Unlock your full potential by mastering the most common Adjustment and Calibration of Grinding Parameters interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Adjustment and Calibration of Grinding Parameters Interview

Q 1. Explain the relationship between grinding wheel speed and surface finish.

Grinding wheel speed significantly impacts surface finish. Think of it like sanding wood: a faster speed with finer grit produces a smoother finish, while a slower speed with coarser grit leaves a rougher surface. In grinding, a higher surface speed generally leads to a better surface finish due to increased material removal rate and a more refined cutting action. However, excessively high speeds can lead to burning or glazing of the wheel, degrading the finish. The optimal speed is a balance between achieving the desired finish and preventing wheel damage. For instance, finishing operations often utilize higher speeds with finer grit wheels to achieve a mirror-like finish on a workpiece, whereas roughing operations might employ lower speeds with coarser wheels for rapid stock removal.

Too slow a speed can lead to a chatter-like finish and inefficient material removal. Too fast a speed, conversely, risks burning the workpiece and glazing the grinding wheel. Therefore, careful selection and control of the grinding wheel speed are critical to obtaining the desired surface quality.

Q 2. Describe the different types of grinding wheels and their applications.

Grinding wheels are classified based on their abrasive material, bonding agent, grain size, and structure. The choice of wheel depends heavily on the material being ground and the desired finish. Common types include:

- Aluminum Oxide (Al2O3): Excellent for grinding ferrous metals, cast iron, and high-strength alloys. These wheels are known for their toughness and sharpness.

- Silicon Carbide (SiC): Ideal for grinding non-ferrous metals like aluminum, brass, and bronze, as well as non-metallic materials such as ceramics and stone. They are harder than aluminum oxide but are more brittle.

- CBN (Cubic Boron Nitride): Used for grinding very hard materials like hardened steels, carbides, and ceramics. CBN wheels offer superior wear resistance.

- Diamond: The hardest abrasive, used for grinding very hard materials and for applications requiring exceptionally fine finishes, often used in precision grinding.

The application dictates the wheel choice. For example, a roughing operation on steel might use a coarse aluminum oxide wheel, while a precision finish grinding operation on a hardened steel part would likely use a fine CBN wheel.

Q 3. How do you determine the optimal depth of cut in a grinding operation?

Determining the optimal depth of cut involves balancing material removal rate with surface finish and wheel life. Too deep a cut leads to excessive heat generation, wheel wear, and potential workpiece damage, resulting in a poor surface finish. Too shallow a cut leads to longer grinding times and reduced productivity. The ideal depth is often determined through experimentation and experience, but several factors are important to consider:

- Material properties: Harder materials typically require smaller depth of cuts.

- Grinding wheel characteristics: Coarser wheels can handle deeper cuts.

- Machine capabilities: The machine’s rigidity and power also influence the allowable depth of cut.

- Desired surface finish: Finer finishes necessitate shallower cuts.

A common approach is to start with a conservative depth of cut and gradually increase it until the desired material removal rate is achieved while maintaining an acceptable surface finish and wheel life. Monitoring wheel wear and workpiece temperature are also crucial during the process. In many instances, a series of progressive cuts with decreasing depths is preferable to ensure optimal results.

Q 4. What are the common causes of grinding wheel glazing and how can they be prevented?

Grinding wheel glazing occurs when the abrasive grains become clogged or dulled, resulting in a shiny, glassy surface on the wheel that loses its cutting ability. This can significantly impact the grinding process, leading to poor surface finish and increased wheel wear. Common causes include:

- Incorrect coolant selection or inadequate coolant flow: Coolant helps to flush away debris and prevent glazing.

- Too high a grinding speed: Excessive speed leads to heat build-up, which can soften the bond and dull the abrasive grains.

- Incorrect wheel selection: Using a wheel with too fine a grit for the material or operation can lead to glazing.

- Workpiece material characteristics: Certain materials tend to be more prone to glazing the wheel.

Prevention involves careful selection of coolant and ensuring adequate flow, selecting the correct wheel for the application, maintaining the recommended grinding speed, using proper dressing techniques to sharpen and clean the wheel regularly, and ensuring the workpiece is properly supported and aligned.

Q 5. Explain the importance of coolant selection in grinding.

Coolant plays a vital role in grinding. It’s not just about cooling; it’s about lubrication, chip removal, and preventing wheel glazing. Proper coolant selection and application are crucial for achieving optimal grinding performance. Key functions include:

- Cooling: Reduces heat generated during grinding, preventing workpiece and wheel damage.

- Lubrication: Reduces friction between the wheel and workpiece, improving surface finish.

- Chip removal: Washes away swarf (metal chips) and prevents clogging of the wheel.

- Corrosion prevention: Protects the workpiece from rust and corrosion.

The choice of coolant depends on the material being ground and other factors. Water-based coolants are common, but oils and synthetic fluids are used for specific applications. For example, a soluble oil-water emulsion might be suitable for grinding steel, while a synthetic coolant may be preferred for grinding aluminum to prevent corrosion. Insufficient coolant flow or improper coolant selection is a major cause of wheel glazing and poor surface finish.

Q 6. How do you calibrate a grinding machine’s trueness and runout?

Calibration of a grinding machine’s trueness and runout is essential for ensuring accuracy and preventing damage to both the wheel and the workpiece. Trueness refers to the concentricity of the wheel, while runout measures the radial variation in the wheel’s rotation. Both are checked using dial indicators or electronic measurement systems.

Trueness Calibration: The wheel is rotated, and a dial indicator is used to measure the radial deviation from the center. Any deviation beyond a specified tolerance requires wheel dressing or replacement. This process aims to establish that the wheel spins perfectly concentric with the spindle axis.

Runout Calibration: Runout is measured by fixing the indicator to the machine’s housing or bed and measuring the variation in wheel position across a single revolution. High runout values indicate an imbalance or flaw that necessitates adjustment or repair of the machine’s spindle or wheel mounting system. This is commonly adjusted by using the machine’s truing and balancing functionalities.

Regular calibration, following manufacturer’s instructions, and adherence to specified tolerances are crucial for maintaining the grinding machine’s accuracy and prolonging its service life. Failure to maintain trueness and runout within tolerances results in inconsistent grinding performance, poor surface finish, and increased risk of workpiece or wheel damage.

Q 7. Describe the process of adjusting the wheelhead angle for precision grinding.

Adjusting the wheelhead angle in precision grinding is crucial for achieving specific geometries and angles on the workpiece. This is often done using a swivel mechanism on the grinding machine’s wheelhead. The angle is typically set using a protractor or digital angle gauge, ensuring accurate positioning.

The process involves:

- Determining the required angle: This is based on the design specifications of the workpiece.

- Loosening the wheelhead locking mechanism: Allows for adjustment of the wheelhead angle.

- Precisely positioning the wheelhead: Utilizing a protractor or digital angle gauge to set the desired angle.

- Tightening the locking mechanism: Secures the wheelhead in its adjusted position.

- Verification: Checking the angle with a measuring device to ensure accuracy.

Precise angle adjustment is particularly critical in applications such as sharpening tools, grinding bevel gears, or creating complex profiles. Incorrect angle adjustment will directly lead to inaccurate workpiece geometry, rendering the part unusable or requiring rework. Therefore, careful and precise adjustment is paramount to quality control.

Q 8. How do you compensate for workpiece deflection during grinding?

Workpiece deflection during grinding, caused by the forces exerted during the process, can significantly impact dimensional accuracy. To compensate, we employ several strategies. One common approach is to use a rigid workpiece and fixturing system that minimizes deformation. Think of it like building a sturdy bridge – the stronger the foundation and structure, the less it will bend under pressure. For more flexible materials, we might apply multiple passes with reduced depth of cut, or use a system with adaptive control, which constantly measures and adjusts the grinding parameters to counter the deflection.

Another crucial technique involves optimizing the support structure during grinding. Imagine trying to grind a long, thin rod – the center might sag under its own weight. Supporting it at multiple points prevents this sagging, and thus deflection. Finally, careful selection of grinding wheel parameters, including the type, size and dressing, minimizes the grinding forces themselves, indirectly reducing deflection.

Q 9. What are the key performance indicators (KPIs) you monitor during a grinding operation?

Monitoring key performance indicators (KPIs) is vital for ensuring efficient and high-quality grinding. We typically monitor several metrics, including:

- Surface Finish: Measured using parameters like Ra (average roughness) or Rz (maximum peak-to-valley height), ensuring the surface meets specifications.

- Dimensional Accuracy: Measured using precision instruments (e.g., calipers, micrometers) to verify dimensions are within tolerance. This is crucial for functionality and interchangeability.

- Grinding Wheel Wear: We track wheel wear rate to determine when dressing or replacement is needed. Excessive wear can lead to inconsistent results.

- Material Removal Rate (MRR): This indicator helps optimize the grinding process for speed and efficiency without compromising quality. It’s a balance between speed and precision.

- Power Consumption: Tracking power usage provides insights into the overall grinding efficiency and can highlight potential issues such as wheel imbalance or excessive friction.

- Coolant Temperature: Monitoring coolant temperature prevents overheating, which can lead to burning or dimensional inaccuracies. It ensures optimal grinding conditions are maintained.

Regularly monitoring these KPIs allows for real-time adjustments and prevents defects. It’s like conducting a health check-up on the process.

Q 10. How do you troubleshoot common grinding problems such as chatter and burn?

Chatter and burn are two common grinding problems. Chatter, characterized by a wavy surface finish caused by vibrations, can be tackled by adjusting grinding parameters such as depth of cut, feed rate, and wheel speed. Sometimes, stiffening the workpiece or machine structure helps. It’s similar to tuning a musical instrument – the right balance prevents unwanted vibrations.

Burn, characterized by discoloration and altered surface properties, typically results from excessive heat. Addressing this often involves increasing the coolant flow rate, using a different coolant, or decreasing the grinding parameters (depth of cut and feed rate). Choosing the correct wheel grade also significantly impacts the likelihood of burn.

Troubleshooting requires systematic investigation. We start by carefully observing the workpiece for signs of chatter or burn. Then we adjust the grinding parameters accordingly. If the problem persists, we assess the machine setup, checking wheel condition and workpiece fixturing. Data logging and analysis of the KPIs are also important aspects of systematic troubleshooting.

Q 11. Explain the difference between centerless and cylindrical grinding.

Centerless grinding and cylindrical grinding are both widely used techniques but differ significantly in workpiece handling and setup. In cylindrical grinding, the workpiece rotates on its own axis while the grinding wheel grinds the outer surface. It is akin to sharpening a pencil with a pencil sharpener. The workpiece is rigidly mounted on centers, ensuring concentricity.

Centerless grinding, on the other hand, employs a rotating grinding wheel and a regulating wheel that acts as a work support. The workpiece doesn’t rotate on its own axis but is guided between the two wheels. It’s like grinding a rod continuously passing through two rollers. Centerless grinding is particularly suitable for mass production of small components.

The key difference lies in how the workpiece is held and supported. Cylindrical grinding requires a center-supported workpiece while centerless grinding supports it using contact with wheels only.

Q 12. Describe your experience with different types of grinding fluids (coolants).

My experience encompasses a variety of grinding fluids, each with its own strengths and weaknesses. These fluids are critical for cooling, lubrication, and chip evacuation. I’ve worked with water-based coolants, which are environmentally friendly and cost-effective, and oil-based coolants, offering better lubrication for specific materials. For some applications, synthetic coolants are preferable, offering excellent corrosion protection and longevity. The specific choice depends heavily on the workpiece material, the grinding operation, and environmental considerations.

For instance, when grinding high-temperature alloys, oil-based coolants would be preferred for their superior lubrication and heat transfer capacity. However, for applications requiring more eco-friendly solutions, water-based fluids with appropriate additives can be a viable option. The optimization process involves testing different fluids to determine which provides the best combination of surface finish, dimensional accuracy, and tool life.

Q 13. How do you ensure dimensional accuracy and surface finish tolerances in grinding?

Achieving dimensional accuracy and surface finish tolerances in grinding relies on a combination of careful planning and precise execution. This starts with selecting the appropriate grinding wheel – the type, grain size, and bond influence the surface finish and material removal rate. Precise machine setup is crucial, involving careful alignment of the workpiece and wheel, and ensuring optimal speeds and feeds.

Process control is key. We regularly monitor parameters like wheel wear, coolant flow, and workpiece temperature using sensors and monitoring systems. Real-time adjustments during the process are often necessary to maintain accuracy. Finally, post-grinding inspection using sophisticated measuring equipment, verifying the dimensions and surface finish against the specifications, ensures the quality of the finished product.

Think of it like building a precise watch – every component must be precisely made and assembled, and regular checks are crucial to ensure accuracy.

Q 14. Explain the importance of regular maintenance of grinding equipment.

Regular maintenance of grinding equipment is paramount for ensuring consistent performance, preventing premature wear, and maintaining safety. Neglecting maintenance can lead to inaccurate grinding, increased downtime, and potentially hazardous situations. We implement a preventative maintenance schedule that includes regular checks and lubrication of moving parts, regular cleaning of the machine and coolant system, and timely replacement of worn components like bearings and belts. It’s essential to check the grinding wheel alignment frequently.

Proper maintenance not only extends the life of the equipment but also ensures consistent quality and accuracy of the grinding process. This involves documenting all maintenance activities, keeping track of wear and tear of parts and creating an accurate history of the machine’s operational life. This proactive approach avoids unexpected breakdowns and ensures operational efficiency, much like scheduled car maintenance ensures reliability and longevity.

Q 15. How do you interpret grinding charts and graphs?

Interpreting grinding charts and graphs is crucial for optimizing the grinding process and ensuring consistent results. These charts typically display parameters like surface finish, material removal rate, wheel wear, and power consumption over time or against different grinding parameters (e.g., wheel speed, feed rate, depth of cut).

For example, a graph showing material removal rate against wheel speed might reveal an optimal speed range for maximum efficiency. Similarly, a chart tracking surface roughness versus feed rate can guide adjustments for achieving the desired surface finish. I look for trends and anomalies in these graphs. A sudden drop in material removal rate might indicate wheel glazing or dulling, requiring dressing or replacement. An unexpected spike in power consumption could suggest a problem with the workholding or an improperly adjusted machine parameter.

My approach involves a careful examination of each parameter’s behaviour. I cross-reference data from multiple charts to gain a holistic understanding of the process. For instance, a high material removal rate coupled with excessive wheel wear might indicate that the grinding process is aggressive and needs refinement for better efficiency and wheel longevity.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with different grinding wheel dressing techniques.

I have extensive experience with various grinding wheel dressing techniques, each suited for specific scenarios and wheel types. These techniques aim to restore the sharpness and profile of the grinding wheel by removing worn or glazed material from the wheel surface.

- Diamond dressing: Uses diamond tools, either single-point or multi-point, to quickly remove significant material. This is effective for heavily glazed wheels or when aggressive material removal is needed. I’ve used this on high-speed steel grinding wheels where efficiency is paramount. Precision is key to avoid uneven dressing.

- Crush dressing: Employs a crushing tool to create a more complex, randomly oriented cutting surface on the wheel. It’s suitable for wheels working on softer metals where a sharp and free-cutting surface is critical for reducing burn and generating optimal surface finish.

- Truing: Focuses on correcting the wheel’s shape and profile. I typically use a truing tool to remove small amounts of material to ensure the wheel remains true and concentric. This is particularly important in precision grinding applications where dimensional accuracy is essential. This can involve manual adjustment or sophisticated automated systems.

The choice of technique depends heavily on the material being ground, the wheel type, the desired surface finish, and the level of wheel wear. I always evaluate the condition of the wheel and select the appropriate technique to achieve optimal results and extend wheel life.

Q 17. How do you determine the proper wheel speed for different materials?

Determining the proper wheel speed is crucial for efficient and effective grinding. The optimal speed varies greatly depending on the type of grinding wheel (bond type, abrasive material, grain size) and the material being ground. Too low a speed results in poor material removal and wheel glazing; too high a speed leads to wheel damage, workpiece burning, and surface defects.

Wheel manufacturers typically provide guidelines regarding appropriate operating speeds for their products. However, practical experience and testing often refine these recommendations. I usually start by consulting these guidelines, then conduct trial runs while monitoring wheel wear, surface finish, and material removal rate. I adjust the speed incrementally to find the optimal balance between efficiency and avoiding damage. For example, when grinding hardened steel, I might need to use a lower wheel speed than when grinding softer materials like aluminum.

The concept of surface speed, which is calculated by considering the wheel diameter and rotational speed, is more reliable in determining appropriate speed than RPM alone. Surface Speed = π x diameter x RPM / 60 The goal is to achieve a consistent and optimal surface speed that achieves maximum cutting without causing damage. This process often requires iterative adjustments and monitoring based on real-time observations.

Q 18. What is the importance of workholding in grinding operations?

Workholding is paramount in grinding operations, ensuring the workpiece is securely and accurately positioned to guarantee both safety and a consistent, high-quality finish. Inaccurate workholding leads to inconsistencies in the ground surface, possibly including dimensional errors and surface defects.

The choice of workholding fixture depends heavily on the workpiece’s shape and size, the type of grinding operation, and the desired precision. Examples include magnetic chucks, collets, vises, and specialized fixtures. For delicate or intricate parts, specialized fixtures with precise clamping mechanisms are critical to prevent damage during grinding. I always prioritize secure clamping to prevent workpiece movement and vibration that can lead to surface inconsistencies or even accidents.

Furthermore, proper workholding minimizes the risk of operator injury. A poorly secured workpiece can shift or even fly off during the grinding process, resulting in injury and machine damage. Before starting any grinding operation, I always meticulously inspect the workpiece and the workholding fixture to ensure proper fit and secure clamping. Regular maintenance of the workholding equipment, such as checking for wear or damage, is also critical for consistent performance and safety.

Q 19. How do you select the right type of grinding wheel for a specific material?

Selecting the right grinding wheel is critical for achieving the desired results in grinding. The choice depends on several factors: the material being ground, the desired surface finish, and the material removal rate. Grinding wheels are characterized by various parameters, including abrasive type (e.g., aluminum oxide, silicon carbide), grain size (coarser for rough grinding, finer for finishing), bond type (vitrified, resinoid, etc.), and structure (porosity).

For example, when grinding hardened steel, I would select a wheel with aluminum oxide abrasive, a medium to fine grain size for finishing, and a vitrified bond for good strength and durability. For softer materials like aluminum, I might use a silicon carbide wheel with a resinoid bond which is softer and may be appropriate for high-speed work. I always refer to manufacturer’s charts and guidelines, which usually provide recommendations based on workpiece material and type of grinding operation.

The grain size has a direct impact on the surface finish. A coarser grain produces a rougher surface, while a finer grain yields a smoother finish. The bond type determines how the abrasive grains are held together and affects the wheel’s life and cutting properties. The process typically involves carefully reviewing the characteristics of the available wheels and matching them to the specific requirements of the grinding job.

Q 20. How do you measure and compensate for wheel wear during grinding?

Wheel wear is inevitable during grinding, gradually reducing the wheel’s efficiency and impacting surface finish. Regular monitoring and compensation are necessary to maintain consistent grinding performance. Measuring wheel wear can involve several methods. I might use a dial indicator or a digital caliper to measure the wheel diameter before and after grinding sessions. More sophisticated systems use sensors embedded in the machine to continuously monitor wheel diameter.

Compensation for wheel wear often involves adjustments to the grinding parameters. As the wheel wears, the infeed rate might need to be adjusted to compensate for the reduced cutting ability. The depth of cut may also need adjustment to maintain the desired material removal rate. Automatic compensation systems in modern CNC grinders automatically adjust these parameters based on real-time wheel wear data.

Regular dressing is crucial to maintain the wheel’s profile and sharpness. Dressing helps prevent excessive wear and ensures a consistent surface finish. In some cases, replacing the wheel may be necessary once the wear becomes significant or if the wheel’s profile is irreparably compromised. This is especially common in very high-precision grinding.

Q 21. Explain your experience with different types of grinding machine controls.

My experience encompasses a wide range of grinding machine controls, from simple manual machines to sophisticated CNC (Computer Numerical Control) systems. I’m proficient in operating and programming various controls, understanding their capabilities and limitations.

Manual grinding machines rely heavily on operator skill and judgment. Precise control of feed rates, wheel speed, and depth of cut requires experience and a keen eye for quality. The operator must carefully monitor the grinding process and make manual adjustments to maintain consistent results.

CNC grinding machines offer significantly greater precision and repeatability. They are programmed using CAM (Computer-Aided Manufacturing) software to execute complex grinding operations automatically. This allows for highly accurate control over all grinding parameters and facilitates the production of parts with very tight tolerances. I’m proficient in developing and editing CNC programs, optimizing parameters for efficiency and quality. Understanding the different control systems, including their programming languages and troubleshooting techniques, is key for efficient operation.

Modern CNC controls often include advanced features such as automated wheel dressing, in-process gauging, and adaptive control systems that adjust grinding parameters dynamically to maintain consistent results. My experience extends to troubleshooting issues with these advanced systems, ensuring optimal machine performance and grinding quality.

Q 22. What is your experience with automated grinding systems?

My experience with automated grinding systems spans over ten years, encompassing various CNC (Computer Numerical Control) grinders and robotic systems. I’ve worked extensively with systems utilizing adaptive control algorithms, which automatically adjust grinding parameters based on real-time feedback from sensors monitoring factors like wheel wear, workpiece temperature, and surface finish. For instance, I implemented a system using a laser sensor to measure the workpiece dimensions during grinding, enabling the system to automatically compensate for variations and maintain tight tolerances. This significantly improved the consistency and efficiency of the grinding process compared to manual operation, reducing both scrap and rework.

I’m also proficient in programming and troubleshooting these automated systems, including experience with PLC (Programmable Logic Controller) programming and diagnostic software for identifying and resolving malfunctions. This includes using predictive maintenance techniques based on sensor data analysis to anticipate potential issues before they impact production. A recent project involved optimizing the robot’s path planning for a complex part geometry, resulting in a 15% reduction in grinding time.

Q 23. How do you ensure safety during grinding operations?

Safety is paramount in grinding operations. My approach involves a multi-layered strategy encompassing preventative measures, proactive monitoring, and emergency response protocols. This starts with ensuring all personnel receive thorough training on safe operating procedures, including the use of appropriate personal protective equipment (PPE) such as safety glasses, hearing protection, and respirators. Regular machine inspections are crucial to identify and address potential hazards, such as worn parts or loose connections. We also implement lock-out/tag-out procedures during maintenance to prevent accidental start-ups.

Beyond these preventative measures, the grinding cells are equipped with safety interlocks and emergency stop buttons readily accessible throughout the work area. Furthermore, we use noise and vibration monitoring systems to alert us to potential equipment malfunctions that could compromise safety. Regular safety audits and training refreshers ensure our commitment to safety is ongoing.

Q 24. Describe your experience with statistical process control (SPC) in grinding.

Statistical Process Control (SPC) is fundamental to maintaining consistent quality in grinding. I’ve extensively utilized SPC methods, particularly control charts (X-bar and R charts, for example), to monitor key process parameters such as surface roughness, dimensional accuracy, and roundness. By tracking these parameters over time, we can identify trends, detect process shifts, and prevent defects before they become widespread.

For example, I implemented an SPC system to monitor the surface roughness of a particular component. Using X-bar and R charts, we identified a subtle increase in variability indicating potential issues with the grinding wheel dressing process. This allowed us to address the root cause proactively, preventing the production of a large number of non-conforming parts. The use of SPC charts not only helps to prevent problems but also provides valuable data for continuous improvement initiatives.

Q 25. How do you handle non-conforming parts produced during grinding?

Handling non-conforming parts involves a systematic approach beginning with thorough investigation and classification of the defect. This investigation includes examining the part for the root cause using techniques such as visual inspection, measurement using CMM (Coordinate Measuring Machine), and material analysis. We meticulously document all findings.

Depending on the severity and root cause, we may implement corrective actions ranging from minor adjustments to the grinding parameters to complete process recalibration or even machine repair. If the defects are minor and rectifiable, rework may be considered. However, if the defects are beyond repair or if the root cause is systemic, the parts are scrapped, and the issue is addressed to prevent recurrence. The scrapped parts are carefully tracked and analyzed to inform continuous improvement efforts. The entire process is documented following established quality management system procedures.

Q 26. Explain your experience with root cause analysis of grinding process failures.

Root cause analysis (RCA) of grinding process failures is crucial to prevent recurrence. I regularly employ various RCA techniques, including the 5 Whys, fishbone diagrams (Ishikawa diagrams), and fault tree analysis. The 5 Whys method is particularly useful for simple failures, whereas complex failures often benefit from a more structured approach like the fishbone diagram, which helps to brainstorm and categorize potential contributing factors.

For instance, during the production of precision bearings, we experienced a sudden increase in out-of-round parts. Using the fishbone diagram, we identified several potential contributing factors, including wheel wear, improper dressing, insufficient coolant flow, and machine vibration. By systematically investigating each factor, we pinpointed the root cause to be excessive vibration due to a worn bearing in the grinding machine. Addressing this issue immediately resolved the problem and prevented further production of non-conforming parts.

Q 27. Describe a time you had to troubleshoot a complex grinding problem.

One particularly challenging situation involved a complex grinding operation on a titanium alloy component requiring extremely tight tolerances. We were experiencing inconsistent surface finish and frequent tool breakage. Initial troubleshooting focused on parameters such as wheel speed, feed rate, and depth of cut, but the problem persisted.

Using a combination of process monitoring tools and data analysis, we discovered that subtle variations in the workpiece’s microstructure were causing unexpected stresses during grinding. By adjusting the grinding fluid and optimizing the coolant flow to better manage heat generation, we significantly improved the surface finish and reduced tool breakage. This case highlighted the importance of understanding the interaction between material properties, grinding parameters, and process control in achieving optimal results.

Q 28. How do you stay current with advancements in grinding technology?

Staying current with advancements in grinding technology is crucial. I achieve this through a multi-faceted approach. I regularly attend industry conferences and workshops, participate in professional organizations like SME (Society of Manufacturing Engineers), and actively read industry journals and publications.

Furthermore, I leverage online resources, such as manufacturers’ websites and technical articles, to keep abreast of new equipment and technologies. I also actively seek out training opportunities on new software and control systems, and I collaborate with colleagues and experts within the field to exchange knowledge and experiences. Continuous learning is vital for maintaining expertise in this rapidly evolving field.

Key Topics to Learn for Adjustment and Calibration of Grinding Parameters Interview

- Understanding Grinding Wheel Characteristics: Explore different wheel types (bonded abrasives, etc.), their impact on surface finish, and how to select the appropriate wheel for a given material and application. Consider factors like grit size, bond type, and structure.

- Grinding Process Variables: Master the influence of parameters like workpiece speed, wheel speed, feed rate, depth of cut, and coolant application on the final product’s quality and efficiency. Understand the interplay between these variables and how adjustments affect surface finish, dimensional accuracy, and material removal rate.

- Calibration Techniques: Familiarize yourself with various calibration methods used to ensure accuracy and consistency in grinding operations. This includes understanding the use of precision measuring instruments and the application of statistical process control (SPC) techniques.

- Troubleshooting Common Grinding Issues: Prepare to discuss practical problem-solving approaches. Learn how to identify and rectify issues like chatter, burning, glazing, and surface imperfections. This includes understanding the root causes and implementing corrective actions.

- Safety Procedures and Regulations: Demonstrate your awareness of safety protocols associated with grinding operations, including personal protective equipment (PPE) usage and machine guarding best practices.

- Advanced Grinding Techniques: Explore more specialized techniques such as creep feed grinding, centerless grinding, or cylindrical grinding, depending on the specific job requirements. Show your willingness to learn and adapt to new methodologies.

- Data Analysis and Interpretation: Be prepared to discuss how data from grinding processes (e.g., surface roughness measurements, dimensional tolerances) is collected, analyzed, and used to improve efficiency and quality. Show your understanding of statistical analysis and its application to process optimization.

Next Steps

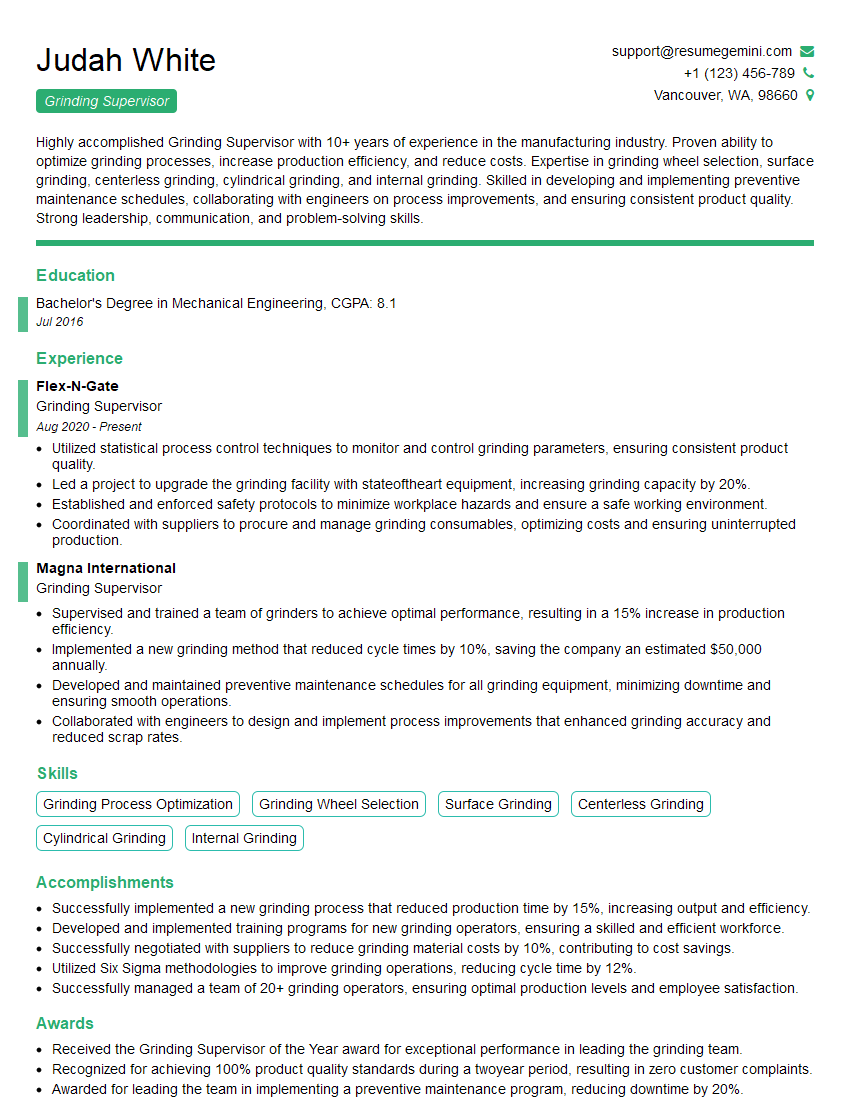

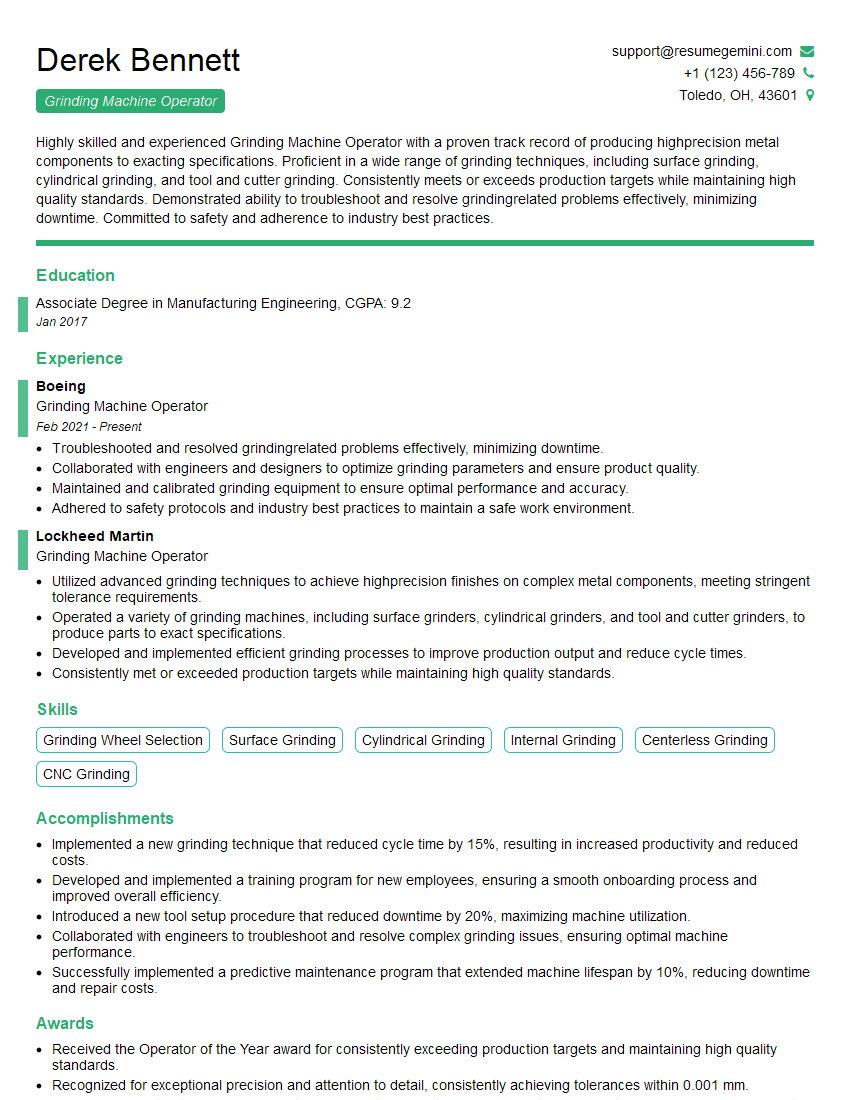

Mastering Adjustment and Calibration of Grinding Parameters is crucial for career advancement in manufacturing and precision engineering. It demonstrates a high level of technical skill and problem-solving ability, opening doors to more challenging and rewarding roles. To significantly boost your job prospects, invest time in creating a strong, ATS-friendly resume that showcases your expertise. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. We offer examples of resumes tailored to Adjustment and Calibration of Grinding Parameters to guide you. Use these resources to present your skills and experience effectively and land your dream job!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good