The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Aviation Support interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Aviation Support Interview

Q 1. Explain the difference between scheduled and unscheduled maintenance.

Scheduled maintenance is preventative, performed at predetermined intervals based on aircraft type, operating hours, or calendar time. Think of it like regular car servicing – oil changes, tire rotations, etc. It’s designed to catch potential problems *before* they become critical. Unscheduled maintenance, conversely, is reactive. It addresses problems that arise unexpectedly, such as a sudden engine malfunction or a component failure. It’s like needing a tow truck because your car broke down unexpectedly.

- Scheduled: Includes tasks like engine inspections, component replacements (based on life limits), and routine checks outlined in the aircraft’s maintenance manual. This minimizes downtime and improves aircraft reliability.

- Unscheduled: Often triggered by a malfunctioning system or damage during operation. This can lead to significant delays and higher costs.

For example, a scheduled maintenance task might involve changing the oil in a helicopter’s engine every 50 flight hours, while an unscheduled task might involve repairing a cracked propeller blade after a bird strike.

Q 2. Describe your experience with troubleshooting aircraft systems.

My experience in troubleshooting aircraft systems involves a systematic approach combining technical knowledge, diagnostic tools, and adherence to safety protocols. I begin by carefully reviewing the aircraft’s maintenance logs and the pilot’s report to identify any relevant clues. Then, I use a combination of built-in diagnostic systems, specialized test equipment (e.g., multimeters, oscilloscopes), and technical manuals to pinpoint the source of the malfunction.

For instance, I once worked on an aircraft experiencing intermittent hydraulic pressure issues. By systematically checking pressure readings at various points in the system, isolating different components and using a specialized hydraulic pressure tester, we identified a faulty pressure relief valve, which was replaced, and the system restored to full functionality.

Throughout the troubleshooting process, safety is paramount. I always follow strict lockout/tagout procedures to prevent accidental power activation or energization during repair, ensuring the aircraft is airworthy before allowing flight operations to resume.

Q 3. What are your familiar with different types of Ground Support Equipment (GSE)?

My familiarity with Ground Support Equipment (GSE) is extensive. I’m proficient in the operation and maintenance of various types, including:

- Towing tractors: Used for moving aircraft around the tarmac. I’m familiar with different types, from small tugs for smaller aircraft to heavy-duty tractors for larger planes.

- Power units (APU): Provide auxiliary power for aircraft when their engines are off. Understanding their operation, maintenance, and troubleshooting is critical.

- Air start units: Provide compressed air to start aircraft engines. I understand safety protocols and operational procedures for these units.

- Aircraft steps and stairs: Ensuring safety in personnel access to the aircraft.

- Baggage loaders and cargo lifts: Used for efficient loading and unloading of baggage and cargo.

- Fuel trucks: I understand the safety procedures for fueling aircraft, including preventing spills and static electricity hazards.

I’m also familiar with GSE maintenance procedures, including regular inspections and preventative maintenance schedules, to ensure equipment safety and reliability.

Q 4. How do you prioritize maintenance tasks during peak operational periods?

Prioritizing maintenance tasks during peak operational periods requires a strategic approach. I utilize a system that combines urgency, safety, and operational impact. This often involves the use of a computerized maintenance management system (CMMS).

- Safety First: Tasks that directly impact flight safety, like critical system repairs or mandatory inspections, always take precedence. Think of a critical engine component needing immediate attention.

- Urgency Assessment: Tasks are categorized based on their urgency – immediate, urgent, and routine. Immediate tasks are addressed instantly. Urgent tasks are planned in the immediate schedule, and routine tasks are scheduled based on available downtime.

- Impact on Operations: Tasks that have the most significant impact on operational efficiency are prioritized. For example, a maintenance issue impacting a high-demand flight would take precedence over a less critical one.

Effective communication with flight crews and operational management is also crucial to ensure alignment between maintenance needs and operational constraints. Sometimes, compromises must be made but always with safety as the top priority.

Q 5. Explain your understanding of aviation safety regulations (e.g., FAA regulations).

My understanding of aviation safety regulations, particularly those set by the FAA (Federal Aviation Administration) in the US, is comprehensive. These regulations encompass various aspects, including aircraft maintenance, airworthiness directives (ADs), and pilot certification.

I am fully versed in the FAA’s Part 43 (Maintenance, Preventive Maintenance, Rebuilding, and Alteration), which details the rules and regulations governing aircraft maintenance. This includes understanding the requirements for maintenance records, mechanic certifications, and the process for returning aircraft to airworthiness. Additionally, I stay updated on ADs which mandate corrective actions for specific aircraft models based on identified safety issues. Regular compliance training, coupled with practical experience, keeps me well-informed about all applicable regulations. Non-compliance can result in significant consequences and compromise safety.

Q 6. Describe your experience with aircraft maintenance documentation and record-keeping.

My experience with aircraft maintenance documentation and record-keeping is meticulous. I understand that accurate and detailed records are critical for maintaining airworthiness, tracing maintenance history, and ensuring compliance with regulations. I’m proficient in using both manual and computerized maintenance tracking systems (CMMS).

Every maintenance action, from a simple oil change to a complex engine overhaul, is meticulously documented, including the date, time, performed work, parts used, mechanic’s signature, and any associated findings. The documentation adheres strictly to FAA guidelines and is accessible for audits or investigations. The use of CMMS allows for efficient tracking of maintenance schedules, managing parts inventory, and generating reports for regulatory compliance.

Q 7. How do you handle a critical maintenance issue that requires immediate attention?

Handling a critical maintenance issue requiring immediate attention necessitates a rapid response rooted in calm, decisive action. My approach involves a series of steps:

- Immediate Assessment: Quickly evaluate the severity of the issue and any immediate safety risks. This may include assessing the affected system and its impact on flight operations.

- Notification: Immediately alert relevant personnel, including maintenance supervisors, flight operations, and engineering support. Clear communication prevents misinterpretations and ensures appropriate resources are mobilized.

- Emergency Response Plan: Initiate the relevant emergency response plan outlining specific actions for the given situation, which may involve contacting specialized technicians or engineers.

- Troubleshooting: While maintaining safety, begin troubleshooting the issue while adhering to safety protocols. This might require isolating the problem area and preventing further damage.

- Temporary Fix (if possible): Depending on the situation, a temporary fix may be implemented to allow a safe return to operation, followed by a thorough repair later.

- Documentation: All actions taken are thoroughly documented, including the initial assessment, troubleshooting steps, temporary fixes (if any), and the final resolution. This documentation is critical for follow-up and preventative measures.

Safety always remains the highest priority. The aim is to resolve the issue quickly and safely, minimizing disruption while ensuring the aircraft remains airworthy.

Q 8. What are your experience with different aircraft maintenance software?

My experience encompasses a range of aircraft maintenance software, from legacy systems to modern, cloud-based solutions. I’ve worked extensively with AMOS (Aircraft Maintenance Management System), a comprehensive system managing maintenance schedules, work orders, and inventory. I’m also proficient in Trax, a system focused on tracking maintenance events and ensuring compliance. Furthermore, I have experience with smaller, specialized software focused on specific aircraft components, allowing for more granular control. For example, I’ve used software dedicated to managing engine maintenance records which helped us to drastically reduce downtime by enabling proactive maintenance planning based on real-time engine data analysis. My experience extends to both the implementation and day-to-day operation of these systems, including data entry, reporting, and system configuration. I understand the importance of data integrity and system optimization for efficient maintenance operations.

Q 9. Describe your experience with aircraft parts inventory management.

Aircraft parts inventory management is crucial for maintaining operational efficiency and safety. My experience involves utilizing both manual and computerized inventory systems. In smaller operations, I relied on manual tracking using spreadsheets and physical inventory checks. This taught me the importance of meticulous record-keeping and the limitations of manual systems in scaling up. In larger organizations, I’ve worked with sophisticated inventory management software integrated with maintenance scheduling systems, allowing for real-time tracking of parts, automated ordering, and forecasting of demand. For instance, I implemented a system that utilized predictive analytics to anticipate parts needed for upcoming maintenance events, minimizing delays and stockouts. This involved close collaboration with procurement and logistics teams to ensure a streamlined process from ordering to receiving and storage. My approach emphasizes minimizing waste, optimizing storage space, and implementing robust control measures to prevent loss or damage.

Q 10. How do you ensure compliance with aviation safety regulations during maintenance?

Ensuring compliance with aviation safety regulations is paramount. My approach is proactive and multi-faceted. It begins with a thorough understanding of applicable regulations like those published by the FAA (Federal Aviation Administration) or EASA (European Union Aviation Safety Agency), depending on the regulatory domain. I make sure all maintenance activities are performed strictly according to the manufacturer’s instructions, and all work is documented meticulously. Regular audits are conducted to verify compliance and identify areas for improvement. I’m responsible for ensuring that all personnel are properly trained and certified to perform their assigned tasks. This includes staying updated on any changes or new regulations, which requires continuous professional development and engagement with regulatory bodies. For example, when new airworthiness directives are issued, I make sure our maintenance schedules are updated promptly and correctly, and our technicians receive the necessary training. A crucial aspect is creating a safety culture where reporting near misses and incidents is encouraged without fear of reprisal, enabling continuous learning and improvement.

Q 11. What is your experience with quality control procedures in aviation maintenance?

Quality control in aviation maintenance is non-negotiable. My experience involves implementing and overseeing rigorous quality control procedures at every stage of the maintenance process. This includes pre-flight inspections, detailed checklists for each task, thorough documentation of all work performed, and post-maintenance inspections. We utilize a multi-tiered system of checks and balances, with supervisors reviewing the work of technicians and a dedicated quality control team performing independent inspections and audits. Statistical process control techniques are employed to identify trends and potential areas of weakness in the maintenance process, allowing us to anticipate and prevent problems. I am familiar with ISO 9001 standards and other industry best practices, and I’ve implemented these principles to create a culture of quality and continuous improvement. In one instance, by implementing a more rigorous inspection process for a specific component, we significantly reduced the number of in-service failures, saving the company significant time and money.

Q 12. How would you handle a conflict with a member of another maintenance team?

Conflict resolution is an essential skill in a collaborative environment like aviation maintenance. My approach focuses on open communication and a professional demeanor. If a conflict arises with a member of another maintenance team, I’d first attempt to understand their perspective and the root cause of the disagreement. I believe in seeking a win-win solution that prioritizes the safe and efficient operation of the aircraft. I’d initiate a direct conversation with the individual, emphasizing respectful dialogue and active listening. If the issue cannot be resolved directly, I would involve a supervisor or manager to mediate the discussion and ensure a fair and equitable resolution. Transparency and documentation of the issue and its resolution are vital. My goal is to maintain a positive working relationship while safeguarding operational integrity and safety.

Q 13. Explain your experience working with different aircraft types.

I’ve worked on a variety of aircraft types, ranging from small single-engine piston aircraft to large commercial airliners. My experience includes working on models from Boeing (737, 777), Airbus (A320, A330), and regional jets like Embraer E-Jets and Bombardier CRJ series. This diverse experience has provided me with a broad understanding of different aircraft systems, maintenance procedures, and regulatory requirements. I’m proficient in interpreting different maintenance manuals and technical publications, and adaptable to working with various teams and technologies. Working with such a range of aircraft helps improve my problem-solving skills, as each aircraft type presents unique challenges and requires a different approach to maintenance. This cross-aircraft experience is highly valuable for identifying best practices and applying them across different platforms.

Q 14. Describe your understanding of aircraft maintenance manuals and technical publications.

Aircraft maintenance manuals and technical publications are the cornerstone of safe and effective maintenance. My understanding extends beyond simply reading them – I am proficient in interpreting them to guide maintenance activities. I’m familiar with various types of publications, including Illustrated Parts Catalogs (IPCs), Maintenance Manuals, Structural Repair Manuals, and Airworthiness Directives (ADs). I understand the importance of cross-referencing information from multiple sources and recognizing potential conflicts or ambiguities. I know how to navigate complex technical drawings and schematics. Furthermore, I understand the importance of staying updated with the latest revisions and amendments to these publications, and I utilize tools like service bulletins and the manufacturer’s websites to keep up with the most current information. A deep understanding of these documents is vital for performing maintenance correctly and ensuring aircraft airworthiness. For example, misinterpreting a maintenance manual can lead to errors which may cause serious safety consequences.

Q 15. How do you stay current with changes in aviation maintenance technology and regulations?

Staying current in aviation maintenance requires a multi-faceted approach. It’s not a passive activity; it’s an ongoing commitment to continuous learning. I utilize several key strategies:

- Subscription to industry publications and online resources: I regularly read journals like Aviation Week & Space Technology and subscribe to online newsletters from organizations like the FAA and EASA. This keeps me informed on the latest technological advancements and regulatory changes.

- Active participation in professional development: I attend conferences, workshops, and seminars organized by industry bodies like SAE International and attend webinars on emerging technologies like predictive maintenance and digital twin technology. This offers valuable networking opportunities and exposure to expert insights.

- Continuous training and certifications: I actively pursue continuing education courses and updates to maintain my certifications and licenses, ensuring my skills are aligned with the latest safety standards and best practices. For instance, I recently completed a course on the latest advancements in composite material repair.

- Mentorship and collaboration: I actively engage with colleagues and mentors within the field, exchanging knowledge and best practices. Learning from others’ experiences is incredibly valuable, especially when troubleshooting complex issues.

This proactive approach allows me to anticipate changes, adapt my practices, and maintain a high level of competence in this dynamic field.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your approach to problem-solving in a high-pressure aviation environment.

Problem-solving in aviation is about methodical, decisive action under pressure. My approach is based on a structured, systematic methodology:

- Rapid Assessment: I prioritize understanding the nature and severity of the problem. This involves quickly gathering all relevant information from the pilots, maintenance logs, and the aircraft itself. For example, if a pilot reports a loss of engine power, I would immediately focus on fuel levels, engine performance data, and any recent maintenance history.

- Systematic Troubleshooting: Once the problem is defined, I use a methodical process of elimination. This often involves checking checklists, consulting technical manuals, and using diagnostic tools to isolate the root cause. I leverage my deep understanding of aircraft systems and prioritize safety at every step.

- Collaboration and Communication: In high-pressure situations, clear and effective communication is crucial. I collaborate with other maintenance technicians, engineers, and flight crew to leverage collective expertise and ensure everyone is on the same page. For example, I’d brief the pilots on my assessment and the proposed course of action, keeping them informed of the progress.

- Documentation: Every step, from initial assessment to final resolution, is meticulously documented. This detailed record is critical for future reference, regulatory compliance, and continuous improvement. This includes not only the solution but also the steps taken to reach the diagnosis.

- Post-incident analysis: After the issue is resolved, I take the time to reflect and analyze the situation. What could have been done differently? Were there any systemic issues that contributed to the problem? This reflective process aids in preventing similar incidents in the future.

This systematic approach ensures efficient problem-solving while maintaining the highest safety standards.

Q 17. How do you ensure the safety and security of aircraft components and parts?

Ensuring the safety and security of aircraft components and parts is paramount. It requires rigorous adherence to regulations and best practices. My approach centers around several key elements:

- Strict adherence to traceability: Every part has a unique identification number. We meticulously track its origin, maintenance history, and any repairs or modifications. This ensures we know exactly the condition and history of each component.

- Regular inspections and testing: Components undergo regular inspections following manufacturer guidelines and regulatory mandates. This includes visual inspections, non-destructive testing (NDT) techniques like ultrasonic or eddy current testing, and functional testing to verify proper operation.

- Proper storage and handling: Components are stored in controlled environments to protect them from damage, corrosion, or contamination. Specific handling procedures are followed to prevent damage during transport or installation.

- Quality control measures: We implement rigorous quality control processes at every stage, from receiving new parts to installing repaired components. This includes inspections, audits, and the use of calibrated tools and equipment.

- Security measures: Access to sensitive aircraft components is strictly controlled to prevent theft, sabotage, or unauthorized modifications. This includes secure storage facilities, access control systems, and regular security checks.

These measures, combined with ongoing training and awareness, ensure the safety and security of every aircraft part.

Q 18. Describe your experience with preventative maintenance programs.

Preventative maintenance programs are crucial for maximizing aircraft safety and operational efficiency. My experience encompasses various aspects:

- Developing and implementing maintenance schedules: I’ve been involved in creating and implementing comprehensive maintenance schedules based on the manufacturer’s recommendations, airworthiness directives (ADs), and operational requirements. These schedules incorporate both time-based and condition-based maintenance tasks.

- Managing maintenance records: I have extensive experience meticulously maintaining accurate and up-to-date records for all maintenance activities. This includes using Computerized Maintenance Management Systems (CMMS) to track work orders, parts usage, and maintenance history.

- Implementing predictive maintenance techniques: I am familiar with integrating predictive maintenance techniques using data analytics and sensor technology. This allows for proactive identification of potential problems before they escalate, improving operational reliability and reducing downtime. For example, analyzing vibration data from engines to predict potential bearing failures.

- Continuous improvement of maintenance processes: I actively look for opportunities to optimize maintenance procedures, improve efficiency, and reduce costs while maintaining safety. This often involves analyzing maintenance data to identify trends and potential areas for improvement. For example, examining the frequency of specific repairs to identify potential root causes and preventive measures.

My experience ensures that preventative maintenance is not just a checklist but a proactive approach to safety and operational effectiveness.

Q 19. What are your skills in using specialized tools and equipment used in aviation maintenance?

My skills encompass a wide range of specialized tools and equipment used in aviation maintenance. This includes:

- Aircraft specific tooling: Proficient in the use of specialized tools for specific aircraft models, including torque wrenches, rivet guns, and specialized diagnostic equipment. I understand the importance of using calibrated tools to ensure accuracy and safety.

- Non-destructive testing (NDT) equipment: Experienced in operating and interpreting results from various NDT techniques, such as ultrasonic testing, eddy current testing, and liquid penetrant inspection. This allows for the detection of internal flaws without damaging the component.

- Avionics test equipment: Familiar with using sophisticated avionics test equipment to diagnose and troubleshoot electrical and electronic systems. This involves understanding complex schematics and using specialized software for diagnosis.

- Engine maintenance equipment: Experienced in the use of engine maintenance equipment, including specialized tools for engine disassembly, inspection, and reassembly. Safety protocols surrounding high-pressure systems and potential hazards are strictly followed.

- Computerized Maintenance Management Systems (CMMS): Proficient in using CMMS software to manage maintenance tasks, track parts inventory, and generate reports. Data analysis from these systems informs better decision-making and helps track key metrics.

My hands-on experience ensures that I can effectively and safely use these tools to maintain aircraft to the highest standards.

Q 20. Explain your experience in working with hazardous materials in an aviation setting.

Working with hazardous materials in aviation requires strict adherence to safety regulations and procedures. My experience includes:

- Handling and disposal of hazardous waste: I am trained in the proper handling, storage, and disposal of hazardous materials, such as paints, solvents, and oils, in accordance with all applicable regulations (e.g., OSHA, EPA). This includes understanding Material Safety Data Sheets (MSDS) and following strict waste disposal protocols.

- Use of personal protective equipment (PPE): I am proficient in selecting and using the appropriate PPE, such as respirators, gloves, and eye protection, to mitigate the risks associated with exposure to hazardous materials. The correct PPE is crucial for worker safety.

- Emergency response procedures: I am familiar with emergency response procedures in case of spills or accidents involving hazardous materials. This includes knowing how to contain spills, notify the appropriate authorities, and follow established cleanup protocols.

- Understanding of relevant regulations: I have a thorough understanding of all relevant safety regulations and procedures pertaining to the handling of hazardous materials in an aviation setting. Staying up-to-date on these evolving regulations is critical.

Safety is my top priority, and I meticulously follow all regulations and best practices to minimize risks when working with hazardous materials.

Q 21. How familiar are you with the concept of Mean Time Between Failures (MTBF)?

Mean Time Between Failures (MTBF) is a key metric used to measure the reliability of a system. It represents the average time between failures of a system or component. A higher MTBF indicates higher reliability.

In aviation, MTBF is crucial for assessing the reliability of various aircraft systems, including engines, avionics, and other critical components. It’s used in several ways:

- Predictive maintenance scheduling: MTBF data helps determine appropriate maintenance intervals to minimize the likelihood of failures. Knowing the historical MTBF of a particular component allows for more effective scheduling of inspections and maintenance tasks.

- Assessing component reliability: MTBF data helps compare the reliability of different components or manufacturers. This data is crucial when choosing components or evaluating the effectiveness of different maintenance strategies.

- Safety assessments: Analyzing MTBF data across different aircraft fleets or operational environments helps identify potential safety concerns and areas requiring further investigation.

For example, if the MTBF of a specific engine model decreases significantly, it might indicate a design flaw or the need for improved maintenance practices. Understanding and interpreting MTBF data is essential for proactive maintenance planning and continuous improvement of aircraft safety and reliability.

Q 22. Explain your understanding of different maintenance programs (e.g., condition-based maintenance).

Aviation maintenance programs are designed to ensure the airworthiness and safety of aircraft. Different programs exist to optimize maintenance strategies based on factors like aircraft type, operational environment, and cost considerations. A key example is Condition-Based Maintenance (CBM), which contrasts sharply with traditional scheduled maintenance.

Scheduled Maintenance: This involves performing maintenance tasks at predetermined intervals specified in the aircraft’s maintenance manual. Think of it like changing your car’s oil every 3,000 miles regardless of its condition. This is often simpler to manage but can lead to unnecessary maintenance.

Condition-Based Maintenance (CBM): This proactive approach utilizes real-time data from sensors and diagnostic systems to determine the actual condition of components. Maintenance is then performed only when necessary, based on the data showing a component is degrading or approaching a failure threshold. Imagine your car having sensors that alert you when the oil needs changing, instead of relying solely on a mileage schedule.

Other programs include:

- Predictive Maintenance: Uses advanced analytics and machine learning to forecast potential failures and schedule maintenance before they occur.

- Preventive Maintenance: Similar to scheduled maintenance but often includes more detailed inspections and checks, aiming to prevent issues before they arise.

- Reliability-Centered Maintenance (RCM): A systematic approach focusing on maintaining the functions of an aircraft, rather than simply adhering to a schedule. It prioritizes the most critical components and systems.

The choice of maintenance program depends on several factors, including the age of the aircraft, its complexity, operational hours, cost constraints, and the available technology. A sophisticated airline might employ a blend of CBM and predictive maintenance for its newer fleet, while relying more on scheduled maintenance for older aircraft.

Q 23. Describe your experience with risk assessment and mitigation in aviation maintenance.

Risk assessment and mitigation are paramount in aviation maintenance. My experience involves a systematic approach, typically following a framework like the Bow Tie Analysis. This visually represents potential hazards (threats), their associated consequences, and the preventative and mitigating controls put in place.

Process:

- Hazard Identification: Identifying potential hazards (e.g., incorrect parts installation, improper maintenance procedures, human error).

- Risk Assessment: Evaluating the likelihood and severity of each hazard occurring and its potential impact on flight safety. We often use a risk matrix to categorize risks as low, medium, or high.

- Mitigation Strategies: Developing and implementing controls to reduce or eliminate the identified risks. This could involve procedural changes, training improvements, technological enhancements (e.g., improved inspection tools), or enhanced supervision.

- Monitoring and Review: Regularly monitoring the effectiveness of the implemented controls and reviewing the risk assessment process periodically to adapt to changing circumstances.

Example: During a recent engine overhaul, we identified a risk of incorrectly installing a critical component. Mitigation involved developing a detailed checklist, enhanced tooling to prevent misalignment, and additional training for technicians, accompanied by thorough verification procedures.

Documentation is crucial; all assessments, mitigation strategies, and their effectiveness are meticulously recorded and reported to relevant authorities.

Q 24. How do you ensure accurate communication with pilots and other flight crew members?

Clear and effective communication with pilots and flight crew is vital for flight safety. I employ several strategies to ensure accuracy:

- Formal Reporting Channels: Utilizing established channels like maintenance logs and discrepancy reports ensures all findings are documented and communicated clearly.

- Precise and Concise Language: Using unambiguous technical terminology and avoiding jargon where possible. If technical terms are used, clear definitions are provided.

- Face-to-Face Briefing (When Possible): Whenever feasible, I prefer direct communication with pilots to explain maintenance findings and their implications for flight operations. This fosters trust and allows for immediate clarification.

- Verification and Acknowledgement: Confirming that the pilots have understood the information through direct questioning and receiving their acknowledgement.

- Technological Aids: Using electronic systems for efficient communication and tracking of maintenance actions, especially for complex issues.

An example would be meticulously explaining the limitations imposed by a temporary repair on an aircraft system, highlighting specific operational restrictions to the pilots and getting their sign-off to ensure they are fully aware of potential consequences.

Q 25. Explain your experience with maintaining and managing aviation safety data.

Maintaining and managing aviation safety data is critical for continuous improvement. My experience involves:

- Data Collection: Systematically gathering data from various sources, including maintenance logs, incident reports, safety audits, and operational data.

- Data Analysis: Using data analysis tools and techniques to identify trends, patterns, and potential safety risks. This might involve statistical analysis and root cause analysis of incidents.

- Reporting and Communication: Creating concise reports to communicate findings to management and relevant stakeholders, including highlighting any significant safety issues and recommended improvements.

- Data Storage and Archiving: Securely storing and archiving safety data according to regulatory requirements and internal procedures. This ensures data is readily accessible for future analysis and investigations.

- Data-Driven Improvements: Using data insights to improve maintenance processes, training programs, and risk mitigation strategies.

For instance, analyzing data on recurring engine malfunctions might reveal a weakness in a specific maintenance procedure, allowing us to revise the procedure and prevent future occurrences.

Q 26. Describe your knowledge of different aviation maintenance certification programs.

I am familiar with several aviation maintenance certification programs, most notably those dictated by national aviation authorities such as the FAA (Federal Aviation Administration) in the US and EASA (European Union Aviation Safety Agency) in Europe. These programs ensure that maintenance organizations and individuals meet stringent safety standards.

These programs cover various aspects of maintenance, including:

- Part 145 (FAA) / Part 145 (EASA): Certification for maintenance organizations, outlining requirements for personnel qualifications, facilities, equipment, and quality control systems.

- Aircraft Type Ratings: Certification for mechanics to work on specific aircraft types, requiring specialized training and examinations.

- Continuing Airworthiness Management Organizations (CAMO): Organizations responsible for managing the continuing airworthiness of aircraft, ensuring they remain airworthy throughout their lifespan.

Understanding these programs ensures compliance with regulations and allows for effective management and oversight of all maintenance activities, which are essential to maintain safety and legal operations.

Q 27. How familiar are you with the use of Computerized Maintenance Management Systems (CMMS)?

I have extensive experience using Computerized Maintenance Management Systems (CMMS). These software systems are integral to modern aviation maintenance, providing a centralized platform for managing all aspects of maintenance. My proficiency includes:

- Work Order Management: Creating, assigning, and tracking work orders, ensuring timely completion of maintenance tasks.

- Inventory Management: Managing aircraft parts inventory, tracking stock levels, and ordering parts as needed. This often includes integration with suppliers.

- Maintenance Scheduling: Scheduling and managing routine and unscheduled maintenance activities, including compliance with airworthiness directives.

- Reporting and Analytics: Generating reports on maintenance performance, costs, and compliance, enabling data-driven decision making.

- Integration with other systems: Working with CMMS systems that interface with other aviation-related software, such as flight operations systems and safety management systems.

A specific example would be using a CMMS to track the life cycles of specific parts, predict potential failures, and schedule proactive maintenance, thus minimizing downtime and optimizing maintenance costs. This integration helps to streamline maintenance operations and improve efficiency considerably.

Q 28. How do you contribute to a positive safety culture within the aviation maintenance team?

Contributing to a positive safety culture involves a multifaceted approach, emphasizing proactive hazard identification and mitigation, open communication, and continuous improvement. Specifically, I:

- Promote Open Communication: Encourage technicians to report safety concerns without fear of retribution, fostering an environment where everyone feels comfortable expressing their opinions and concerns.

- Lead by Example: Strictly adhering to safety procedures and regulations, demonstrating a strong commitment to safety in all aspects of my work.

- Encourage Teamwork: Promoting collaboration and knowledge sharing among team members, ensuring that everyone is working together towards a common goal of safety.

- Participate in Safety Meetings: Actively participating in safety meetings to discuss safety-related incidents, near misses, and potential hazards, contributing to effective root cause analysis and the development of preventative measures.

- Continuous Learning: Staying abreast of the latest safety regulations, technologies, and best practices through training and professional development, sharing knowledge with the team.

An example would be implementing a peer-to-peer observation program where team members are encouraged to observe each other’s work, identify potential hazards, and provide constructive feedback, enhancing a culture of continuous improvement and shared responsibility for safety.

Key Topics to Learn for Aviation Support Interview

- Aircraft Maintenance & Repair: Understanding different maintenance schedules (A, B, C checks), common aircraft systems (hydraulic, electrical, pneumatic), and troubleshooting techniques. Practical application: Describe your experience with fault diagnosis and resolution in a specific aircraft system.

- Safety Regulations & Compliance: Familiarity with FAA (or equivalent) regulations, safety procedures, and risk management principles. Practical application: Explain how you ensure adherence to safety protocols in a high-pressure environment.

- Logistics & Supply Chain Management: Understanding inventory management, parts procurement, and supply chain optimization within the aviation industry. Practical application: Describe a situation where you optimized a logistical process to improve efficiency.

- Ground Support Equipment (GSE): Knowledge of various GSE types, their operation, and maintenance. Practical application: Explain your experience with troubleshooting GSE malfunctions.

- Aviation Communication & Teamwork: Effective communication skills and ability to work collaboratively within a team. Practical application: Describe a situation where your communication skills were crucial for successful teamwork in an aviation setting.

- Technical Problem Solving & Decision Making: Ability to analyze complex problems, identify root causes, and implement effective solutions under pressure. Practical application: Detail your approach to solving a challenging technical problem within an aviation context.

Next Steps

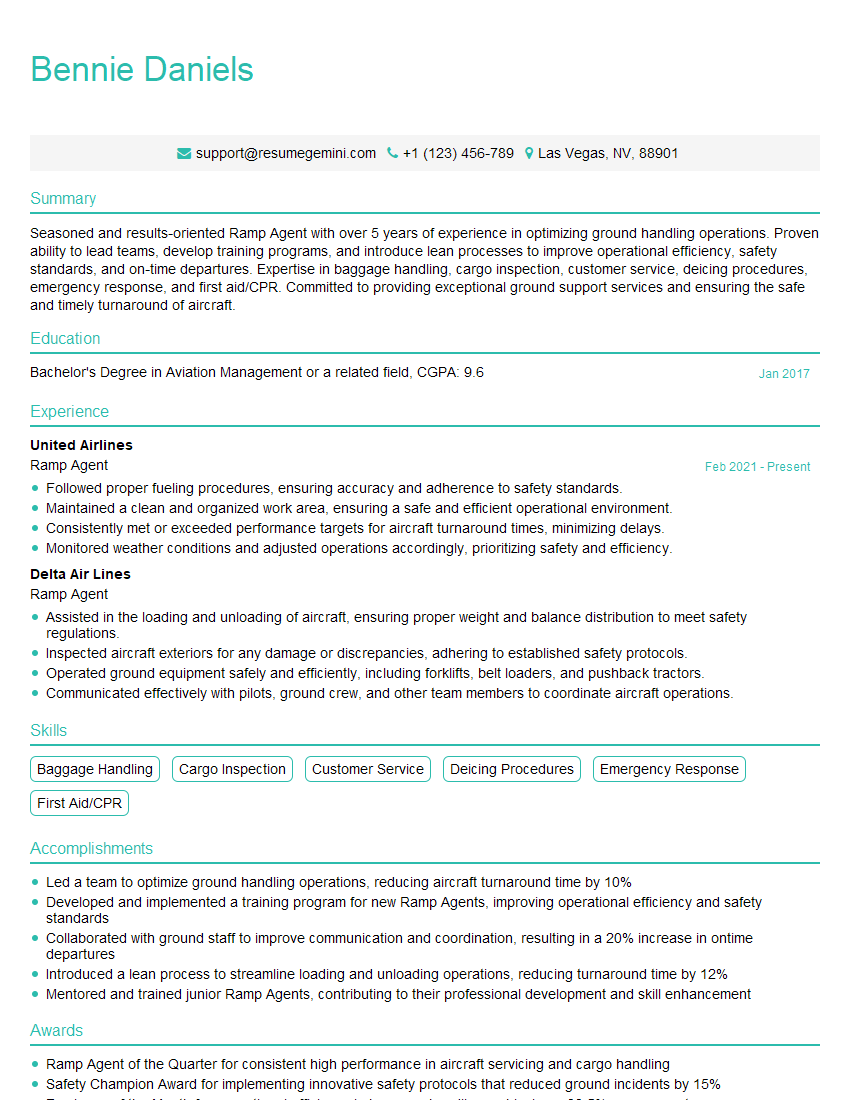

Mastering Aviation Support opens doors to a rewarding career with diverse opportunities for growth and specialization. To maximize your job prospects, it’s crucial to present your skills and experience effectively through an ATS-friendly resume. ResumeGemini is a trusted resource that can help you create a professional and impactful resume, significantly increasing your chances of landing your dream job. Examples of resumes tailored to Aviation Support are available to guide you. Invest time in crafting a compelling resume – it’s your first impression with potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good