The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to 3D Modeling and Prototyping interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in 3D Modeling and Prototyping Interview

Q 1. Explain your experience with various 3D modeling software (e.g., SolidWorks, AutoCAD, Blender, Maya).

My 3D modeling experience spans a range of software, each with its strengths and applications. SolidWorks is my go-to for precise, parametric modeling, ideal for mechanical engineering projects where design changes need to be easily propagated throughout the model. I’ve used it extensively for designing intricate parts, assemblies, and simulations. AutoCAD, on the other hand, shines in its 2D drafting capabilities and its integration with architectural and engineering workflows; I utilize it for creating detailed technical drawings and collaborating with other disciplines. Blender offers unparalleled flexibility for organic modeling and animation, perfect for creating realistic characters or environments, while Maya is my preferred choice for high-end animation and visual effects, particularly in projects requiring complex rigging and simulations. Each software provides a unique toolset for tackling different project needs, and my proficiency in them allows me to choose the best tool for the job. For example, I recently used SolidWorks to design a custom robotic arm, leveraging its simulation tools to optimize its functionality. Then, I used Blender to create a photorealistic rendering of the completed arm for presentation purposes.

Q 2. Describe your process for creating a 3D model from a 2D sketch or concept.

My process for creating a 3D model from a 2D sketch or concept is iterative and involves several key steps. First, I carefully analyze the 2D source, paying close attention to proportions, dimensions, and details. Then, I decide on the appropriate 3D modeling software based on the complexity and type of model (organic, mechanical, etc.). Next, I begin the 3D modeling process, starting with basic shapes and gradually refining the model based on the 2D reference. I frequently employ techniques like extruding, revolving, and lofting to build up the geometry. Throughout this process, I regularly check the model’s accuracy against the 2D sketch using various projection and measurement tools. Finally, I iterate on the design, refining the details, and ensuring overall consistency and aesthetic appeal. Imagine taking a blueprint of a house; I’d start by building the basic walls and then add the doors, windows, and other features, constantly comparing my progress to the blueprint to maintain accuracy.

Q 3. How do you handle complex geometries and high polygon counts in your models?

Handling complex geometries and high polygon counts requires a strategic approach. For complex geometries, I often employ techniques like Boolean operations (union, subtraction, intersection) to combine or subtract simpler shapes, creating intricate designs. For high polygon counts, optimization is crucial. I use techniques like decimation (reducing the number of polygons while maintaining visual fidelity), retopology (creating a new, lower-poly mesh that closely matches the high-poly model), and level of detail (LOD) modeling (creating multiple versions of the model with different levels of detail). Tools like the Decimate modifier in Blender or the similar functions in other software are indispensable. For instance, when creating a highly detailed car model, I might create a high-poly model for rendering and a lower-poly version for real-time applications in a game engine. This prevents slowdowns without compromising visual quality where it matters.

Q 4. What are your preferred methods for optimizing 3D models for 3D printing?

Optimizing 3D models for 3D printing involves several crucial steps. First, I ensure the model is manifold (meaning every edge is shared by exactly two faces), watertight (no holes or gaps), and has a consistent thickness. Next, I check for self-intersections, which can cause printing failures. Then, I analyze the model’s orientation and support structures, optimizing placement to minimize support material usage and potential warping. I also employ tools to check for overhangs and thin walls, which often require manual adjustments or support generation. For FDM printing, I would ensure that the model’s wall thickness is sufficient and that there are no extremely fine details that would be difficult to print. For SLA or SLS printing, the tolerances are often less strict, but I still aim for efficient designs that minimize material usage and post-processing effort. Ultimately, a well-optimized 3D model translates directly to a successful and efficient print.

Q 5. Explain your understanding of different 3D printing technologies (e.g., FDM, SLA, SLS).

My understanding of 3D printing technologies encompasses several key methods. Fused Deposition Modeling (FDM) is an additive process that extrudes molten thermoplastic filament layer by layer. It’s cost-effective and relatively accessible, but the resolution is limited compared to other methods. Stereolithography (SLA) uses a UV laser to cure liquid resin, resulting in high-resolution, detailed prints. It’s well-suited for intricate geometries and smooth surfaces but can be more expensive. Selective Laser Sintering (SLS) uses a laser to fuse powdered materials, allowing for the creation of strong, durable parts from various materials, including nylon and metals. SLS is ideal for functional prototypes but is often more expensive than FDM or SLA. Understanding these differences is critical for selecting the appropriate technology based on the project requirements, budget, and desired properties of the final part. For instance, I might choose FDM for a quick prototype, but SLA for a highly detailed model.

Q 6. How do you ensure the accuracy and precision of your 3D models?

Ensuring the accuracy and precision of 3D models is paramount. I use precise measurements throughout the modeling process, regularly checking dimensions and tolerances. I leverage the software’s measurement and analysis tools to detect errors or inconsistencies early. For complex assemblies, I utilize constraints and features to maintain accurate relationships between components. During the export process, I select the appropriate file format and resolution based on the intended application (e.g., STL for 3D printing, OBJ for rendering). Finally, I often conduct a thorough review of the exported file using dedicated inspection software or plugins to identify any potential issues before proceeding to prototyping. This meticulous approach guarantees that the final product matches the digital design as closely as possible, minimizing errors and rework.

Q 7. Describe your experience with creating realistic textures and materials in 3D models.

Creating realistic textures and materials is a crucial aspect of enhancing visual fidelity. I use a variety of techniques, from procedural textures generated within the modeling software to externally created textures using dedicated software like Substance Painter. For procedural textures, I can create patterns and variations within the software itself, often making adjustments on the fly. For more complex and detailed textures, I would use external tools. I pay close attention to details like roughness, reflectivity, and bump mapping to simulate the surface properties of real-world materials. Libraries of pre-made textures and materials are often used as a starting point, and I adjust these based on specific needs. For instance, I can simulate the rough texture of concrete or the glossy surface of metal. The final result is a 3D model that not only looks realistic but also accurately reflects the properties of the materials used.

Q 8. How do you collaborate with other team members on 3D modeling projects?

Collaboration on 3D modeling projects relies heavily on effective communication and the right tools. We typically utilize cloud-based platforms like Autodesk Collaboration for Revit or similar solutions that allow for real-time co-authoring and version control. This ensures everyone is working on the most up-to-date version of the model.

Beyond the software, regular team meetings, clear task assignments, and a well-defined project workflow are crucial. For example, we might assign one team member to focus on the high-poly model, another on the low-poly model for game engines, and a third on texturing. We use project management software to track progress, deadlines, and any outstanding issues. This structured approach prevents conflicts and ensures seamless integration of individual contributions into a cohesive final product.

We also leverage efficient file naming conventions and versioning to avoid confusion and facilitate easy tracking of changes. Clear communication channels, whether through instant messaging, email, or video conferencing, are maintained to address any questions or concerns promptly.

Q 9. How do you handle revisions and feedback during the 3D modeling process?

Handling revisions and feedback is a vital part of the iterative 3D modeling process. We usually employ a structured feedback loop. Once a milestone is reached, say, a completed base model, we present it to the client or stakeholders for review. This is often done through digital presentations, incorporating annotated screenshots highlighting key features and design choices.

We use revision tracking software to meticulously document all changes implemented based on the received feedback. This allows us to easily revert to previous versions if necessary. Feedback is categorized as either major revisions, requiring significant model changes, or minor adjustments. We prioritize the implementation of major revisions first, ensuring they are thoroughly discussed and understood by the entire team. For instance, a major revision might involve a complete redesign of a component, while a minor adjustment could be a simple color change or dimensional tweak.

We strive for clear and concise communication to address all feedback points. We might create updated renderings or animations to visually demonstrate the implemented changes. This transparent process ensures that everyone is on the same page and promotes client satisfaction.

Q 10. Describe your experience with rapid prototyping techniques.

My experience with rapid prototyping spans various techniques, including 3D printing (SLA, FDM, SLS), CNC machining, and vacuum casting. I’m proficient in using software like Cura (for FDM 3D printing), Simplify3D (for more advanced FDM control), and various CAD slicing software for other processes. For example, I’ve used SLA 3D printing to create highly detailed prototypes with smooth surfaces, perfect for visualizing intricate designs, while FDM was ideal for functional prototypes, due to its speed and cost-effectiveness.

I’ve also used CNC machining for creating robust prototypes with precise dimensions, particularly useful for parts needing high strength or specific material properties like metal alloys. Vacuum casting is perfect for creating multiple copies of a master prototype made by SLA or similar methods, improving the efficiency and cost-effectiveness of evaluating different design iterations.

I am familiar with the limitations and strengths of each technique. For example, I’m able to choose the best method based on the required accuracy, material properties, production volume and budget constraints of the project. This allows me to deliver functional and aesthetically pleasing prototypes that effectively evaluate the design concept.

Q 11. Explain your understanding of different prototyping materials and their properties.

Selecting the right prototyping material is crucial for a successful prototype. The choice depends heavily on the intended use and properties needed. For example:

- PLA (Polylactic Acid): A common FDM 3D printing material, PLA is biodegradable, relatively inexpensive, and easy to print, but less durable than other options. Ideal for initial concepts and form studies.

- ABS (Acrylonitrile Butadiene Styrene): Stronger and more heat-resistant than PLA, ABS is suitable for functional prototypes requiring higher durability. However, it requires a heated bed and has a stronger odor during printing.

- SLS (Selective Laser Sintering) Nylon: Offers high strength and complex geometry capabilities, making it ideal for prototypes requiring intricate details and robust structural integrity. It’s more expensive than FDM options.

- Stereolithography (SLA) Resins: These produce high-resolution prototypes with smooth surfaces, excellent for visual prototypes needing a polished finish. However, they can be brittle and are usually more expensive than other methods.

- Aluminum or other metals: Used for prototypes requiring high strength and precision, often machined using CNC milling. This provides the most durable and accurate prototypes, but it’s the most expensive and time-consuming.

Understanding these properties allows for informed decision-making, ensuring the prototype effectively represents the final product’s intended behavior and aesthetics.

Q 12. How do you select the appropriate prototyping method for a given project?

Selecting the appropriate prototyping method is a multi-faceted decision. I consider several factors:

- Project Goals: What needs to be tested or demonstrated? Is it functionality, aesthetics, fit, or a combination?

- Budget: Different methods have vastly different costs. FDM 3D printing is generally the cheapest, while CNC machining and casting can be significantly more expensive.

- Time Constraints: FDM and some 3D printing methods are relatively fast, while CNC machining and casting can take much longer.

- Required Accuracy and Detail: SLA 3D printing and CNC machining offer high accuracy, while FDM might suffice for less demanding applications.

- Material Properties: The required strength, durability, flexibility, and other material properties dictate the material and method.

For example, a quick concept model for client review might use FDM 3D printing with PLA, while a functional prototype needing high strength and precision might require CNC machining of aluminum.

Q 13. What are the limitations of different prototyping methods?

Each prototyping method has its limitations:

- FDM 3D Printing: Layer lines are visible, limiting surface finish. Strength can be an issue depending on the material and orientation. Complex geometries can be challenging.

- SLA 3D Printing: Can be brittle; supports are needed for overhanging features, adding to post-processing time. Materials are often more expensive than FDM.

- SLS 3D Printing: Porous structure can affect strength and surface finish. Powder removal post-processing can be time-consuming.

- CNC Machining: Limited to subtractive manufacturing; tooling costs can be significant; complex undercuts may be difficult to machine.

- Vacuum Casting: Requires a master pattern, making it less suitable for quick iterations. Detail fidelity is limited by the master pattern’s quality.

Understanding these limitations allows me to make informed choices and manage client expectations accordingly. For instance, we may need to adjust the design to compensate for limitations of chosen prototyping techniques.

Q 14. How do you evaluate the success of a prototype?

Evaluating prototype success is done through a combination of objective and subjective assessments. Objective assessment involves physical measurements, testing against design specifications, and functional performance evaluations. This could involve things like drop tests, stress tests, or dimensional accuracy checks using calipers and measuring tools.

Subjective assessment considers aesthetic appeal, usability, and overall user experience. We often gather feedback from users or stakeholders through surveys or usability testing. We analyze this data to identify areas for improvement and determine if the prototype meets the project’s goals. For example, the functionality of a phone case would be measured against drop test results and user satisfaction ratings concerning grip and ease of button access.

Detailed documentation of all testing procedures and results is crucial, allowing for informed decision-making during the design refinement process. This data-driven approach ensures that the prototype effectively serves its purpose, providing valuable insights for final product development.

Q 15. Describe your experience with reverse engineering.

Reverse engineering in 3D modeling involves creating a digital 3D model from an existing physical object. This process often begins with detailed measurements and scans of the object, using tools like 3D scanners or CMMs (Coordinate Measuring Machines). The gathered data is then processed and imported into CAD software. I’ve used a variety of techniques, including point cloud processing, surface reconstruction, and feature recognition, to create accurate and usable models. For instance, I once reverse-engineered a vintage clock mechanism to create a replacement part that was no longer available. This involved carefully disassembling the mechanism, scanning individual components, and then assembling the digital parts in CAD, meticulously recreating the intricate gear teeth and linkages. The process involved significant attention to detail and iterative refinement to ensure functional accuracy.

The challenges in reverse engineering often lie in dealing with imperfections in the source object (wear and tear, manufacturing inconsistencies), interpreting complex geometries, and ensuring the final model is suitable for its intended use (e.g., manufacturing, analysis, or animation). Overcoming these issues requires careful planning, rigorous quality control, and a deep understanding of the underlying manufacturing processes.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your understanding of tolerance and fit in engineering design.

Tolerance and fit are critical in engineering design. Tolerance refers to the permissible variation in a dimension or feature of a part. Fit describes how two or more parts interact based on their tolerances. Imagine trying to assemble two cylindrical parts – a shaft and a hole. The tolerance on the shaft diameter specifies the acceptable range of its size, and similarly, the hole has a tolerance range. The relationship between these tolerances determines the fit.

- Clearance Fit: The shaft is smaller than the hole, allowing for easy assembly and some degree of movement.

- Interference Fit: The shaft is larger than the hole, requiring force to assemble, resulting in a tight connection.

- Transition Fit: Falls between clearance and interference, offering a compromise between ease of assembly and tightness.

Defining appropriate tolerances is crucial for functionality and manufacturability. Too tight tolerances can be costly and difficult to achieve, while loose tolerances can lead to poor performance or even failure. Software like CAD packages have built-in tools for tolerance analysis and simulation, allowing engineers to virtually assess the impact of tolerance variations before manufacturing.

Q 17. How do you manage file formats and data exchange in 3D modeling workflows?

Efficient file format management is key to smooth 3D modeling workflows. Different formats excel in different situations. For example, .STEP (STEP AP214) and .IGES are commonly used for neutral data exchange between different CAD software. They maintain geometry but not design history or features. .STL (Stereolithography) is prevalent for 3D printing, focusing on surface geometry. Native formats, like .sldprt (SolidWorks) or .prt (Creo), retain all design data and are best used within their respective software ecosystems.

To prevent data loss or corruption, I maintain a structured file naming convention and organize projects into folders. When exchanging files, I carefully choose the most appropriate format based on the recipient’s software and the intended use. For complex assemblies, I often employ a modular approach – breaking down the design into smaller, manageable components, each saved in its respective file. This promotes better organization and reduces the file size of individual files, making them easier to manage and share.

Q 18. Describe your experience with version control systems for 3D models.

Version control is essential for collaborative 3D modeling projects. I’ve extensively used Git, often in conjunction with platforms like GitLab or GitHub, although other systems like SVN are also suitable. Using Git allows for tracking changes, managing revisions, and collaborating seamlessly with team members. I utilize branching strategies to manage parallel development and ensure that everyone is working with the most up-to-date and stable version of the model. For instance, I might create a branch for a specific feature, develop that feature on the branch, and then merge it back into the main branch once it’s tested and approved. This reduces the risk of conflicts and makes it easy to revert to previous versions if needed.

To further streamline the process, I typically commit changes regularly with clear and concise commit messages describing the modifications made. This creates a comprehensive history that is easily searchable and understandable. A good version control system keeps the design process organized and reduces the chances of irreversible errors or overwritten work.

Q 19. How do you troubleshoot common issues encountered in 3D modeling and prototyping?

Troubleshooting in 3D modeling involves a systematic approach. I start by identifying the specific problem: Is it a geometric error, a rendering issue, a software bug, or a problem with the hardware? Common issues include:

- Geometric Errors: These might involve non-manifold geometry (surfaces intersecting incorrectly), gaps or overlaps, or incorrect dimensions. I usually diagnose these visually using the model’s analysis tools within the CAD software. Solutions often involve using Boolean operations to correct intersections and using repair tools to address surface anomalies.

- Rendering Issues: Problems like incorrect shading, texture mapping errors, or slow rendering speeds can be addressed by reviewing rendering settings, checking texture paths, and optimizing the model’s geometry for rendering performance.

- Software Bugs: These can be tricky to solve, and the solution often depends on the specific software. I usually try restarting the software, updating to the latest version, and searching for solutions online.

- Hardware Issues: Insufficient RAM or graphics card issues can slow down rendering, or even lead to crashes. Upgrading hardware might be the necessary solution.

In short, my troubleshooting methodology uses a process of elimination, focusing on recreating the issue, reviewing the error messages, and experimenting with solutions to pinpoint the root cause.

Q 20. What are your strategies for managing deadlines and project timelines?

Effective deadline management requires meticulous planning and proactive communication. I start by breaking down large projects into smaller, manageable tasks with clearly defined milestones and deliverables. I then create a detailed schedule, assigning timelines to each task, considering potential dependencies between tasks. Using project management tools (like Trello or Asana) helps visualize the progress and identify potential bottlenecks. Regular progress reviews, both self-assessments and team meetings, help track progress, identify deviations from the schedule and allow for adjustments.

Proactive communication is crucial. I maintain open lines of communication with stakeholders to inform them of progress and any potential delays. If unforeseen circumstances arise, I address them promptly and propose solutions collaboratively, adjusting the schedule as needed. Prioritizing tasks based on urgency and importance ensures that critical deliverables are met on time, even if minor adjustments need to be made to the overall schedule.

Q 21. Describe a challenging 3D modeling project you worked on and how you overcame the challenges.

One particularly challenging project involved designing a complex, articulated robotic arm for a research lab. The challenge stemmed from the intricate design and tight tolerances required for smooth, precise movement. The design included multiple degrees of freedom, requiring careful consideration of joint mechanisms, linkages, and potential interference. Initial attempts to model the arm using standard CAD techniques proved difficult due to the complexity of the moving parts and the need to ensure they all moved smoothly without collisions.

To overcome this, I employed a combination of techniques. I started by designing the individual components of the arm separately, focusing on creating accurate kinematic models of each joint. I then utilized simulation tools to verify the motion of each joint and to detect potential collisions or interferences before assembling the entire arm digitally. Once the components were simulated and verified separately, I then assembled them in the CAD software. This modular approach, coupled with rigorous simulation, ensured that the final design met the stringent requirements for functionality and precision. The project successfully demonstrated the power of combining meticulous design with robust simulation for complex mechanical systems.

Q 22. What are your strengths and weaknesses as a 3D modeler and prototyper?

My greatest strength as a 3D modeler and prototyper lies in my ability to seamlessly integrate artistic vision with technical precision. I excel at translating abstract concepts into tangible, functional 3D models, paying meticulous attention to detail and ensuring dimensional accuracy. I’m proficient in various modeling techniques, from organic sculpting to precise hard-surface modeling. For example, I recently completed a project where I had to model a complex piece of medical equipment, requiring both a deep understanding of anatomical structures and the ability to create highly detailed, accurate mechanical components. My weakness, if I had to identify one, is sometimes getting overly invested in perfecting minute details, which can occasionally impact project deadlines. I’m actively working on improving my time management skills and prioritizing tasks more effectively to mitigate this. I use project management tools to break down tasks and ensure deadlines are met.

Q 23. How do you stay updated with the latest advancements in 3D modeling and prototyping?

Staying current in the rapidly evolving fields of 3D modeling and prototyping requires a multi-pronged approach. I actively participate in online communities like forums and LinkedIn groups dedicated to 3D design, where I engage in discussions, share knowledge, and learn from others’ experiences. I subscribe to industry publications and newsletters, and regularly attend webinars and online courses offered by industry leaders like Autodesk and other software providers. Additionally, I dedicate time to exploring and experimenting with new software features and plugins, constantly seeking ways to improve my workflow and efficiency. For example, recently I explored the use of AI-powered tools in 3D modeling to streamline certain aspects of my workflow, significantly improving speed and accuracy. I also keep an eye on emerging technologies like 3D printing advancements and new materials.

Q 24. What are your salary expectations?

My salary expectations are commensurate with my experience and skill set, and I’m open to discussing a competitive compensation package that aligns with the industry standards and the specific requirements of this role. I’m confident that my contributions will significantly benefit your company.

Q 25. Why are you interested in this position?

I’m highly interested in this position because it offers a unique opportunity to leverage my expertise in 3D modeling and prototyping within a dynamic and innovative environment. The job description aligns perfectly with my skills and career aspirations, particularly the emphasis on [mention specific aspects from the job description, e.g., ‘collaborative team projects’ or ‘complex product development’]. I’m particularly excited about the prospect of contributing to [mention a specific project or company goal mentioned in the job description]. My previous experience in [mention relevant past experience] has prepared me well to excel in this role and make significant contributions to your team.

Q 26. What are your long-term career goals?

My long-term career goals involve becoming a recognized leader in the field of 3D modeling and prototyping. I aspire to take on increasingly challenging projects, mentoring junior team members, and contributing to the advancement of design and manufacturing processes. I envision myself potentially leading a team of 3D modelers and playing a pivotal role in shaping the future of product design and development. Ultimately, I want to be involved in creating innovative products that solve real-world problems and improve people’s lives.

Q 27. Do you have any questions for me?

Yes, I do have a few questions. I’d like to learn more about [mention specific questions relevant to the job description and company, e.g., the company’s current projects, the team dynamics, professional development opportunities].

Q 28. Describe your experience with specific CAD software relevant to the job description (mention specific software if listed in the job description).

My experience with CAD software is extensive. I’m highly proficient in [mention specific software from job description, e.g., SolidWorks, Autodesk Inventor, Fusion 360]. For instance, in my previous role at [previous company], I utilized SolidWorks to design and model a range of complex mechanical assemblies, including [mention specific example projects demonstrating expertise in the software]. I’m also adept at using the software’s simulation tools to test designs for functionality and stress analysis before prototyping. My proficiency extends to [mention other relevant software if applicable, e.g., Blender for organic modeling or Zbrush for sculpting]. I understand the nuances of different file formats and can seamlessly transition between various software packages as required by the project.

Key Topics to Learn for Your 3D Modeling and Prototyping Interview

- 3D Modeling Software Proficiency: Demonstrate a strong understanding of at least one major 3D modeling software (e.g., Blender, Maya, 3ds Max, SolidWorks). Be prepared to discuss your experience with modeling techniques, workflows, and common shortcuts.

- Prototyping Techniques: Showcase your knowledge of various prototyping methods, including additive manufacturing (3D printing), subtractive manufacturing (CNC machining), and rapid prototyping techniques. Be ready to discuss material selection and its impact on the final product.

- Geometric Modeling Concepts: Understand fundamental geometric principles like NURBS, polygon modeling, and Boolean operations. Be able to explain how these concepts are applied in practical scenarios.

- Texture Mapping and Materials: Demonstrate your expertise in applying textures and materials to 3D models, achieving realistic visuals and enhancing the overall quality of your prototypes.

- Digital Asset Management: Discuss your approach to organizing and managing 3D models, textures, and other digital assets throughout the design process. Efficient file management is crucial in professional environments.

- Version Control and Collaboration: Explain your understanding and experience with version control systems (e.g., Git) and collaborative workflows in a 3D modeling environment.

- Problem-Solving and Troubleshooting: Be ready to discuss how you approach and solve technical challenges encountered during the modeling and prototyping process. Highlight your analytical skills and ability to find creative solutions.

- Design Principles and Aesthetics: Demonstrate understanding of fundamental design principles, such as form, function, and ergonomics, and how these principles influence your modeling and prototyping choices.

Next Steps

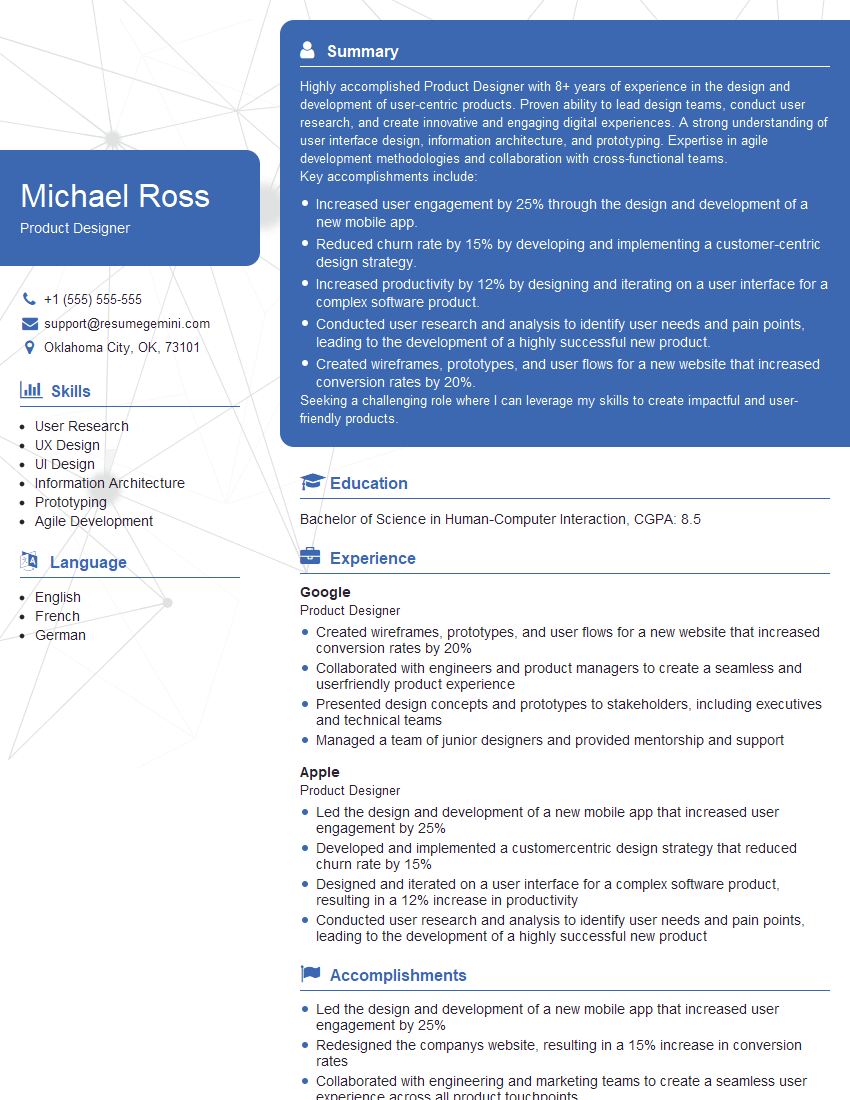

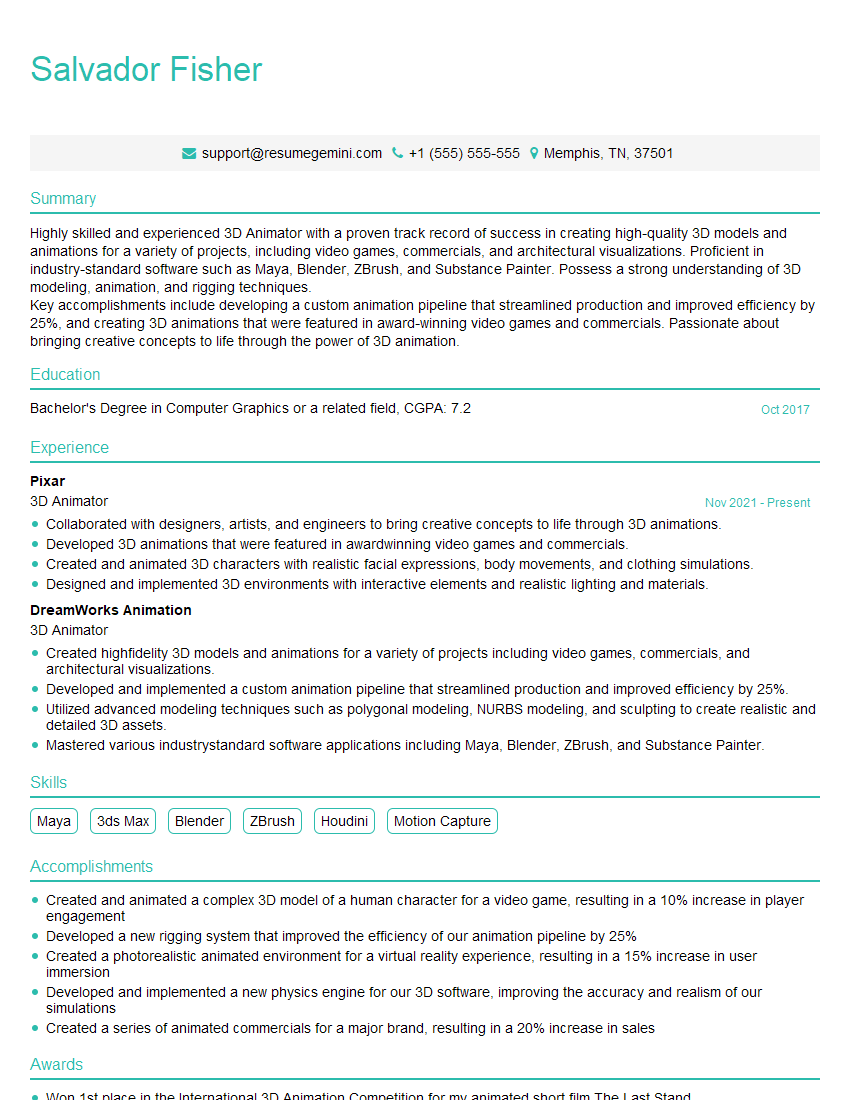

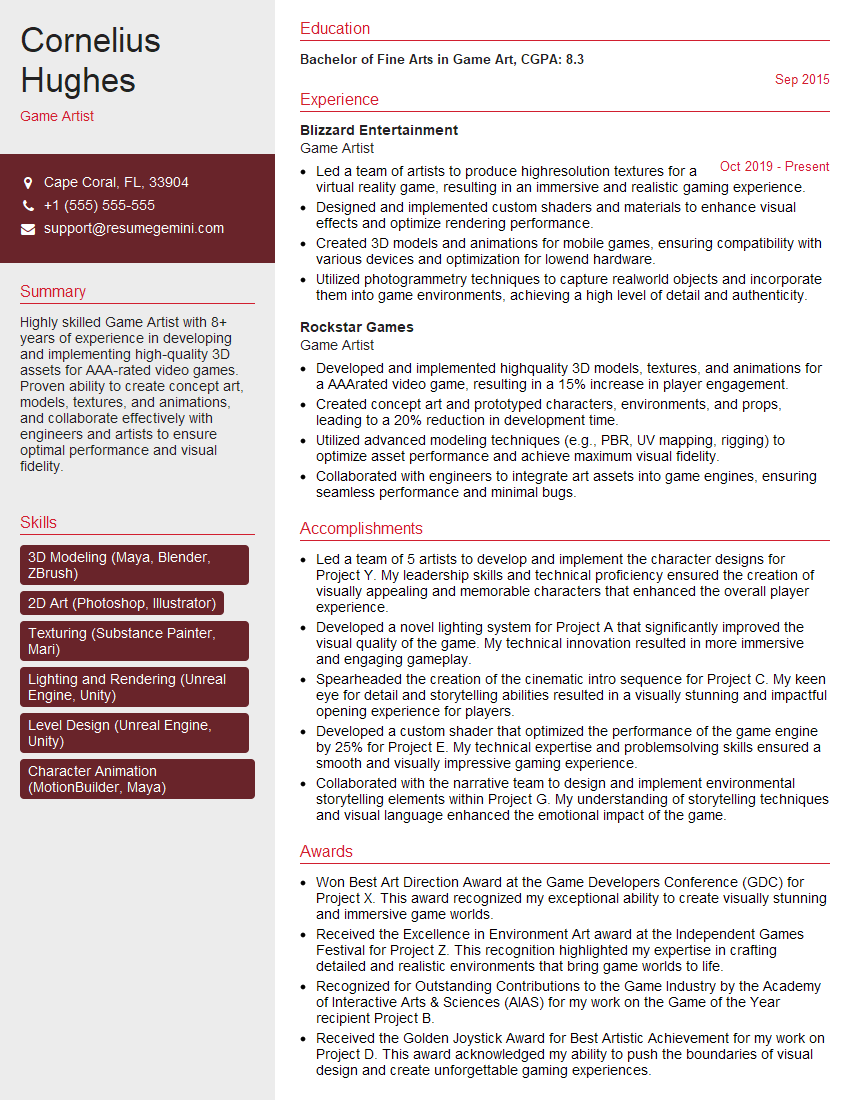

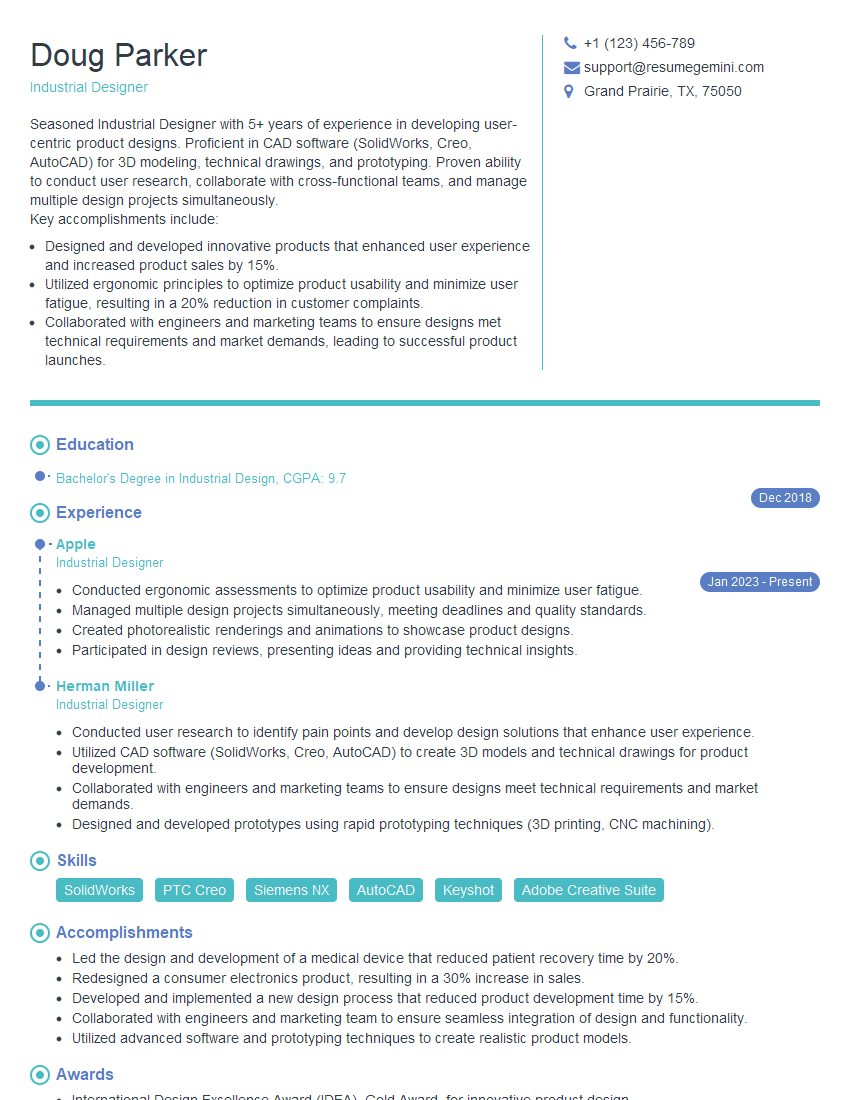

Mastering 3D modeling and prototyping opens doors to exciting career opportunities in various industries. To maximize your job prospects, creating a strong, ATS-friendly resume is crucial. This ensures your qualifications are effectively communicated to potential employers. ResumeGemini is a trusted resource to help you build a professional and impactful resume. They provide examples of resumes tailored to the 3D Modeling and Prototyping field, guiding you towards a successful job search. Take the next step and craft a resume that truly showcases your skills and experience.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good