Cracking a skill-specific interview, like one for Construction Safety Inspection, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Construction Safety Inspection Interview

Q 1. Describe your experience with OSHA regulations.

My experience with OSHA regulations is extensive. I’ve worked on numerous construction projects requiring strict adherence to OSHA standards, including OSHA 1926 (Construction). This includes a deep understanding of general industry standards that also apply to construction. I’m proficient in interpreting OSHA regulations, applying them to site-specific hazards, and ensuring compliance through regular inspections and safety training. For instance, I’ve successfully implemented fall protection plans in accordance with OSHA 1926 Subpart M, ensuring the use of appropriate guardrails, safety nets, and personal fall arrest systems. I’ve also been directly involved in the development and implementation of hazard communication programs, lockout/tagout procedures, and emergency action plans, all in strict compliance with OSHA requirements. My experience extends to conducting regular safety inspections and documenting findings to maintain compliance records. I understand the importance of record-keeping and reporting requirements to OSHA as well.

Q 2. Explain the hierarchy of hazard controls.

The hierarchy of hazard controls is a fundamental principle in occupational safety and health. It prioritizes control methods to minimize risk, starting with the most effective and progressing to less effective measures. The hierarchy is generally presented as follows:

- Elimination: This is the most effective control. It involves removing the hazard entirely. For example, replacing a hazardous chemical with a less hazardous alternative.

- Substitution: Replacing a hazardous material or process with a less hazardous one. Instead of using scaffolding that needs to be erected and dismantled multiple times, using prefabricated modular scaffolding.

- Engineering Controls: Implementing physical changes to the work environment to minimize exposure to hazards. Examples include installing guardrails, using machine guarding, or improving ventilation.

- Administrative Controls: Implementing changes in work practices, procedures, or policies to reduce risk. This might include job rotation, providing safety training, establishing safe work permits, or enforcing work restrictions.

- Personal Protective Equipment (PPE): Providing workers with PPE to protect them from hazards. While PPE is crucial, it’s the last line of defense and should be used in conjunction with other controls. Examples include hard hats, safety glasses, and hearing protection.

Following this hierarchy ensures that the most effective controls are implemented first, significantly reducing the likelihood of accidents and injuries.

Q 3. How do you conduct a job hazard analysis (JHA)?

Conducting a Job Hazard Analysis (JHA) is a systematic process to identify and control hazards associated with a specific task or job. Here’s a step-by-step approach:

- Identify the task: Clearly define the specific job or task to be analyzed.

- List steps: Break down the task into its individual steps in chronological order.

- Identify potential hazards: For each step, identify all potential hazards, including physical, chemical, biological, ergonomic, and psychosocial hazards.

- Identify who might be harmed: Determine which workers or others could be exposed to these hazards.

- Evaluate the risk: Assess the likelihood and severity of harm for each hazard. This often involves a risk matrix considering frequency and consequence.

- Recommend control measures: Based on the hierarchy of controls, suggest specific measures to eliminate or mitigate each hazard.

- Document findings: Record the findings of the JHA, including the identified hazards, risk assessments, and control measures. This document becomes a critical part of the overall safety plan.

- Review and update: The JHA should be reviewed and updated regularly, especially after incidents or changes in work procedures.

For example, a JHA for installing drywall might identify hazards such as falls from heights, cuts from sharp tools, and back injuries from lifting heavy materials. The JHA would then recommend control measures, such as using harnesses and scaffolding for falls, providing cut-resistant gloves, and utilizing lifting equipment to reduce back strain.

Q 4. What are the key elements of a comprehensive safety program?

A comprehensive safety program is the cornerstone of a safe construction site. Key elements include:

- Safety Policy and Commitment from Leadership: A clear statement of commitment to safety from top management, demonstrating that safety is a core value.

- Hazard Identification and Risk Assessment: A systematic process for identifying hazards and assessing associated risks. This includes JHAs, regular inspections, and incident investigations.

- Training and Education: Providing all workers with comprehensive safety training tailored to their specific job tasks and potential hazards. This includes regular refreshers and updates.

- Emergency Action Plan: A detailed plan outlining procedures for various emergencies, including fire, medical emergencies, and evacuations. Regular drills ensure preparedness.

- Personal Protective Equipment (PPE) Program: Providing and ensuring the proper use of appropriate PPE for all tasks. Regular inspections and maintenance of PPE are crucial.

- Incident Investigation and Reporting: A thorough investigation of all incidents, near misses, and accidents to identify root causes and prevent future occurrences. Detailed reporting allows for trend analysis.

- Communication and Consultation: Open communication channels to encourage reporting of hazards and near misses. Regular safety meetings and toolbox talks are essential.

- Monitoring and Evaluation: Continuous monitoring of the safety program’s effectiveness, including leading and lagging indicators. Regular audits and reviews help to identify areas for improvement.

These elements work together to create a culture of safety where everyone takes responsibility for their own safety and the safety of others.

Q 5. How do you identify and mitigate fall hazards on a construction site?

Identifying and mitigating fall hazards is paramount on a construction site. It begins with proactive hazard identification during the planning phase. This involves a thorough review of blueprints and plans to pinpoint potential fall risks.

Identification: Common fall hazards include working at heights, unprotected edges, unguarded openings, and slippery surfaces. I use checklists and visual inspections to identify these, paying close attention to areas like scaffolding, roofs, and elevated walkways.

Mitigation: My mitigation strategies follow the hierarchy of controls.

- Elimination: If possible, I’d redesign the work to eliminate the need to work at heights.

- Engineering Controls: Guardrails, safety nets, and covers over openings are essential engineering controls. I ensure they are properly installed and maintained. Fall arrest systems, including harnesses and lifelines, are crucial for work where falls are unavoidable.

- Administrative Controls: Implementing procedures for working at heights, including safe work permits, training on fall protection, and supervision. Regular inspections of fall protection equipment are critical.

- PPE: Hard hats are always mandatory and fall protection equipment such as harnesses are vital when working at heights.

Regular inspections and training are key to maintaining a safe working environment, and the constant reinforcement of safe practices is critical.

Q 6. Describe your experience with incident investigation and reporting.

My experience with incident investigation and reporting is extensive. I follow a systematic approach to investigate incidents, aiming to identify root causes and implement corrective actions to prevent recurrence.

Investigation Process:

- Secure the Scene: Prioritize the safety of personnel and secure the area to preserve evidence.

- Gather Information: Collect information from witnesses, reviewing any surveillance footage, examining physical evidence, and referencing relevant documentation.

- Analyze the Data: This involves a thorough analysis of the gathered information to identify contributing factors and root causes.

- Develop Corrective Actions: Based on the analysis, develop specific and actionable corrective actions to address the root causes.

- Implement and Monitor: Implement the corrective actions and monitor their effectiveness to ensure the issue is resolved.

- Report Findings: Prepare a comprehensive report that includes the findings, root causes, and corrective actions.

I’ve successfully managed numerous investigations, ranging from minor incidents to more serious ones. Each investigation is thoroughly documented, shared with relevant stakeholders, and utilized to improve safety practices and prevent future incidents.

Q 7. What are your strategies for communicating safety information to construction workers?

Communicating safety information effectively to construction workers is crucial. I utilize a multi-faceted approach that leverages various communication channels and techniques to ensure the message reaches everyone and is understood.

- Toolbox Talks: Regular short meetings at the beginning of the workday to discuss specific safety concerns or reinforce key messages.

- Safety Meetings: Formal meetings to discuss safety performance data, address issues, and provide safety training.

- Visual Aids: Using posters, signs, and other visual aids to communicate safety messages in a clear and concise manner.

- Written Materials: Providing safety manuals, checklists, and other written materials to reinforce safety procedures.

- Training Programs: Conducting regular training programs to address specific hazards and safety procedures.

- Technology: Utilizing technology such as mobile apps or email to deliver safety information and updates.

- Language Accessibility: Ensuring all communication is easily understandable by all workers, including translation services if needed.

- Two-way Communication: Encouraging feedback from workers to ensure their concerns are addressed and they feel comfortable raising safety issues.

A combination of these strategies ensures that safety messages are consistently reinforced and workers feel empowered to contribute to a safe work environment. I always prioritize clear, concise, and relatable communication, ensuring everyone understands their responsibilities and feels comfortable raising concerns.

Q 8. Explain your knowledge of personal protective equipment (PPE).

Personal Protective Equipment (PPE) refers to the clothing, helmets, goggles, or other garments or equipment designed to protect the wearer’s body from injury or infection. My knowledge encompasses a wide range of PPE, from the basics like hard hats, safety glasses, and high-visibility vests to more specialized equipment such as respirators, fall protection harnesses, and hearing protection. I understand the importance of selecting the appropriate PPE for specific hazards present on a construction site. For example, working at heights requires a full-body harness, appropriate anchorage points, and fall arrest systems. Working with hazardous materials necessitates selecting the right respirator based on the specific material’s safety data sheet (SDS).

Beyond selection, I’m proficient in ensuring PPE is properly fitted, maintained, and used correctly. Regular inspections are crucial to identify damage or wear and tear, ensuring workers are protected. I also understand the importance of training workers on the proper use and limitations of their PPE. For instance, a safety helmet protects against falling objects, but it doesn’t offer protection from electrical hazards. Proper training ensures workers understand these limitations.

Q 9. How do you ensure compliance with safety regulations on a construction site?

Ensuring compliance with safety regulations is a multifaceted process that begins with a thorough understanding of all applicable OSHA (or relevant regional) standards and regulations specific to the construction project. This includes reviewing blueprints, understanding site-specific hazards, and developing a comprehensive safety plan. I implement this by conducting regular safety inspections, both planned and impromptu, to identify potential hazards and ensure workers are adhering to safety protocols. Documentation is key; I meticulously maintain records of inspections, safety meetings, training, and incident reports.

I utilize a proactive approach, not just reactive. This means implementing preventive measures before accidents occur. This includes enforcing the use of PPE, establishing clear safety procedures for all tasks, and providing regular safety training and toolbox talks. I also establish clear lines of communication between management, supervisors, and workers to foster a safety-conscious culture. Finally, I conduct thorough investigations of any incidents or near misses to determine root causes and implement corrective actions to prevent recurrence. This creates a feedback loop, continuously improving safety performance.

Q 10. Describe your experience with lockout/tagout procedures.

Lockout/Tagout (LOTO) procedures are crucial for preventing accidental energization of equipment during maintenance or repair, protecting workers from serious injury or death. My experience includes training workers on the proper steps involved in LOTO, from identifying energy sources to verifying isolation and de-energization. I’m familiar with various types of lockout devices and the importance of using appropriate tags to clearly identify who has locked out the equipment and why.

I ensure compliance by conducting regular audits to verify that LOTO procedures are being followed correctly and that the equipment remains properly locked out until authorized. I also stress the importance of proper documentation, including the creation of LOTO procedures specific to each piece of equipment, along with a detailed log documenting each lockout/tagout event. I use real-world examples, like showing videos of accidents caused by failure to follow LOTO, to emphasize the critical importance of these procedures and the severe consequences of non-compliance.

Q 11. How do you handle conflicts or disagreements regarding safety protocols?

Conflicts regarding safety protocols are addressed promptly and professionally, prioritizing the safety of all workers. My approach involves facilitating open communication and creating a safe space for voicing concerns. I start by actively listening to all parties involved, ensuring everyone feels heard and understood. The goal is not to assign blame, but to find solutions collaboratively. I often use a step-by-step approach:

- Identify the root cause of the disagreement: Is it a misunderstanding of the protocol, a concern about practicality, or something else?

- Review the relevant safety regulations: This provides an objective baseline for decision-making.

- Seek consensus: Work with all involved to find a mutually agreeable solution that complies with regulations and addresses safety concerns.

- Document the resolution: This ensures clarity and avoids future misunderstandings.

If a resolution cannot be reached, I escalate the matter to the appropriate supervisor or management for further intervention, ensuring a fair and equitable outcome.

Q 12. What are your methods for training workers on safety procedures?

My worker training methods are comprehensive and tailored to the specific hazards present on the job site. Training incorporates various methods for effective knowledge transfer, including:

- Classroom instruction: Lectures, presentations, and discussions covering relevant safety regulations and procedures.

- Hands-on training: Practical demonstrations and exercises allow workers to practice using safety equipment and following procedures in a controlled environment.

- On-the-job training: Mentorship and observation by experienced workers, providing real-world application of learned skills.

- Interactive simulations and videos: Engaging multimedia content enhances understanding and retention.

- Regular toolbox talks: Short, focused sessions addressing specific hazards or recent incidents.

Training isn’t a one-time event. I conduct regular refresher courses and incorporate ongoing feedback to ensure workers stay up-to-date and maintain competency. Pre and post-training assessments are used to gauge understanding and identify areas needing further attention. I also keep detailed records of all training sessions and employee participation.

Q 13. Explain your experience with hazard communication and SDS.

Hazard communication and Safety Data Sheets (SDS) are critical for worker safety. My experience involves ensuring that all hazardous materials on the construction site are properly identified, labeled, and that workers have access to up-to-date SDSs. I train workers on how to locate and interpret SDS information, understanding the hazards, appropriate PPE, and emergency response procedures. I ensure that SDSs are readily available at the worksite in a designated area and that workers know where to find them.

Beyond simple access, I emphasize the importance of understanding the information contained within the SDS. This includes recognizing hazard pictograms, understanding the health effects of exposure, and following recommended precautions. I utilize real-world scenarios and case studies to highlight the consequences of inadequate hazard communication, demonstrating the vital role of SDSs in preventing workplace injuries and illnesses. I also regularly check for updated SDSs and ensure that all labels are current and legible.

Q 14. How do you conduct a site safety inspection?

Conducting a site safety inspection involves a systematic and thorough evaluation of the construction site to identify potential hazards and ensure compliance with safety regulations. My approach follows a structured process:

- Planning: Defining the scope of the inspection, identifying areas of focus based on recent activity, and gathering necessary documentation.

- Inspection: A systematic walkthrough of the site, observing work practices, examining equipment, and checking for compliance with safety regulations and procedures. I use checklists and photography to document findings.

- Documentation: Thorough record-keeping of identified hazards, including location, type of hazard, severity, and corrective actions needed. Photographic evidence is crucial.

- Reporting: Communicating findings to relevant personnel, including supervisors, management, and workers. This includes prioritizing critical hazards and proposing corrective actions.

- Follow-up: Verifying that corrective actions have been implemented and that hazards have been mitigated.

I use a combination of observation, questioning workers, and reviewing documentation to ensure a comprehensive assessment. The goal is not just to identify problems, but to understand the root causes and implement preventative measures to avoid future incidents. Regular inspections are crucial for maintaining a safe working environment.

Q 15. What are the common causes of construction accidents?

Construction accidents stem from a multitude of factors, often interconnected. They rarely happen in isolation but are the result of a chain of events. Common causes can be broadly categorized as:

- Falls: Falls from heights remain a leading cause, often due to inadequate fall protection systems, improper scaffolding, or unsafe working surfaces. For instance, a worker might fall from a roof if the guardrails are insufficient or improperly installed.

- Struck-by Hazards: Workers can be struck by falling objects, swinging loads, or heavy equipment. Proper site organization, using designated areas for material storage, and implementing spotters for heavy machinery operations are crucial.

- Caught-in/Between Hazards: This includes being caught between objects or equipment, such as being crushed by collapsing structures or machinery. Regular inspections, proper machine guarding, and lockout/tagout procedures are essential to mitigating this risk. Think of a worker getting caught between a forklift and a wall.

- Electrocution: Contact with energized electrical equipment is a significant hazard. Strict adherence to electrical safety regulations, proper grounding, and use of personal protective equipment (PPE) are paramount.

- Repetitive Strain Injuries (RSIs): These injuries result from repetitive movements or awkward postures, often affecting the back, wrists, and shoulders. Proper ergonomics, job rotation, and providing appropriate tools and equipment can significantly reduce RSIs. Imagine a construction worker constantly lifting heavy bricks without proper lifting techniques.

Ultimately, most accidents are preventable through proactive safety measures, thorough risk assessments, and worker training.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you use safety data to improve site safety?

Safety data is crucial for identifying trends, pinpointing problem areas, and implementing targeted interventions. I use safety data in a multi-step process:

- Data Collection: This involves meticulously recording all incidents, near misses, and observations. This might include using incident report forms, near miss reporting systems, and conducting regular safety audits.

- Data Analysis: The collected data is analyzed to identify patterns and trends. For example, we might find a cluster of falls in a particular area or a high number of injuries related to specific tasks or equipment.

- Root Cause Analysis: Once trends are identified, a root cause analysis (RCA) is conducted to determine the underlying reasons for the incidents. Tools like the ‘5 Whys’ technique are very helpful here.

- Corrective Actions: Based on the RCA, corrective actions are developed and implemented. These actions might involve modifying procedures, improving equipment, providing additional training, or enhancing site organization. For instance, if falls from scaffolding are a recurring issue, we might implement additional safety training on scaffold erection and use, or provide fall arrest systems.

- Monitoring and Evaluation: The effectiveness of the implemented corrective actions is monitored over time to ensure they are achieving the desired results. Key performance indicators (KPIs) such as incident rates and near miss rates are tracked to assess progress.

By consistently using this data-driven approach, we can proactively mitigate risks and create a safer work environment.

Q 17. Explain your experience with confined space entry procedures.

Confined space entry is a high-risk activity requiring strict adherence to established protocols. My experience involves:

- Pre-entry Planning: This includes conducting a thorough risk assessment to identify potential hazards such as oxygen deficiency, toxic gases, and engulfment. A detailed entry permit system is crucial, specifying the atmospheric conditions, rescue plans, and designated personnel.

- Atmospheric Monitoring: Before entry, the confined space atmosphere is tested for oxygen levels, flammable gases, and toxic substances using appropriate monitoring equipment. Readings are recorded and documented to ensure safety.

- Ventilation and Purge: Adequate ventilation is essential to remove hazardous gases and ensure sufficient oxygen. Purging procedures might involve using inert gases to displace hazardous atmospheres.

- Entry Procedures: Entry is only permitted once all safety checks are completed and a qualified attendant is stationed outside, monitoring the entrant’s condition and the atmosphere within the confined space. Communication systems are also necessary.

- Rescue Plan: A detailed rescue plan is in place before entry, including procedures for immediate evacuation in case of emergencies.

- Post-entry Procedures: Following completion of the work, the confined space is re-tested, and the area is secured until it’s deemed safe.

I’ve overseen numerous confined space entries, ranging from tanks and silos to underground utilities, always prioritizing a safe and controlled environment.

Q 18. How do you manage safety risks associated with heavy machinery?

Managing risks associated with heavy machinery requires a multi-pronged approach:

- Operator Training and Certification: Ensuring operators are properly trained and certified on the specific machinery they operate is fundamental. Regular refresher training and competency assessments are essential.

- Pre-Operational Checks: Daily pre-operational checks of machinery are crucial to identify any defects or malfunctions before operation. Checklists ensure consistency and thoroughness.

- Safe Operating Procedures: Clear, concise, and readily available safe operating procedures (SOPs) must be followed strictly. These SOPs cover aspects like starting, stopping, maneuvering, and emergency procedures.

- Site Organization and Traffic Management: Proper site organization, designated traffic routes, and clear signage minimize the risk of collisions between machinery and workers. This also includes establishing exclusion zones around operating machinery.

- Personal Protective Equipment (PPE): Appropriate PPE, such as high-visibility clothing, safety helmets, and hearing protection, should be worn by all personnel in the vicinity of operating heavy machinery.

- Regular Maintenance: Regular maintenance and servicing of equipment are crucial to prevent mechanical failures and ensure the machinery operates safely.

For example, on a recent project, we implemented a system of spotters for all crane operations, significantly reducing the risk of ‘struck-by’ accidents.

Q 19. Describe your experience with scaffolding safety.

Scaffolding safety is paramount, and my experience encompasses all aspects of its lifecycle, from design and erection to dismantling and inspection:

- Proper Scaffold Design and Erection: Scaffolds must be designed and erected according to manufacturer’s instructions and relevant safety standards. This includes proper base plates, bracing, and guardrails.

- Regular Inspections: Regular inspections, both before and during use, are crucial to identify any damage, defects, or unsafe conditions. A designated competent person should conduct these inspections, and any issues should be addressed immediately.

- Load Capacity: Understanding the load capacity of the scaffold is critical to prevent overloading. Only approved materials and equipment should be placed on the scaffold.

- Safe Access and Egress: Providing safe access and egress to and from the scaffold is crucial. This typically involves using proper ladders and access points.

- Fall Protection: Appropriate fall protection measures, such as guardrails, toe boards, and harnesses, must be employed to prevent falls from height.

- Training: All workers using or working near scaffolds need appropriate training in safe erection, use, and dismantling techniques.

I’ve overseen the construction and dismantling of various scaffold structures, from simple hand-built scaffolds to complex system scaffolds, consistently enforcing rigorous safety protocols.

Q 20. How do you ensure the proper use of cranes and other lifting equipment?

Ensuring the proper use of cranes and lifting equipment demands strict adherence to safety protocols:

- Crane Certification and Operator Training: Only certified operators who have received appropriate training and hold the necessary licenses should operate cranes. Regular competency checks are essential.

- Pre-operational Inspections: Thorough pre-operational inspections are mandatory before each use, verifying the crane’s structural integrity, braking system, and other safety features.

- Load Charts and Capacity Limits: The crane’s load charts and capacity limits must be strictly adhered to. Overloading a crane can lead to catastrophic failure.

- Safe Lifting Practices: Proper lifting techniques, including smooth movements, maintaining stability, and the use of appropriate rigging equipment, are critical.

- Clear Communication and Signaling: Clear communication and signaling between the crane operator and the ground crew are crucial to ensure the safe and efficient execution of lifting operations.

- Exclusion Zones: Establishing clear exclusion zones around the crane’s operational area protects workers and other equipment from potential hazards.

- Regular Maintenance and Inspections: Regular maintenance and scheduled inspections are essential to ensure the crane’s continued safe operation.

One example from my experience includes implementing a system of ‘blind lifts’ to minimize the risk of striking workers during crane operations.

Q 21. What are your strategies for preventing slips, trips, and falls?

Slips, trips, and falls are among the most common accidents on construction sites. My strategies for prevention focus on:

- Housekeeping: Maintaining a clean and organized worksite is crucial. This includes promptly removing debris, spills, and obstructions from walkways and work areas.

- Proper Lighting: Adequate lighting is essential, particularly in poorly lit areas or during night work. This reduces the risk of tripping over unseen hazards.

- Appropriate Flooring: Ensuring the use of appropriate non-slip flooring or providing anti-slip mats in high-risk areas reduces the chances of slips.

- Good Housekeeping Practices: Implementing good housekeeping practices, such as using designated storage areas for materials and tools, avoids clutter which could cause tripping hazards.

- Personal Protective Equipment (PPE): Encouraging and enforcing the use of appropriate PPE, such as safety footwear with good grip, can prevent many slips and falls.

- Spill Management Plan: Having a clear spill management plan in place, to quickly and effectively clean up any spills, prevents accidents. This includes providing the correct cleanup materials and training staff on how to use them.

- Regular Inspections: Conducting regular safety inspections to identify potential hazards, such as uneven walkways or damaged flooring, before they cause accidents is crucial.

By focusing on these preventative measures, we can create a much safer environment and reduce the incidence of slips, trips, and falls significantly.

Q 22. Describe your experience with fire prevention and emergency response plans.

Fire prevention and emergency response are paramount on construction sites. My experience encompasses developing and implementing comprehensive plans that comply with all relevant codes and regulations. This includes conducting regular fire safety inspections, ensuring adequate fire extinguishers are available and properly maintained, establishing clear evacuation routes, and training personnel on fire safety procedures.

For example, on a recent high-rise project, I developed a detailed fire safety plan incorporating specific procedures for different floor levels and considering the unique challenges posed by the building’s height. This involved working closely with the fire department to conduct drills and ensure that our plan aligned with their best practices. The plan included detailed escape route diagrams, specific responsibilities for designated fire wardens, and regular testing of fire suppression systems. We also incorporated the use of fire-resistant materials throughout the construction process. Furthermore, I’ve incorporated the use of technology; for instance, implementing a fire alarm system with remote monitoring capabilities for immediate response and reporting.

Q 23. Explain your experience with environmental protection on a construction site.

Environmental protection is a critical aspect of construction site safety. My experience involves implementing measures to minimize the site’s environmental impact. This includes managing waste disposal, stormwater runoff, air quality, and noise pollution. I have experience creating and enforcing site-specific environmental plans, ensuring compliance with permits and regulations.

For instance, on a recent road construction project, we implemented a robust stormwater management plan involving the installation of silt fences and sediment basins to prevent soil erosion and runoff contamination. We also utilized dust suppression techniques, including regular watering of exposed soil areas and the use of specialized equipment. We meticulously tracked and documented all waste materials, ensuring their proper disposal in accordance with local and federal guidelines. We also conducted regular air quality monitoring and implemented noise reduction measures to mitigate disturbance to the surrounding community. Proper documentation and communication with relevant regulatory agencies were paramount to avoid penalties and ensure compliance.

Q 24. How do you ensure the safety of subcontractors on a construction site?

Ensuring subcontractor safety is crucial for overall site safety. My approach involves pre-qualification of subcontractors based on their safety records and insurance coverage. This includes reviewing their safety programs and ensuring they align with our overall safety standards. I conduct regular safety orientations for all subcontractors, emphasizing site-specific hazards and safety protocols. I then conduct frequent inspections of their work areas to ensure compliance.

Imagine a scenario where a subcontractor is working at heights. Before they begin, I would ensure they have the proper fall protection equipment, understand the site-specific fall protection plan, and have completed necessary training. Regular communication is key; I conduct daily safety talks with all workers, including subcontractor teams, to discuss potential hazards and reinforce safe work practices. Open communication channels help to identify and resolve safety concerns proactively, establishing a collaborative safety culture across all teams.

Q 25. Describe your familiarity with different types of safety training programs.

I’m familiar with a wide range of safety training programs, including OSHA 10-hour and 30-hour construction safety courses, CPR and First Aid training, fall protection training, hazard communication training, and specialized training for specific tasks like working with hazardous materials or operating heavy machinery. I also have experience developing and delivering customized training programs based on the specific needs of a project or work crew.

For instance, on a project involving confined space entry, I developed and conducted a tailored training program that included instruction on hazard identification, atmospheric monitoring, rescue procedures, and the use of specialized equipment such as SCBA (Self-Contained Breathing Apparatus). This customized approach ensures workers possess the precise skills and knowledge needed for safe and efficient work execution. The selection of training programs aligns with project-specific risks and regulatory requirements ensuring all workers are fully prepared for the tasks at hand.

Q 26. How do you measure the effectiveness of a safety program?

Measuring the effectiveness of a safety program involves a multi-faceted approach. Key indicators include the number and severity of accidents and incidents, the frequency of near misses, employee participation in safety training, and overall employee satisfaction with the safety program.

I utilize leading indicators such as the number of safety observations, the number of corrective actions implemented, and the participation rates in safety training to predict potential future accidents. Lagging indicators such as incident rates and lost time injuries are tracked to measure the effectiveness of the implemented corrective actions. Data analysis and reporting are crucial to identify trends and areas needing improvement. Regular safety meetings, audits, and reviews provide valuable feedback and opportunities for program adjustments. A reduction in accident rates, improved safety culture, and positive feedback from employees are all signs of a successful safety program.

Q 27. Explain your experience with near-miss reporting and analysis.

Near-miss reporting and analysis are critical for proactive hazard identification. I’ve implemented systems where employees are encouraged to report near misses without fear of reprisal. These reports are then analyzed to identify underlying causes and implement corrective actions to prevent future incidents. This process involves thoroughly investigating each near miss, identifying root causes using methods such as the ‘5 Whys’ analysis, and developing preventive measures.

For example, if a near miss involved a worker almost being struck by falling debris, we would investigate the cause – perhaps inadequate scaffolding or a lack of proper fall protection measures. The analysis might reveal a lack of supervision or training. Corrective actions would then focus on enhancing these areas, for instance, implementing additional training on hazard identification, improving scaffolding procedures, and enforcing stricter supervision protocols. This proactive approach prevents potentially serious accidents from occurring.

Q 28. What is your approach to proactively identifying and addressing potential safety hazards?

Proactive hazard identification involves a systematic approach. This begins with a thorough pre-construction site assessment to identify potential hazards, followed by ongoing monitoring and inspections during the construction phase. I utilize a combination of methods such as Job Hazard Analyses (JHAs), toolbox talks, and regular safety inspections to identify potential hazards.

For example, a JHA would be conducted before commencing work on a complex task such as the installation of a heavy piece of equipment. This process meticulously identifies every step in the task, its associated hazards, and the control measures needed. Regular safety inspections also ensure ongoing compliance with safety plans and identify potential hazards that might have emerged during the course of the project. Proactive hazard identification is an iterative process; it requires consistent monitoring, communication, and a commitment to improving safety protocols throughout the project lifecycle. This helps to build a culture of safety and prevent incidents.

Key Topics to Learn for Construction Safety Inspection Interview

- OSHA Regulations and Standards: Understand key OSHA regulations (e.g., 1926 Subpart C, Subpart M) and their practical application on construction sites. Be prepared to discuss specific standards and how they relate to various construction activities.

- Hazard Identification and Risk Assessment: Demonstrate your ability to identify potential hazards (e.g., fall hazards, trenching, electrical hazards) and conduct thorough risk assessments to mitigate those hazards. Practice explaining your methodology for hazard identification and control.

- Inspection Techniques and Documentation: Master the art of conducting comprehensive safety inspections, including proper documentation techniques and the use of checklists. Be prepared to discuss different inspection methods and the importance of accurate record-keeping.

- Personal Protective Equipment (PPE): Discuss the various types of PPE required in different construction scenarios, their proper use, and limitations. Be able to explain how to ensure compliance with PPE requirements.

- Emergency Response and Procedures: Demonstrate your knowledge of emergency response protocols, including first aid, evacuation plans, and communication procedures in case of accidents or incidents. Explain your approach to handling emergencies on a construction site.

- Communication and Teamwork: Highlight your ability to effectively communicate safety concerns to workers, supervisors, and management. Explain how you foster a positive safety culture through teamwork and collaboration.

- Safety Training and Education: Discuss your experience in conducting or participating in safety training programs. Be prepared to discuss different training methods and their effectiveness in promoting a safe work environment.

- Incident Investigation and Reporting: Explain your understanding of incident investigation methodologies, including root cause analysis, and the importance of accurate and timely reporting of incidents and near misses.

Next Steps

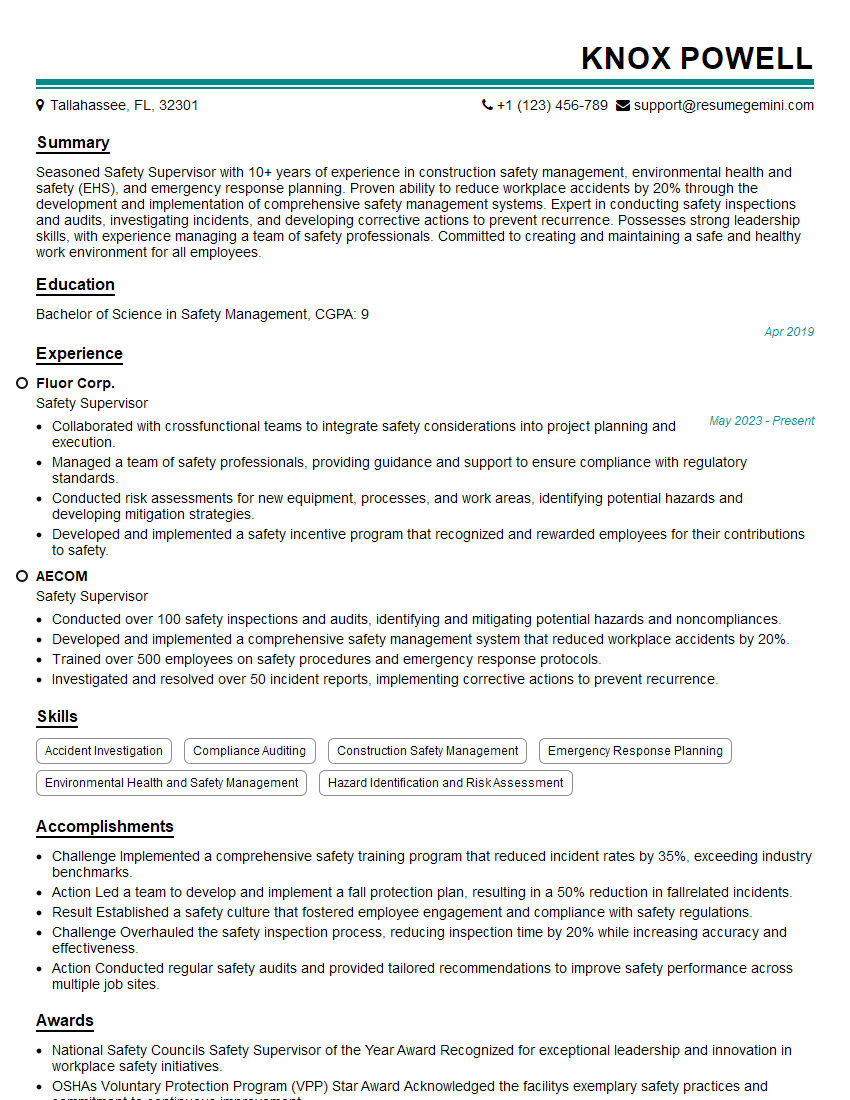

Mastering Construction Safety Inspection is crucial for career advancement, opening doors to leadership roles and higher earning potential. A strong resume is your first step. Creating an ATS-friendly resume significantly increases your chances of getting noticed by recruiters. ResumeGemini can help you build a professional and impactful resume tailored to the Construction Safety Inspection field. Examples of resumes specifically designed for this career path are available to help guide you. Take the next step in your career journey with a well-crafted resume that highlights your skills and experience.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good