Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Advanced CNC Machine Operation interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Advanced CNC Machine Operation Interview

Q 1. Explain the difference between G-code and M-code.

G-code and M-code are both essential parts of the language CNC machines understand, but they serve distinct purposes. Think of it like a recipe: G-code tells the machine what to do (movements, speeds, feeds), while M-code tells it how to do it (turning on the spindle, activating coolant, etc.).

G-code (Preparatory Codes): These codes define the geometry of the part. For example,

G01 X10 Y20 F50moves the tool linearly to coordinates X10, Y20 at a feed rate of 50 units per minute. Different G-codes control various movements like rapid positioning (G00), circular interpolation (G02/G03), and more. They are the backbone of the machining process, dictating the toolpath.M-code (Miscellaneous Codes): These codes control auxiliary functions.

M03 S1000starts the spindle at 1000 RPM.M05stops the spindle.M30signifies the end of the program. They manage the machine’s operational states, ensuring the machining process runs smoothly and safely.

In essence, G-code creates the shape, while M-code manages the machine’s actions during the shaping process. They work together seamlessly to create the final part.

Q 2. Describe your experience with various CNC machine types (e.g., mills, lathes, routers).

My experience spans a wide range of CNC machine types, including 3-axis and 5-axis vertical mills, horizontal lathes (both chucking and bar-fed), and CNC routers. I’ve worked extensively with machines from various manufacturers, such as Haas, Fanuc, and Okuma, allowing me to develop a strong understanding of their unique characteristics and capabilities.

Mills: I’m proficient in programming and operating both 3-axis and 5-axis vertical milling machines. My experience includes complex milling operations like pocketing, contouring, and surface finishing, demanding precision and knowledge of toolpath optimization strategies. I’ve worked on projects ranging from simple prototypes to intricate molds and fixtures.

Lathes: My lathe experience includes both chucking and bar-feeding operations on horizontal lathes. I’m skilled in turning, facing, boring, threading, and parting off operations. I understand the importance of selecting appropriate cutting tools and parameters based on material properties and desired surface finish.

Routers: I’ve worked with CNC routers for applications such as woodworking, sign making, and prototyping. This experience has sharpened my skills in programming complex 2D and 3D profiles, material selection, and bit optimization for diverse materials like wood, plastics, and composites.

This diverse experience gives me a comprehensive understanding of CNC machining principles and allows me to adapt quickly to new machine types and applications.

Q 3. How do you troubleshoot common CNC machine errors?

Troubleshooting CNC machine errors requires a systematic approach. I typically follow these steps:

Safety First: Always prioritize safety. Turn off the machine and lock out/tag out power before attempting any repairs.

Identify the Error: Examine the machine’s error messages, alarm codes, and any visual indicators (e.g., flashing lights, unusual noises). Machine manuals are invaluable resources at this stage.

Check the Obvious: Look for simple issues like tool breakage, insufficient coolant, or loose connections. These are often overlooked but can be the root cause.

Review the Program: Analyze the G-code and M-code for errors like incorrect coordinates, missing commands, or feed rate issues. Simulation software can help in this step.

Examine Workholding: Ensure the workpiece is securely clamped and that the workholding system itself is functioning correctly. A loose workpiece can cause significant problems.

Test Components: If the problem persists, it might be necessary to test individual components like limit switches, encoders, and motors to isolate the faulty part. A multimeter can be helpful here.

Seek Expert Assistance: If the problem remains unresolved after exhausting these steps, it’s best to contact qualified technicians or the machine manufacturer for support.

For example, if a machine displays a “Spindle Overload” error, I’d first check the program for excessive cutting parameters. If those are fine, I’d then inspect the spindle motor itself, checking for issues with the drive system or bearings. Documenting each step and finding the root cause rather than just treating symptoms is key to efficient troubleshooting.

Q 4. What are your preferred methods for setting up and verifying a CNC program?

Setting up and verifying a CNC program is crucial to ensure accurate and efficient machining. My preferred methods involve a combination of simulation and physical verification:

Program Simulation: I use CAM (Computer-Aided Manufacturing) software to simulate the toolpath before running the program on the machine. This allows me to identify potential collisions, toolpath errors, and other problems without risking damage to the machine or workpiece.

Dry Run: After simulation, I perform a dry run on the machine. This involves running the program without activating the spindle or coolant. This verifies the machine’s movement and ensures the toolpath is correct. I always use a visual inspection and may even use a dial indicator to confirm positioning.

Test Cut: Finally, I conduct a test cut on a scrap piece of the same material. This confirms cutting parameters, tool engagement, and surface finish. Any adjustments to the program or parameters are made based on this test cut.

Tool Verification: Accurate tool length and diameter offset setup is essential. I use a variety of methods to ensure accuracy, including tool setters, pre-setting machines, and edge finders, depending on the machine’s capabilities.

This multi-stage approach minimizes errors, maximizes efficiency, and ensures the final part meets the required specifications. It’s a proactive approach, preventing expensive mistakes and downtime.

Q 5. Explain the concept of workholding and its importance in CNC machining.

Workholding is the system used to securely clamp or otherwise restrain the workpiece during CNC machining. Its importance cannot be overstated; it directly impacts the accuracy, efficiency, and safety of the machining process.

Poor workholding can lead to:

Inaccurate Machining: A workpiece that moves during machining will produce a part that is out of tolerance.

Tool Breakage: If the workpiece shifts, it can cause the tool to deflect or even break.

Machine Damage: Excessive forces from a poorly held workpiece can damage the machine’s components.

Safety Hazards: A poorly secured workpiece can be dangerous, potentially causing injury.

Selecting the appropriate workholding method depends on the part’s geometry, material, and the machining operation. Common methods include:

Vices: Suitable for smaller, simpler parts.

Chucks: Used primarily on lathes for rotational machining.

Fixtures: Custom-designed for complex parts to ensure precise and repeatable clamping.

Vacuum Chucks: Suitable for holding flat or slightly curved workpieces.

Proper workholding is not merely a matter of clamping down hard; it requires a thorough understanding of clamping forces, workpiece stability, and potential for deflection.

Q 6. How do you ensure dimensional accuracy and tolerances in CNC machining?

Ensuring dimensional accuracy and tolerances in CNC machining requires attention to detail at every stage of the process. This begins with the design and extends to the final inspection.

Accurate CAD Modeling: The design process starts with accurate CAD modeling, specifying precise dimensions and tolerances. This is the foundation for all subsequent steps.

Precise CAM Programming: The CAM software needs to be configured correctly to accurately translate the CAD model into a toolpath that adheres to the specified tolerances. This includes careful selection of cutting tools and speeds, feeds, and depths of cut.

Regular Machine Maintenance: A well-maintained machine is crucial. Regular calibration, lubrication, and inspection of critical components ensures the machine’s accuracy. Ball screw backlash, for example, can accumulate errors over time.

Proper Workholding: As discussed earlier, secure and stable workholding is paramount for maintaining accuracy throughout the machining process. Rigidity is crucial to prevent deflection.

Tool Management: Accurate tool length and diameter compensation is essential. Regular tool pre-setting and verification are crucial to prevent accumulated errors.

Post-Process Inspection: After machining, thorough inspection using precision measuring instruments (e.g., CMMs, calipers, micrometers) is critical to ensure that the final part conforms to the specified tolerances.

Dimensional accuracy is a cumulative effect. Each step must be carefully executed to minimize errors and achieve the desired tolerances. Regular checks and adherence to best practices are paramount in this pursuit.

Q 7. Describe your experience with different cutting tools and their applications.

My experience encompasses a wide variety of cutting tools, each suited to specific materials and machining operations.

End Mills: Used for milling operations, end mills come in various designs (ball nose, square, bull nose) to create different surface finishes and geometries. Material selection (carbide, high-speed steel) depends on the material being machined and the required tool life.

Drills: Used for creating holes, drills are selected based on hole size, material, and desired surface finish. Twist drills are common, but specialized drills exist for various applications.

Turning Tools: Used on lathes, these tools include various inserts (carbide, ceramic) for different operations such as turning, facing, and boring. The geometry of the insert affects the surface finish and cutting forces.

Routers Bits: Used for woodworking and other applications, router bits come in a wide variety of profiles and materials (carbide, high-speed steel). The bit selection greatly impacts the quality of the finished product.

Specialized Tools: This category includes tools like reamers, taps, and dies used for more specialized machining operations. Selecting the appropriate tool is essential to achieving the required tolerances and surface finish.

Selecting the right cutting tool is crucial. The wrong tool can lead to poor surface finish, tool breakage, or even machine damage. I consider factors like material hardness, required surface finish, machining operation, and available cutting parameters to make the optimal choice.

Q 8. How do you calculate cutting speeds and feeds?

Calculating cutting speeds and feeds is crucial for efficient and safe CNC machining. It involves determining the optimal rotational speed of the cutting tool (Spindle Speed) and the rate at which the tool advances into the workpiece (Feed Rate). These values are interdependent and influence factors like surface finish, tool life, and machining time.

Spindle Speed (S): This is typically expressed in revolutions per minute (RPM). The formula is:

S = (1000 * V) / (π * D)Where:

S= Spindle speed (RPM)V= Cutting speed (m/min or ft/min – choose a consistent unit)π= Pi (approximately 3.14159)D= Cutter diameter (mm or inches – consistent withV)

The cutting speed (V) depends on the material being machined and the cutting tool material. These values are often found in manufacturer’s cutting data sheets.

Feed Rate (F): This represents the rate at which the tool advances into the material. It’s typically expressed in mm/rev (millimeters per revolution) or mm/min (millimeters per minute) for milling and in mm/rev for turning. The optimal feed rate depends on factors like the material, cutting tool geometry, depth of cut, and desired surface finish. Lower feed rates yield better surface finishes but increase machining time. Higher feed rates can reduce machining time but may lead to premature tool wear or damage. Manufacturers’ data sheets are your best resource here.

Example: Let’s say we’re machining aluminum with a 10mm diameter carbide end mill. The recommended cutting speed for this combination is 150 m/min. Using the formula:

S = (1000 * 150) / (π * 10) ≈ 4775 RPMWe would then select an appropriate feed rate from the manufacturer’s data sheet considering the depth of cut and desired surface finish.

Q 9. Explain the importance of proper lubrication and coolant usage in CNC machining.

Proper lubrication and coolant usage are paramount in CNC machining for several key reasons:

- Heat dissipation: Machining generates significant heat. Coolant helps to remove this heat, preventing tool wear, workpiece distortion, and potential machine damage. Think of it like a radiator for your CNC machine.

- Lubrication: Coolant acts as a lubricant, reducing friction between the cutting tool and the workpiece. This minimizes wear on the cutting tool, improves surface finish, and extends tool life. This is particularly crucial for harder materials.

- Chip evacuation: Coolant flushes away chips, preventing them from clogging the cutting area. This ensures consistent cutting and helps avoid damage to the workpiece or the cutting tool.

- Improved surface finish: The lubricating and cooling effects of the coolant contribute to a smoother surface finish.

The type of coolant used depends on the material being machined. Water-based coolants are common for many applications, while oil-based coolants might be needed for certain materials or operations. Selecting the wrong coolant can lead to corrosion, poor surface finish, or even fire hazards. Always refer to the material and tool manufacturer’s recommendations.

Practical Example: When machining stainless steel, a soluble oil coolant is often preferred due to its superior lubricating properties and ability to prevent built-up edge on the cutting tool.

Q 10. Describe your experience with various CNC control systems.

I have extensive experience with various CNC control systems, including Fanuc, Siemens, and Heidenhain. My experience spans both traditional conversational programming and more advanced ladder logic and PLC programming (for Fanuc and Siemens).

My proficiency with Fanuc systems includes programming using G-code and M-code, utilizing macro programming to automate complex tasks, and troubleshooting system errors. With Siemens, I’m proficient in ShopMill and ShopTurn programming environments. My experience with Heidenhain involves their user-friendly TNC controls, known for their intuitive interface and ease of use, particularly on milling machines.

I’m comfortable working with different control panels, understanding various diagnostic messages, and adapting to new control interfaces quickly.

Q 11. What is your experience with CAM software (specify software)?

I have extensive experience with Mastercam and Fusion 360 CAM software. With Mastercam, I’ve created complex toolpaths for milling, turning, and wire EDM operations across a wide range of materials and parts.

In Mastercam, I am adept at using dynamic milling strategies, optimizing toolpaths for efficiency, and ensuring tool collision avoidance. I also possess strong skills in post-processor configuration and customization to ensure that the generated G-code optimally suits the specific CNC machine and its control system. I am equally comfortable with Fusion 360’s intuitive interface and have used its toolpath generation capabilities to create efficient and effective programs, particularly for smaller, more intricate parts.

I’m proficient in using the simulation capabilities of both systems to verify toolpaths before sending them to the CNC machine, thus minimizing the risk of errors and preventing potential damage.

Q 12. How do you handle tool breakage or machine malfunctions?

Tool breakage and machine malfunctions are inevitable in CNC machining. My approach involves a systematic troubleshooting process:

- Safety First: Immediately stop the machine and ensure the area is safe. This is the most important step.

- Identify the Problem: Carefully assess the situation. Is it a tool breakage, a machine alarm, or an unexpected behavior? Review the machine logs and error codes.

- Isolate the Cause: This involves investigating potential issues such as incorrect tool parameters, improper clamping, material defects, or machine-specific problems. Often the machine alarm code points toward the solution.

- Implement Corrective Action: This may involve replacing a broken tool, adjusting machine settings, repairing a faulty component, or contacting maintenance personnel. Documenting the issue and solution is critical.

- Prevent Recurrence: Once the issue is resolved, I analyze the root cause to prevent future occurrences. This might involve modifying the machining process, adjusting parameters, or improving maintenance procedures.

For example, if a tool breaks due to excessive cutting force, I would investigate factors such as the feed rate, depth of cut, and cutting speed. I’d adjust these parameters according to the manufacturer’s recommendations and possibly use a more robust tool.

Q 13. Describe your experience with different machining processes (e.g., milling, turning, drilling).

I have extensive experience in various machining processes, including milling, turning, and drilling, on a range of CNC machines.

Milling: My experience encompasses face milling, end milling, slot milling, and profile milling. I’m skilled in selecting appropriate cutting tools, optimizing cutting parameters, and programming complex 3D milling operations. I understand the importance of cutter path strategies for efficiency and surface finish.

Turning: My turning expertise includes roughing, finishing, facing, and boring operations. I’m familiar with different turning tool geometries and know how to select the right tool for each operation. I understand the concepts of speed, feed, depth of cut, and their impact on surface finish and tool life.

Drilling: I’m experienced in various drilling techniques, including spot drilling, pilot drilling, and deep hole drilling. I know how to select the appropriate drill bits and cutting parameters for each material and application. I understand the importance of proper clamping to prevent workpiece movement and ensure accurate hole placement.

My experience spans diverse materials, including steel, aluminum, plastics, and composites.

Q 14. Explain the concept of coordinate systems in CNC programming (e.g., machine, work, and part coordinates).

Understanding coordinate systems is fundamental to CNC programming. Three main coordinate systems are commonly used:

- Machine Coordinates (MC): This system is fixed to the machine itself. The origin (0,0,0) is typically located at a physical point on the machine, usually at the intersection of the machine axes. All movements are referenced relative to this fixed point. Think of this as the machine’s “own” coordinate system.

- Work Coordinates (WC): This system is defined by the programmer. The origin (0,0,0) is set at a specific point on the workpiece or the workpiece fixture. This system simplifies programming by allowing the programmer to reference points relative to the workpiece, independent of the machine’s physical location. It’s like placing a grid on your workpiece.

- Part Coordinates (PC): This system refers to a coordinate system established on the part’s geometry itself. The origin might be located at a significant feature point on the part. This system is often used in complex parts to describe features relative to design specifications.

Relationship: The relationship between these coordinate systems is crucial for accurate machining. The machine’s control system uses transformations to convert the programmer’s commands (usually in work coordinates) into machine movements relative to the machine coordinates. Part Coordinates are commonly used in CAD/CAM software before transformation into Work Coordinates.

Example: You might set the work coordinate origin (0,0,0) at a corner of a block of aluminum. Then, you would program movements to mill a specific feature relative to this origin (e.g., drilling a hole at X=25mm, Y=50mm). The machine’s control system translates these work coordinates into the necessary machine movements based on the machine coordinate system and the workpiece’s positioning on the machine.

Q 15. How do you interpret and understand engineering drawings and specifications?

Interpreting engineering drawings and specifications is fundamental to successful CNC machining. It’s like reading a recipe for a highly precise and complex dish. I begin by thoroughly examining the drawing, focusing on several key aspects:

- Views: I carefully analyze all orthographic views (top, front, side) to understand the part’s three-dimensional geometry. I look for details like dimensions, tolerances, surface finishes, and any special features.

- Dimensions and Tolerances: I meticulously check all dimensions and tolerances (e.g., ±0.005 inches). Understanding tolerances is crucial to ensure the finished part meets specifications. A tolerance of ±0.005 inches means the actual dimension can vary by up to 0.005 inches in either direction. This directly influences tool selection and machining strategies.

- Material Specifications: The drawing always specifies the material (e.g., Aluminum 6061, Steel 1018). This dictates the cutting tools, speeds, feeds, and coolants required for optimal machining.

- Surface Finish: The required surface roughness (Ra value) influences the choice of cutting tools and machining parameters. A smoother finish requires finer tools and potentially more passes.

- Bill of Materials (BOM): I will cross-reference with the BOM to ensure I have all necessary components (raw material, fixtures, cutting tools).

For example, recently I was working on a project involving a complex aerospace component. The drawing specified tight tolerances, demanding a high degree of accuracy. I meticulously studied the drawing, identified critical dimensions, and developed a machining strategy that minimized errors and ensured the part met all the specifications. This involved using specific tooling, precise setup procedures and careful monitoring throughout the process.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with CNC machine maintenance and preventative measures?

CNC machine maintenance is paramount for ensuring accuracy, productivity, and safety. My experience encompasses both preventative maintenance and reactive troubleshooting. Preventative maintenance follows a structured schedule and includes:

- Regular Inspections: Daily checks include checking coolant levels, lubricating moving parts, inspecting for any signs of wear or damage on the machine structure, spindle, and tooling. Weekly, I’d check the air pressure and filters. Monthly, a more extensive check of the electrical components, emergency stop functions, and safety systems is implemented.

- Tooling Management: Proper tool storage and maintenance (regular sharpening or replacement) prevent premature wear and tear. This is critical as dull tools can result in inaccurate machining and potentially damage the part or machine.

- Coolant System Maintenance: Regular cleaning and filter changes prevent coolant contamination and ensure proper cooling of the cutting tools. This extends tool life and prevents overheating.

- Software Updates: Keeping the CNC machine’s control software updated is important for optimal performance, added features and security updates.

Reactive maintenance involves addressing unexpected problems. I have experience troubleshooting various issues, from spindle bearing malfunctions to electrical faults, and implement repairs or call in qualified specialists as needed. For example, I once identified and resolved a recurring vibration issue in the spindle by replacing worn-out bearings. Proactive maintenance prevented costly downtime and ensured consistent machining precision.

Q 17. How do you manage and organize CNC programs and data?

Organizing CNC programs and data is vital for efficient workflow. I employ a systematic approach:

- Version Control: Every program is saved with a clear naming convention (e.g., Part_Number_Revision_Date). Version control ensures easy retrieval and tracking of changes. This also aids in troubleshooting if any problems arise later.

- Backup System: Regular backups are crucial to prevent data loss. I use a combination of local and cloud-based storage to maintain redundancy.

- Program Library: Programs are categorized and stored in a well-organized library, making them readily accessible. The library is carefully documented, indicating the machine it is compatible with, the material used, and any specific settings.

- Metadata Management: Each program’s metadata (part number, material, tooling, cutting parameters) is documented thoroughly. This enables efficient retrieval and reuse of programs.

- Data Security: Access to CNC programs and data is restricted to authorized personnel.

In one project, organizing our program library saved us valuable time during a high-demand production run. Having access to previous programs allowed the team to quickly adapt and re-use code which minimized programming time and sped up production.

Q 18. Explain your experience with different types of materials commonly used in CNC machining.

My experience encompasses a wide range of materials commonly used in CNC machining, including:

- Aluminum Alloys (e.g., 6061, 7075): These are relatively easy to machine, requiring moderate cutting speeds and feeds. Different alloy compositions will change the machinability profile, requiring adjustments in speeds and feeds.

- Steels (e.g., 1018, 4140): Steels are tougher to machine than aluminum, needing higher cutting speeds, optimized feed rates and appropriate cutting fluids. Different grades of steel require different approaches to prevent tool wear and ensure surface finish quality.

- Stainless Steels: Stainless steel is harder and more resistant to cutting. Specialized tools and cutting fluids are necessary to avoid tool wear and get the desired surface finish.

- Plastics (e.g., ABS, Delrin, Nylon): Plastic machining requires specific tooling and parameters to avoid melting or burning. The type of plastic is a major influencing factor on the approach.

- Titanium Alloys: Titanium is very difficult to machine, requiring specialized tools, cutting fluids, and very precise speed and feed settings to prevent tool breakage.

The choice of material dictates the selection of cutting tools, cutting speeds, feeds, and coolants. For example, machining titanium requires specialized carbide tools and high-pressure coolant to control heat generation and tool wear. Selecting the incorrect material processing method can result in catastrophic tool failure and part damage.

Q 19. How familiar are you with safety procedures and regulations related to CNC machine operation?

Safety is my top priority. I am well-versed in all safety procedures and regulations related to CNC machine operation. This includes:

- Lockout/Tagout (LOTO): Before any maintenance or repair, I strictly follow LOTO procedures to ensure the machine is completely powered down and safe to work on.

- Personal Protective Equipment (PPE): I always wear appropriate PPE, including safety glasses, hearing protection, and machine-specific safety gear. This includes using proper apparel like long sleeves and pants to protect against sharp edges and chips.

- Emergency Procedures: I am familiar with all emergency procedures, including how to respond to machine malfunctions, accidents, or injuries.

- Machine Guards: I ensure that all machine guards are in place and functioning correctly to prevent accidental contact with moving parts.

- Regular Safety Inspections: Before each operation, I conduct a thorough machine inspection to identify and resolve any potential safety hazards.

Safety training and adherence to regulations are non-negotiable. In my previous role, I initiated a safety training program that improved adherence to safety protocols and increased overall safety awareness.

Q 20. Describe your experience with using measuring instruments for verifying dimensions (e.g., calipers, micrometers).

Precise measurement is critical for verifying dimensions in CNC machining. I regularly use various measuring instruments, including:

- Calipers: I use calipers to measure outside diameters, inside diameters, and depths with high accuracy. Understanding the zero setting and proper measurement techniques is essential.

- Micrometers: Micrometers provide even higher accuracy for precise dimensional measurements. This is vital for checking very tight tolerances.

- Height Gauges: For accurate height measurements and setup procedures.

- Dial Indicators: To check runout, alignment and parallelism of fixtures and tools, improving the accuracy and repeatability of the parts produced.

- Coordinate Measuring Machines (CMMs): In situations demanding extremely high precision, CMMs are utilized for complex 3D measurements.

For example, I once detected a minute dimensional error (0.002 inches) on a critical part using a micrometer. This subtle discrepancy would have impacted the final assembly. By identifying and correcting the error early, I prevented significant rework and potential project delays.

Q 21. How do you optimize CNC programs for efficiency and productivity?

Optimizing CNC programs for efficiency and productivity involves several strategies:

- Toolpath Optimization: Efficient toolpaths minimize machining time and reduce tool wear. This involves selecting the optimal cutting parameters such as feed rates, cutting depth and spindle speed for different stages of the machining operation.

- Cut Optimization: I analyze the program for redundant or unnecessary movements. This can be easily seen in visual simulation and is optimized by removing extra movements.

- G-Code Optimization: Using canned cycles (pre-programmed subroutines) can significantly reduce programming time. These cycles are very efficient and can provide time savings without compromising accuracy.

- Material Removal Rate (MRR): Maximizing MRR (while staying within the limitations of the machine and the workpiece material) reduces machining time. This is accomplished by finding the balance of speed and feed rates to allow efficient material removal.

- Simulation and Dry Runs: Simulating the program before actual machining is crucial to detect potential issues and optimize toolpaths.

In a recent project, I optimized a CNC program by re-arranging the machining sequence and selecting better tools. This resulted in a 15% reduction in machining time, thus improving overall productivity. Often overlooked during programming, these minor changes can result in significant savings in production and improve overall efficiency.

Q 22. Explain your experience with using various types of tooling (e.g., end mills, drills, taps).

My experience with various CNC tooling is extensive, encompassing a wide range of applications. I’m proficient in selecting and utilizing different types of end mills, from roughing to finishing, considering factors like material, desired surface finish, and cutting speed. For example, I regularly use ball-nose end mills for intricate 3D contours and high-speed steel (HSS) end mills for less demanding operations on softer materials. I also have significant experience with twist drills, selecting drill bit sizes and speeds based on the material being drilled and hole tolerances. When it comes to tapping, I’m adept at using various tap types, including spiral point, spiral flute, and machine taps, carefully considering the material and thread pitch to ensure clean, consistent threads. I always prioritize tool life and optimize cutting parameters to maximize efficiency and precision. My experience also includes working with specialized tooling such as reamers, counterbores and form tools for achieving particular geometric shapes and high precision features.

- End Mills: Ball nose, flat end, bull nose, corner radius, etc., for various machining operations.

- Drills: Twist drills, step drills, core drills for different hole sizes and materials.

- Taps: Hand taps, machine taps, bottoming taps, for creating internal threads.

Q 23. What is your understanding of different types of CNC machine control (e.g., point-to-point, continuous path)?

CNC machine control encompasses point-to-point and continuous path methodologies. Point-to-point control moves the tool to a specific location without concern for the path taken between points. Think of it like a robot arm picking up objects; the precise path doesn’t matter, only the start and end positions. This method is efficient for simple tasks like drilling holes or spot facing. Continuous path control, on the other hand, dictates the exact path the tool takes throughout the entire operation. This is crucial for complex shapes and smooth surface finishes. Imagine a sculptor carving a delicate statue; the precise path of the tool is paramount. I’ve worked extensively with both, often incorporating both within a single project. For instance, I might use point-to-point for drilling a series of holes then switch to continuous path for milling out the surrounding material. This approach ensures both efficiency and quality.

Furthermore, I understand the importance of different interpolation methods in continuous path control, such as linear and circular interpolation, and how to select them based on the geometry of the part.

Q 24. Explain your experience with different types of cutting fluids (e.g., oil, water-soluble).

My experience with cutting fluids is extensive, focusing on selecting the appropriate fluid for the material being machined and the specific operation. Water-soluble cutting fluids, often called coolants, are commonly used for their effectiveness in cooling the tool and workpiece, and flushing away chips. They’re generally preferred for aluminum and other non-ferrous metals, but the correct concentration is crucial to avoid corrosion. I understand the importance of regularly checking coolant concentration and changing it when necessary. Oil-based cutting fluids are usually used for harder materials like steel and cast iron, as they offer better lubrication and help prevent tool wear. However, they present disposal challenges. The selection also involves considering factors such as environmental concerns and the health and safety of the operator. I always choose the appropriate fluid based on the Material Safety Data Sheet (MSDS) and best practices for the specific operation. In addition to oil and water-soluble fluids, I am familiar with synthetic fluids and other specialized cutting fluids for specific applications.

Q 25. How do you ensure the quality and consistency of your CNC machining work?

Ensuring quality and consistency is paramount in CNC machining. My approach is multifaceted and begins with meticulous planning. This includes accurately interpreting CAD designs, selecting the appropriate tooling, and programming the CNC machine with optimized parameters, considering factors like feed rate, depth of cut, and spindle speed. Rigorous quality checks are implemented at each stage. This involves performing test cuts before proceeding to the full production run, meticulously inspecting the workpiece at various stages for dimensional accuracy and surface finish. Regular machine maintenance is another key factor, including calibrating the machine, inspecting and replacing worn tools, and maintaining the cleanliness of the machine and work area. Moreover, utilizing appropriate fixturing and clamping to minimize workpiece deflection and vibrations is extremely important. Finally, adhering to all safety procedures ensures consistent high quality while minimizing risks and errors.

Q 26. Describe your experience with using computer aided design (CAD) software.

I’m highly proficient in several CAD software packages, including SolidWorks, AutoCAD, and Mastercam. My experience goes beyond simply creating 2D drawings. I regularly use CAD software to model complex 3D parts, generating detailed drawings, and creating toolpaths for CNC machining. For example, I’ve used SolidWorks to model intricate components, generating multiple views and sections, creating exploded diagrams for assembly instructions. In Mastercam, I’ve developed efficient toolpaths for various machining operations, optimizing the process for reduced cycle time and improved surface finish. I understand the importance of design for manufacturability (DFM), considering constraints such as material properties, tooling limitations, and manufacturing processes during the design phase, ensuring that the final product is both functional and efficiently manufacturable.

Q 27. How familiar are you with different types of clamping systems used in CNC machining?

I have extensive experience with a variety of clamping systems, choosing the most appropriate system for the workpiece material, size, and shape. Common methods include using vises, workholding fixtures, and vacuum chucks. Vises are suitable for simple parts, but for complex shapes, custom fixtures are often necessary to ensure proper support and avoid workpiece deflection during machining. Vacuum chucks are extremely efficient for holding flat workpieces and sheets but require a smooth surface for proper vacuum seal. Choosing the right clamping system also depends on the machine capabilities. For instance, a 5-axis machine provides more flexibility in orientation, allowing the use of more simplified fixturing compared to a 3-axis machine. Proper clamping not only ensures workpiece stability but also operator safety and prevents costly errors.

Q 28. Describe a time you had to troubleshoot a complex CNC machining problem.

During a project involving a complex titanium component, we encountered a recurring issue with surface imperfections in a specific region of the part. Initial troubleshooting pointed towards tool wear, but replacing the tools didn’t fully resolve the problem. After a thorough investigation, I noticed slight variations in the workpiece temperature during machining, leading to uneven thermal expansion and subsequent surface defects. This problem was particularly challenging due to titanium’s high thermal conductivity. The solution involved implementing a controlled coolant flow system with sensors to regulate temperature throughout the process. By monitoring and controlling the coolant flow, thermal expansion was minimized, eliminating the surface defects and achieving a consistent, high-quality finish. This experience highlighted the importance of systematic troubleshooting and looking beyond the obvious solutions to identify root causes of issues in complex machining operations.

Key Topics to Learn for Advanced CNC Machine Operation Interview

- G-Code Programming & Optimization: Understanding advanced G-code commands, including complex milling cycles, macro programming, and efficient code generation for minimizing machining time and maximizing accuracy. Practical application: Optimizing a program to reduce cycle time by 15% while maintaining part tolerances.

- CNC Machine Tool Setup & Calibration: Mastering the precise setup and calibration of advanced CNC machines, including multi-axis machining centers and lathes. This involves understanding tool presetting, workholding techniques, and machine diagnostics. Practical application: Troubleshooting a machine error resulting in inaccurate part dimensions and implementing corrective measures.

- Advanced Cutting Tools & Materials: Deep knowledge of various cutting tools (end mills, drills, inserts), their applications, and optimal selection based on material properties (steel, aluminum, composites). Understanding wear mechanisms and tool life optimization. Practical application: Selecting the appropriate cutting tool and parameters for machining a challenging material like hardened steel.

- CNC Machine Diagnostics & Troubleshooting: Developing the ability to diagnose and troubleshoot common CNC machine issues, including mechanical, electrical, and software problems. Proficient in using diagnostic tools and understanding error codes. Practical application: Identifying and resolving a recurring machine alarm that’s impacting productivity.

- CAD/CAM Software Proficiency: Demonstrating a strong understanding of CAD/CAM software (e.g., Mastercam, Fusion 360) for creating CNC programs, including toolpath simulation and verification. Practical application: Generating efficient toolpaths for complex 3D parts while minimizing material waste.

- Quality Control & Inspection: Understanding precision measurement techniques, utilizing CMMs or other inspection equipment, and applying statistical process control (SPC) methods to maintain part quality. Practical application: Implementing a quality control plan to reduce the rate of defective parts.

- Safety Procedures & Best Practices: A thorough understanding and adherence to all safety regulations and best practices related to operating advanced CNC machinery. Practical application: Demonstrating safe practices for handling cutting tools, machine guarding, and emergency procedures.

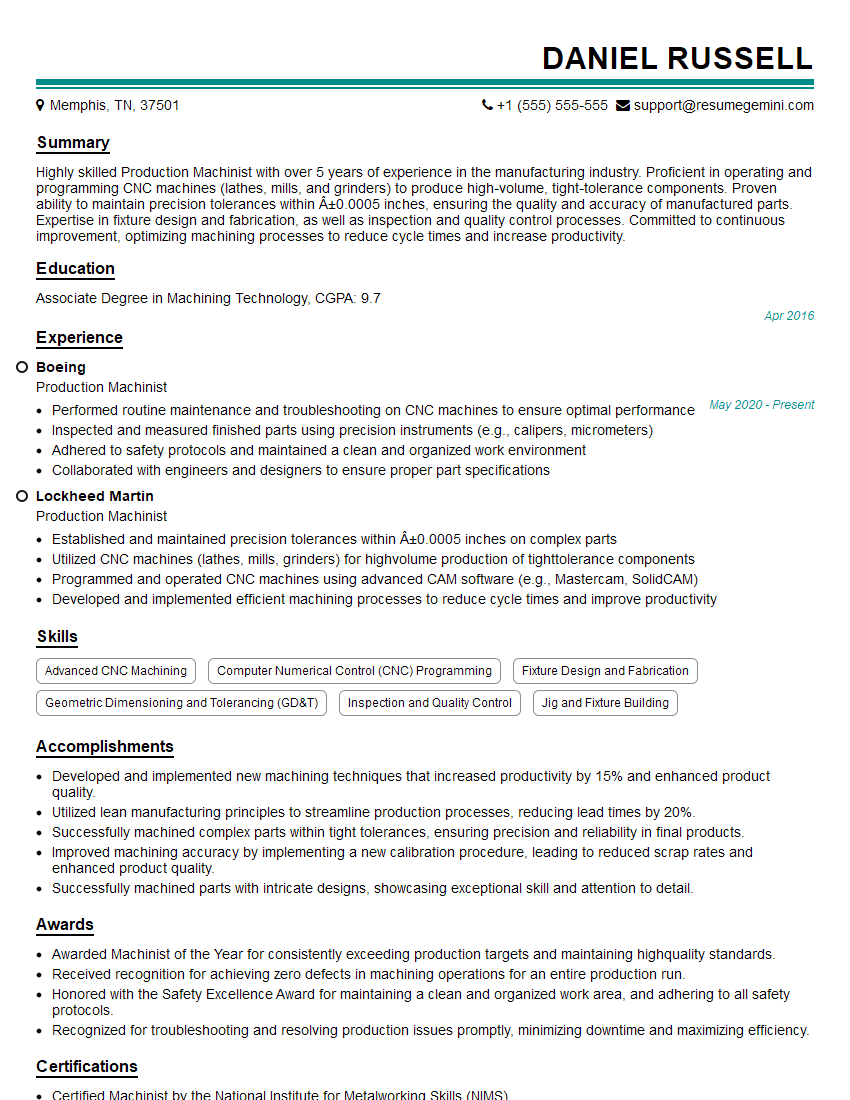

Next Steps

Mastering Advanced CNC Machine Operation opens doors to highly skilled, well-compensated positions within manufacturing and related industries. To significantly boost your job prospects, creating an ATS-friendly resume is crucial. ResumeGemini is a trusted resource designed to help you build a professional, impactful resume that gets noticed. We provide examples of resumes tailored to Advanced CNC Machine Operation to help guide your creation. Take the next step towards your dream career – build your best resume with ResumeGemini today.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good