The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Aerial Equipment Operation interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Aerial Equipment Operation Interview

Q 1. What are the different types of aerial equipment you are familiar with?

My experience encompasses a wide range of aerial equipment, including several types of boom lifts (articulating, telescopic, and knuckle boom), scissor lifts (electric and bi-fuel), and various crane configurations. I’m also familiar with smaller aerial work platforms like cherry pickers and personnel lifts. Each type has its own advantages and limitations regarding reach, lifting capacity, and maneuverability, making choosing the right one crucial for safety and efficiency on any job.

- Boom Lifts: Offer greater reach and versatility due to their articulated arms.

- Scissor Lifts: Ideal for lifting heavier loads to moderate heights with a simpler, more stable platform.

- Cranes: Used for extremely heavy lifting and often require specialized certifications and operating knowledge.

Q 2. Describe the pre-operational inspection checklist for a boom lift.

The pre-operational inspection of a boom lift is a critical safety procedure. I always follow a standardized checklist, ensuring all systems are functioning correctly before operation. This checklist typically includes:

- Visual Inspection: Checking for any visible damage to the boom, platform, tires, and hydraulic system.

- Hydraulic System Check: Testing the boom’s movement in all directions for smooth operation and checking for any leaks.

- Emergency Systems: Verifying the functionality of the emergency stop button and lowering mechanism.

- Controls and Gauges: Inspecting all control levers, switches, and gauges to ensure they are responding correctly and within the appropriate ranges.

- Leveling and Outriggers: Ensuring the outriggers are properly deployed and the lift is level.

- Load Capacity Check: Verifying the load capacity and ensuring the weight to be lifted does not exceed this limit.

- Documentation: Completing a pre-operational inspection report.

For example, I once noticed a small hydraulic leak during a pre-op inspection. This allowed me to rectify the issue before any serious accident occurred, highlighting the importance of diligent checks.

Q 3. Explain the safe operating procedures for a scissor lift.

Safe operation of a scissor lift necessitates adherence to several key procedures. These procedures are designed to minimize the risk of accidents and injuries.

- Pre-Operational Inspection: Checking the machine’s overall condition as well as the battery and hydraulics.

- Ground Conditions: Ensuring the ground is level and stable to prevent tipping.

- Load Capacity: Never exceeding the scissor lift’s rated load capacity.

- Operator Training: Only certified and trained personnel should operate the equipment.

- Awareness of Surroundings: Maintaining constant awareness of the surroundings including overhead obstructions and nearby personnel.

- Safe Work Practices: Following all safety regulations and using appropriate personal protective equipment (PPE), such as safety harnesses.

- Emergency Procedures: Being familiar with emergency shutdown and lowering procedures.

For instance, I once prevented a potential accident by carefully assessing the ground before deploying a scissor lift, realizing that the seemingly stable ground was near a recently dug trench and would be unsafe.

Q 4. What are the load capacity limitations for the different aerial equipment you’ve operated?

Load capacity varies significantly depending on the specific make and model of the aerial equipment. For example:

- Boom Lifts: The capacity can range from a few hundred pounds to several tons, depending on the size and type of the boom. I’ve operated machines with capacities ranging from 500 lbs to 10,000 lbs.

- Scissor Lifts: Typically have a capacity ranging from 500 lbs to 2,000 lbs, although larger models are available.

- Cranes: Crane capacity varies drastically, from relatively small capacities to hundreds of tons depending on the boom length, configuration, and type of crane.

It is crucial to always check the manufacturer’s specifications and never exceed the stated capacity. Overloading is a major safety hazard.

Q 5. How do you ensure stability and prevent tipping during aerial operations?

Maintaining stability is paramount in aerial equipment operation. Several strategies ensure stability and prevent tipping:

- Proper Ground Conditions: Operating on level, firm ground is crucial.

- Outrigger Deployment (Boom Lifts): Fully extending and properly leveling outriggers before raising the boom. This creates a wider base of support.

- Load Distribution: Evenly distributing the load on the platform to prevent imbalance.

- Wind Conditions: Avoiding operation in high winds; wind can easily topple these machines.

- Swing Radius Awareness (Cranes): Understanding and staying within the safe swing radius of the crane to prevent tipping.

- Appropriate Ballasting (Cranes): Using appropriate counterweights for heavy lifts.

One time, I had to deal with unexpectedly soft ground during a boom lift operation. By carefully assessing the situation and repositioning the equipment to a firmer area, I managed to complete the work safely.

Q 6. Describe your experience with different types of crane configurations (e.g., lattice boom, telescopic boom).

My experience includes working with both lattice boom and telescopic boom cranes. The choice depends on the specific job requirements.

- Lattice Boom Cranes: These are generally used for heavier lifting capacities at greater heights. They are strong but slower to set up. I’ve used these on large construction projects where heavy materials need to be lifted to significant heights.

- Telescopic Boom Cranes: These are known for their compact design and faster setup times. They’re more versatile but generally have a lower lifting capacity than lattice boom cranes. I’ve used them for smaller construction jobs and material handling tasks.

Understanding the strengths and limitations of each type is vital for selecting the appropriate crane for the job. The design of the crane will drastically affect its capabilities.

Q 7. What are the different types of rigging techniques you’re familiar with?

My rigging experience covers various techniques, always prioritizing safety and efficiency. This includes:

- Basic Knots: I’m proficient in tying various knots essential for securing loads, including bowlines, clove hitches, and figure-eight knots.

- Wire Rope Handling: Safe handling and inspection of wire ropes, including checking for damage or fraying.

- Load Securing Techniques: Utilizing appropriate straps, chains, and shackles to secure loads to prevent slippage or damage.

- Lifting Points: Careful consideration and identification of appropriate lifting points on the load to ensure stable lifting.

- Rigging Inspections: Performing thorough inspections of all rigging equipment before lifting.

For example, using the wrong type of sling to lift a particular load could lead to a dangerous situation. Selecting the correct rigging based on the load’s weight and its distribution is critical.

Q 8. How do you handle emergency situations, such as equipment malfunctions or power outages?

Emergency situations require swift, decisive action. My approach is based on a structured protocol prioritizing safety. First, I immediately cease operations and assess the situation: is there an immediate danger to myself or others? If so, I initiate the appropriate emergency procedures, which may include evacuating the area or activating emergency services. If the malfunction is equipment-related, I follow the manufacturer’s troubleshooting guide and utilize the equipment’s built-in safety features, such as emergency lowering systems. For example, during a recent power outage on a boom lift, I smoothly lowered the platform using the manual override system, ensuring the safe descent of the personnel. Power outages demand careful planning – I always check the battery backup systems and ensure sufficient lighting for safe evacuation.

For less critical malfunctions, I conduct a methodical diagnostic check. This involves visually inspecting all components, checking for loose connections, and verifying fluid levels (hydraulic, etc.). If I cannot diagnose and fix the issue, I immediately report it to my supervisor and suspend operations until the problem is resolved by qualified personnel.

Q 9. What are the safety regulations and legal requirements related to aerial equipment operation in your region?

Safety regulations governing aerial equipment operation in my region are stringent and I adhere to them meticulously. These include, but aren’t limited to, adhering to the guidelines set forth by OSHA (Occupational Safety and Health Administration) and relevant local and state regulations. This encompasses regular equipment inspections, operator certifications and training, proper load calculations, and the use of Personal Protective Equipment (PPE) such as harnesses, helmets, and safety glasses. We have strict rules on working heights, wind speeds, and proximity to power lines. For example, I’m rigorously trained and certified in the safe operation of aerial lifts and always maintain the required documentation. I am also familiar with and comply with all permit requirements when working near public spaces or roadways.

Legal requirements encompass comprehensive documentation of inspections, maintenance records, operator training certifications, and incident reports. Any deviation from these regulations can lead to serious consequences, including fines and legal action. My understanding extends to liability issues; I am aware of the legal responsibilities in ensuring the safety of myself, my crew, and the public during aerial operations.

Q 10. Describe your experience with load charts and weight calculations.

Load charts are fundamental to safe aerial equipment operation. They provide crucial information on weight limits and center of gravity, ensuring the stability and safety of the equipment. My experience involves thoroughly understanding and interpreting these charts for each specific piece of equipment. I accurately calculate the total weight of the load, including personnel, materials, and the equipment itself. I always account for the effects of wind and other environmental factors on load capacity. Before lifting any load, I double-check my calculations and compare them to the load chart’s specifications. For instance, I recently worked on a project involving lifting heavy construction materials. I meticulously calculated the weight of each component and factored in potential additional weight due to unexpected rainfall. I ensured the total weight, including all materials and personnel, was well within the safe operating limits outlined in the load chart before initiating the lift.

Inaccurate weight calculations can lead to catastrophic equipment failure. A crucial aspect of my process involves using calibrated scales to weigh materials and thoroughly understanding the equipment’s limitations. Any doubt always leads to seeking clarification from a supervisor or engineer.

Q 11. How do you communicate effectively with ground personnel during aerial operations?

Effective communication with ground personnel is paramount to safe aerial operations. I use a multi-faceted approach, incorporating clear, concise verbal communication, hand signals, and two-way radios. Before commencing any operation, I conduct a thorough briefing with the ground crew, explaining the task, outlining safety procedures, and establishing communication protocols. This includes designating specific hand signals for various actions, such as hoisting, lowering, moving left or right. Two-way radios are crucial for maintaining constant communication, particularly during complex operations or when visibility is limited.

For instance, when working on a high-rise building, I use hand signals to direct ground personnel on the safe placement of materials while using the radio to communicate any potential hazards or delays. I emphasize active listening and confirm instructions to prevent misunderstandings. Clear communication is the cornerstone of successful and safe aerial operations, preventing accidents and ensuring efficiency.

Q 12. Explain the importance of using proper signaling techniques.

Proper signaling techniques are essential for avoiding miscommunication and ensuring safety during aerial operations. Standardized hand signals, understood by both the operator and ground personnel, eliminate ambiguity. These signals are usually visually distinct, eliminating confusion, even in noisy environments. They are particularly critical when radio communication is unavailable or unreliable. Signals are specific to actions such as lift, lower, swing, stop, and emergency stop, often accompanied by verbal confirmation. For example, a hand signal indicating ‘lower’ would involve a slow, downward movement of the hand, confirmed verbally by the operator: “Lowering now.”

Inconsistency in signaling can lead to misinterpretations resulting in accidents. Consistent training and adherence to established signaling conventions are vital. I always ensure the ground crew is aware of and understands these signals before we begin any task.

Q 13. What are the different types of ground conditions that affect aerial equipment operation?

Ground conditions significantly impact aerial equipment operation, affecting stability and safety. Soft ground, such as mud or loose soil, can cause equipment instability, leading to tipping. Uneven ground necessitates careful positioning to ensure level and stable operation. Hard, compacted surfaces provide better stability, but can be slippery when wet or icy. Obstacles like rocks, debris, or underground utilities require careful maneuvering to prevent damage to the equipment or the surrounding area. I always conduct a thorough site survey before commencing work, assessing the ground’s consistency and identifying any potential hazards. This helps me determine the appropriate equipment and operating techniques.

For example, if operating on soft ground, I might use outriggers or stabilizers to increase the equipment’s stability. On uneven ground, careful positioning is key to maintaining balance and preventing tipping. Identifying underground utilities prevents accidental damage, a key aspect of pre-operation site safety.

Q 14. How do you adapt your operating techniques to different weather conditions (e.g., wind, rain, snow)?

Weather conditions significantly impact aerial equipment operation, demanding adaptability and safety precautions. High winds can severely affect stability and control, exceeding safe operating limits for many aerial devices. Rain and snow can reduce visibility and make surfaces slippery, impacting both ground and aerial operations. Extreme temperatures can affect equipment performance. I carefully monitor weather forecasts and adjust my operating techniques accordingly. If conditions exceed safe operating limits, I halt operations immediately.

For example, during windy conditions, I would reduce operating height and speed, taking extra care with positioning. If visibility is impacted, I would halt operations or implement additional safety measures. I am trained to assess weather-related risks and make informed decisions to ensure safety. This might involve delays or cancellations to avoid potential hazards.

Q 15. Describe your experience with aerial equipment maintenance and troubleshooting.

My experience with aerial equipment maintenance encompasses preventative measures and troubleshooting malfunctions. Preventative maintenance includes regular inspections of hydraulic systems, checking fluid levels, lubricating moving parts, and examining tire pressure and condition. I meticulously document all inspections and maintenance activities, adhering to manufacturer’s recommendations and company safety protocols.

Troubleshooting involves systematically identifying the source of a problem. For example, if a boom lift refuses to extend, I’d first check the hydraulic fluid level and pressure. If that’s fine, I’d move to check for electrical faults, hydraulic leaks, or mechanical obstructions. I use diagnostic tools, such as pressure gauges and electrical testers, to pinpoint the issue. I’m proficient in repairing minor issues and know when to call in specialized technicians for major repairs, ensuring equipment remains safe and operational.

A memorable instance involved a scissor lift with a faulty hydraulic pump. After isolating the hydraulic system and eliminating other possibilities, I identified a failing pump, resulting in downtime of only a few hours due to our proactive preventative maintenance schedule. Replacing the pump quickly restored functionality.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with fall protection and safety harnesses?

Fall protection is paramount in my line of work. My experience includes extensive training and practical application of various fall protection systems, including full-body harnesses, lanyards, shock absorbers, and anchorage points. I’m adept at selecting appropriate equipment based on the specific task and work environment. For instance, a horizontal lifeline system might be appropriate for working along a long narrow structure, while a self-retracting lifeline is more suitable for vertical access.

I understand the critical importance of proper harness fitting and inspection. I regularly check for any signs of wear and tear, ensuring all components are functional and meet safety standards. Before every lift operation, I perform a thorough pre-use inspection of all safety equipment, a habit deeply ingrained through years of experience. Incorrect usage can lead to serious consequences, emphasizing the need for rigorous safety checks.

Q 17. How do you identify and avoid potential hazards in the work area?

Identifying potential hazards involves a systematic approach. Before commencing any work, I conduct a thorough site survey, focusing on factors like overhead power lines, unstable ground conditions, nearby obstructions, and weather conditions. I visually inspect the area for any potential tripping hazards or hidden dangers. I also consider the environmental factors such as strong winds, rain, or extreme temperatures that could impact operations. Communication with the ground crew is key to address any potential risks identified.

For example, if working near power lines, I maintain a safe distance, often using spotters to guide the equipment and ensure clearance. If unstable ground is detected, I’ll seek alternative access points or employ additional support measures. Risk assessment is an integral part of my routine. It’s not just about spotting the obvious; it’s about anticipating potential problems.

Q 18. Describe your experience working at heights and managing potential risks.

My experience working at heights spans many years and various aerial platforms. I’m familiar with the potential risks associated with working at elevation, including falls, equipment failure, and environmental factors. My approach to managing these risks is based on a combination of careful planning, appropriate safety measures, and adherence to established protocols. This includes using approved access equipment and ensuring it’s properly inspected and maintained.

For instance, when operating a boom lift, I ensure the outriggers are properly deployed on stable ground and that the load is evenly distributed. I never exceed the rated capacity of the equipment and I always use appropriate fall protection, as I’ve mentioned previously. I’ve experienced situations requiring immediate risk mitigation, such as a sudden gust of wind, where I’ve swiftly lowered the platform to a safe position. Experience has taught me to remain vigilant, anticipate challenges, and act decisively to safeguard myself and others.

Q 19. What is your experience with confined space entry procedures when using aerial equipment?

My experience with confined space entry procedures while using aerial equipment is limited to situations where the aerial equipment is used to access the confined space itself, rather than conducting work within the confined space. Aerial platforms are often used to deploy personnel and equipment to the entrance of a confined space. However, I am trained in the recognition of confined space hazards and understand the need for specialized training and permits for entry into such environments. I would never enter a confined space without proper training, permits, and safety equipment.

Before assisting in any operation near a confined space, I would ensure that the appropriate safety measures are in place, including atmospheric monitoring, proper ventilation, and rescue plans. My role would primarily focus on providing safe access to the confined space entrance via the aerial equipment, maintaining a safe working area, and coordinating with the confined space entry team.

Q 20. Explain your understanding of load charts and weight limitations.

Load charts are critical for safe operation of aerial equipment. They specify the maximum weight capacity of the equipment at different boom extensions and angles. I have extensive experience interpreting load charts for various aerial platforms and rigorously adhere to these limitations. Exceeding these limits compromises structural integrity and creates a significant risk of catastrophic failure.

Before lifting any load, I carefully consult the load chart to determine the safe operational limits. This involves considering factors such as the weight of the equipment, the weight of the personnel, and the weight of any additional materials being lifted. I frequently double-check my calculations to ensure I remain well within safe operational parameters. Safety is always paramount.

Q 21. What is your experience with different types of control systems on aerial equipment?

I’m proficient in operating aerial equipment with various control systems. This includes both mechanical and electronic control systems. Mechanical systems often involve levers and manual controls, requiring more physical input. Electronic systems typically utilize joysticks and programmable settings offering greater precision and control. My experience encompasses both types and allows me to adapt quickly to new equipment.

For instance, I’m comfortable operating boom lifts with both proportional and non-proportional control systems. Proportional systems provide fine-tuned control, while non-proportional systems offer a more basic level of control. Understanding the nuances of each system allows me to adapt my operating technique for optimal safety and efficiency. Regular training ensures I maintain my competence and proficiency across different control mechanisms.

Q 22. How do you perform a pre-operational inspection of a crane?

A pre-operational crane inspection is crucial for safety and preventing accidents. Think of it like a thorough health check for your crane before you start any work. It’s a systematic process, not a quick glance. I always follow a checklist, ensuring every component is checked meticulously.

- Visual Inspection: I start with a visual inspection of the entire crane, looking for any obvious damage like cracks, bends, or leaks in hydraulic lines. I check the condition of the boom, jib, and all other structural components.

- Mechanical Checks: This involves checking the functionality of all moving parts – hoist mechanisms, slewing mechanisms, and the braking system. I’ll test each movement for smooth operation and ensure there’s no unusual noise or vibration. For example, I’ll carefully check the brakes to ensure they engage and disengage properly.

- Electrical System: I inspect the electrical wiring and connections for any damage, ensuring proper insulation. Lights, controls, and emergency stop buttons are all thoroughly tested.

- Load-Indicating Devices: The load indicator is critical; I verify its accuracy and functionality. I perform a test lift with a known weight to confirm readings.

- Documentation: Finally, I complete all necessary documentation, recording any findings and addressing any issues identified. Any defects, no matter how minor they seem, are reported immediately and rectified before operation.

For instance, during an inspection, I once discovered a hairline crack in a boom section that wasn’t immediately visible. This could have led to catastrophic failure. My thorough inspection prevented a potential disaster.

Q 23. Explain the different types of crane hooks and their applications.

Crane hooks are crucial for safely lifting and carrying loads. Different hook types cater to specific needs and load characteristics. Think of them as specialized tools for different jobs.

- Standard Hooks: These are the most common type, usually made of forged steel, and are suitable for general lifting tasks. They’re durable and readily available but may not be ideal for all applications.

- Clevis Hooks: Featuring a clevis (a U-shaped metal fitting) at the end, these hooks allow for quick and easy attachment of shackles or other lifting devices. They are excellent for quick connections and disconnections.

- Grab Hooks: These hooks have a more pronounced curve and are designed to grip or clamp onto materials like logs or bundles of materials. Their design is specialized for gripping irregular shapes.

- Heavy-Duty Hooks: These are built for high-capacity lifts and feature enhanced strength and durability, typically used in demanding applications involving substantial weight.

The choice of hook depends entirely on the load being lifted. For instance, I’d never use a standard hook for lifting awkward, bulky items – a grab hook would be far more suitable and safer.

Q 24. How do you calculate the safe working load for a given lift?

Calculating the safe working load (SWL) for a lift is paramount for safety. The SWL is the maximum load a crane can lift safely under specific conditions. It’s not simply a matter of looking at the crane’s maximum capacity; several factors must be considered.

The calculation is complex and often involves referencing the crane’s data plate and using load charts provided by the manufacturer. These charts consider factors such as:

- Crane Model and Configuration: Different crane models have different capacities, and the boom length significantly affects the SWL. A longer boom reduces the safe load capacity.

- Radius of Lift: The distance of the load from the crane’s center (radius) influences the load capacity. A longer radius implies a lower SWL.

- Wind Speed and Direction: Strong winds drastically reduce the SWL. Crane operators need to check weather conditions and adjust the lift accordingly or suspend operations if needed.

- Ground Conditions: Uneven or soft ground can reduce the crane’s stability, thus affecting the SWL.

Example: A crane’s data plate might show a maximum capacity of 100 tons, but the actual SWL could be considerably lower depending on the factors above. Suppose the lift radius is 50 meters, and the wind speed is moderate; the SWL might be reduced to 60 tons. Always consult the manufacturer’s charts and other relevant documents to determine the SWL.

Q 25. What are the different types of wire rope and their characteristics?

Wire ropes are essential components of cranes, providing the strength to lift heavy loads. Choosing the correct type is vital for safety and longevity.

- 6×19 (Six strands of nineteen wires): This is a popular choice, offering good flexibility and fatigue resistance. It’s often used for general lifting operations.

- 6×36 (Six strands of thirty-six wires): This construction provides improved fatigue resistance and is better suited for applications with frequent bending and flexing, such as those with smaller sheaves (pulleys).

- 6×37 (Six strands of thirty-seven wires): Similar to 6×36 but with slightly higher fatigue resistance. Again, useful for situations with frequent bending.

- 8×19 (Eight strands of nineteen wires): This type offers even higher flexibility, making it suitable for applications with frequent bending and small sheaves, but slightly lower fatigue resistance than 6×36.

Each type has unique characteristics influencing its suitability for specific applications. For example, 6×19 is a good all-around choice, but 6×36 or 6×37 are preferable where frequent bending and flexing are expected.

Regular inspection for wear, corrosion, or damage is critical. Wire rope failure can be catastrophic, so maintaining it is non-negotiable. I always meticulously check for broken wires, kinks, and other damage during my inspections.

Q 26. Describe your experience with swing radius and its importance in crane operation.

Swing radius refers to the horizontal distance between the crane’s center of rotation and the outermost point of the load being lifted. Understanding and managing the swing radius is critical for preventing accidents.

Importance: A large swing radius necessitates greater attention to potential obstructions. The swing of the load can easily impact nearby structures, equipment, or personnel.

Experience: In my experience, careful planning and communication are key. Before commencing any lift, I always establish a safe swing radius, making sure it’s clear of any obstructions and taking into account all possible movements. This includes mapping out the swing radius visually and using any available software to simulate potential swings. I inform everyone in the vicinity of the crane’s operating area about the swing radius and make sure they maintain a safe distance.

For example, in one project, we had to lift a very heavy piece of equipment close to a newly constructed building. By properly calculating and marking the swing radius, we prevented any potential collision.

Q 27. How do you manage different types of ground conditions during crane operation?

Ground conditions significantly impact crane stability and the safe working load. Unstable ground can lead to crane tipping, a very serious hazard.

Management Strategies:

- Ground Assessment: Before setting up, a thorough assessment is required. This involves visually inspecting the ground for softness, unevenness, slopes, or potential obstacles. Geotechnical reports may be necessary for large or complex projects.

- Ground Preparation: Depending on the ground conditions, preparation may include leveling the ground, compacting soft soil, using ground mats or cribbing for support, or opting for a different crane placement.

- Outriggers: Cranes are often equipped with outriggers that provide additional stability. Proper deployment and extension of outriggers are crucial. The ground pressure under the outriggers must be checked to ensure it doesn’t exceed the ground bearing capacity.

- Crane Type Selection: Different crane types are better suited for different ground conditions. For example, crawler cranes are ideal for soft or uneven ground because of their track system, providing superior stability.

I’ve encountered numerous situations where soft soil threatened crane stability. In those instances, we used ground mats and cribbing to distribute the weight and improve stability. Always prioritize safety. If the ground conditions are unsuitable, it’s better to postpone or cancel the lift than risk an accident.

Q 28. What are the emergency procedures for a crane malfunction?

Emergency procedures for crane malfunctions are critical and must be well-rehearsed. Think of it as a fire drill, but for a crane.

Steps:

- Immediate Actions: If a malfunction occurs, the first response is to immediately stop all crane operations using the emergency stop button. This is the highest priority.

- Assessment: Once the crane is stopped, perform a quick assessment of the situation. Determine the nature of the malfunction – is it a mechanical issue, an electrical fault, or something else?

- Communication: Communicate the situation to the site supervisor, safety officer, and any other relevant personnel. Clear communication prevents further accidents.

- Evacuation: If the situation warrants it, evacuate the area around the crane. Clear the area of personnel to prevent any potential injuries.

- Emergency Services: If the malfunction is serious or beyond immediate resolution, contact emergency services and follow their instructions.

- Investigation: After the emergency, a full investigation is necessary to determine the cause of the malfunction and prevent future incidents. This may involve engineers or external experts.

Regular safety training and drills are essential in ensuring everyone knows how to react during a crane malfunction. It’s not enough to know the procedures; everyone must be able to execute them effectively and calmly under pressure.

Key Topics to Learn for Aerial Equipment Operation Interview

- Equipment Familiarization: Understanding the various types of aerial equipment (cranes, boom lifts, scissor lifts, etc.), their capabilities, limitations, and safety features. This includes knowing the differences in operational procedures and safety protocols.

- Pre-Operational Checks and Maintenance: Mastering pre-flight checklists, daily inspections, and routine maintenance procedures to ensure equipment functionality and operator safety. This includes practical application of identifying potential hazards before operation.

- Safe Operation Procedures: Thorough understanding and application of safe operating procedures, including load capacity calculations, working at heights, emergency protocols, and communication with ground crews. This encompasses theoretical knowledge translated into real-world scenarios.

- Risk Assessment and Mitigation: Ability to identify potential hazards, assess risks, and implement appropriate mitigation strategies before, during, and after operation. This includes problem-solving skills related to unexpected situations on-site.

- Regulations and Compliance: Knowledge of relevant safety regulations, industry standards, and legal compliance requirements for operating aerial equipment. This extends to understanding the implications of non-compliance.

- Emergency Procedures: Detailed understanding and practical knowledge of emergency response procedures, including equipment failure, accidents, and rescue operations. This involves theoretical knowledge and application in simulated scenarios.

- Communication and Teamwork: Effective communication skills with ground crews, supervisors, and other personnel to ensure safe and efficient operation. This emphasizes the collaborative nature of aerial equipment operation.

Next Steps

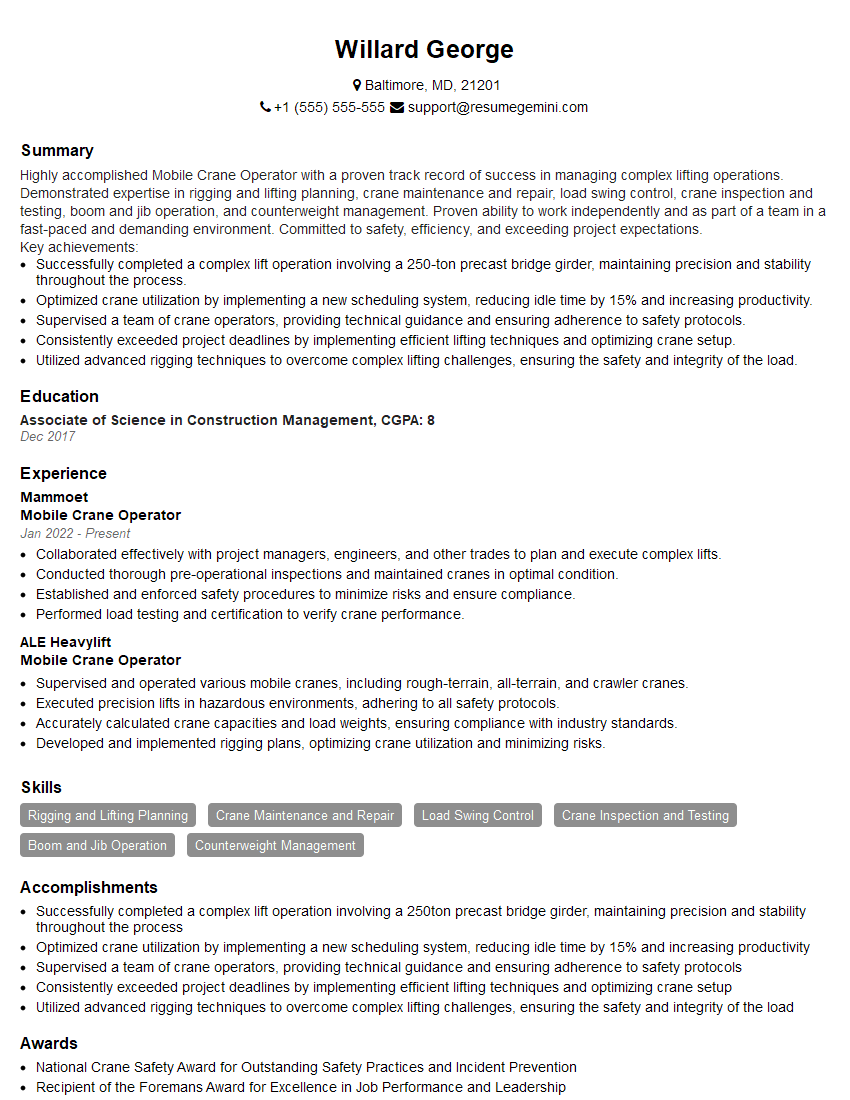

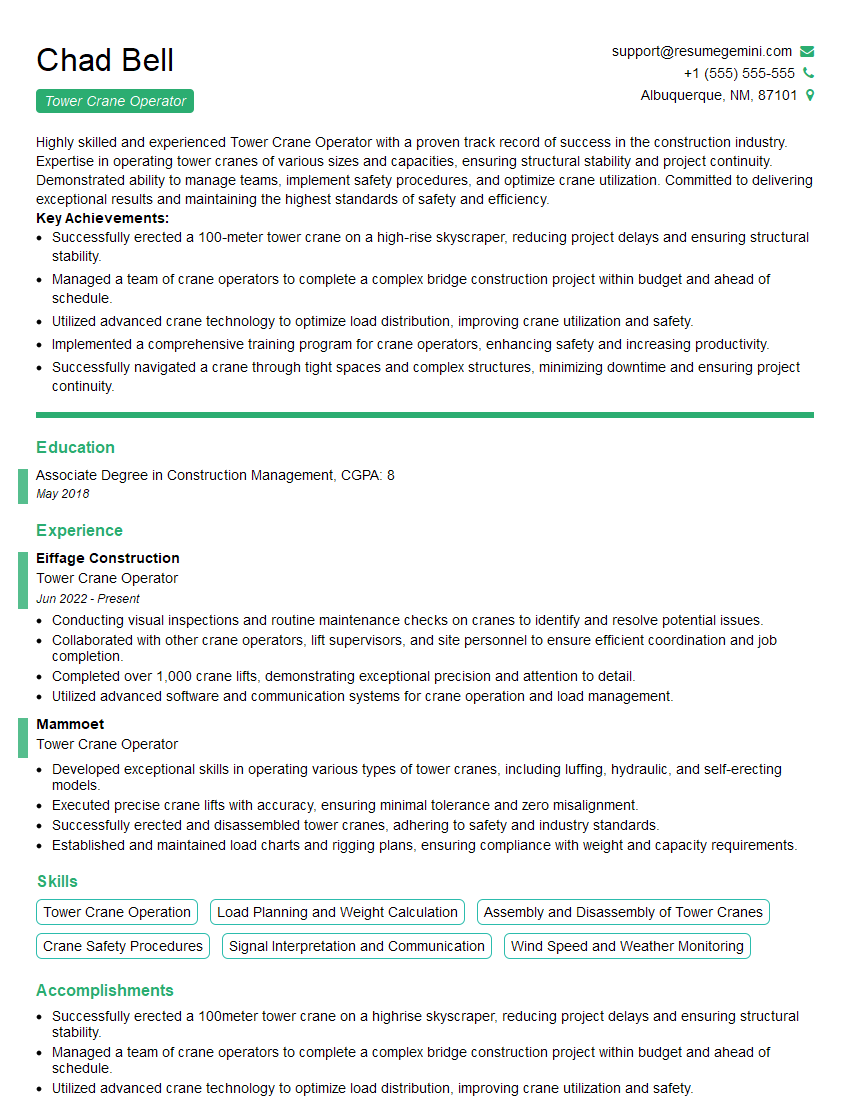

Mastering Aerial Equipment Operation opens doors to exciting career opportunities with excellent growth potential in construction, infrastructure, and various other industries. To maximize your job prospects, it’s crucial to have a strong, ATS-friendly resume that showcases your skills and experience effectively. ResumeGemini is a trusted resource to help you create a professional and impactful resume that gets noticed by recruiters. We provide examples of resumes tailored to Aerial Equipment Operation to guide you in highlighting your unique qualifications. Invest the time to build a compelling resume – it’s your key to unlocking your career aspirations.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good