Unlock your full potential by mastering the most common Abrasive Blast Finishing interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Abrasive Blast Finishing Interview

Q 1. What are the different types of abrasive blasting media and their applications?

Abrasive blasting media selection is crucial for achieving the desired surface finish. The choice depends on the material being blasted, the required surface profile, and the budget. Here are some common types:

- Glass Beads: These produce a very fine, smooth finish, ideal for delicate parts or when preserving the underlying material’s integrity is paramount. Think of cleaning delicate antique glass or preparing surfaces for a high-gloss finish.

- Aluminum Oxide: A versatile and widely used media, aluminum oxide offers a good balance between aggressiveness and finish quality. It’s commonly used for removing rust, paint, and other coatings from steel and other metals. Imagine prepping a steel component for powder coating.

- Steel Grit: A more aggressive media, steel grit is used for heavy-duty cleaning and surface preparation, such as removing heavy rust, mill scale, or old coatings from thick steel structures. This is ideal for preparing surfaces for welding.

- Copper Slag: A relatively inexpensive and durable media, copper slag is useful for removing heavier coatings and creating a rougher surface profile. It’s often used in situations where cost-effectiveness is important.

- Walnut Shell: A softer, environmentally friendly media, walnut shell is often used for deburring, cleaning, and finishing sensitive materials like wood or plastics, avoiding damage. Think of cleaning delicate wooden furniture.

The selection process involves considering the material’s hardness, the desired surface profile, the material’s sensitivity, and environmental impact. Each media type offers a unique trade-off between cleaning aggressiveness and surface finish.

Q 2. Explain the safety procedures involved in abrasive blasting.

Safety is paramount in abrasive blasting. It’s a hazardous operation requiring strict adherence to safety protocols. Key procedures include:

- Respiratory Protection: Abrasive blasting generates substantial dust and potentially harmful particles. Operators must wear appropriate respirators, certified for the specific media being used, to prevent inhalation of harmful substances.

- Eye Protection: Safety glasses or a full-face shield are essential to protect against flying debris and high-velocity particles that could cause serious eye injuries.

- Hearing Protection: The operation is very noisy. Hearing protection, such as earplugs or muffs, is mandatory to prevent noise-induced hearing loss.

- Skin Protection: Protective clothing, including coveralls, gloves, and boots, is necessary to prevent skin irritation or abrasions from the abrasive media or rebounding particles.

- Containment: The blasting area needs to be properly enclosed or shielded to contain the abrasive media and prevent dust from escaping and contaminating the surrounding environment. This might include blast booths or using appropriate enclosures.

- Emergency Procedures: Having a well-defined emergency plan in place, including procedures for dealing with injuries or equipment malfunctions, is essential. Training and regular drills are critical.

- Proper Ventilation: Ensure adequate ventilation to remove dust and fumes, especially in enclosed blasting areas.

Regular safety training and adherence to established safety protocols are essential for minimizing risks and ensuring a safe working environment.

Q 3. Describe the process of surface preparation before abrasive blasting.

Thorough surface preparation before abrasive blasting is crucial for achieving optimal results. It ensures good adhesion of subsequent coatings and maximizes the effectiveness of the blasting process. Steps include:

- Cleaning: Remove loose dirt, debris, grease, and other contaminants from the surface using appropriate methods such as solvent cleaning, brushing, or pressure washing. This ensures the blasting media focuses on the target material.

- Rust Removal (if applicable): If the surface has rust, it may need to be removed manually or using other pre-treatment methods before blasting to avoid embedding rust particles deeper into the material.

- Masking (if needed): Protecting areas that should not be blasted is crucial. Masking tape and other protective materials should be used to cover sensitive parts or surfaces.

- Surface Evaluation: Assessing the surface’s condition helps determine the appropriate abrasive media, pressure, and blasting duration. Knowing the level of contamination or existing surface profiles can prevent problems.

The goal is to provide a clean, consistent surface that’s free from contaminants which could interfere with the abrasive blasting process or compromise the quality of the final finish.

Q 4. How do you determine the appropriate blasting pressure and nozzle size?

Determining the appropriate blasting pressure and nozzle size is a critical aspect of abrasive blasting. It influences the surface profile, cleaning efficiency, and the overall quality of the finished product. Several factors influence this:

- Material Thickness: Thicker materials require higher pressure and potentially larger nozzles to remove heavy coatings or scale.

- Material Type: Different materials have varying sensitivities to blasting pressure. Softer materials require lower pressure to prevent damage.

- Desired Surface Profile: A rough profile requires higher pressure, while a smoother finish needs lower pressure and potentially finer media.

- Abrasive Media: The type of media dictates appropriate pressure; harder media can handle higher pressures.

- Nozzle Distance: The distance between the nozzle and the surface affects pressure distribution. Closer distances deliver more concentrated impact.

Experience and testing are key. Starting with lower pressure and gradually increasing it while monitoring the surface is a safe approach. Too much pressure can damage the material, while insufficient pressure may leave the surface inadequately cleaned. Experimentation and adjusting parameters based on the observed results will lead to the optimal combination of pressure and nozzle size for the specific application.

Q 5. What are the common surface profiles achieved through abrasive blasting?

Abrasive blasting can achieve a wide range of surface profiles, depending on the media, pressure, and blasting technique used. Some common profiles include:

- Smooth Finish: Achieved using fine media like glass beads at lower pressures, ideal for applications where a smooth, even surface is required, such as preparing for painting or polishing.

- Slightly Rough Finish: A slightly textured surface achieved using moderate pressure and a relatively fine media like aluminum oxide. This is suitable for improving adhesion properties for coatings.

- Rough Finish: Created by using coarse media and higher pressure. This is usually for applications that need strong adhesion or increased surface area, like preparing metal for welding.

- Profiled Finish: Specific surface profiles can be achieved by controlling the blasting angle and the media type. This is often used in specialized applications like creating a non-slip surface.

The surface profile is often measured using a surface roughness tester to quantify the achieved texture. Knowing the desired profile helps select the optimal blasting parameters.

Q 6. How do you ensure the quality of the abrasive blasting process?

Ensuring quality in abrasive blasting involves several steps:

- Pre-blasting Inspection: A thorough inspection of the surface before blasting identifies areas needing special attention or masking.

- Process Monitoring: Regularly checking the blasting process—media flow, pressure, and nozzle wear—ensures consistent results.

- Regular Equipment Maintenance: Proper maintenance of blasting equipment is vital for consistent performance and reduces the risk of malfunctions.

- Post-blasting Inspection: A detailed visual and tactile inspection after blasting verifies that the desired surface profile and cleanliness have been achieved. This is often followed by a thorough cleaning to remove blasted media.

- Documentation: Recording process parameters, media type, pressure, and other relevant information is essential for maintaining consistency and troubleshooting issues. This includes documenting surface profile measurements and any issues.

Implementing a robust quality control system, incorporating inspections at each stage, guarantees consistent and high-quality results.

Q 7. What are the potential hazards associated with abrasive blasting and how are they mitigated?

Abrasive blasting presents several potential hazards that must be mitigated:

- Respiratory Hazards: Inhalation of dust and particulate matter can lead to various respiratory illnesses. Mitigation involves using appropriate respirators and ensuring adequate ventilation.

- Eye Injuries: High-velocity particles can cause severe eye injuries. Protection using safety glasses or full-face shields is mandatory.

- Hearing Loss: The high noise levels can lead to hearing damage. Hearing protection is crucial.

- Skin Irritation: Abrasive media and rebounding particles can irritate the skin. Protective clothing is essential.

- Fire Hazards: In some cases, the abrasive media or the materials being blasted can be flammable, requiring special precautions and fire suppression systems.

- Material Damage: Excessive pressure or inappropriate media can damage the surface being blasted.

Mitigation strategies include following strict safety procedures, using appropriate personal protective equipment (PPE), proper containment, and regular equipment maintenance. Comprehensive safety training and a robust safety management system are essential.

Q 8. How do you inspect a surface after abrasive blasting?

Inspecting a surface after abrasive blasting is crucial to ensure the job meets specifications. It’s like a thorough quality check after a deep clean. We use a combination of visual inspection and sometimes specialized tools.

- Visual Inspection: This involves carefully examining the surface for cleanliness, profile (surface roughness), and the presence of any remaining contaminants or imperfections. We’re looking for a consistently clean, uniform surface, free from rust, scale, paint, or other unwanted materials. A flashlight can help highlight shadowed areas where residues might hide.

- Surface Profile Measurement: A surface profile meter or a comparator gauge measures the surface roughness, ensuring it meets the required specifications for the subsequent coating or process. The desired profile depends on the application; a rougher profile provides better adhesion for paint, for instance.

- Testing for Contaminants: We might use specialized tests, such as solvent wipes, to ensure complete removal of contaminants like oil or grease. This is particularly important before applying coatings.

For example, in preparing a steel bridge for repainting, we need to ensure complete removal of rust and old paint to achieve a strong bond for the new coat. A thorough inspection guarantees the longevity and safety of the structure.

Q 9. Describe the different types of abrasive blasting equipment.

Abrasive blasting equipment varies greatly depending on the scale and type of project. Think of it as having different tools for different jobs.

- Pressure Pot Systems: These are commonly used for smaller projects or detailed work. The abrasive is stored in a pressure vessel and propelled by compressed air. They’re versatile and relatively portable.

- Suction Blasting Systems: These systems use a vacuum to recover the abrasive after it impacts the surface. They’re particularly useful for indoor work or when dust control is paramount. Imagine using this in a sensitive electronics factory.

- Vacuum Blasting Systems: Similar to suction blasting but with more aggressive dust collection. Essential for containing hazardous materials.

- Wheel Abrasive Blasters: These systems use a rotating wheel to propel the abrasive. They’re ideal for larger-scale projects and offer higher efficiency but can be less precise for detailed work.

- Automated Systems: Larger industrial operations often use robotic or automated blasting systems for consistent and efficient results. This is common in automotive or aerospace manufacturing.

The choice depends on factors like the size of the job, the type of substrate, environmental considerations, and desired surface finish.

Q 10. Explain the importance of proper ventilation during abrasive blasting.

Proper ventilation during abrasive blasting is paramount for both worker safety and environmental protection. It’s like having a well-ventilated kitchen to prevent smoke buildup; neglecting it has serious consequences.

Abrasive blasting generates significant amounts of dust, which can contain hazardous materials like lead, silica, or heavy metals. Inhaling these materials can lead to severe respiratory illnesses like silicosis. Adequate ventilation removes these airborne particles, preventing exposure to the workers.

Ventilation systems might involve local exhaust ventilation (LEV) systems positioned close to the blasting area, or general ventilation, ensuring adequate air exchange within the entire workspace. The specific requirements depend on factors like the type of abrasive being used, the area being blasted, and local regulations. Using respiratory protection is always mandatory, even with adequate ventilation.

Failure to provide adequate ventilation can lead to serious health problems for workers and environmental pollution.

Q 11. How do you handle different types of substrates during abrasive blasting?

Handling different substrates during abrasive blasting requires careful consideration of their properties and sensitivities. It’s like tailoring your cleaning approach based on the material you’re cleaning—you wouldn’t use the same method for glass as you would for wood.

- Steel: Steel is relatively robust and can handle higher blasting pressures. Careful selection of abrasive media is essential to avoid damage.

- Aluminum: Aluminum is softer and more susceptible to damage. Lower pressures and softer abrasives are usually necessary.

- Concrete: Concrete blasting requires specialized techniques and equipment due to its hardness and potential for creating dust.

- Plastics: Plastics can be easily damaged by blasting. Lower pressures, softer abrasives, and shorter blasting times are vital.

The key is to select the appropriate abrasive media, pressure, and nozzle distance to achieve the desired cleaning level without damaging the substrate. Testing on a small, inconspicuous area before proceeding with the full blast is always a good practice.

Q 12. What are the environmental considerations related to abrasive blasting?

Environmental considerations are paramount in abrasive blasting. It’s about being a responsible steward of our surroundings. The primary environmental concerns involve:

- Air Pollution: Abrasive blasting releases dust into the atmosphere, which can contain hazardous materials. Proper ventilation, dust suppression techniques (like water injection), and the use of appropriate air filters are crucial.

- Water Pollution: If water is used for dust suppression, proper disposal of the wastewater is necessary to prevent contamination of waterways.

- Waste Disposal: Spent abrasive media and any removed contaminants need to be disposed of responsibly, adhering to local regulations and potentially using recycling options.

- Noise Pollution: Abrasive blasting can be noisy. Noise reduction measures may be required, such as using quieter equipment or implementing noise barriers.

Following best practices and adhering to environmental regulations are essential to minimize the impact of abrasive blasting on the environment.

Q 13. How do you select the appropriate abrasive blasting media for a specific application?

Selecting the appropriate abrasive blasting media is crucial for achieving the desired surface finish and avoiding damage to the substrate. It’s like choosing the right tool for the job – a screwdriver for screws, not a hammer.

Factors to consider include:

- Material Hardness: Harder abrasives are better for removing tough contaminants like rust or scale, while softer abrasives are better for delicate substrates.

- Abrasive Shape and Size: Different shapes and sizes of abrasives produce different surface profiles. Angular abrasives create a rougher surface, while rounded abrasives produce a smoother finish.

- Substrate Material: The hardness and sensitivity of the substrate dictate the type of abrasive that can be used without causing damage.

- Desired Surface Finish: The desired roughness or smoothness of the final surface determines the choice of abrasive and blasting parameters.

Common media include glass beads (for a fine finish), aluminum oxide (for general-purpose cleaning), silica sand (for aggressive cleaning), and steel grit (for heavy-duty removal of rust and scale). The selection is a critical step that should be carefully considered for each individual project.

Q 14. What are the signs of a poorly performed abrasive blasting job?

Identifying a poorly performed abrasive blasting job involves looking for inconsistencies and signs of damage or incomplete cleaning. It’s like noticing imperfections in a freshly painted wall – uneven coverage or drips.

- Uneven Surface Finish: A poorly performed job will have inconsistencies in the surface profile, with some areas being too rough or too smooth.

- Incomplete Cleaning: Residual contaminants like rust, paint, or scale may remain on the surface.

- Damage to Substrate: Over-blasting can damage the substrate, leaving pits, gouges, or other imperfections. This is especially true for softer materials like aluminum or plastics.

- Excessive Dust: Poor dust control measures result in excessive dust lingering in the surrounding area.

A poorly performed job can compromise the integrity of the surface and lead to premature failure of subsequent coatings or processes. It’s always best to have a thorough inspection before proceeding with any further work.

Q 15. How do you troubleshoot common problems encountered during abrasive blasting?

Troubleshooting abrasive blasting problems involves a systematic approach. First, identify the issue: is it poor surface preparation, inconsistent blasting, equipment malfunction, or something else? Then, examine the variables involved. This includes the abrasive media (type, size, and age), air pressure, nozzle type and distance, blasting angle, and the substrate material. Let’s consider some examples:

- Problem: Uneven surface finish. Possible causes: Inconsistent air pressure, incorrect nozzle distance, worn nozzle, or improper media selection. Troubleshooting steps: Check air pressure gauge, adjust nozzle distance, inspect and replace nozzle if necessary, and potentially switch to a different abrasive media size or type.

- Problem: Excessive dust generation. Possible causes: Incorrect abrasive media, inadequate dust collection system, or too high air pressure. Troubleshooting steps: Consider a dust-suppressing media, ensure the dust collection system is operating properly (check filters and suction), and reduce air pressure if possible.

- Problem: Damage to the substrate. Possible causes: Too high air pressure, improper nozzle angle, abrasive media that’s too hard or aggressive for the material. Troubleshooting steps: Lower air pressure, adjust the blasting angle to be less direct, and select a softer or finer abrasive media.

Remember to always prioritize safety and wear appropriate PPE during troubleshooting. A methodical approach, coupled with an understanding of the blasting process and equipment, is crucial for effective problem-solving.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the difference between sandblasting and shot blasting.

While both sandblasting and shot blasting are abrasive blasting techniques used to clean, prepare, or finish surfaces, they differ primarily in the abrasive media they use. Sandblasting, as the name suggests, traditionally utilizes sand as the abrasive. However, this is becoming less common due to environmental and health concerns related to silica dust.

Shot blasting, on the other hand, employs metallic abrasives like steel shot, chilled iron grit, or even glass beads. This offers several advantages. Metallic abrasives generally last longer and produce a more consistent surface finish compared to sand. They also generate less dust, making them safer for the operator and the environment. The choice between them depends on the specific application, the substrate material, and the desired surface finish. For instance, steel shot is often preferred for cleaning and preparing steel surfaces for painting or welding, while glass beads are better suited for delicate surfaces where a fine finish is required.

Q 17. What are the different types of blasting nozzles and their uses?

Blasting nozzles come in various shapes and sizes, each designed for specific applications. The nozzle’s design dictates the abrasive flow pattern and the impact intensity. Some common types include:

- Venturi Nozzles: These utilize the Venturi effect to draw in and accelerate the abrasive media. They’re versatile and commonly used for general-purpose blasting.

- Pressure Nozzles: These rely solely on air pressure to propel the abrasive. They offer more control over the blasting intensity and are often preferred for precise work.

- Rotating Nozzles: These nozzles spin, producing a wider and more even blast pattern, improving efficiency and reducing the risk of localized damage.

- Specialized Nozzles: These are designed for specific tasks, such as close-quarter blasting or precise surface profiling. They might have different orifice shapes or sizes to customize the blast pattern.

The choice of nozzle depends on factors like the surface area being blasted, the desired finish, the type of abrasive media, and the air pressure available. For example, a wider nozzle might be used for cleaning large areas quickly, while a smaller, more precise nozzle would be preferred for intricate detail work.

Q 18. How do you maintain and care for abrasive blasting equipment?

Maintaining abrasive blasting equipment is crucial for safety, efficiency, and longevity. Regular maintenance includes:

- Daily checks: Inspect hoses, connections, and nozzles for wear and tear. Check air pressure gauges and ensure proper functionality. Clean the equipment thoroughly after each use.

- Regular cleaning: Clean the blasting cabinet (if applicable), hopper, and air lines regularly to prevent blockages and ensure efficient operation. This involves removing any accumulated abrasive media and dust.

- Nozzle maintenance: Inspect nozzles regularly for wear and tear, and replace worn or damaged nozzles promptly. Worn nozzles can lead to inconsistent blasting, increased media consumption, and reduced efficiency.

- Air filter maintenance: Clean or replace air filters as needed. Clogged filters restrict airflow and can damage the compressor or reduce blasting efficiency.

- Scheduled maintenance: Perform more thorough maintenance checks and potential repairs as per manufacturer’s recommendations. This might include lubrication of moving parts and inspections by a qualified technician.

Proper maintenance not only prolongs the lifespan of your equipment but also ensures consistent performance and minimizes the risk of accidents or equipment failure during operation.

Q 19. Describe the process of cleaning and disposing of abrasive blasting media.

Cleaning and disposing of abrasive blasting media requires careful attention to safety and environmental regulations. The process usually involves these steps:

- Recovery: Recover as much spent abrasive media as possible using a suitable recovery system, such as a cyclone separator or vacuum system. This reduces waste and can often allow for reclamation of the media.

- Cleaning: The recovered media will likely contain dust and debris. This can be removed by using a sieve or other filtration methods. For some media types, this cleaning process may allow for reuse.

- Disposal: Spent abrasive media that cannot be reused must be disposed of properly according to local environmental regulations. This may involve specialized waste disposal services, depending on the type of media used. Proper labeling is essential.

- Dust Control: Throughout the entire process, effective dust control measures should be implemented to minimize airborne dust and protect workers and the environment. This can include water sprays, enclosed systems, and high-efficiency particulate air (HEPA) filtration.

Remember to consult your local environmental regulations for specific guidelines on media disposal and handling.

Q 20. What are the regulations and standards related to abrasive blasting?

Abrasive blasting is subject to various regulations and standards that prioritize worker safety and environmental protection. These regulations vary by location, but common areas of concern include:

- Occupational Safety and Health Administration (OSHA): OSHA guidelines in the US cover aspects such as personal protective equipment (PPE), exposure limits for airborne contaminants, and safe operating procedures.

- Environmental Protection Agency (EPA): The EPA regulates the disposal of waste materials, including spent abrasive media, to prevent environmental contamination.

- Local regulations: Many jurisdictions have specific regulations regarding abrasive blasting, including permits, licensing, and noise limitations.

- Industry Standards: Organizations like the Society for Protective Coatings (SSPC) provide industry best practices and standards for abrasive blasting techniques and surface preparation.

It’s crucial to be aware of and comply with all relevant regulations and standards to ensure legal compliance and responsible operation. Failure to comply can result in penalties and legal ramifications.

Q 21. Explain the importance of personal protective equipment (PPE) in abrasive blasting.

Personal Protective Equipment (PPE) is paramount in abrasive blasting due to the inherent hazards involved. The high-velocity abrasive stream, airborne dust, and noise levels pose significant risks to operators’ health and safety. Essential PPE includes:

- Respiratory protection: A properly fitted air-supplied respirator is essential to prevent inhalation of harmful dust particles. This can be a self-contained breathing apparatus (SCBA) or an air-fed respirator.

- Eye protection: Safety glasses or a full-face shield provide protection against flying debris and abrasive particles.

- Hearing protection: Ear plugs or ear muffs are essential to protect against noise-induced hearing loss.

- Protective clothing: Coveralls or other protective clothing prevent abrasive particles from contacting the skin.

- Gloves: Heavy-duty gloves protect hands from cuts and abrasions.

- Footwear: Steel-toe safety boots protect feet from dropped objects.

The use of appropriate PPE reduces the risks of serious injury and health problems. Regular inspection and maintenance of PPE are also vital to ensure ongoing protection. Never compromise on safety; always use appropriate PPE as required by regulations and best practices.

Q 22. How do you calculate the required amount of abrasive blasting media for a project?

Calculating the required abrasive blasting media is crucial for efficient project management and cost control. It’s not a simple one-size-fits-all calculation; it depends on several key factors. Think of it like baking a cake – you need the right amount of each ingredient for the perfect result. In abrasive blasting, those ‘ingredients’ are surface area, desired profile, material type, and abrasive properties.

Firstly, you need to accurately determine the surface area to be blasted. This might involve using blueprints, laser scanning, or simply meticulous on-site measurements, breaking down complex shapes into smaller, measurable areas. Then, consider the material you’re blasting. Steel will require a different approach and media consumption than softer materials like aluminum. The desired surface profile (roughness) plays a huge role; a rougher finish requires more abrasive. The abrasive’s characteristics—like its size, hardness, and density—also directly impact consumption. A harder, denser media may last longer, reducing overall volume needed. Finally, the efficiency of your blasting equipment will affect the amount used.

A common approach involves using a combination of these factors in an empirically derived formula, often refined through experience and past project data. For example, a simple estimation could be based on square footage per unit weight of abrasive. However, this is a rough guide. More accurate predictions often require specialized software or consultations with experienced blasting contractors who can provide detailed estimates based on project specifications.

Q 23. What are the different methods for measuring surface profile roughness?

Measuring surface profile roughness after abrasive blasting is essential to ensure the quality and conformity to specifications. Several methods exist, each with its strengths and weaknesses. Think of it like checking the texture of a fabric – you might use your hands for a general feel, a magnifying glass for a closer look, or a specialized device for precise measurements.

- Profilometer: This is a precise instrument that uses a stylus to trace the surface profile, creating a 3D representation. It’s the gold standard for precise measurements, providing data like Ra (average roughness), Rz (ten point height), and Ry (maximum peak-to-valley height).

- Surface Comparator (or Roughness Comparator): This device provides a visual comparison of the surface against standardized roughness samples. While less precise than a profilometer, it offers a quick and cost-effective assessment suitable for on-site checks and quality control.

- Replica Technique: This involves making a mold of the blasted surface using a special tape or material, which is then examined under a microscope. This is a useful method for preserving a record of the surface profile.

- Digital Microscopes: Modern digital microscopes with image processing software can provide detailed surface profile analysis. These are becoming increasingly popular due to their ease of use and image sharing capabilities.

The choice of method depends on the required accuracy, budget, and accessibility. For critical aerospace or medical applications, a profilometer is preferred; for simpler projects, a surface comparator might suffice.

Q 24. How do you ensure the consistency of abrasive blasting across a large surface area?

Maintaining consistency in abrasive blasting across large surface areas requires careful planning and execution. It’s like painting a large wall – you wouldn’t expect a uniform finish if you just randomly splashed paint. Several factors contribute to consistent blasting:

- Consistent Abrasive Flow Rate: This is controlled by the blasting equipment. Regular calibration and monitoring are critical to ensure a steady supply of abrasive.

- Uniform Blasting Distance: Maintaining a consistent distance between the nozzle and the surface minimizes variations in intensity. Using specialized equipment that maintains a fixed distance is highly beneficial.

- Controlled Abrasive Pressure: Too much pressure can lead to deep pitting and damage, while too little will result in an insufficient surface profile. Precise pressure regulation is key.

- Proper Nozzle Movement: Overlapping passes are necessary to ensure even coverage. Trained operators with experience and skill are crucial in achieving uniform blasting.

- Regular Media Inspection: The abrasive media degrades over time, affecting its effectiveness. Regular checks and replacement are crucial to maintain consistency.

In large projects, using multiple blasting units simultaneously often becomes necessary. Careful coordination and operator training are essential to ensure all units work in harmony, producing consistent results across the entire area.

Q 25. Describe your experience with different types of abrasive blasting projects.

My experience encompasses a wide range of abrasive blasting projects. I’ve worked on everything from preparing large steel structures for painting (bridges, tanks, ships) to delicate surface restoration of historical artifacts. In the industrial sector, I’ve been involved in projects requiring removal of coatings, rust, and mill scale from various metals and alloys.

One particularly challenging project involved the restoration of a historic clock tower. The delicate nature of the stonework required a very controlled approach, using a specialized low-pressure system and a fine abrasive media to avoid damaging the surface. Conversely, I’ve also worked on massive industrial projects involving the removal of heavy coatings from steel structures using high-pressure, high-volume systems. Each project requires a unique strategy involving media selection, blasting parameters, and safety protocols. This diversity has honed my skills in adaptability and problem-solving.

My experience also includes projects in the aerospace industry, where surface preparation for bonding and other critical operations requires precise control over the surface profile and cleanliness.

Q 26. What are the limitations of abrasive blasting?

While abrasive blasting is a highly effective surface treatment method, it does have limitations. It’s not a one-size-fits-all solution, and understanding these limitations is crucial for successful project planning.

- Material Damage: Improperly controlled blasting can damage the underlying material, leading to pitting, deformation, or even fracturing, especially with brittle materials.

- Environmental Concerns: Abrasive blasting generates dust, which can be hazardous to both human health and the environment. Proper dust control measures are essential.

- Accessibility Limitations: Blasting can be challenging in confined spaces or areas with complex geometries, requiring specialized equipment and expertise.

- Cost Considerations: Abrasive blasting can be a relatively expensive process, particularly for large projects, including media costs, labor, and equipment rental or purchase.

- Surface Profile Control: Achieving precise control of the surface profile can be challenging, requiring experienced operators and careful parameter selection.

It’s important to carefully weigh the advantages and disadvantages before opting for abrasive blasting, considering alternative surface treatment options if necessary.

Q 27. How do you deal with unexpected issues during an abrasive blasting project?

Unexpected issues during abrasive blasting projects are inevitable. My approach involves proactive planning and a systematic problem-solving methodology. Think of it as being prepared for unexpected weather when climbing a mountain – you need contingency plans.

Firstly, I meticulously assess potential risks before commencing the project. This involves reviewing the project specifications, material properties, and environmental conditions. Secondly, I establish a robust communication protocol with the team to quickly identify and address any issues as they arise. Thirdly, I keep a detailed log of the blasting parameters, so that if problems occur, I can analyze the data and identify potential causes.

For example, if unexpected subsurface contamination is discovered during blasting, I’d immediately halt the process, assess the situation, and determine the appropriate course of action. This might involve using a different abrasive media, adjusting blasting parameters, or employing additional surface preparation techniques. The key is a calm, methodical response, prioritizing safety and finding solutions that maintain project quality and schedule.

Q 28. What are your salary expectations for this position?

My salary expectations are commensurate with my experience and skills within the abrasive blasting field. I’m confident that my expertise in project management, safety protocols, and problem-solving makes me a valuable asset. Considering my extensive experience, proven ability to manage complex projects, and consistent track record of delivering high-quality results, I am seeking a competitive salary within the range of [Insert Salary Range Here]. I am open to discussing this further based on the specifics of the position and the company’s compensation structure.

Key Topics to Learn for Abrasive Blast Finishing Interview

- Abrasive Media Selection: Understanding the properties of different abrasive materials (e.g., glass beads, aluminum oxide, steel grit) and their suitability for various substrates and surface finishes. Consider factors like particle size, hardness, and impact on the finished product.

- Blast Equipment Operation and Maintenance: Gaining familiarity with different types of blast equipment (pressure pot, suction blast, centrifugal blast) and their operational procedures. Understanding routine maintenance, troubleshooting common issues, and safety protocols is crucial.

- Surface Preparation Techniques: Mastering the techniques involved in preparing surfaces for abrasive blasting, including masking, cleaning, and pre-treatment methods to achieve optimal results. This includes understanding the importance of surface cleanliness and profile.

- Safety Procedures and Regulations: Demonstrating a thorough understanding of safety regulations and best practices related to abrasive blasting, including personal protective equipment (PPE) usage, ventilation requirements, and waste disposal methods.

- Quality Control and Inspection: Knowing the methods used to inspect and ensure the quality of the abrasive blast finished surfaces. This includes visual inspection, measurement techniques, and understanding industry standards.

- Applications of Abrasive Blasting: Being able to discuss various applications of abrasive blasting across different industries (e.g., automotive, aerospace, construction) and highlighting specific use cases and challenges faced.

- Environmental Considerations: Understanding the environmental impact of abrasive blasting and the measures taken to minimize dust and waste generation, adhering to environmental regulations.

Next Steps

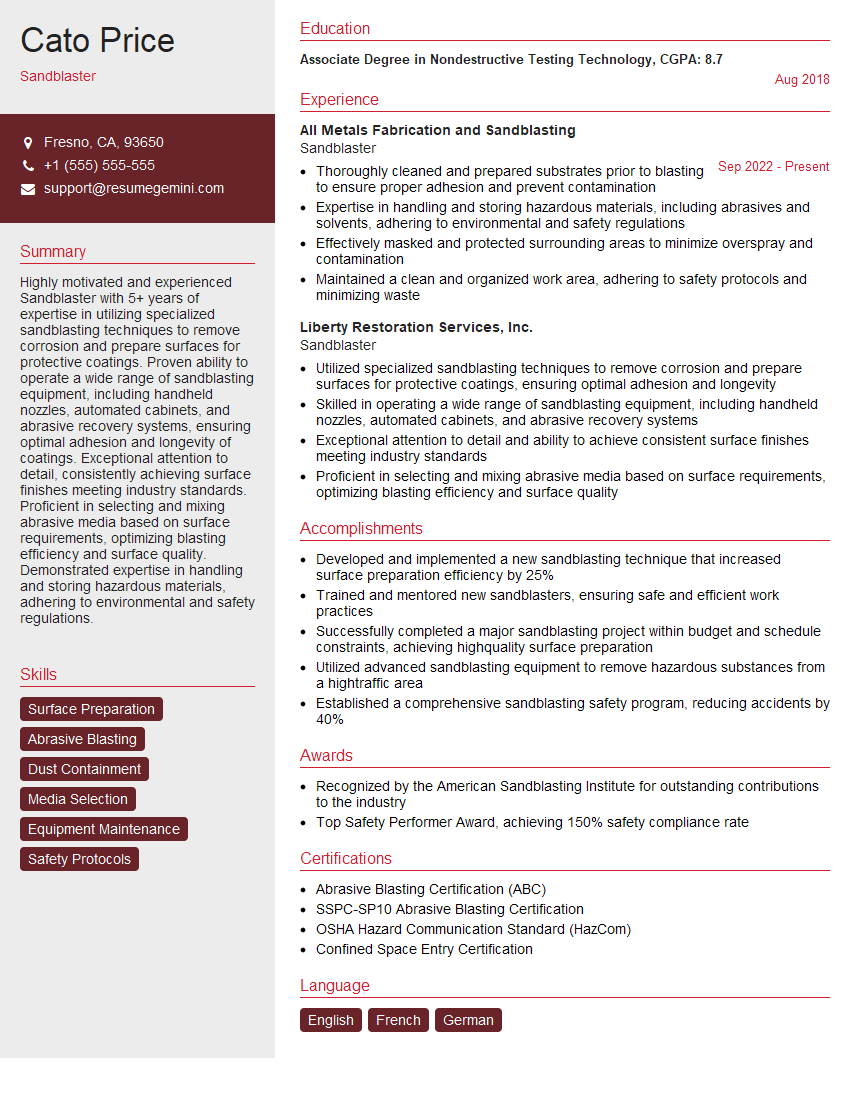

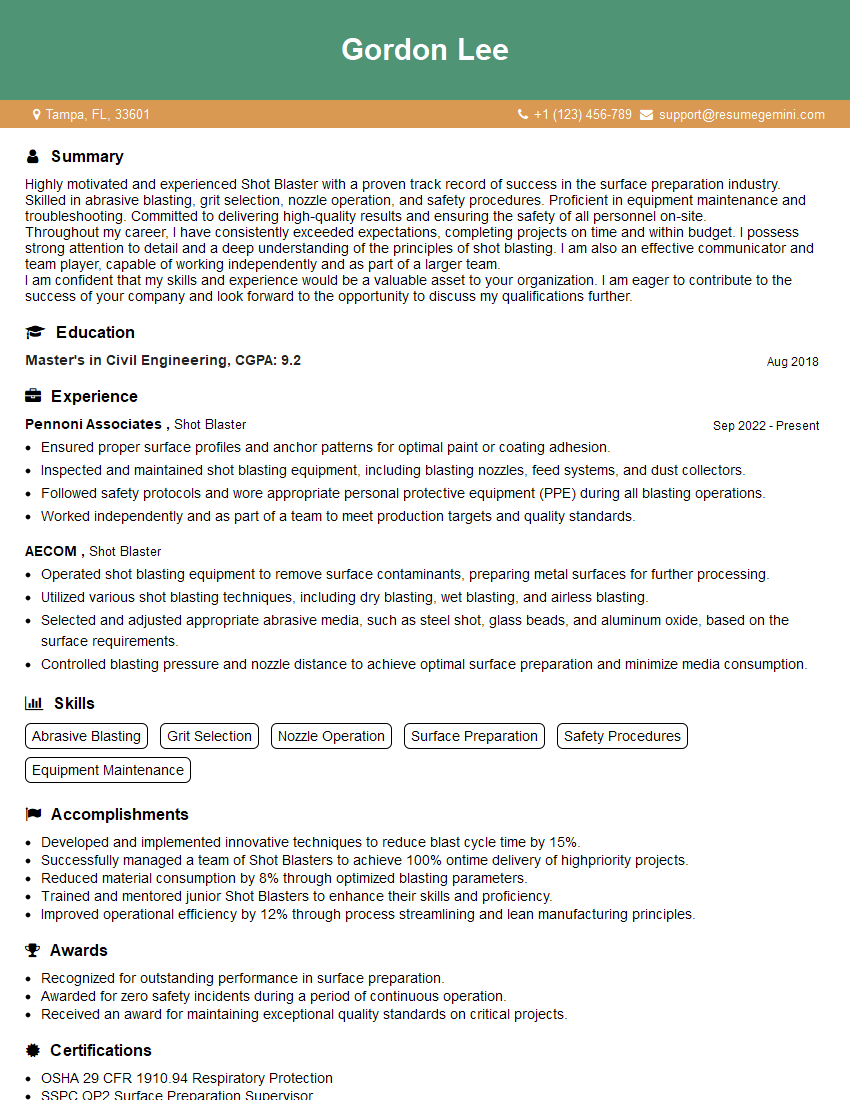

Mastering Abrasive Blast Finishing opens doors to rewarding careers in manufacturing, construction, and various specialized industries. To increase your chances of landing your dream job, a well-crafted resume is essential. An ATS-friendly resume ensures your application gets noticed by recruiters and hiring managers. We recommend using ResumeGemini to build a professional and impactful resume that highlights your skills and experience effectively. ResumeGemini offers examples of resumes tailored to the Abrasive Blast Finishing industry to help guide you. Invest the time to create a strong resume – it’s a crucial step in your job search journey.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good