Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Ability to Prepare and Interpret Cotton Test Reports interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Ability to Prepare and Interpret Cotton Test Reports Interview

Q 1. What are the key parameters assessed in a standard cotton fiber test report?

A standard cotton fiber test report provides a comprehensive profile of the cotton’s quality, encompassing various crucial parameters. These parameters are essential for determining the suitability of the cotton for different textile applications. Key parameters assessed typically include:

- Fiber Length (and Length Uniformity): This indicates the overall length of the fibers and how consistent those lengths are. Longer, more uniform fibers generally produce stronger and finer yarns.

- Fiber Strength: This measures the force required to break a single fiber. Stronger fibers lead to more durable fabrics.

- Micronaire: This measures the fiber fineness and maturity, influencing yarn and fabric properties.

- Fiber Maturity: This reflects the degree of fiber wall development. Mature fibers are generally stronger and more resistant to damage.

- Fiber Fineness: This refers to the diameter of the cotton fibers, influencing the softness and drape of the finished fabric.

- Trash Content: This refers to the percentage of impurities like leaves, seeds, and other foreign materials present in the cotton sample. High trash content negatively impacts the spinning process and fabric quality.

- Color/Color Grade: This assesses the overall color of the cotton, crucial for certain applications where specific shades are required.

The specific parameters and testing methods can vary slightly depending on the laboratory and the intended use of the cotton, but these are consistently reported in most standard tests.

Q 2. Explain the significance of fiber length (length uniformity) in cotton quality.

Fiber length and its uniformity are paramount in determining cotton quality. Think of it like building a rope: longer fibers create a stronger, more consistent rope, while shorter, uneven fibers result in a weaker, more fragile one. Similarly, longer cotton fibers produce yarns with greater strength and finer counts. Longer fibers also contribute to better spinning performance and reduce yarn imperfections. Length uniformity (the consistency of fiber lengths within a sample) is equally important. Uniformity leads to smoother, less hairy yarns and fabrics, enhancing the final product’s quality and aesthetic appeal. A high level of uniformity improves spinnability and reduces the number of yarn defects, leading to more efficient production.

For example, cotton intended for high-quality apparel, such as premium shirts, requires long and uniform fibers, ensuring a luxurious feel and durability. Conversely, shorter and less uniform fibers might be suitable for coarser fabrics, like denim, where strength and fineness are less critical.

Q 3. How does micronaire affect yarn and fabric properties?

Micronaire is a crucial parameter that reflects both the fiber fineness and maturity. It influences yarn and fabric properties significantly. A higher micronaire value indicates thicker, more mature fibers, leading to stronger yarns but potentially coarser fabrics. Conversely, a lower micronaire suggests finer, less mature fibers, resulting in softer, more delicate fabrics, but potentially weaker yarns. The optimal micronaire value varies depending on the desired end-use.

Imagine baking a cake: the flour’s fineness affects the cake’s texture. Similarly, micronaire affects the feel and strength of the finished fabric. A perfectly balanced micronaire is essential for achieving the desired combination of strength and softness in the final product. For instance, cotton with a medium micronaire might be ideal for creating comfortable yet durable clothing, while a lower micronaire might be preferred for finer apparel like lingerie.

Q 4. What are the implications of high or low fiber strength in cotton?

Fiber strength directly impacts the durability and performance of the resulting yarns and fabrics. High fiber strength is desirable as it leads to stronger, more tear-resistant fabrics and yarns. Such fabrics can withstand greater stress and wear, making them more durable and suitable for various applications, including workwear or outdoor clothing. Conversely, low fiber strength results in weaker, more easily damaged fabrics and yarns. These fabrics are prone to tearing and are less suitable for applications demanding high durability.

For example, low fiber strength could lead to excessive yarn breakage during spinning, decreasing productivity and increasing production costs. Additionally, garments made from low-strength cotton may not hold up well under stress and will wear out faster, affecting customer satisfaction and brand reputation.

Q 5. Describe the different methods used to determine cotton fiber maturity.

Cotton fiber maturity refers to the degree of fiber wall development. Several methods are used to determine fiber maturity:

- Micronaire: As previously discussed, it indirectly indicates maturity. Higher micronaire values often correlate with higher maturity.

- Cavity Length: This measures the length of the central cavity in the fiber. More mature fibers have shorter cavities.

- Microscopic Examination: Observing the fiber cross-section under a microscope allows for a visual assessment of wall thickness. Thicker walls indicate higher maturity.

- Chemical Methods: Certain chemical treatments can assess the degree of cellulose polymerization, indirectly indicating maturity.

The choice of method depends on the available resources and the required level of precision. Often, a combination of methods is employed for a more comprehensive assessment.

Q 6. How is cotton fiber fineness measured, and what are its implications?

Cotton fiber fineness refers to the diameter of the individual fibers and is typically measured using instruments like the AFIS (Advanced Fiber Information System) or HVI (High Volume Instrument). These instruments use advanced optical techniques to measure the diameter of a large number of fibers, providing an average fineness value. Fineness is often expressed in micrometers (µm).

Finer fibers generally produce softer, smoother yarns and fabrics with a better drape and luxurious feel. However, finer fibers can be weaker than coarser fibers. The implication of fineness depends on the desired end-use. Finer fibers are suitable for high-quality garments requiring softness and comfort, while coarser fibers might be more appropriate for durable fabrics such as workwear or denim.

Q 7. What is the significance of trash content in a cotton sample?

Trash content refers to the percentage of undesirable materials present in the cotton sample, such as leaves, stems, seeds, dirt, and other foreign matter. High trash content significantly impacts the quality and processing of the cotton. It can cause damage to machinery during the spinning process, leading to increased downtime and maintenance costs. It also affects yarn quality, resulting in unevenness, strength reduction, and an increase in yarn defects.

In the finished fabric, high trash content can result in an unsightly appearance and affect the overall feel and durability of the fabric. Therefore, low trash content is essential for producing high-quality yarns and fabrics, making it a key parameter in cotton quality assessment. The acceptable level of trash content varies based on the intended use of the cotton; higher-quality applications demand significantly lower trash levels.

Q 8. Explain the relationship between cotton fiber properties and yarn quality.

The quality of yarn is intrinsically linked to the properties of the cotton fibers used to create it. Think of it like building a house – you wouldn’t use weak bricks to build a skyscraper. Similarly, strong, long fibers result in stronger, more durable yarn.

- Fiber Length (Fiber Length Uniformity): Longer fibers are generally better because they create stronger, smoother yarns with fewer weak points. Shorter fibers lead to weaker, more hairy yarns prone to breakage. Uniformity in length is crucial; variations cause inconsistencies in the yarn.

- Fiber Strength: This refers to the fiber’s resistance to breaking under stress. Strong fibers translate directly to strong yarns that can withstand higher tension during processing and in the final fabric.

- Fiber Fineness (Micronaire): This indicates the fiber’s diameter. The optimal fineness varies depending on the desired yarn properties. Too fine, and the yarn is weak; too coarse, and it is harsh and less smooth.

- Fiber Maturity: Mature fibers are thicker-walled and stronger than immature fibers. Immature fibers are more prone to breakage and reduce yarn quality.

- Fiber Color and Trash Content: Clean fibers without excessive impurities lead to a more consistent and aesthetically pleasing yarn. Impurities can weaken the yarn and affect its appearance.

For example, a cotton with high fiber length and strength will produce a strong, even yarn suitable for durable fabrics like denim. Conversely, a cotton with short, weak fibers will produce a weak, uneven yarn better suited for less demanding applications.

Q 9. How do you interpret the results of a yarn strength test related to cotton fiber properties?

A yarn strength test measures the force required to break a yarn sample. Interpreting these results in relation to cotton fiber properties involves understanding the correlation between fiber characteristics and yarn strength.

High Yarn Strength: Typically indicates cotton with long, strong, and mature fibers. A high strength value suggests good raw material and efficient spinning. The yarn is less likely to break during weaving or knitting and produces more durable fabrics.

Low Yarn Strength: Suggests issues with fiber properties, such as short fiber length, low fiber strength, immature fibers, or high trash content. It might also indicate problems during the spinning process. Low strength results in a weaker yarn prone to breaking, leading to fabric defects and lower quality.

Variations in Strength: Inconsistent strength along the yarn length reflects variations in fiber properties, like poor fiber length uniformity. This suggests the raw cotton needs better processing or selection.

To effectively interpret the results, it’s vital to compare the yarn strength data with the fiber properties data of the same cotton batch. A significant discrepancy warrants investigation into the processing or testing procedures. For example, if fiber strength testing shows high strength, but yarn strength is low, then we must investigate the spinning process.

Q 10. What are the common indicators of cotton degradation in a test report?

Cotton degradation manifests in several ways in test reports, often indicating damage during growth, harvesting, processing, or storage.

- Reduced Fiber Length and Strength: Degradation often shows up as shorter fiber lengths and reduced tensile strength. This is usually due to weathering, microbial attack, or harsh processing.

- Increased Fiber Fineness Variation (Micronaire): Degraded cotton might show wider ranges in micronaire values, signifying inconsistent fiber diameter.

- Elevated Trash Content: Degradation can increase the presence of foreign materials like leaf fragments, seeds, and dirt.

- Increased Fiber Immaturity: Damaged fibers show a higher percentage of immature fibers compared to the healthy ones.

- Yellowing or Discoloration: Oxidative degradation can lead to changes in fiber color, suggesting deterioration in quality.

- Reduced Fiber Maturity: A lower maturity ratio suggests inadequate development of the cotton fibers, indicating a weakness that may have been caused or compounded by degradation.

Imagine a cotton bale that’s been exposed to excessive moisture. The test report might show lower strength, shorter fibers, and possibly even signs of discoloration, all pointing toward degradation.

Q 11. How do you identify and interpret inconsistencies or anomalies in cotton test data?

Identifying inconsistencies in cotton test data requires careful analysis and comparison across multiple tests and samples.

- Statistical Analysis: Use statistical methods (e.g., standard deviation, control charts) to check for outliers and unusual patterns. An unusually high or low value might be a data entry error or indicate a genuine anomaly in the sample.

- Cross-referencing with other Tests: Inconsistencies can often be identified by cross-checking results from different tests on the same sample. For example, if the length is short but strength is high, there might be an error.

- Visual Inspection: Sometimes, visual inspection of the cotton sample itself is crucial to identify anomalies not easily captured by instrumental analysis. Are there unusual impurities or signs of damage?

- Repeatability and Reproducibility Checks: Run multiple tests on the same or similar samples. Significant discrepancies between the results might suggest systematic errors in the testing methodology.

- Sample Preparation: Review the sample preparation process for any potential errors that could have introduced bias. Did the sample adequately represent the whole cotton batch?

For instance, if a fiber length measurement is significantly lower than the rest of the dataset, one would investigate the reason. Was there a problem with the specific sample tested? Or was it a measurement error?

Q 12. Describe the process of preparing a cotton sample for testing.

Proper sample preparation is critical for obtaining reliable cotton test results. It aims to ensure that the tested sample accurately reflects the properties of the entire cotton bale or lot.

- Sample Selection: A representative sample must be drawn from various locations within the bale to avoid bias. This involves strategically selecting portions from the top, middle, and bottom.

- Cleaning: The sample needs to be carefully cleaned to remove extraneous materials like leaves, seeds, and dust. This is typically done manually or using automated cleaning equipment.

- Conditioning: The sample is then conditioned to a standard atmospheric environment (usually 20°C and 65% relative humidity) for a specific duration to ensure uniform moisture content across the sample. This standardizes the testing environment.

- Preparation for Specific Tests: Depending on the test, further preparation might be needed. For example, for fiber strength testing, the sample needs to be carefully prepared into small tufts or lap.

Imagine preparing a cake batter – you don’t just grab flour from one place in the bag; you ensure it’s evenly mixed to get a consistent result. Similarly, for cotton testing, a representative sample is paramount for accurate results.

Q 13. What are the limitations of different cotton testing methods?

Every cotton testing method has its limitations. Understanding these limitations is key to interpreting the results accurately and avoiding misinterpretations.

- Fiber Length Measurement: Different methods (e.g., AFIS, high volume instrument) have varying levels of precision and might show discrepancies. AFIS is more accurate but expensive, while high volume instruments are faster but potentially less precise.

- Fiber Strength Measurement: The results can be affected by factors like fiber maturity, testing conditions, and instrument calibration. A slight change in clamp pressure can affect the measured strength.

- Micronaire Measurement: The accuracy of the measurement can be affected by the sample preparation (moisture content, cleanliness) and the proper calibration of the instrument.

- Subjectivity in Visual Assessment: Methods involving visual assessment (e.g., trash content) are prone to human error and variability. Different assessors may have different interpretations.

It’s like using different measuring tools – a ruler and a measuring tape will both measure length, but they may have slightly different precision. Similarly, understanding the limitations of each method helps interpret the findings and use them cautiously.

Q 14. How do you ensure the accuracy and reliability of cotton test results?

Ensuring the accuracy and reliability of cotton test results requires careful attention to various factors throughout the testing process.

- Proper Calibration and Maintenance of Instruments: Regular calibration of testing instruments (e.g., strength testers, length testers) is crucial. Instruments should be maintained according to manufacturer’s recommendations.

- Standard Operating Procedures: Following established standard operating procedures (SOPs) for sample preparation, testing, and data analysis ensures consistency and reduces human error.

- Quality Control Checks: Include quality control checks throughout the process, such as running duplicate tests and analyzing the results for consistency. Large deviations highlight potential problems.

- Use of Certified Reference Materials: Comparing results against certified reference materials helps validate the accuracy of the testing methods and instruments.

- Trained Personnel: Properly trained and experienced personnel are essential to conduct the tests accurately and interpret the data correctly. It’s not enough to have the equipment; the people must know how to use it effectively.

Think of it like a medical laboratory – strict protocols and skilled technicians ensure accurate test results. The same principle applies to cotton testing: rigorous quality control throughout the process safeguards reliable and accurate results.

Q 15. Explain the difference between fiber length and fiber length uniformity.

Fiber length refers to the average length of individual cotton fibers in a sample. It’s a crucial indicator of yarn strength and fabric quality. Longer fibers generally produce stronger, smoother, and more lustrous yarns. Fiber length uniformity, on the other hand, measures the consistency of fiber lengths within a sample. It’s expressed as the Uniformity Index (UI) or Uniformity Ratio (UR). A high UI or UR indicates that the fibers are mostly of similar length, leading to better yarn quality and less breakage during spinning. Think of it like this: fiber length is the average height of students in a class, while fiber length uniformity describes how similar their heights are. A class with students of mostly similar heights has high uniformity.

For example, a cotton sample might have an average fiber length of 30mm, but a low uniformity index, meaning many fibers are much shorter or longer than the average, resulting in weaker yarns. In contrast, another sample might have a slightly shorter average length (28mm) but a high uniformity index, resulting in stronger, more even yarns.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How does moisture content affect cotton testing results?

Moisture content significantly impacts cotton testing results because it affects the weight and dimensions of the fibers. Since many tests rely on weight measurements (like fiber strength and micronaire), variations in moisture can lead to inaccurate results. For instance, a higher moisture content will inflate the apparent weight of the sample, leading to an overestimation of fiber strength or a miscalculation of other properties. Standard testing procedures always account for moisture content by determining the ‘oven-dry’ weight, which is the weight after all moisture is removed. Differences in moisture between samples, even seemingly small ones, can cause substantial variations in reported test results which is why standardized conditioning of samples before testing is crucial.

Q 17. What are the standard units used in reporting cotton fiber properties?

Standard units used in reporting cotton fiber properties include:

- Fiber Length: Millimeters (mm) or inches (in)

- Fiber Strength: Grams per tex (g/tex) or pounds per square inch (psi)

- Fiber Uniformity: Uniformity Index (UI) or Uniformity Ratio (UR) (unitless)

- Micronaire: Micronaire units (unitless)

- Moisture Content: Percentage (%)

- Color: Various scales exist, often involving numerical readings based on instruments that quantify color differences.

Understanding these units is essential for comparing and interpreting test results from different sources and ensuring consistent evaluation of cotton quality.

Q 18. What is the significance of cotton color in different textile applications?

Cotton color is a significant factor in textile applications. For instance, in higher-end apparel, whiter cotton is preferred for brighter, cleaner-looking fabrics. In other applications, specific shades might be desirable. For example, naturally colored cottons (e.g., browns, creams) may be preferred for certain home textiles or apparel lines that prioritize natural or rustic aesthetics. In industrial applications like towels or denim, color may be less crucial, and the emphasis shifts to other properties like strength and durability. Color variations can also indicate the presence of contaminants or variations in growing conditions. Therefore, color assessment is an integral part of cotton quality evaluation.

Q 19. How does the type of cotton influence its test results?

The type of cotton significantly influences its test results. Different cotton varieties possess inherent variations in fiber length, strength, fineness, maturity, and other properties. For example, extra-long staple cottons like Pima or Egyptian cotton generally show superior length, strength, and uniformity compared to shorter staple Upland cotton. These inherent differences impact yarn quality, fabric hand feel, and the end-use suitability of the cotton. Knowing the type of cotton being tested is paramount for accurate interpretation and comparison of results. The origin and growing conditions also play significant roles.

Q 20. What are the key differences between Upland and Pima cotton in terms of their test results?

Upland and Pima cotton exhibit distinct differences in their test results, mainly due to their genetic makeup and growing conditions. Pima cotton, an extra-long staple variety, typically demonstrates longer fiber length (often exceeding 35mm), higher strength, and superior uniformity compared to Upland cotton. Upland cotton, while widely cultivated and a staple of the textile industry, has shorter fiber lengths (generally 24-30mm), lower strength, and less uniformity. This translates to differences in yarn quality—Pima cotton yields finer, stronger yarns suitable for premium apparel, while Upland cotton is often used in more general-purpose applications. These differences are consistently reflected in their respective test reports.

Q 21. How do you identify and interpret different types of cotton contaminants?

Identifying and interpreting cotton contaminants requires careful visual inspection and sometimes advanced techniques like microscopic analysis. Common contaminants include:

- Leaf trash: Fragments of cotton leaves, easily identified by their shape and texture.

- Seed coat fragments: Small, dark particles derived from the cotton seeds.

- Motes: Immature seed particles, often fuzzy and dark.

- Foreign fibers: Fibers from other plants or materials, often identifiable based on their unique characteristics.

- Dust and dirt: Usually easy to observe as discoloration or visible particles.

The presence and type of contaminants influence the processing efficiency and the final quality of the yarn and fabric. High levels of contamination can reduce strength, impact spinning performance, and lead to defects in the finished product. Accurate identification and quantification of contaminants are essential for assessing cotton quality and determining its suitability for various applications.

Q 22. What quality control measures would you implement to ensure consistent cotton quality?

Ensuring consistent cotton quality requires a multi-faceted approach encompassing all stages, from the field to the final product. My strategy centers around a robust quality control system that begins with rigorous input checks and continues through processing and testing.

- Sampling: Implementing a statistically sound sampling plan is crucial. We need to ensure representative samples are taken from various parts of the bale to account for potential variations.

- Fiber Testing: Regular testing using industry-standard methods is paramount. This includes testing for fiber length, strength, uniformity, micronaire (fiber fineness), and color. We’d employ instruments like AFIS (Advanced Fiber Information System) for detailed fiber property analysis.

- Process Control: Monitoring every step of the process, from ginning to spinning, helps identify deviations early. This requires clear process parameters and regular checks against those parameters. For example, consistent cleaning and carding settings would be monitored to prevent fiber damage and maintain quality.

- Data Analysis: Regularly analyzing the test data allows us to spot trends and address any emerging quality issues. Statistical process control (SPC) charts can help visualize these trends and identify outliers effectively.

- Supplier Relationships: Building strong relationships with cotton suppliers and conducting regular audits of their practices helps ensure consistent input quality. Open communication is crucial for addressing any supply-chain issues.

For instance, if we consistently find lower fiber strength in incoming bales, we can investigate the cause with the supplier, potentially adjusting our acceptance criteria or working collaboratively on improved cultivation practices. This proactive approach minimizes disruptions and ensures higher quality throughout the process.

Q 23. How do you troubleshoot issues that arise during cotton testing?

Troubleshooting in cotton testing involves a systematic approach. It starts with identifying the issue, isolating the possible causes, and then implementing corrective actions.

- Instrument Calibration: The first step is always checking the calibration of the testing instruments. An incorrectly calibrated instrument will produce erroneous results. Regular calibration checks using certified standards are essential.

- Sample Preparation: Improper sample preparation can significantly impact test results. This includes checking for proper cleaning, conditioning, and weighing of the samples.

- Testing Procedures: Any deviation from the standardized testing procedures can lead to inaccurate results. We’d carefully review the testing protocols and ensure all steps are followed precisely.

- Environmental Factors: Temperature and humidity can influence certain cotton properties. We need to ensure the testing environment is carefully controlled and within the specified parameters.

- Data Review: After checking equipment, sample prep, and methodology, a review of the data itself helps us pinpoint anomalies. Outliers might signal a problem that needs further investigation.

For example, if we repeatedly get unusually high micronaire readings, we might first check the instrument’s calibration. If that’s fine, we’d then examine our sampling and preparation procedures. If the problem persists, we might investigate factors like the cotton’s growing conditions or processing methods.

Q 24. How do you communicate complex cotton test data to non-technical audiences?

Communicating complex cotton test data to non-technical audiences requires clear and concise language, avoiding jargon as much as possible. Visual aids are essential for simplifying complex information.

- Visualizations: Graphs, charts, and tables are excellent tools for representing data visually. Bar charts can show comparisons of different fiber properties, while scatter plots can illustrate relationships between variables.

- Analogies and Metaphors: Using simple analogies can help explain technical concepts. For example, we can explain fiber length as the length of individual threads in a fabric, correlating longer fibers with better strength and quality.

- Summarization: Focus on presenting the key findings in a concise manner, highlighting only the most relevant information. Avoid overwhelming the audience with excessive details.

- Plain Language: Use simple and everyday language. Instead of saying “high coefficient of variation,” explain it as a significant variation in fiber length, making the quality less consistent.

- Storytelling: Weaving a narrative around the data adds context and engagement. We could relate how specific fiber characteristics influence fabric drape or durability, making the data more relevant to the listener.

For example, instead of saying “the fiber strength averaged 28 g/tex with a standard deviation of 2.5 g/tex,” we could say “The cotton fibers are generally strong, but there’s some variation in strength among the individual fibers.”

Q 25. What are the latest advancements in cotton testing technologies?

Cotton testing is constantly evolving. Recent advancements focus on automation, higher precision, and faster analysis.

- Automated Testing Systems: Automated systems can significantly reduce testing time and human error. These systems handle sample preparation, testing, and data analysis with minimal manual intervention.

- High-Throughput Instruments: Instruments capable of testing a large number of samples rapidly are becoming increasingly popular, enabling efficient quality control in high-volume production.

- Image Analysis Techniques: Advanced image analysis techniques are improving the precision and detail of fiber property measurements. For instance, more sophisticated image analysis helps measure fiber maturity more accurately.

- Near-Infrared Spectroscopy (NIRS): NIRS is becoming a common tool for fast, non-destructive analysis of various cotton properties. It requires minimal sample preparation and provides rapid results.

- Machine Learning and AI: Machine learning algorithms are being employed to analyze complex datasets, predict cotton quality, and optimize testing protocols. This allows for predictive modeling of potential issues.

For instance, the use of NIRS eliminates the need for time-consuming and potentially destructive tests like the traditional fiber strength test (using a Stelometer), providing rapid quality assessments during processing.

Q 26. Describe your experience with different cotton testing instruments and equipment.

My experience encompasses a wide range of cotton testing instruments and equipment, both traditional and advanced.

- AFIS (Advanced Fiber Information System): I’m proficient in operating and interpreting data from AFIS, a widely used instrument for detailed fiber property analysis including length, strength, uniformity, and maturity.

- HVI (High Volume Instrument): I have extensive experience with HVI systems for rapid, high-throughput measurements of cotton properties like micronaire, length, strength, and color.

- Uster Tester: I’m familiar with using Uster technologies for assessing fiber imperfections and analyzing yarn uniformity, which are vital for identifying potential weaving and knitting issues.

- Fiber Length Tester (e.g., Stelometer): I’m well-versed in using traditional fiber length testers, providing me with a solid understanding of the fundamental techniques.

- Color Measurement Instruments: I have experience using colorimeters and spectrophotometers for objective assessment of cotton color, crucial for ensuring color consistency throughout the textile manufacturing process.

My familiarity with diverse testing methods helps me select the most appropriate technique for a particular quality control need. The choice often depends on factors like the quantity of samples, the level of detail required, and the available resources.

Q 27. How do you maintain and calibrate cotton testing instruments?

Proper maintenance and calibration of cotton testing instruments are crucial for ensuring accurate and reliable results. This is a critical aspect of data integrity.

- Regular Cleaning: Instruments should be cleaned regularly according to the manufacturer’s instructions. Accumulated dust and debris can interfere with the testing process.

- Calibration Checks: Regular calibration checks, using certified reference materials, are essential for ensuring the accuracy of the instruments. The frequency of calibration depends on the instrument and its usage.

- Preventive Maintenance: Regular preventive maintenance, including lubrication and adjustments, helps prevent major breakdowns and prolongs the instrument’s lifespan.

- Documentation: Maintaining detailed records of all maintenance and calibration procedures is vital for compliance and traceability. This creates an auditable history of the equipment’s performance.

- Troubleshooting: Knowing how to troubleshoot minor problems can minimize downtime and prevent costly repairs. This may involve simple fixes or knowing when to seek professional help.

For example, if the HVI instrument consistently provides inaccurate micronaire readings, we would first check its calibration using a certified reference material. If the calibration is off, adjustments would be made and documented. If the problem persists after calibration, we might need to consult the manufacturer or a service technician.

Q 28. How do you stay updated on the latest standards and best practices in cotton testing?

Staying updated on the latest standards and best practices in cotton testing is vital for maintaining professional competence. This involves a multi-pronged strategy.

- Industry Publications: I regularly read industry journals, magazines, and technical publications to stay informed about new technologies, methods, and best practices.

- Professional Organizations: Active participation in professional organizations like the American Society for Testing and Materials (ASTM) International provides access to the latest standards and networking opportunities.

- Conferences and Workshops: Attending industry conferences and workshops allows me to learn from experts and keep abreast of current trends and advancements.

- Online Resources: Utilizing online resources such as databases of scientific literature, and industry websites is an efficient way to access updated information.

- Collaboration: Engaging in discussions and collaborating with fellow professionals and experts in the field facilitates the exchange of knowledge and best practices.

By actively participating in these activities, I ensure my testing methods align with the latest standards and that I am constantly refining my expertise in this field.

Key Topics to Learn for Ability to Prepare and Interpret Cotton Test Reports Interview

- Understanding Fiber Properties: Learn about the key characteristics of cotton fibers, including fiber length, strength, maturity, fineness, and uniformity. Understand how these properties influence yarn and fabric quality.

- Test Methodologies: Familiarize yourself with standard testing methods used to determine cotton fiber properties (e.g., High Volume Instrument (HVI) testing, AFIS testing). Understand the principles behind each method and the limitations of each approach.

- Data Analysis and Interpretation: Develop your ability to analyze and interpret data from cotton test reports. Practice visualizing data and identifying trends to make informed decisions about cotton quality.

- Quality Control and Assurance: Understand how cotton test reports are used in quality control and assurance processes within the textile industry. Learn how to identify potential issues and suggest solutions based on test results.

- Practical Applications: Explore real-world applications of cotton testing in different stages of textile production, from raw material selection to finished product evaluation. Consider the economic implications of cotton quality.

- Problem-Solving: Practice identifying and troubleshooting potential issues based on discrepancies in cotton test reports. Develop your ability to analyze data, identify root causes, and propose effective solutions.

- Reporting and Communication: Learn to effectively communicate your findings from cotton test reports to different stakeholders, including colleagues, supervisors, and clients. Practice clear and concise reporting.

Next Steps

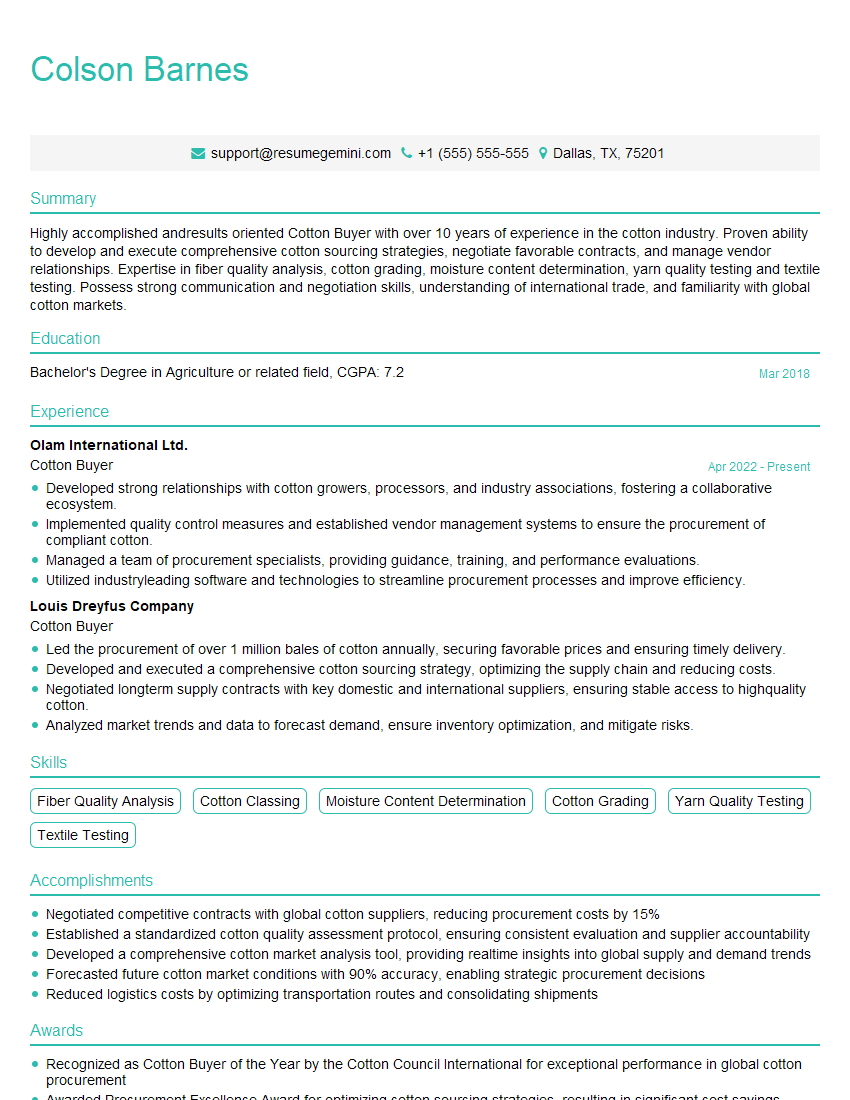

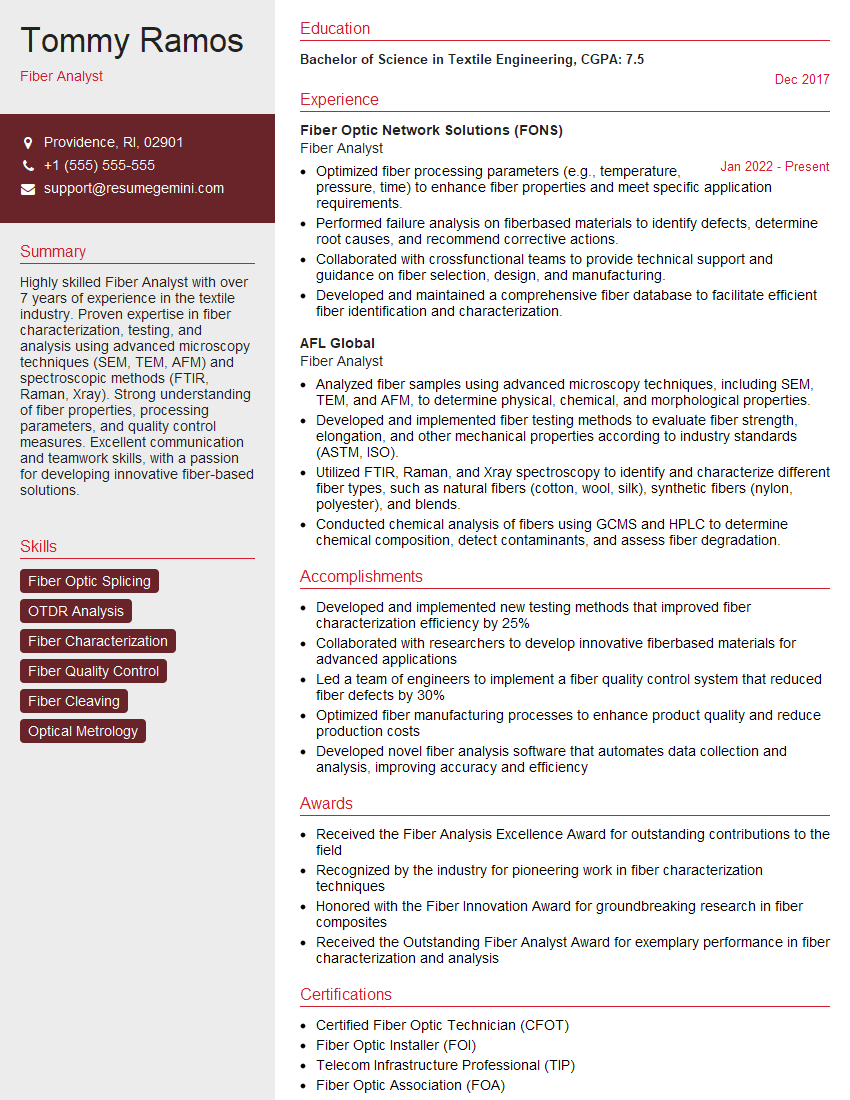

Mastering the ability to prepare and interpret cotton test reports is crucial for career advancement in the textile industry. A strong understanding of cotton quality directly impacts efficiency, cost-effectiveness, and the final product’s quality. To maximize your job prospects, it’s vital to create an ATS-friendly resume that highlights your skills and experience. ResumeGemini is a trusted resource for building professional and effective resumes. They provide examples of resumes tailored to roles requiring expertise in Ability to Prepare and Interpret Cotton Test Reports, allowing you to showcase your skills effectively and increase your chances of landing your dream job.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good