The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Ability to lift and handle heavy loads interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Ability to lift and handle heavy loads Interview

Q 1. Describe your experience lifting and handling heavy loads.

Throughout my career, I’ve consistently handled heavy loads, ranging from materials in warehouse settings to equipment in construction projects. My experience encompasses various lifting scenarios, including using manual handling techniques, operating forklifts, and employing cranes when appropriate. I’ve worked with materials like pallets of goods weighing up to 1000kg, construction materials such as concrete blocks and steel beams, and machinery weighing several hundred kilograms. This experience has provided a deep understanding of safe lifting procedures and the importance of assessing the load before initiating any lifting activity.

For example, in my previous role at Acme Warehouse, I regularly loaded and unloaded trucks, ensuring the proper distribution of weight to prevent accidents and damage to goods. In another role at BuildStrong Construction, I participated in the safe lifting and placement of prefabricated components, often requiring careful coordination with a team and the use of specialized lifting equipment.

Q 2. What is your maximum comfortable lifting weight?

My maximum comfortable lifting weight without assistance is 25 kilograms. This is based on my training, physical capabilities, and an understanding of the potential risks associated with exceeding this weight. It’s crucial to remember that this is a personal limit and shouldn’t be generalized. Factors like the object’s size, shape, distance to be carried, and the environment all significantly impact lifting capacity. For heavier loads exceeding 25 kg, I would always use mechanical assistance like hand trucks, forklifts, or cranes to ensure safety and prevent injury.

Q 3. Explain proper lifting techniques to prevent injuries.

Proper lifting techniques are paramount to preventing back injuries and other musculoskeletal disorders. The core principle is to minimize strain on the back by engaging the leg muscles and maintaining proper posture. This technique involves:

- Assessment: Before lifting, assess the weight, size, and shape of the object, ensuring a clear path and a stable base.

- Stance: Position yourself close to the object, feet shoulder-width apart, with one foot slightly ahead of the other for balance.

- Lift with Legs: Bend your knees and hips, keeping your back straight, and grasp the object firmly. Avoid twisting or bending at the waist.

- Controlled Lift: Lift the object smoothly using your leg muscles, keeping your back straight. Avoid jerking motions.

- Maintain Posture: Keep your back straight and core engaged while carrying the object.

- Lower Carefully: Lower the object slowly using the same techniques as lifting, avoiding sudden movements.

Think of it like lifting a heavy suitcase – you wouldn’t bend over and yank it up; you’d bend your knees, keep your back straight, and use your legs to power the lift.

Q 4. What safety precautions do you take when lifting heavy objects?

Safety is my top priority. Before lifting any heavy object, I always take the following precautions:

- Assess the environment: Check for obstacles, uneven surfaces, and slippery conditions.

- Use appropriate equipment: When necessary, I utilize hand trucks, dollies, cranes, or other mechanical lifting devices.

- Get help if needed: For exceptionally heavy or awkward loads, I seek assistance from colleagues to ensure safe handling.

- Wear safety equipment: I always wear appropriate safety footwear and other personal protective equipment (PPE) as required by the job.

- Communicate clearly: I communicate with co-workers to coordinate lifts and to ensure everyone is aware of the lifting plan.

- Follow company procedures: I strictly adhere to all company safety policies and procedures related to lifting heavy objects.

Q 5. How do you assess the weight of an object before lifting?

Assessing the weight of an object before lifting involves a combination of visual inspection and physical estimation. For smaller items, I can usually estimate their weight accurately. For larger or unfamiliar objects, I might attempt a slight lift (a ‘test lift’) to gauge the weight. If uncertain, I’ll look for weight labels or markings. If no weight information is available, I’ll err on the side of caution and seek assistance rather than risk injury.

For example, if I’m unsure about a box’s weight, I might try to lift one corner. If it feels too heavy, I’ll get help. This cautious approach prevents me from attempting a lift that’s beyond my capabilities.

Q 6. Describe a situation where you had to lift a heavy object in an awkward position. How did you handle it?

During a renovation project, I had to lift a heavy marble slab into an awkward position – a tight corner on a second-floor landing. The slab was too heavy for a single person, and there wasn’t enough room to use a hoist. To manage this, I first used a hand truck to move the slab as close as possible to the final position. Then, working with a colleague, we used strong straps and a pulley system rigged temporarily to ease the weight and carefully maneuver the slab into place. We maintained constant communication, took small incremental steps, and prioritized safety throughout the process. The teamwork and proper equipment ensured the task was completed without incident.

Q 7. What are the signs of potential back injury?

Signs of potential back injury following heavy lifting can vary, but some common indicators include:

- Pain: Sharp, persistent pain in the lower back, radiating to the legs or buttocks.

- Muscle spasms: Involuntary muscle contractions in the back.

- Stiffness: Difficulty bending or twisting, or limited range of motion.

- Numbness or tingling: Sensations in the legs or feet.

- Weakness: Difficulty supporting weight or maintaining balance.

- Inflammation: Swelling in the affected area.

If any of these signs appear, immediate medical attention should be sought. Early diagnosis and treatment are crucial to prevent long-term complications.

Q 8. What is your understanding of ergonomics in lifting?

Ergonomics in lifting focuses on designing the work environment and using techniques that minimize the risk of musculoskeletal injuries. It’s all about adapting the task to the person, not the other way around. This involves considering factors like posture, force exertion, repetition, and the object’s characteristics to reduce strain on the body. Think of it as optimizing the human-machine interface for safe and efficient lifting.

For instance, good ergonomic lifting principles encourage keeping the load close to the body, bending at the knees, and maintaining a straight back. Avoiding twisting motions and lifting smoothly rather than jerking are also crucial. Ignoring these principles can lead to back pain, sprains, and other serious injuries.

Q 9. Have you ever used lifting aids or equipment? Which ones?

Yes, I’ve extensively used various lifting aids and equipment. My experience includes using:

- Hand trucks/dollies: Essential for moving heavy, bulky objects across distances. They significantly reduce strain by transferring the weight to the wheels.

- Lever systems (e.g., pallet jacks): These provide mechanical advantage, enabling the movement of extremely heavy pallets and loads with minimal effort.

- Lifting slings and straps: Used for safely securing loads to overhead cranes or hoists, distributing weight evenly and preventing slippage.

- Vacuum lifters: Ideal for lifting smooth, flat objects like glass panels or large sheets of metal without causing damage.

- Engine hoists and other specialized lifting equipment: These tools are crucial in the context of vehicle repair or large-scale industrial operations.

The choice of equipment always depends on the object’s size, weight, shape, and the environment. Safety is paramount in the selection and application of any lifting aid.

Q 10. How do you ensure the stability of an object during lifting and movement?

Maintaining object stability during lifting and movement is critical to preventing accidents. Several techniques are employed:

- Secure Grip: Always maintain a firm, balanced grip on the object. Using appropriate gloves or handling equipment when necessary improves grip and reduces risk of slippage.

- Proper Center of Gravity: Understanding the object’s center of gravity is key. Lifting from the center or keeping it close to the body helps prevent imbalance and twisting.

- Support and Balance: If the object is unusually shaped or heavy, additional support may be necessary. This could involve using straps, teammates, or other support structures to prevent it from tipping or shifting.

- Controlled Movement: Lifting should be a smooth, controlled operation. Sudden movements increase the chance of losing balance or dropping the object.

- Awareness of Surroundings: Be aware of potential obstacles or hazards that could compromise stability.

For example, when moving a large, unwieldy box, I would first assess its center of gravity, ensuring a firm grip, and potentially enlist a teammate to assist in maintaining balance during transport.

Q 11. What are the potential hazards associated with improper lifting techniques?

Improper lifting techniques can lead to a range of serious hazards:

- Musculoskeletal Injuries: These are the most common, encompassing back injuries, sprains, strains, and tears in muscles, ligaments, and tendons. Back injuries can be particularly debilitating, potentially leading to long-term pain and disability.

- Dropped Objects: Losing control of a heavy object can result in damage to property, injuries to oneself or others, or even fatalities.

- Crushes: Heavy objects falling or being dropped can crush body parts, causing severe trauma.

- Hernias: Straining during lifting can cause hernias, requiring surgical intervention.

- Carpal Tunnel Syndrome: Repetitive or forceful lifting motions can contribute to carpal tunnel syndrome.

These risks underscore the importance of adhering to proper lifting techniques and using appropriate equipment.

Q 12. How do you determine the best lifting technique for different objects and environments?

Determining the best lifting technique depends on a thorough assessment of several factors:

- Object Characteristics: Weight, size, shape, center of gravity, and fragility all influence the technique. A small, light box requires a different approach than a long, heavy beam.

- Environment: Space constraints, uneven surfaces, and the presence of obstacles dictate how the object will be moved.

- Physical Capabilities: The lifter’s strength, flexibility, and experience should be taken into account. A less experienced lifter might need more support or a simpler technique.

- Available Equipment: Access to lifting aids like hand trucks, hoists, or slings significantly alters the optimal lifting method.

For example, lifting a heavy sack of cement would involve bending at the knees, keeping the back straight, lifting using leg muscles, and keeping the load close to the body, whereas lifting a long, thin pipe would require more support and potentially two people.

Q 13. Describe a time you had to lift a heavy object with a team. How did you coordinate?

During a warehouse move, we needed to lift a large, heavy pallet of machinery. It was too heavy for one person. We coordinated using these steps:

- Risk Assessment: We first assessed the weight and dimensions, identifying potential hazards like uneven flooring.

- Team Briefing: We communicated a plan including hand signals to indicate readiness, lifting simultaneously, and maintaining a coordinated pace during movement.

- Proper Lifting Technique: We each positioned ourselves to lift from the sides, maintaining a straight back and bending at our knees.

- Clear Communication: Throughout the process, we maintained verbal communication, ensuring everyone was comfortable and the pallet was moving safely.

- Safe Placement: Once in place, we carefully lowered the pallet, ensuring it was stable and secure.

This collaborative effort minimized risk and ensured the safe and efficient movement of a heavy load.

Q 14. Explain your understanding of load capacity and its importance.

Load capacity refers to the maximum weight an individual, piece of equipment, or structure can safely handle. Understanding load capacity is paramount to prevent injuries and damage. It’s a critical factor in workplace safety and structural integrity.

For example, a forklift has a designated load capacity that must never be exceeded. Similarly, the maximum weight a single person can safely lift varies based on individual strength and the lifting technique employed, typically not exceeding 50 pounds without assistance.

Ignoring load capacity can lead to serious consequences, ranging from equipment failure to severe injury or death. Always ensure that the load capacity is known and respected before initiating any lifting activity.

Q 15. What are the different types of lifting equipment you are familiar with?

I’m familiar with a wide range of lifting equipment, categorized broadly into manual handling aids and powered equipment. Manual aids include things like hand trucks, pallet dollies, lifting straps, and come-alongs, each suited to different load types and weights. Powered equipment includes forklifts, cranes (both overhead and mobile), scissor lifts, and powered pallet jacks. My experience spans the safe and efficient use of all these, taking into account factors like load capacity, stability, and the specific work environment.

- Hand Trucks: Excellent for moving smaller, lighter, and oddly shaped loads over short distances.

- Pallet Jacks: Ideal for moving palletized goods across relatively flat surfaces.

- Forklifts: Crucial for heavier loads, higher stacking, and navigating larger warehouses.

- Overhead Cranes: Best for lifting extremely heavy items in industrial settings, requiring specialized training and certification.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle unexpected obstacles when lifting heavy objects?

Unexpected obstacles require immediate adaptation and a focus on safety. For instance, if I encounter an unexpected bump in the floor while operating a pallet jack, I would immediately stop, assess the situation, and reposition the load to navigate the obstacle safely. If there’s a sudden obstruction in the path of a load being moved by a crane, the operation would be halted until the obstruction is cleared. Communication is vital in such situations. I would alert any nearby workers to avoid the area and then work with supervisors to find a solution, perhaps involving different lifting equipment or a revised path.

My approach is always to prioritize safety over speed. It’s better to take extra time to adjust than to risk injury or damage.

Q 17. Describe your experience using a pallet jack or forklift.

I’ve extensive experience with both pallet jacks and forklifts, possessing certifications for safe operation. With pallet jacks, I’m proficient in maneuvering them in tight spaces and across varying floor surfaces, always ensuring the load is stable and securely placed. My forklift experience involves operating various models, from sit-down to stand-up, and I’m confident in performing tasks like loading and unloading trucks, stacking pallets, and maneuvering in busy warehouse environments. I strictly adhere to safety protocols, including pre-operation checks, load capacity limits, and maintaining appropriate speeds. For example, I always conduct a thorough pre-shift inspection of both machines, checking for any mechanical faults or fluid leaks before commencing work.

Q 18. How do you maintain safe working practices when lifting?

Maintaining safe working practices when lifting involves a multi-faceted approach. It starts with a thorough risk assessment, ensuring proper lifting techniques are employed, using appropriate equipment where necessary, and maintaining a clear communication channel between team members. I always assess the weight and stability of the load before attempting to lift it and if uncertain about my ability to lift something safely, I request assistance. I maintain a firm grip on the object, ensuring my back is straight to avoid strain. Proper lifting technique is paramount, bending at the knees and using leg power to lift rather than straining the back.

I also regularly review safety guidelines and participate in training sessions to stay updated on best practices. This includes regular training on equipment operation and understanding updated safety procedures.

Q 19. What is your process for reporting injuries or near misses?

Reporting injuries or near misses is a critical part of workplace safety. My process involves immediately reporting any incident to my supervisor, detailing the circumstances, the individuals involved, and any witnesses. I would also participate in any subsequent investigations and follow the company’s reporting procedures, often including completing incident report forms that document the details systematically. If the incident involved a serious injury, I would cooperate with emergency services and ensure appropriate medical attention is received. The goal is to learn from incidents to prevent similar occurrences in the future.

Q 20. How would you react if you witnessed someone lifting incorrectly?

If I witnessed someone lifting incorrectly, I would approach them in a non-confrontational way. I would politely explain the correct lifting technique, referencing safety guidelines if necessary. My primary concern is their safety, so I wouldn’t judge but rather offer assistance and guidance. If they continue to lift incorrectly despite my advice, I would then escalate the matter to my supervisor, ensuring the person’s safety and adherence to company policy.

Q 21. Explain the importance of pre-lift assessment.

A pre-lift assessment is crucial for preventing injuries and ensuring efficiency. This involves evaluating several factors before lifting: the weight and dimensions of the load, its center of gravity, the distance it needs to be moved, the available space and path, and the condition of the floor. This assessment helps determine if assistance is needed, what equipment might be appropriate, and the safest lifting technique to employ. Skipping this assessment can lead to strain, injury, or damage to goods or property. For example, a pre-lift assessment might reveal that a heavy, awkwardly-shaped object requires a lifting strap or two people to lift safely, instead of relying on one person lifting the object without assistance.

Q 22. What training have you received in safe lifting techniques?

My training in safe lifting techniques is extensive. I’ve completed several certified courses, including OSHA’s comprehensive training on hazard communication and safe lifting practices. This training covered the fundamentals of proper posture, weight distribution, and the importance of using mechanical aids whenever possible. For example, I learned the proper way to use my legs, keeping my back straight and avoiding twisting motions. I also received hands-on training using various lifting aids such as pallet jacks and lifting straps, ensuring I could safely and efficiently move heavy objects of different sizes and shapes. Furthermore, I’ve received regular refresher training throughout my career to stay updated on best practices and address any new regulations or techniques.

Q 23. How would you handle a heavy object that’s unexpectedly unstable?

Encountering an unexpectedly unstable heavy object requires immediate adaptation. My first step would be to assess the situation – checking for any visible damage or cracks and identifying the center of gravity. I would never attempt to lift it alone; I’d immediately call for assistance. Then, we’d work together to use appropriate lifting equipment and techniques. This could include securing the object using straps or ropes to stabilize it before lifting. If it’s a pallet, we’d consider using a pallet jack. If it’s something less defined, we’d carefully examine how to create support. Imagine lifting a heavy box that’s unexpectedly tilting – using a second person to secure one side and creating a more stable base is crucial before any attempt to lift it is made. Safety is paramount – a rushed or ill-planned lift can result in injury to us or damage to the object.

Q 24. What are your strategies for preventing back strain while lifting?

Preventing back strain during lifting is critical. My strategies involve several key steps. First, maintaining proper posture is vital – feet shoulder-width apart, knees bent, and back straight. Second, I always keep the object close to my body to reduce leverage and strain on my back. Third, I lift using my leg muscles, not my back. Fourth, I avoid twisting my body while lifting. If I need to change direction, I’ll reposition my feet first. Finally, I know my limits. If an object is too heavy or awkward, I’ll seek assistance or use mechanical lifting devices. Imagine lifting a heavy filing cabinet – bending at the knees, keeping the cabinet close, and lifting smoothly minimizes strain. If it feels too heavy, I’ll get a second pair of hands or a hand truck immediately.

Q 25. How do you adapt your lifting technique to different weights and sizes?

Adapting my technique depends on the weight and size of the object. For lighter objects, a simple bend-and-lift is often sufficient. However, heavier or bulkier items require a different approach. I use a broader base of support, lower my center of gravity, and use proper lifting aids like straps or dollies as needed. For example, a small box might be lifted directly, but a large, heavy pallet would require a pallet jack. Size also matters; awkward shapes might need additional support or a different grip to prevent dropping or injury. I always prioritize safety by choosing the most suitable technique for the specific situation, considering weight, size, and accessibility. For instance, a long, narrow object like a metal pipe requires a better grip and careful control to avoid losing balance.

Q 26. Describe your experience with different types of lifting straps and harnesses.

My experience includes working with various lifting straps and harnesses. I’m proficient with different types of straps, including webbing straps for securing objects to pallets or lifting heavy bags, and chain slings for heavier loads requiring more robust support. I understand the importance of inspecting these before each use, checking for wear and tear and ensuring they’re properly rated for the weight. Harnesses are essential for working at height or in situations requiring additional safety precautions. I am experienced in using both full-body harnesses and specialized lifting harnesses and understand the proper attachment points and safety procedures. For example, using nylon webbing straps for securing large bundles is preferable to rope due to their flexibility and ease of use, while chain slings offer maximum strength for very heavy, potentially sharp, objects.

Q 27. How do you communicate with your team members to lift heavy loads safely and efficiently?

Clear communication is crucial for safe and efficient teamwork when lifting heavy loads. Before beginning any lift, I ensure we have a plan. This includes identifying the weight of the object, the best lifting technique, and assigning roles. We use clear verbal cues like “ready,” “lift,” and “set” to coordinate movements. I also emphasize the importance of maintaining eye contact and staying synchronized. During the lift, we communicate any adjustments needed or potential problems. For example, if one person feels the object is shifting, they’ll immediately communicate it to the team. Open communication prevents accidents and ensures everyone’s safety.

Q 28. What are the legal requirements and regulations related to manual handling in your country?

(Note: This answer will vary depending on the country. The following is a general example and should be replaced with specific legal requirements and regulations of a particular country.) In many jurisdictions, legislation surrounding manual handling focuses on risk assessment and prevention. Employers are legally obliged to conduct thorough risk assessments to identify hazards associated with manual handling tasks and implement control measures to minimize risk. This often includes providing appropriate training, equipment, and supervision. Regulations typically specify maximum weight limits for manual handling and mandate the use of mechanical aids where feasible. Failure to comply with these regulations can result in penalties and legal action. Employees also have a responsibility to follow safety guidelines and report any unsafe conditions.

Key Topics to Learn for Ability to Lift and Handle Heavy Loads Interview

- Understanding Ergonomics and Body Mechanics: Learn the principles of proper lifting techniques to minimize risk of injury to yourself and others. This includes understanding posture, leverage, and the importance of using your legs.

- Safe Lifting Practices and Procedures: Familiarize yourself with common workplace safety protocols and regulations concerning heavy lifting. This includes understanding load limits, using appropriate equipment (e.g., pallet jacks, forklifts), and recognizing hazardous situations.

- Equipment Usage and Maintenance: Demonstrate knowledge of various lifting and handling equipment, their capabilities, and limitations. Understanding basic maintenance procedures and safety checks will be beneficial.

- Assessing Load Weight and Stability: Develop the ability to accurately estimate the weight of objects and assess their stability before attempting to lift or move them. This includes understanding center of gravity principles.

- Teamwork and Communication: Discuss the importance of clear communication and teamwork when lifting heavy loads, especially in collaborative work environments. This includes signaling, coordinating lifts, and ensuring a safe working environment for all involved.

- Injury Prevention and Response: Explain how to prevent injuries related to heavy lifting and what actions to take in case of an accident or injury. This includes understanding first aid principles and reporting procedures.

- Adapting to Different Lifting Situations: Be prepared to discuss how lifting techniques are adapted based on varying factors such as object shape, size, surface conditions, and environmental factors.

Next Steps

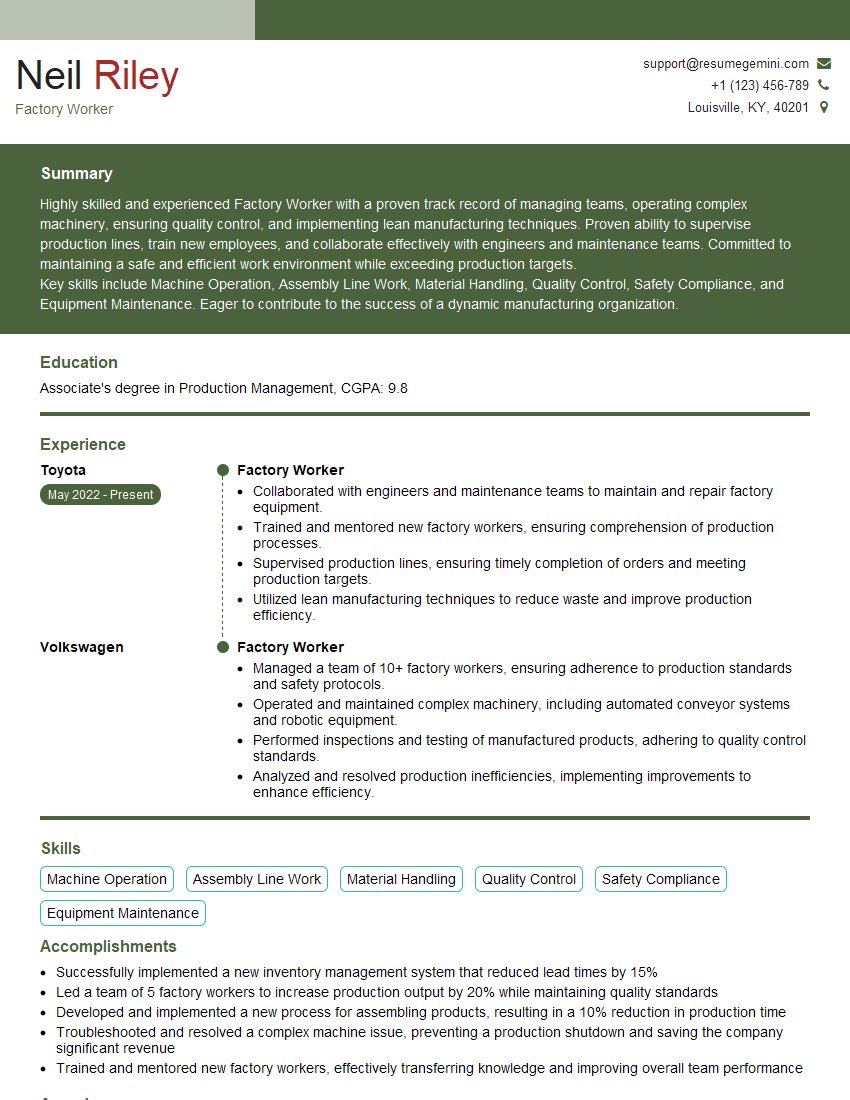

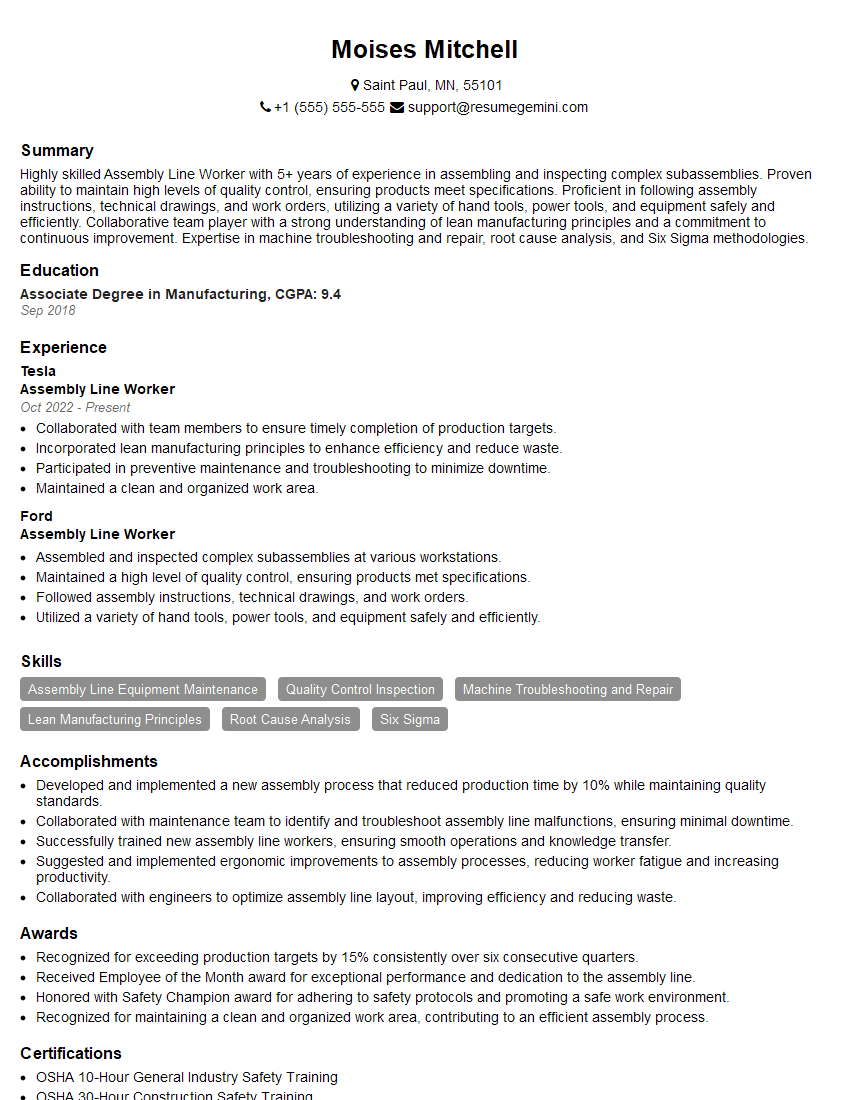

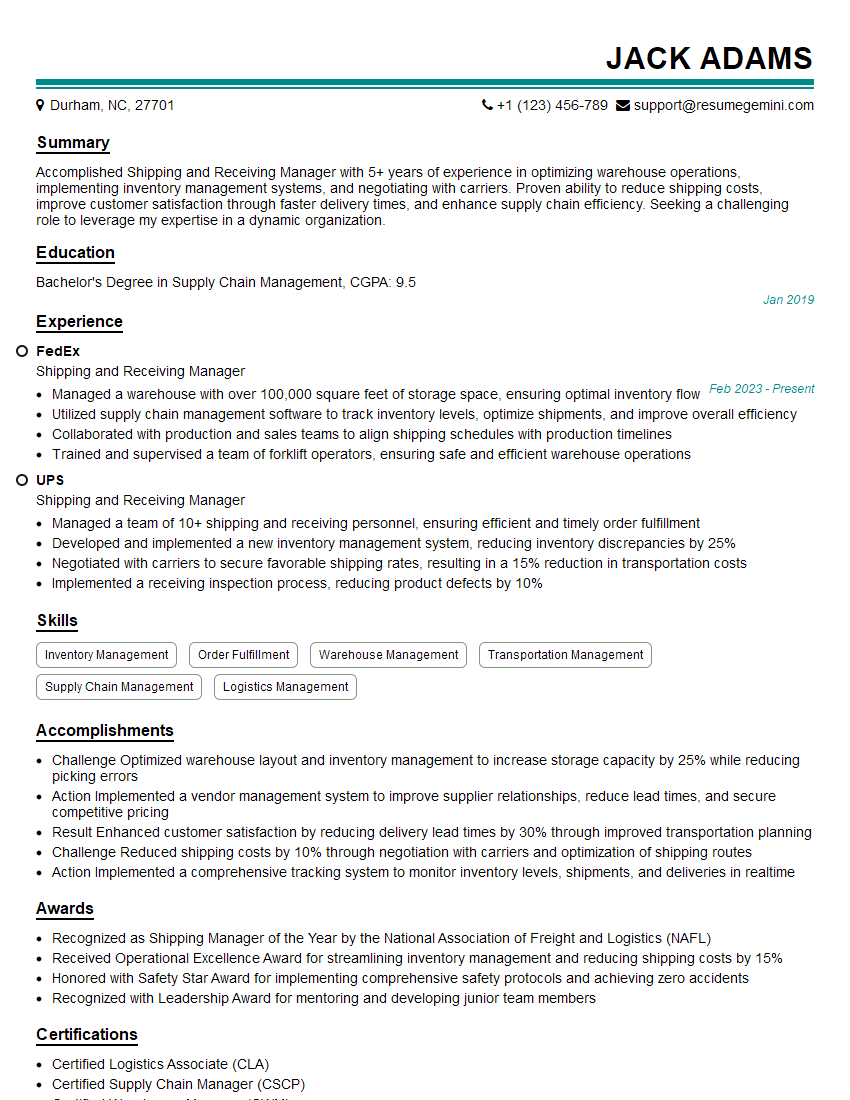

Mastering the ability to safely lift and handle heavy loads is crucial for many roles, significantly boosting your employability and career prospects. It demonstrates your commitment to workplace safety and your physical capability to handle demanding tasks. To increase your chances of landing your dream job, it’s essential to craft an ATS-friendly resume that effectively highlights your skills and experience. ResumeGemini can help you build a professional and impactful resume that stands out from the competition. Take advantage of our resources, including examples of resumes tailored to highlight experience in lifting and handling heavy loads, to create a winning application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good