Preparation is the key to success in any interview. In this post, we’ll explore crucial Ability to Determine Fiber Length, Strength, and Micronaire Value interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Ability to Determine Fiber Length, Strength, and Micronaire Value Interview

Q 1. Explain the relationship between fiber length and yarn strength.

Fiber length is fundamentally linked to yarn strength. Imagine trying to build a strong rope with short pieces of string versus long ones. Longer fibers can intertwine more effectively, creating a more cohesive and robust structure. This translates directly to yarn: longer fibers result in yarns with greater tensile strength, meaning they can withstand more force before breaking. The longer the fiber, the more effectively they can align and bond during spinning, leading to improved yarn quality and strength. Shorter fibers, on the other hand, tend to create weaker, more easily broken yarns, because they lack the length needed for extensive interfiber bonding.

For example, extra-long staple (ELS) cotton, known for its exceptional fiber length, produces yarns significantly stronger than those made from short-staple cotton. This is why ELS cotton is often preferred for high-quality textiles.

Q 2. How does micronaire value affect yarn spinning performance?

Micronaire value, a measure of fiber fineness and maturity, significantly impacts yarn spinning performance. It essentially reflects the fiber’s air permeability and surface characteristics. An ideal micronaire value ensures proper fiber alignment and cohesion during the spinning process. Too high a value (coarse fibers) can lead to poor yarn quality due to unevenness and weak interfiber bonding. Think of trying to spin a yarn with thick, stiff wires – it would be difficult and the result would be inconsistent. Conversely, a value that is too low (fine, thin fibers) can result in increased fiber breakage during spinning and weaker yarns, as the fibers lack the necessary bulk for good cohesion. A balanced micronaire value is crucial for efficient spinning and high-quality yarn production.

For instance, cotton with a micronaire value that’s too low might result in excessive fly in the spinning process, while a value that’s too high might lead to uneven yarn and decreased strength.

Q 3. Describe the different methods for determining fiber length.

Several methods exist for determining fiber length, each with its strengths and limitations. These include:

- AFIS (Advanced Fiber Information System): This is a highly automated, sophisticated method that measures fiber length, strength, and other properties using digital image analysis. It’s considered the industry standard for accurate and comprehensive fiber analysis.

- High Volume Instrument (HVI): Another automated system, HVI, provides rapid analysis of fiber length, strength, and micronaire. While less detailed than AFIS, it’s faster and widely used for high-throughput testing.

- Comb Sorter: A more traditional method, the comb sorter separates fibers based on length using a series of combs. This provides a visual representation of the fiber length distribution, but it’s less precise and more time-consuming than automated methods.

- Projection Microscopic Methods: This involves projecting a magnified image of the fibers onto a screen for length measurement. It’s a less efficient method, suitable only for smaller samples.

Q 4. What are the limitations of each fiber length measurement method?

Each fiber length measurement method has its limitations:

- AFIS: While highly accurate, AFIS can be expensive and requires specialized training and maintenance. It may not be suitable for all fiber types.

- HVI: Though fast and widely used, HVI might provide less precise length distribution data compared to AFIS.

- Comb Sorter: This method is subjective, labor-intensive, and less precise, providing only an approximate length distribution.

- Projection Microscopic Methods: This is time-consuming and prone to human error, limiting its suitability for large-scale analysis.

The choice of method depends on factors like budget, required accuracy, sample size, and available resources. A small textile laboratory might opt for HVI for routine analysis, while a research institution may prefer AFIS for in-depth studies.

Q 5. How does fiber fineness impact yarn quality?

Fiber fineness, often expressed as micronaire value or fiber diameter, significantly impacts yarn quality. Finer fibers (lower micronaire) generally produce smoother, softer yarns, but they might also be weaker and more prone to breakage during processing. Think of silk versus wool – silk fibers are finer, resulting in a much smoother fabric. However, coarser fibers (higher micronaire) produce stronger, more durable yarns, but may feel rougher to the touch. The optimal fineness depends on the desired yarn properties, such as strength, softness, and drape. For example, fine fibers are preferred for delicate fabrics, while coarser fibers are used where strength is paramount.

A balanced approach often considers the interplay between fiber fineness and other factors like fiber length and maturity to achieve the desired yarn quality.

Q 6. Explain the concept of fiber maturity and its effect on strength.

Fiber maturity refers to the degree of cell wall development in the cotton fiber. Mature fibers have thick, well-developed walls, leading to increased strength and durability. Conversely, immature fibers have thin, underdeveloped walls, resulting in weaker and less resilient yarns. Imagine comparing a fully ripe fruit to a green one – the ripe fruit is stronger and more robust. Similarly, mature cotton fibers contribute significantly to yarn strength. The level of maturity is directly correlated to the fiber’s ability to withstand stress and contribute to the overall strength of the yarn.

Assessing fiber maturity is crucial for predicting yarn quality and optimizing spinning parameters. Techniques like using the maturity index obtained from instruments like AFIS and HVI helps determine the overall maturity of cotton fibers within a sample.

Q 7. What are the ideal micronaire values for different types of cotton?

Ideal micronaire values vary depending on the type of cotton and the desired end-use. There’s no single ideal value, but rather a range deemed suitable for specific applications. Generally, values between 3.5 and 5.0 are considered acceptable for many cotton types. However, longer-staple cottons often benefit from a slightly lower micronaire value, while shorter-staple cottons may require a higher value to achieve sufficient strength.

Specific ideal ranges must be determined based on the desired yarn properties and spinning system. A yarn spinner would collaborate with cotton breeders and researchers to identify the optimum micronaire range depending on the type of cotton being processed and the desired end-product characteristics. The precise value will also vary depending on the specific needs and preferences of the end user.

Q 8. How do you interpret a fiber fineness test report?

A fiber fineness test report details the characteristics of textile fibers, primarily focusing on their fineness, length, and strength. Interpreting it involves understanding the different metrics and their impact on yarn and fabric quality. The report typically includes:

- Fiber Length: Measured in millimeters (mm), it indicates the average length of fibers in the sample. Longer fibers generally produce stronger and smoother yarns.

- Fiber Strength: Expressed in grams per tex (g/tex) or centiNewtons per tex (cN/tex), it measures the force required to break a single fiber. Higher strength means better yarn durability.

- Fiber Fineness (Micronaire): This measures the fiber’s diameter and maturity, influencing its air permeability and spinning behavior. It’s expressed as a micronaire value (a unitless number), with higher values indicating coarser, less mature fibers, and lower values indicating finer, more mature ones.

- Fiber Uniformity: This assesses the consistency of fiber length and diameter within the sample. High uniformity leads to better yarn quality and fewer imperfections.

- Fiber Length Distribution: Provides a detailed breakdown of the proportion of fibers of different lengths. A narrower distribution means more consistent fiber length.

For example, a report might state: ‘Average Fiber Length: 35 mm, Fiber Strength: 30 g/tex, Micronaire: 4.0, Uniformity Index: 85%.’ This suggests relatively long, strong fibers with average maturity and good uniformity, indicative of high-quality cotton.

Q 9. Describe the relationship between fiber strength and tensile strength of yarn.

Fiber strength is directly related to the tensile strength of the yarn. Think of it like this: each fiber is a tiny strand in a rope (the yarn). A rope made of strong, individual strands will be stronger than one made of weak strands. Similarly, yarn made from fibers with high strength will exhibit higher tensile strength, meaning it can withstand more force before breaking. The relationship is not perfectly linear, however, as factors like yarn twist, fiber arrangement, and other processing steps also impact yarn strength.

Imagine trying to build a bridge. You wouldn’t use weak, brittle wooden planks; you’d choose strong, durable materials. Similarly, high-quality textiles rely on strong fibers to ensure the final product’s durability and performance.

Q 10. What instruments are used to measure fiber strength?

Several instruments are used to measure fiber strength, each with its own methodology:

- Stelometer: This classic instrument measures the force required to break a single fiber. A clamp holds the fiber, and a motorized mechanism applies force until the fiber breaks. The force at the breaking point is recorded as fiber strength.

- AFIS (Advanced Fiber Information System): A sophisticated automated instrument that analyzes numerous fibers simultaneously, providing detailed information on strength, length, fineness, and other properties. It offers a more comprehensive analysis compared to Stelometer.

- Uster Tester: This versatile instrument is used for various yarn and fiber testing, including strength. It provides data on fiber bundle strength, which is more relevant to yarn manufacturing.

The choice of instrument depends on the required level of detail, budget, and the type of fiber being tested. For quick assessments of single fiber strength, a stelometer might suffice, while AFIS offers detailed information and higher throughput for large-scale quality control.

Q 11. How do you troubleshoot issues related to low fiber strength?

Troubleshooting low fiber strength requires a systematic approach, investigating various factors from cultivation to processing:

- Identify the Stage: Determine if the low strength is inherent to the fiber (e.g., due to poor growing conditions) or introduced during processing (e.g., damage during ginning or spinning).

- Check Growing Conditions: Assess environmental factors such as rainfall, temperature, pest infestations, and nutrient availability during the growing season. Stressful conditions often lead to weaker fibers.

- Analyze Processing: Examine the processes involved, paying attention to potential points of damage: ginning (removing seeds), carding (cleaning and aligning fibers), combing (removing short fibers), and spinning. Excessive mechanical stress can weaken fibers.

- Fiber Maturity: Immature fibers tend to be weaker. Micronaire testing can highlight the maturity level of the fibers.

- Microscopic Examination: Analyze fiber samples under a microscope to look for physical damage, such as breaks or irregularities.

Addressing low fiber strength often requires implementing corrective actions at the source, improving cultivation practices or refining processing parameters to minimize fiber damage.

Q 12. Explain the significance of fiber uniformity in textile production.

Fiber uniformity is crucial in textile production because it directly influences the quality and consistency of the final product. Uniform fibers of consistent length and diameter produce yarns with better evenness, strength, and appearance. Inconsistent fibers lead to uneven yarns with weak points, resulting in inferior fabrics. Think of it like building a wall with bricks – uniform bricks create a smoother, stronger wall compared to a wall with bricks of varying sizes and shapes.

Uniformity also simplifies the manufacturing process. Machines designed for consistent fiber input work more efficiently with uniformly sized fibers, leading to reduced waste and improved productivity.

Q 13. What are the implications of high or low micronaire values on yarn properties?

Micronaire value significantly impacts yarn properties. It represents the balance between fiber fineness and maturity.

- High Micronaire Values (Coarse, Less Mature Fibers): These often result in yarns that are coarser, less smooth, and have lower strength. They might be more prone to breakage and have a less refined appearance. However, they might be suitable for certain applications requiring increased bulk or warmth.

- Low Micronaire Values (Fine, More Mature Fibers): These usually result in finer, smoother, stronger yarns. They are generally preferred for high-quality textiles requiring excellent evenness, drape, and hand feel. However, they can be more challenging to spin and might be less suitable for applications requiring higher bulk.

The ideal micronaire value depends on the desired yarn properties and the end-use application. For example, a fine cotton yarn for a luxury shirt would require low micronaire fibers, while a coarser yarn for a durable towel might benefit from higher micronaire values.

Q 14. How does fiber length distribution affect yarn evenness?

Fiber length distribution significantly influences yarn evenness. A narrow fiber length distribution, meaning most fibers are of similar length, leads to more uniform yarns. This uniformity translates to better yarn strength, less hairiness, fewer imperfections, and a more consistent appearance in the final fabric.

Conversely, a wide fiber length distribution, with a significant variation in fiber lengths, results in uneven yarns with thick and thin sections. This unevenness affects the yarn’s strength and overall quality. The short fibers tend to stick out, leading to a hairy, rough appearance.

Imagine building a rope with strands of varying lengths. The rope would be uneven, weaker, and less aesthetically pleasing compared to a rope made with strands of uniform length.

Q 15. Describe the process of preparing a fiber sample for testing.

Preparing a fiber sample for testing is crucial for obtaining accurate and reliable results. The process depends heavily on the fiber type and the specific tests being conducted (length, strength, micronaire). However, some general steps are common to most methods. First, a representative sample of the fiber needs to be taken, ensuring it accurately reflects the entire batch. This often involves techniques like taking samples from multiple locations within a bale of cotton or a yarn package. Next, the sample is cleaned to remove any extraneous materials, such as leaves, seeds, or other contaminants. This might involve hand-picking, using air currents, or more sophisticated cleaning machinery. The cleaned sample is then prepared for the specific testing instrument. For example, for length measurements, fibers might need to be carefully aligned and positioned, while for strength testing, they may need to be clamped into a testing device. The amount of sample preparation will depend on the testing method and the type of fiber being tested. For example, cotton requires different preparation than wool or synthetic fibers.

Imagine preparing a batch of cookies – you wouldn’t test only one cookie; you would take several to ensure your assessment is fair. The same concept applies to fiber testing.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure accurate and reliable fiber testing results?

Ensuring accurate and reliable fiber testing hinges on several key factors. First, using calibrated and regularly maintained instruments is paramount. These instruments, such as AFIS (Advanced Fiber Information System) for fiber length and strength testing, and a Micronaire instrument, need to be checked against known standards to guarantee their accuracy. Second, a standardized testing procedure must be followed meticulously. This includes adhering to established protocols for sample preparation, instrument operation, and data recording. Any deviation from these protocols can introduce systematic errors. Third, skilled and trained personnel are vital. They must be proficient in handling the instruments, interpreting the results, and recognizing potential sources of error. Finally, multiple tests should be conducted on different subsamples to reduce the impact of random variation and improve the reliability of the results, allowing for calculation of averages and standard deviations, thereby increasing the statistical significance of the data. Replication and thorough documentation are essential in minimizing uncertainties.

Q 17. What are the common sources of error in fiber testing?

Several sources of error can affect fiber testing. Sample preparation is a major one – improper cleaning or handling can lead to biased results. Instrument calibration and maintenance are also critical; a poorly calibrated instrument will give inaccurate readings. Operator skill and technique are crucial; inconsistencies in handling samples or operating the equipment can introduce errors. Environmental factors such as temperature and humidity can influence fiber properties and should be controlled. Lastly, inherent fiber variability itself is a source of error; fibers within a given batch will never be perfectly uniform. Understanding and mitigating these sources of error are key to generating reliable results. It is also worth noting that different testing instruments have inherent limitations, leading to variations between results obtained from distinct equipment or laboratories.

Q 18. How do you interpret data from a fiber property testing instrument?

Interpreting data from a fiber property testing instrument involves understanding the specific parameters measured and their significance. For instance, an AFIS instrument provides data on fiber length (e.g., upper half mean length, length uniformity), strength (e.g., gram-weight, tensile strength), and other parameters like maturity and fineness. Micronaire values indicate the air permeability of the cotton, providing insights into fiber maturity and processing characteristics. The data is typically presented in tables, graphs, or reports. Analysis involves comparing results to industry standards or specifications for a given fiber type and grade. Outliers or unusual patterns need to be carefully examined, considering potential sources of error. For example, unusually low strength may indicate damage during harvesting or processing. Statistical analysis techniques can help identify trends, assess variability, and provide confidence intervals, leading to informed decision-making regarding fiber quality.

Q 19. Explain the importance of fiber testing in quality control.

Fiber testing plays a crucial role in quality control across numerous industries. In the textile industry, it ensures that the raw materials meet the required specifications for downstream processes like spinning, weaving, and knitting. Consistent fiber quality translates to consistent yarn and fabric quality, impacting the final product’s performance, appearance, and durability. Fiber testing helps manufacturers identify and address quality issues early on, minimizing waste and maximizing efficiency. For example, detecting low strength fibers early can prevent production problems and reduce costly rework or product recalls. In quality control, fiber testing serves as a gatekeeper, guaranteeing that the raw material meets the minimum requirement of quality before the textile manufacturing process even starts. It is an objective measure that reduces uncertainty in the production cycle.

Q 20. How do different fiber types (e.g., cotton, wool, polyester) affect testing methods?

Different fiber types require different testing methods and interpretations. Cotton, for example, is commonly tested for length, strength, micronaire, and maturity. Wool testing focuses on fiber length, diameter, strength, and crimp. Synthetic fibers like polyester are evaluated for tenacity (strength), elongation, and other properties relevant to their intended applications. The instruments used, the sample preparation techniques, and the interpretation of the results will vary significantly depending on the fiber type. A test designed for cotton might be unsuitable for wool because of significant differences in fiber structure and properties. For instance, the mechanical properties of the instruments need to be adjusted accordingly to take into account the difference in strength and elasticity. Each fiber has its own unique characteristics, and tailor-made tests are necessary to accurately assess its quality.

Q 21. What are the industry standards for fiber length, strength, and micronaire value measurements?

Industry standards for fiber testing are established by various organizations, including international standards bodies (e.g., ISO) and national organizations (e.g., ASTM in the US). These standards define the testing methods, instrumentation, and reporting procedures to ensure consistency and comparability of results across different laboratories and manufacturers. Specific standards exist for fiber length (e.g., AFIS method), strength (e.g., using a tensile testing machine), and micronaire (specific instruments and procedures). Adherence to these standards is crucial for fair trading, accurate quality assessment, and effective communication within the industry. These standards also ensure that the results obtained are comparable and reproducible, regardless of where the test is conducted. For instance, the ASTM has detailed specifications for the methods used to measure cotton fiber properties, and similar standards exist for other fiber types.

Q 22. How do you handle discrepancies between expected and actual fiber properties?

Discrepancies between expected and actual fiber properties are a common challenge in textile manufacturing. Identifying the root cause requires a systematic approach. First, I’d meticulously review the testing procedures to rule out any errors in sampling, preparation, or instrument operation. This often involves checking calibration logs, repeating tests with different equipment or technicians, and comparing results against established control samples.

If the testing process is sound, the discrepancy points to a variation in the raw material itself. This could stem from inconsistencies in the cultivation, harvesting, or processing of the fiber. Further investigation might involve analyzing the entire supply chain, looking for potential changes in farming practices, ginning techniques, or storage conditions. Statistical process control (SPC) charts are invaluable in identifying trends and potential outliers within batches of fiber.

For instance, if the micronaire value (a measure of fiber fineness and maturity) is lower than expected, it could indicate insufficient drying or damage during processing. Addressing this requires collaborating with the suppliers to pinpoint the specific stage of the supply chain responsible and implementing corrective actions. Ultimately, documenting all findings, analyses, and corrective actions is crucial for continuous improvement and preventing future discrepancies.

Q 23. Describe a situation where your fiber testing expertise helped solve a production problem.

During a production run of high-quality cotton yarn, we experienced a significant increase in yarn breakage. Initial troubleshooting focused on the spinning process, but the problem persisted. My expertise in fiber testing was crucial in identifying the root cause. We analyzed samples of the cotton fiber using high-volume instrument (HVI) testing, which revealed a significant drop in fiber strength compared to previous batches.

Further investigation through microscopic analysis showed increased fiber damage, likely due to changes in the cotton ginning process at the supplier’s facility. By presenting this data to the supplier, we collaboratively identified the source of the problem – an improperly adjusted ginning machine. Correcting the ginning process resulted in improved fiber strength and resolved the yarn breakage issue, saving the company significant losses in production time and material costs. This demonstrated the importance of proactive fiber testing in preventing costly downstream problems.

Q 24. How do you maintain the accuracy and calibration of fiber testing equipment?

Maintaining accurate and calibrated fiber testing equipment is paramount for reliable results. This involves a multi-faceted approach. First, we adhere to a strict preventative maintenance schedule for all instruments, including regular cleaning, lubrication, and component checks. This is documented meticulously to ensure traceability and compliance with quality standards.

Regular calibration is crucial, using certified reference materials traceable to national or international standards. We perform calibrations at set intervals, often daily or weekly for high-usage instruments, recording the results in detailed calibration logs. Any deviations from established standards trigger a thorough investigation to identify and rectify the problem. Furthermore, we use quality control samples (with known fiber properties) during each testing run to validate the accuracy of the equipment and the consistency of the testing process. This helps us catch and address any potential drift or malfunction early.

Q 25. What are some new technologies or developments in fiber testing?

The field of fiber testing is constantly evolving. Recent advancements include the integration of automated and high-throughput testing systems. These systems dramatically reduce manual handling, increase speed, and minimize human error. For example, image analysis techniques are becoming increasingly sophisticated, allowing for more precise and objective measurements of fiber length and other morphological characteristics.

Another exciting development is the application of advanced spectroscopic methods, such as near-infrared (NIR) spectroscopy, for rapid and non-destructive assessment of fiber properties. NIR spectroscopy can provide quick estimations of fiber composition, maturity, and strength, reducing the reliance on more time-consuming conventional methods. Furthermore, the use of machine learning and artificial intelligence (AI) is showing great potential in analyzing complex datasets from fiber testing and predicting fiber behavior in different textile processes.

Q 26. How do environmental factors influence fiber properties?

Environmental factors significantly influence fiber properties, particularly during growth, harvesting, and storage. Humidity levels play a crucial role in fiber strength and moisture content. High humidity can lead to increased fiber swelling, reducing its strength and making it more susceptible to damage. Conversely, low humidity can make fibers brittle.

Temperature also affects fiber properties. Extreme temperatures can cause fiber degradation, impacting its strength and overall quality. Exposure to sunlight during storage can cause photodegradation, reducing fiber strength and color. Furthermore, exposure to pollutants or contaminants in the environment can alter fiber properties and reduce its overall quality. Proper control of temperature and humidity during storage is essential to maintain the integrity of the fibers. Implementing best practices in storage and handling can minimize environmental impacts and ensure the consistent quality of fibers.

Q 27. What are the implications of different fiber lengths for different textile applications?

Fiber length is a critical determinant of yarn and fabric properties and is directly linked to the final textile application. Longer fibers generally produce stronger and finer yarns, leading to smoother, more durable fabrics. This is because longer fibers provide more points of contact and intertwining within the yarn structure. Consequently, longer staple fibers are preferred for high-quality garments and other demanding applications such as denim or upholstery fabrics.

Shorter fibers, on the other hand, are suitable for applications where strength and fineness are less critical. They may be used in coarser yarns or non-woven fabrics. The selection of fiber length is therefore a careful balance between cost and performance. Using longer fibers than necessary increases the cost without significant benefit, while using shorter fibers than needed compromises the quality and durability of the final product. A thorough understanding of the desired end-use properties is key to selecting the optimal fiber length.

Q 28. How do you communicate complex fiber testing results to non-technical stakeholders?

Communicating complex fiber testing results to non-technical stakeholders requires clear and concise language, devoid of technical jargon. I typically use visual aids like charts and graphs to present the data in a digestible format. Instead of focusing on raw data like ‘micronaire value,’ I translate the findings into meaningful implications for the product.

For instance, instead of saying ‘fiber strength is below the specified range,’ I might explain ‘the yarn produced from this fiber batch is more prone to breakage, potentially impacting the efficiency of the production process and reducing the quality of the final product.’ I use relatable analogies to explain complex concepts. For example, I might compare fiber strength to the strength of a rope—a longer, stronger fiber is like a thicker, more durable rope. By emphasizing the practical consequences of the findings, I make the information relevant and actionable for non-technical audiences.

Key Topics to Learn for Ability to Determine Fiber Length, Strength, and Micronaire Value Interview

- Fiber Length Measurement Techniques: Understanding different methods like AFIS (Advanced Fiber Information System), high-volume instrument (HVI) testing, and their applications in various fiber types (cotton, wool, etc.). This includes knowing the advantages and limitations of each method.

- Fiber Strength Analysis: Grasping the concept of fiber tensile strength, its significance in yarn and fabric quality, and the techniques used to measure it (e.g., single-fiber strength testing). Consider the impact of different factors (humidity, temperature) on strength measurements.

- Micronaire Value and its Implications: Learning how micronaire relates to fiber fineness, maturity, and its impact on processing, spinning, and yarn properties. Understanding the interpretation of micronaire values and their correlation with fabric quality.

- Practical Applications: Explore real-world examples of how these measurements are used in quality control, process optimization, and product development within the textile industry. Consider scenarios involving troubleshooting issues related to fiber quality.

- Data Interpretation and Analysis: Develop skills in analyzing data obtained from fiber testing. This includes understanding statistical analysis, identifying trends, and drawing conclusions based on the results.

- Fiber Properties and their Interrelation: Understand how fiber length, strength, and micronaire are interconnected and how changes in one property can affect the others. This includes the impact of these properties on the final textile product.

- Troubleshooting and Problem-Solving: Develop the ability to identify potential problems based on fiber test results and propose solutions to improve fiber quality and processing efficiency.

Next Steps

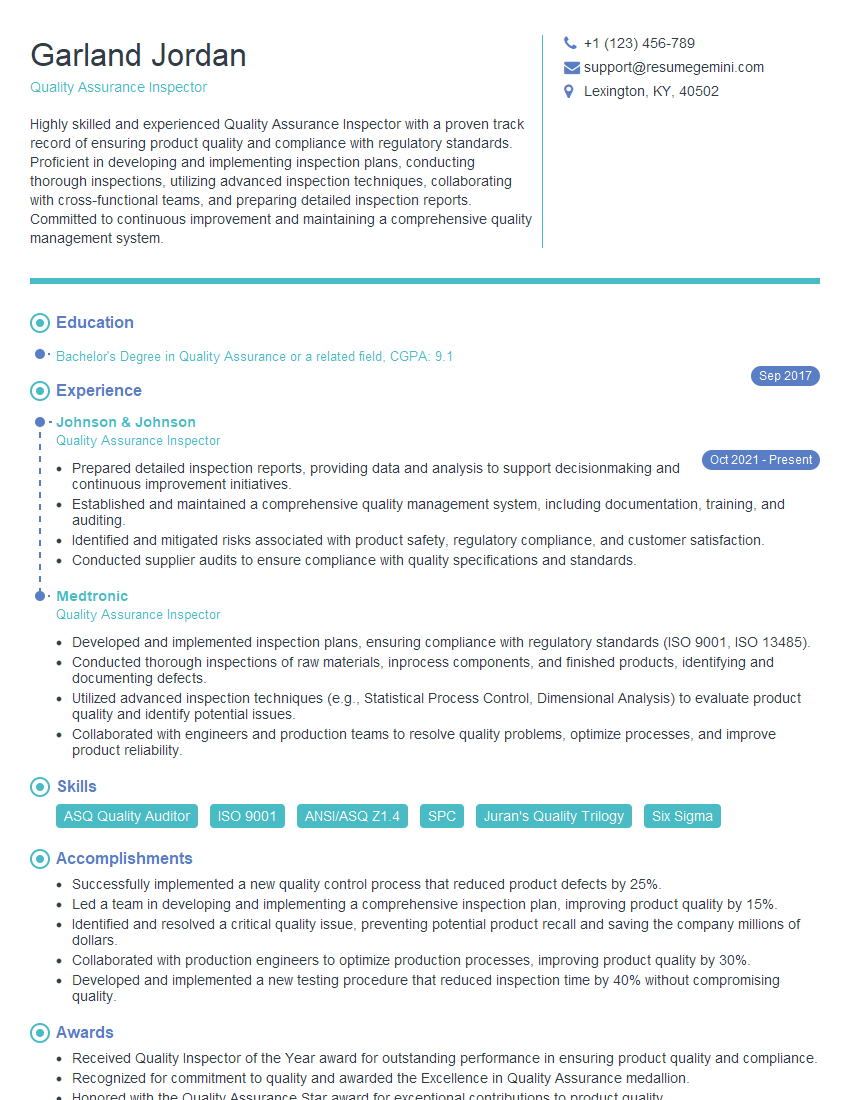

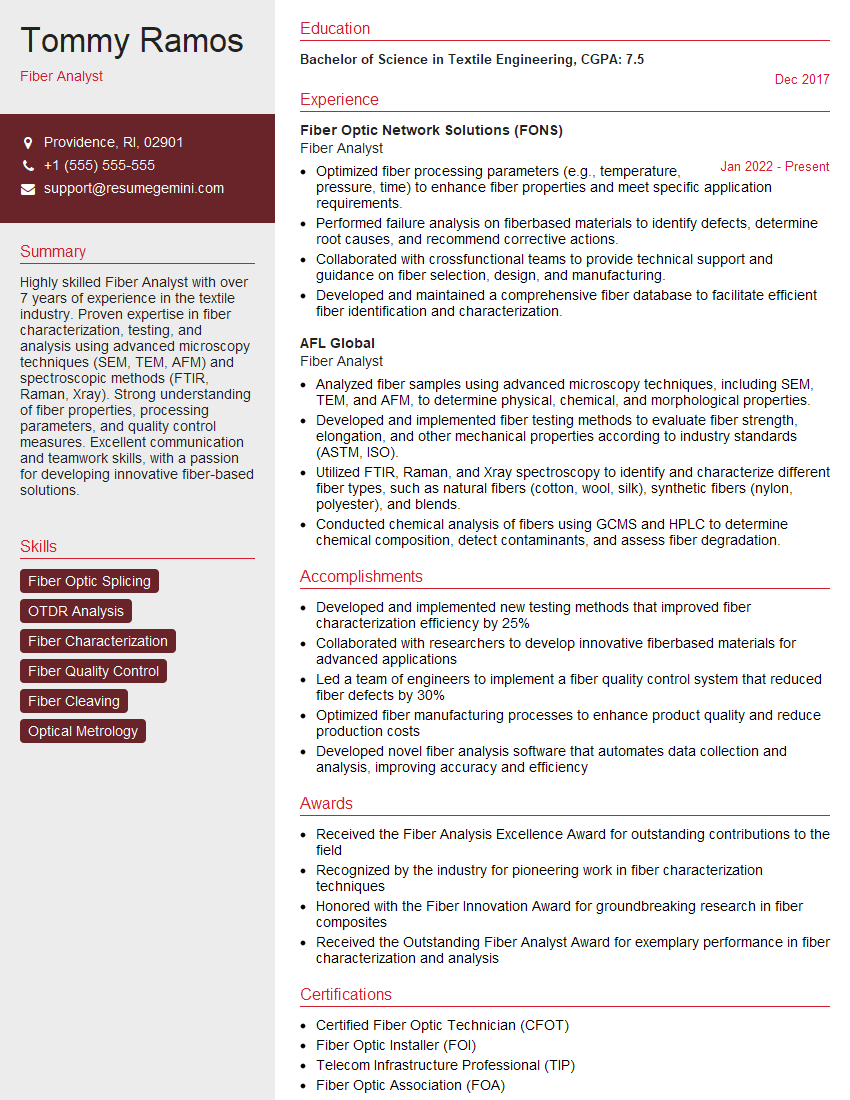

Mastering the ability to determine fiber length, strength, and micronaire value is crucial for a successful career in the textile industry, opening doors to specialized roles and higher responsibilities. A well-crafted resume is your key to unlocking these opportunities. Creating an ATS-friendly resume is essential to get your application noticed. ResumeGemini can help you build a professional, impactful resume that highlights your skills and experience effectively. ResumeGemini provides examples of resumes tailored to highlight expertise in Ability to Determine Fiber Length, Strength, and Micronaire Value, giving you a head start in your job search.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good