removal of material, ideal for intricate repairs or creating complex features that would be difficult or impossible to achieve with traditional methods. For instance, we use EDM to repair damaged punch and die components.

Grinding is another crucial technique, used for sharpening punches, removing burrs, and correcting minor misalignments. Different types of grinding machines, such as surface grinders and cylindrical grinders, are selected depending on the specific task. For example, we use a surface grinder to ensure the precise flatness of a die surface. The choice of tool depends on factors such as material properties, required precision, and the extent of the repair. Each technique requires precise control and a thorough understanding of the machine’s capabilities to prevent damage to the die.

Q 21. What is your experience with die tryout and setup?

Die tryout and setup is a critical phase in the die-making process. It’s where the die is tested and adjusted to ensure it meets the required specifications. The process typically begins with a trial run to check for any issues such as misalignment, improper clearances, or material flow problems. This trial run involves running a smaller batch of parts, carefully inspecting each one for defects.

Based on the observations from the trial run, adjustments are made to the die. This might involve minor adjustments to the punch and die components, fine-tuning the press settings, or modifying the die’s setup within the press. We use various measuring instruments to check the dimensions of the produced parts and compare them to the design specifications. Iterative adjustments are made until the parts consistently meet the required quality standards. For example, if the parts are consistently undersized, we might adjust the punch dimensions or press settings. This meticulous process ensures that the die is producing parts that meet specifications before full-scale production.

Q 22. How do you maintain accurate records of die maintenance and repairs?

Maintaining accurate die maintenance records is crucial for maximizing die lifespan and minimizing downtime. I utilize a comprehensive, computerized Maintenance Management System (CMMS). This system allows for detailed logging of every inspection, repair, and preventative maintenance task. Each record includes the die’s identification number, date of service, type of work performed (e.g., sharpening, crack repair, component replacement), materials used, labor hours, and the technician’s signature. We also incorporate digital photography and sometimes even video recordings of significant repairs to document the process and the die’s condition before and after. This detailed record-keeping facilitates trend analysis, helping us identify potential problems and implement proactive maintenance strategies. For example, if we notice a particular die consistently requires sharpening after a certain number of press strokes, we can adjust the maintenance schedule to prevent premature wear.

In addition to the CMMS, we maintain a physical filing system with hard copies of critical records, ensuring data redundancy and accessibility even in case of system failure. This dual system provides a safety net and guarantees the long-term preservation of essential maintenance information.

Q 23. Explain your knowledge of various die types used in different manufacturing processes.

My experience encompasses a wide range of die types used in various manufacturing processes. I’m familiar with progressive dies, which perform multiple operations in a single stroke, significantly increasing production efficiency. These are commonly used for high-volume parts like automotive components. I’ve also worked extensively with compound dies, which combine multiple operations into a single die set, and lamination dies, which are specialized for creating layered composite structures.

- Progressive Dies: Imagine a stamping machine creating a complex part in one smooth motion; this is what progressive dies excel at. They’re particularly useful for mass production and intricate designs.

- Compound Dies: These dies perform two or more operations on a workpiece at the same time, resulting in reduced cycle times and increased productivity.

- Bending Dies: These are critical for forming sheet metal into specific shapes. I have expertise in maintaining and repairing dies used to bend metal into a wide variety of shapes and angles.

- Drawing Dies: I understand the intricacies of maintaining and repairing drawing dies, used to form cups, shells, and other deep-drawn parts, where precise tolerances are essential.

Furthermore, I have experience with dies used in forging, extrusion, and injection molding processes, each requiring specialized maintenance and repair techniques due to the unique materials and forces involved. My knowledge spans different material types as well, including steel, carbide, and even specialized alloys depending on the specific application.

Q 24. How do you ensure the longevity of a die?

Ensuring die longevity involves a multi-faceted approach encompassing preventative maintenance, proper operation, and skilled repair. Preventative maintenance is paramount. This includes regular inspections to detect wear and tear, lubrication of moving parts, and cleaning to remove debris that can cause damage. We use specific lubricants designed for the materials and operating conditions, ensuring they don’t react negatively with the die components. Proper die handling during installation and removal is also crucial to avoid damage. Operators are trained to follow specific procedures for die changes, minimizing the risk of mishandling.

Beyond preventative maintenance, prompt and effective repair is essential. When issues arise, a thorough assessment is performed to identify the root cause of the problem, rather than just addressing the symptom. For instance, if a die is experiencing premature wear, we investigate if there are machine setting issues or material defects contributing to the problem. This proactive approach prevents the issue from recurring. We regularly update our maintenance techniques based on the latest industry best practices and technological advancements.

Q 25. Describe your experience in working with different types of press machines.

My experience with press machines covers a broad spectrum of types and sizes, including mechanical, hydraulic, and pneumatic presses. I’m comfortable working with both single-action and multi-action presses, understanding the unique challenges each presents. I’m proficient in the safety protocols and maintenance requirements for each type. For instance, mechanical presses require regular lubrication and adjustment of linkages, while hydraulic presses demand attention to fluid levels, pressure settings, and seal integrity. Pneumatic presses require a thorough understanding of air pressure regulation and component wear. I’m also familiar with different control systems, from simple mechanical controls to sophisticated computer numerical control (CNC) systems. My experience also includes troubleshooting malfunctioning press machines and collaborating with electricians and other maintenance personnel when necessary, a skill that involves understanding electrical diagrams and safety procedures.

I’ve worked on presses ranging from small benchtop models used for prototyping to massive production presses capable of exerting hundreds of tons of force. This diverse experience has given me a broad understanding of various press mechanics, safety procedures, and maintenance needs.

Q 26. What are your methods for improving the efficiency of die maintenance processes?

Improving die maintenance efficiency involves a systematic approach. One key strategy is implementing a Preventative Maintenance (PM) program based on data analysis from our CMMS. By analyzing historical repair data, we can predict potential failures and schedule maintenance proactively, minimizing unexpected downtime. We use statistical methods to identify trends and patterns, helping us optimize maintenance schedules and resource allocation. For instance, if data shows a particular component frequently fails after a certain number of cycles, we can adjust the maintenance schedule to replace that component before failure.

Another strategy is improving the organization of our workshop. We’ve implemented a lean manufacturing approach, improving workflow efficiency and reducing unnecessary movement of dies and parts. This includes dedicated storage areas for dies, tools, and spare parts, easily accessible to technicians. We regularly review and refine our processes based on feedback from maintenance technicians, continuously seeking improvements in efficiency and effectiveness.

Q 27. How do you communicate effectively with other maintenance personnel and production staff?

Effective communication is vital in a maintenance setting. I prioritize clear and concise communication with both maintenance personnel and production staff. When communicating with maintenance personnel, I use precise technical terminology to ensure everyone understands the nature of the problem and the necessary repairs. I utilize shared digital platforms like the CMMS or shared document drives to keep all personnel updated on maintenance activities, work orders, and the status of repairs. This shared platform eliminates the need for constant email chains or phone calls and ensures information remains centralized and easily accessible.

With production staff, I emphasize clarity and simplicity. When explaining a planned shutdown or a potential delay due to die maintenance, I use plain language, avoiding jargon, and focusing on the impact on production schedules. Regular meetings and open communication channels are also essential for building strong working relationships and facilitating smooth problem-solving. I also actively listen to their concerns and feedback, creating a collaborative environment focused on addressing problems and maximizing uptime.

Key Topics to Learn for Maintaining and Repairing Dies Interview

- Die Design and Functionality: Understanding the various types of dies (progressive, compound, etc.), their components, and how they function within a manufacturing process. Consider the materials used and their properties.

- Preventive Maintenance Procedures: Developing and implementing regular inspection and maintenance schedules to identify potential problems before they cause significant downtime or damage. This includes lubrication, cleaning, and component checks.

- Troubleshooting and Repair Techniques: Diagnosing common die malfunctions (e.g., breakage, wear, misalignment) and applying appropriate repair methods, including using precision measuring tools and various repair techniques. Consider the impact of different repair choices on the die’s lifespan and performance.

- Die Material Selection and Properties: Understanding the characteristics of different die materials (e.g., steel, carbide) and how they relate to die life, cost, and performance in different applications. This includes hardness, wear resistance, and machinability.

- Safety Procedures and Regulations: Adhering to relevant safety protocols, including proper use of personal protective equipment (PPE) and safe handling of machinery and tools within a die maintenance environment. Understanding lockout/tagout procedures is crucial.

- Precision Measurement and Tooling: Proficiency in using various precision measuring instruments (e.g., micrometers, calipers) to accurately assess die dimensions and identify wear or damage. Knowing the use and maintenance of various hand and power tools used in die repair is essential.

- Documentation and Record Keeping: Maintaining detailed records of die maintenance, repairs, and inspections. Understanding how to use this information for preventative measures and continuous improvement.

Next Steps

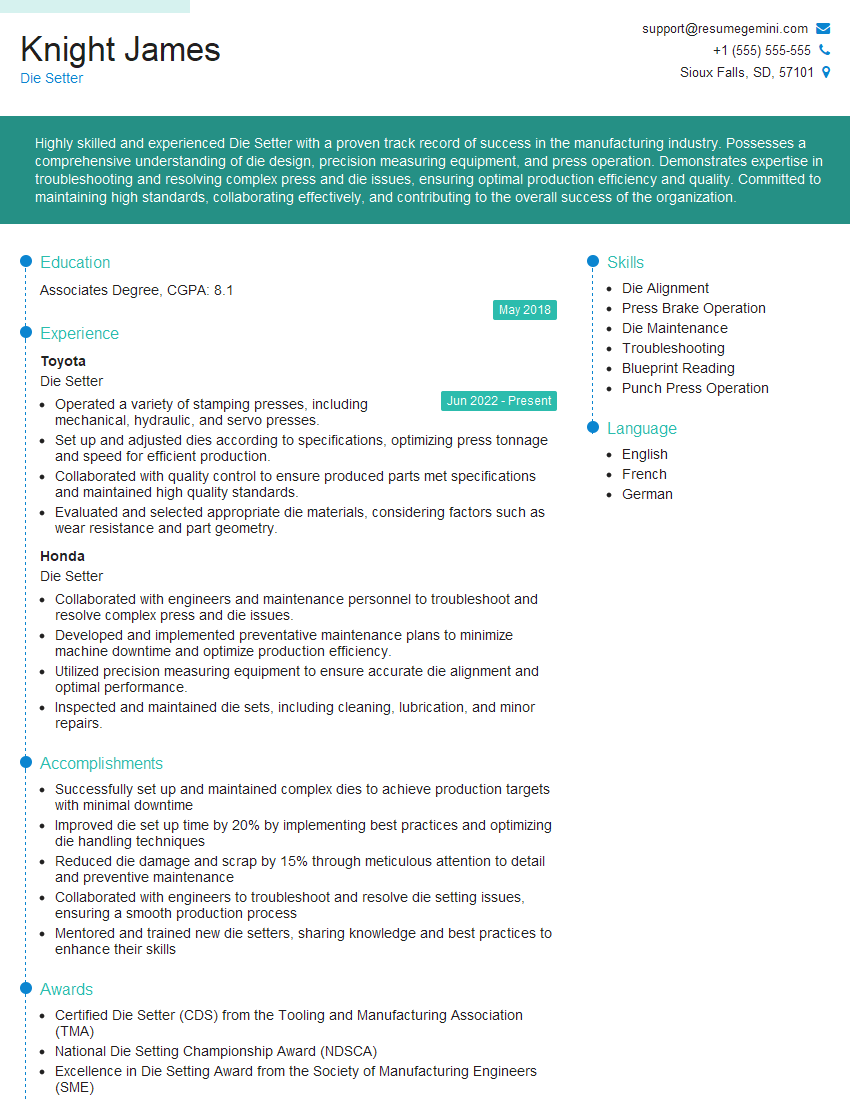

Mastering the maintenance and repair of dies is crucial for a successful and rewarding career in manufacturing. It demonstrates a valuable skill set highly sought after by employers. To maximize your job prospects, create an ATS-friendly resume that highlights your expertise and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume. We provide examples of resumes tailored to Maintaining and Repairing Dies to help guide your creation process. Let us help you showcase your skills and land your dream job.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good