Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Aerospace Optics interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Aerospace Optics Interview

Q 1. Explain the principles of Gaussian beam propagation.

Gaussian beam propagation describes how a laser beam, modeled as a Gaussian beam, changes its characteristics – such as its width and curvature – as it travels through space or an optical system. Imagine throwing a perfectly round pebble into a still pond; the ripples spreading outwards represent the beam’s propagation.

The core principle lies in the beam’s complex amplitude profile, which is a Gaussian function of the radial distance from the beam’s center. This profile is characterized by its beam waist (the narrowest point), its wavelength, and its Rayleigh range (the distance over which the beam’s width approximately doubles). As the beam propagates, its waist expands, and its wavefront curvature changes.

Mathematically, we use the ABCD matrix formalism to model Gaussian beam propagation through optical components. This matrix describes how the beam parameters (waist, radius of curvature, etc.) transform after passing through a lens, free space, or other optical elements. By tracing the beam using the ABCD matrix, we can precisely predict the beam size and divergence at any point along its path. This is crucial for designing laser systems, optical communication links, and many other applications where precise beam control is essential.

For instance, in satellite laser communication, accurately predicting the Gaussian beam’s expansion over vast distances is critical for maintaining a strong signal. Incorrect prediction leads to significant signal degradation or complete signal loss.

Q 2. Describe different types of optical aberrations and their correction methods.

Optical aberrations are imperfections in an optical system that cause light rays to not converge perfectly at a single point, resulting in blurry or distorted images. Think of it like a slightly misshapen lens distorting the image on a camera. There are several primary aberrations:

- Spherical Aberration: Rays passing through the outer edges of a lens focus at a different point than rays passing through the center.

- Chromatic Aberration: Different wavelengths of light are refracted by different amounts, leading to colored fringes.

- Coma: Off-axis points appear as comet-shaped images.

- Astigmatism: The image is smeared in two perpendicular directions.

- Field Curvature: The image is sharply focused only on a curved surface, not a flat plane.

- Distortion: The image is magnified differently across the field of view, leading to stretching or compression.

Correction methods involve careful lens design, using multiple lenses with different shapes and refractive indices to compensate for each other’s aberrations. Aspheric lenses (non-spherical surfaces) can also significantly reduce spherical aberration. Chromatic aberration is often mitigated by using achromats – combinations of lenses made from different glasses with different dispersive properties. Sophisticated computer-aided design software plays a vital role in optimizing lens shapes and arrangements for aberration correction in complex optical systems.

Q 3. What are the key considerations for designing an optical system for a space-based application?

Designing an optical system for space-based applications poses unique challenges due to the harsh environmental conditions. Key considerations include:

- Extreme Temperatures: The system must withstand extreme temperature variations experienced during launch and operation in space.

- Radiation Hardening: Components must be resistant to damaging radiation from the sun and cosmic rays. This often involves using radiation-hardened materials and design techniques.

- Vacuum Environment: Outgassing of materials can contaminate the optical surfaces, so materials with low outgassing rates are crucial.

- Micrometeoroid and Orbital Debris (MMOD) Protection: The design needs to incorporate protection against impact from micrometeoroids and space debris, which can damage the optics or spacecraft.

- Thermal Stability: Maintaining a stable temperature within the optical system is critical to ensure consistent performance.

- Mass and Size Constraints: Spacecraft have limitations on mass and size, impacting the design of the optical system.

- Power Consumption: Minimizing power consumption is crucial for extending the mission life.

- Launch Loads: The optical system must withstand the tremendous forces encountered during launch.

For instance, the James Webb Space Telescope’s complex design addresses these challenges with multi-layered sunshades for thermal control, highly polished mirrors to withstand launch loads and maintain precision in a vacuum, and radiation-hardened sensors and electronics.

Q 4. How do you choose the appropriate optical materials for a specific application?

Choosing the right optical material is crucial for optimal performance. The selection depends on several factors including:

- Refractive Index: Determines the amount of light bending. Higher refractive index often means smaller and more compact optical systems.

- Dispersion: How much the refractive index varies with wavelength, affecting chromatic aberration. Low dispersion is desirable for minimizing chromatic effects.

- Transmission Range: The range of wavelengths the material transmits effectively. Different materials are suitable for different spectral regions (UV, visible, IR).

- Thermal Properties: Coefficient of thermal expansion affects how the material’s dimensions change with temperature. Low thermal expansion is important for stability.

- Mechanical Properties: Strength, hardness, and resistance to scratches and damage are important.

- Environmental Durability: Resistance to radiation, vacuum, and extreme temperatures. For space applications, this is paramount.

- Cost: Some materials are significantly more expensive than others.

For example, fused silica is frequently used in space applications due to its excellent transmission in the UV-VIS-NIR, low thermal expansion, and radiation resistance. However, for applications requiring high refractive indices, materials like germanium or zinc selenide are preferred, even though they may be more sensitive to environmental factors.

Q 5. Explain the concept of diffraction limit and its implications in optical design.

The diffraction limit describes the fundamental limitation on the resolution of an optical system imposed by the wave nature of light. It’s not a defect, but a physical constraint. Imagine trying to resolve two closely spaced stars with a telescope; at some point, the light waves from the stars will interfere with each other, making it impossible to distinguish them as separate points.

The diffraction limit is expressed by the Rayleigh criterion, which states that two point sources can be resolved if the center of the diffraction pattern of one source coincides with the first minimum of the diffraction pattern of the other. The angular resolution is approximately proportional to the wavelength of light and inversely proportional to the diameter of the aperture (e.g., the telescope lens or mirror). A smaller wavelength or a larger aperture leads to better resolution.

This has significant implications for optical design because it sets a theoretical upper limit on the achievable image quality. No matter how perfect the lens, the image cannot be sharper than the diffraction limit allows. This is especially crucial for high-resolution imaging systems like telescopes and microscopes. For instance, high-resolution space telescopes often use large mirrors to overcome this limit and achieve sharper images of distant stars and galaxies.

Q 6. Describe different types of optical coatings and their applications.

Optical coatings are thin layers of materials deposited on optical surfaces to enhance their performance. They can dramatically change how light interacts with a surface. Think of them as a specialized sunscreen for lenses, but instead of UV protection, they manipulate light’s reflection, transmission, and polarization.

- Anti-reflection (AR) coatings: Reduce reflections from optical surfaces, increasing transmission. These are crucial for minimizing light loss in optical systems. Common examples include single-layer MgF2 coatings or multilayer dielectric coatings.

- High-reflection (HR) coatings: Increase the reflectivity of a surface, useful for mirrors and laser cavities. Dielectric multilayer stacks are commonly used.

- Dichroic coatings: Reflect certain wavelengths of light and transmit others, used to split light into different colors (like in a beam splitter).

- Polarizing coatings: Transmit or reflect light with a specific polarization state, useful in polarization-sensitive imaging or laser applications. These often involve wire grid polarizers.

- Protective coatings: Protect the underlying optical surface from scratches, environmental degradation, or contamination.

The choice of coating depends on the specific application. For a space-based telescope, radiation-hardened coatings are crucial to maintain performance over the long term. For laser systems, coatings with very high reflectivity and low absorption are essential for efficient operation.

Q 7. What are the challenges in testing optical systems in a space environment?

Testing optical systems in a space environment presents numerous challenges:

- Cost and Access: Launching instruments into space is extremely expensive and complex.

- Limited Accessibility: Once deployed, repairing or recalibrating a system in space is incredibly difficult and expensive or often impossible.

- Environmental Factors: Testing in a vacuum, under extreme temperature variations, and with radiation exposure is challenging to reproduce accurately on Earth.

- Verification of Performance: Measuring the performance of the optical system in space requires specialized instruments and remote sensing techniques.

- Ground-Based Testing Limitations: While ground-based testing is essential, it can’t fully replicate the space environment. Many effects, such as radiation damage, can only be evaluated in orbit.

To address these difficulties, rigorous testing is carried out on Earth under simulated conditions, using thermal vacuum chambers and radiation testing facilities. However, on-orbit validation is still crucial to verify the design’s success in the actual space environment. This is often done with on-board test equipment and telemetry systems that transmit performance data back to Earth. For instance, the Hubble Space Telescope benefited from several servicing missions to correct initial optical defects and upgrade its instruments; however, this is not feasible for all missions.

Q 8. Explain the principles of interferometry and its use in optical testing.

Interferometry is a powerful technique used to measure extremely small distances, often fractions of a wavelength of light. It works by combining two or more light waves and analyzing the resulting interference pattern. This pattern reveals information about the shape and surface quality of the optical components under test. In optical testing, we exploit this principle to assess the precision of lenses, mirrors, and other optical elements.

For example, a common technique is the Twyman-Green interferometer. Here, a beam of light is split into two paths: one reflects off the test surface, and the other reflects off a reference surface (usually a high-quality mirror). The recombined beams interfere, creating a pattern of bright and dark fringes. The shape and spacing of these fringes directly indicate deviations from the ideal surface shape. A perfectly flat surface will produce uniform fringes, while irregularities show up as distortions in the fringe pattern. This allows us to quantify the surface imperfections with incredible accuracy, down to nanometers.

Another example is Fizeau interferometry, commonly used to test the flatness of optical flats. Here, a light source illuminates the test surface and a reference flat. The interference pattern produced provides detailed information about the surface irregularities of the test flat. These techniques are crucial for ensuring the high precision demanded in aerospace optics, where even minute imperfections can significantly impact performance.

Q 9. How do you design for thermal stability in an optical system?

Designing for thermal stability in an optical system is paramount for maintaining performance in varying environmental conditions. Changes in temperature cause materials to expand or contract, leading to misalignment and degradation of image quality. Several strategies are employed to mitigate these effects.

- Material Selection: Choosing materials with low coefficients of thermal expansion (CTE) is vital. Materials like Invar or Zerodur are commonly used because their dimensions change very little with temperature fluctuations.

- Mechanical Design: Careful mechanical design minimizes stress on optical components. Using kinematic mounts that provide stable support and limiting the number of points of contact helps. Additionally, designing for symmetry reduces the impact of thermal gradients.

- Thermal Compensation: Active or passive thermal compensation methods can be implemented. Passive methods might involve using materials with different CTEs to balance out expansion/contraction. Active methods involve using heaters or coolers to maintain a constant temperature within the optical system.

- Thermal Modeling: Finite Element Analysis (FEA) software is used to model the thermal behavior of the system. This allows us to predict the effects of temperature changes and optimize the design for stability. For example, simulating various temperature profiles can show potential stress points that can be addressed through design modifications.

In practice, a combination of these strategies is often employed. Consider a space-based telescope: The extreme temperature variations experienced in orbit necessitate the use of low-CTE materials, passive compensation techniques, and robust mechanical design, all verified through rigorous thermal modeling.

Q 10. Describe different types of optical sensors and their applications.

Aerospace applications utilize a diverse range of optical sensors, each with specific strengths and applications. Here are a few examples:

- Photodiodes: These are simple, robust, and widely used for detecting light intensity. Applications include star trackers for spacecraft orientation and light detection in remote sensing systems.

- Charge-Coupled Devices (CCDs) and Complementary Metal-Oxide-Semiconductors (CMOS): These are imaging sensors that capture two-dimensional images. They are essential components in high-resolution cameras for Earth observation, astronomy, and aerial photography. CCDs are known for high sensitivity and low noise, while CMOS sensors generally offer faster readout speeds.

- Infrared (IR) Sensors: These sensors detect infrared radiation, allowing for imaging in low-light conditions or at wavelengths invisible to the human eye. Applications include thermal imaging for target acquisition, atmospheric monitoring, and guidance systems. There are various types of IR detectors such as microbolometers, photoconductive, and photovoltaic detectors, each with its own performance characteristics.

- Spectrometers: These devices measure the intensity of light as a function of wavelength, providing spectral information about the observed object. Applications include atmospheric composition analysis, material identification, and remote sensing.

The choice of sensor depends on the specific application requirements. Factors such as sensitivity, spectral range, resolution, size, weight, and power consumption all play a crucial role in the selection process. For instance, a high-resolution camera for Earth observation from space would need to have a large sensor area, high quantum efficiency, and excellent radiation hardness to withstand the harsh space environment.

Q 11. What are the key considerations for designing a high-resolution imaging system?

Designing a high-resolution imaging system involves careful consideration of multiple factors that contribute to the overall image quality. The primary goals are to maximize spatial resolution, minimize aberrations, and ensure good signal-to-noise ratio (SNR).

- Aperture Size: A larger aperture gathers more light, improving SNR, especially in low-light conditions. However, larger apertures also introduce greater manufacturing challenges.

- Focal Length: The focal length determines the field of view and magnification. Longer focal lengths provide higher magnification but narrower fields of view, requiring careful consideration of the desired application.

- Optical Design: Minimizing optical aberrations (distortion, coma, astigmatism, spherical aberration) is critical. This often involves complex lens designs with multiple elements and aspheric surfaces. Advanced optical design software like Code V or Zemax is essential for optimizing performance.

- Sensor Resolution: The sensor’s pixel count directly impacts the spatial resolution of the image. However, larger sensors also mean higher data rates and increased power consumption.

- Signal Processing: Advanced signal processing algorithms can enhance image quality, reduce noise, and improve resolution, even beyond the theoretical limits set by the optical system’s diffraction limit. This often includes techniques like deconvolution or super-resolution.

For instance, consider a satellite imaging system designed for high-resolution Earth observation. This system would require a large aperture telescope, a high-resolution sensor, sophisticated optical design to minimize aberrations, and advanced image processing to extract maximum information from the acquired data.

Q 12. Explain the concept of Modulation Transfer Function (MTF) and its importance.

The Modulation Transfer Function (MTF) is a crucial metric in evaluating the image quality of an optical system. It describes how well the system transmits different spatial frequencies of an object. In essence, it quantifies the system’s ability to reproduce fine details in the image.

The MTF is expressed as a function of spatial frequency (measured in cycles/mm or line pairs/mm). An MTF of 1 indicates perfect transmission of that frequency, while an MTF of 0 indicates no transmission. A higher MTF at higher spatial frequencies signifies better resolution and sharper image details. For example, if an MTF at 10 cycles/mm is 0.8, it means the system transmits 80% of the contrast of an object with that specific spatial frequency.

The MTF is a critical design parameter because it allows us to predict the performance of the system before it’s built. We use MTF curves to compare different optical designs, assess the impact of various aberrations, and evaluate the overall image quality. Analyzing the MTF helps determine whether the system will meet the required resolution and image sharpness.

In aerospace optics, the MTF is crucial for evaluating the performance of imaging systems used in satellites, aircraft, and telescopes. Meeting stringent resolution requirements in these applications necessitates precise control over the MTF of the entire system, from the optical design to the image sensor characteristics. For example, a high-resolution Earth observation satellite would demand a high MTF across a wide range of spatial frequencies, ensuring detailed images even for fine features on the Earth’s surface.

Q 13. How do you perform tolerancing analysis for an optical system?

Tolerancing analysis is a crucial step in optical system design. It determines the allowable manufacturing tolerances for individual components without significantly degrading the overall system performance. The goal is to balance the desired level of performance with the cost and feasibility of manufacturing.

The process typically involves:

- Defining Tolerances: Identifying all the parameters that can vary during manufacturing, such as lens radii, thicknesses, surface irregularities, center thicknesses, and spacing between optical components. Each parameter is assigned an allowable tolerance.

- Sensitivity Analysis: Assessing the sensitivity of the system performance (e.g., MTF, spot size, wavefront error) to variations in each tolerance. This is often done using optical design software through Monte Carlo simulations, which simulate many instances of component variations. The software then computes how each parameter affects the overall image quality.

- Tolerance Budgeting: Allocating the total allowable tolerance across various parameters. Parameters that have a more significant impact on the system’s performance will receive tighter tolerances. This often involves trade-offs between cost and performance.

- Optimization: Iteratively adjusting tolerances and design parameters to optimize the balance between cost and performance. The goal is to achieve the desired performance while minimizing the manufacturing costs and complexities.

For example, in designing a high-precision space telescope, tolerancing analysis is critical. Tight tolerances are needed for surface figures and component spacing to meet stringent resolution requirements. However, imposing excessively tight tolerances drives up manufacturing costs, requiring a careful trade-off. Advanced tolerancing software offers sophisticated tools to assess the sensitivity of the system to various fabrication errors, guiding the optical engineer towards an optimized, manufacturable design.

Q 14. Describe different types of optical telescopes and their advantages/disadvantages.

Various types of optical telescopes are employed in aerospace applications, each offering unique advantages and disadvantages:

- Reflector Telescopes (e.g., Cassegrain, Ritchey-Chrétien): These telescopes use mirrors to focus light. They are particularly suitable for large apertures because mirrors are easier and cheaper to manufacture than large lenses. Cassegrain designs offer compact configurations, making them ideal for space missions. Ritchey-Chrétien designs are known for their excellent image quality across a wide field of view, commonly used in space-based telescopes.

- Refractor Telescopes: These use lenses to focus light. They offer excellent color correction but are limited in size due to difficulties in manufacturing large, high-quality lenses. They are simpler in design than reflectors and easier to maintain.

- Schmidt Telescopes: These are catadioptric telescopes (using both lenses and mirrors), known for their wide field of view. The use of a corrector plate helps correct for spherical aberration, making them suitable for astronomical surveys.

- Achromatic Doublets (used in smaller telescopes): These use two lenses of different types of glass to correct for chromatic aberration in a compact and cost-effective design. They are often found in smaller telescopes used in guidance systems or aerial reconnaissance.

The choice of telescope type depends on the specific mission requirements, such as aperture size, field of view, image quality, cost, and weight limitations. For instance, large space telescopes often employ reflector designs (like the Hubble Space Telescope, a Ritchey-Chrétien design) to achieve high resolution, while smaller, simpler telescopes in aircraft or spacecraft may use refractor or Schmidt designs to provide more compact and robust systems. The trade-offs between image quality, cost, size, and weight are carefully considered when choosing a telescope type for a particular aerospace application.

Q 15. What are the challenges of integrating optical systems with other aerospace subsystems?

Integrating optical systems into aerospace platforms presents unique challenges due to the harsh environment and the need for seamless interaction with other subsystems. The primary concerns revolve around:

- Weight and Size Constraints: Aerospace applications demand lightweight and compact designs, which often conflicts with the size and weight requirements of complex optical systems.

- Environmental Factors: Extreme temperatures, vibrations, shocks, and radiation encountered in space significantly impact the performance and longevity of optical components. A successful integration requires robust designs capable of withstanding these stressors.

- Thermal Management: Optical systems generate heat, particularly lasers and detectors. Efficient thermal management is crucial to prevent performance degradation and potential damage to adjacent subsystems.

- Power Consumption: Minimizing power consumption is vital in aerospace applications. This necessitates the selection of energy-efficient optical components and control systems.

- Interfacing with Other Subsystems: Optical systems need to be integrated with other subsystems, such as power supplies, data acquisition units, and control electronics. This requires careful consideration of data formats, communication protocols, and physical interfaces.

- Electromagnetic Compatibility (EMC): Optical systems must be designed to avoid electromagnetic interference with other avionics components. Careful shielding and grounding are essential to ensure reliable operation.

For example, consider integrating a high-resolution camera system onto a satellite. Minimizing the camera’s weight and power consumption while ensuring its radiation hardness and thermal stability requires sophisticated engineering solutions and trade-off analyses.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the principles of optical fiber communication and its application in space.

Optical fiber communication relies on transmitting information as light pulses through optical fibers. This technology is exceptionally well-suited for space applications due to its high bandwidth, low signal loss, and immunity to electromagnetic interference.

Principles: A light source (typically a laser diode) encodes data into light pulses. These pulses travel through a very thin glass fiber, guided by total internal reflection. At the receiving end, a photodetector converts the light pulses back into electrical signals.

Space Applications:

- Satellite Communication: Optical fibers are extensively used for internal communication within satellites, enabling high-speed data transfer between various instruments and subsystems. This is far superior to traditional electrical wiring, which suffers from electromagnetic interference and signal degradation.

- Inter-Satellite Links: Free-space optical communication (FSO) uses lasers to transmit data between satellites. FSO offers significantly higher bandwidth compared to radio frequency systems and is increasingly crucial for large-scale satellite constellations.

- Deep Space Missions: Optical fibers play a critical role in transmitting data over long distances within spacecraft navigating to distant planets. Their low signal attenuation is an advantage in deep space where maintaining a strong signal is vital.

Imagine a deep-space probe sending back images from a distant planet. The high data rates required necessitate using optical fiber communication to transmit the large volume of image data effectively.

Q 17. How do you design for radiation hardness in optical components?

Designing for radiation hardness in optical components requires careful selection of materials and implementation of protective strategies. The effects of radiation include:

- Displacement Damage: High-energy particles can displace atoms in the lattice structure of optical materials, leading to changes in refractive index and optical absorption.

- Ionization: Radiation creates electron-hole pairs, affecting the performance of optoelectronic devices like photodetectors and lasers.

Mitigation Techniques:

- Material Selection: Radiation-hard materials like fused silica and sapphire are preferred for their high resistance to radiation-induced damage. Certain types of radiation-hardened detectors are used as well.

- Redundancy: Implementing redundant components and pathways allows for continued operation even if one component fails due to radiation damage.

- Shielding: Shielding optical components with radiation-hard materials, such as lead or tungsten, can reduce the radiation dose they receive.

- Error Correction Codes: Implementing error correction codes in the data transmission process helps to mitigate data corruption caused by radiation-induced errors.

- Annealing: Some radiation damage can be partially reversed by subjecting the components to controlled heating, a process known as annealing.

For instance, space telescopes often employ radiation-hardened CCD detectors to minimize the impact of radiation on image quality. Selecting appropriate shielding materials becomes crucial in designing radiation-hardened optical systems for missions to planets where radiation levels are high.

Q 18. Describe different types of laser systems and their applications in aerospace.

Aerospace applications utilize various laser systems, each offering specific advantages:

- Solid-State Lasers: These lasers utilize a solid-state gain medium, often doped crystals or glasses. They are compact, efficient, and reliable, making them suitable for diverse applications like laser rangefinders, laser altimeters, and laser communication systems. Examples include Nd:YAG lasers and fiber lasers.

- Gas Lasers: These lasers utilize a gaseous gain medium. They often provide high power output and good beam quality, suitable for applications requiring high energy such as laser cutting, lidar systems, and laser-induced breakdown spectroscopy.

- Semiconductor Lasers: These lasers are compact, low-cost, and readily integrated into smaller systems. They find application in optical communication systems, laser pointers, and laser-based sensors.

- Chemical Lasers: These lasers generate light through chemical reactions, often offering exceptionally high power output but are significantly larger and more complex than other types, usually applied in very specialized applications.

Aerospace Applications:

- Laser Rangefinding and Altimetry: Measuring distances and altitudes using laser pulses.

- Laser Communication: High-speed data transmission between satellites and ground stations.

- Lidar (Light Detection and Ranging): Remote sensing of the atmosphere and the Earth’s surface.

- Laser Guidance Systems: Precisely guiding missiles and bombs.

For example, the Landsat satellites utilize lidar systems to create detailed topographical maps, relying on the precise measurement capabilities of laser technology.

Q 19. What are the key considerations for designing an optical system for a satellite?

Designing an optical system for a satellite presents unique challenges, necessitating careful consideration of several key factors:

- Orbital Environment: The harsh space environment includes extreme temperatures, radiation, micrometeoroids, and vacuum. The system must withstand these conditions without performance degradation.

- Mission Requirements: The specific objectives of the mission dictate the optical system’s requirements, including resolution, field of view, spectral range, and signal-to-noise ratio.

- Power Consumption: Power is a limited resource in space; the optical system must be designed for minimal power consumption.

- Weight and Size: Spacecraft have stringent weight and size constraints, demanding a compact and lightweight design.

- Thermal Management: Temperature control is critical to maintain the optical system’s stability and performance. Effective thermal management mechanisms are essential.

- Pointing and Stability: Accurate pointing and stability are crucial for many satellite-based optical systems, necessitating precise control mechanisms.

- Radiation Hardness: Protecting optical components from radiation damage is paramount. Radiation-hardened materials and shielding strategies are essential.

- Testability and Maintainability: Designing for testability and maintaining functionality in space, even with component failure, should be planned for during the design phase.

Consider designing an optical system for an Earth observation satellite. The required resolution, field of view, and spectral range would influence the selection of lenses, sensors, and filters. Meeting the requirements while minimizing weight and power consumption requires careful engineering optimization.

Q 20. Explain the concept of stray light and its mitigation techniques.

Stray light refers to unwanted light that reaches the detector in an optical system, degrading image quality and potentially causing measurement errors. It can originate from various sources such as reflections from internal surfaces, scattering from particles, and external light sources. This phenomenon impacts image contrast, introduces noise, and affects the overall accuracy of measurements.

Mitigation Techniques:

- Baffles: These are strategically placed structures designed to block stray light by preventing direct light paths to the detector.

- Light Traps: These are designed to absorb stray light, typically using black coatings which efficiently absorb light to prevent reflection.

- Scattering Reduction: Minimizing scattering within the optical system, by careful selection of materials with low scattering properties, and through techniques to minimize surface roughness, can greatly reduce stray light.

- Surface Treatments: Applying anti-reflection coatings to optical surfaces reduces reflections and minimizes stray light.

- Mechanical Design: Carefully designing the optical system’s mechanical layout to minimize the possibility of direct or indirect light paths contributing to stray light is important.

In astronomical telescopes, stray light from the sun or moon can significantly affect image quality. Minimizing this stray light is crucial for achieving optimal performance. In a space telescope, the impact is even greater due to the presence of external sources of stray light.

Q 21. How do you perform optical system alignment and calibration?

Optical system alignment and calibration are critical steps to ensure optimal performance. The process typically involves:

- Alignment: This involves precisely positioning optical components to achieve the desired optical path and focus. Laser collimators and autocollimators are frequently employed in this step to achieve very high precision.

- Calibration: This involves determining the system’s optical characteristics and correcting for any aberrations or errors. This often involves specialized optical testing equipment.

Methods:

- Autocollimators: Used for precise angular measurements to ensure the correct orientation of components.

- Laser Interferometers: Precisely measure distances and ensure proper component spacing.

- Optical Test Bench: Provides a stable platform to carry out alignment and calibration procedures.

- Software Tools: Sophisticated software packages are employed for simulating and optimizing optical system performance.

Calibration Procedures: Typically involve using known reference sources and measuring the system’s response to these sources. This data then gets used to correct and compensate for known optical aberrations like chromatic aberration or spherical aberration. This is achieved by adjusting component positions and potentially by adding corrective optics.

For example, aligning a space-based telescope involves precisely positioning the primary and secondary mirrors to ensure that all light is focussed onto the focal plane. Calibration involves characterizing the telescope’s image quality and correcting for optical aberrations.

Q 22. Describe different types of optical filters and their applications.

Optical filters are essential components in aerospace optics, selectively transmitting or blocking specific wavelengths of light. They’re crucial for managing the spectral content reaching a sensor or protecting sensitive optical elements. Different filter types exist, each suited to particular applications.

- Bandpass Filters: These transmit light within a specific wavelength range, blocking light outside this range. Imagine a spotlight – a bandpass filter is like choosing a specific color of light to shine, while blocking the rest. Applications include isolating a specific spectral line for spectroscopy or creating narrow-band imaging for remote sensing.

- Longpass Filters (High-Pass): Transmit wavelengths longer than a specified cutoff wavelength. Think of sunglasses blocking UV light—they’re acting as a longpass filter. These are useful for removing shorter wavelengths that could interfere with observations.

- Shortpass Filters (Low-Pass): Transmit wavelengths shorter than a specified cutoff. A common example is in fluorescence microscopy, where a shortpass filter removes excitation light allowing only the emitted fluorescence to reach the detector.

- Neutral Density (ND) Filters: Reduce the intensity of light across a broad spectral range without altering its color significantly. This is like dimming a light without changing its hue. ND filters are widely used to control light levels in cameras or to protect sensors from overexposure.

- Interference Filters: These filters use interference phenomena to achieve highly selective wavelength transmission, offering extremely narrow bandwidths. They are commonly used in hyperspectral imaging systems for detailed spectral analysis.

The choice of filter depends heavily on the specific application. For example, a satellite imaging system might use a combination of bandpass filters to capture images in different spectral bands (visible, near-infrared, etc.), allowing scientists to differentiate vegetation types or mineral compositions. A space telescope might utilize narrowband filters to observe faint spectral lines from distant stars.

Q 23. What are the challenges in designing for extreme environmental conditions (e.g., vacuum, temperature extremes)?

Designing optical systems for extreme environments like those encountered in space presents significant challenges. Vacuum, extreme temperatures, and radiation all impact the performance and longevity of optical components.

- Vacuum: In a vacuum, outgassing from materials becomes a major concern. Outgassing can deposit contaminants on optical surfaces, degrading image quality. Materials must be carefully selected to minimize outgassing, and the optical design might include baffles to prevent stray light and contaminant buildup.

- Temperature Extremes: Temperature fluctuations cause thermal expansion and contraction of optical components, leading to misalignment and performance degradation. This requires the use of materials with low coefficients of thermal expansion (CTE) or implementing precise temperature control mechanisms. The design must also account for changes in refractive indices with temperature.

- Radiation: Radiation damage can cause degradation of optical materials, particularly in the case of long duration space missions. This requires careful selection of radiation-hardened materials, including specially designed glasses and coatings.

To mitigate these issues, aerospace optical engineers employ sophisticated modeling techniques, rigorous testing protocols, and specialized materials. For instance, we might use finite element analysis (FEA) to simulate the effects of temperature changes on the optical system, ensuring it maintains its alignment and performance under all expected operating conditions. Redundancy and fault tolerance are also crucial aspects of the design.

Q 24. Explain the principles of polarization optics and their applications.

Polarization optics deals with light’s polarization state, referring to the direction of its electric field oscillation. Unpolarized light oscillates in all directions, while polarized light oscillates in a specific direction. This property is exploited in various applications.

- Polarizers: These components transmit light with a specific polarization direction while blocking light with orthogonal polarization. Polaroid sunglasses are a common example, reducing glare by blocking horizontally polarized light reflected from surfaces.

- Waveplates: These optical elements alter the polarization state of light. A quarter-wave plate transforms linearly polarized light into circularly polarized light, and vice-versa. This is used in numerous applications, including enhancing signal-to-noise ratio in remote sensing and creating specific polarization states for laser systems.

- Polarization Beam Splitters (PBS): These split an incoming beam of light into two beams with orthogonal polarization states. This is used in interferometry, optical coherence tomography, and various laser applications.

In aerospace, polarization optics finds applications in areas like remote sensing, where it helps to reduce atmospheric scattering effects and improve image contrast. It’s also crucial in laser communication systems for maximizing signal strength and minimizing interference. For example, a satellite might use a polarizing filter to reduce glare from sunlight reflected off Earth’s surface, improving the quality of its Earth observation data.

Q 25. How do you choose the appropriate detector for a specific application?

Choosing the right detector for a specific aerospace application is crucial for mission success. The choice depends on numerous factors, including the wavelength range of interest, sensitivity requirements, speed, size, and environmental conditions.

- Wavelength Range: Different detectors are sensitive to different wavelengths. For example, silicon-based detectors are commonly used in the visible and near-infrared range, while InGaAs detectors are suitable for the near-infrared and shortwave infrared (SWIR).

- Sensitivity: This refers to the detector’s ability to detect low light levels. Applications requiring detection of faint signals, such as deep-space astronomy, will require high-sensitivity detectors.

- Speed: The detector’s readout speed determines how quickly it can acquire data. High-speed applications, like tracking fast-moving objects, demand fast detectors.

- Size and Format: The physical size and pixel format of the detector must be compatible with the optical system’s design and the required spatial resolution.

- Environmental Conditions: The detector must be able to withstand the environmental conditions of its intended application, including temperature extremes, radiation, and vacuum.

For instance, a satellite imaging system might use a large-format CCD or CMOS detector for high-resolution visible imagery, while a space telescope designed for infrared astronomy would use a specialized infrared detector like a mercury cadmium telluride (MCT) detector. A careful consideration of these factors ensures optimal performance and accurate data acquisition.

Q 26. Describe different types of optical benches and their applications.

Optical benches are platforms designed to precisely position and mount optical components, providing stability and alignment for optical systems. Different types cater to various needs.

- Rigid Optical Benches: These are robust, typically made of metal (aluminum or steel), offering excellent stability for static optical setups. They are often used in laboratory settings or for applications where high stability is paramount, such as calibration or precision measurement systems.

- Modular Optical Benches: These are highly versatile, using a system of interconnected components (beams, posts, clamps) that allow for flexible arrangements. They are ideal for prototyping or quickly reconfiguring optical setups. This modularity proves very valuable in research and development.

- Kinematic Mounts: These mounts constrain the optical component’s position using three points of contact, providing precise alignment and minimizing strain. This ensures high stability and repeatability, crucial for sensitive interferometers or other high-precision optical systems. The use of kinematic mounts also aids in thermal stability, a crucial design consideration for aerospace applications.

In aerospace applications, the choice of optical bench often depends on the size, weight, and stability requirements. For a space telescope, a rigid, lightweight, and thermally stable bench might be employed to minimize vibrations and maintain alignment during launch and operation. A smaller, lighter optical bench with kinematic mounts might be more appropriate for a smaller satellite sensor.

Q 27. Explain the use of Zemax or Code V in optical design and analysis.

Zemax and Code V are leading optical design and analysis software packages widely used in aerospace optics. They provide a powerful set of tools for designing, simulating, and optimizing optical systems.

These software packages enable engineers to:

- Design optical systems: Define lens shapes, materials, and other optical components, and then simulate their performance.

- Perform ray tracing: Trace the paths of light rays through the optical system to assess image quality, aberrations, and other performance parameters.

- Optimize designs: Use optimization algorithms to automatically adjust design parameters to achieve desired performance goals (e.g., minimize aberrations, maximize throughput).

- Analyze tolerance: Assess the impact of manufacturing tolerances on the optical system’s performance. This is essential for ensuring the system meets its specifications even with slight variations in component dimensions.

- Conduct tolerancing studies: Determine the sensitivity of the optical system performance to manufacturing errors and environmental factors.

Imagine designing a camera for a Mars rover. Using Zemax or Code V, engineers can model the optical system, considering factors like the atmosphere of Mars, and simulate the effects of dust and temperature variations on image quality. This allows them to refine the design and optimize the system’s performance before building a physical prototype.

Both Zemax and Code V offer similar functionalities but differ in their user interface and specific features. The choice often depends on personal preference and specific project needs. The software generates detailed reports and visualizations that provide invaluable insights into the optical system’s performance, allowing engineers to identify and correct design flaws before building and testing physical hardware.

Key Topics to Learn for Your Aerospace Optics Interview

- Optical Design and Engineering: Understand principles of geometrical optics, diffraction, interference, and polarization as applied to aerospace systems. Explore different optical design software and methodologies.

- Optical Materials and Coatings: Familiarize yourself with the properties of various optical materials (e.g., glass, crystals, polymers) and the purpose of anti-reflection and high-reflection coatings in aerospace applications. Consider the environmental challenges (temperature, pressure, radiation) these materials face.

- Optical Testing and Metrology: Learn about various techniques for characterizing optical components and systems, such as interferometry, wavefront sensing, and optical scattering measurements. Understand the importance of precision and accuracy in these measurements.

- Remote Sensing and Imaging: Explore the principles of aerial and satellite imaging systems, including sensor technologies, image processing, and data analysis techniques. Understand the challenges of acquiring high-quality images in diverse atmospheric conditions.

- Laser Systems and Applications: Familiarize yourself with different types of lasers used in aerospace applications (e.g., rangefinding, communication, lidar) and their underlying principles. Understand safety protocols and regulatory compliance.

- Fiber Optics and Integrated Optics: Understand the advantages of using fiber optics for communication and sensing in aerospace environments. Explore the principles of integrated optics and their potential applications in miniaturized aerospace systems.

- Optical Instrumentation and Control: Gain knowledge of the design and implementation of optical instruments used in aerospace applications, including the integration of control systems for precise positioning and operation.

- Problem-solving and Analytical Skills: Develop your ability to approach complex optical problems systematically, using both theoretical knowledge and practical experience to find effective solutions. Practice applying fundamental physics principles to real-world scenarios.

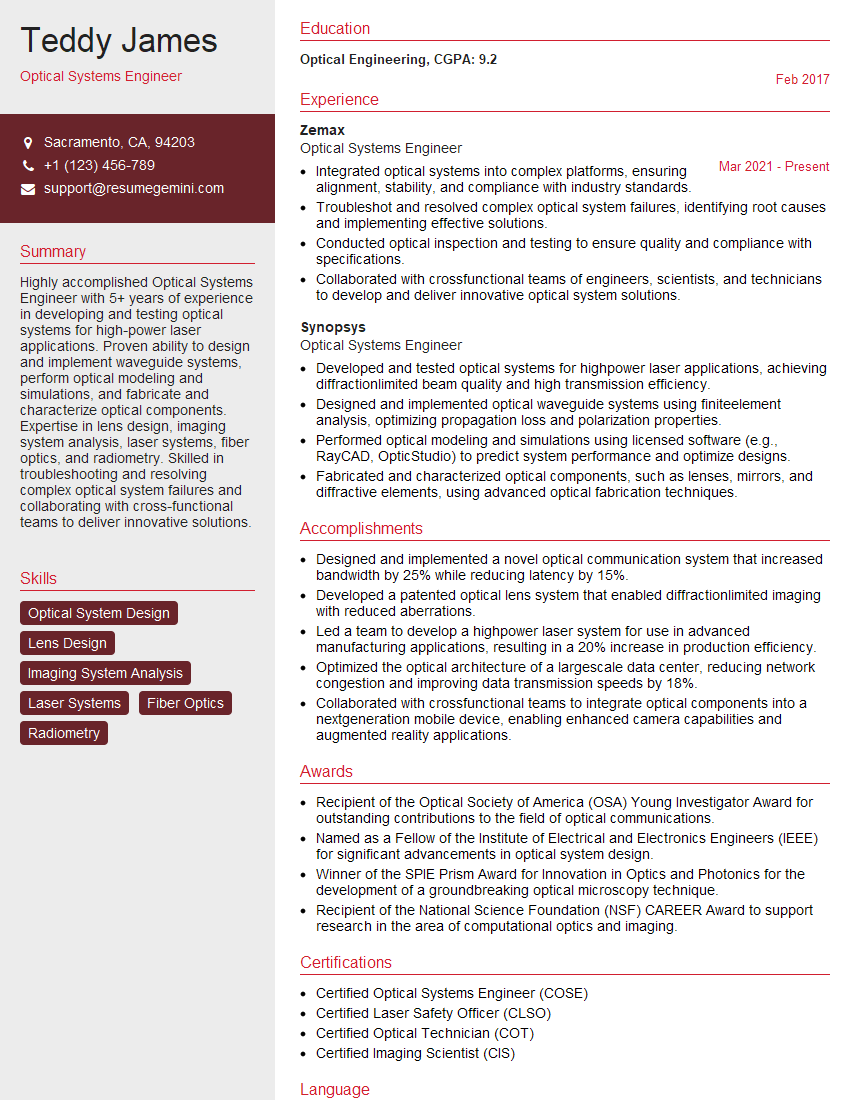

Next Steps

Mastering Aerospace Optics opens doors to exciting and impactful careers in a dynamic field. Your expertise will be highly sought after in companies pushing the boundaries of technological innovation. To significantly enhance your job prospects, creating a compelling and ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional resume tailored to highlight your unique skills and experience. We provide examples of resumes specifically crafted for Aerospace Optics professionals to help you get started. Invest in your future – invest in your resume.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good