Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Ability to use basic hand tools interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Ability to use basic hand tools Interview

Q 1. What safety precautions do you take when using hand tools?

Safety is paramount when using hand tools. My approach is built around a few key principles: preparation, proper technique, and awareness.

- Preparation: Before starting any task, I inspect my tools for damage – cracks, loose handles, or dull blades. I ensure I have the right tool for the job and wear appropriate personal protective equipment (PPE), including safety glasses, work gloves, and closed-toe shoes. I also clear the work area of obstructions to prevent trips and falls.

- Proper Technique: I always use tools as intended. For example, I never use a screwdriver as a chisel, as this can lead to breakage and injury. I maintain a firm grip, but avoid excessive force. I’m mindful of my body mechanics to prevent strain.

- Awareness: I am constantly aware of my surroundings and potential hazards. This includes being mindful of electrical wires, sharp objects, and other people in the area. I’m cautious about working overhead and take extra care when using sharp or pointed tools.

For instance, once I was working on a project involving removing a stubborn screw. Instead of forcing the screwdriver, I used penetrating oil to loosen the screw, a far safer and more effective approach.

Q 2. Describe your experience using a hammer for different tasks.

My experience with hammers spans various tasks, from light carpentry to demolition work. The technique differs based on the task:

- Light Tapping: For delicate work like setting nails in trim, I use a lighter hammer (like a tack hammer) and apply gentle taps to avoid damaging the material. Precision is key here.

- Driving Nails: For general nailing, I use a claw hammer, gripping the handle firmly near the end for more control. I start with light blows to set the nail straight, gradually increasing the force as it goes deeper. I always ensure the nail is perpendicular to the surface.

- Demolition: In demolition work, I use a heavier sledgehammer and focus on controlled swings, delivering powerful blows to break apart materials safely.

I’ve learned to judge the force required based on the material being worked on and the size/type of the nail or fastener. Years of experience have honed my ability to assess and adjust my hammer technique to suit the task.

Q 3. How do you select the appropriate screwdriver for a specific screw type?

Selecting the correct screwdriver is crucial for both efficiency and safety. The key is matching the tip of the screwdriver to the type of screw head.

- Phillips Head: This cross-shaped head requires a Phillips screwdriver with the appropriate size and length. Using the wrong size can strip the screw head.

- Slotted Head: These have a single slot and require a flat-head screwdriver. Again, the size must be correct for a proper fit.

- Torx Head: This star-shaped head requires a Torx screwdriver; using the wrong type will damage the screw head.

- Square Head: Requires a square-drive screwdriver.

- Hex Head: Usually requires a hex key or Allen wrench.

I always consider the size and length of the screwdriver in relation to the screw and the application. A longer screwdriver provides better leverage, especially for stubborn screws, but using one that’s too long can make the job more awkward and potentially dangerous. Matching the tip size precisely prevents cam-out and damage.

Q 4. Explain the proper technique for using a wrench to tighten a bolt.

Proper wrench usage is fundamental for preventing bolt damage and ensuring a secure fastening. My technique follows these steps:

- Choose the Correct Wrench: Select a wrench that precisely fits the bolt head or nut. Using the wrong size can round off the corners.

- Position the Wrench: Place the wrench firmly on the nut or bolt head, ensuring that it’s properly seated.

- Apply Pressure: Use a firm grip, but avoid excessive force, especially with delicate materials. Apply steady, even pressure in a push-pull motion to increase effectiveness.

- Avoid Jerky Movements: Smooth, controlled movements are essential. Jerky motions can cause the wrench to slip, resulting in damage or injury.

- Check the Tightness: Once tightened, check the tightness of the bolt to make sure it is properly secured without over-tightening.

I often use a pipe wrench for extra leverage when dealing with very tight or stubborn bolts, but always take precautions to avoid damaging the bolt head.

Q 5. How do you ensure the safety and maintenance of your hand tools?

Maintaining hand tools is crucial for their longevity and safety. My routine includes:

- Cleaning: After each use, I clean the tools, removing dirt, debris, and rust. I use a wire brush for stubborn dirt and apply lubricant to the moving parts.

- Sharpening: I regularly sharpen blades (e.g., chisels, knives) to maintain their effectiveness and prevent slips. I use a sharpening stone or a honing guide, depending on the tool.

- Storage: I store my tools properly to prevent damage and rust. I keep them in a toolbox or tool organizer, ensuring that they are not exposed to moisture or extreme temperatures.

- Inspection: Before each use, I thoroughly inspect the tools for damage. Any damaged tools are either repaired or replaced.

- Lubrication: Moving parts on tools, such as hinges and joints, benefit from regular lubrication with an appropriate lubricant.

For example, I’ve had screwdrivers for over ten years that are still in perfect condition thanks to consistent cleaning, oiling, and proper storage. Neglecting these steps would undoubtedly shorten their lifespan and potentially compromise safety.

Q 6. What are the different types of pliers and their uses?

Pliers are versatile hand tools with diverse applications. Here are some common types:

- Slip-Joint Pliers: These have adjustable jaws, allowing them to grip objects of varying sizes. Useful for general gripping and turning.

- Needle-Nose Pliers: With their long, slender jaws, they are ideal for reaching tight spaces and gripping small objects.

- Lineman’s Pliers: These heavy-duty pliers have cutting edges, making them suitable for cutting wire and gripping larger objects.

- Locking Pliers (e.g., Vise-Grips): Their jaws lock into place, providing a secure grip without needing constant pressure. Great for holding workpieces while working on them.

- Diagonal Cutters (Dikes): Used for cutting wire and other small materials.

The type of pliers I select depends entirely on the task. For instance, I’d use slip-joint pliers for a general grip, but needle-nose pliers for working on delicate electronics.

Q 7. Describe your experience using a measuring tape and level.

Measuring tapes and levels are essential for accurate and precise work. My experience involves using them for various applications:

- Measuring Tape: I use measuring tapes to accurately measure distances, lengths, and dimensions. I ensure the tape is extended straight and read the measurement carefully from the hook. I often use a chalk line to mark long straight lines.

- Level: Levels ensure surfaces are perfectly horizontal or vertical. I use them for various tasks, from hanging pictures to installing cabinets and ensuring proper foundation setting.

For example, when building a shelf, I’d first use the measuring tape to determine the exact dimensions of the shelf and then use a level to ensure that the shelf is perfectly aligned and horizontal. Inaccurate measurements would lead to an unstable and visually unappealing product.

Q 8. How do you identify and address a damaged or worn hand tool?

Identifying and addressing damaged or worn hand tools is crucial for safety and efficiency. A damaged tool can lead to injury or poor workmanship. I always inspect my tools before each use, looking for:

- Cracks or breaks: Any fracture, no matter how small, compromises the tool’s structural integrity. For example, a cracked hammer head could shatter during use.

- Loose parts: Screwdrivers with loose handles, or pliers with wobbly joints, are dangerous and ineffective.

- Worn blades or edges: Dull blades require more force, increasing the risk of slipping and injury. For example, a dull chisel requires excessive hammering and could chip.

- Rust or corrosion: Rust weakens the metal, making tools brittle and prone to breakage. This is particularly important for tools with moving parts.

Addressing the damage depends on the severity. Minor rust can be cleaned with steel wool and oil. Loose parts may require tightening or replacement. Severely damaged tools, such as those with cracks or significant rust, should be discarded immediately and replaced. Never attempt to repair a tool if you lack the expertise, as a poorly repaired tool is more dangerous than a discarded one.

Q 9. What is the proper way to use a hacksaw?

Using a hacksaw correctly involves a few key steps. First, select the right blade for the material you’re cutting. A fine-tooth blade is best for thin materials, while a coarser blade works better for thicker materials. Then, secure the workpiece firmly in a vise or clamp. Never try to hold it by hand!

Hold the hacksaw with a relaxed grip, using your entire arm to generate the sawing motion, not just your wrist. Pull the saw back and forth, using short, controlled strokes. Apply steady pressure on the forward stroke, but don’t force it. Excess pressure can cause the blade to break or bind. The correct angle of cutting is around 45 degrees. Maintain a consistent pace and avoid erratic movements. Frequent lubrication of the blade with cutting oil helps prevent overheating and makes the process smoother and easier. Remember to always wear safety glasses to protect your eyes from flying debris.

Q 10. Describe your experience with using chisels and other woodworking tools.

I have extensive experience using chisels and other woodworking tools, including various types of chisels (e.g., mortise chisels, paring chisels, gouges), wood planes, and hand saws. My experience spans various projects from intricate joinery to more basic tasks like shaping wood and removing excess material. For example, I’ve used mortise chisels to create precise joints for chair construction and paring chisels for fine detail work on wooden sculptures.

When using chisels, proper technique is paramount. It’s crucial to use a mallet to strike the chisel head correctly – avoid glancing blows. The chisel should be sharp to minimize effort and risk of slipping. Understanding the grain of the wood is critical to avoid splitting. I also have experience sharpening these tools, ensuring that they are always in optimal condition. My work with planes involves selecting the appropriate plane for the task (smooth, jack, fore) and adjusting the blade accordingly for the desired smoothness. Ultimately, my experience with woodworking tools demonstrates my ability to carefully select and use them for a variety of tasks.

Q 11. How do you use a drill bit effectively and safely?

Effective and safe drill bit use hinges on several factors. Firstly, choose the correct drill bit for the material you are working with – different materials require different types of bits. For example, wood requires a wood bit, while metal requires a high-speed steel (HSS) bit. The size of the bit should be appropriate for the intended hole.

Secure the workpiece firmly in a vise or clamp. Always wear safety glasses to protect your eyes from flying debris. Start by drilling a pilot hole, particularly with harder materials; this prevents the bit from slipping or wandering. Apply even pressure during drilling, avoiding forcing the bit. Excessive pressure can break the bit or damage the workpiece. Use the correct speed setting for your drill and material. Higher speeds are typically used for softer materials, while lower speeds are better for harder materials. If the bit gets too hot, take breaks to prevent damage or injury. Never drill into something without knowing what’s behind it. Always use the correct safety equipment.

Q 12. Explain the difference between various types of saws (e.g., hand saw, coping saw).

Different saws are designed for specific tasks. A hand saw is a general-purpose saw for straight cuts in wood. It’s versatile but less precise than specialized saws. A coping saw, on the other hand, has a narrow blade that can be adjusted for various angles, making it ideal for intricate curves and cuts in thin materials such as wood, plastic, and metal. A back saw has a reinforced spine that helps prevent the blade from flexing, enabling accurate cuts, particularly in precise joinery work. A tenon saw is a fine-toothed back saw used for cutting tenons in joinery.

The choice of saw depends entirely on the task and the material being cut. For large, straight cuts in softwood, a hand saw suffices. For intricate curves in thin wood, a coping saw is necessary. The differences lie primarily in blade type, size, tooth design, and overall construction to achieve their specific cutting objectives.

Q 13. How do you sharpen a hand tool?

Sharpening a hand tool is a skill that requires practice and the right tools. For most hand tools, such as chisels and plane blades, I use a sharpening stone. It’s essential to use the correct grit of stone – starting with a coarser grit to remove more material and then moving to a finer grit for a sharper, smoother edge. I hold the tool at the correct angle relative to the stone, usually around 20-30 degrees. This angle needs to be consistent throughout the sharpening process. Using a honing guide can help maintain a consistent angle.

I apply even pressure and use a smooth, consistent stroke. This process involves creating a burr and then removing it, leading to a sharp, keen edge. I apply sharpening oil to the stone to reduce friction and aid in the process. The technique involves a combination of strokes – one to create a bevel and the other to hone the edge. This differs from tool to tool and even with each material. Finally, I strop the tool on a leather strop with polishing compound to remove any remaining burrs and polish the edge.

Q 14. What are the safety considerations when using a utility knife?

Safety when using a utility knife is paramount. Always use a sharp blade. A dull blade requires more pressure, increasing the risk of slippage and injury. Never use the knife while rushing. It’s extremely important to properly position the material being cut to prevent your hand from getting in the way. Use the proper grip on the knife – not too tight, not too loose. Keep the blade retracted when not in use.

Always wear gloves when appropriate to prevent cuts. Store the utility knife properly, out of reach of children. If the blade becomes damaged, replace it immediately. Dispose of broken blades safely. Never attempt to cut anything without knowing what’s behind it. In short, treat the utility knife with the respect it deserves – it’s a sharp instrument capable of causing serious injury if mishandled.

Q 15. Explain the proper use of a pipe wrench.

A pipe wrench, also known as a crescent wrench, is designed for gripping and turning pipes and other cylindrical objects. Proper use involves understanding its jaw mechanism and applying force effectively to avoid damage.

- Grip Placement: Position the wrench jaws around the pipe, ensuring a firm and even grip. The more surface area you cover, the better the grip and less likely you’ll slip.

- Jaw Adjustment: Adjust the jaws to firmly grasp the pipe. Don’t overtighten; too much pressure can damage the wrench or pipe. A slight gap between the jaws is okay.

- Force Application: Apply force smoothly and steadily. Push and pull motions rather than jerky movements are preferable. The closer your hand is to the pipe, the greater your leverage and efficiency. If necessary, use a cheater bar for extra leverage, but be cautious to avoid damaging the pipe or wrench.

- Safety First: Always wear work gloves to protect your hands, and be aware of your surroundings to prevent accidental injury. Ensure the pipe is securely supported before applying force.

Example: When tightening a pipe fitting, start with a small amount of force and gradually increase it, checking frequently for tightness. If the pipe won’t budge, consider lubricating the threads with an appropriate lubricant.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How would you troubleshoot a stripped screw?

A stripped screw is a frustrating problem, but there are several ways to troubleshoot it. The best approach depends on the severity of the damage and the type of screw.

- Rubber Band or Grip Enhancer: For slightly stripped screws, placing a rubber band over the screw head can increase the grip of your screwdriver. Alternatively, products designed to improve grip are also available.

- Screw Extractor: If the screw head is severely damaged, a screw extractor kit is your best bet. These specialized tools drill into the stripped screw, allowing for its removal. You’ll need to choose the correct size extractor for your stripped screw.

- Drilling it Out: As a last resort, you can drill out the screw. This requires precision and the right drill bit size to avoid damaging the surrounding material. Be extremely careful to avoid slipping and potentially damaging your workpiece.

- Penetrating Oil: Before attempting any of the above, try applying a penetrating oil (like WD-40) to the screw. Let it sit for some time to loosen any corrosion or debris that may be hindering removal.

Example: I once encountered a stripped screw on a delicate piece of antique furniture. Instead of forceful methods, I carefully applied penetrating oil and used a smaller screwdriver with a rubber band for extra grip. This painstaking approach ensured the removal of the screw without further damage.

Q 17. Describe your experience with different types of fasteners (screws, bolts, nails).

My experience with fasteners is extensive, covering various types and applications. I’m familiar with different screw types (Phillips, flathead, slotted, Torx, etc.), bolt types (carriage bolts, machine bolts, hex bolts, etc.), and various nail types (common nails, finish nails, brads, etc.).

- Screws: I understand the differences in drive types and how each affects torque and the potential for stripping. I’m proficient in selecting the correct screw for the material (wood, metal, plastic) and the application.

- Bolts: I’m knowledgeable about different bolt heads, threads (coarse, fine), and materials (steel, stainless steel). I’m aware of the importance of using appropriate washers and nuts for different applications.

- Nails: I can distinguish between different nail types based on their purpose and material. This impacts considerations like the type of wood and hammering technique.

Example: In a recent project involving assembling a metal frame, I used high-strength stainless steel bolts with appropriate washers to ensure secure and corrosion-resistant connections. The selection was dictated by the need for a durable, outdoor-ready structure.

Q 18. How do you determine the appropriate size of a wrench for a specific bolt?

Determining the appropriate wrench size for a specific bolt is crucial to avoid damaging both the bolt and the wrench. The wrench’s size should exactly match the bolt’s head size. Improper sizing can lead to slippage and rounding of the bolt head.

- Measurement: Use a measuring tool (such as a caliper) to measure the distance across the flats of the bolt head (for hex bolts) or the width of the nut or bolt head (for other types).

- Wrench Size Marking: Wrenches are typically marked with their size (e.g., 1/4″, 3/8″, 10mm, etc.).

- Trial and Error (Careful): If you lack precise measuring tools, carefully try different size wrenches until you find one that fits snugly. Avoid forcing a wrench; if it doesn’t fit easily, it’s the wrong size.

Example: For a bolt with a head measuring 1/2″, I would select a 1/2″ wrench to ensure a secure and proper grip. Forcing a smaller wrench would risk rounding the bolt head, making removal much more difficult.

Q 19. What are some common hand tool materials and their properties?

Hand tools are made from a variety of materials, each with its own properties and advantages. The choice of material influences durability, strength, and cost.

- Steel: A common material offering high strength and durability but susceptible to rust unless treated.

- Stainless Steel: Offers high strength and excellent corrosion resistance, making it ideal for outdoor or wet applications.

- Aluminum: Lightweight and corrosion-resistant but not as strong as steel.

- Wood: Often used for handles, offering a good grip and insulation from cold or electrical shock.

- Plastics: Used for non-metal parts; some are impact-resistant but can be brittle under high stress.

Example: A high-quality wrench might be made from chrome vanadium steel for its strength and durability, while the handle might be made of wood or plastic for comfort and grip.

Q 20. How do you handle different types of materials (wood, metal, plastic) with hand tools?

Handling different materials requires adjusting techniques to avoid damage. The tool choice and application pressure differ significantly.

- Wood: Use sharp tools to avoid splitting. Apply pressure steadily, adjusting techniques based on the wood’s grain direction.

- Metal: Require more force and potentially specialized tools. Using the correct sized wrench and applying steady pressure are important to avoid stripping threads or damaging the material. Lubricants can aid in this.

- Plastic: More susceptible to cracking and scratching. Apply less pressure, use softer tools, and be aware of the plastic’s melting point, especially when using power tools.

Example: When drilling into wood, I’d use a sharp drill bit and pilot hole to prevent splitting. When working with metal, I would use the correct sized drill bit and apply cutting oil to help facilitate the drilling process and prevent heat buildup.

Q 21. Describe your experience using a level to ensure a surface is plumb or level.

A level is a fundamental tool for ensuring surfaces are plumb (vertical) or level (horizontal). Accuracy depends on proper use and tool maintenance.

- Surface Preparation: Clean the surface to ensure the level rests firmly and accurately.

- Level Placement: Place the level on the surface, ensuring it spans the area being checked. For long distances, multiple measurements may be needed.

- Bubble Reading: Observe the air bubble in the vial. It should be centered within the markings. The deviation indicates the degree of unlevelness.

- Adjustment: If the surface isn’t level, use shims or other adjustment methods to correct it. Repeat level checks until the bubble is centered.

Example: When installing shelves, I use a level to ensure they are both level and plumb. I make sure the level is placed directly on the surface to prevent errors. I recheck multiple times after adjustment and before securing the shelves.

Q 22. How do you measure accurately with a tape measure and ruler?

Accurate measurement is fundamental to any woodworking or construction project. With a tape measure, ensure the end hook is properly positioned at the starting point – it’s designed to compensate for the hook’s width. Keep the tape measure taut to avoid inaccurate readings, and read the measurement from the end of the hook, not from the metal casing. For finer measurements, use a ruler; lay it flat against the surface, ensuring your eye is directly above the measurement to prevent parallax error (apparent shift in position of an object when viewed from different angles). Always double-check your measurements before cutting or marking.

Example: When measuring a piece of wood for a shelf, I’d first position the tape measure’s hook at the edge, pull it taut to the desired length, and read the measurement. I might then use a ruler to verify a critical dimension like the width of a dado cut – achieving accuracy to a fraction of an inch is essential.

Q 23. What are some common problems encountered when using hand tools, and how do you solve them?

Common problems with hand tools often stem from improper use, poor maintenance, or dull blades. A dull chisel, for instance, will slip and cause injury. Stripped screw heads are another frequent issue. Solutions include: sharpening tools regularly (using sharpening stones or honing guides); selecting the right tool for the job (using the correct size screwdriver); using the correct technique (avoiding excessive force); and maintaining tools properly (cleaning and lubricating where necessary).

- Dull blades: Sharpening with appropriate stones or using a sharpening steel.

- Stripped screws: Using a screw extractor, or if possible, drilling out the screw and replacing it.

- Bent tools: Straightening gently (if possible) or replacing.

- Loose handles: Tightening screws or using epoxy to secure.

I always prioritize safety first; if a tool seems damaged, I will replace it instead of risking injury.

Q 24. Explain how you would choose the right hand tools for a specific task.

Choosing the right hand tools depends entirely on the specific task. For example, if I need to drive a number of large, thick nails into hardwood, I’d select a heavy-duty claw hammer with a long handle for leverage. For finer work, like assembling a small wooden box, I might opt for a smaller hammer, along with chisels, a hand saw, and clamps. Consider the material being worked with, the size and complexity of the project, and the precision required. Always prioritize safety and choose tools that are in good working condition.

Example: Building a birdhouse requires different tools than building a deck. A birdhouse might necessitate fine-tipped screwdrivers, small chisels, and a coping saw, while a deck demands heavier tools like a circular saw (though, this is a power tool), a heavy hammer, and a drill.

Q 25. Describe your experience working with power tools in conjunction with hand tools.

Power tools significantly increase efficiency, but hand tools often play a vital supporting role. For example, I might use a circular saw to cut larger pieces of wood to rough dimensions, but then use hand planes and chisels to refine the edges and create precise joinery. Likewise, I might use a drill to pre-drill pilot holes before driving screws manually – this prevents splitting the wood and provides more control. The combination of power and hand tools allows for a blend of speed and precision.

Example: I recently built a custom bookshelf. A jigsaw helped cut the curves for the decorative supports, but the fine details were done with hand tools, creating a smoother, more professional finish. Safety is paramount in combining power and hand tools; I always disconnect power tools before handling hand tools near them.

Q 26. How do you maintain a clean and organized workspace when using hand tools?

A clean and organized workspace is crucial for efficiency and safety. Before starting, I lay out my tools systematically, arranging them in an order that allows for easy access and prevents accidental damage. I utilize tool organizers and trays to keep smaller items from getting lost. During the project, I regularly clear away shavings and debris to avoid tripping hazards and maintain clear visibility. After completion, I clean and lubricate my tools, and then return them to their designated storage spaces.

Example: I use a pegboard to hang frequently used tools, keeping them easily accessible and preventing clutter. I also use labeled containers to organize screws, nails, and other small parts.

Q 27. How do you handle different types of fasteners (nails, screws, bolts)?

Handling different fasteners requires the right tools and techniques. Nails are driven with hammers, with the size and type of hammer chosen based on the nail size and material. Screws require screwdrivers (Phillips, flathead, etc.) that match the screw head. Bolts usually require wrenches or sockets, depending on the bolt head type. The correct tool ensures proper seating and prevents damage to the fastener or the material. Pre-drilling pilot holes for screws is essential to avoid splitting the wood. Over-tightening fasteners should be avoided, as it can strip the threads or damage the material. I use specialized tools like nail sets to countersink nails and get a flush surface.

Q 28. What is your experience with using specialized hand tools such as punches or awls?

I have experience using specialized hand tools like punches and awls for specific tasks. Punches are used to create precise holes or marks in metal or other materials. Different types of punches exist, such as center punches for marking drill locations or hollow punches for creating holes. Awls are pointed tools used for creating small holes or marking fabric or leather. Their precision is important for tasks like starting holes for screws in tougher materials or creating consistent markings. The use of these tools requires precision and a steady hand to avoid damage or injury.

Example: I’ve used punches to mark locations for drilling holes in metal brackets and awls to create starting points for stitching leather.

Key Topics to Learn for Ability to use basic hand tools Interview

- Safety Procedures: Understanding and applying safe practices when using hand tools, including proper handling, storage, and maintenance to prevent accidents.

- Tool Identification and Selection: Knowing the purpose and application of common hand tools (e.g., hammers, screwdrivers, wrenches, pliers, saws) and selecting the appropriate tool for a given task. This includes understanding different types within each category (e.g., Phillips vs. flathead screwdrivers).

- Basic Tool Usage and Techniques: Demonstrating proficiency in using various hand tools correctly and efficiently. This includes understanding proper grip, applying appropriate force, and achieving desired results.

- Measurement and Marking Techniques: Accurately measuring and marking materials before cutting, drilling, or assembling. This involves using measuring tapes, rulers, and marking tools effectively.

- Troubleshooting and Problem Solving: Identifying and addressing common issues encountered while using hand tools, such as stripped screws, jammed tools, or material damage. This includes developing strategies for overcoming these challenges.

- Material Knowledge: Understanding the properties of common materials (wood, metal, plastic) and how to work with them using different hand tools. This includes recognizing potential challenges based on material type.

- Maintenance and Care: Knowing how to properly clean, lubricate, and store hand tools to ensure their longevity and safe operation.

Next Steps

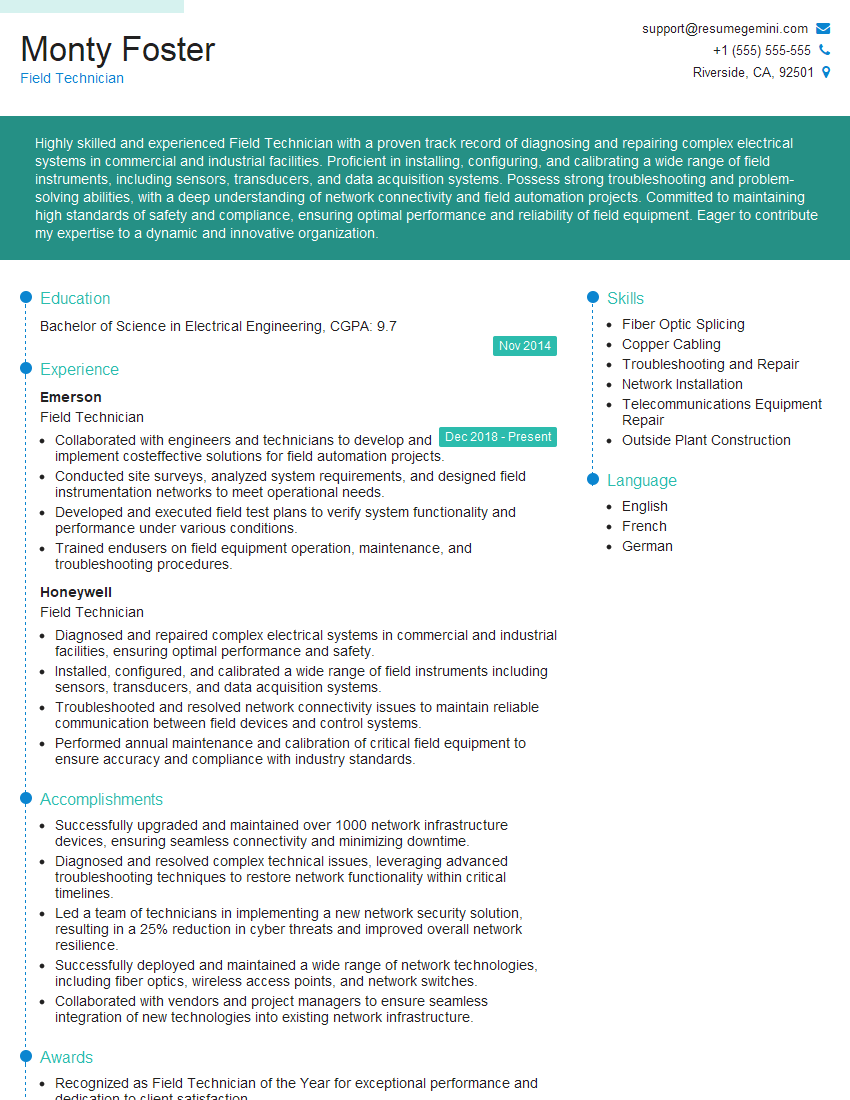

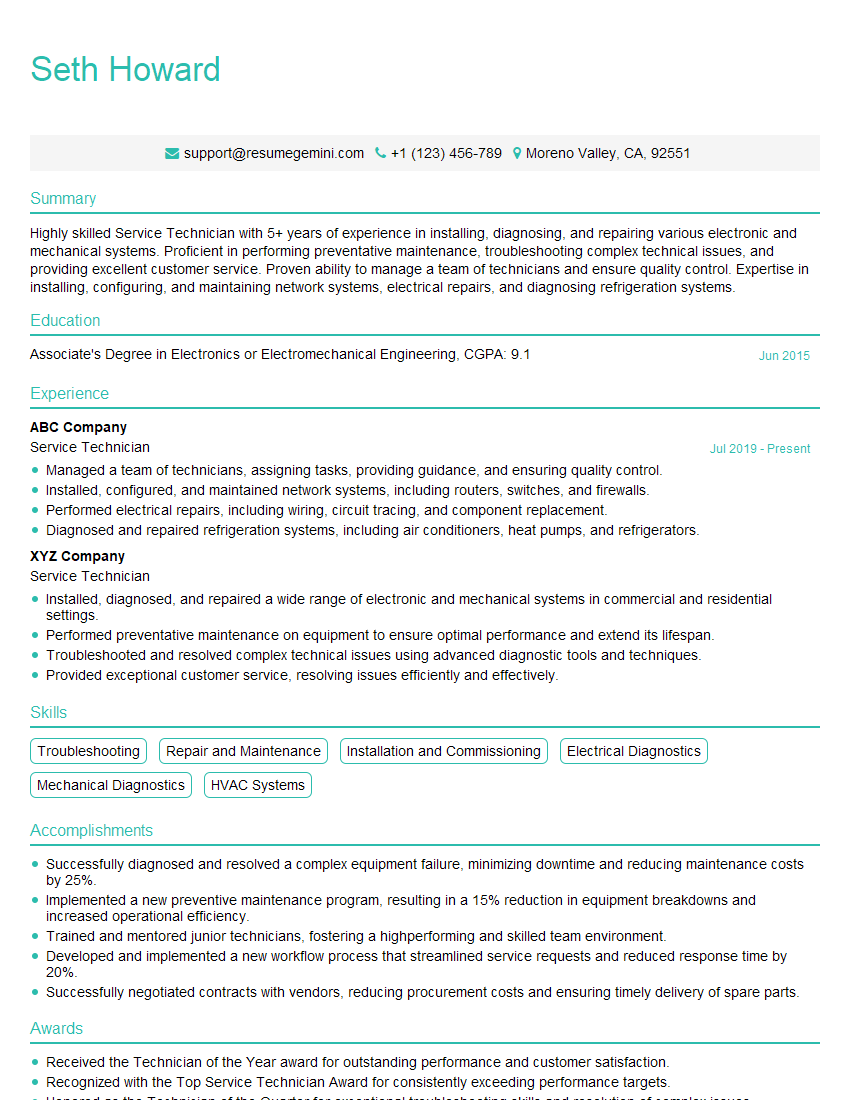

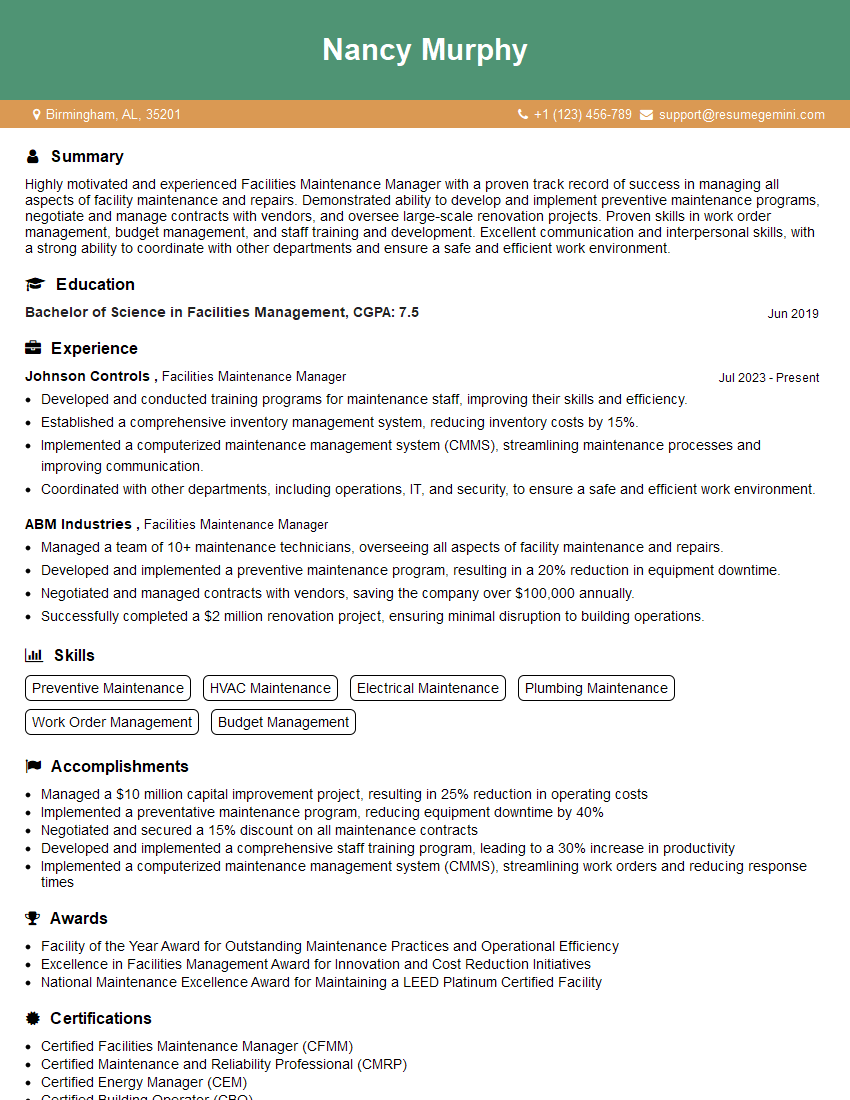

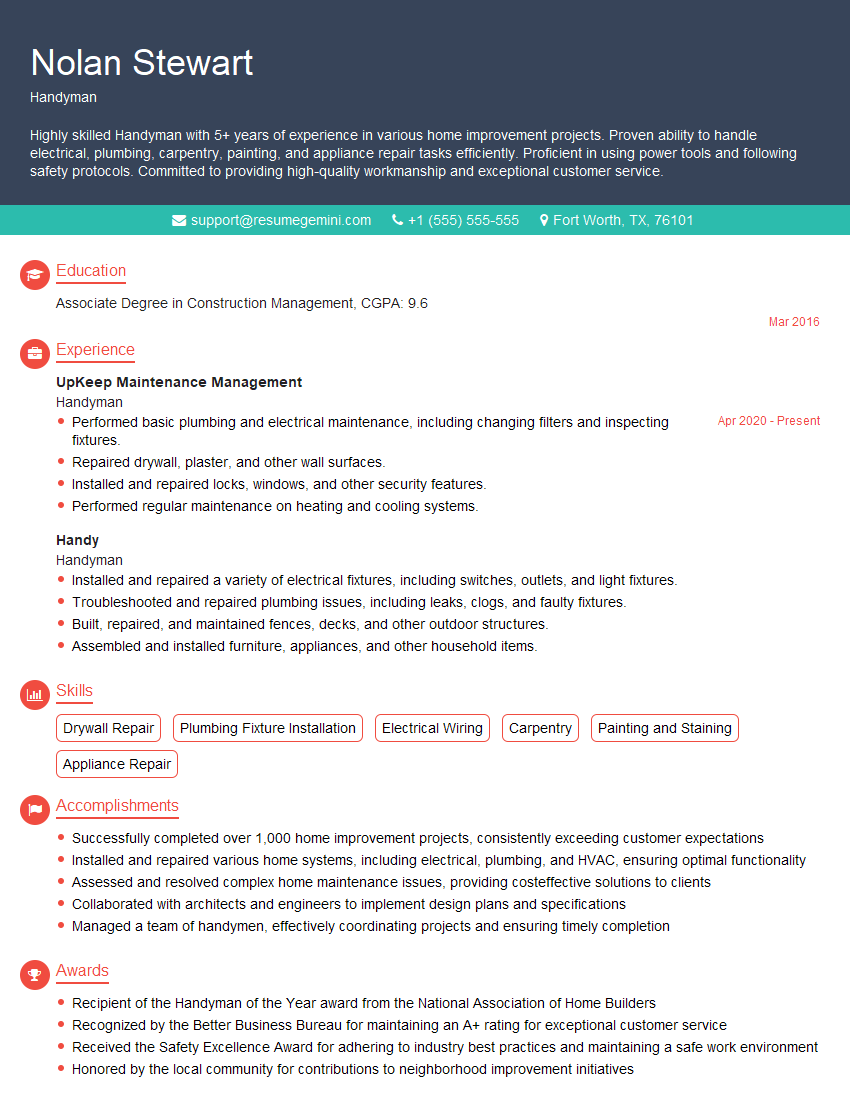

Mastering the ability to use basic hand tools effectively is crucial for many roles, significantly enhancing your skills and marketability. A strong foundation in these skills opens doors to a wide range of opportunities and demonstrates your practical aptitude and attention to detail. To help you showcase these skills effectively, creating an ATS-friendly resume is essential. ResumeGemini can help you build a professional and impactful resume that highlights your abilities and increases your chances of landing your dream job. ResumeGemini provides examples of resumes tailored to highlight proficiency in using basic hand tools, helping you present your qualifications compellingly.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good