Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Ability to work with a variety of chemicals interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Ability to work with a variety of chemicals Interview

Q 1. Describe your experience handling corrosive chemicals.

Handling corrosive chemicals requires meticulous attention to safety. Corrosive substances, like strong acids (e.g., sulfuric acid) and bases (e.g., sodium hydroxide), can cause severe burns and damage to skin, eyes, and respiratory systems. My experience involves working with these chemicals in a controlled laboratory setting, always adhering to strict safety protocols.

- Personal Protective Equipment (PPE): I always wear appropriate PPE, including lab coats, safety glasses or goggles, chemically resistant gloves (e.g., nitrile or neoprene), and sometimes face shields, depending on the procedure and quantity of chemical being handled.

- Ventilation and Containment: Working under a well-ventilated fume hood is crucial to minimize exposure to corrosive fumes. Using secondary containment, like trays or spill kits, prevents accidental spills from spreading and causing further damage.

- Safe Handling Procedures: I use slow, deliberate movements when handling corrosive chemicals. Spills are dealt with immediately using appropriate neutralizing agents and absorbent materials, following established spill response protocols. I am familiar with the proper techniques for transferring these chemicals, including careful pouring and using appropriate pipetting techniques.

- Emergency Procedures: I am trained in emergency procedures, including eye washes, safety showers, and knowing the location of emergency contact information.

For example, during a research project involving concentrated sulfuric acid, I meticulously followed all safety protocols, including working under a fume hood, wearing appropriate PPE, and preparing a spill kit beforehand. This ensured a safe and successful completion of the experiment.

Q 2. Explain the proper procedures for disposing of chemical waste.

Proper chemical waste disposal is paramount to environmental protection and worker safety. The procedure varies depending on the chemical’s properties (corrosive, flammable, toxic, reactive). I always refer to the Material Safety Data Sheet (MSDS) for specific disposal instructions.

- Segregation: Different types of chemical waste are segregated into separate, clearly labeled containers. This prevents incompatible chemicals from mixing and causing potentially hazardous reactions. For instance, acids and bases are never mixed together.

- Neutralization (if required): Some chemicals require neutralization before disposal to reduce their hazard. For example, strong acids are often neutralized with a base to produce less harmful salts and water.

- Proper Container Selection: The containers must be chemically compatible with the waste, appropriately labeled, and securely sealed to prevent leaks.

- Waste Tracking and Documentation: Detailed records of the type and quantity of waste disposed of are meticulously maintained for tracking and compliance with environmental regulations.

- Designated Disposal Route: I always utilize the designated collection and disposal routes and procedures approved by the facility. This may include contracting with licensed waste disposal companies.

In my previous role, we followed a strict waste disposal protocol. We had designated containers for different waste streams and a detailed logbook to track everything, ensuring compliance with all relevant regulations.

Q 3. What safety precautions do you take when working with flammable chemicals?

Flammable chemicals pose a significant fire hazard. Safety precautions are critical to prevent accidents. My approach emphasizes proactive measures and strict adherence to safety regulations.

- No Open Flames: The most important rule is to avoid any open flames or ignition sources in the vicinity of flammable chemicals. This includes Bunsen burners, hot plates that aren’t properly shielded, and even static electricity.

- Proper Storage: Flammable chemicals are stored in designated areas away from ignition sources, ideally in flammability-rated cabinets. These cabinets are designed to contain fires and prevent their spread.

- Ventilation: Adequate ventilation is crucial to prevent the buildup of flammable vapors. Fume hoods are essential, and working in well-ventilated spaces is a must.

- Grounding: Grounding electrical equipment helps prevent static discharge sparks that could ignite flammable vapors.

- PPE: Appropriate PPE, including safety glasses and lab coats, is worn at all times.

- Spill Response Plan: A detailed spill response plan should be readily available and understood by all personnel involved.

For example, during experiments with ethanol, a highly flammable solvent, we always ensured the area was well-ventilated, used grounded equipment, and had a designated spill kit readily available. We also had a fire extinguisher nearby and training on its proper use.

Q 4. How do you identify unknown chemicals?

Identifying unknown chemicals requires careful consideration and multiple analytical techniques. It is crucial to never assume the identity of an unknown chemical and to approach the process with extreme caution.

- Visual Inspection: First, perform a visual inspection, noting the physical properties like color, odor (carefully and cautiously!), state (solid, liquid, gas), and any visible impurities.

- Chemical Tests: Simple chemical tests (e.g., pH tests with litmus paper or pH meter) can provide clues about the chemical’s nature (acidic, basic, neutral). Always follow safety guidelines when performing these tests.

- Instrumental Analysis: Sophisticated analytical techniques are often necessary for definitive identification. These include Gas Chromatography-Mass Spectrometry (GC-MS), High-Performance Liquid Chromatography (HPLC), and Nuclear Magnetic Resonance (NMR) spectroscopy, which can identify the chemical based on its molecular fingerprint.

- Safety Precautions: Any analysis of an unknown substance should be conducted under appropriate safety precautions, including the use of PPE, a fume hood, and careful handling procedures.

In a real-world scenario, if faced with an unknown chemical, I would prioritize safety and then leverage available resources, such as MSDS databases and laboratory instrumentation, to identify the chemical’s composition.

Q 5. Explain your understanding of Material Safety Data Sheets (MSDS).

Material Safety Data Sheets (MSDS), now often referred to as Safety Data Sheets (SDS), are crucial documents providing comprehensive information on the hazards of a chemical and how to handle it safely. They are essential for ensuring workplace safety and compliance with regulations.

- Hazard Identification: SDSs clearly identify the chemical’s hazards, including health effects (e.g., toxicity, carcinogenicity), flammability, reactivity, and environmental impacts.

- First Aid Measures: They provide guidance on first aid procedures in case of exposure.

- Handling and Storage: SDSs specify appropriate handling procedures, storage requirements, and personal protective equipment (PPE) to use.

- Spill Response: They provide guidance on how to handle spills and leaks effectively.

- Disposal Methods: SDSs detail safe methods for disposing of the chemical and its waste.

I always consult the SDS before working with any chemical. It’s my primary reference for understanding the potential risks and ensuring I follow all necessary safety precautions.

Q 6. Describe your experience with different types of chemical reactions.

My experience encompasses a range of chemical reactions, including acid-base reactions, redox reactions, precipitation reactions, and organic reactions. Understanding reaction mechanisms is crucial for predicting reaction outcomes and controlling reaction conditions.

- Acid-Base Reactions: I’ve worked extensively with acid-base titrations, understanding the neutralization of acids with bases and the use of indicators to determine equivalence points.

- Redox Reactions: I have experience in redox reactions, such as oxidation of alcohols and reduction of ketones, utilizing various oxidizing and reducing agents.

- Precipitation Reactions: I’m familiar with precipitation reactions and their use in qualitative and quantitative analysis, employing techniques like gravimetric analysis.

- Organic Reactions: My expertise extends to organic reactions, including synthesis, purification, and characterization of organic compounds using techniques like recrystallization and chromatography.

For instance, I synthesized aspirin in a laboratory setting, which involved an esterification reaction, demonstrating a clear understanding of reaction stoichiometry and purification techniques to obtain a pure product.

Q 7. How do you ensure the accuracy and precision of chemical measurements?

Accuracy and precision in chemical measurements are fundamental to experimental success and data reliability. I employ several strategies to ensure accurate and precise results.

- Proper Calibration: I always begin by ensuring that all equipment, such as balances, volumetric glassware (pipettes, burettes, volumetric flasks), and spectrophotometers are properly calibrated and functioning correctly.

- Appropriate Techniques: I utilize appropriate measurement techniques. For example, I use volumetric glassware for accurate volume measurements and analytical balances for precise mass measurements. I also understand the limitations of different instruments and methods.

- Multiple Measurements: I typically perform multiple measurements for each data point and calculate the average and standard deviation to assess the precision and uncertainty of the measurements. This improves the reliability of the results.

- Proper Handling: I carefully handle all chemicals and equipment to avoid contamination and errors. This includes using clean glassware, avoiding cross-contamination, and following proper handling procedures for delicate equipment.

- Data Recording and Analysis: I meticulously record all data with appropriate units and significant figures. Data analysis includes error analysis, considering uncertainties associated with the measurements.

For instance, when preparing a standard solution, I would carefully weigh the solute on an analytical balance to obtain a precise mass, transfer it quantitatively to a volumetric flask, and add the solvent to the calibration mark, ensuring the final volume is accurate. I would repeat this process at least three times to obtain precise and reproducible results.

Q 8. What are the common hazards associated with working with chemicals?

Working with chemicals presents a multitude of hazards, broadly categorized into health risks, fire hazards, and reactivity hazards. Health risks include acute effects like burns, irritations, and poisoning from direct contact, inhalation, or ingestion. Chronic exposure can lead to serious health problems like organ damage, cancer, or reproductive issues. Fire hazards stem from the flammability of many chemicals; some are highly volatile and ignite easily. Reactivity hazards involve dangerous reactions between chemicals, potentially causing explosions, fires, or the release of toxic gases. For example, mixing strong acids with strong bases can generate significant heat and potentially cause a violent reaction. Another example is the risk of explosion when handling certain organic peroxides which are highly sensitive to heat and shock.

- Health Hazards: Toxicity (acute and chronic), skin irritation, respiratory problems, carcinogenicity.

- Fire Hazards: Flammability, autoignition, explosive properties.

- Reactivity Hazards: Explosions, fire, formation of toxic gases, incompatible chemical mixtures.

Q 9. Explain your experience with using various laboratory equipment for chemical handling.

My experience encompasses a wide range of laboratory equipment crucial for safe and effective chemical handling. I’m proficient in using various glassware, including beakers, Erlenmeyer flasks, volumetric flasks, and graduated cylinders for accurate measurement and mixing of chemicals. I have extensive experience with specialized equipment such as rotary evaporators for solvent removal, reflux condensers for controlled heating reactions, and separatory funnels for liquid-liquid extractions. Furthermore, I’m adept at operating sophisticated analytical instruments such as gas chromatographs (GC), high-performance liquid chromatographs (HPLC), and spectrophotometers for qualitative and quantitative analysis of chemical compounds. During my work on the synthesis of novel organometallic compounds, I extensively used gloveboxes to handle air-sensitive reagents and ensure safety. Proper use and maintenance of these devices are crucial for preventing accidents and ensuring reliable results.

Q 10. How do you handle spills involving hazardous chemicals?

Handling chemical spills, particularly those involving hazardous materials, requires immediate and decisive action. The first step is to ensure personal safety by evacuating the area and contacting emergency services if necessary. Next, the type of chemical spilled needs to be identified to determine the appropriate cleanup procedure. This information is typically found on the chemical’s Safety Data Sheet (SDS). For smaller spills, absorbent materials like vermiculite or spill pads are used to soak up the liquid, preventing further spread. Larger spills may necessitate specialized containment equipment. After containment, the waste is disposed of according to established safety protocols, often involving neutralization, dilution, or special waste containers. For example, in one instance I had to handle a concentrated sulfuric acid spill, where I first neutralized it with a sodium bicarbonate solution, then carefully collected the neutralized solution for disposal as hazardous waste. Always follow the instructions detailed in the SDS and your organization’s spill response plan.

Q 11. Describe your experience with chemical synthesis.

I have significant experience in chemical synthesis, covering a range of methodologies and reaction types. My work includes the synthesis of organic molecules, organometallic compounds, and inorganic materials. I am familiar with various reaction conditions, including different solvents, temperatures, and catalysts. My expertise also encompasses purification techniques like recrystallization, distillation, and chromatography. For instance, I successfully synthesized a novel palladium catalyst using a multi-step Grignard reaction followed by purification via column chromatography. This project demanded meticulous attention to detail, including strict adherence to safety protocols and precise control of reaction conditions. Data logging, analysis and troubleshooting were an integral part of this synthesis.

Q 12. What are the different types of chemical bonds, and how do they affect chemical properties?

Chemical bonds are the forces that hold atoms together in molecules and compounds. The primary types are ionic, covalent, and metallic bonds. Ionic bonds involve the electrostatic attraction between oppositely charged ions, formed when one atom loses electrons (becoming a cation) and another gains electrons (becoming an anion). For example, sodium chloride (NaCl) features an ionic bond where sodium loses an electron to become Na+ and chlorine gains an electron to become Cl–. Covalent bonds involve the sharing of electrons between atoms. These bonds are typically found in molecules like water (H2O) where hydrogen atoms share electrons with the oxygen atom. Metallic bonds occur in metals and involve the delocalized sharing of electrons among a lattice of metal atoms. These different bond types significantly impact a molecule’s properties. Ionic compounds tend to have high melting points and be soluble in water, while covalent compounds often have lower melting points and varying solubility. Metallic compounds are excellent conductors of electricity and heat. Understanding bond types is crucial for predicting the properties of compounds.

Q 13. Explain your understanding of stoichiometry and its application in chemical calculations.

Stoichiometry is the quantitative relationship between reactants and products in a chemical reaction. It’s based on the law of conservation of mass, which states that matter is neither created nor destroyed in a chemical reaction. This means the total mass of reactants equals the total mass of products. Stoichiometric calculations involve using balanced chemical equations and molar masses to determine the amounts of reactants needed or products formed. For instance, consider the reaction: 2H2 + O2 → 2H2O. The balanced equation shows that 2 moles of hydrogen react with 1 mole of oxygen to produce 2 moles of water. Using this, we can calculate the mass of water produced from a given mass of hydrogen or oxygen. This principle is fundamental in many chemical processes, including industrial chemical production, determining the yield of reactions, and optimizing reaction conditions.

Q 14. Describe your experience with chromatography techniques.

I have substantial experience with various chromatographic techniques, including Thin-Layer Chromatography (TLC), Gas Chromatography (GC), and High-Performance Liquid Chromatography (HPLC). TLC is a simple and rapid method for separating and identifying compounds based on their differential adsorption onto a stationary phase (e.g., silica gel). It is useful for monitoring reaction progress and assessing the purity of compounds. GC separates volatile compounds based on their boiling points and interaction with a stationary phase within a column. I have used GC extensively in analyzing the composition of organic mixtures and identifying unknown compounds. HPLC offers higher resolution and is suitable for separating non-volatile and thermally labile compounds. I have applied HPLC to purify and analyze a wide array of chemical compounds, including pharmaceuticals and natural products. The choice of chromatographic technique depends on the properties of the compounds to be separated and the desired level of resolution. Careful selection of the stationary phase, mobile phase, and other parameters is essential to achieving successful separation.

Q 15. How do you maintain a clean and organized laboratory environment when working with chemicals?

Maintaining a clean and organized lab environment when working with chemicals is paramount for safety and accurate results. It’s not just about tidiness; it’s about preventing accidents and ensuring reproducibility. My approach is multifaceted:

- Pre-experiment planning: Before starting any experiment, I meticulously plan the workflow, anticipating potential spills or waste generation. This includes designating specific areas for different tasks and pre-preparing solutions to minimize clutter.

- Designated areas for chemicals: Chemicals are stored according to their hazard classification, with clearly labeled containers. This prevents accidental mixing and simplifies cleanup.

- Immediate cleanup: Spills are addressed immediately using appropriate absorbent materials and neutralization techniques, depending on the spilled chemical. For instance, acid spills require careful neutralization with a base, and vice versa, always ensuring proper ventilation.

- Regular cleaning: The lab is cleaned regularly, both during and after experiments. This includes wiping down benches, cleaning glassware thoroughly, and disposing of waste according to regulations.

- Proper waste disposal: Waste chemicals are segregated based on their compatibility and disposed of according to established protocols and local regulations. This might involve specialized containers for organic solvents, heavy metals, or corrosive materials.

Think of it like a well-organized kitchen – a clean and organized space allows for efficient and safe work, minimizing errors and potential hazards. In a lab setting, this translates to reliable results and a safer work environment.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with using Personal Protective Equipment (PPE)?

Personal Protective Equipment (PPE) is non-negotiable in my work with chemicals. My experience encompasses the consistent and appropriate use of various PPE, depending on the specific chemicals and procedures involved. This includes:

- Safety glasses or goggles: Always worn to protect eyes from splashes or fumes.

- Lab coats: Provide a barrier between my clothing and chemicals.

- Gloves: The type of glove varies depending on the chemical. Nitrile gloves are common, but more specialized gloves (e.g., neoprene, butyl rubber) are used for handling highly corrosive or reactive chemicals. I always check for glove degradation before each use.

- Respirators: Used when working with volatile or toxic substances, selected according to the specific hazard.

- Appropriate footwear: Closed-toe shoes are essential to protect feet from spills.

I am trained in the proper selection, donning, doffing, and disposal of PPE. I never compromise on safety, and I always ensure that my PPE is in good condition. It’s not just about following rules; it’s about a mindset of proactive safety.

Q 17. Describe your experience with different chemical separation techniques.

I have extensive experience with various chemical separation techniques, each chosen based on the properties of the mixture being separated. These include:

- Distillation: Used to separate liquids with different boiling points. For instance, separating ethanol from water in a fermentation process.

- Extraction: Separating a compound from a mixture by using a solvent that preferentially dissolves the target compound. A classic example is extracting caffeine from coffee beans.

- Chromatography: A powerful technique to separate components of a mixture based on their differential affinities for a stationary and mobile phase. This includes techniques like thin-layer chromatography (TLC), column chromatography, and high-performance liquid chromatography (HPLC), each suited for specific applications and scales.

- Filtration: Separating solids from liquids, using a filter paper or membrane. Simple, but vital for many lab procedures.

- Recrystallization: Purifying a solid compound by dissolving it in a hot solvent, then allowing it to cool and crystallize, leaving impurities in solution. Useful for purifying solid products of chemical reactions.

Selecting the appropriate technique is crucial and depends on factors such as the scale of the separation, the nature of the compounds involved, and the desired purity of the separated components.

Q 18. How do you ensure the quality and purity of chemicals used in experiments?

Ensuring chemical quality and purity is vital for reliable experimental results. My approach is multi-pronged:

- Source reputable suppliers: I always source chemicals from reputable suppliers with certifications guaranteeing purity and quality. This ensures that the starting materials meet the required specifications.

- Check Certificates of Analysis (CoA): Before use, I always carefully review the CoA provided by the supplier, verifying the purity, identity, and any relevant safety information.

- Proper storage: Chemicals are stored according to their specific requirements, often in a desiccator or under inert conditions to maintain their integrity. This is especially important for moisture- or air-sensitive reagents.

- Purification techniques: If necessary, I employ appropriate purification techniques, such as recrystallization, distillation, or chromatography, to further enhance the purity of chemicals before use.

- Regular audits: We maintain a system of regular stock audits and checks of expiration dates to maintain chemical quality and avoid using outdated or degraded reagents.

Maintaining high chemical purity is not just a matter of convenience; it is essential for the validity and reproducibility of research findings. It requires careful attention to detail at each step, from sourcing to storage.

Q 19. Explain your experience with using and maintaining laboratory instrumentation.

My experience with laboratory instrumentation includes both routine operation and preventative maintenance. I’m proficient in operating and maintaining a range of instruments, including:

- Spectrophotometers: Used for measuring absorbance or transmittance of light through a solution, crucial for quantitative analysis.

- pH meters: Measure the acidity or basicity of a solution, critical for many chemical reactions and analyses.

- Titrators: Automated systems for performing titrations, determining the concentration of an analyte.

- Balances: Precise weighing of chemicals is essential for accurate measurements.

- Chromatography systems (HPLC, GC): Require advanced training and understanding for both operation and data interpretation.

I understand the importance of preventative maintenance, including regular calibration, cleaning, and troubleshooting. Proactive maintenance prevents downtime and ensures the accuracy and reliability of results. I always follow manufacturer’s instructions and maintain detailed logs of instrument use and maintenance.

Q 20. What are the different types of chemical reactions?

Chemical reactions are broadly classified into several categories, often overlapping:

- Combination reactions (synthesis): Two or more reactants combine to form a single product. Example:

2H₂ + O₂ → 2H₂O - Decomposition reactions: A single reactant breaks down into two or more products. Example:

2H₂O₂ → 2H₂O + O₂ - Single displacement reactions: A more reactive element replaces a less reactive element in a compound. Example:

Zn + 2HCl → ZnCl₂ + H₂ - Double displacement reactions (metathesis): Two compounds exchange ions to form two new compounds. Example:

AgNO₃ + NaCl → AgCl + NaNO₃ - Acid-base reactions: An acid reacts with a base to form salt and water (neutralization). Example:

HCl + NaOH → NaCl + H₂O - Redox reactions (oxidation-reduction): Reactions involving the transfer of electrons. One species is oxidized (loses electrons), while another is reduced (gains electrons). Example:

Fe + Cu²⁺ → Fe²⁺ + Cu

Understanding these categories helps predict the products of a reaction and design experiments accordingly. The type of reaction influences the conditions required (temperature, pressure, catalysts) to achieve a desired outcome.

Q 21. Explain the concept of chemical equilibrium.

Chemical equilibrium is the state in a reversible reaction where the rates of the forward and reverse reactions are equal. This means that the concentrations of reactants and products remain constant over time, even though the reactions are still occurring. It’s a dynamic equilibrium – not a static one.

Consider a simple reversible reaction: A ⇌ B

At equilibrium, the rate of conversion of A to B is equal to the rate of conversion of B to A. This equilibrium is described by the equilibrium constant (K), which is the ratio of the product concentrations to the reactant concentrations at equilibrium. A large K indicates that the equilibrium favors the products, while a small K indicates that the equilibrium favors the reactants.

Factors that affect equilibrium include temperature, pressure (for gaseous reactions), and concentration. Le Chatelier’s principle states that if a change of condition is applied to a system in equilibrium, the system will shift in a direction that relieves the stress. For example, increasing the concentration of a reactant will shift the equilibrium towards the products.

Understanding chemical equilibrium is vital in many chemical processes, from industrial synthesis to biological systems. It allows us to predict and control reaction yields and optimize reaction conditions.

Q 22. Describe your understanding of chemical kinetics.

Chemical kinetics is the study of reaction rates and the factors that influence them. It explores how quickly chemical reactions proceed, and what conditions (temperature, concentration, catalysts, etc.) affect that speed. Think of it like this: you’re baking a cake. Chemical kinetics would help us understand how fast the ingredients combine and the cake bakes, depending on oven temperature (analogous to reaction temperature) and the amount of baking powder (analogous to a catalyst).

We often use rate laws to describe reaction rates mathematically. For example, a simple rate law might be: Rate = k[A][B], where ‘k’ is the rate constant, and [A] and [B] represent the concentrations of reactants A and B. This tells us the rate is directly proportional to the concentrations of both A and B. A higher concentration means a faster reaction. We also analyze activation energy (the energy barrier reactants need to overcome to form products), which determines how temperature affects the reaction rate.

In my work, understanding chemical kinetics has been crucial for optimizing reaction conditions in synthesis. For example, by carefully controlling temperature and reactant concentrations, I was able to significantly increase the yield of a desired product in a pharmaceutical synthesis.

Q 23. How do you interpret and analyze chemical data?

Interpreting and analyzing chemical data involves a multi-step process that starts with careful data collection and ends with meaningful conclusions. I begin by critically evaluating the data’s quality – checking for outliers, inconsistencies, and potential sources of error. This often involves visualizing the data using graphs and charts (scatter plots, bar graphs, etc.).

Next, I apply appropriate statistical methods, depending on the data type. This could involve calculating means, standard deviations, or using more advanced techniques like regression analysis to identify correlations between variables. For example, I might use linear regression to determine the relationship between reactant concentration and reaction rate. I always document my methods and reasoning meticulously.

Software plays a significant role. I am proficient with various statistical software packages (e.g., R, Python with SciPy and Pandas libraries) to assist in data analysis and visualization. The goal is to go beyond simply presenting numbers to derive actionable insights, which I then use to improve experimental design or develop new hypotheses.

Q 24. Explain your understanding of the different states of matter and their properties.

Matter exists in three primary states: solid, liquid, and gas. Solids have a defined shape and volume due to strong intermolecular forces holding their constituent particles tightly together. Liquids have a defined volume but take the shape of their container; intermolecular forces are weaker allowing for more movement. Gases have neither a defined shape nor volume, expanding to fill their container because intermolecular forces are minimal.

Beyond these three, we also recognize plasma (a superheated gas with ionized particles) and Bose-Einstein condensates (a state of matter at extremely low temperatures where atoms behave as a single entity). Each state possesses unique properties like density, viscosity, and melting/boiling points which directly relate to the arrangement and interactions of their constituent particles. These properties are vital for choosing appropriate storage and handling methods for different chemicals.

For instance, understanding the volatility of a liquid (its tendency to evaporate) is crucial for preventing losses during storage and handling. Similarly, knowing the solid’s melting point helps determine its suitability for a particular reaction.

Q 25. Describe your experience with using and calibrating analytical instruments.

I have extensive experience with a variety of analytical instruments, including Gas Chromatography-Mass Spectrometry (GC-MS), High-Performance Liquid Chromatography (HPLC), UV-Vis spectrophotometers, and titration equipment. Calibration is critical to ensure accurate and reliable results. This involves using certified standards to create calibration curves that relate instrument response to known concentrations.

For example, with HPLC, I would inject solutions of known concentrations of the analyte into the system and plot the resulting peak areas against concentration. This calibration curve is then used to determine the concentration of the analyte in unknown samples. Regular maintenance and calibration checks are vital for maintaining instrument accuracy. I meticulously record all calibration data and follow strict protocols to guarantee data integrity.

Troubleshooting instrument malfunctions is another aspect of my expertise. I have a systematic approach to diagnosing issues, from checking connections and replacing components to seeking technical support when necessary.

Q 26. What is your experience with chemical analysis techniques such as titration and spectrophotometry?

Titration is a quantitative chemical analysis technique used to determine the concentration of an unknown solution (analyte) by reacting it with a solution of known concentration (titrant) until the reaction is complete. The endpoint is often detected using an indicator that changes color. For example, acid-base titrations use indicators like phenolphthalein. I’ve used titrations extensively for determining the concentration of acids and bases in various samples.

Spectrophotometry measures the absorbance or transmission of light through a sample at specific wavelengths. This can be used to determine the concentration of a substance based on its light absorption properties (Beer-Lambert law). UV-Vis spectrophotometry is commonly used to quantify substances with chromophores (light-absorbing groups) and I frequently use it to monitor reaction progress or quantify protein concentration.

In one project, I combined titration and spectrophotometry to analyze a complex mixture. Titration helped to determine the total concentration of a particular component, while spectrophotometry provided additional information about its chemical form.

Q 27. How do you prevent chemical contamination in the laboratory?

Preventing chemical contamination requires a multi-pronged approach emphasizing cleanliness, proper technique, and organizational strategies. The lab environment itself must be maintained in a clean and organized manner. Work surfaces should be cleaned before and after each experiment using appropriate solvents and disinfectants. Dedicated glassware and equipment should be used for different chemicals to prevent cross-contamination.

Proper handling techniques are crucial. This includes using appropriate personal protective equipment (PPE) such as gloves and lab coats to minimize contamination from skin contact. Reagents should be handled carefully to avoid spills or exposure to air and moisture. Using clean pipettes and avoiding touching the inside of containers prevents contamination.

Finally, a well-organized lab reduces risks. Chemicals should be properly labeled and stored, with incompatible substances kept separate. Regular cleaning and maintenance of equipment minimize contamination risks.

Q 28. Describe your experience with working under strict safety regulations and guidelines.

Throughout my career, I have consistently worked under strict safety regulations and guidelines, prioritizing safety above all else. I am highly familiar with Material Safety Data Sheets (MSDS) and understand the hazards associated with the chemicals I handle. I always follow proper procedures for handling, storage, and disposal of hazardous waste. This includes understanding and adhering to waste segregation protocols and ensuring proper disposal through authorized channels.

My experience includes working in labs with stringent safety protocols, including those related to chemical hygiene, waste management, and emergency response procedures. I am trained in handling hazardous materials and am adept at using safety equipment such as fume hoods, eye washes, and safety showers. I’ve participated in regular safety training programs and actively contribute to maintaining a safe lab environment. I believe that proactive safety measures prevent accidents and foster a productive research environment.

In one instance, I noticed a small leak in a gas cylinder. I immediately informed my supervisor, evacuated the area, and followed established procedures for containing the leak, preventing a potentially dangerous situation.

Key Topics to Learn for Ability to work with a variety of chemicals Interview

- Chemical Safety and Handling: Understanding Material Safety Data Sheets (MSDS), proper personal protective equipment (PPE) selection and use, safe storage and disposal procedures, and emergency response protocols.

- Chemical Reactivity and Compatibility: Knowing the potential hazards of mixing different chemicals, understanding chemical reactions and their implications, and applying this knowledge to prevent accidents and optimize processes.

- Quantitative Chemical Analysis: Familiarity with techniques like titration, spectroscopy, and chromatography, and the ability to interpret results accurately and apply them to problem-solving.

- Chemical Synthesis and Purification: Understanding the principles of chemical synthesis, including reaction mechanisms and stoichiometry, and experience with purification techniques like recrystallization and distillation.

- Laboratory Techniques and Instrumentation: Proficiency in using various laboratory equipment, such as balances, glassware, and specialized instruments relevant to chemical analysis and synthesis. Understanding maintenance and calibration procedures.

- Waste Management and Environmental Considerations: Knowledge of proper waste disposal procedures, environmental regulations related to chemical handling, and sustainable laboratory practices.

- Record Keeping and Documentation: Ability to maintain accurate and detailed laboratory notebooks, following good laboratory practices (GLP) and adhering to data integrity standards.

Next Steps

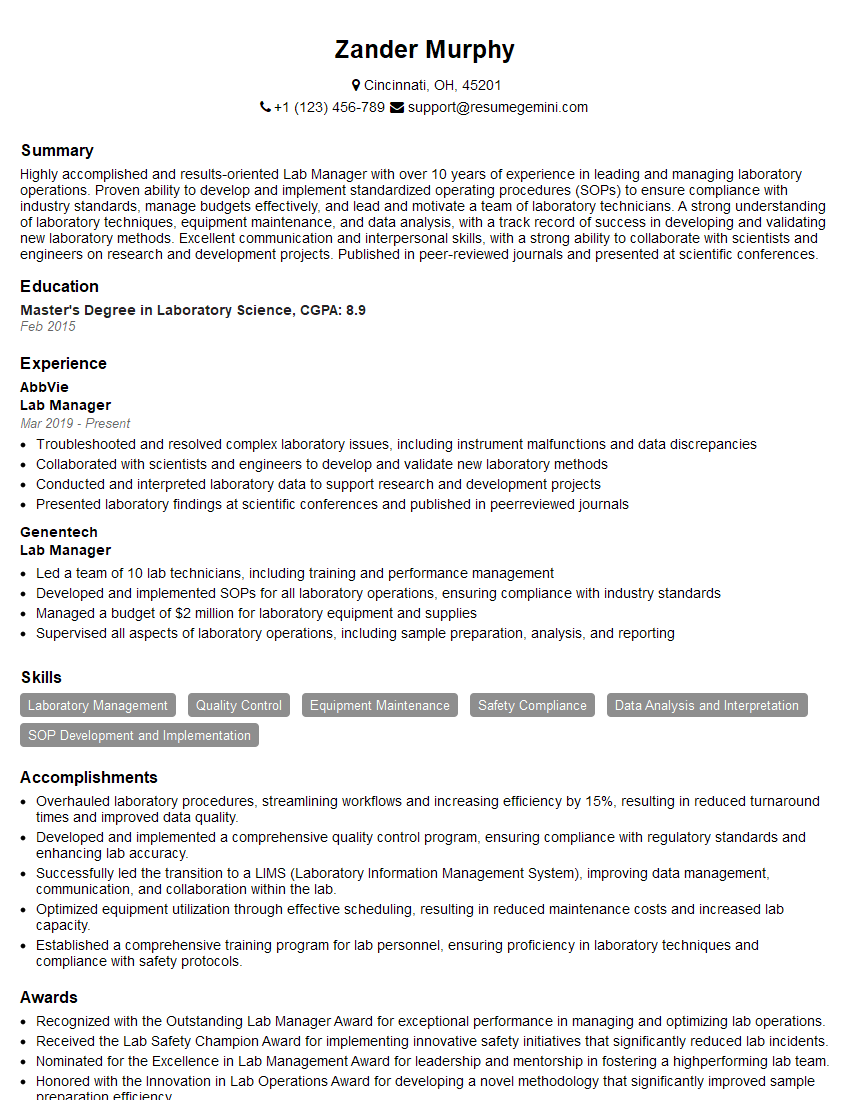

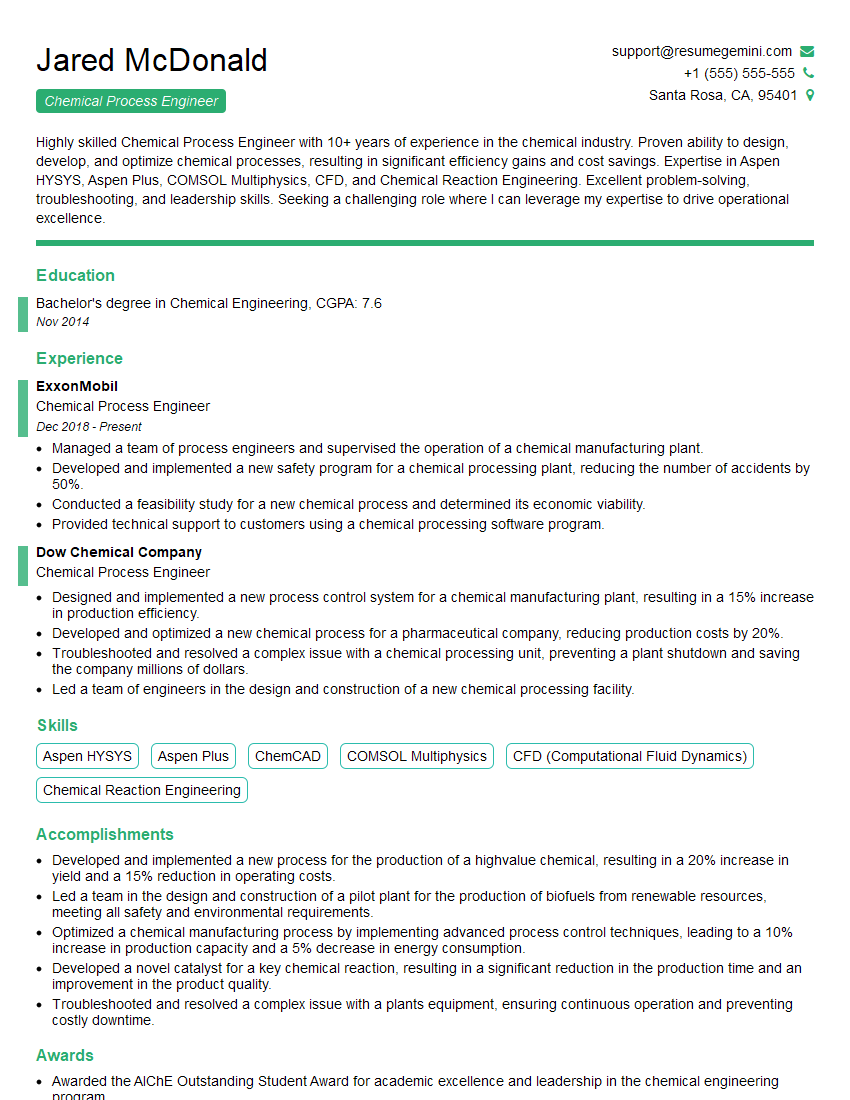

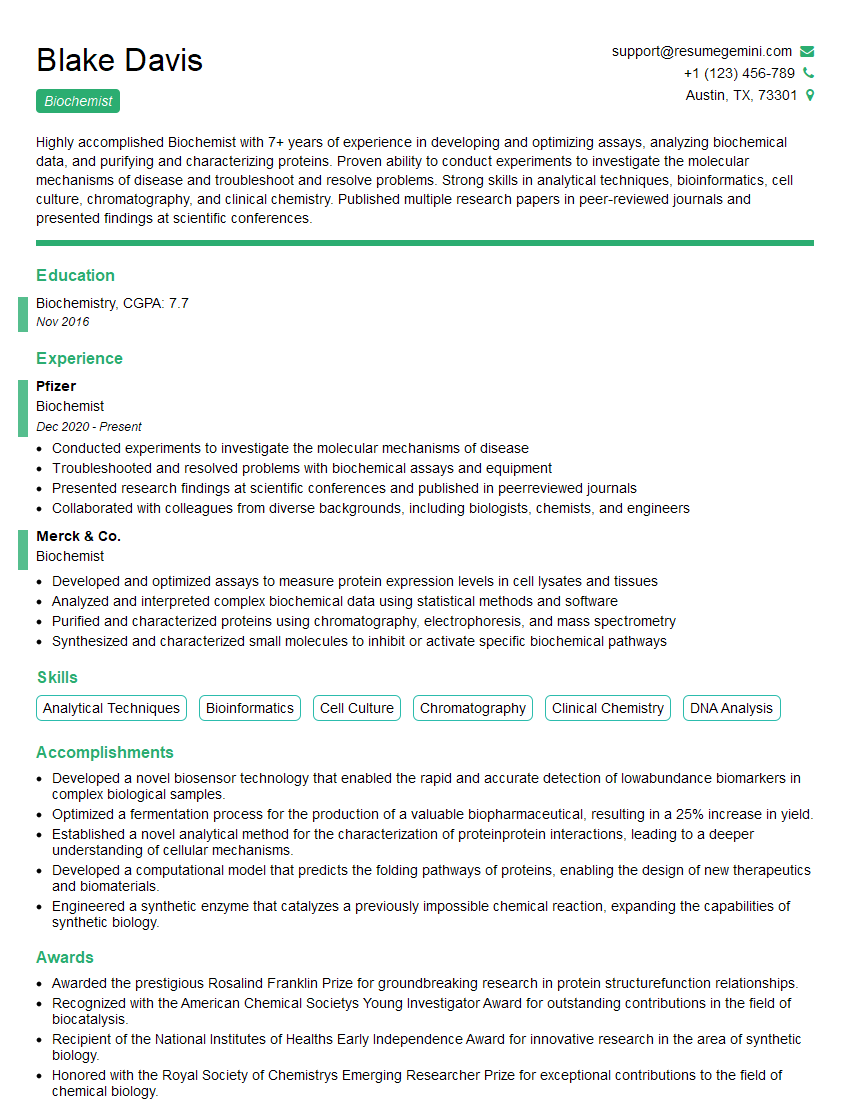

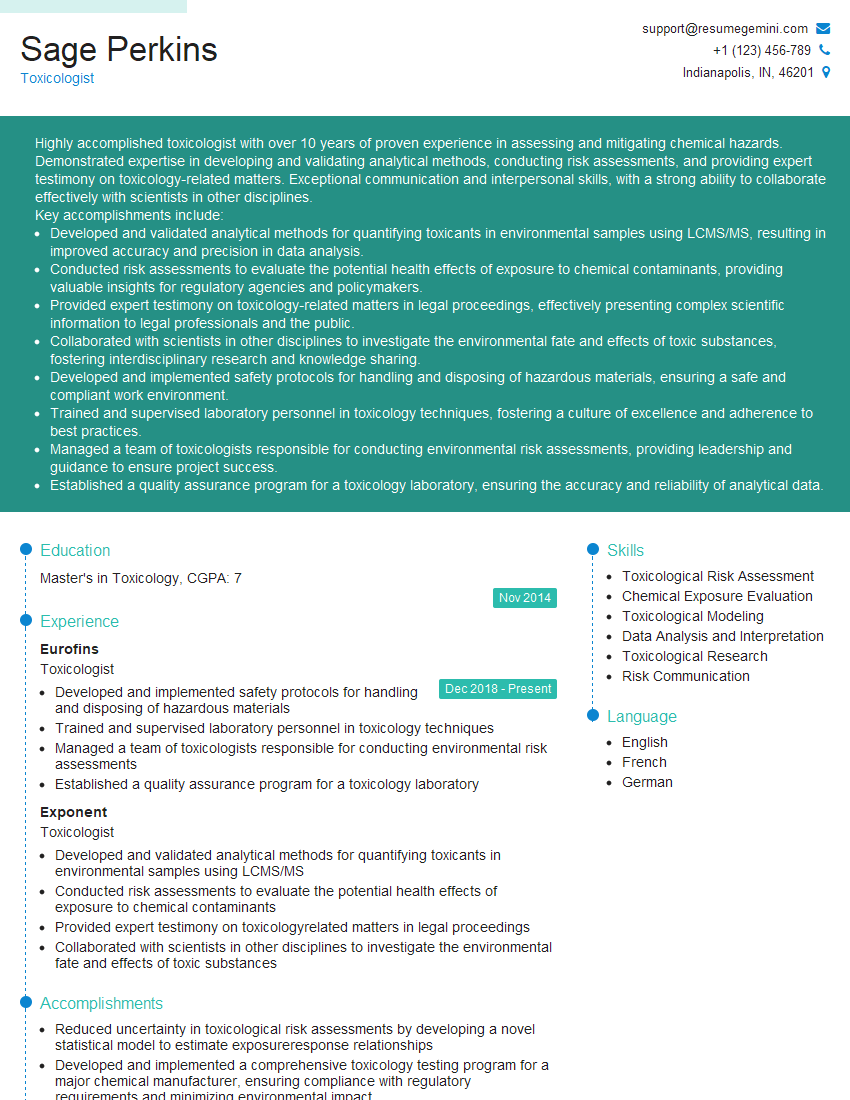

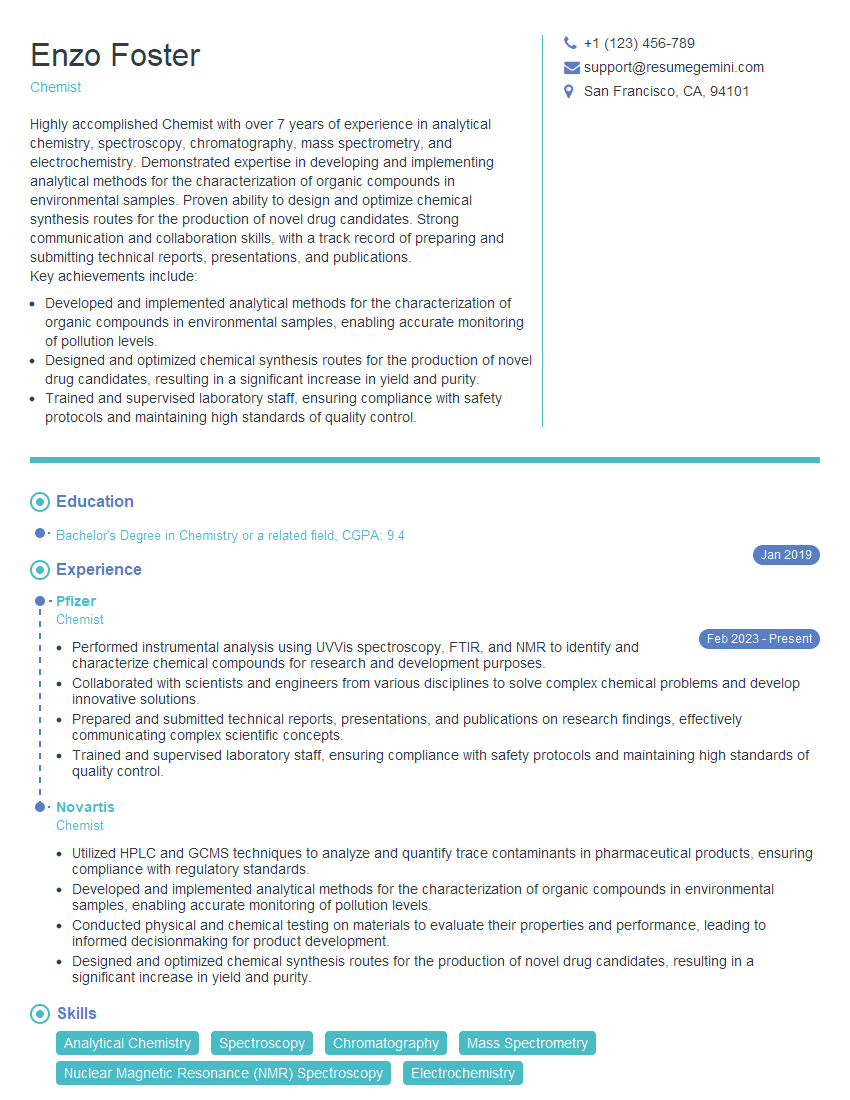

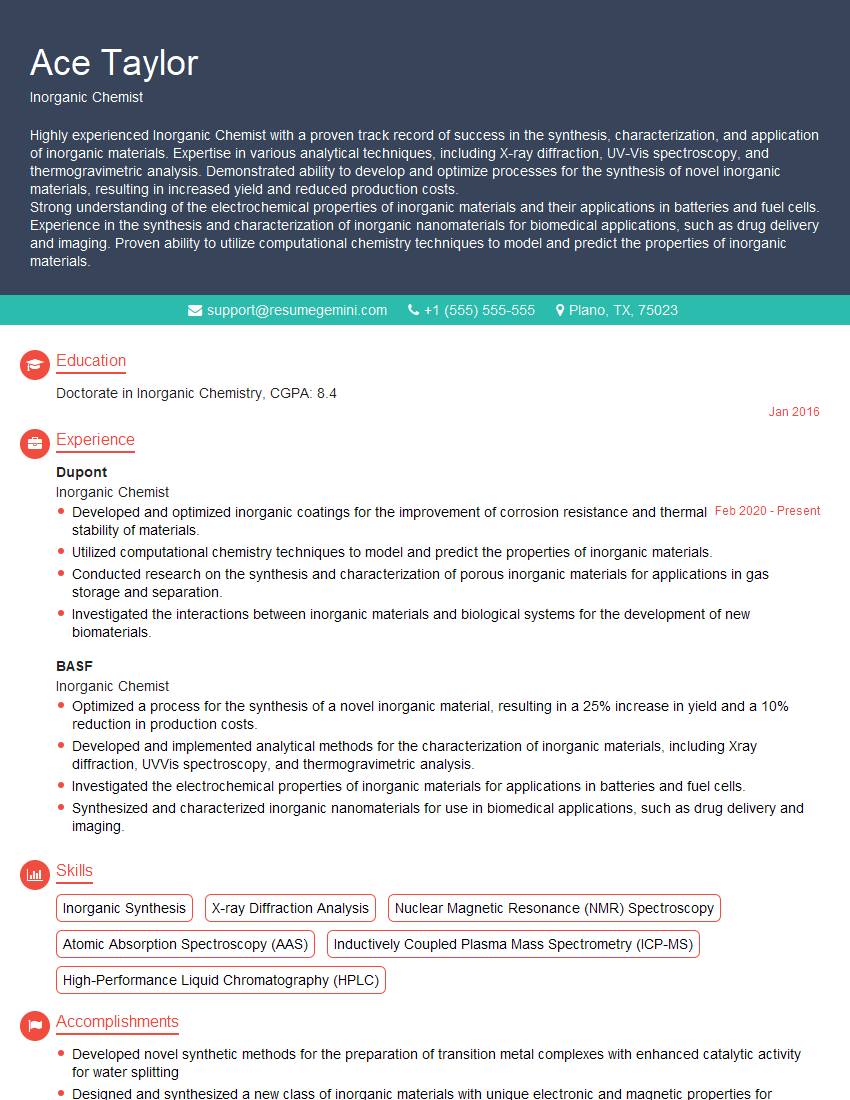

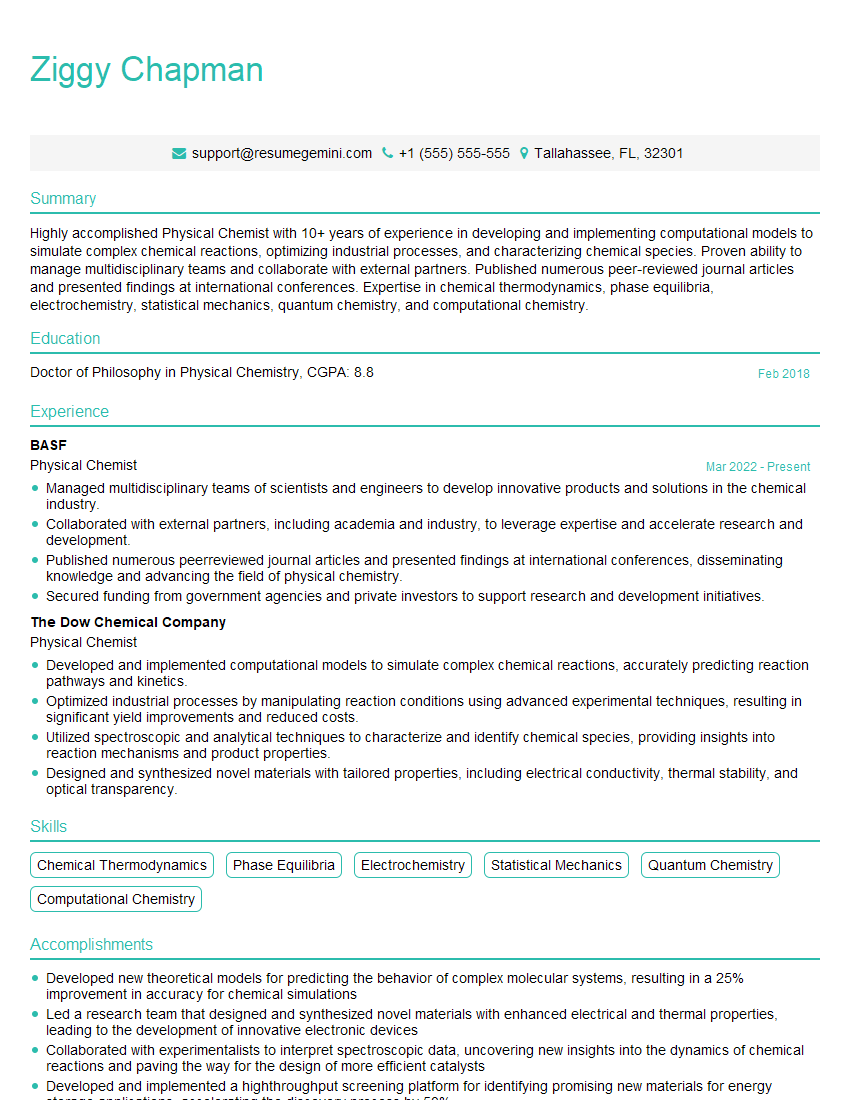

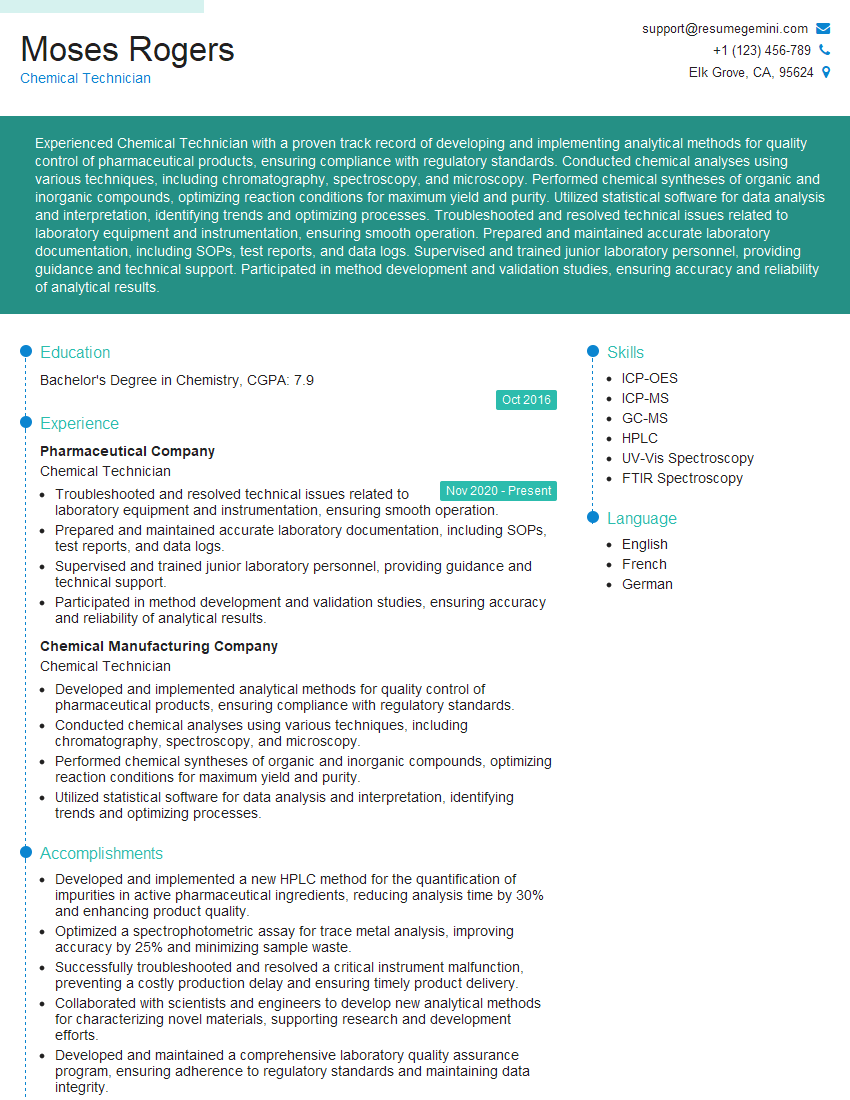

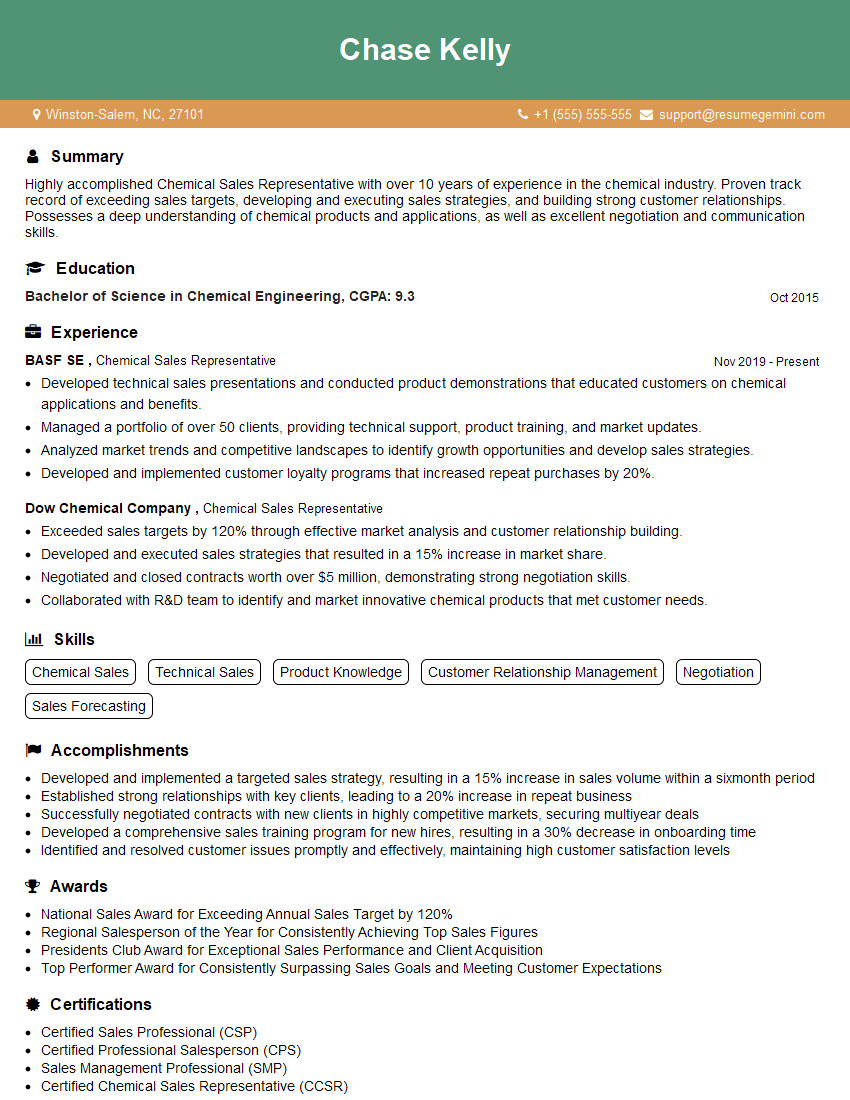

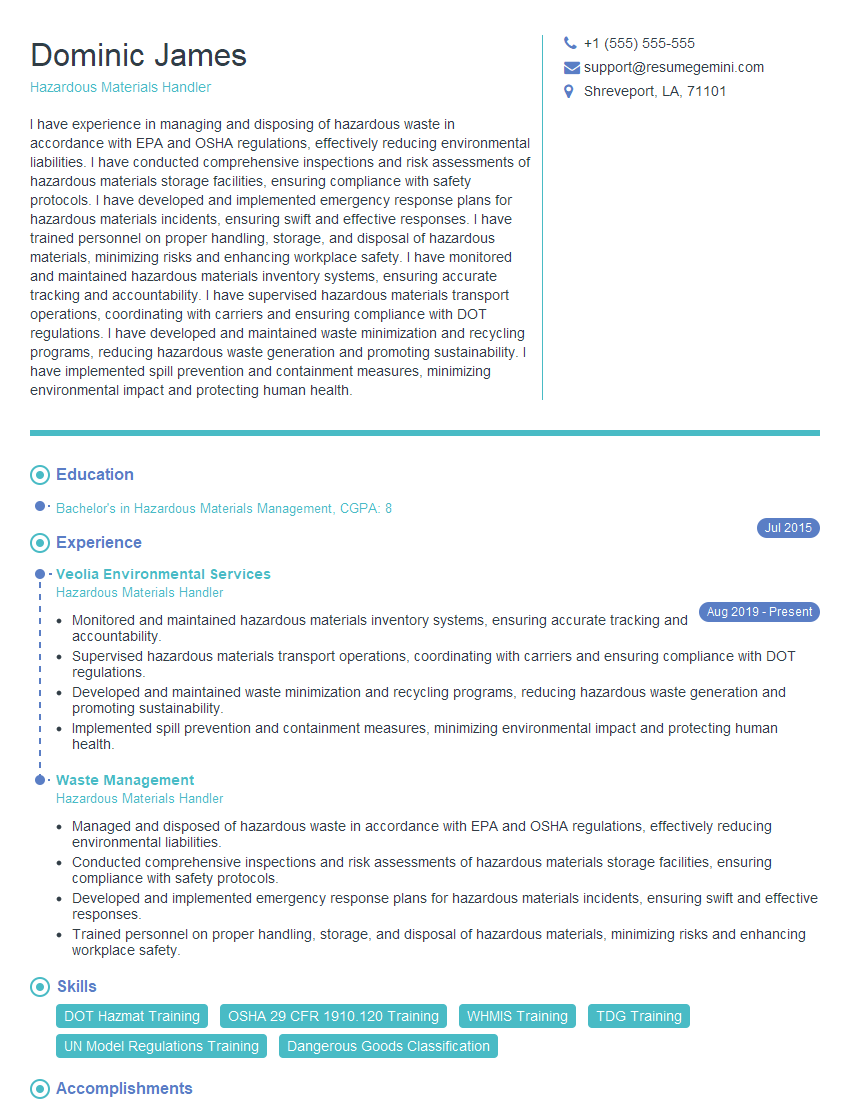

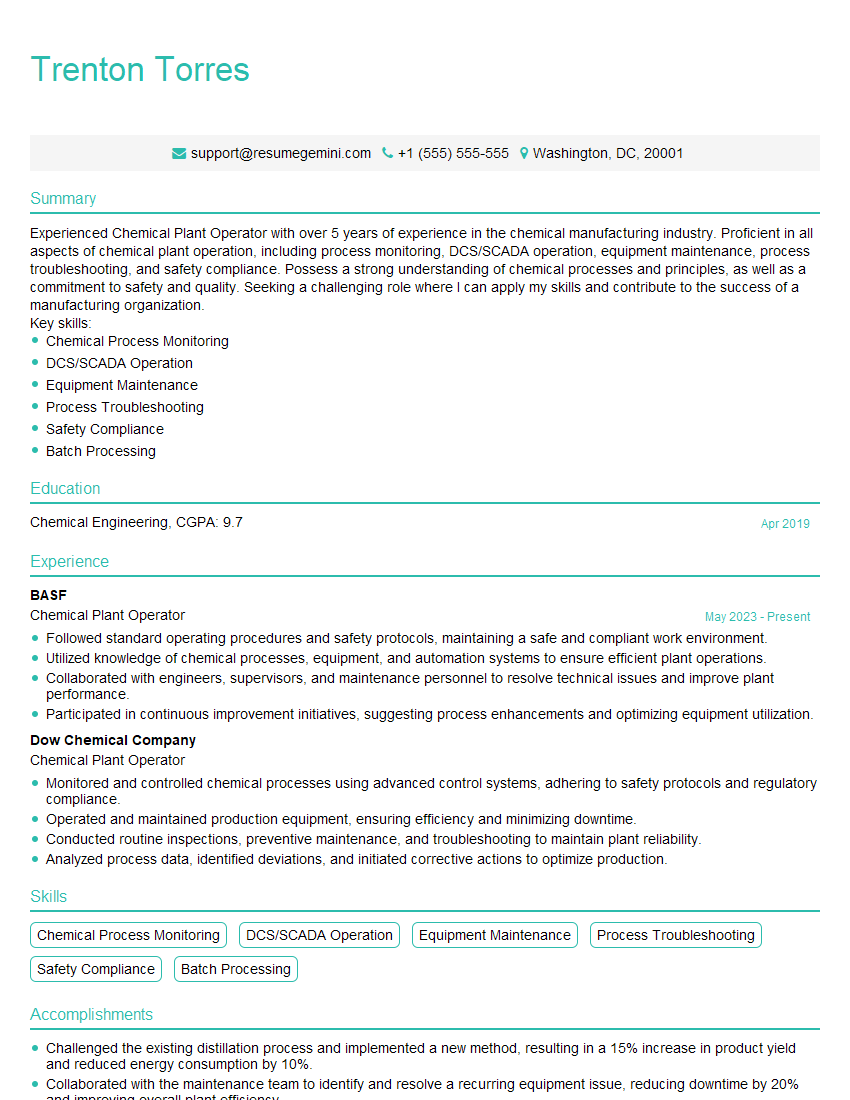

Mastering the ability to work safely and effectively with a variety of chemicals is crucial for career advancement in many scientific and technical fields. It demonstrates a commitment to safety, precision, and a deep understanding of chemical principles. To significantly increase your job prospects, it’s essential to create a resume that highlights these skills effectively and is optimized for Applicant Tracking Systems (ATS). ResumeGemini can help you build a professional, ATS-friendly resume that showcases your expertise. We provide examples of resumes tailored to highlight experience with a variety of chemicals, giving you a head start in crafting your perfect application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good