Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Ability to interpret blueprints and specifications interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Ability to interpret blueprints and specifications Interview

Q 1. Explain the difference between an architectural blueprint and a structural blueprint.

Architectural blueprints and structural blueprints, while both crucial parts of a construction project, focus on different aspects of the building. Think of it like this: the architectural blueprint is the ‘what’ and the structural blueprint is the ‘how’.

Architectural blueprints primarily deal with the building’s design and aesthetics. They show the layout of rooms, the placement of doors and windows, finishes, and overall spatial arrangement. They’re concerned with how the building looks and functions from a user’s perspective. For example, an architectural blueprint will show the location of kitchen appliances, the style of flooring in each room, and the overall flow of the space.

Structural blueprints, on the other hand, focus on the building’s physical stability and integrity. They detail the structural elements like foundations, beams, columns, and the load-bearing capacity of different parts of the building. These are the plans that ensure the building can withstand various forces and remain safe. A structural blueprint will illustrate the size and placement of support beams, the type of foundation required for the soil conditions, and the calculation of load-bearing capacities. They often include detailed calculations and engineering specifications.

Q 2. How do you identify different line types and their significance on a blueprint?

Blueprint line types are crucial for understanding the different components and their relationships within a building design. They use a standardized system of weights and patterns to convey specific information. Here’s a breakdown:

- Solid lines: These represent visible outlines of walls, doors, and other features. Think of them as the primary elements you’d see when looking at the structure.

- Dashed lines: These indicate hidden or concealed features, such as walls behind finishes or elements not immediately visible. Imagine looking through a wall to see the framing underneath.

- Center lines: Thin, long and short dashed lines that indicate the center of a symmetrical object or element, like a column or a room. These help with accurate measurements and alignment.

- Dimension lines: Thin lines with arrowheads at each end used to indicate distances and measurements within the plan. These lines are essential for verifying sizes.

- Section lines: Used to show the cut-away view of a building element within a section drawing, usually accompanied by hatch lines to indicate material. This allows for a clear depiction of inner structure.

- Break lines: Short, zig-zagged lines used to shorten long, continuous elements in the drawing to save space without losing information.

Understanding these line types is fundamental to accurately interpreting blueprints and extracting the necessary information for construction or renovation projects.

Q 3. Describe your experience interpreting building codes and specifications.

Interpreting building codes and specifications is an integral part of my blueprint reading process. It’s not enough to simply understand the drawings; one must ensure the design complies with all applicable regulations and standards. My experience involves meticulously reviewing local, state, and national building codes to verify that a blueprint adheres to requirements for fire safety, structural integrity, accessibility, and energy efficiency.

I’m proficient in referencing relevant sections of the International Building Code (IBC) and other specialized codes, comparing specifications provided by architects and engineers with these requirements. For example, I’ve worked on projects where I had to ensure proper fire-rated wall assemblies were detailed on the blueprints, verifying that the specified materials and construction methods met code requirements for fire separation. I also have experience identifying discrepancies and proposing solutions that ensure compliance while minimally impacting the design.

This process involves careful cross-referencing between different sections of the drawings, specifications, and code books, often requiring a deep understanding of construction materials, methods, and their properties.

Q 4. How do you identify potential conflicts or errors in a set of blueprints?

Identifying potential conflicts or errors in a set of blueprints requires a systematic and detailed approach. I typically employ a multi-step process:

- Cross-referencing: Carefully comparing different drawings within the set (architectural, structural, MEP, etc.) to identify any discrepancies. For instance, checking if a door location shown in the architectural plan conflicts with a structural column indicated in the structural plan.

- Dimension verification: Checking dimensions throughout the plans for consistency and accuracy. Errors in dimensioning can lead to significant problems on site.

- Code compliance check: Verifying adherence to all relevant building codes and regulations, as mentioned previously. Any non-compliance should be highlighted.

- Material compatibility: Ensuring the specified materials are compatible and suitable for their intended use. For example, making sure that a chosen flooring material is appropriate for a high-traffic area.

- Spacing and clearance checks: Verifying adequate spacing for circulation, mechanical equipment installation, and other necessary clearances.

My approach combines technical understanding with a keen eye for detail to uncover potential issues before they become costly problems during construction.

Q 5. Explain your process for verifying dimensions and scaling on a blueprint.

Verifying dimensions and scaling is critical for accurate interpretation of blueprints. My process involves several steps:

- Identifying the scale: The blueprint should always state the scale (e.g., 1:50, 1/4″=1′). This indicates the ratio between the drawing and the real-world dimensions.

- Using a scale rule: A properly calibrated scale rule or architectural scale is used to measure distances on the blueprint and convert them to actual dimensions. This avoids manual calculations.

- Cross-checking dimensions: I systematically measure critical dimensions multiple times and cross-check them against other dimensions and related drawings to catch any discrepancies. This often involves working with a team or another set of eyes.

- Checking for dimension notations: Verifying that all dimensions are clearly indicated and easily understood. Any missing or unclear dimensions should be addressed.

- Utilizing software: In digital formats (like DWG), CAD software can be used to precisely measure distances and calculate areas, enhancing the accuracy of verification.

This methodical approach ensures that the dimensions on the blueprints are accurate and consistent, preventing costly errors during construction.

Q 6. How do you interpret symbols and abbreviations commonly used on blueprints?

Blueprints are filled with symbols and abbreviations, a sort of shorthand language for construction professionals. Familiarizing oneself with these is crucial. I have a deep understanding of common symbols, including those representing doors, windows, plumbing fixtures, electrical outlets, and structural elements. I’ve created my own reference guide over the years.

For example, a simple circle might represent an electrical outlet, while a specific symbol might indicate a specific type of valve in the plumbing system. Abbreviations are also frequently used, such as ‘W.C.’ for water closet (toilet) or ‘F.F.’ for finished floor. My familiarity extends to less common symbols and abbreviations which I often research through industry standards and specification documents, as well as using online resources and collaborating with colleagues.

Understanding these conventions is essential for correctly interpreting design details and ensuring consistency in my work. Using a standard symbol key and cross referencing with the specifications is essential to accurate interpretation.

Q 7. Describe your experience working with different types of blueprint formats (e.g., PDF, DWG).

Throughout my career, I’ve worked extensively with various blueprint formats, including PDFs, DWGs, and even older paper-based drawings. Each format presents its own set of challenges and advantages.

PDFs are widely used for sharing and archiving, offering a universal, easily accessible format. However, they are usually not ideal for editing or making precise measurements. I typically use measurement tools within PDF viewers and rely on the inherent accuracy of the source document.

DWGs, on the other hand, are native AutoCAD files, offering the flexibility of being edited and manipulated using CAD software. This allows for detailed analysis, precise measurements, and potentially detecting minor errors that might be missed in a static PDF. I often use measurement and annotation tools within the CAD software to ensure accurate interpretation.

My experience with older paper-based drawings requires careful handling and often includes the use of specialized equipment for reproduction and measurement. This process sometimes involves utilizing large format scanners and specialized software. Each format demands the use of suitable tools and a thorough understanding of how they represent the design.

Q 8. How do you utilize blueprints in conjunction with written specifications?

Blueprints and specifications are two sides of the same coin; they provide a complete picture of a construction project. Blueprints offer the visual representation – the layout, dimensions, and spatial relationships of various elements. Specifications, on the other hand, provide the detailed written descriptions of materials, methods, and standards to be used. I use them in tandem. For example, a blueprint might show a wall, but the specifications would detail the type of brick, mortar, insulation, and any specific construction techniques required.

My approach is to first thoroughly review the specifications to understand the project’s requirements and standards. Then, I meticulously examine the blueprints, cross-referencing details with the specifications. This ensures that the visual representation aligns with the written requirements, identifying any potential conflicts or ambiguities early on. It’s like following a recipe (specifications) while looking at a picture of the finished dish (blueprints).

Q 9. Explain your experience using blueprints to estimate material quantities.

Estimating material quantities is a crucial aspect of my work, and blueprints are indispensable for this process. I leverage the dimensional information provided on the blueprints – lengths, widths, heights, and areas – to calculate the required quantities of materials like concrete, lumber, bricks, or roofing tiles. For instance, if a blueprint shows a concrete slab with dimensions 10ft x 20ft x 6 inches, I calculate the volume (100 cubic feet) and then convert this to the required cubic yards, considering wastage factors.

I also use scaling and area calculations extensively. For example, when dealing with irregular shapes, I break them down into simpler geometrical forms (rectangles, triangles) to make the calculation manageable and accurate. My experience has taught me to always add a contingency factor (typically 5-10%) to account for unforeseen circumstances or waste during construction.

In one project, I was tasked with estimating the amount of lumber needed for a complex roof truss system. By meticulously measuring from the blueprints, I calculated the length of each beam, then considered the number of trusses, leading to an accurate estimation that saved the project significant costs by avoiding material overages.

Q 10. How do you communicate technical information derived from blueprints to non-technical personnel?

Communicating complex technical information from blueprints to non-technical personnel requires a clear and concise approach. I avoid using technical jargon and opt for simple language and visual aids. I use annotated diagrams extracted from blueprints to illustrate key aspects. For example, instead of saying “the HVAC ductwork needs to be routed along the perimeter wall”, I would point to the marked route on a simplified diagram.

I often employ analogies or real-world comparisons. For instance, explaining a complex structural system by comparing it to a bridge or building blocks simplifies understanding. I also prepare concise summaries that highlight the key features and implications without getting into technical details. If the information is particularly dense, I might create a short presentation or infographic.

In a recent project involving a complicated plumbing layout, I created a labeled diagram showing the main water lines and drainage systems, which helped the client visualize the process without needing to understand the intricacies of plumbing codes.

Q 11. Describe a time you encountered an unclear or ambiguous detail on a blueprint. How did you resolve it?

During a renovation project, the blueprints showed conflicting information about the location of an electrical conduit running through a specific wall. One section of the blueprint indicated the conduit was 6 inches from the edge, while another showed it 12 inches away. This ambiguity could have led to the conduit being damaged during demolition or causing significant electrical issues.

To resolve this, I first cross-referenced the conflicting information with other relevant documents such as the electrical specifications or field survey notes. I then contacted the project architect and the electrical engineer to clarify the discrepancy. After a joint site visit, it was determined that the later blueprint revision was accurate, and the older version had an error. This problem-solving process showcased the necessity of careful attention to detail and effective communication among the team.

Q 12. How do you ensure the accuracy of your interpretation of blueprints and specifications?

Ensuring accuracy in blueprint interpretation is paramount. My approach involves a multi-step verification process. First, I always cross-check dimensions and details across multiple sheets of the blueprints. Inconsistent information is a red flag. Second, I verify the blueprint scale – a seemingly small error in scale can have significant consequences during construction. Third, I look for any revisions or notes indicating changes or corrections made to the original plan.

I also rely on my experience and knowledge of building codes and industry standards. If something looks unusual or inconsistent with accepted practices, I flag it for review. Finally, when feasible, I conduct site visits to verify the actual conditions on the ground against the blueprint’s representation. This helps to spot discrepancies between the design and reality.

Q 13. Explain your proficiency with CAD software and its role in blueprint interpretation.

I am proficient in several CAD software packages, including AutoCAD and Revit. These programs are crucial for interpreting and manipulating blueprints. CAD software allows for easy zooming, panning, and measurement of elements on the blueprint. I often use the measuring tools to verify dimensions and calculate areas more accurately than simply using a ruler on a paper print. The layering capabilities in CAD allow me to isolate specific elements for detailed study without the clutter of other information.

Furthermore, I can use CAD to create 3D models from the 2D blueprints, aiding visualization and further enhancing my understanding of the design’s spatial relationships. This is particularly helpful for complex projects involving multiple systems. In a recent project, I used Revit to detect potential clashes between the HVAC system and structural elements by building a 3D model. This prevented costly rework later in the construction phase.

Q 14. How familiar are you with different drawing scales and their applications?

I am very familiar with various drawing scales and their applications. Understanding scales is fundamental to accurately interpreting blueprints. Common scales include 1:10, 1:20, 1:50, and 1:100. A scale of 1:50 means that 1 unit on the blueprint represents 50 units in reality. The choice of scale depends on the size and complexity of the project.

For instance, larger-scale drawings (e.g., 1:10) are used for detailed work such as architectural drawings, while smaller scales (e.g., 1:100) are suitable for showing the overall site layout. I consistently verify the scale used before any measurements or calculations are made. Misinterpreting the scale can lead to significant errors in material ordering or construction.

Q 15. Describe your understanding of sectional views, elevation views, and plan views on blueprints.

Blueprints utilize several view types to represent a structure’s design in 2D. Think of it like slicing a cake: each view shows a different slice.

- Plan Views: These are like looking down on the structure from above. They show the layout of rooms, walls, and other features as if the building were horizontally sliced. Imagine a bird’s-eye view of your house; that’s a plan view. They are crucial for spatial understanding and placement of elements. Common examples include floor plans, roof plans, and site plans.

- Elevation Views: These are like looking at the structure straight on from one side. Each elevation view shows the exterior wall structure from a particular direction (e.g., North, South, East, West elevation). They illustrate the height and exterior features of walls, windows, and doors. Think of it as a photograph of a building’s face. These are essential for understanding the building’s facade and external dimensions.

- Sectional Views: Imagine cutting through the building to see its internal structure. These views show the internal layout at a specific cut plane. They are especially useful for visualizing how different elements (walls, floors, beams, etc.) intersect and relate to each other in three dimensions. For instance, a section through a wall might show the thickness of the wall, the insulation, and the location of electrical wiring.

Understanding these three views is fundamental to interpreting blueprints accurately and comprehensively. Each contributes crucial information, and together they provide a complete picture of the design.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you use blueprints to identify potential safety hazards on a construction site?

Identifying safety hazards on a construction site using blueprints requires careful review and attention to detail. I’d look for several key things:

- Unprotected edges and openings: Plan views will show the locations of stairwells, openings for elevators, and other potential fall hazards. Sectional views reveal the heights of these features and the presence (or absence) of safety measures like railings. A missing railing in a sectional view is a clear safety hazard.

- Conflicting utilities: Blueprints often overlay utility information (electrical conduits, plumbing, gas lines). Discrepancies or insufficient clearances between different utility lines identified during the blueprint review stage could lead to potential hazards during construction.

- Structural weaknesses: Sectional and detail drawings allow for assessments of structural members such as beams, columns, and foundations. Any potential weaknesses or deviations from specified design parameters highlighted in the blueprints should be flagged as potential hazards.

- Egress routes: Plan views are critical for verifying the adequacy of escape routes and exit pathways. Insufficient width or obstacles in those routes highlighted on the blueprints constitute a safety problem.

- Hazardous materials: Blueprint notes or specifications can indicate the presence of asbestos, lead paint, or other hazardous materials. Knowing their location, as shown in the drawings, is vital for proper handling and safety protocols.

By systematically checking for these and other potential risks during the blueprint review process, I can proactively identify and mitigate hazards before they become significant issues during construction.

Q 17. How do you handle revisions and updates to existing blueprints and specifications?

Handling revisions and updates requires a systematic approach to ensure accuracy and avoid confusion. I follow these steps:

- Version Control: I ensure that all revisions are clearly numbered and dated. This prevents misinterpretations and allows for easy tracking of changes. We often use digital tools with built-in revision control features.

- Cloud Storage and Collaboration: Storing blueprints in a cloud-based system (like Dropbox, BIM 360) permits real-time collaboration and ensures everyone works with the most current version.

- Clear Markings: All changes on the blueprint should be clearly marked with revision clouds, notes, and revision dates to indicate added, deleted, or modified components. The nature of the change should be clearly explained.

- Distribution Control: We use a controlled distribution process to ensure that all stakeholders receive the updated versions promptly and that outdated copies are removed from circulation.

- Confirmation of Receipt: I confirm the receipt and understanding of the revisions from all relevant parties.

This structured process minimizes the risks associated with working with outdated or incomplete information, resulting in safer and more efficient construction.

Q 18. How familiar are you with industry-specific standards and regulations related to blueprint interpretation?

My familiarity with industry standards and regulations related to blueprint interpretation is extensive. I have a strong understanding of:

- Building Codes (e.g., IBC, local codes): I am adept at referencing relevant building codes to ensure blueprint compliance. I use these codes to verify that the design meets minimum safety and accessibility requirements.

- Accessibility Standards (e.g., ADA): I thoroughly review blueprints to ensure they comply with accessibility standards for ramps, doorways, and other features impacting individuals with disabilities.

- Structural Engineering Standards (e.g., ASCE): I’m aware of the standards for structural design and can assess the structural integrity of a design based on the blueprints and associated calculations.

- Electrical and Plumbing Codes (e.g., NEC, IPC): My understanding extends to ensuring compliance with electrical and plumbing codes, referencing the relevant sections to check for proper sizing, clearances, and safety measures.

- National and International Standards Organizations (e.g., ISO): I am familiar with the various standards set by organizations like ISO that are relevant to the construction industry. I know where to locate and reference standards when required.

This comprehensive knowledge allows me to interpret blueprints correctly, identify potential code violations, and ensure that designs are safe, functional, and compliant with all applicable regulations.

Q 19. How do you ensure that your interpretation of blueprints aligns with project requirements?

Ensuring alignment between blueprint interpretation and project requirements is a crucial aspect of my work. My approach involves several steps:

- Thorough Project Review: I begin by thoroughly reviewing the project specifications, design briefs, and any other relevant documentation to fully grasp the overall project goals and requirements.

- Blueprint Cross-Referencing: I carefully cross-reference the blueprints with the project specifications to ensure that the design reflected in the drawings meets the stated requirements. Any inconsistencies are noted and addressed.

- Detailed Calculations and Verification: I often conduct independent calculations (e.g., area calculations, volume calculations) to verify the accuracy of quantities indicated on the blueprints.

- Regular Communication: I maintain open communication with the project architect, engineer, and other stakeholders to clarify any ambiguities or discrepancies and ensure that my interpretation aligns with their intentions.

- Mockups and 3D Modeling: When necessary, we utilize 3D modeling software to build a virtual model from the blueprints, allowing us to visualize and identify potential issues.

This multifaceted approach minimizes the risk of misinterpretations and ensures that the project is executed in accordance with the approved design and project requirements.

Q 20. Explain your approach to problem-solving when encountering discrepancies between blueprints and specifications.

Discrepancies between blueprints and specifications are addressed systematically. My process includes:

- Documentation: I meticulously document the discrepancies, noting the specific locations and the nature of the conflict using precise references (e.g., sheet number, drawing number, specific location on the drawing).

- Prioritization: I prioritize the discrepancies based on their potential impact on the project. Critical discrepancies (e.g., structural issues) are addressed immediately.

- Source Verification: I try to trace back the source of the discrepancy. Was it a drafting error? An oversight in the specifications? An update not properly reflected?

- Communication: I communicate the discrepancies to the relevant stakeholders (architect, engineer, contractor) to initiate a resolution process. This involves clear and concise communication, using the documented discrepancies as a starting point.

- Resolution and Documentation: Once a resolution is reached, I ensure it is formally documented (e.g., through revisions to the blueprints or specifications) and communicated to all affected parties.

This approach ensures that issues are addressed promptly and transparently, minimizing errors and project delays.

Q 21. Describe your experience with using blueprints to conduct site inspections.

Blueprints are essential tools for conducting effective site inspections. My experience includes:

- Pre-Construction Site Visits: Before construction begins, I use the blueprints to verify the site conditions and ensure they match the design. I identify any potential discrepancies between the site and the planned construction.

- Verification of Construction Progress: During construction, I use the blueprints to verify that work is progressing according to the design. This involves comparing the actual construction to the plans to catch any deviations early.

- Quality Control: I use the blueprints to check the quality of workmanship and ensure that components and materials are installed correctly and meet the specified requirements.

- Issue Identification and Resolution: I use the blueprints to document and report any construction defects, discrepancies, or changes that need to be addressed.

- Change Order Management: I use blueprints to understand the scope of change orders and to ensure that any revisions are correctly implemented and documented.

By using blueprints effectively during site inspections, I can ensure the project is built to the design specifications, maintain quality, and identify and address problems before they become major issues. It’s like having a roadmap for the project’s physical realization, guiding every step of the way.

Q 22. How do you utilize 3D models derived from blueprints in your work?

3D models, often derived from blueprints using software like Revit or ArchiCAD, are invaluable tools for visualizing and analyzing a project. I use them extensively throughout the design and construction phases.

- Design Review: Before construction begins, I use 3D models to identify potential clashes between different systems (e.g., plumbing and electrical). This proactive approach avoids costly rework later on.

- Coordination: The models allow for better coordination with subcontractors. For instance, I can show a mechanical contractor exactly where ductwork needs to be routed to avoid conflicts with structural elements.

- Quantity Takeoff: Accurate material quantities are easily extracted from the model, improving budget estimations and material procurement.

- Client Presentation: 3D models provide a compelling visual representation of the project, enabling clearer communication and understanding with clients who may lack technical expertise.

- Construction Sequencing: By simulating the construction process within the 3D model, potential logistical challenges can be identified and mitigated before they arise on site.

For example, on a recent high-rise project, the 3D model revealed a clash between the elevator shaft and a large duct. By adjusting the duct’s position in the model, we avoided a costly on-site modification.

Q 23. Explain your experience using blueprints to coordinate work activities with other trades.

Effective coordination with other trades relies heavily on a shared understanding of the blueprints. My approach involves several key steps:

- Pre-Construction Meetings: I participate actively in meetings with all trades to review the blueprints collaboratively and address potential conflicts early on. This involves clarifying responsibilities and identifying potential scheduling challenges.

- Detailed Coordination Drawings: I often create detailed coordination drawings that highlight critical interfaces between different trades. For example, showing the exact location of electrical conduits within a wall section for the drywall contractor.

- Regular Site Visits and Communication: Consistent communication and on-site observations help resolve unforeseen issues that may not be explicitly shown in the blueprints. Daily logs and shared communication platforms ensure everyone is updated.

- Clash Detection Software: Using software capable of detecting conflicts between different 3D models (BIM) allows for proactive issue resolution before physical construction.

In one instance, a conflict arose between the plumbing and HVAC systems in a hospital renovation. By carefully analyzing the blueprints and engaging with both subcontractors early, we were able to reroute pipes and ducts, avoiding significant delays and cost overruns.

Q 24. How familiar are you with different types of construction materials and their representation on blueprints?

I possess a thorough understanding of various construction materials and their standard representations on blueprints. This includes recognizing symbols, abbreviations, and notations used to indicate material types, thicknesses, and properties.

- Structural Materials: I’m familiar with the symbols for steel, concrete, timber, masonry, and their respective specifications (e.g., concrete strength, steel grade).

- Finishes: I can interpret symbols indicating types of flooring, wall coverings, roofing materials, and their thicknesses.

- Insulation: I understand how insulation is denoted, including its type and R-value.

- MEP Systems: I am well-versed in the representation of plumbing fixtures, pipes, ducts, and electrical wiring on blueprints.

For instance, understanding the symbol for ‘6×6 pressure-treated lumber’ allows for accurate ordering and installation. Similarly, knowing the color-coding for various types of pipes (e.g., water, gas, drainage) is crucial for safety and functionality.

Q 25. How do you use blueprints to track progress and manage project timelines?

Blueprints serve as a roadmap for tracking progress and managing project timelines. My approach utilizes several methods:

- Baseline Schedule: I develop a baseline schedule based on the blueprint information and task durations. This schedule is then compared against actual progress.

- Regular Progress Monitoring: I regularly visit the construction site and compare the work in progress against the plans. Photographs and annotations are used to document progress.

- Milestone Tracking: Key milestones (e.g., foundation completion, framing completion) are identified on the blueprints and tracked against the schedule.

- Issue Tracking and Reporting: Any discrepancies between the plans and the actual construction are documented and communicated to the project team for timely resolution.

Using a Gantt chart in conjunction with the blueprints provides a clear visual representation of the schedule and progress. Any delays or issues are promptly identified and solutions are implemented to keep the project on track.

Q 26. Describe your experience in identifying and resolving discrepancies between blueprints and as-built conditions.

Identifying and resolving discrepancies between blueprints and as-built conditions is a critical aspect of my work. My process typically involves:

- Thorough Site Surveys: Conducting meticulous site surveys to compare actual construction with the plans, using precise measurements and documentation.

- As-Built Drawings: Creating as-built drawings that document any variations or changes made during construction. These drawings are essential for future maintenance and renovations.

- Issue Logging and Reporting: Documenting all discrepancies in a detailed log with photographic evidence and proposed solutions. Communication with relevant stakeholders is vital.

- Collaboration and Problem-Solving: Working collaboratively with architects, engineers, and contractors to develop solutions that address discrepancies while maintaining project integrity and safety.

In a recent project, we discovered a misalignment of a structural beam during construction. By documenting the discrepancy, we collaborated with the structural engineer to develop a solution that ensured the structural integrity of the building without requiring extensive rework.

Q 27. How would you explain the information on a blueprint to someone without a technical background?

Explaining blueprints to someone without a technical background requires clear and simple language, avoiding jargon whenever possible. I typically approach it in this way:

- Start with the Big Picture: Begin by showing them a general overview of the plans, highlighting key areas like the building’s footprint, entrances, and major rooms.

- Use Analogies: Relate blueprint symbols and notations to familiar objects. For example, a plumbing symbol might be compared to a familiar household fixture.

- Focus on Relevant Details: Only explain the sections of the blueprints that are pertinent to their needs or questions. Avoid overwhelming them with unnecessary details.

- Use Visual Aids: 3D models or even simple sketches can be more easily understood than complex technical drawings.

- Engage in Dialogue: Encourage questions and address them patiently. The goal is to ensure understanding, not just to present information.

Imagine explaining a house plan to a prospective buyer. Instead of discussing ‘bearing walls’ you would say, ‘These are the main walls that support the structure’. Using simple, everyday terms makes the information much more accessible and understandable.

Key Topics to Learn for Ability to Interpret Blueprints and Specifications Interviews

- Blueprint Fundamentals: Understanding scales, dimensions, annotations, and symbols common across different blueprint types (architectural, mechanical, electrical).

- Reading and Interpreting Views: Mastering the ability to visualize 3D structures from 2D representations (plans, elevations, sections, details).

- Specification Comprehension: Deciphering technical specifications, material lists, and tolerances to understand project requirements.

- Identifying Conflicts and Discrepancies: Developing skills in detecting inconsistencies or errors between blueprints and specifications, and proposing solutions.

- Practical Application: Relating theoretical knowledge to real-world scenarios, such as estimating material quantities, identifying potential construction challenges, or troubleshooting design flaws.

- Common Design Standards and Codes: Familiarity with relevant building codes, industry standards, and best practices impacting blueprint interpretation.

- Communication and Collaboration: Demonstrating the ability to clearly communicate technical information derived from blueprints and specifications to colleagues and stakeholders.

- Problem-Solving Techniques: Articulating a structured approach to analyzing blueprint information, identifying problems, and proposing effective solutions.

Next Steps

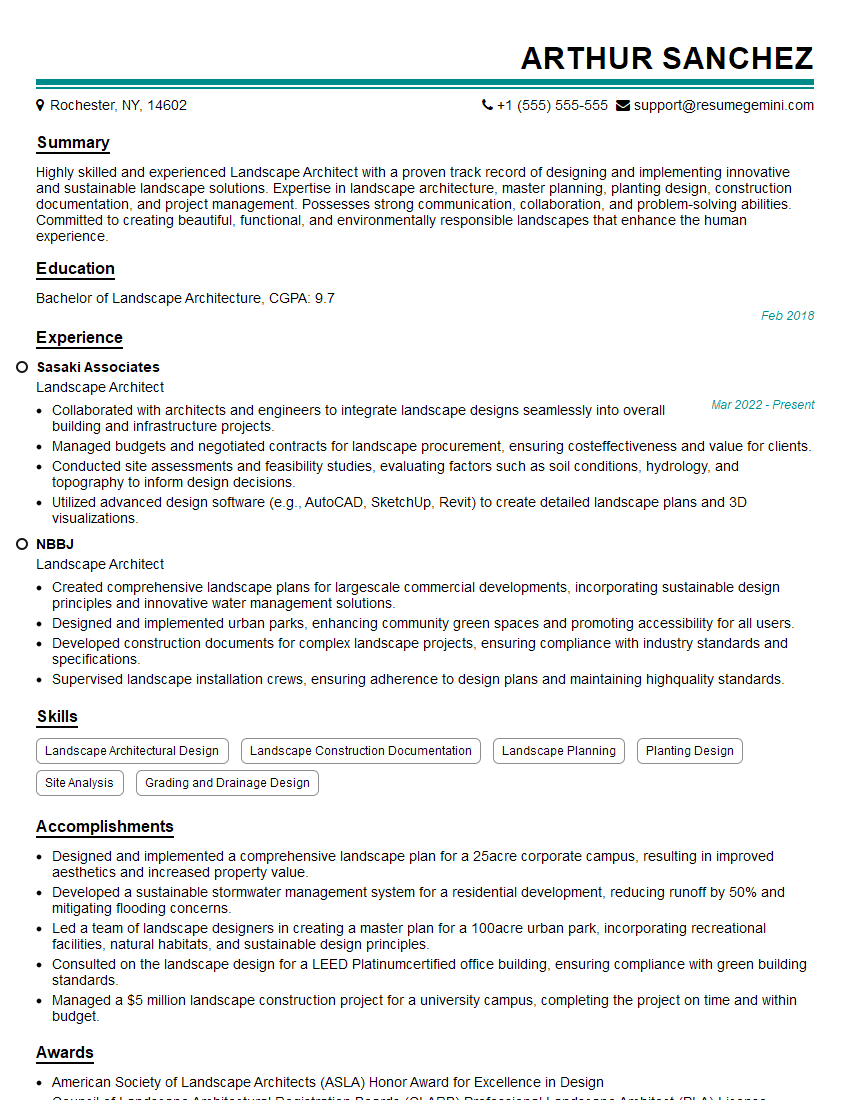

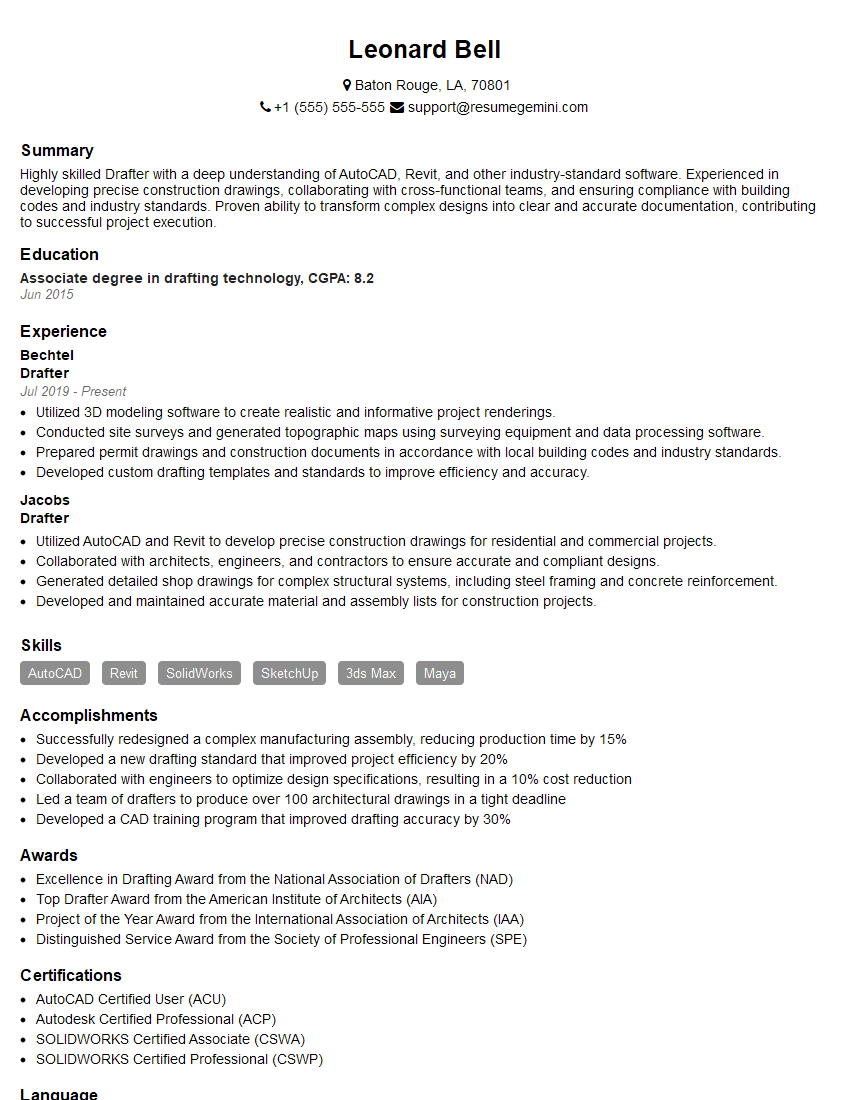

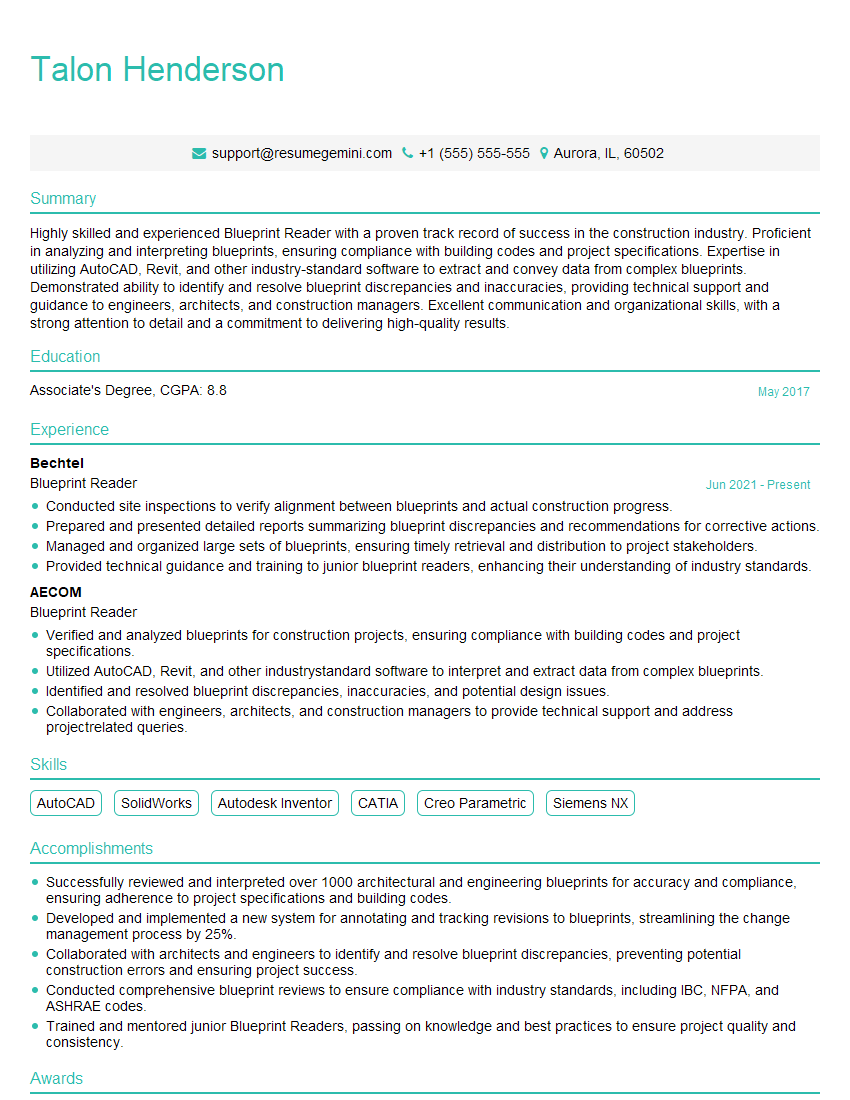

Mastering the ability to interpret blueprints and specifications is crucial for career advancement in many technical fields. A strong understanding of this skill demonstrates your attention to detail, problem-solving capabilities, and technical proficiency – qualities highly valued by employers. To maximize your job prospects, it’s essential to create an ATS-friendly resume that effectively showcases these skills. ResumeGemini can be a trusted resource in building a professional and impactful resume that highlights your expertise. We offer examples of resumes tailored to “Ability to interpret blueprints and specifications” to help you get started. Take the next step towards your dream career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good