Unlock your full potential by mastering the most common Asphalt Paving Inspection interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Asphalt Paving Inspection Interview

Q 1. What are the key components of a successful asphalt paving project?

A successful asphalt paving project hinges on meticulous planning and execution across several key areas. Think of it like baking a cake – you need the right ingredients and process to achieve a perfect result. These components include:

Proper Design: This involves selecting the right asphalt mix design, considering factors like traffic volume, climate, and subgrade conditions. A poorly designed mix is like using the wrong flour for a cake – it simply won’t work.

Quality Materials: Using high-quality aggregates, asphalt binder, and any additives is crucial. Imagine using spoiled eggs in your cake – the final product will be compromised.

Adequate Subgrade Preparation: A stable subgrade is the foundation. Poor compaction or unsuitable soil will lead to cracking and failure, much like a cake that collapses because the oven temperature was wrong.

Effective Compaction: Achieving the optimal density is critical for durability and performance. Think of it as ensuring the cake is baked evenly – any gaps lead to weakness.

Skilled Workforce: Experienced paving crews ensure proper placement and compaction techniques. A skilled baker knows exactly when the cake is done.

Quality Control/Quality Assurance (QC/QA): Regular testing and inspection throughout the process guarantee that the project meets specifications. This is like carefully checking the recipe and the ingredients as you’re making the cake.

Q 2. Describe the different types of asphalt binders and their applications.

Asphalt binders are the glue that holds the aggregate together in an asphalt mixture. Different types cater to various needs. Here are a few:

Penetration-graded Asphalt Cements (PG): These are the most common type, classified by their penetration grade (a measure of hardness). A higher penetration grade indicates a softer binder, suitable for colder climates, while a lower grade is used in warmer climates. Think of it like choosing the right oil for your car engine – the viscosity needs to be appropriate for the temperature.

Performance-graded Asphalt Binders (PG): These are specified based on performance requirements, accounting for factors like temperature susceptibility and aging. They offer better durability and performance compared to penetration-graded binders. It’s like using a special blend of ingredients to make your cake last longer and taste better.

Polymer-modified Asphalt Binders: Adding polymers to the asphalt binder enhances its properties, increasing its durability, flexibility, and resistance to cracking. This is similar to adding special additives to your cake mix to improve its texture and taste.

The choice of binder depends on the project requirements, climate, and desired lifespan of the pavement.

Q 3. Explain the importance of aggregate gradation in asphalt mixtures.

Aggregate gradation refers to the distribution of particle sizes in the asphalt mixture. It’s crucial for achieving a dense, stable, and durable pavement. Think of it as building a brick wall – you need different sizes of bricks to fill all the gaps and create a strong structure. Poor gradation leads to voids in the mixture, weakening the pavement and making it susceptible to damage.

A well-graded mixture has a proper balance of coarse, fine, and filler materials, minimizing voids and maximizing density. This is determined using sieve analysis, where the aggregate is sieved through a series of sieves of different sizes. The results are plotted on a gradation curve, which helps determine if the mixture meets specifications. An ideal gradation curve shows a consistent distribution of particle sizes, ensuring optimal compaction and performance.

Q 4. How do you determine the optimal asphalt content for a specific project?

Determining the optimal asphalt content, also known as the optimum asphalt binder content (OABC), is essential for achieving the desired pavement properties. It’s found through laboratory testing, typically using the Marshall Mix Design method or similar procedures.

The process usually involves preparing several asphalt specimens with varying asphalt contents. These specimens are then subjected to various tests, including stability, flow, air voids, and voids filled with asphalt. The OABC is the asphalt content that provides the best combination of these properties, typically maximizing stability while maintaining acceptable air voids and voids filled with asphalt. This ensures the pavement is strong enough to withstand traffic loads while maintaining flexibility and resistance to damage. It’s a balance between strength and flexibility – too much asphalt can lead to rutting, while too little can lead to cracking.

Q 5. What are the common defects found in asphalt pavements, and how are they identified?

Numerous defects can occur in asphalt pavements. These are identified through visual inspection and sometimes more advanced techniques. Common defects include:

Cracking: This can manifest as alligator cracking (interconnected cracks), longitudinal cracking (parallel to the road’s centerline), transverse cracking (perpendicular to the centerline), or fatigue cracking (a network of small cracks). Cracks indicate weakness in the pavement structure.

Rutting: This is a deformation in the wheelpaths, characterized by the pavement sinking under heavy loads. Rutting suggests insufficient compaction or poor mix design.

Pot Holes/Ravelling: These are areas where the asphalt surface has deteriorated, exposing the underlying layers. This often indicates poor compaction, inadequate drainage, or material degradation.

Bleeding/Flushing: Excess asphalt binder comes to the surface, creating a slick and potentially dangerous condition. It signifies that too much asphalt binder was used or that the pavement’s temperature was too high during construction.

Identification involves a systematic visual inspection, noting the type, location, and severity of the defects. More advanced techniques such as ground-penetrating radar (GPR) may be used to identify subsurface issues.

Q 6. Describe the different methods for testing asphalt density.

Several methods exist for testing asphalt density, each with its own advantages and limitations:

Nuclear Density Gauge: This non-destructive method uses gamma rays to measure the density in situ. It’s quick and efficient but requires specialized equipment and trained personnel. It’s like using a sophisticated scanner to see inside the cake without cutting it.

Core Sampling and Laboratory Testing: This involves extracting cylindrical cores from the pavement and determining the density in a laboratory setting using water displacement or other methods. This is more accurate than in-situ methods but is destructive and more time-consuming. It’s like carefully cutting a piece of cake and analyzing its density.

Sand Cone Method: This is a field method used to determine the in-situ density. It involves excavating a small hole, weighing the excavated material, and then filling the hole with a known volume of sand. It is less precise than other methods.

The choice of method depends on the project requirements, budget, and desired level of accuracy.

Q 7. Explain the significance of compaction in asphalt paving.

Compaction is the process of removing air voids from the asphalt mixture to achieve the desired density. It’s absolutely critical for achieving a durable and long-lasting pavement. Think of it as pressing down on your cake batter to remove air bubbles before baking – it ensures a smoother and more stable result.

Proper compaction ensures the pavement’s strength, stability, and resistance to deformation under traffic loads. Insufficient compaction leads to reduced strength, increased permeability (allowing water to enter, leading to damage), and increased susceptibility to rutting and cracking. Achieving optimal density depends on factors such as the asphalt mixture design, the type of compaction equipment, and the weather conditions. Compaction is monitored throughout the paving process using density tests.

Q 8. What are the standard specifications for asphalt paving (e.g., AASHTO)?

Standard specifications for asphalt paving are crucial for ensuring quality and consistency. These specifications are often based on guidelines from organizations like the American Association of State Highway and Transportation Officials (AASHTO). AASHTO publishes detailed standards (e.g., AASHTO MP 1, various materials specifications) that cover various aspects, from material properties (like aggregate gradation and asphalt binder properties) to construction methods (like compaction requirements and thickness tolerances). These specifications dictate the acceptable range for parameters like asphalt binder content, air voids, density, and gradation. For example, AASHTO MP 1 details the various tests required to ensure quality control and assurance. The specific standard employed may vary based on the project location and regulatory requirements, but the core principles remain the same: achieving a durable and long-lasting pavement structure. In essence, these specifications serve as the blueprint for a successful asphalt paving project.

Q 9. How do you interpret asphalt pavement test results?

Interpreting asphalt pavement test results is paramount to ensuring the quality of the finished product. These results provide insights into whether the pavement meets the specified requirements. For example, a low air void content might indicate excellent compaction, while a high air void content might suggest insufficient compaction. Similarly, a Marshall stability test measures the strength of the asphalt mix; low stability indicates a weak mix, prone to rutting. Other key tests include the nuclear gauge for density, which measures in-place density; the Hveem Stabilometer, evaluating the strength and resistance to deformation; and various tests evaluating the properties of the asphalt binder itself, like penetration and viscosity. The goal is to compare the obtained test results against the specified limits defined in the project specifications. If the results are outside the acceptable range, it signals potential issues that necessitate corrective action, such as adjusting the mix design or construction techniques. Think of it like a health check-up for the pavement – these tests diagnose its overall health and identify areas requiring attention.

Q 10. What are the different types of asphalt pavement designs?

Asphalt pavement designs vary depending on traffic loading, subgrade conditions, and project requirements. Common types include:

- Flexible pavements: These consist of multiple layers, with each layer playing a specific role in load distribution. A typical flexible pavement might consist of an asphalt concrete surface layer, a base layer (e.g., crushed stone), and a subbase layer. The different layers act together, much like a layered cake, each layer contributing to overall strength and stability.

- Rigid pavements: These typically utilize concrete slabs for the wearing course. While we are focusing on asphalt, it’s important to understand the context.

- Full-depth asphalt pavements: These employ a single layer of asphalt concrete directly on the prepared subgrade, suitable for low-volume roads.

- Open-graded friction courses: These have larger aggregate voids to provide better drainage and skid resistance, often used as surface layers.

The choice of design involves careful consideration of factors like traffic volume, climate, and the strength of the underlying soil. The design process often employs sophisticated analytical tools and empirical models to predict the pavement’s long-term performance under various loading conditions.

Q 11. Explain the process of asphalt pavement construction from start to finish.

Asphalt pavement construction is a meticulous process. It starts with:

- Subgrade preparation: This involves grading, compacting, and stabilizing the existing soil to provide a stable base for the pavement.

- Base and subbase construction: These layers are constructed according to the design specifications, often using crushed stone or other granular materials and compacted to the required density.

- Asphalt mix production: The asphalt mix (a blend of aggregates and asphalt binder) is produced in a hot-mix asphalt plant according to the specified design.

- Placement and compaction: The hot mix asphalt is transported to the site and placed in layers using paving equipment (pavers). This is followed by thorough compaction using rollers to achieve the specified density and air void content. This is a crucial step, often requiring multiple passes with different types of rollers to achieve the optimal density.

- Finishing and curing: The pavement surface is then finished to the desired profile and allowed to cool and cure.

- Quality control testing: Throughout the construction process, various tests are performed to ensure the pavement meets the specified requirements.

Each step requires careful attention to detail. Imagine building a house – each step is crucial for the overall stability and longevity of the final structure; asphalt paving is no different.

Q 12. Describe the role of quality control in asphalt paving.

Quality control (QC) in asphalt paving is crucial for ensuring the finished pavement meets the specified standards and performs as intended. This involves a systematic approach to monitoring and controlling all aspects of the construction process. This starts with the incoming materials – aggregates and asphalt binder – with checks on their properties against specifications. During mix production, temperature and composition are monitored and recorded. On-site QC involves regular testing of the mix’s properties such as density and air voids using devices like nuclear gauges and density testing methods. The thickness and smoothness of the pavement are measured using profilometers and other surveying tools. Documentation and record-keeping are critical, forming a traceable record of every step and test result. Regular reporting keeps all stakeholders updated about the project’s progress and conformity to standards. A robust QC plan helps prevent costly rework and ensures a high-quality, durable pavement.

Q 13. How do you handle non-conforming work on an asphalt paving project?

Handling non-conforming work requires a systematic approach. First, the non-conformance needs to be clearly identified and documented, including the location, type of defect, and extent of the problem. Next, the cause of the non-conformance should be investigated to prevent recurrence. This might involve analyzing test results, reviewing construction methods, or examining material properties. Corrective action is then implemented – this could involve removing and replacing the non-conforming work, adjusting construction techniques, or modifying the mix design. The corrective actions should be documented and verified through testing to confirm they resolve the issue. Finally, a formal acceptance process ensures that the corrected work meets the project specifications. The entire process should be meticulously documented and communicated to all stakeholders to maintain transparency and accountability. Think of it like a quality assurance audit – fixing the problem, ensuring it’s not repeated, and documenting every step.

Q 14. What are the environmental considerations in asphalt paving?

Environmental considerations are increasingly important in asphalt paving. Key aspects include:

- Air emissions: Asphalt plants and paving equipment can produce emissions. Modern plants often incorporate pollution control technologies to reduce emissions, such as particulate filters and scrubbers. Responsible contractors will focus on this.

- Water pollution: Runoff from asphalt paving projects can contain pollutants such as hydrocarbons and aggregates. Best management practices (BMPs) are necessary, like using sediment control measures and minimizing the use of water during construction.

- Waste management: Waste generated during asphalt paving, such as excess mix or contaminated materials, requires proper disposal to avoid environmental contamination. Recycling asphalt materials is becoming increasingly common, reducing landfill waste and conserving resources.

- Noise pollution: Construction activities generate noise. Mitigation strategies include using quieter equipment and implementing noise barriers.

Sustainable practices are becoming increasingly important, with an emphasis on using recycled materials and minimizing the environmental footprint of projects. It’s not just about building the road; it’s about building it responsibly and considering the long-term environmental impact.

Q 15. What safety precautions are necessary during asphalt paving inspection?

Safety is paramount during asphalt paving inspection. Think of it like this: you’re working in a dynamic environment with heavy machinery and hot materials. Neglecting safety can lead to serious injuries.

- High-visibility clothing: Wearing bright, fluorescent clothing makes you easily visible to equipment operators.

- Personal Protective Equipment (PPE): This includes safety glasses or goggles to protect your eyes from flying debris, hard hats to protect against falling objects, and sturdy work boots with steel toes to prevent foot injuries. Hearing protection is also crucial due to the noise of machinery.

- Traffic control: Inspectors must be aware of traffic patterns and ensure adequate safety measures, like cones and flaggers, are in place, especially near roadways.

- Designated work areas: Stay clear of active paving operations, and clearly mark inspection areas to prevent accidents.

- Emergency preparedness: Know the location of first aid kits and emergency contact information. Have a clear communication plan with the paving crew.

For example, I once witnessed an inspector get slightly injured by a stray stone flung from a paving machine. This highlighted the absolute need for proper safety eyewear at all times.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you document your inspections and findings?

Thorough documentation is the backbone of effective asphalt paving inspection. It’s not just about noting problems; it’s about building a comprehensive record that can be used for quality control, troubleshooting, and future maintenance planning.

- Detailed inspection reports: These reports should include the date, time, location, project name, weather conditions, and a description of the pavement section inspected.

- Photographs and video recordings: Visual documentation is invaluable. Pictures and videos clearly show the extent and location of any distresses or defects.

- Sketches and diagrams: Hand-drawn sketches can be very useful for illustrating the location and severity of defects, particularly in complex situations.

- Measurement data: This includes measurements of rutting, cracking, and other distresses, using appropriate measuring tools.

- Use of a standardized form: Consistency is key. Using a pre-designed form ensures all relevant information is collected for every inspection.

I typically use a combination of digital photography, detailed written reports, and a customized spreadsheet to record data efficiently. This allows for easy data analysis and reporting.

Q 17. What software or tools do you use for asphalt inspection?

Technology plays an increasingly important role in asphalt inspection, enhancing efficiency and accuracy. It’s not just about using a simple measuring tape anymore.

- Digital cameras and drones: High-resolution cameras provide detailed images for documentation, while drones provide a bird’s-eye view for large-scale inspections.

- GPS and GIS software: These tools help pinpoint the precise location of defects for easy tracking and future reference.

- Specialized software for pavement distress analysis: Some software packages can automatically analyze images to identify and quantify different types of pavement distresses, saving considerable time and effort. This offers quantitative data beyond visual assessment.

- Data loggers and sensors: These devices can record real-time data such as temperature and moisture content, which can impact asphalt performance.

- Mobile devices and tablets: These are useful for collecting data in the field and instantly syncing it with cloud-based systems for efficient report generation.

For instance, I recently used drone imagery to quickly assess the extent of cracking on a long stretch of highway, a task that would have been much more time-consuming with traditional methods.

Q 18. Explain the importance of proper mix design in asphalt paving.

Proper mix design is crucial because it directly impacts the longevity and performance of the asphalt pavement. Think of it as baking a cake – you need the right ingredients in the right proportions to achieve the desired result. A poorly designed mix can lead to premature failure and costly repairs.

The mix design involves selecting the right type and proportion of aggregates (stone, sand, etc.), asphalt binder (bitumen), and fillers to achieve the required properties like stability, durability, and workability. Factors like traffic volume, climate, and the type of pavement structure all influence the optimal mix design. A well-designed mix should resist cracking, rutting, and other forms of distress under expected traffic and environmental conditions.

For example, a mix designed for a high-traffic urban road needs to be much more durable than one for a low-traffic residential street. Incorrect proportions can lead to rapid deterioration, requiring costly and disruptive repairs.

Q 19. Describe the different types of asphalt pavement distresses.

Asphalt pavements are subjected to various stresses that can cause different types of distresses. Understanding these distresses is essential for effective pavement management.

- Cracking: This includes alligator cracking (interconnected cracks), longitudinal cracking (parallel to the pavement centerline), transverse cracking (perpendicular to the centerline), and fatigue cracking.

- Rutting: The permanent deformation of the pavement surface under wheel loads, resulting in a grooved appearance.

- Pot holes: Localized areas of pavement loss, usually caused by water damage and repeated traffic loading.

- Ravelling: The loss of aggregate particles from the pavement surface, leading to a rough and uneven texture.

- Shoving: Lateral movement of the pavement surface under heavy traffic, often observed at intersections or curves.

- Bleeding: The extrusion of asphalt binder to the pavement surface, resulting in a shiny or sticky surface.

Each type of distress indicates potential underlying problems, such as insufficient compaction, improper mix design, or inadequate drainage.

Q 20. How do you assess the rutting resistance of an asphalt pavement?

Rutting resistance is a crucial property indicating the ability of the asphalt pavement to resist permanent deformation under traffic loads. A pavement with poor rutting resistance will develop ruts, leading to discomfort and potential damage to vehicles.

Rutting is assessed through field measurements using instruments like a rut depth gauge. The depth of the rut, measured at specific intervals, indicates the severity of the rutting. We also take into account factors like the type and volume of traffic, the age of the pavement, and climatic conditions. For example, a heavily trafficked highway section may show more significant rutting compared to a low-volume residential street, even with identical pavement designs.

Furthermore, laboratory tests on asphalt cores can provide insights into the mix’s rheological properties that influence rutting resistance, helping to explain observed field performance.

Q 21. What are the different methods for measuring the skid resistance of an asphalt pavement?

Skid resistance is a vital aspect of pavement safety, as it determines the friction between a tire and the pavement surface. Low skid resistance increases the risk of accidents, particularly during wet conditions.

- British Pendulum Tester (BPT): This portable device measures the skid resistance of the pavement surface by measuring the friction between a pendulum and the surface. It provides a numerical value, called the British Pendulum Number (BPN), reflecting the skid resistance.

- Side-Force Measuring Devices: These devices measure the lateral force required to skid a tire across the pavement surface, providing more comprehensive and realistic data compared to the BPT.

- Locked-Wheel Trailer (LWT): This method uses a trailer equipped with a locked wheel, pulled at a controlled speed, to assess the skid resistance under various conditions, including wet and dry surfaces.

Regular skid resistance measurements are essential for identifying sections of pavement that need maintenance or resurfacing to ensure adequate safety for drivers.

Q 22. How do you determine the required thickness of an asphalt pavement layer?

Determining the required thickness of an asphalt pavement layer is crucial for ensuring its structural integrity and longevity. It’s not a simple calculation but depends on several interacting factors. Think of it like building a house – you need a strong foundation to support the weight of the structure. Similarly, the asphalt layer needs to withstand traffic loads and environmental stresses.

- Traffic Load: Heavier traffic demands thicker layers. For example, a highway carrying numerous heavy trucks requires a thicker asphalt layer than a residential street with lighter traffic.

- Subgrade Strength: The underlying soil’s ability to support the pavement is critical. A weak subgrade needs a thicker asphalt layer to compensate for its lack of stability. We use soil tests like CBR (California Bearing Ratio) to determine this.

- Design Life: The expected lifespan of the pavement influences thickness. A pavement designed for 20 years will generally require a thicker layer than one designed for 10 years.

- Climate Conditions: Freezing and thawing cycles, significant temperature variations, and rainfall can impact the pavement’s performance. Colder climates often necessitate thicker layers.

- Asphalt Mixture Properties: The type of asphalt binder and aggregate used directly influence the pavement’s strength and durability. Different mixtures have varying capabilities to support traffic loads.

Engineers utilize sophisticated pavement design software and empirical methods like the AASHTO (American Association of State Highway and Transportation Officials) design guide to calculate the optimal thickness. This involves considering all the factors mentioned above and often results in multiple asphalt layers of varying thickness, each with a specific function.

Q 23. What is your experience with different types of asphalt testing equipment?

My experience with asphalt testing equipment is extensive, ranging from basic field tests to sophisticated laboratory analyses. I’m proficient in using equipment for evaluating various aspects of asphalt, from its composition and physical properties to its performance in the field.

- Nuclear Density Gauge: This device uses nuclear radiation to measure the density of the compacted asphalt layer. It’s a quick and efficient way to check compaction on-site, ensuring that the asphalt is dense enough to resist rutting and cracking. A low density indicates insufficient compaction, potentially compromising pavement life.

- Core Sampling and Laboratory Testing: We extract cylindrical cores from the pavement for detailed lab analysis. Tests like Marshall Stability, Hubbard-Field, and Dynamic Creep test help determine the asphalt mixture’s strength, stiffness, and resistance to deformation under various stresses.

- Falling Weight Deflectometer (FWD): The FWD is a non-destructive testing method that measures the pavement’s response to an impact load. This data helps assess the pavement’s structural capacity and identify areas needing repair. It’s like giving the pavement a ‘stress test’ without damaging it.

- Superpave Gyratory Compactor (SGC): This lab-based equipment simulates the compaction process in the field, helping us to optimize the asphalt mix design for optimal compaction and durability.

Familiarity with these and other instruments is essential for accurate assessment of asphalt pavement quality and performance. Knowing the limitations of each instrument and interpreting the data correctly are equally critical.

Q 24. Describe your experience with asphalt pavement rehabilitation projects.

I’ve been involved in numerous asphalt pavement rehabilitation projects, ranging from small-scale repairs to extensive overlays on major roadways. My experience encompasses all phases, from planning and design to construction oversight and quality control.

One particularly challenging project involved rehabilitating a heavily trafficked section of highway with severely deteriorated pavement. The existing pavement had significant cracking, rutting, and alligator cracking. A simple overlay wasn’t sufficient. We had to develop a comprehensive rehabilitation plan, which involved:

- Detailed Pavement Assessment: Thorough investigation of the pavement’s condition using FWD, coring, and visual inspection.

- Subgrade Evaluation: Assessing the subgrade’s strength and stability to determine the best approach for rehabilitation. We found some areas with significant settlement that needed attention.

- Design Optimization: Developing a design that addressed the specific distress mechanisms and provided a long-term solution. This included a combination of milling, base repairs, and a new asphalt overlay.

- Construction Management: Overseeing the construction process to ensure quality control and compliance with specifications. We employed strict quality control measures to ensure proper compaction and material quality.

The success of this project relied on careful planning, meticulous execution, and a collaborative approach involving engineers, contractors, and stakeholders. The resulting pavement significantly improved the road’s condition, ensuring a safer and smoother ride for drivers.

Q 25. How do you manage your time and prioritize tasks during asphalt inspections?

Effective time management and prioritization are critical during asphalt inspections. I utilize several strategies to ensure efficiency and thoroughness. My approach is akin to conducting an orchestra – each instrument (task) needs to play its part harmoniously and in the right order.

- Pre-Inspection Planning: Reviewing the project plans, specifications, and relevant documentation before arriving at the site helps me to focus on key areas and anticipate potential issues.

- Systematic Inspection: I follow a standardized inspection checklist to ensure consistency and thoroughness. This helps avoid missing critical details.

- Prioritization Based on Risk: I prioritize areas exhibiting significant distress or those with higher potential safety hazards. Think of it like triage – addressing the most critical issues first.

- Technology Utilization: I leverage technology to streamline tasks, such as using mobile devices for data collection and reporting, GPS for navigation, and photo documentation for record keeping.

- Regular Communication: Maintaining clear communication with the project team and stakeholders ensures everyone is aware of progress and potential challenges. Prompt communication is essential in avoiding project delays.

By combining planning, systematization, prioritization, and efficient use of resources, I can effectively manage my time and prioritize tasks during asphalt inspections, leading to accurate assessments and timely completion of the inspection.

Q 26. Explain your experience with different types of pavement markings and their inspection.

My experience encompasses various pavement markings, including thermoplastic, paint, and raised pavement markers (RPMs). Inspection of these markings requires attention to detail and understanding of their function and expected lifespan.

- Thermoplastic Markings: These markings are durable and long-lasting, ideal for high-traffic areas. During inspection, I look for cracking, fading, and wear to assess their condition and adherence to specifications.

- Paint Markings: Paint markings are less durable than thermoplastics and are frequently used for temporary or low-traffic applications. I examine them for proper visibility, reflectivity, and overall integrity. Fading is a particular concern.

- Raised Pavement Markers (RPMs): These markers enhance visibility, particularly at night or in poor weather. My inspection focuses on their proper placement, secure attachment, and reflectivity. Missing or damaged RPMs pose a significant safety risk.

Inspection of pavement markings requires understanding relevant standards and specifications to assess their compliance. For example, ensuring that the retroreflectivity of markings meets the required standards is vital for maintaining driver safety.

Q 27. How do you ensure compliance with relevant regulations and standards?

Ensuring compliance with regulations and standards is paramount in asphalt pavement inspection. This involves a multi-faceted approach that blends knowledge of applicable codes, thorough documentation, and proactive communication.

- Knowledge of Codes and Standards: I maintain a strong understanding of relevant standards and specifications, such as those published by AASHTO, ASTM (American Society for Testing and Materials), and local transportation agencies. These standards define requirements for material properties, construction methods, and quality control procedures.

- Thorough Documentation: Detailed documentation is essential for demonstrating compliance. My documentation includes inspection reports, photographs, test results, and any non-compliances identified. This serves as a record for future reference and potential disputes.

- Proactive Communication: Open communication with contractors and stakeholders is crucial to ensuring compliance throughout the project lifecycle. Any deviations from specifications are reported promptly and corrective actions are identified and implemented.

- Regular Audits: Conducting regular audits and reviews of documentation helps identify potential compliance gaps and ensures ongoing adherence to standards. This proactive approach minimizes issues and reduces the risk of costly rework.

By diligently following these steps, I strive to ensure that all projects meet or exceed regulatory requirements and standards, ultimately contributing to the construction of safe and durable asphalt pavements.

Q 28. Describe a challenging asphalt inspection situation and how you resolved it.

One of the most challenging situations I faced involved a major highway project where the contractor’s asphalt mixture failed to meet the specified density requirements. This was discovered during routine inspections using a nuclear density gauge. Initially, the contractor attributed the low density to equipment malfunction. However, further investigation revealed a more significant problem.

My steps to resolve this included:

- Independent Verification: We conducted independent density tests using multiple gauges and core samples to verify the initial findings. This confirmed the low density across multiple sections of the pavement.

- Root Cause Analysis: We worked closely with the contractor to investigate the root cause of the problem. It turned out that the contractor had inadvertently used a different asphalt mix design than specified, resulting in insufficient compaction. This was documented in their production records, albeit unintentionally overlooked.

- Corrective Action Plan: A corrective action plan was developed which involved milling the affected sections of the pavement and replacing them with asphalt meeting the required specifications. This required careful coordination with the contractor and the traffic management team to minimize disruption.

- Quality Control Enhancement: We implemented stricter quality control measures for the remaining sections of the project, including more frequent testing and closer monitoring of the asphalt production process. This ensured the project met all specifications moving forward.

This situation highlighted the importance of thorough inspection, independent verification, and effective communication in resolving quality control issues. Ultimately, the issue was resolved successfully, leading to a final product meeting all design standards. The entire process reinforced the need for comprehensive quality control throughout all phases of an asphalt pavement project.

Key Topics to Learn for Asphalt Paving Inspection Interview

- Material Properties: Understanding the characteristics of asphalt binders, aggregates, and other components. This includes knowledge of viscosity, stability, and durability.

- Construction Methods: Familiarity with various asphalt paving techniques like hot-mix asphalt (HMA) placement, compaction methods, and their impact on pavement quality. Be prepared to discuss practical application and quality control measures during each stage.

- Quality Control Testing: Thorough understanding of in-place density testing, core sampling, and other methods used to assess the quality of the finished pavement. Discuss the significance of test results and how they inform decision-making.

- Pavement Design Principles: Basic knowledge of pavement structural design, including layer thicknesses, material selection, and their influence on pavement performance and lifespan.

- Specifications and Standards: Familiarity with relevant industry standards and specifications (e.g., AASHTO, ASTM) used to guide asphalt paving construction and inspection. Be prepared to discuss how these standards ensure project quality.

- Problem-Solving and Troubleshooting: Ability to identify and diagnose common problems encountered during asphalt paving, such as segregation, rutting, cracking, and improper compaction. Develop examples illustrating your problem-solving approach.

- Safety Regulations and Procedures: Demonstrate a strong understanding of safety protocols and regulations pertaining to asphalt paving construction and inspection. Showcase your commitment to workplace safety.

- Documentation and Reporting: Experience with maintaining detailed records, preparing inspection reports, and communicating effectively with project stakeholders. Practice clear and concise reporting techniques.

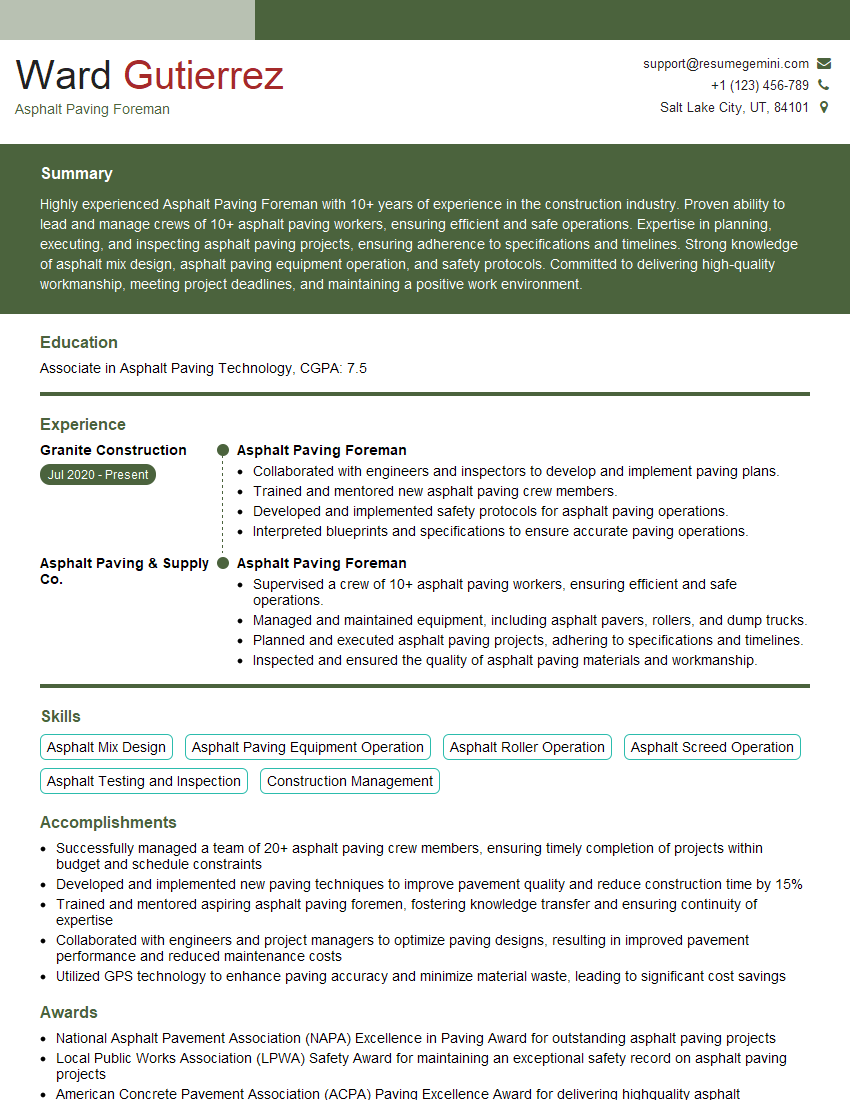

Next Steps

Mastering asphalt paving inspection opens doors to rewarding career opportunities with excellent growth potential. A strong understanding of these crucial aspects will significantly enhance your interview performance and set you apart from other candidates. To maximize your job prospects, create an ATS-friendly resume that effectively highlights your skills and experience. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. We offer examples of resumes tailored specifically to Asphalt Paving Inspection to guide you. Take the next step towards your career success today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good