Cracking a skill-specific interview, like one for OSHA and MSHA Regulations Compliance, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in OSHA and MSHA Regulations Compliance Interview

Q 1. Explain the difference between OSHA and MSHA regulations.

OSHA (Occupational Safety and Health Administration) and MSHA (Mine Safety and Health Administration) are both federal agencies responsible for worker safety, but they regulate different industries. OSHA sets and enforces safety and health standards for most private sector workplaces, along with some federal agencies. Think of it as the general safety watchdog for most workplaces you’d encounter daily – construction sites, factories, offices, etc. MSHA, on the other hand, focuses specifically on the mining industry, encompassing coal, metal, and other mineral mines. MSHA’s regulations are often more stringent due to the inherent dangers associated with mining operations. Essentially, if you work in a mine, MSHA is your primary safety regulator; otherwise, it’s likely OSHA.

For example, a construction company building a skyscraper would fall under OSHA jurisdiction, while a coal mine would fall under MSHA.

Q 2. Describe the General Duty Clause of OSHA.

The General Duty Clause of OSHA, found in Section 5(a)(1) of the Occupational Safety and Health Act, is a cornerstone of worker safety. It states that each employer has a general duty to furnish each of his employees a place of employment free from recognized hazards that are causing or are likely to cause death or serious physical harm. It’s like a catch-all provision for situations not specifically covered by other OSHA standards. If a hazard exists, and it’s recognized in the industry as dangerous, the employer must take steps to protect their workers, even without a specific OSHA standard addressing it.

For example, if a new piece of machinery is introduced with an obvious hazard not yet addressed by a specific OSHA regulation, the employer still has a responsibility under the General Duty Clause to mitigate that hazard (e.g., by providing guarding, training, etc.). OSHA can cite an employer for violating this clause if they fail to address a recognized hazard.

Q 3. What are the key components of an OSHA inspection?

An OSHA inspection typically involves several key components. It often starts with an opening conference where the inspector explains the purpose of the visit and the scope of the inspection. This might be a programmed inspection (random selection), an inspection triggered by a complaint, or an inspection following a fatality or serious accident.

Next comes the walkaround, where the inspector physically examines the workplace, observes worker practices, and reviews documentation. They’ll focus on areas of potential hazard and compliance with standards. They might interview employees to assess their understanding of safety procedures and any concerns they may have. Then there’s the closing conference, where the inspector discusses findings and any citations that will be issued, if any. The entire process is carefully documented, with a detailed report that includes any violations and the proposed penalties.

Imagine it as a thorough health check for your workplace – a detailed examination to identify weaknesses and areas for improvement in safety protocols.

Q 4. How do you conduct a job hazard analysis (JHA)?

A Job Hazard Analysis (JHA) is a systematic process to identify and assess hazards associated with a specific job task. It’s a proactive approach to prevent injuries and accidents. A typical JHA follows these steps:

- Select a job task: Choose a specific job or task that will be analyzed, for instance, operating a forklift.

- Identify potential hazards: Brainstorm all potential hazards associated with that task. For forklift operation, this could include collisions, falls, tipping, struck-by hazards, etc.

- Analyze the hazards: Determine the severity and likelihood of each hazard occurring. A collision, for example, might be a high-severity, moderate-likelihood hazard.

- Develop hazard controls: Identify and implement engineering controls (e.g., better lighting, improved forklift design), administrative controls (e.g., standardized procedures, training), and personal protective equipment (PPE) (e.g., high-visibility vests, safety glasses).

- Document the JHA: Create a written record of the analysis that details the identified hazards, risk assessments, and implemented controls. This record serves as a training tool and helps ensure consistency.

Regularly reviewing and updating the JHA is crucial, as conditions and procedures can change.

Q 5. What are the different types of PPE required in a construction environment?

The types of PPE required in a construction environment vary considerably depending on the specific task. However, common PPE includes:

- Hard hats: Protection against falling objects.

- Safety glasses or goggles: Eye protection from flying debris and chemicals.

- Hearing protection: Earplugs or muffs to reduce noise exposure.

- Respiratory protection: Dust masks, respirators for working in environments with hazardous air contaminants.

- High-visibility clothing: To increase worker visibility on construction sites.

- Gloves: Protection against cuts, abrasions, chemicals, and extreme temperatures.

- Safety footwear: Steel-toe boots to protect feet from falling objects and crushing hazards.

- Fall protection harnesses and lanyards: For work at heights.

The choice of PPE is crucial; it should be appropriate for the specific hazard, fit properly, and be used correctly. Employers have a responsibility to provide and ensure the proper use of PPE.

Q 6. Explain the hierarchy of hazard controls.

The hierarchy of hazard controls outlines a prioritized approach to managing workplace hazards. The goal is to eliminate hazards whenever possible, moving down the hierarchy only if elimination isn’t feasible.

- Elimination: Removing the hazard entirely is the most effective control. For example, replacing a dangerous chemical with a safer alternative.

- Substitution: Replacing the hazard with a less hazardous alternative. For instance, using a less toxic cleaning agent.

- Engineering controls: Modifying the workplace or equipment to reduce or eliminate the hazard. This might involve installing guards on machinery or improving ventilation.

- Administrative controls: Implementing work practices, training, and procedures to reduce exposure to hazards. This includes job rotation, safety training, and limiting exposure time.

- Personal Protective Equipment (PPE): Providing workers with PPE as a last resort when other controls are insufficient. This should always be coupled with other control measures.

Imagine it as a ladder – you start at the top (elimination) and only move down if necessary. The most effective solutions are always those that prevent the hazard from existing in the first place.

Q 7. What are the reporting requirements for workplace accidents under OSHA?

OSHA’s reporting requirements for workplace accidents depend on the severity of the incident. Fatalities and hospitalizations must be reported to OSHA within 24 hours. This is done using the OSHA 300A form (summary of work-related injuries and illnesses). For accidents that result in a lost workday, restricted work activity, or transfer to another job, reporting is required, depending on the state.

There are specific recordkeeping requirements, and failure to report or maintain accurate records can result in penalties. Employers must keep records of injuries and illnesses and make them available to employees upon request. Timely and accurate reporting is critical for identifying trends, preventing future accidents, and ensuring compliance with OSHA standards.

Think of it like an emergency response system for workplace incidents; quick and accurate reporting is essential for effective intervention and preventing further incidents.

Q 8. Describe your experience with OSHA Form 300.

OSHA Form 300 is the log of work-related injuries and illnesses. It’s a crucial component of OSHA’s recordkeeping requirements for employers with 10 or more employees in most industries. My experience encompasses not only completing the form accurately but also understanding its implications for injury prevention and proactive safety management. This involves:

- Data Entry and Accuracy: I’ve been responsible for accurately recording all work-related injuries and illnesses, ensuring consistent adherence to OSHA’s definitions and classification criteria. A single error can have significant consequences during an OSHA inspection.

- Trend Analysis: Beyond simply recording data, I utilize Form 300 data to identify trends and patterns in workplace injuries. This allows for targeted interventions and proactive safety improvements. For example, if we see a spike in back injuries, we might investigate whether proper lifting techniques are being consistently applied or if ergonomic improvements are needed.

- Compliance with OSHA Regulations: I have a thorough understanding of OSHA’s recordkeeping regulations, including the specific requirements for completing and maintaining Form 300, 300A, and 301. I know the nuances of what constitutes a recordable injury and how to properly investigate and classify incidents.

- Prevention Strategies: The data from Form 300 isn’t just for record-keeping; it’s a tool for improvement. By analyzing the data, we can identify areas for safety training, equipment upgrades, or process changes to prevent future injuries.

For example, in a previous role, we noticed a significant increase in hand injuries related to a specific machine. Analyzing Form 300 data revealed this trend, leading to the implementation of additional safety guards and retraining on proper machine operation, resulting in a substantial decrease in hand injuries the following year.

Q 9. How do you develop and implement a safety training program?

Developing and implementing a safety training program requires a systematic approach. It starts with a thorough needs assessment, identifying hazards and the skills and knowledge employees need to work safely. The program should then be designed, implemented, evaluated, and updated regularly.

- Needs Assessment: This involves identifying workplace hazards through job hazard analyses (JHAs), walk-through inspections, and reviewing incident reports (like those recorded on OSHA Form 300). This helps pinpoint specific training needs.

- Program Design: Based on the needs assessment, I develop a tailored training program including learning objectives, methods (lectures, demonstrations, hands-on practice, simulations), materials (presentations, manuals, videos), and assessment methods (tests, quizzes, observations).

- Implementation: The training is delivered to employees using appropriate methods. It’s crucial to make training engaging and interactive. I often incorporate real-world scenarios and case studies to improve understanding and retention. Regular refresher training is also essential.

- Evaluation: The effectiveness of the training program needs to be evaluated. Methods might include post-training tests, observation of employees on the job, and tracking injury rates. This data guides future improvements to the program.

- Updates: Training programs must be updated regularly to reflect changes in regulations, technology, or processes. New hazards or incidents might also necessitate training revisions.

For instance, if a new piece of equipment is introduced, specialized training on its safe operation is critical before employees use it. Similarly, if we see a pattern of injuries due to a particular hazard, the safety training program will be updated to address that hazard more explicitly.

Q 10. Explain the importance of lockout/tagout procedures.

Lockout/Tagout (LOTO) procedures are critical for preventing accidental energization of machinery or equipment during maintenance or repair. They are designed to isolate energy sources and ensure that equipment remains safely de-energized while work is being performed. The importance of LOTO cannot be overstated; failing to follow proper procedures can result in serious injury or fatality.

- Preventing Accidental Start-up: LOTO prevents unexpected energization of machines, preventing injuries from moving parts or electrical shocks.

- Protecting Workers: It protects maintenance and repair personnel from exposure to hazardous energy sources during servicing or repair.

- Compliance with OSHA: OSHA’s LOTO standard (29 CFR 1910.147) requires employers to develop and implement energy control procedures to protect employees.

- Minimizing Downtime: While LOTO procedures may temporarily stop production, the risk of a serious accident far outweighs the inconvenience of downtime.

Imagine a scenario where a worker is repairing a machine without properly locking out the power. If the machine unexpectedly starts, the consequences could be catastrophic. LOTO procedures, when correctly followed, create a system of checks and balances ensuring worker safety.

Q 11. What are the common causes of workplace injuries?

Workplace injuries stem from a variety of causes, often interacting in complex ways. Common causes include:

- Unsafe Acts: These are actions performed by employees that violate safety rules or procedures. Examples include failing to wear personal protective equipment (PPE), using equipment incorrectly, or taking shortcuts.

- Unsafe Conditions: These are physical hazards present in the workplace, such as inadequate lighting, slippery surfaces, exposed wiring, or poorly maintained equipment.

- Lack of Training: Inadequate training leads to employees performing tasks without the necessary knowledge or skills to do so safely.

- Human Factors: Factors such as fatigue, stress, distraction, and poor communication can increase the likelihood of accidents.

- Ergonomic Issues: Poor workplace design, improper lifting techniques, and repetitive motions can cause musculoskeletal disorders.

- Environmental Factors: Exposure to hazardous substances, extreme temperatures, or noise can cause injuries or illnesses.

Understanding these root causes is crucial for implementing effective prevention measures. A comprehensive approach considers both human factors and environmental conditions.

Q 12. How do you investigate and report workplace accidents?

Investigating and reporting workplace accidents is a critical process for learning from mistakes and preventing future incidents. My approach follows a structured methodology:

- Secure the Scene: The first step is to secure the accident scene to prevent further injury and preserve evidence.

- Gather Information: This includes interviewing witnesses, reviewing documentation (maintenance logs, training records, etc.), taking photographs and measurements, and examining the damaged equipment.

- Identify Root Causes: Through a thorough analysis of the gathered information, the underlying causes of the accident are identified using methods like the “5 Whys” technique to delve into the root cause beyond the initial event.

- Develop Corrective Actions: Based on the identified root causes, corrective actions are developed to prevent similar accidents from happening in the future. This might involve engineering controls (e.g., machine guards), administrative controls (e.g., improved procedures), or personal protective equipment (PPE).

- Report the Accident: The accident is reported according to OSHA regulations, using forms like OSHA Form 301. The report should detail the incident, root causes, and corrective actions taken.

- Follow-up: It’s crucial to follow up on corrective actions to ensure their effectiveness and make further adjustments if needed.

A well-documented investigation not only meets legal requirements but also contributes significantly to a safer workplace.

Q 13. Explain your understanding of confined space entry permits.

Confined space entry permits are crucial for protecting workers entering confined spaces, which are defined as areas with limited access, posing potential hazards. The permit system ensures a controlled and safe entry process.

- Hazard Identification: The permit identifies the hazards present in the confined space, such as oxygen deficiency, toxic gases, or engulfment hazards.

- Testing and Monitoring: Before entry, the confined space must be tested and monitored for atmospheric hazards. This often includes measuring oxygen levels, flammable gases, and toxic gases.

- Emergency Procedures: The permit outlines emergency procedures, including communication protocols, rescue plans, and emergency contact information.

- Authorized Personnel: Only authorized personnel who have received specific training on confined space entry are allowed to enter.

- Permit-Required Conditions: Certain conditions necessitate a confined space entry permit, such as the presence of hazardous atmospheres, engulfment potential, or other significant hazards.

- Log and Review: A log of confined space entries is maintained to track entries and monitor the safety of the process. Regular reviews of the permit system help ensure its effectiveness.

The permit-required system acts as a checklist ensuring that all necessary precautions are taken before workers enter. It is vital for preventing serious injury or fatality within confined spaces.

Q 14. Describe your experience with incident investigations.

My experience with incident investigations spans a variety of scenarios across different industries. I utilize a structured approach emphasizing root cause analysis and the development of preventative measures. This involves:

- Data Collection: Gathering comprehensive data—witness statements, photographic and video evidence, equipment logs, and relevant safety documentation—forms the foundation of any thorough investigation.

- Fact-Finding: This involves carefully analyzing all collected data to establish a clear timeline of events and identify contributing factors.

- Root Cause Analysis: Techniques such as the “5 Whys” or fault tree analysis help pinpoint the underlying causes of the incident, going beyond surface-level observations.

- Corrective Action Development: Once root causes are identified, I develop specific and measurable corrective actions to mitigate the risks that led to the incident. This might include engineering controls, administrative changes, or updated safety training.

- Reporting and Follow-up: A comprehensive report is prepared outlining the incident, root causes, corrective actions, and recommendations for prevention. Regular follow-ups ensure that corrective actions are implemented effectively and that their impact is evaluated.

For example, in one investigation, a seemingly simple fall from a ladder was traced back to inadequately maintained ladder rungs and a lack of regular safety inspections. This led to a revised inspection protocol and replacement of older ladders, preventing similar incidents.

Q 15. What are the specific regulations regarding fall protection?

Fall protection regulations under OSHA (29 CFR 1926 Subpart M) and MSHA (30 CFR Part 75) are crucial for preventing fatal falls. These regulations mandate the use of fall protection systems when working at heights exceeding six feet. This isn’t a rigid rule, however; certain exceptions apply, depending on the specific task and conditions.

Key aspects of fall protection include:

- Fall Arrest Systems: These systems aim to arrest a fall and prevent a worker from hitting the ground. They typically consist of a harness, anchorage point, and connecting device (e.g., lanyard, lifeline).

- Fall Restraint Systems: These systems prevent a worker from reaching a fall hazard in the first place. They involve the use of guardrails, safety nets, or personal fall arrest systems used to keep the worker from reaching the edge.

- Training: Comprehensive training is vital for all workers involved in fall protection. Training should cover the proper selection, use, inspection, and maintenance of fall protection equipment, as well as emergency procedures.

- Inspections: Regular inspections are mandatory. Equipment needs to be inspected before each use and any damage must be reported and remedied immediately.

- Competent Person: A competent person must oversee the implementation and maintenance of the fall protection program, ensuring its effectiveness.

Example: In a construction setting, a worker installing roofing needs a fall arrest system, including a harness, a lanyard connecting to an anchorage point, and potentially a lifeline system if traversing along the roofline. Without these, the worker faces a significant fall hazard.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure compliance with hazard communication standards?

Hazard communication, as outlined in OSHA’s Hazard Communication Standard (29 CFR 1910.1200), ensures workers are informed about the hazards associated with the chemicals they handle. Compliance demands a multifaceted approach.

- Chemical Inventory: Maintain a comprehensive inventory of all hazardous chemicals present in the workplace.

- Safety Data Sheets (SDS): SDSs provide detailed information on the hazards of each chemical, including its physical and chemical properties, health effects, handling precautions, and emergency response procedures. These must be readily accessible to all employees.

- Labeling: All containers of hazardous chemicals must be properly labeled with the chemical name, hazard warnings, and appropriate pictograms.

- Employee Training: Employees must receive training on the hazards associated with the chemicals they use, the information contained in SDSs, and safe handling practices.

- Written Hazard Communication Program: Employers are required to develop and implement a written hazard communication program that outlines their procedures for managing chemical hazards.

Example: In a manufacturing plant using solvents, each container must be clearly labeled. Employees must receive training on the hazards of the solvents and the proper procedures for handling them, including personal protective equipment (PPE) requirements and emergency response protocols. They must have easy access to the SDSs for those chemicals.

Q 17. Explain your experience with respiratory protection programs.

A comprehensive respiratory protection program is essential where employees might encounter airborne hazards. OSHA’s Respiratory Protection Standard (29 CFR 1910.134) provides the framework. My experience covers the entire lifecycle of such a program:

- Hazard Assessment: Thoroughly assessing the workplace to identify potential respiratory hazards is the first step. This includes determining the types of airborne contaminants present, their concentrations, and the duration of exposure.

- Respirator Selection: Choosing the right respirator is crucial. This depends on the specific hazard identified. The program must select respirators that provide adequate protection against the identified hazards. Fit testing is essential to ensure a proper seal.

- Training: Comprehensive training on the proper use, maintenance, and limitations of respirators is vital. Employees need to know when to use respirators, how to put them on and take them off correctly, and how to recognize and respond to respirator malfunctions.

- Medical Evaluation: Employees who use respirators must undergo a medical evaluation to determine their suitability for respirator use. This ensures the employee’s health is compatible with respirator usage.

- Maintenance and Cleaning: Proper respirator cleaning, storage, and maintenance are crucial to ensure their effectiveness and longevity.

Example: In a paint spraying operation, employees must wear appropriate respirators to protect against paint fumes. The program will necessitate choosing the correct respirator type, providing comprehensive training on its use and maintenance, and conducting regular fit testing. Medical evaluations will be performed.

Q 18. How do you conduct safety audits and inspections?

Safety audits and inspections are proactive measures to identify and correct potential hazards. My approach is systematic and thorough:

- Planning: Defining the scope of the audit, identifying areas to be inspected, and assembling a checklist based on relevant regulations and standards.

- Observation: Conducting a thorough visual inspection of the work areas, equipment, and processes. Paying close attention to details such as housekeeping, PPE usage, and adherence to safety procedures.

- Documentation: Meticulously documenting findings, including photographs and written descriptions of any observed hazards or non-compliance issues.

- Analysis: Analyzing the findings to identify trends, root causes of hazards, and areas needing improvement.

- Reporting: Providing a comprehensive report outlining the findings, recommendations for corrective actions, and a timeline for implementation.

- Follow-up: Following up to ensure that the recommended corrective actions have been implemented and the hazards have been mitigated.

Example: During a safety audit in a warehouse, I observed improper stacking of materials, leading to a potential collapse hazard. This was documented, and a recommendation for improved storage practices was issued, along with a timeline for implementation and responsible parties.

Q 19. What are the key aspects of a successful safety management system?

A successful safety management system is built upon several key pillars:

- Leadership Commitment: Strong leadership commitment is paramount. Top management must actively champion safety, allocate necessary resources, and clearly communicate safety expectations.

- Employee Participation: Actively involving employees in the safety process through participation in safety committees, hazard reporting programs, and safety training increases ownership and effectiveness.

- Hazard Identification and Risk Assessment: Regularly identifying and assessing potential hazards is vital. This helps prioritize risk reduction efforts and allocate resources effectively.

- Hazard Control: Implementing appropriate controls to eliminate or mitigate identified hazards. Controls may include engineering controls, administrative controls, and PPE.

- Training and Communication: Providing comprehensive safety training and clear communication to ensure everyone understands their roles and responsibilities in maintaining a safe workplace.

- Incident Investigation: Thoroughly investigating incidents to determine root causes and implement corrective actions to prevent recurrence.

- Continuous Improvement: Regularly reviewing and improving the safety management system to ensure its effectiveness and responsiveness to changing conditions.

Example: A successful safety management system in a manufacturing facility will involve regular safety meetings, job-specific safety training, a robust hazard reporting system, and a dedicated safety committee involving management and workers. The system will be regularly audited and improved based on ongoing performance data.

Q 20. Describe your experience with emergency response plans.

Effective emergency response plans are crucial for minimizing injury and damage during emergencies. My experience covers the development, implementation, and testing of these plans:

- Hazard Identification: Identifying all potential emergencies, such as fires, explosions, chemical spills, or natural disasters.

- Emergency Procedures: Developing detailed procedures for responding to each identified emergency, including evacuation plans, first aid procedures, and communication protocols.

- Training and Drills: Providing comprehensive training to employees on the emergency response plan and conducting regular drills to ensure everyone is familiar with the procedures.

- Communication: Establishing clear communication protocols, including alarm systems, emergency contact lists, and designated assembly points.

- Emergency Equipment: Ensuring adequate emergency equipment is available and readily accessible, such as fire extinguishers, first-aid kits, and emergency eyewash stations.

- Post-Incident Review: Conducting post-incident reviews to identify areas for improvement in the emergency response plan.

Example: A manufacturing facility will have a detailed emergency response plan, including procedures for fire response, chemical spills, and medical emergencies. The plan will involve regular drills, designated assembly points, and clear communication procedures.

Q 21. What are the specific MSHA requirements for underground mining?

MSHA regulations for underground mining (30 CFR Part 75) are extremely stringent due to the inherent hazards. Key requirements include:

- Ventilation: Maintaining adequate ventilation to control the buildup of harmful gases and dust.

- Ground Control: Implementing measures to prevent roof and rib falls, including regular inspections and support systems.

- Emergency Escapeways: Providing multiple, well-maintained escapeways to allow miners to safely exit the mine in case of an emergency.

- Lighting: Ensuring adequate illumination in all areas of the mine.

- Fire Prevention and Suppression: Implementing measures to prevent fires and provide for rapid suppression should a fire occur.

- Training: Providing miners with extensive training on mine safety procedures and emergency response.

- Maintenance: Regular and thorough maintenance of all mine equipment and infrastructure is essential to prevent accidents.

- Pre-shift and daily inspections: Miners must conduct thorough pre-shift and daily inspections before commencing work, actively looking for and reporting any potential hazards.

Example: A coal mine must have a detailed ventilation plan, regular roof bolting programs, multiple escapeways, and a comprehensive fire suppression system. Miners undergo specific training on hazard recognition and response protocols in this high-risk environment. Failure to comply can result in severe penalties and potential mine closure.

Q 22. What are the MSHA regulations regarding ventilation in mines?

MSHA’s ventilation regulations are paramount to ensuring a safe and breathable atmosphere in mines. They focus on controlling the air quality by removing harmful gases like methane and carbon monoxide, as well as controlling the spread of dust. The regulations mandate specific requirements based on the type of mine and the hazards present. For example, mines with significant methane emissions must have a robust ventilation system, including powerful exhaust fans, strategically placed airways, and continuous monitoring of methane levels. These systems are designed to dilute methane concentrations below the explosive limit. Further, the regulations stipulate regular inspections and maintenance to ensure the ventilation systems are functioning correctly. Failure to maintain adequate ventilation can lead to explosions, asphyxiation, and other severe incidents.

Imagine a coal mine; its ventilation system is not just about fresh air, but a lifeline. Every aspect, from the placement of ventilation shafts to the air velocity in the working areas, is meticulously designed to minimize dangerous gas accumulation and ensure the safety of miners.

Q 23. How do you identify and mitigate hazards in a mining environment?

Hazard identification and mitigation in mining requires a multi-faceted approach. It starts with a thorough understanding of the specific mine environment, including the geological formations, mining methods employed, and the materials being extracted. This often involves pre-shift inspections, regular monitoring (air quality, methane, etc.), and employing hazard-specific tools such as gas detectors and dust monitors. For example, if there’s a risk of roof collapse, regular roof bolting and support installation would be a key mitigation strategy. Similarly, if dust generation is high, then water sprays, dust suppression systems, and respirators become crucial mitigation elements. Risk assessments, based on historical data and potential scenarios, are fundamental in identifying and prioritizing hazards.

Imagine a scenario where loose ground conditions exist. A comprehensive hazard analysis would identify this risk. Mitigation then involves detailed geological studies, proper ground control techniques, and potentially using specialized equipment or modifying the mining method to reduce the risk of falls or cave-ins. This highlights the necessity for collaboration between mining engineers, safety officers, and miners to ensure a safe working environment.

Q 24. What is your understanding of the MSHA Part 46 Subpart G (Emergency Preparedness)?

MSHA Part 46 Subpart G, Emergency Preparedness, outlines the mandatory procedures and plans mines must have in place to respond effectively to various emergencies. This includes detailed emergency action plans, escapeway maintenance, emergency communication systems, mine rescue teams, and regular training exercises. The plan must address every conceivable emergency, from roof collapses and fires to equipment malfunctions and medical emergencies. It’s not just a document, but a living, evolving plan based on regular reassessments and incident investigations.

A critical aspect is the readily available and adequately maintained escapeways, which are often multiple escape routes. Each route is mapped, regularly inspected, and designed to allow for efficient and safe evacuation. Think of it like a well-rehearsed fire drill but on a much grander scale. Regular drills ensure that the plan is tested, that personnel knows their roles and escape routes, and that any shortcomings in the plan can be addressed.

Q 25. Describe your experience with mine rescue teams.

I’ve been involved in numerous mine rescue team operations, both as a team member and a trainer. My experience encompasses all aspects of rescue team function, including training and certification, equipment maintenance and familiarization, and participation in simulated and actual rescue operations. We undergo rigorous training in confined space rescue, gas detection and monitoring, first aid and CPR, and mine ventilation systems. The training ensures we are proficient in using specialized equipment, like self-contained breathing apparatus (SCBA) and rescue hoists. The emphasis is not just on technical skills but also on teamwork, decision-making under pressure, and efficient communication. The lives of miners depend on the proficiency of the rescue team; therefore, continual training and practice are critical.

One specific incident involved a simulated methane explosion scenario. The teamwork, precision in handling the rescue equipment, and our proficiency in navigating the mine, despite limited visibility, allowed for a successful rescue within the allotted time frame. This exercise underlined the importance of continuous practice and the significance of a well-coordinated and highly trained team.

Q 26. Explain the importance of pre-shift safety inspections in mining.

Pre-shift safety inspections are critical in preventing accidents. They are a systematic examination of the workplace before the start of work, ensuring that the environment is safe for operations. Miners and supervisors systematically inspect their designated areas, checking for hazards such as loose ground, damaged equipment, gas leaks, water accumulation, or electrical hazards. This proactive approach allows for immediate identification and mitigation of hazards before they cause injuries or accidents.

Think of it as a daily ‘health check’ for the mine. It ensures that potential issues, even minor ones, are identified and addressed promptly. A consistent pre-shift inspection program is vital for preventing accidents and promoting a strong safety culture within the mine.

Q 27. What are the MSHA regulations regarding dust control?

MSHA has stringent regulations on dust control in mines, primarily to mitigate the risks associated with silicosis and other respiratory illnesses. These regulations mandate the use of various dust control methods, depending on the type of dust and the mining operation. These can include water sprays, ventilation systems designed to dilute dust concentrations, and the use of respiratory protection equipment. Regular monitoring of dust levels is also mandatory, and the results must be carefully documented and analyzed. Compliance with these regulations often involves the use of specialized equipment, and regular maintenance is paramount.

For example, in underground coal mines, water sprays are frequently used to suppress dust at the source, while effective ventilation systems are vital to remove dust from the working areas. Furthermore, miners may be required to use respirators in high-dust areas to further protect their respiratory health.

Q 28. How do you ensure compliance with MSHA’s requirements for training and certification?

Ensuring compliance with MSHA’s training and certification requirements involves a multifaceted strategy. This starts with a comprehensive training program that covers all aspects of mine safety and health, including hazard recognition, emergency procedures, and the use of safety equipment. The training must be tailored to the specific job roles and hazards encountered in the mine. Following the training, individuals must undergo certification testing to demonstrate their understanding and competence. Records of all training and certification must be meticulously maintained and readily available for MSHA inspections. Furthermore, ongoing refresher training is crucial to keep miners updated on best practices and new regulations.

I always emphasize practical application in the training. We incorporate real-world scenarios and simulations to make the training relatable and effective. Regular audits and reviews of the training programs further guarantee continued adherence to the highest safety standards.

Key Topics to Learn for OSHA and MSHA Regulations Compliance Interview

- Hazard Identification and Risk Assessment: Understanding methods for identifying workplace hazards (OSHA 300/301 forms, MSHA Part 46, etc.) and conducting thorough risk assessments to determine appropriate control measures.

- Hazard Control Hierarchy: Applying the hierarchy of controls (elimination, substitution, engineering controls, administrative controls, PPE) to mitigate identified risks in practical scenarios. Be prepared to discuss examples where you’ve applied this hierarchy.

- OSHA and MSHA Recordkeeping: Familiarize yourself with the regulations surrounding incident reporting, recordkeeping, and maintaining accurate documentation for OSHA 300 logs and MSHA Part 50 requirements. Understanding the implications of inaccurate or incomplete records is crucial.

- Emergency Response Planning: Demonstrate your knowledge of developing and implementing emergency action plans, including evacuation procedures, first aid response, and communication protocols relevant to OSHA and MSHA standards. Be prepared to discuss practical examples.

- Inspections and Compliance Audits: Understanding the procedures involved in conducting workplace safety inspections, identifying violations, and ensuring compliance with relevant regulations. This includes familiarity with common inspection techniques and documentation.

- Permits-Required Confined Space Entry (OSHA): Thorough understanding of the procedures and regulations for safely entering and working in confined spaces. Knowing the roles and responsibilities of personnel involved is essential.

- Mine Safety and Health Administration (MSHA) Specific Regulations: This includes understanding the unique challenges and regulations relevant to underground and surface mining operations, such as ventilation, ground control, and equipment safety.

- Employee Training and Communication: Demonstrate your understanding of the importance of effective employee training programs to ensure compliance and a safe work environment. Be prepared to discuss methods for delivering and verifying training effectiveness.

- Regulatory Updates and Changes: Staying current on changes and updates to both OSHA and MSHA regulations is crucial. Show your commitment to ongoing professional development in this area.

Next Steps

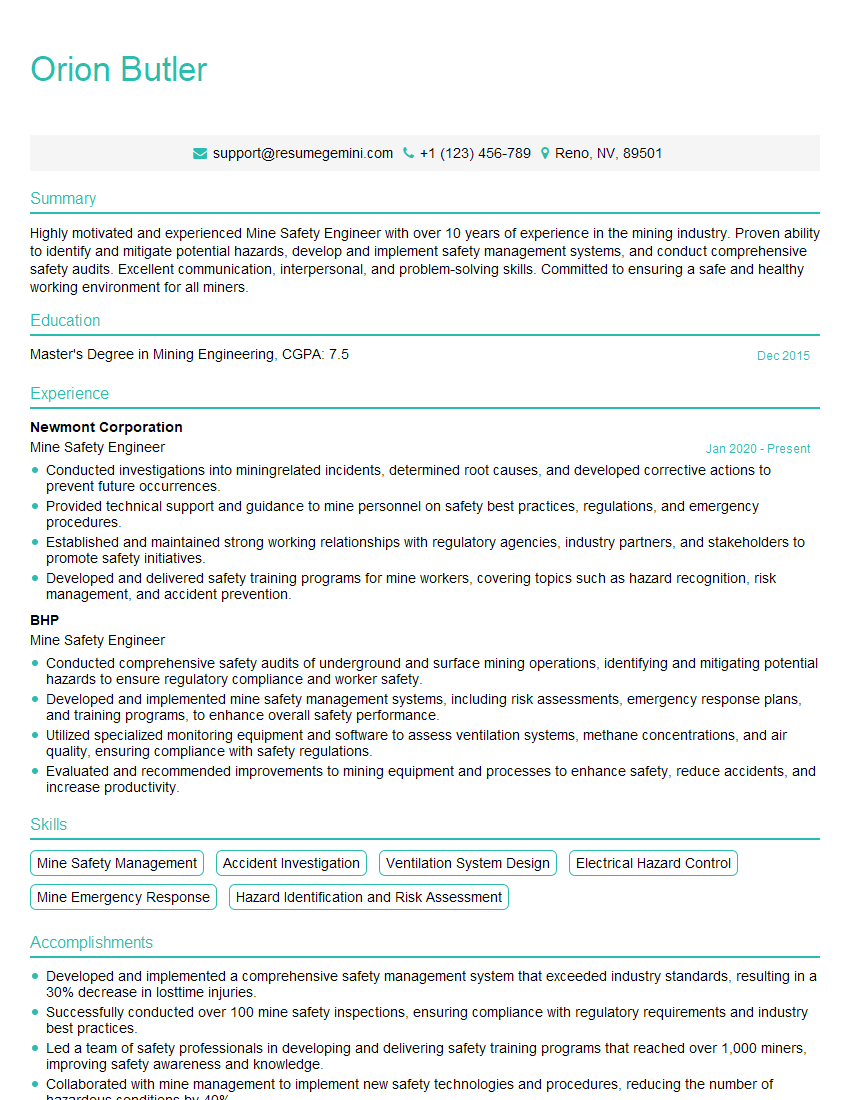

Mastering OSHA and MSHA Regulations Compliance significantly enhances your career prospects in safety and health management, opening doors to leadership roles and increased earning potential. To maximize your job search success, crafting an ATS-friendly resume is vital. ResumeGemini is a trusted resource that can help you build a powerful, professional resume that gets noticed by employers. ResumeGemini provides examples of resumes tailored to OSHA and MSHA Regulations Compliance to guide you. Take advantage of these resources to elevate your job search and secure your dream role.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good