Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Concrete Paving Inspection interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Concrete Paving Inspection Interview

Q 1. Describe your experience with various concrete paving materials and their properties.

My experience encompasses a wide range of concrete paving materials, each with unique properties influencing performance and durability. For instance, I’ve worked extensively with Portland cement concrete, the most common type, known for its strength and versatility. Its properties are highly adjustable through the mix design, allowing for variations in compressive strength, workability, and durability. I’ve also had experience with high-performance concrete (HPC), which incorporates supplementary cementitious materials like fly ash or silica fume to enhance strength, reduce permeability, and increase resistance to aggressive environments like de-icing salts. Furthermore, I’m familiar with concrete containing fibers (steel or synthetic) to improve its resistance to cracking, particularly under heavy traffic loads. Finally, I’ve worked with roller-compacted concrete (RCC), a leaner mix ideal for large-scale projects where high strength isn’t paramount, but cost-effectiveness is crucial. Understanding these material differences is vital for selecting the appropriate type for each project, considering factors like budget, traffic volume, and environmental conditions.

For example, in a high-traffic area like a major highway, HPC would be preferred due to its increased durability and resistance to cracking. Conversely, in a large parking lot, RCC may prove a more economical choice.

Q 2. Explain the different types of concrete pavement joints and their purpose.

Concrete pavement joints are critical for accommodating the inevitable movement and expansion of concrete due to temperature fluctuations and load variations. There are several types:

- Contraction Joints: These are intentionally weakened areas created to allow for controlled cracking. They’re typically saw-cut after the concrete has cured to a certain strength, creating a clean break rather than random cracking. This prevents large, uncontrolled cracks from forming.

- Expansion Joints: These are wider gaps filled with a flexible material like asphalt or sealant. They allow for significant expansion and contraction, minimizing stress on the pavement. These are crucial in long stretches of pavement.

- Construction Joints: These are formed when pouring concrete needs to be stopped and resumed later. Careful placement and preparation are necessary to ensure a strong bond between the two sections.

- Isolation Joints: These separate the pavement from other structures, like bridges or buildings, preventing stress transfer.

The purpose of each joint type is to control cracking and prevent damage to the pavement. Improper joint design or construction can lead to premature pavement failure.

Q 3. How do you ensure proper compaction of concrete during paving?

Proper compaction is paramount to achieving high-strength, durable concrete pavements. It removes air voids, ensuring a dense structure resistant to damage. The process involves using mechanical vibrators, both internal and external, to consolidate the concrete.

- Internal vibrators, also known as immersion vibrators, are inserted into the fresh concrete to remove air bubbles from within the mix. They are particularly effective for thicker slabs and heavily reinforced areas. The right type and speed of vibrator is critical, as excessive vibration can lead to segregation (separation of the components of the mix).

- External vibrators, like table vibrators or form vibrators, vibrate the forms containing the concrete, helping to consolidate the mix and ensure proper consolidation against the forms.

The success of compaction is assessed visually and by monitoring the concrete’s surface finish. A properly compacted surface will be smooth, free of significant air pockets or segregation, and free from honeycombing.

Imagine trying to build a sandcastle – without compacting the sand, it crumbles easily. Similarly, without proper compaction, concrete is weaker and more prone to damage.

Q 4. What are the common defects found in concrete pavements and their causes?

Many defects can occur during concrete pavement construction and service life. Some common ones include:

- Cracking: This can stem from several sources, including shrinkage (due to drying), temperature changes, overloaded traffic, poor compaction, and inadequate joint design. Different types of cracks (e.g., map cracking, longitudinal cracking, transverse cracking) indicate different underlying causes.

- Scaling: This is the surface deterioration caused by freeze-thaw cycles, de-icing salts, or chemical attack. It appears as small pieces flaking off the surface.

- D-Cracking (Durability Cracking): This type of cracking is caused by a high-alkali cement reaction that affects the durability of the concrete.

- Spalling: This is the breaking away of concrete pieces from the surface or interior. Causes include freeze-thaw cycles, alkali-aggregate reaction, and improper curing.

- Surface Defects: These include honeycombing (voids near the surface), laitance (a weak layer of cement paste on the surface), and bleeding (excess water rising to the surface).

Understanding the cause of the defect is key to remediation. For example, if cracking is due to inadequate joint spacing, the solution may involve adding more joints. If it’s due to poor compaction, the solution may be to improve compaction techniques on future projects.

Q 5. How do you interpret concrete mix design specifications?

Concrete mix design specifications are crucial for ensuring the pavement meets the required strength, durability, and workability. They detail the proportions of cement, aggregates (sand, gravel), water, and any admixtures (chemicals that modify concrete properties). I interpret these specifications by understanding the notation and what each component contributes. For example, a specification might read:

1:1.5:3 (Cement:Sand:Gravel) with 0.5 water-cement ratio and a slump of 75-100 mm.This indicates a mix ratio where the cement, sand, and gravel are in a ratio of 1:1.5:3. The water-cement ratio helps determine the workability and strength, while the slump describes how fluid the mixture is (a higher slump indicates more workability). I use this information to ensure the concrete batching is done according to these specifications. Any deviation can significantly affect the final product’s quality.

Q 6. What are the standard testing methods for concrete strength and durability?

Standard testing methods are essential for evaluating concrete strength and durability. For strength, the most common test is the compressive strength test. Cylindrical or cubic specimens are cast and cured according to standard procedures, and then compressed to failure in a testing machine. The resulting compressive strength is expressed in MPa (megapascals). For durability, several tests are employed, depending on the anticipated environmental conditions. These may include:

- Freeze-thaw testing: This exposes specimens to repeated freezing and thawing cycles to assess their resistance to damage from ice formation.

- Scaling resistance test: This involves exposing concrete specimens to cycles of wetting and drying with de-icing chemicals to determine the amount of scaling.

- Abrasion resistance test: This determines the resistance of concrete to wear and tear under traffic conditions.

- Permeability testing: This measures the ease with which water can penetrate the concrete, which is crucial for assessing durability against aggressive chemicals and corrosion.

Results from these tests provide valuable insights into the long-term performance of the concrete pavement and help assess its suitability for specific applications.

Q 7. Describe your experience using different concrete testing equipment.

My experience with concrete testing equipment is extensive. I’m proficient in using a range of equipment, including:

- Compression testing machines: These are used to determine the compressive strength of concrete cylinders or cubes.

- Slump cones: These are used to assess the consistency and workability of fresh concrete.

- Air content meters: Used to determine the amount of entrained air in the concrete mix.

- Rebound hammers (Schmidt hammers): These provide an estimate of the in-situ compressive strength of hardened concrete. Though less precise than lab testing, this method provides quick assessments on-site.

- Various other equipment used in permeability and durability testing including rapid chloride permeability testers, and equipment for freeze-thaw testing chambers.

Proper calibration and maintenance of all this equipment are crucial for obtaining accurate and reliable test results, ensuring the accuracy of the assessment of the concrete.

Q 8. How do you monitor and control the curing process of concrete pavements?

Monitoring and controlling the curing process of concrete pavements is crucial for achieving the desired strength and durability. Curing is the process of maintaining adequate moisture and temperature to allow the hydration of cement, which is the chemical reaction that hardens the concrete. We use a multi-pronged approach:

- Water Curing: This involves keeping the concrete surface continuously moist, typically using ponding (covering the surface with water), membrane curing (using a plastic sheet), or spraying water regularly. For example, on a large highway project, we might use a combination of ponding and membrane curing, adjusting the technique based on weather conditions and the specific concrete mix design.

- Curing Compounds: These are chemical compounds applied to the concrete surface to retard moisture loss. They create a barrier that helps maintain moisture within the concrete. The choice of compound depends on environmental conditions and project specifications. For instance, a high-humidity environment might allow for a less aggressive curing compound.

- Temperature Monitoring: Extreme temperatures (both hot and cold) can negatively impact the curing process. We use sensors or thermometers to monitor the temperature of the concrete and adjust our curing methods accordingly. For example, in hot weather we may need to shade the pavement or increase the frequency of water spraying.

- Inspection and Documentation: Regular visual inspections ensure the curing process is effective. We check for cracking, discoloration, and any signs of inadequate moisture retention. Thorough documentation, including photos and temperature logs, is essential for demonstrating compliance with project specifications and identifying any potential issues early on.

Ultimately, the goal is to maintain optimal moisture content and temperature for a sufficient duration, typically several days, to allow the concrete to reach the required strength. The specific duration will depend on factors such as the concrete mix design, ambient conditions, and project requirements.

Q 9. What are the key factors affecting the longevity of concrete pavements?

The longevity of concrete pavements is affected by a complex interplay of factors. We can categorize them broadly into design, construction, and environmental factors:

- Design Factors: The thickness of the pavement, the type of concrete mix used (including strength and air content), and the pavement design (e.g., jointed or continuously reinforced) all significantly influence its lifespan. A poorly designed pavement will inherently be more susceptible to damage.

- Construction Factors: Proper subgrade preparation, accurate placement and consolidation of the concrete, and effective curing are paramount. For example, insufficient compaction of the subgrade can lead to settling and cracking, while improper curing can result in premature deterioration. Construction practices directly impact the quality of the final product.

- Environmental Factors: Factors such as freeze-thaw cycles, de-icing salt application, traffic loading, and exposure to ultraviolet (UV) radiation play a significant role. In colder climates, the use of de-icing salts can accelerate deterioration. Heavier traffic leads to increased wear and tear. We consider all these elements during design and maintenance planning.

For instance, a pavement designed for light traffic in a mild climate might last for decades with minimal maintenance, whereas a pavement subjected to heavy truck traffic in a freeze-thaw environment may require more frequent repairs and may have a shorter lifespan. A holistic understanding of all these factors is essential for predicting and enhancing pavement longevity.

Q 10. How do you assess the quality of subgrade preparation for concrete paving?

Assessing subgrade quality is a critical step in concrete paving. A poorly prepared subgrade can lead to cracking, settling, and ultimately, premature pavement failure. We employ a number of methods:

- Visual Inspection: A thorough visual inspection checks for the presence of organic matter, rocks, or other debris that could compromise the stability of the subgrade. This is a fundamental first step and allows identification of potential issues early on.

- Density Testing: Nuclear density gauges or other methods are used to measure the density of the compacted subgrade. This helps ensure the subgrade meets the specified density requirements, which are crucial for supporting the pavement load. We need to make sure that the subgrade is sufficiently dense to prevent settlement.

- Bearing Capacity Tests: These tests, such as plate bearing tests or cone penetration tests, assess the strength and stability of the subgrade. These assessments help quantify the subgrade’s ability to withstand the anticipated loads from the pavement and traffic. The results inform the choice of pavement design.

- Moisture Content Testing: The moisture content of the subgrade is crucial. Excessive moisture can lead to weakening and instability, whereas very dry soil may not compact properly. We perform moisture-content tests to ensure it falls within acceptable limits.

The results of these tests determine whether the subgrade needs further preparation, such as additional compaction, removal of unsuitable materials, or the addition of stabilizing agents. Documentation of these assessments is important for quality control and to maintain a record of subgrade conditions.

Q 11. Explain the significance of proper drainage in concrete pavement design.

Proper drainage is absolutely essential for the longevity and performance of concrete pavements. Water accumulation beneath the pavement can lead to frost heave (in cold climates), weakening of the subgrade, and the formation of voids that contribute to cracking and deterioration. We ensure proper drainage through:

- Subbase and Base Layers: These layers help to filter water and improve drainage. Properly designed and installed drainage layers are critical. We use geotextiles to separate layers and improve drainage.

- Gradients and Cross Slopes: The pavement surface should have a slight cross-slope to direct water away from the pavement. Adequate longitudinal gradients also help in efficient water flow.

- Drainage Structures: Features such as culverts, ditches, and catch basins are incorporated to collect and divert water away from the pavement. The location and design of these structures are carefully considered to avoid ponding of water.

- Joint Design: Proper joint design, including the use of sealed joints, minimizes water infiltration into the pavement. We choose joint design based on factors like climate and expected traffic.

In essence, proper drainage design prevents water from becoming a destructive force. The consequences of inadequate drainage can be costly in terms of maintenance and repairs. In one project, we had to rework a section of pavement because poor drainage led to severe cracking within the first year.

Q 12. How do you manage conflicts between different stakeholders on a construction project?

Managing stakeholder conflicts is an unavoidable aspect of large construction projects. I use a proactive and collaborative approach.

- Open Communication: Regular meetings and transparent communication are key. I make sure that all stakeholders – the client, engineers, subcontractors, and inspectors – have a clear understanding of the project goals, timelines, and potential challenges. This prevents misunderstandings and encourages collaborative problem-solving.

- Early Conflict Identification: Proactive identification of potential conflicts, such as differing interpretations of specifications or scheduling issues, is vital. Addressing them early minimizes their impact on the project’s timeline and budget. We create a communication plan at the start of the project to streamline this.

- Collaborative Problem Solving: When conflicts arise, I facilitate a collaborative environment where stakeholders can openly discuss their concerns and work towards mutually acceptable solutions. Mediation, if necessary, is employed to help bridge gaps between differing perspectives.

- Documentation: Maintaining detailed records of all communication, agreements, and decisions is crucial for accountability and dispute resolution. We maintain meticulous records of all meetings and decisions, which helps in avoiding conflicts that might arise due to lack of clarity.

For example, on a recent project, there was a dispute between the contractor and the subcontractor about the responsibility for repairing a damaged section of pavement. By bringing them together, clarifying the contract terms, and facilitating a discussion of the repair method, we were able to reach a solution that satisfied both parties. Successful conflict management is not just about resolving disputes, but also maintaining positive relationships.

Q 13. Describe your experience in reading and interpreting construction drawings and specifications.

I have extensive experience in reading and interpreting construction drawings and specifications. My approach involves a systematic process:

- Understanding the Scope: I begin by reviewing the project overview and understanding the overall scope of work. This gives me context for the specific drawings and specifications I’ll be examining.

- Review of Drawings: I systematically review all relevant drawings, including site plans, grading plans, pavement sections, and details. I pay close attention to dimensions, materials, and construction techniques. I use specialized software to review and even create 3D renderings from drawings.

- Interpretation of Specifications: I carefully review the project specifications, which outline the required materials, quality standards, construction methods, and testing procedures. I identify any discrepancies or ambiguities between the drawings and the specifications.

- Cross-Referencing: I cross-reference information between the drawings and specifications to ensure consistency and to identify any conflicts or missing information. This avoids any mistakes arising due to inconsistency.

- Understanding Symbols and Notations: Proficiency in interpreting common symbols, abbreviations, and notations used in construction drawings is essential. Familiarity with industry standards and relevant codes is also critical.

Over my career, I’ve worked on numerous projects with varying levels of complexity, refining my ability to interpret technical drawings and specifications accurately and efficiently. Misinterpretations can lead to significant delays and costly errors, so meticulous attention to detail is essential. I’ve found that working collaboratively with the design team helps resolve any ambiguities during the early design stage.

Q 14. What are the relevant safety regulations and procedures for concrete paving projects?

Safety is paramount on any concrete paving project. Compliance with relevant safety regulations and procedures is non-negotiable. Key aspects include:

- Personal Protective Equipment (PPE): All workers must wear appropriate PPE, including safety helmets, safety glasses, high-visibility clothing, safety boots, and hearing protection. This is strictly enforced, and any worker not in compliance is immediately sent off the worksite.

- Traffic Control: Proper traffic control measures are crucial to protect workers and the public. This may involve using lane closures, barriers, signage, and flaggers, especially on projects involving highways or roads.

- Heavy Equipment Safety: Safe operation of heavy equipment, such as bulldozers, excavators, and concrete pavers, is ensured through training, regular inspections, and adherence to safe operating procedures. We have mandatory training sessions on safe equipment handling.

- Fall Protection: For work at heights, appropriate fall protection measures, such as safety harnesses and guardrails, must be in place. Work at height is only carried out by experienced personnel and using safety measures.

- Hazard Communication: Workers must be informed of potential hazards and provided with necessary training on safe work practices. We hold regular safety meetings to ensure everyone’s safety is being considered.

- Emergency Response: Emergency response plans must be in place to deal with any accidents or incidents. This includes having first aid supplies available, trained first aiders on-site, and access to emergency services.

Compliance with OSHA (Occupational Safety and Health Administration) regulations, or equivalent national standards, is mandatory. We conduct regular safety audits and inspections to ensure adherence to these regulations. A safe work environment is not just a legal requirement; it’s a moral imperative.

Q 15. How do you document your inspection findings and prepare reports?

Documenting inspection findings and preparing reports is crucial for ensuring project quality and accountability. My process involves a multi-step approach starting with meticulous on-site observations. I use a combination of digital photography, video recording, and detailed written notes to capture all aspects of the pavement, including areas of concern. This data is then meticulously organized and analyzed.

My reports are comprehensive and include:

- Project overview: Details about the project scope, location, and dates.

- Methodology: Description of the inspection methods used (e.g., visual inspection, thickness measurements, crack surveys).

- Findings: Detailed description of any defects or deviations from the specifications, supported by photographic evidence. This includes type, location, severity, and extent of the defects (e.g., cracks, spalling, surface irregularities). I use a standardized defect classification system, ensuring consistent reporting.

- Recommendations: Specific recommendations for repair or remediation, including prioritizing urgent issues and suggesting appropriate techniques.

- Conclusion: A summary of the overall pavement condition and compliance with project specifications.

I typically use software to generate professional reports with clear visuals. This ensures consistency and makes the data easily accessible for stakeholders.

Career Expert Tips:

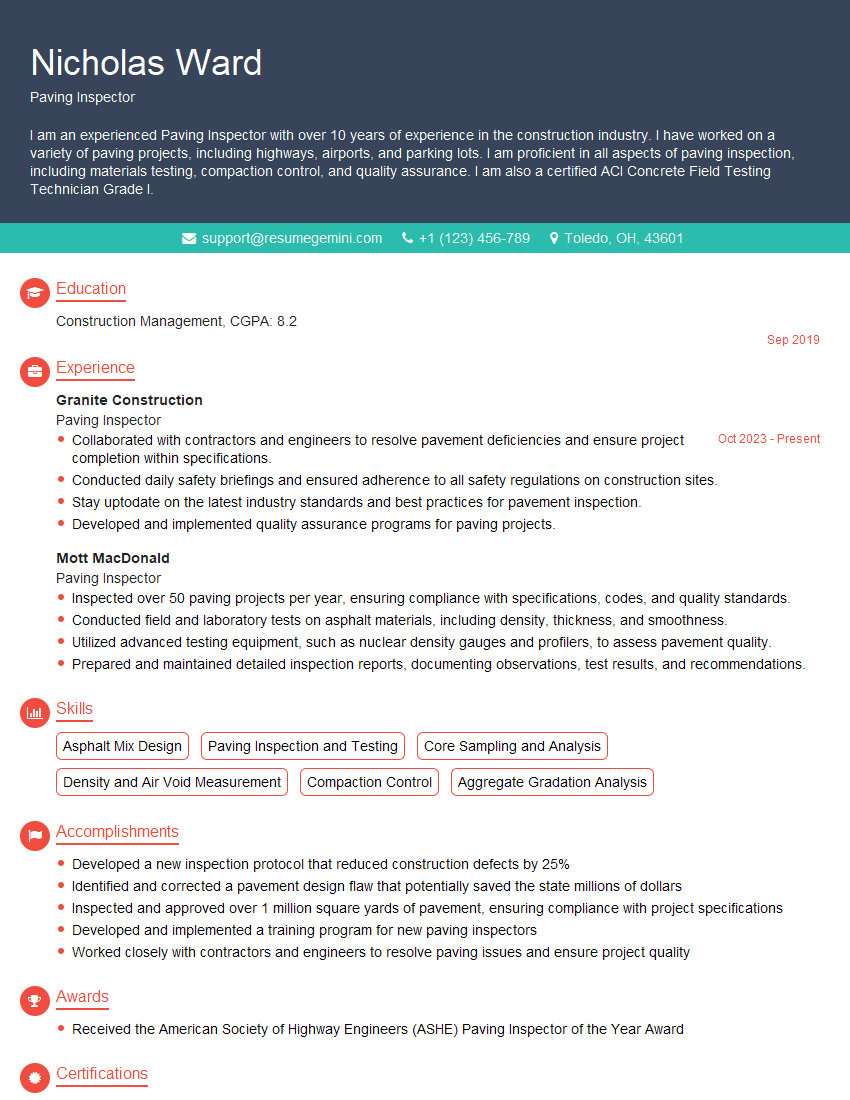

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with concrete pavement rehabilitation and repair methods.

Concrete pavement rehabilitation and repair is a multifaceted field. My experience encompasses a wide range of methods, selected based on the type and severity of damage. For instance, I’ve worked extensively on projects involving:

- Crack sealing: Addressing surface cracks using appropriate sealants to prevent water ingress and further deterioration. The choice of sealant depends on crack width and depth.

- Patching: Repairing localized areas of damage, such as potholes or spalling, using high-quality concrete mixes matched to the existing pavement. Proper preparation of the area to be patched is essential for a long-lasting repair.

- Full-depth patching: A more involved repair, typically needed for significant damage extending through the full thickness of the pavement. This involves removing the damaged section completely and replacing it with new concrete. Careful attention to compaction and curing is crucial.

- Overlaying: Applying a new layer of concrete over the existing pavement to improve ride quality, extend service life, and address surface irregularities. Proper design and execution are key to achieving a successful overlay.

- Diamond grinding: Used to improve surface texture and remove minor surface irregularities. This technique provides a smooth, uniform surface and enhances skid resistance.

I carefully consider factors such as the type of concrete, traffic load, and environmental conditions when selecting the most appropriate rehabilitation technique. Each project demands a tailored solution.

Q 17. Explain the principles of quality control and quality assurance in concrete paving.

Quality control (QC) and quality assurance (QA) are intertwined yet distinct aspects of concrete paving. QA focuses on preventing defects before they occur, while QC focuses on identifying and correcting defects during construction.

Quality Assurance (QA) involves proactive measures like:

- Material testing: Ensuring that the aggregates, cement, and admixtures meet the specified requirements. This often involves laboratory testing to verify strength, consistency, and other properties.

- Mix design: Developing a concrete mix that meets the project’s performance requirements while considering environmental factors.

- Pre-construction planning: Thorough planning, including site preparation, equipment selection, and work sequencing, minimizes the risk of defects.

- Contractor training and supervision: Ensuring that the construction crew is properly trained and supervised to follow established procedures.

Quality Control (QC) involves reactive measures like:

- Regular inspections: Frequent on-site inspections to monitor compliance with specifications, including formwork, reinforcement, concrete placement, and finishing. This involves checking factors like slump, air content, and surface finish.

- Testing in place: Performing tests during construction to verify strength, thickness, and other properties of the concrete. This can include in-situ testing such as rebound hammer tests and core sampling.

- Defect identification and correction: Promptly identifying and addressing any non-conformances or defects as they arise to minimize the impact on the final product.

- Documentation: Maintaining detailed records of all inspections, tests, and corrective actions. This documentation is crucial for project auditing and future reference.

By implementing robust QA and QC processes, we ensure a high-quality, durable concrete pavement that meets or exceeds project requirements.

Q 18. How do you handle non-conforming work during a concrete paving project?

Handling non-conforming work is a critical aspect of my role. My approach involves a systematic process:

- Immediate Identification and Documentation: I immediately document any non-conforming work with detailed photographs, measurements, and a description of the defect. I also note the location and potential impact on the project’s overall quality.

- Notification to Contractor: I promptly notify the contractor of the non-conforming work, clearly outlining the deficiencies and referencing the project specifications.

- Joint Investigation: The contractor and I work together to determine the root cause of the non-conformance and the extent of the rework required. We consider the severity of the issue, the potential for repair vs. replacement, and the impact on the project schedule and budget.

- Corrective Action Plan: We develop a corrective action plan, outlining the steps needed to rectify the non-conforming work. This plan includes details on materials, methods, and timeline for completion.

- Re-inspection and Verification: Once the corrective actions are complete, I perform a thorough re-inspection to verify that the work meets the required standards. This ensures the problem is resolved effectively and doesn’t reappear.

- Documentation and Reporting: All aspects of the non-conforming work, including the root cause analysis, corrective actions, and re-inspection results, are documented in a detailed report. This ensures transparency and accountability throughout the process.

A collaborative approach with the contractor is essential for effectively resolving non-conforming work while maintaining a positive working relationship.

Q 19. What software or applications do you use for inspection and reporting?

Technology plays a vital role in modern concrete paving inspection. I utilize several software and applications to streamline my workflow and improve reporting accuracy.

- Field Data Collection Apps: I use mobile apps to record inspection data directly in the field. These apps allow for real-time data entry, including GPS coordinates, photos, and detailed descriptions of defects. This eliminates the need for manual transcription and improves data accuracy.

- Cloud-Based Data Management Systems: The collected field data is synchronized to cloud-based systems for secure storage and easy access by all stakeholders. This centralized approach enables real-time collaboration and improved project management.

- Reporting Software: I use specialized reporting software to generate comprehensive and professional reports. These tools allow me to integrate photos, videos, and data into clear, concise reports, highlighting key findings and recommendations.

- Digital Imaging Software: I utilize software to enhance and analyze digital images, helping to identify subtle defects that may be missed with the naked eye. This can involve image stitching for large-area coverage and specialized analysis for identifying cracks or other anomalies.

- GIS (Geographic Information System) Software: For large projects, GIS software can help map defects and track repairs, providing a visual representation of the overall pavement condition.

The choice of software depends on the project’s complexity and specific requirements. My aim is to leverage technology to optimize my efficiency and improve the overall quality of my inspection reports.

Q 20. Describe your experience with different types of pavement surface finishes.

My experience encompasses a variety of pavement surface finishes, each with its own characteristics and application considerations. The choice of finish affects factors such as skid resistance, durability, and aesthetics.

- Broomed Finish: A textured surface created by brushing the concrete with a broom. This is a common finish for pavements requiring good skid resistance, particularly in areas with moderate to high traffic volume. The texture depth and direction can be controlled to optimize performance.

- Troweled Finish: A smooth finish created by troweling the concrete surface. This type of finish is often preferred for pavements requiring a smooth, aesthetically pleasing surface, but it may offer less skid resistance than a broomed finish. Different troweling techniques can create various levels of smoothness.

- Exposed Aggregate Finish: A decorative finish where aggregates are exposed by washing away the cement paste from the surface. This creates a unique and visually appealing surface, but it requires more skilled workmanship and careful attention to detail.

- Stamped Concrete: A decorative finish achieved by stamping patterns onto the concrete surface before it sets. This allows for creating various textures and designs, increasing the pavement’s aesthetic appeal. This is often used in decorative paving projects.

- Power Float Finish: A smooth finish created using a power float, offering a balance between smoothness and texture. This technique is often used to provide a consistent, flat surface suitable for various applications.

I understand the strengths and limitations of each type of finish and can guide project teams on selecting the most suitable option based on functional and aesthetic requirements.

Q 21. How do you measure the thickness and uniformity of concrete pavements?

Measuring the thickness and uniformity of concrete pavements is crucial for ensuring quality and durability. I employ a range of methods to obtain accurate measurements:

- Nuclear Gauge: A non-destructive method using radiation to measure concrete thickness. It provides quick and accurate measurements but requires trained personnel and adherence to safety regulations. This method is particularly useful for measuring the thickness of existing pavements without causing damage.

- Core Drilling: A destructive method that involves drilling cores from the pavement and measuring their diameter. This provides direct measurement of the concrete thickness and allows for analysis of the concrete composition and quality. Cores are then used for laboratory testing for compressive strength.

- Ground Penetrating Radar (GPR): A non-destructive method using electromagnetic waves to measure the pavement thickness and detect internal defects. It is useful for assessing large areas of pavement quickly but requires skilled interpretation of the data. It’s best used in conjunction with other methods like core sampling for validation.

- Ultrasonic Testing: A non-destructive method using sound waves to measure the pavement thickness. It is a relatively quick and easy method but can be affected by factors such as moisture content and internal defects.

The choice of method depends on the project’s specific requirements and constraints. For instance, nuclear gauges are typically ideal for large areas, while core drilling provides the most accurate results for localized measurements. I always strive to choose a method that maximizes accuracy while minimizing cost and disruption. Uniformity is assessed through multiple measurements across the paving area and comparing them against project specifications; variations beyond the acceptable tolerance limits should be investigated.

Q 22. How do you perform a visual inspection of concrete pavements and identify potential problems?

A visual inspection of concrete pavements is the cornerstone of quality control. It involves systematically examining the pavement surface and its surroundings for any signs of distress or defects. Think of it like a thorough medical check-up for your pavement.

Surface Cracks: I look for cracks of different types – map cracking (interconnected cracks resembling a map), transverse cracking (cracks running perpendicular to the pavement), longitudinal cracking (parallel to the pavement), and others. Their size, width, and pattern reveal potential underlying issues like poor base preparation, shrinkage, or overloading.

Deterioration: I assess the pavement’s surface for scaling (loss of surface material), potholes, raveling (loss of aggregates), and spalling (chipping or breaking away of concrete). The severity and extent of these are noted.

Joint Condition: Pavement joints are carefully examined for faulting (vertical displacement), spalling, and sealing integrity. Joint deterioration significantly impacts pavement durability.

Drainage: I check for proper drainage to ensure water doesn’t pool on the surface, leading to freeze-thaw damage or erosion. Proper drainage is crucial for longevity.

Surrounding Area: The surrounding environment is also assessed. Factors such as tree roots, soil erosion, and proximity to structures can significantly affect pavement performance. For instance, tree roots can cause heaving and cracking.

I use standardized documentation to record my findings, including photographs and detailed descriptions, which helps in tracking deterioration and planning for repairs.

Q 23. Explain the different types of pavement markings and their application methods.

Pavement markings are crucial for road safety and traffic management. They provide visual guidance to drivers and pedestrians. Different types serve different purposes:

Center Line Markings: Typically yellow, they separate opposing traffic flows. These are often applied using thermoplastic paint or preformed thermoplastic stripes for high durability.

Edge Lines: Usually white, they delineate the edge of the pavement and separate traffic from shoulders or sidewalks. Similar application methods to center lines are used.

Lane Lines: White lines separate traffic lanes in the same direction. Again, thermoplastic or paint is commonly used.

Crosswalks: These markings are usually white and indicate pedestrian crossing areas. Often thicker lines than lane lines and sometimes enhanced with raised pavement markers.

Symbols and Letters: These markings provide specific instructions or warnings, such as turn arrows or speed limits, usually applied with paint or specialized stencils.

Application methods vary depending on the marking type and material. Thermoplastic markings are applied hot and adhere well to the pavement surface offering high visibility and longevity. Paint is applied via line stripers or spray equipment, offering a more economical option but generally requiring more frequent repainting.

Q 24. How do you manage and resolve issues related to material delivery and availability?

Managing material delivery and availability is crucial for timely project completion. It requires proactive planning and strong communication.

Pre-planning and Ordering: I work closely with suppliers to estimate material requirements accurately and place orders well in advance, considering potential lead times and weather conditions. This prevents delays.

Supplier Relationships: Establishing strong relationships with reliable suppliers is critical. Knowing their capabilities and track record helps mitigate risks.

Material Tracking: Throughout the project, I closely monitor material deliveries and ensure they arrive on schedule and meet quality standards. This involves reviewing delivery slips and conducting inspections.

Contingency Planning: Unexpected delays or shortages can occur. Having a contingency plan, such as identifying alternative suppliers or using substitute materials (where appropriate and approved), is essential to keep the project on track.

Inventory Management: Careful management of on-site materials is essential to prevent theft or damage.

For example, during a recent project, an unexpected concrete shortage arose due to a supplier issue. My prior establishment of a relationship with an alternate supplier allowed me to swiftly source the needed material, minimizing project disruption.

Q 25. Describe your experience with different types of concrete finishing tools and techniques.

Concrete finishing is a critical phase influencing the pavement’s final quality and durability. I’m experienced with a range of tools and techniques:

Bull Floats: Used for initial leveling and consolidation of the concrete after placement. The operator skillfully manipulates this long, hand-held tool to achieve a smooth surface.

Power Trowels: These motorized tools provide a high-quality, smooth finish by rotating blades that further consolidate and level the surface.

Hand Floats: Used for fine finishing and removing any minor imperfections after power troweling.

Edgers: Create neat and uniform edges along the pavement borders, preventing crumbling.

Groovers: Cut controlled grooves into the surface to create contraction joints, helping to control cracking during curing and prevent random cracking.

The choice of tools and techniques depends on factors such as the pavement’s thickness, intended use, and desired surface texture. For instance, high-traffic areas might require more extensive power troweling for a highly durable surface.

Q 26. Explain your understanding of the different types of concrete curing methods.

Concrete curing is the process of maintaining moisture and temperature to allow the cement to properly hydrate and gain strength. Inadequate curing leads to weakened concrete and reduced durability. Common methods include:

Water Curing: The simplest method, involving keeping the surface continuously wet for a specified period (often several days). This can be done by ponding, spraying, or covering with wet burlap.

Membrane Curing: Using a liquid membrane curing compound creates a vapor barrier, preventing moisture loss. This is efficient and reduces labor compared to water curing.

Moisture-Retaining Covers: Materials like polyethylene sheets or wet burlap are placed on the surface to prevent moisture evaporation. This is particularly effective in hot, dry climates.

Steam Curing: This accelerated method uses steam to achieve faster strength development, often used in precast concrete production.

The best curing method depends on factors such as weather conditions, project schedule, and budget. I always select the method that best balances effectiveness with practicality and cost.

Q 27. What are the common causes of cracking in concrete pavements?

Cracking in concrete pavements is a common problem with several causes:

Shrinkage Cracking: As concrete dries, it shrinks, which can lead to cracking if the shrinkage isn’t properly managed. This is often seen as fine, random cracks.

Plastic Shrinkage Cracking: This occurs during the initial setting and hardening of the concrete due to rapid moisture loss. It’s common in hot, windy conditions.

Thermal Cracking: Temperature fluctuations cause expansion and contraction of the concrete, potentially leading to cracking, especially if joints aren’t placed effectively.

Load-Related Cracking: Excessive loads from traffic can cause fatigue cracking, especially in areas with weak subgrades or inadequate pavement design.

Settlement Cracking: Uneven settlement of the underlying soil can cause cracking. This is often seen as stepped cracks.

Poor Construction Practices: Inadequate compaction of the base material, improper mixing of concrete, or insufficient curing can all contribute to cracking.

Understanding the cause of cracking is critical for effective repair and preventative measures. For example, if shrinkage cracking is prevalent, adjustments to the concrete mix design or curing practices might be necessary.

Q 28. How do you use data analysis to improve the quality of concrete pavement construction?

Data analysis plays a vital role in improving concrete pavement quality. I utilize data from various sources to identify trends, optimize construction practices, and enhance overall performance.

Material Testing Data: I analyze data from concrete testing (e.g., slump, compressive strength) to ensure the mix design meets specifications and identify any material-related issues. Consistent data helps in optimizing mix design for better strength and durability.

Construction Process Data: Tracking data such as placement rates, curing times, and temperature readings allows identification of potential bottlenecks or deviations from best practices. This data reveals areas for process optimization and improved efficiency.

Inspection Data: Recording of visual inspection findings and measurements of cracks and other defects allows for tracking of pavement deterioration over time. This data is crucial for preventative maintenance and repair prioritization.

Traffic Load Data: Analyzing traffic volume and weight data informs pavement design and selection of appropriate materials to withstand anticipated loads.

Statistical Analysis: Techniques such as regression analysis can help establish correlations between different factors (e.g., material properties and cracking incidence) to guide future projects and improve decision-making.

For example, using historical data on cracking patterns and weather conditions, we identified a correlation between high temperatures during curing and increased transverse cracking. This led to implementing better curing strategies, resulting in a noticeable reduction in cracking in subsequent projects.

Key Topics to Learn for Concrete Paving Inspection Interview

- Understanding Concrete Mix Designs: Knowing the different types of concrete mixes and their suitability for various paving applications. This includes understanding the impact of water-cement ratio, aggregate size, and admixtures.

- Formwork and Subgrade Preparation: Inspecting the proper preparation of the subgrade, including compaction and drainage considerations, and the correct setup and alignment of formwork to ensure a smooth, level surface.

- Concrete Placement and Finishing Techniques: Understanding the proper methods for placing and finishing concrete to achieve the desired surface texture, smoothness, and density. This includes identifying potential issues during the placement process.

- Curing and Protection: Knowing the importance of proper curing methods to ensure the strength and durability of the concrete pavement and recognizing potential issues with curing methods.

- Quality Control Testing: Familiarity with common quality control tests used in concrete paving, such as slump tests, air content tests, and compressive strength testing. Understanding how to interpret test results and identify potential problems.

- Joint Design and Construction: Understanding the different types of joints used in concrete pavements (e.g., contraction, expansion, construction) and how to ensure proper construction to prevent cracking and deterioration.

- Defect Identification and Remediation: Ability to identify common defects in concrete pavements (e.g., cracking, scaling, spalling) and propose appropriate remediation strategies.

- Safety Regulations and Best Practices: Understanding and adhering to all relevant safety regulations and best practices related to concrete paving inspection.

- Relevant Codes and Standards: Familiarity with applicable building codes and industry standards related to concrete paving.

- Problem-Solving and Decision-Making: Ability to analyze situations, identify problems, and make sound decisions based on your knowledge and experience.

Next Steps

Mastering Concrete Paving Inspection opens doors to rewarding career opportunities with excellent growth potential within the construction industry. A strong understanding of these key concepts will significantly improve your chances of success in interviews. To further enhance your job prospects, it’s crucial to create an ATS-friendly resume that highlights your skills and experience effectively. We strongly recommend using ResumeGemini to build a professional and impactful resume. ResumeGemini offers valuable tools and resources, including examples of resumes tailored to Concrete Paving Inspection, to help you stand out from the competition.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good