Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Corrective Action Plans interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Corrective Action Plans Interview

Q 1. Describe your experience in developing and implementing Corrective Action Plans.

Throughout my career, I’ve been heavily involved in developing and implementing Corrective Action Plans (CAPAs) across various industries, primarily in manufacturing and healthcare. My experience encompasses the entire CAPA lifecycle, from initial problem identification and root cause analysis to corrective action implementation, verification, and preventative action planning. For example, in a previous role at a medical device company, I led the team that developed a CAPA addressing a recurring issue with a specific component’s failure rate. This involved collaborating with engineers, quality assurance personnel, and production staff to identify the root cause, implement corrective actions such as redesigning the component and enhancing the manufacturing process, and subsequently verifying the effectiveness of these changes. In another instance, at a pharmaceutical company, I was responsible for implementing a CAPA addressing deviations in a manufacturing process, which involved working with regulatory bodies to ensure compliance.

Q 2. Explain the steps involved in a typical Corrective Action Plan process.

A typical Corrective Action Plan process follows these key steps:

- Problem Identification: Clearly define the problem, including its impact and severity. This often involves documenting non-conformances, deviations, or customer complaints.

- Root Cause Analysis (RCA): Identify the underlying causes of the problem, not just the symptoms. This is crucial for preventing recurrence.

- Corrective Action Determination: Develop specific, measurable, achievable, relevant, and time-bound (SMART) actions to address the root cause(s).

- Implementation: Put the corrective actions into practice. This may involve process changes, training, equipment upgrades, or other improvements.

- Verification: Confirm that the implemented corrective actions have effectively resolved the problem and prevented recurrence. This often involves monitoring key metrics and conducting audits.

- Preventative Action Determination: Identify and implement actions to prevent similar issues from happening in the future. This might involve improving processes, enhancing training programs, or implementing new controls.

- Documentation: Thoroughly document every step of the CAPA process, including findings, actions taken, and verification results. This is essential for audit trails and continuous improvement.

Q 3. How do you identify the root cause of a problem requiring a CAPA?

Identifying the root cause is paramount to creating an effective CAPA. It’s about digging deeper than surface-level symptoms. We use a combination of techniques to thoroughly investigate the problem. We start by gathering all relevant data: production records, test results, customer complaints, and employee interviews. Then, we analyze this data, looking for patterns and trends that might point to the root cause. We avoid making assumptions and focus on objective evidence. For example, if a product consistently fails a certain test, we wouldn’t simply assume it’s a material defect. We’d investigate the entire process: supplier quality, storage conditions, manufacturing parameters, and testing procedures, systematically eliminating possibilities until we isolate the true root cause.

Q 4. What methods do you use for root cause analysis (e.g., 5 Whys, Fishbone diagram)?

Several powerful methods aid in root cause analysis. The 5 Whys is a simple yet effective technique where we repeatedly ask “Why?” to drill down to the root cause. For example, if a machine breaks down (problem), we might ask: Why did it break down? (Wear and tear). Why did it experience wear and tear? (Lack of lubrication). Why wasn’t it lubricated? (Maintenance schedule wasn’t followed). Why wasn’t the schedule followed? (Insufficient training). The final “Why” reveals a lack of training as a root cause. Another valuable technique is the Fishbone diagram (Ishikawa diagram). This visually organizes potential causes categorized by factors like people, methods, machines, materials, environment, and measurement. It’s particularly helpful in brainstorming sessions involving multiple stakeholders, allowing for a collaborative approach to root cause identification.

Q 5. How do you prioritize multiple CAPAs?

Prioritizing multiple CAPAs requires a systematic approach. We typically use a risk-based prioritization matrix, considering factors like the severity of the problem, the likelihood of occurrence, and the potential impact on the business or patients (in healthcare settings). A high-severity, high-likelihood problem would naturally take precedence over a low-severity, low-likelihood issue. We might use a scoring system to quantify these factors and rank CAPAs accordingly. For instance, a critical problem resulting in a product recall would be prioritized over a minor cosmetic defect. Furthermore, regulatory requirements and deadlines heavily influence prioritization. In short, it’s a balance of urgency and impact.

Q 6. How do you ensure the effectiveness of implemented corrective actions?

Ensuring the effectiveness of implemented corrective actions requires rigorous verification and validation. We monitor key performance indicators (KPIs) related to the problem after implementing corrective actions. For example, if the CAPA addressed a high defect rate, we would closely track the defect rate post-implementation. Regular audits and reviews are also crucial to verify that the corrective actions are consistently followed and are producing the desired results. If the problem persists or recurs, we must revisit the root cause analysis and corrective actions, possibly requiring further investigation and refinement of the CAPA.

Q 7. How do you measure the success of a Corrective Action Plan?

Measuring the success of a CAPA is achieved through several key metrics. A reduction in the frequency or severity of the problem is the most direct indicator of success. For instance, if a CAPA aimed to reduce customer complaints, a significant decrease in the number of complaints would indicate effectiveness. Other metrics could include improved process yields, reduced downtime, increased product quality, improved employee satisfaction, and enhanced regulatory compliance. We regularly review these metrics and document our findings, demonstrating the long-term impact and sustainability of the CAPA. Effective CAPAs not only solve immediate problems but also contribute to a culture of continuous improvement within the organization.

Q 8. Describe a situation where a CAPA failed. What went wrong, and what did you learn?

One CAPA failure I encountered involved a recurring issue with a medical device’s sterilization process. We implemented a CAPA that focused solely on retraining the sterilization technicians. While the retraining improved individual technique, we failed to address the underlying problem: inconsistencies in the sterilization equipment’s calibration. The problem recurred because the root cause wasn’t properly identified. We thought we’d solved the issue, but we only addressed a symptom. What we learned was the critical importance of a thorough root cause analysis (RCA) before implementing any corrective action. A proper RCA should involve data analysis, 5 Whys questioning, and input from all relevant stakeholders to get to the heart of the problem, not just surface-level solutions.

Moving forward, we implemented a new process that involved a multi-disciplinary team, including engineers, technicians, and quality assurance personnel. This team employed a structured RCA methodology, meticulously documenting findings, and ensuring that all possible contributing factors were considered. We also incorporated regular equipment calibration checks and automated alerts for any deviations from established parameters. This comprehensive approach prevented similar failures from reoccurring.

Q 9. How do you involve stakeholders in the CAPA process?

Stakeholder involvement is paramount to a successful CAPA. Think of a CAPA as a team effort – it’s not a solo act. We employ a multi-stage approach. Firstly, during the initial investigation phase, we identify all impacted stakeholders. This might include production staff, quality control, engineering, regulatory affairs, and even external vendors if the problem involves a supplier. We leverage meetings and structured communication channels to ensure everyone’s perspectives are included in the root cause analysis.

During the corrective action development stage, we actively solicit input on proposed solutions. We use techniques like brainstorming sessions and surveys to gather diverse ideas and ensure buy-in from all relevant parties. Finally, throughout the implementation and verification phase, regular updates and feedback loops keep stakeholders informed of progress, challenges, and any necessary adjustments. This transparent and participatory process guarantees a shared understanding and accountability throughout the entire CAPA lifecycle.

Q 10. How do you document a Corrective Action Plan?

Proper documentation is the backbone of a robust CAPA system. We use a standardized template that ensures all critical information is captured consistently. The documentation must clearly and concisely define the problem, outlining the non-conformance, its impact, and the affected products or processes. A detailed root cause analysis, including evidence and data supporting the findings, is crucial.

The proposed corrective actions, preventative actions (to prevent recurrence), and assigned responsibilities are meticulously outlined. Verification and validation steps, including specific metrics and timelines for completion, are defined. Finally, the documentation includes a record of all completed actions, review dates, and any necessary revisions. We use a digital system that allows for version control and audit trails. This ensures the integrity and traceability of the entire CAPA process. Think of the documentation as a story that tracks the problem, its solution, and the steps taken to prevent its return.

Q 11. What are the key performance indicators (KPIs) you use to monitor CAPA effectiveness?

We track several KPIs to measure CAPA effectiveness. These include the percentage of CAPAs closed within the defined timeframe, the recurrence rate of similar issues, the time taken to complete the root cause analysis, and the effectiveness of implemented corrective actions. We also monitor customer complaints related to the issue that initiated the CAPA. These metrics are collected and analyzed regularly to identify areas for improvement in our CAPA process itself.

For example, a high recurrence rate might indicate deficiencies in the root cause analysis or the effectiveness of the corrective actions implemented. A long time to closure may indicate process bottlenecks or a lack of resources. These insights drive continuous improvement in our overall quality management system.

Q 12. How do you ensure CAPA compliance with regulations (e.g., FDA, ISO)?

Ensuring CAPA compliance with regulations like FDA 21 CFR Part 820 and ISO 13485 requires a rigorous and documented approach. This starts with a thorough understanding of the specific requirements applicable to our industry and products. We establish procedures that align with these regulations, including clear roles and responsibilities, documented processes, and regular audits. Our CAPA system is designed to meet the regulatory requirements for investigation, corrective action, preventative action, verification, and record-keeping.

We conduct internal audits regularly and participate in external audits to validate our compliance. We maintain a robust document control system, ensuring that all CAPA-related documents are readily accessible, version-controlled, and archived according to regulatory requirements. Compliance isn’t a one-time event, it’s an ongoing commitment that involves continuous monitoring and improvement of our CAPA system.

Q 13. How do you handle CAPAs that require cross-functional collaboration?

Cross-functional collaboration is essential for handling complex CAPAs, especially those involving multiple departments or external partners. We use a project management approach, assigning a CAPA team leader with clear authority and responsibility. The team consists of representatives from all relevant functions, ensuring a broad range of perspectives and expertise. We utilize collaborative tools like shared document repositories, project management software, and regular team meetings to facilitate effective communication and coordination.

Clear communication protocols, including defined roles, responsibilities, and escalation paths, are essential. Regular status meetings track progress, address roadblocks, and ensure that all team members are aligned with the CAPA objectives. A well-defined communication plan is critical for efficient collaboration and a successful resolution.

Q 14. What software or tools have you used to manage CAPAs?

Throughout my career, I’ve used various software and tools to manage CAPAs. Initially, we relied on spreadsheets and shared network drives, but this approach quickly became cumbersome and lacked the necessary traceability and reporting features. Currently, we utilize a dedicated quality management system (QMS) software, which streamlines the entire CAPA lifecycle. This software facilitates the creation, tracking, and closure of CAPAs, providing automated workflows, notifications, and dashboards for monitoring progress.

Features like audit trails, version control, and integrated reporting functionalities are crucial for ensuring regulatory compliance. The software also allows for seamless integration with other quality-related systems, providing a comprehensive view of our quality management system. The choice of software depends on the complexity of our operations and regulatory requirements. The key is selecting a system that supports efficient CAPA management and enhances overall quality.

Q 15. Explain the difference between corrective actions and preventive actions.

Corrective Actions (CAs) address existing problems, focusing on fixing the immediate issue. Preventive Actions (PAs), on the other hand, anticipate and prevent future problems. Think of it like this: a CA is like fixing a flat tire, while a PA is like ensuring your tires are properly inflated and rotated to prevent flats in the future.

- Corrective Action: Addresses a nonconformance that has already occurred. For example, if a batch of product fails a quality test, the CA would involve investigating the failure, identifying the root cause, and rectifying the defective batch. This might include discarding the bad batch and implementing immediate process adjustments.

- Preventive Action: Prevents nonconformances from occurring. In the same example, a PA might be to implement a new testing procedure to catch potential problems earlier in the manufacturing process or to update equipment to improve precision and reduce error rates.

Both CAs and PAs are crucial components of a robust Corrective Action Preventive Action (CAPA) system. They work in tandem to ensure product quality and process improvement.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you prevent CAPAs from recurring?

Preventing CAPA recurrence requires a multi-pronged approach that goes beyond simply fixing the immediate problem. It’s about understanding the ‘why’ behind the issue and implementing lasting solutions.

- Thorough Root Cause Analysis: Don’t just treat the symptoms; dig deep to find the underlying causes using tools like 5 Whys, Fishbone diagrams, or Fault Tree Analysis.

- Effective Corrective Actions: Implement actions that directly address the root cause(s) identified. These actions should be clearly defined, assigned to specific individuals with deadlines, and verified for effectiveness.

- Preventive Actions: Develop and implement actions to prevent similar issues from happening again. This might involve process improvements, employee training, equipment upgrades, or changes to work instructions.

- Robust Documentation: Maintain detailed records of the entire CAPA process, including the initial problem, the investigation, the implemented actions, and the effectiveness verification. This documentation is critical for future reference and continuous improvement.

- Regular Monitoring and Review: Regularly review the effectiveness of implemented actions. Are the issues truly resolved? Are there any signs of recurrence? This ongoing monitoring allows for timely adjustments and prevents future problems.

- Employee Engagement: Encourage employees to report potential issues and participate in the CAPA process. A culture of continuous improvement is crucial for preventing recurrences.

For instance, if a recurring issue is due to inadequate employee training, a PA would be to develop and implement a comprehensive training program, including regular refresher courses and competency assessments.

Q 17. How do you communicate CAPA progress and results to management?

Communication is vital for successful CAPA management. I typically use a combination of methods to keep management informed.

- Regular Status Reports: I provide concise, regular reports (weekly or bi-weekly, depending on urgency) outlining the progress of each open CAPA. These reports include key milestones, timelines, and any roadblocks encountered.

- Management Meetings: I present updates in management meetings, highlighting critical CAPAs and their impact on overall quality and compliance. This allows for real-time discussion and decision-making.

- Dashboards and Metrics: I utilize dashboards to visually track CAPA performance metrics, such as the number of open CAPAs, time to resolution, and recurrence rates. This provides management with a high-level overview of the CAPA system’s effectiveness.

- Formal Documentation: All CAPA progress and results are meticulously documented, including the effectiveness verification of implemented actions. This documented evidence is crucial for audits and demonstrating compliance.

The key is to tailor the communication approach to the audience and the specific CAPA. Critical or high-risk CAPAs warrant more frequent and detailed communication than low-risk issues.

Q 18. Describe your experience with different types of CAPA investigations.

My experience encompasses a wide range of CAPA investigations, including those related to:

- Manufacturing Processes: Investigating deviations in manufacturing processes, such as equipment malfunctions, incorrect material usage, or deviations from standard operating procedures.

- Product Quality: Analyzing customer complaints, product failures, or out-of-specification results to identify root causes and implement corrective actions.

- Laboratory Procedures: Examining errors in laboratory testing, calibrations, or data handling to ensure accuracy and reliability.

- Supplier Issues: Investigating problems related to supplier quality, including nonconforming materials or late deliveries.

- Compliance Issues: Addressing compliance violations, such as deviations from regulatory requirements or internal policies.

Each investigation utilizes appropriate tools and techniques based on the nature of the problem. For instance, a statistical analysis might be employed for manufacturing deviations, while a root cause analysis (like 5 Whys) might be used for more complex issues.

Q 19. How do you handle situations where the root cause of a problem is unclear?

When the root cause is unclear, a systematic and thorough investigation is crucial. I typically employ the following approach:

- Data Gathering: Collect as much relevant data as possible, including production records, test results, witness statements, and maintenance logs.

- Brainstorming and Team Discussions: Engage a cross-functional team to brainstorm potential root causes. Diverse perspectives are invaluable in uncovering hidden issues.

- Root Cause Analysis Tools: Use various root cause analysis tools, such as the 5 Whys, Fishbone diagrams, or Fault Tree Analysis, to systematically investigate potential causes and eliminate unlikely scenarios.

- Process Mapping: Visually map out the affected process to identify potential bottlenecks or areas of weakness.

- Data Analysis: Use statistical tools to analyze data and identify patterns or trends that could indicate the root cause.

- Expert Consultation: If necessary, seek the expertise of external consultants or specialists to gain a deeper understanding of the issue.

It is important to document the investigation process thoroughly, even if the root cause remains elusive. This documentation allows for a more informed decision-making process regarding interim corrective actions and further investigation.

Q 20. How do you ensure that CAPAs are implemented within defined timelines?

Ensuring timely CAPA implementation involves careful planning, clear communication, and effective monitoring.

- Prioritization: Prioritize CAPAs based on their severity and potential impact. Critical issues requiring immediate attention should be addressed first.

- Clear Timelines: Establish realistic timelines for each stage of the CAPA process, from investigation to implementation and effectiveness verification.

- Responsibility Assignment: Assign ownership and responsibility for each task to specific individuals or teams.

- Regular Monitoring: Regularly monitor progress against the established timelines and identify any potential delays or roadblocks.

- Escalation Procedures: Establish clear escalation procedures for issues that are not resolved within the allocated timeframe.

- Project Management Tools: Employ project management tools (like Gantt charts or Kanban boards) to track progress and manage tasks effectively.

For example, a Gantt chart can provide a visual representation of the timeline and dependencies for various tasks associated with the CAPA, enabling better monitoring and management of deadlines.

Q 21. How do you manage CAPAs that involve multiple departments or teams?

Managing CAPAs involving multiple departments or teams requires a collaborative approach and strong leadership.

- Cross-Functional Team: Establish a cross-functional team with representatives from all relevant departments. This ensures that everyone has a voice and contributes their expertise.

- Clearly Defined Roles and Responsibilities: Clearly define the roles and responsibilities of each team member to avoid confusion and overlaps.

- Regular Team Meetings: Hold regular team meetings to discuss progress, address challenges, and make decisions collaboratively.

- Centralized Communication: Utilize a centralized communication platform (e.g., shared document repository or project management software) to ensure all team members have access to the latest information.

- Effective Leadership: Strong leadership is crucial to coordinate efforts, resolve conflicts, and ensure the successful implementation of the CAPA.

Think of it like building a house: various teams (electricians, plumbers, carpenters) work independently but collaboratively to complete the project on time. The same principles apply to multi-department CAPAs. Effective communication and clear roles are essential for a successful outcome.

Q 22. How do you balance the urgency of corrective actions with the need for thorough investigation?

Balancing the urgency of corrective actions with thorough investigation is crucial for effective CAPA management. Think of it like treating a patient – you need to address immediate symptoms (urgency) while also diagnosing the underlying cause (thorough investigation) to prevent recurrence. A rushed solution might provide temporary relief but fail to address the root problem.

My approach involves a structured, risk-based prioritization. We use a matrix to categorize issues based on severity and likelihood of recurrence. High-severity, high-likelihood issues receive immediate attention with interim actions to mitigate risks while the full investigation progresses. Lower-priority issues are addressed systematically, ensuring thorough investigation without delaying critical actions. For example, if a critical machine malfunctions causing a production halt, we’d implement immediate corrective actions (e.g., switching to a backup) while simultaneously launching a comprehensive investigation into the root cause of the failure.

This process ensures a balanced approach, using tools like Fault Tree Analysis (FTA) or 5 Whys to delve deep into the root cause while effectively controlling immediate risks.

Q 23. What is your experience with CAPA review and closure processes?

My experience with CAPA review and closure processes is extensive. I’ve been involved in every stage, from initial identification of nonconformances through to verification of effectiveness. I’ve worked with various QMS frameworks like ISO 9001, ISO 13485, and GMP, which all have slightly different requirements, but the core principles remain the same.

A typical process I follow involves:

- Review of the proposed CAPA: Assessing the adequacy of the proposed corrective and preventive actions to address the root cause and prevent recurrence. This includes reviewing the effectiveness of the proposed actions and ensuring they are feasible and practical.

- Verification of Implementation: Ensuring that the CAPA is implemented as planned. This often involves audits, reviews of documented changes and monitoring implementation timelines.

- Effectiveness Verification: This is the crucial step demonstrating that the implemented CAPA has achieved its intended result. Data analysis is key here – trends, metrics, and other relevant evidence should demonstrate that the problem has been resolved and is unlikely to reoccur.

- Documentation and Closure: Meticulous documentation of all steps, including decisions made, evidence gathered, and verification results. Once effectiveness is verified, the CAPA is formally closed.

I’ve successfully led CAPA reviews resulting in significant improvements in product quality, process efficiency and reduced nonconformances. For example, in a previous role, we implemented a new training program addressing a recurring issue with product defects. Post-training, we saw a 75% reduction in defect rates, demonstrating the effectiveness of our CAPA.

Q 24. How familiar are you with different quality management systems (QMS)?

I am very familiar with various Quality Management Systems (QMS). My experience spans ISO 9001 (general quality management), ISO 13485 (medical devices), and GMP (Good Manufacturing Practices) standards. I understand the unique requirements of each and how they impact CAPA processes. For instance, ISO 13485 places a greater emphasis on risk management within CAPA processes, reflecting the higher regulatory scrutiny in the medical device industry.

Beyond the specific standards, I’m comfortable working within any QMS framework that emphasizes a structured approach to problem-solving and continuous improvement. This includes understanding documentation requirements, audit trails, and management review processes specific to each system. My experience allows me to seamlessly adapt my approach to any QMS, ensuring effective CAPA management within its specific context.

Q 25. Describe your experience with using data analysis to inform CAPA development.

Data analysis is the cornerstone of effective CAPA development. It allows us to move beyond anecdotal evidence and understand the true root cause of problems.

I have extensive experience using various data analysis techniques to inform CAPA development. This includes:

- Statistical Process Control (SPC): Identifying trends and patterns in data to pinpoint areas needing improvement.

- Failure Mode and Effects Analysis (FMEA): Proactively identifying potential failure modes and their impact, allowing us to implement preventive actions.

- Root Cause Analysis (RCA): Using tools like the 5 Whys, fishbone diagrams, and fault tree analysis to delve deep into the root causes of nonconformances.

For example, using SPC charts on defect rates, I was able to identify a seasonal trend in a particular type of defect. This led to an investigation which revealed the impact of temperature and humidity on a specific component of the manufacturing process. The CAPA involved implementing environmental controls to mitigate the issue, leading to a significant reduction in defects.

Q 26. How do you ensure the CAPA documentation is auditable and traceable?

Ensuring auditable and traceable CAPA documentation is paramount. It not only facilitates effective CAPA management but also demonstrates regulatory compliance and supports continuous improvement efforts.

My approach involves the following key elements:

- Unique Identification Numbers: Each CAPA is assigned a unique identifier for easy tracking and retrieval.

- Version Control: All documents are version-controlled to maintain a clear audit trail of changes made.

- Electronic Documentation System: Using a secure, electronic documentation system ensures easy access, version control, and prevents loss of data.

- Detailed Records: Maintaining complete records of all activities undertaken, from initial reporting to final closure, including dates, names of personnel involved, decisions made, and evidence gathered.

- Cross-referencing: Linking CAPA documentation to other relevant documents such as nonconformances reports, investigations, and corrective action records.

This structured approach ensures that the entire CAPA process is transparent, easily auditable, and fully traceable.

Q 27. How do you handle resistance to implementing CAPAs?

Resistance to implementing CAPAs can stem from various sources, including lack of understanding, resource constraints, or fear of change. Addressing this requires a combination of diplomacy, collaboration, and clear communication.

My approach involves:

- Clearly Communicating the Benefits: Highlighting the positive impact of the CAPA on safety, quality, efficiency, or cost savings.

- Involving Stakeholders: Engaging individuals involved in the process early on to gain buy-in and address concerns. This might involve workshops, open forums, or individual discussions.

- Addressing Concerns: Actively listening to and addressing concerns raised by stakeholders. This can involve finding alternative solutions or providing additional resources.

- Phased Implementation: If significant changes are involved, implementing the CAPA in phases can reduce resistance and allow for feedback and adjustments.

- Leadership Support: Securing support from management to demonstrate the importance of the CAPA and address potential roadblocks.

For example, I once encountered resistance to a CAPA requiring significant changes to a well-established work process. By actively involving the team in the design and implementation of the solution, and demonstrating the clear benefits through data-driven analysis, I successfully overcame resistance and ensured smooth implementation.

Key Topics to Learn for Corrective Action Plans Interview

- Understanding the CAPA Process: Learn the fundamental steps involved in creating and implementing a Corrective Action Plan, from identifying the root cause to verifying effectiveness.

- Root Cause Analysis Techniques: Familiarize yourself with various methods like the 5 Whys, Fishbone diagrams, and Fault Tree Analysis to effectively pinpoint the origin of problems.

- Defining Effective Corrective Actions: Explore strategies for developing actions that are specific, measurable, achievable, relevant, and time-bound (SMART).

- Preventive Action Planning: Understand how to design preventative measures to avoid similar issues from recurring in the future.

- Documentation and Reporting: Master the crucial aspects of documenting the entire CAPA process, including tracking progress and reporting results.

- Regulatory Compliance and Industry Standards: Gain knowledge of relevant regulations and industry best practices for CAPA implementation (e.g., FDA, ISO).

- Data Analysis and Interpretation: Learn how to use data to identify trends, assess effectiveness of actions, and support decision-making within the CAPA process.

- Communication and Collaboration: Understand the importance of clear and effective communication among stakeholders involved in the CAPA process.

- Risk Assessment and Prioritization: Learn to assess the risks associated with identified issues and prioritize CAPA efforts accordingly.

- Continuous Improvement and Process Optimization: Understand how CAPA contributes to a culture of continuous improvement and process optimization within an organization.

Next Steps

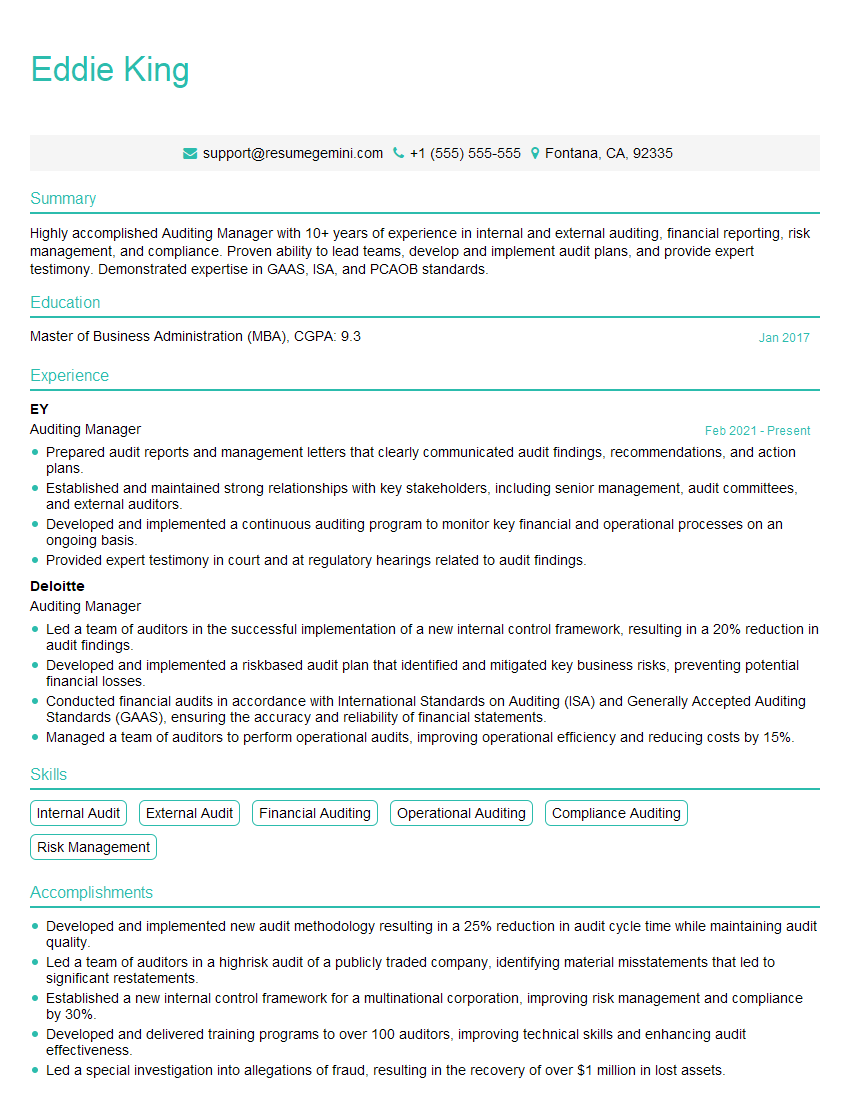

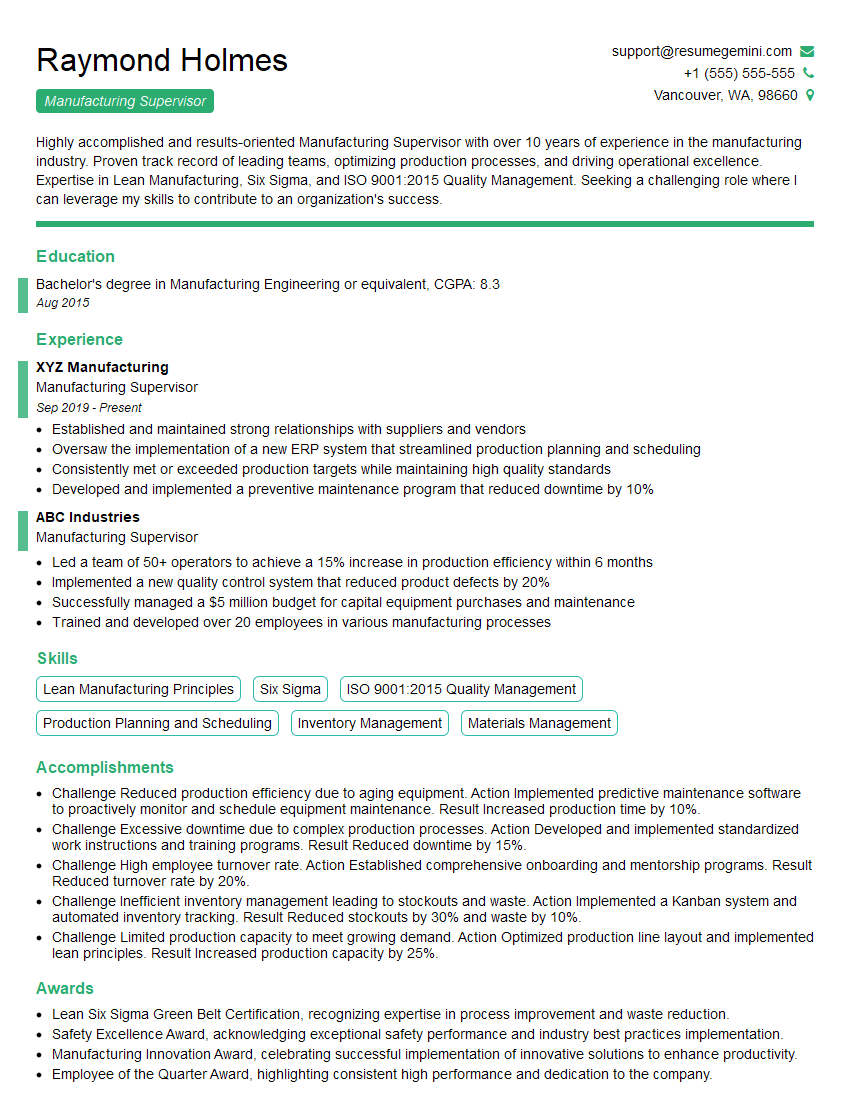

Mastering Corrective Action Plans significantly enhances your problem-solving skills and demonstrates your commitment to quality and continuous improvement – highly valued attributes in many industries. This expertise will open doors to a wider range of opportunities and faster career progression. To maximize your job search success, focus on creating a strong, ATS-friendly resume that effectively highlights your CAPA skills. ResumeGemini is a trusted resource to help you build a professional and impactful resume tailored to your experience. Examples of resumes specifically tailored for candidates with Corrective Action Plan experience are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good