The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Advanced knowledge of construction techniques, materials, and building codes interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Advanced knowledge of construction techniques, materials, and building codes Interview

Q 1. Explain the difference between Type I, II, III, IV, and V construction.

Building codes often categorize construction types (I-V) based on fire resistance. This classification dictates the materials used and their fire-resistant properties, influencing the building’s structural integrity and safety during a fire. Think of it like assigning a fire-safety rating to the entire building.

- Type I (Fire-Resistive): This is the most fire-resistant type, utilizing non-combustible materials like reinforced concrete or protected steel for structural elements. These buildings can withstand intense fires for extended periods, minimizing damage and maximizing time for evacuation. Think of skyscrapers or large hospitals.

- Type II (Non-Combustible): Similar to Type I, but allows for some non-structural components to be made of combustible materials, provided they meet specific fire-resistance requirements. Examples might include office buildings with steel frames and non-combustible exterior walls.

- Type III (Ordinary): Uses non-combustible exterior walls but allows for interior structural elements to be made of wood, provided they meet certain fire-resistance standards. Commonly found in smaller commercial buildings or apartment complexes.

- Type IV (Heavy Timber): Employs large, heavy timber for structural elements without fireproofing. The large dimensions of the timber provide inherent fire resistance. Historically used in warehouses and industrial buildings, though now used more selectively.

- Type V (Wood-Framed): This is the least fire-resistant type, utilizing wood for both structural and non-structural components. Typically used for residential construction, often requiring more stringent fire-safety measures such as sprinklers.

The choice of construction type is dictated by building codes, occupancy requirements (e.g., residential vs. commercial), and the overall design intent. A high-rise residential building would never be Type V, for example.

Q 2. Describe your experience with different concrete mix designs and their applications.

My experience encompasses a wide range of concrete mix designs, tailored to specific project needs and site conditions. I’ve worked with everything from high-strength concrete for critical structural elements like columns and foundations, to low-strength concrete for pavements or less demanding applications. The key is understanding the relationship between the mix design parameters and the resulting concrete properties.

For instance, in a high-rise project, we might use a high-strength, low-slump concrete (C35/45 or higher) with admixtures to enhance workability and durability. This ensures the strength needed to support the immense loads. In contrast, a simple residential foundation might employ a standard-strength mix with a higher slump to allow for easier placement and consolidation (C20/25 or similar). I have also extensively utilized fiber-reinforced concrete for applications where impact resistance or crack control are critical. Each project requires careful consideration of factors like compressive strength, flexural strength, durability, and workability, which influence the choice of cement type, aggregate gradation, water-cement ratio, and any admixtures used.

During my career, I’ve dealt with instances where insufficient consideration of concrete mix design led to problems. For example, a poorly designed mix resulted in excessive shrinkage cracking in a parking garage. This highlighted the importance of detailed analysis of site conditions and the long-term performance requirements of the concrete.

Q 3. What are the key considerations for selecting appropriate building materials in seismic zones?

Seismic zones demand careful material selection to ensure building safety and structural integrity during earthquakes. The primary considerations are strength, ductility, and energy dissipation.

- High-Strength Materials: Using materials with high compressive and tensile strength, such as high-strength concrete, reinforced steel, and high-performance fibers, is crucial to resist seismic forces. This allows the structure to withstand significant lateral loads.

- Ductility: The ability of materials to deform significantly under stress without fracturing is paramount. Ductile materials absorb seismic energy, preventing catastrophic failure. Reinforced concrete, with its ductile steel reinforcement, is a good example.

- Energy Dissipation: Materials and systems capable of absorbing and dissipating seismic energy are essential. Seismic dampers, base isolation systems, and special detailing of structural connections contribute to this aspect.

- Proper Connections: The way structural elements are connected is crucial. Strong, ductile connections prevent premature failure and ensure the structure’s integrity during shaking. Examples include special moment-resisting connections in steel structures.

Ignoring these considerations can lead to significant structural damage or even collapse during a seismic event. I’ve personally witnessed the devastation caused by improper construction practices in earthquake-prone areas, reinforcing the importance of adhering to strict seismic design guidelines and using appropriate materials.

Q 4. How do you ensure compliance with building codes throughout a construction project?

Ensuring code compliance is a continuous process, not just a final check. It starts with meticulous planning and extends throughout every stage of construction. We do this through a multi-pronged approach:

- Pre-construction Planning: Thorough review of all relevant building codes and regulations at the design stage, ensuring the design meets all requirements. This includes using approved design professionals, such as structural and civil engineers.

- Regular Inspections: Conducting regular on-site inspections to verify that the construction process adheres to the approved plans and specifications. These inspections are often mandated by local authorities.

- Material Testing: Performing laboratory tests on materials to ensure they meet the required strength and quality standards specified in the design documents and building codes. This includes concrete, steel, and other key elements.

- Documentation and Record-Keeping: Maintaining a detailed record of all inspections, tests, and approvals. This documentation is essential for demonstrating compliance during inspections by building officials.

- Collaboration with Authorities: Working closely with building inspectors and other relevant authorities to address any issues or discrepancies promptly and obtain necessary approvals. This proactive approach prevents delays and potential conflicts.

Code compliance isn’t just about avoiding penalties; it’s about constructing safe and reliable buildings that meet the community’s needs. I’ve seen projects delayed and even halted due to neglecting code compliance, leading to considerable cost overruns and reputational damage.

Q 5. Explain your experience with different foundation types and their suitability for various soil conditions.

Foundation selection is crucial for structural stability and depends heavily on the soil conditions. Different foundation types are suitable for varying soil characteristics. The wrong foundation can lead to structural problems, such as settlement or failure.

- Shallow Foundations (Slabs, Footings, Strip Footings): Suitable for stable, well-drained soils with high bearing capacity. A simple slab foundation works well for smaller structures on strong soils. Footings are used for individual columns or walls where the soil is less consistent.

- Deep Foundations (Piles, Caissons, Piers): Necessary when dealing with weak or unstable soils, or when heavier loads need to be transferred to deeper, stronger strata. Piles, for instance, are driven deep into the ground, providing support for tall buildings or structures on soft soils. Caissons are large, hollow shafts filled with concrete, providing excellent support for heavy loads.

Soil investigation is the first step. I always insist on geotechnical investigations to understand the soil profile, bearing capacity, and groundwater levels before selecting a foundation type. In one project, a poorly conducted soil investigation led to significant settlement problems in a new apartment building, requiring expensive corrective measures. It emphasized the critical importance of accurate geotechnical data.

Q 6. Describe your familiarity with different framing techniques (e.g., wood, steel, concrete).

My experience with different framing techniques spans wood, steel, and concrete. Each method presents distinct advantages and challenges, and selection depends on factors such as budget, project requirements, and aesthetic considerations.

- Wood Framing: Cost-effective and commonly used for residential and smaller commercial projects. It’s quick to erect but has limitations in terms of span and fire resistance. Proper treatment for pest control and fire retardants is vital.

- Steel Framing: Offers high strength-to-weight ratios, excellent spans, and fire resistance when properly protected. It’s more expensive than wood framing but ideal for high-rise buildings or projects requiring large open spaces.

- Concrete Framing: Provides exceptional strength, fire resistance, and durability. Commonly used for high-rise buildings, industrial structures, and large infrastructure projects. It is more expensive and requires specialized labor and equipment. Post-tensioning techniques allow for greater spans and efficient use of concrete.

I’ve overseen projects using all three techniques, and the success of each relies on proper design, detailing, and execution. For example, in a recent project using steel framing, we employed advanced connection techniques to enhance seismic resilience, resulting in a much safer and robust structure.

Q 7. How do you manage construction schedules and resources effectively?

Effective construction schedule and resource management requires a multi-faceted approach. It’s not just about creating a schedule; it’s about proactively managing potential issues and optimizing resource allocation.

- Detailed Planning: Begin with a thorough understanding of the project scope, creating a realistic schedule that accounts for potential delays. Critical Path Method (CPM) scheduling is invaluable here, identifying tasks that are crucial to the project’s timely completion.

- Resource Allocation: Efficiently allocate labor, equipment, and materials to avoid bottlenecks. This often requires careful coordination with subcontractors and suppliers.

- Regular Monitoring and Control: Track progress against the schedule regularly and identify potential problems early. This allows for proactive adjustments, minimizing the impact of unexpected delays.

- Risk Management: Identify potential risks and develop contingency plans to mitigate their impact. This could include weather delays, material shortages, or labor disputes.

- Communication and Collaboration: Maintain open communication between all stakeholders – architects, engineers, contractors, and subcontractors – ensuring everyone is informed and working towards common goals.

In one instance, we faced an unexpected supplier delay for critical materials. By immediately activating our contingency plan, including sourcing the materials from an alternative supplier and adjusting the schedule, we minimized the project delay to just two weeks.

Q 8. What are your preferred methods for quality control and inspection?

My approach to quality control and inspection is multifaceted and proactive, starting even before construction begins. It relies on a robust system of checks and balances throughout the project lifecycle.

- Pre-Construction Phase: Thorough review of plans and specifications, material selection verification, and subcontractor pre-qualification are crucial. We utilize Building Information Modeling (BIM) to identify potential clashes and issues early on.

- During Construction: Daily site inspections are mandatory, focusing on adherence to plans, quality of workmanship, and safety protocols. We use checklists and digital documentation to track progress and identify any deviations. Regular quality assurance testing of materials, such as concrete strength testing or soil compaction tests, is performed.

- Post-Construction: A final inspection, following a punch list review, ensures that all aspects meet the required standards and specifications. We also conduct commissioning to verify that building systems are operating efficiently. This includes, where applicable, final inspections with the relevant authorities before handover.

For example, on a recent high-rise project, our meticulous inspection process identified a minor deviation in the steel framing early on, preventing a significant problem later. This prevented costly rework and ensured structural integrity.

Q 9. Describe your experience with different types of roofing systems and their maintenance.

My experience encompasses a wide range of roofing systems, including low-slope, steep-slope, and specialized roofing like green roofs. Each system requires specific knowledge for installation and maintenance.

- Low-Slope Roofing: These are typically used on flat or low-pitched roofs and often utilize materials such as modified bitumen, single-ply membranes (TPO, EPDM, PVC), and built-up roofing (BUR). Maintenance involves regular inspections for ponding water, punctures, and degradation of the membrane.

- Steep-Slope Roofing: Common materials include asphalt shingles, clay tiles, slate, and metal panels. Maintenance is primarily focused on inspecting for damaged or missing shingles or tiles, as well as ensuring proper flashing and gutter function to prevent water damage.

- Green Roofs: These offer environmental benefits, but require specialized maintenance, including irrigation management, vegetation care, and drainage system monitoring.

Understanding the specific characteristics of each system—its lifespan, vulnerability to environmental factors, and required maintenance schedule—is paramount for preventing costly repairs or premature failure. For instance, I once saved a client considerable expense by recommending proactive repairs to a BUR roof after noticing signs of premature aging during a routine inspection.

Q 10. Explain your knowledge of various insulation materials and their R-values.

Insulation is critical for energy efficiency and thermal comfort. Different materials provide varying levels of thermal resistance, measured by their R-value (resistance to heat flow).

- Fiberglass: A common and cost-effective option, available in batts, rolls, or loose-fill forms. R-values vary depending on thickness and density.

- Spray Foam: Offers excellent air-sealing properties and high R-values. It conforms to irregular shapes effectively.

- Cellulose: Made from recycled paper, it’s a sustainable option with good insulation properties.

- Mineral Wool: Inorganic materials such as rock wool or glass wool offer good thermal and fire resistance.

The selection of insulation depends on factors like climate, building design, and budget. For example, in colder climates, higher R-values are necessary. In a recent project, we opted for spray foam insulation in a high-performance building to maximize energy efficiency and minimize air leakage, which is especially useful in cold climates. The R-values are expressed in units of ft²·°F·hr/Btu (or m²·K/W in the SI system).

Q 11. How do you handle unexpected site challenges or changes in project scope?

Unexpected site challenges are inevitable in construction. My approach involves a combination of proactive planning and decisive on-site problem-solving.

- Documentation and Communication: Thorough documentation of all changes, including reasons and solutions, is vital. This requires clear communication among the project team, clients, and subcontractors.

- Value Engineering: When scope changes occur, we explore alternative solutions to maintain the project’s functionality within budget. This might involve substituting materials or adjusting construction methods.

- Contingency Planning: Having a contingency plan for potential issues (e.g., unforeseen subsurface conditions) helps mitigate delays and cost overruns.

For instance, during one project, we discovered unexpected bedrock that wasn’t indicated in the site survey. We immediately collaborated with the geotechnical engineer and adjusted the foundation design to address this issue, keeping the project on track albeit with a modified approach.

Q 12. What are your strategies for mitigating construction risks?

Mitigating construction risks requires a proactive and comprehensive approach.

- Risk Assessment: A thorough risk assessment at the beginning of the project identifies potential hazards and their probability and impact. This involves considering financial, safety, and schedule risks.

- Insurance and Bonding: Appropriate insurance policies and surety bonds protect the project from unforeseen events and financial losses.

- Contractual Agreements: Clearly defined contracts with subcontractors, outlining responsibilities, payment schedules, and dispute resolution mechanisms, minimizes conflicts.

- Safety Measures: A robust safety program, including regular safety training and site inspections, protects workers and minimizes accidents.

For example, on a large-scale project, we implemented a comprehensive risk management plan that included weather-related contingency plans, which proved invaluable during an unexpected hurricane that threatened to disrupt the project schedule.

Q 13. Describe your experience with different types of exterior wall assemblies.

Exterior wall assemblies play a vital role in building performance, encompassing structural support, thermal insulation, and weather protection. My experience includes various assemblies.

- Wood Frame: Common in residential and light commercial construction. They often include sheathing, insulation, and exterior cladding (e.g., siding, brick veneer).

- Steel Frame: Used in high-rise buildings and structures requiring high strength and fire resistance. Steel framing requires careful consideration of thermal bridging and fire protection.

- Concrete Masonry Unit (CMU): Offers excellent fire resistance and structural strength, but requires careful attention to insulation and moisture control. Common in multifamily housing and commercial buildings.

- Structural Insulated Panels (SIPs): Pre-fabricated panels providing exceptional thermal performance and reduced construction time.

Choosing the appropriate assembly depends on the project requirements, budget, and climate. I once helped a client choose SIPs for a project in a cold climate to maximize energy efficiency and minimize construction time. The choice of assembly deeply affects overall cost and performance.

Q 14. Explain your knowledge of building codes regarding fire safety and egress.

Building codes related to fire safety and egress are crucial for ensuring occupant safety. I have extensive knowledge of these codes, including the International Building Code (IBC) and local variations.

- Fire Resistance: This involves specifying appropriate fire-rated assemblies for walls, floors, and roofs, ensuring adequate fire separation between spaces. This includes the use of fire-resistant materials and construction methods.

- Means of Egress: This includes ensuring adequate exit pathways, including sufficient width, number, and accessibility. Exit signs, emergency lighting, and fire extinguishers must also meet code requirements.

- Sprinkler Systems: The design and installation of sprinkler systems, where required, must adhere to specific code provisions, concerning pipe sizing, water pressure, and placement of sprinkler heads.

- Smoke Detection and Alarm Systems: Proper installation and maintenance of smoke detectors and alarm systems are essential components of life safety.

Understanding and applying these codes are non-negotiable, not just to meet legal requirements but most importantly to ensure safety. I’ve had instances where I identified code violations on existing projects and successfully helped rectify them, thereby improving safety for building occupants. The legal implications of not complying with fire codes can be very serious.

Q 15. How do you ensure the safety of workers on a construction site?

Worker safety is paramount on any construction site. It’s not just a moral imperative, but a legal one, mandated by OSHA (Occupational Safety and Health Administration) and similar international regulations. My approach is multifaceted and proactive, focusing on prevention rather than reaction.

- Pre-construction planning: Before the first shovel hits the ground, I ensure thorough risk assessments are conducted, identifying potential hazards like falls, trench collapses, electrocution, and equipment malfunctions. This involves reviewing blueprints, site surveys, and material specifications.

- Site safety protocols: This includes establishing and enforcing clear safety rules, providing proper personal protective equipment (PPE) like hard hats, safety glasses, and high-visibility vests. Regular toolbox talks are crucial for addressing specific hazards and reinforcing safe work practices.

- Training and supervision: All workers receive appropriate safety training tailored to their specific roles. Competent supervisors are tasked with monitoring adherence to safety rules and addressing any deviations immediately. This also includes emergency response planning and regular drills.

- Regular inspections: Routine inspections of the site, equipment, and safety systems are conducted to identify and rectify any potential hazards before they lead to incidents. This includes checking scaffolding stability, proper use of fall protection, and the functionality of safety equipment.

- Incident reporting and investigation: A robust system for reporting and investigating accidents or near misses is essential for identifying underlying causes and implementing corrective actions to prevent future occurrences. This ensures continuous improvement of safety measures.

For example, on a recent high-rise project, we implemented a comprehensive fall protection system, including guardrails, safety nets, and harnesses, leading to a zero-incident record. This involved rigorous training, regular inspections, and prompt response to any identified safety concerns.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with sustainable construction practices.

Sustainable construction is a core principle in my practice. It’s about minimizing the environmental impact of building projects throughout their lifecycle, from design to demolition. My experience encompasses several key strategies:

- Material selection: I prioritize using recycled and sustainably sourced materials like reclaimed timber, recycled steel, and locally sourced stone. This reduces transportation emissions and supports responsible resource management. We also favor materials with low embodied carbon, opting for concrete mixes with lower cement content, for instance.

- Energy efficiency: Implementing energy-efficient designs and technologies is critical. This includes maximizing natural light, utilizing high-performance insulation, and incorporating renewable energy sources like solar panels. We often use Building Performance Simulation software to optimize energy usage.

- Water conservation: Designing for water efficiency is vital. This involves using low-flow fixtures, rainwater harvesting systems, and greywater recycling where feasible. This reduces reliance on potable water and minimizes wastewater discharge.

- Waste management: Minimizing construction waste is a crucial aspect. This involves meticulous planning, efficient material handling, and on-site recycling and waste separation programs. This reduces landfill burden and conserves resources.

- LEED certification: I have significant experience pursuing LEED (Leadership in Energy and Environmental Design) certifications for projects. This demonstrates a commitment to sustainable building practices and provides a framework for achieving high environmental performance.

For example, in a recent school project, we achieved a LEED Gold certification by incorporating sustainable materials, implementing energy-efficient systems, and minimizing construction waste, setting a benchmark for future green building initiatives.

Q 17. What are the different phases of a construction project?

Construction projects typically follow a series of well-defined phases, although the exact names and sequencing might vary slightly depending on the project’s complexity and type.

- Pre-construction phase: This involves feasibility studies, site investigation, design development, permitting, and securing financing. This phase lays the groundwork for the entire project.

- Construction phase: This is the main phase where the actual building takes place. It’s usually broken down into sub-phases: site preparation, foundation work, framing, roofing, MEP (Mechanical, Electrical, and Plumbing) installation, interior finishes, and exterior works.

- Commissioning phase: This involves testing and verifying that all building systems are functioning correctly and meet the design specifications. This ensures that the building is ready for occupancy.

- Post-construction phase: This includes final inspections, obtaining occupancy permits, and handing over the completed project to the client. It might also include a period of warranty and maintenance.

Think of it like baking a cake; pre-construction is gathering ingredients and preparing the recipe, construction is the actual baking, commissioning is checking if the cake is baked correctly, and post-construction is serving and enjoying the final product.

Q 18. Explain your understanding of BIM (Building Information Modeling).

BIM, or Building Information Modeling, is a process involving the creation and management of digital representations of physical and functional characteristics of places. It’s far more than just 3D modeling; it’s a collaborative platform integrating all aspects of a building project.

- 3D Modeling: BIM creates a detailed 3D model of the building, allowing for visualization and spatial coordination.

- Data Integration: BIM integrates various data sets, including architectural, structural, MEP, and cost information, into a single, unified model.

- Collaboration: BIM facilitates collaboration among different disciplines and stakeholders, improving communication and reducing errors.

- 4D (Time) and 5D (Cost) Modeling: BIM can extend beyond 3D to include 4D scheduling (construction sequencing) and 5D cost estimation, providing valuable insights into project timelines and budgets.

- Clash Detection: BIM can detect conflicts between different building systems (e.g., a duct running through a beam), preventing costly rework during construction.

For example, on a recent hospital project, BIM helped us identify and resolve clashes between MEP systems and structural elements early in the design phase, saving significant time and money.

Q 19. How do you manage project budgets and costs effectively?

Effective budget management is crucial for successful project completion. My approach involves a combination of proactive planning, meticulous tracking, and responsive adjustments.

- Detailed Cost Estimation: Developing a thorough budget based on detailed cost estimations for labor, materials, equipment, and contingencies is paramount. This involves using cost estimating software and historical data.

- Value Engineering: Regularly reviewing the budget and exploring cost-saving opportunities without compromising quality is essential. This could involve substituting materials, optimizing designs, or streamlining processes.

- Change Management: Establishing a clear process for managing change orders and their associated costs is vital. This involves documenting all changes, obtaining approvals, and updating the budget accordingly.

- Progress Tracking: Regular monitoring of project progress against the budget is crucial. This involves comparing actual costs to the projected costs and identifying any variances early on.

- Reporting and Analysis: Providing regular budget reports to stakeholders, analyzing variances, and implementing corrective actions are essential for maintaining control over project costs.

For example, on a recent renovation project, we implemented a robust cost control system that resulted in a 5% reduction in overall project costs without affecting the quality of the work.

Q 20. What is your experience with different types of structural support systems?

I have extensive experience with various structural support systems, ranging from traditional to modern methods. Understanding their strengths, weaknesses, and applications is vital for selecting the appropriate system for each project.

- Bearing Walls: Traditional load-bearing walls use masonry or concrete to support the building’s weight. They are simple but can limit design flexibility.

- Steel Frames: Steel structures offer high strength-to-weight ratios and allow for large spans, ideal for high-rise buildings and industrial structures. They are susceptible to corrosion.

- Concrete Frames: Reinforced concrete frames provide excellent fire resistance and durability, suitable for various building types. They are heavy and require skilled labor.

- Timber Frames: Timber framing, using engineered wood products, is a sustainable and cost-effective option for smaller buildings. Proper treatment is essential for durability.

- Hybrid Systems: Combining different systems, such as a steel frame with concrete shear walls, can optimize structural performance and efficiency.

For instance, on a recent commercial building project, we used a hybrid system combining steel framing for the main structure and concrete shear walls for enhanced seismic resistance, resulting in an optimized design that met both strength and safety requirements.

Q 21. Describe your understanding of construction drawings and specifications.

Construction drawings and specifications are the blueprint for a construction project. They provide a comprehensive set of instructions and details for all aspects of the project. A thorough understanding is crucial for successful execution.

- Drawings: These include architectural, structural, MEP, and site plans. They visually represent the building’s design, dimensions, and layout. They need careful interpretation and coordination.

- Specifications: These documents describe the quality, materials, methods, and standards required for construction. They complement the drawings and resolve ambiguities.

- Coordination: Effective coordination between the drawings and specifications is essential. Discrepancies can lead to errors and conflicts.

- Interpretation: Interpreting the drawings and specifications correctly and resolving any ambiguities is a key skill. This often involves collaboration with architects, engineers, and subcontractors.

- Building Codes: The drawings and specifications must comply with all relevant building codes and regulations, ensuring safety and compliance.

For example, on a recent project, we discovered a discrepancy between the architectural drawings and the structural specifications regarding the location of a load-bearing wall. By promptly identifying and resolving this issue, we avoided significant rework and delays.

Q 22. Explain your familiarity with different types of waterproofing methods.

Waterproofing is crucial for protecting structures from water damage, preventing costly repairs and ensuring longevity. My familiarity spans various methods, categorized broadly into membrane systems, coating systems, and drainage systems.

Membrane Systems: These involve installing a continuous barrier to prevent water penetration. Examples include EPDM (Ethylene Propylene Diene Monomer) rubber sheets, TPO (Thermoplastic Polyolefin) membranes, and PVC (Polyvinyl Chloride) membranes. I’ve extensively used EPDM on flat roofs, appreciating its durability and ease of installation, particularly its ability to handle thermal expansion and contraction. TPO, on the other hand, offers superior UV resistance, making it ideal for exposed areas.

Coating Systems: These apply a liquid waterproof layer directly to the substrate. Common types include cementitious coatings, acrylic coatings, and polyurethane coatings. Cementitious coatings are robust and excellent for below-grade applications, while acrylics are versatile and often used for exterior walls. I once successfully utilized a high-performance polyurethane coating on a bridge deck, exceeding expected lifespan due to its superior crack-bridging capabilities.

Drainage Systems: These aim to divert water away from the structure. This includes techniques like installing gravel backfill, weep holes, and properly graded landscaping. Effective drainage is often overlooked but is critical, especially in areas prone to high rainfall. On a recent project, incorporating a sophisticated drainage mat beneath a plaza prevented water accumulation and subsequent structural issues.

Selecting the appropriate waterproofing method depends heavily on factors such as the application (roof, basement, foundation), the material of the substrate, and the local climate conditions. My experience ensures I choose the most effective and cost-efficient solution for each specific project.

Q 23. How do you handle conflicts between different trades on a construction site?

Trade conflicts are inevitable on construction sites, but effective management is key to maintaining schedule and budget. My approach is proactive and collaborative. I start by fostering open communication amongst all trades from the project’s outset. This includes regular meetings, clear delineation of responsibilities in the contract documents, and a well-defined conflict resolution process.

When conflicts arise, my strategy involves:

Immediate identification: Addressing issues as soon as they surface, preventing escalation. This often involves on-site observation and quick communication with the relevant supervisors.

Joint problem-solving: Bringing together the involved parties – foremen, subcontractors, and potentially myself – to discuss the issue, identify the root cause, and collaboratively find a solution that considers all perspectives. This approach fosters a sense of shared responsibility.

Fair and objective mediation: If a consensus cannot be reached, I step in as a neutral mediator, ensuring fair consideration of all perspectives. I rely on the project contract, building codes, and industry best practices to guide decisions. I document all discussions and resolutions meticulously.

Escalation protocol: If mediation fails, the issue is escalated to the project manager and potentially the client, following a pre-defined procedure.

Ultimately, successful conflict resolution depends on strong leadership, clear communication, and a commitment to finding solutions that benefit the entire project.

Q 24. What is your experience with value engineering and cost optimization?

Value engineering and cost optimization are critical for project success. My approach involves a thorough review of the design and specifications at every stage of the project, identifying opportunities to reduce costs without compromising quality or functionality.

Here’s how I approach it:

Early involvement: Participating in the design phase allows for cost-effective solutions to be incorporated from the outset rather than costly modifications later on.

Material substitution: Exploring alternative materials that offer comparable performance at a lower cost. For example, substituting certain types of steel for others with equivalent structural capacity but a lower price point.

Design optimization: Modifying design elements to streamline construction, reduce material waste, and simplify installation processes. For instance, standardizing component sizes or optimizing building layout for efficient workflow.

Constructability review: Analyzing the construction process for potential inefficiencies and proposing solutions to improve productivity and reduce labor costs. This might involve exploring different construction methods or technologies.

Lifecycle cost analysis: Considering long-term operational and maintenance costs when evaluating design alternatives. A seemingly cheaper option upfront might be more expensive in the long run.

I’ve successfully implemented value engineering on numerous projects, resulting in significant cost savings without compromising the project’s overall quality or performance. A recent example involved substituting a complex prefabricated wall system with a more efficient modular design, resulting in a 15% reduction in construction costs without affecting the final product’s structural integrity or aesthetic appeal.

Q 25. Describe your proficiency with construction software and technology.

Proficiency with construction software and technology is essential for efficient project management and collaboration. I’m adept at utilizing a variety of software solutions, including:

Building Information Modeling (BIM) software (Revit, ArchiCAD): I’m experienced in using BIM software for 3D modeling, design coordination, clash detection, and quantity takeoff. BIM allows for accurate cost estimation and improved collaboration among different disciplines.

Project management software (Procore, Microsoft Project): I use these to track progress, manage schedules, allocate resources, and monitor budgets. These tools provide real-time insights into project performance.

Estimating software (PlanSwift, Timberline): I utilize these for accurate cost estimations, material takeoffs, and creating detailed budgets.

Collaboration platforms (Bluebeam, Slack): These facilitate efficient communication and document sharing among the project team, both internally and with external stakeholders.

Furthermore, I’m familiar with emerging technologies like drones for site surveying and laser scanning for as-built documentation. Continuous learning and adaptation to new technologies are crucial in this evolving industry, allowing me to deliver projects effectively and efficiently.

Q 26. What are your strategies for effective communication on a construction project?

Effective communication is paramount to a successful construction project. My approach is multi-faceted and incorporates several key strategies:

Regular meetings: Holding frequent meetings with the project team, subcontractors, and clients to discuss progress, address challenges, and ensure everyone is aligned on goals and expectations.

Clear and concise communication: Using plain language, avoiding jargon, and ensuring all communication (written and verbal) is clear, concise, and easily understood by all parties.

Multiple communication channels: Employing a range of communication tools—emails, project management software, daily reports, and face-to-face meetings—to cater to different communication preferences and ensure information reaches everyone.

Active listening: Giving careful consideration to what others are saying, asking clarifying questions, and ensuring everyone feels heard and valued.

Documentation: Maintaining detailed records of all communications, decisions, and changes made to the project, creating a transparent and auditable trail.

Conflict resolution: Having a clearly defined process for addressing conflicts and disagreements promptly and fairly.

I believe that fostering a culture of open communication and collaboration is crucial for building strong relationships and creating a successful project.

Q 27. Explain your understanding of different types of concrete finishes.

Concrete finishes significantly impact a structure’s aesthetics, durability, and functionality. My understanding encompasses a wide range of finishes, each suited for different applications and desired outcomes.

Smooth finish: Achieved through troweling and floating, it’s common for interior floors and walls requiring a clean, polished look. This is often used in residential settings or commercial spaces where a polished look is desired.

Broomed finish: Created by brushing the surface with a stiff broom, this provides a textured, slip-resistant surface ideal for exterior pavements, patios, and walkways. The broom marks help provide drainage and prevent slipping.

Exposed aggregate finish: This aesthetically pleasing finish exposes the aggregate (stones, gravel) within the concrete mix, adding visual interest. This is often seen in high-end architectural projects where a unique appearance is valued.

Stamped concrete finish: Imprinting patterns onto the concrete surface using stamps, creating the illusion of other materials like brick, stone, or tile. This cost-effective option can mimic more expensive materials and is widely used in patios and driveways.

Stained concrete finish: Applying stains to the concrete surface to enhance its color and create a unique look. Stains penetrate the concrete, providing a durable and long-lasting finish.

Polished concrete finish: Grinding and polishing the concrete surface to a high gloss, revealing its natural beauty. This produces a durable, low-maintenance floor often used in commercial or industrial settings.

The choice of concrete finish is driven by the intended use, aesthetic preferences, budget constraints, and the environmental conditions.

Q 28. Describe your experience with commissioning and building system testing.

Commissioning and building system testing are crucial for ensuring that building systems perform as designed and meet the owner’s operational needs. My experience includes all phases, from pre-design to final handover.

My involvement typically encompasses:

Pre-design phase: Reviewing design documents to ensure the design is commissionable and identifying potential issues early on. This often includes discussions with designers and engineers to improve the design for easier commissioning.

Design development phase: Developing the commissioning plan, defining the scope of work, and establishing testing protocols. This involves identifying specific testing parameters and procedures for each building system.

Construction phase: Observing construction to ensure the systems are being installed according to the design and specifications. This includes reviewing submittals and shop drawings, and witnessing factory acceptance tests.

Testing and commissioning phase: Conducting thorough testing and verification of all building systems, including HVAC, plumbing, electrical, fire protection, and other building automation systems. This stage involves detailed documentation, reporting, and resolving any identified discrepancies.

Post-commissioning phase: Providing operational training to building staff and documenting the performance of the building systems. This often includes recommendations for optimizing energy efficiency and reducing operational costs.

A successful commissioning process minimizes operational problems, improves energy efficiency, and increases building longevity. I have consistently ensured project compliance with relevant codes and standards across multiple projects, resulting in optimized building performance and client satisfaction.

Key Topics to Learn for Advanced Construction Techniques, Materials, and Building Codes Interviews

- Structural Engineering Principles: Understanding load-bearing capacities, stress distribution, and the behavior of various structural systems (e.g., steel, concrete, timber). Consider practical applications like analyzing building plans for structural integrity.

- Material Science & Selection: Deep dive into the properties of common construction materials (concrete mixes, steel grades, lumber types) and their suitability for different applications. Explore case studies where material selection impacted project success or failure.

- Building Codes and Regulations (IBC, local codes): Mastering relevant building codes, including fire safety, accessibility, and energy efficiency standards. Practice interpreting code sections and applying them to hypothetical scenarios.

- Construction Methods and Techniques: Explore advanced techniques like prefabrication, BIM (Building Information Modeling), and sustainable construction practices. Be ready to discuss their advantages, limitations, and real-world applications.

- Quality Control and Inspection: Understand the importance of quality control throughout the construction process, including inspection methods and documentation. Be prepared to discuss quality assurance procedures and problem-solving in construction.

- Estimating and Cost Control: Gain a strong understanding of cost estimation techniques, material takeoffs, and project budgeting. Prepare examples demonstrating your ability to analyze project costs and identify potential cost savings.

- Safety Regulations and Practices: Demonstrate comprehensive knowledge of OSHA regulations and safety protocols relevant to construction. Be ready to discuss risk assessment and mitigation strategies.

Next Steps

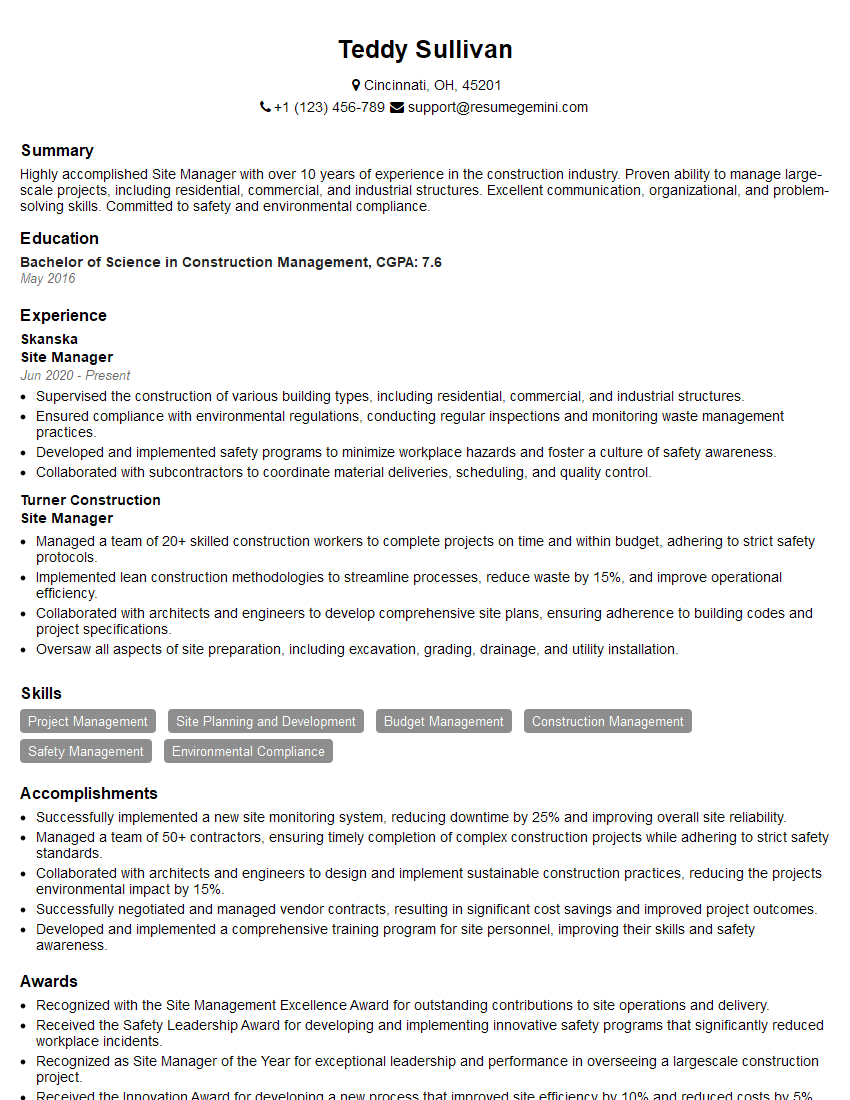

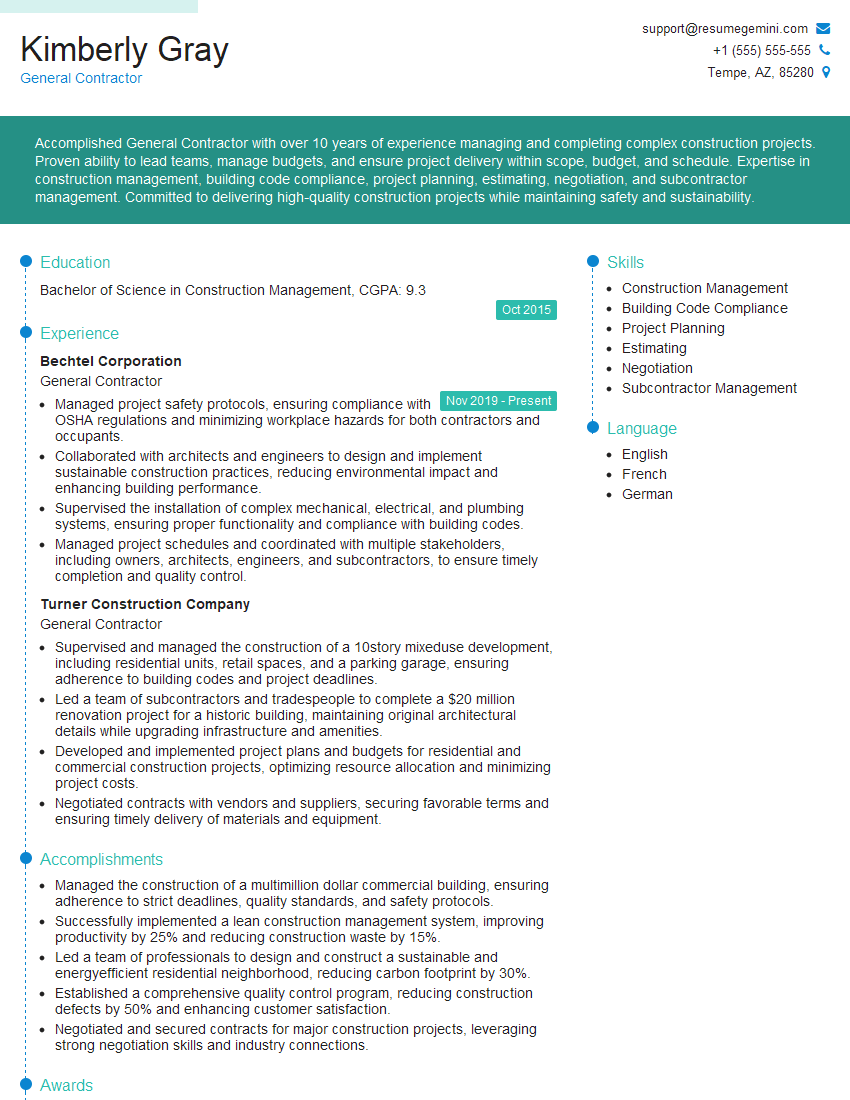

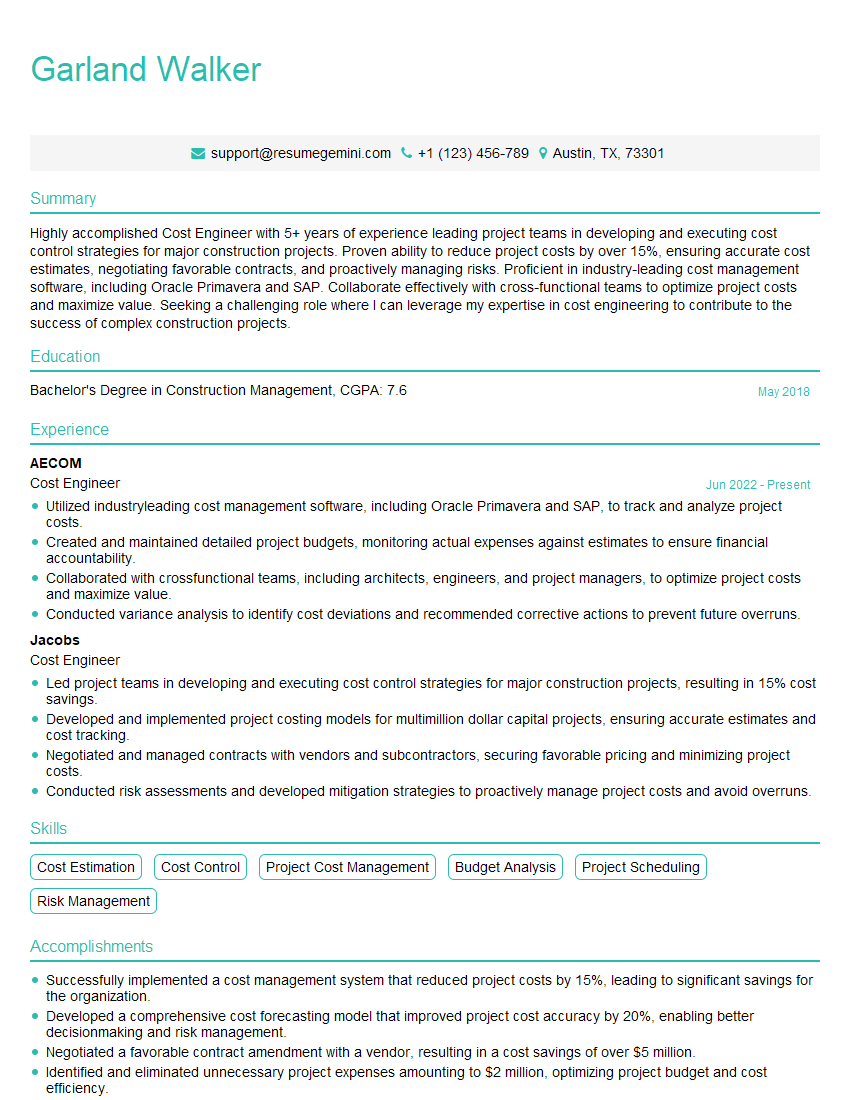

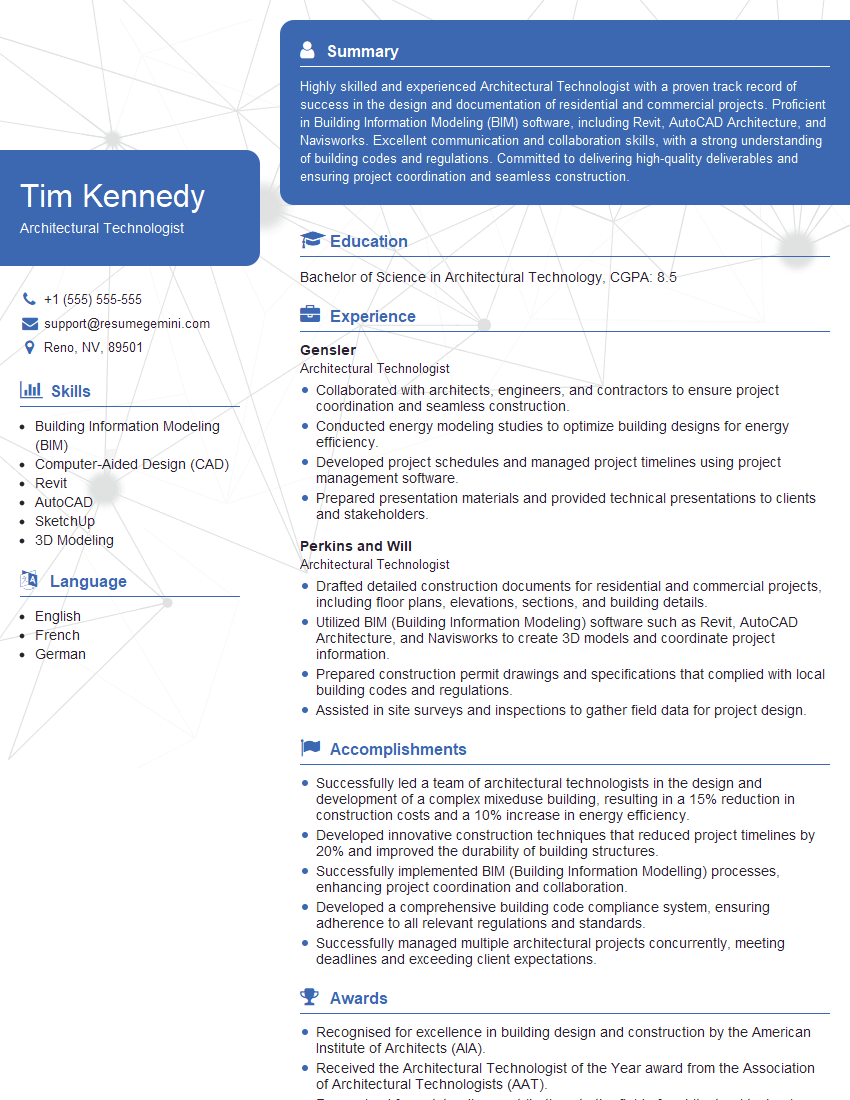

Mastering advanced construction techniques, materials, and building codes is crucial for career advancement in the construction industry. A strong understanding of these areas opens doors to higher-paying roles, leadership positions, and greater project responsibility. To maximize your job prospects, create an ATS-friendly resume that highlights your expertise effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to the specific requirements of your target roles. Examples of resumes specifically designed for candidates with advanced knowledge of construction techniques, materials, and building codes are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good