Are you ready to stand out in your next interview? Understanding and preparing for Agricultural Structures interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Agricultural Structures Interview

Q 1. Explain the principles of structural design for agricultural buildings.

Designing agricultural structures requires a deep understanding of structural mechanics, material science, and agricultural practices. The core principle is to create a safe, durable, and cost-effective building that meets the specific needs of the agricultural operation. This involves analyzing loads (live loads like livestock, stored crops, snow; and dead loads like the building’s weight), considering environmental factors (wind, snow, seismic activity), and selecting appropriate materials and construction methods to withstand these forces. For instance, a poultry house needs to withstand significant live load from the birds, while a grain storage facility must account for the immense weight of harvested grain. The design must also factor in the building’s lifespan and the potential for expansion or modification.

Engineers use sophisticated software and calculations to ensure the structural integrity of the building. This process often involves detailed drawings and specifications to guide the construction process. A critical aspect is to ensure that the foundation is strong enough to support the entire structure, preventing settling or collapse.

Q 2. Describe different types of roofing systems used in agricultural structures.

Agricultural buildings utilize various roofing systems, each with its strengths and weaknesses. The choice depends on factors like climate, budget, and intended use.

- Gabled roofs: Simple, economical, and effective at shedding snow and rain. They are commonly seen on barns and other storage structures.

- Hip roofs: Offer better wind resistance than gabled roofs, making them suitable for areas with high wind speeds. They are often preferred for larger structures.

- Gambrel roofs: Have a double slope, maximizing interior space while maintaining good water runoff. These are frequently found in barns, providing ample storage space.

- Monitor roofs: Feature a raised central section, improving ventilation and natural light in structures like greenhouses and livestock facilities.

- Arched roofs: Used in some greenhouses and other specialized buildings, arched roofs provide strength and can be cost-effective due to the simplified construction.

Material selection varies: metal roofing is durable and low-maintenance; wood offers a more traditional aesthetic but requires regular maintenance. Asphalt shingles are a common choice for simpler structures but have a shorter lifespan compared to metal.

Q 3. What are the key considerations for designing a livestock facility?

Designing a livestock facility demands careful consideration of animal welfare, hygiene, and operational efficiency. Key factors include:

- Space allocation: Sufficient space per animal is crucial to prevent stress and disease. Regulations and animal welfare standards should guide this design aspect.

- Ventilation: Proper airflow is vital to maintain optimal temperature and humidity levels, minimizing ammonia buildup and respiratory problems in the animals. This requires carefully positioned ventilation systems, often incorporating fans and inlets.

- Waste management: Effective manure management is critical for hygiene and environmental protection. Design should incorporate features for easy cleaning and waste removal, often using slatted floors or other specialized systems.

- Climate control: Temperature and humidity control can be crucial for certain livestock, particularly during extreme weather conditions. Insulation, heating, and cooling systems may be incorporated, depending on the climate and type of animal.

- Biosecurity: Preventing the spread of disease requires careful planning of traffic flow, isolation areas, and disinfection protocols. This aspect is crucial for the overall health of the herd.

For example, a dairy farm needs to consider milk handling and storage space, while a pig farm will prioritize waste management and efficient cleaning systems.

Q 4. How do you ensure proper ventilation in a greenhouse?

Proper ventilation in a greenhouse is essential for maintaining optimal growing conditions for plants. This involves balancing temperature, humidity, and CO2 levels. Effective ventilation prevents overheating, condensation, and the buildup of harmful gases.

Ventilation strategies typically involve a combination of:

- Natural ventilation: Utilizing vents, windows, and roof openings to allow air circulation driven by temperature differences. Placement of these openings is critical to optimize airflow.

- Forced ventilation: Using fans to extract hot, humid air and draw in fresh air. Fan size and placement are crucial factors, calculated based on greenhouse dimensions and climate.

- Air circulation: Implementing fans within the greenhouse to move air around the plants, improving uniformity of temperature and humidity.

Monitoring CO2 levels is important, as plants require a balance of CO2 for photosynthesis. In some cases, supplemental CO2 may be introduced.

The design must also consider the vulnerability of greenhouses to strong winds; proper windbreaks and structural reinforcement may be necessary.

Q 5. Discuss the factors affecting the selection of building materials for agricultural structures.

Material selection for agricultural structures is a crucial decision impacting cost, durability, and maintenance. Factors influencing this choice include:

- Cost: Budget constraints often dictate material choices, with cost-effective options like wood or metal often preferred.

- Durability: Materials should withstand the harsh environmental conditions, including extreme temperatures, moisture, and wind. Concrete, steel, and certain treated woods are known for their durability.

- Maintenance: Low-maintenance materials minimize long-term costs. Metal roofing, for example, is often chosen for its durability and low maintenance needs.

- Sustainability: Using sustainably sourced materials is increasingly important, with options like recycled steel or responsibly harvested timber becoming more prevalent.

- Specific use: The intended use of the building influences material choices. A poultry house might utilize materials resistant to ammonia corrosion, while a grain storage facility would prioritize fire resistance.

For example, a simple hay storage barn might use readily available lumber, while a high-tech greenhouse may incorporate specialized plastics and reinforced steel.

Q 6. Explain the importance of proper drainage around agricultural buildings.

Proper drainage around agricultural buildings is essential for preventing water damage and maintaining a hygienic environment. Poor drainage can lead to foundation problems, structural damage, and the creation of muddy areas, which can harbor pests and disease.

Effective drainage involves:

- Grading: Sloping the land away from the building’s foundation to direct water runoff. This prevents water from accumulating around the building.

- Gutters and downspouts: Directing rainwater away from the building’s walls and foundation.

- Drainage ditches or swales: Channels to collect and divert water away from the building.

- French drains: Underground drainage systems that collect subsurface water and channel it away.

- Permeable paving: Using materials that allow water to seep into the ground, reducing surface runoff.

Neglecting proper drainage can lead to costly repairs and affect animal health and productivity in livestock facilities.

Q 7. Describe different types of foundation systems suitable for agricultural structures.

The choice of foundation system for an agricultural building depends on several factors, including soil conditions, building size, and budget.

- Spread footings: Simple and economical for smaller structures on stable soil. These are individual concrete footings supporting each column or wall section.

- Continuous footings: Used for longer walls or structures where spread footings would be impractical. They are typically continuous strips of concrete.

- Slab-on-grade: A concrete slab poured directly onto the ground, suitable for lighter structures and stable soil. It’s common for smaller barns or greenhouses.

- Pier and beam foundations: Involve concrete piers supporting the building’s structure, with beams connecting them. This system is suitable for areas with poor soil conditions or where a crawlspace is desired.

- Basement foundations: Provides usable space below the ground, but are more expensive and complex, requiring excavation and waterproofing. These are less common in agricultural applications, unless there is a need for specific storage or functionality.

Geotechnical investigations are often conducted to determine the appropriate foundation type for a specific site. The soil’s bearing capacity plays a crucial role in selecting the foundation system.

Q 8. How do you design for seismic activity in agricultural buildings?

Designing agricultural structures for seismic activity involves understanding the local seismic zone and incorporating strategies to withstand earthquake forces. This isn’t just about preventing collapse; it’s about minimizing damage and ensuring continued operational functionality after an earthquake. We aim to achieve this through several key design elements.

- Site Selection: Choosing a stable site away from fault lines is crucial. Geotechnical investigations are essential to understand soil properties and potential liquefaction risks.

- Foundation Design: Strong foundations are paramount. Options include shallow foundations (spread footings, rafts) for stable soils, and deep foundations (piles, caissons) for weaker or liquefiable soils. The foundation’s design needs to distribute the building’s weight effectively and resist lateral forces during shaking.

- Structural System: The choice of structural system significantly impacts seismic performance. Moment-resisting frames, braced frames, and shear walls provide excellent lateral resistance. The use of ductile materials that can deform significantly without fracturing is critical. Steel and reinforced concrete are commonly used. We also consider the use of base isolation systems in high-risk areas, which decouple the building from the ground movement.

- Connections: Strong and ductile connections between structural elements are crucial to ensure the structure behaves as a unified system during an earthquake. Proper detailing of connections is critical to prevent brittle failures.

- Regular Inspections and Maintenance: Regular inspections and maintenance are vital to identify and address any potential issues before they become significant problems. Early detection can prevent catastrophic damage during a seismic event.

For example, a dairy barn in a high seismic zone might utilize a reinforced concrete frame with shear walls, ensuring stability and minimizing damage during an earthquake. This allows for quicker recovery and reduces the economic impact of the event.

Q 9. What are the considerations for designing a silo for grain storage?

Designing a silo for grain storage involves careful consideration of several critical factors to ensure structural integrity, efficient storage, and safety. These factors include:

- Capacity and Dimensions: The silo’s size and shape should be determined by the volume of grain to be stored. The diameter and height are key considerations, influencing structural stability and material requirements.

- Material Selection: Common materials include steel, concrete, and wood. Each has its advantages and disadvantages in terms of cost, durability, and maintenance. Steel silos offer flexibility and are relatively easy to construct, while concrete silos provide excellent durability but require more specialized construction techniques. Wood is less common for larger silos.

- Structural Design: The silo must be designed to withstand the significant lateral pressures exerted by the stored grain. This requires meticulous calculations to ensure stability and prevent collapse. The design should account for factors like grain weight, friction, and potential settlement.

- Foundation: A strong foundation is crucial to distribute the silo’s weight and resist settlement and uplift. The soil conditions must be thoroughly evaluated to determine the appropriate foundation type.

- Aeration and Ventilation: Proper ventilation is essential to prevent grain spoilage and insect infestation. Incorporating aeration systems allows for controlled air circulation throughout the silo.

- Discharge System: Efficient grain discharge is vital. This typically involves incorporating mechanisms such as hopper bottoms or augers to facilitate smooth and rapid removal of stored grain. This minimizes the risk of bridging (grain clogging) and ensures proper outflow.

- Safety Features: Safety features are paramount. This includes features like access ladders, safety rails, and emergency exits, ensuring safe access and operation.

For example, a large steel silo for corn storage in a flat, stable region would necessitate a robust foundation and precise structural calculations to account for the weight of the grain, especially when full. Proper aeration and discharge systems are crucial to maintain grain quality and allow for efficient harvesting.

Q 10. Explain the principles of designing for efficient energy use in agricultural buildings.

Designing for efficient energy use in agricultural buildings focuses on minimizing energy consumption while maintaining a comfortable and productive environment. This involves a multi-faceted approach.

- Building Orientation and Shape: Optimizing building orientation to minimize solar heat gain in summer and maximize solar heat gain in winter can significantly reduce heating and cooling loads. A compact building shape reduces surface area, minimizing heat loss or gain.

- Insulation and Air Sealing: Proper insulation of walls, roofs, and floors reduces heat transfer, minimizing the need for heating and cooling. Air sealing prevents drafts and reduces infiltration losses.

- High-Performance Windows and Doors: Energy-efficient windows and doors with low U-values (a measure of heat transfer) are crucial for reducing heat loss in winter and heat gain in summer.

- Natural Ventilation: Utilizing natural ventilation strategies, such as strategically placed openings and wind catchers, can reduce reliance on mechanical ventilation systems.

- Energy-Efficient Lighting: Employing LED lighting systems can significantly reduce electricity consumption compared to traditional lighting.

- Renewable Energy Sources: Incorporating renewable energy sources like solar panels or wind turbines can offset energy consumption and reduce reliance on the grid.

- Building Management Systems: Implementing smart building management systems that monitor and control environmental conditions can optimize energy use and ensure a comfortable environment.

For example, a poultry barn could incorporate solar panels to offset electricity consumption, utilize natural ventilation during moderate temperatures, and employ high-performance insulation to minimize heat loss in winter. A well-designed greenhouse might utilize passive solar heating and natural ventilation to minimize energy use for heating and cooling.

Q 11. How do you incorporate sustainable practices in agricultural structure design?

Incorporating sustainable practices in agricultural structure design extends beyond energy efficiency. It encompasses a holistic approach that minimizes environmental impact throughout the building’s lifecycle.

- Material Selection: Using locally sourced, recycled, or renewable materials such as timber from sustainably managed forests, recycled steel, or straw bales reduces transportation costs and environmental impact. Consider the embodied energy associated with different materials.

- Water Management: Implementing rainwater harvesting systems can provide a sustainable source of water for irrigation and other uses. Designing for water efficiency within the structure (e.g., low-flow fixtures) is important.

- Waste Management: Minimizing construction waste through careful planning and material selection is crucial. Recyclable materials should be prioritized, and disposal of non-recyclable materials should adhere to environmental regulations.

- Lifecycle Assessment: Conducting a lifecycle assessment helps evaluate the environmental impact of the structure from design to demolition, allowing for informed decisions about material selection and construction methods.

- Site Selection and Landscape Design: Minimizing land disturbance and preserving natural habitats during site selection is vital. Integrating the structure with the landscape through appropriate planting and design enhances its sustainability.

For example, a dairy barn might utilize rammed earth walls for thermal mass and structural stability, locally sourced timber for framing, and rainwater harvesting for cleaning. A greenhouse could leverage natural light and ventilation to minimize energy use and incorporate recycled materials in its construction.

Q 12. What are the building codes and regulations relevant to agricultural structures in your region?

Building codes and regulations for agricultural structures vary by region and are often less stringent than those for residential or commercial buildings. However, they are crucial for ensuring public safety and structural integrity. In my region, relevant codes often address:

- Structural Requirements: These specify design loads (wind, snow, etc.), material specifications, and structural detailing requirements to ensure the building can withstand anticipated forces.

- Fire Safety: Regulations covering fire prevention and suppression systems, emergency exits, and fire-resistant materials are essential, especially for structures housing livestock or flammable materials.

- Accessibility: Depending on the type of agricultural building, codes may specify accessibility requirements for people with disabilities.

- Environmental Regulations: Regulations pertaining to environmental impacts, such as runoff management, waste disposal, and air quality, are increasingly important.

- Animal Welfare: For structures housing livestock, codes often include specific requirements for animal welfare, such as adequate ventilation, space allowances, and hygiene standards.

It is essential to consult the specific building codes and regulations of the relevant jurisdiction before commencing any agricultural construction project. These regulations are subject to change, so staying informed is vital.

Q 13. Describe the process of obtaining permits for agricultural construction projects.

Obtaining permits for agricultural construction projects typically involves a multi-step process:

- Preliminary Planning and Design: Develop a detailed design plan including site plans, structural drawings, and specifications that comply with all applicable building codes and regulations.

- Application Submission: Submit a formal application to the relevant authorities (county or municipal building department, planning commission, etc.) This usually involves filling out application forms, providing necessary drawings and documentation, and paying application fees.

- Review and Approval: The permitting authority reviews the application to ensure compliance with regulations. This may involve inspections of the proposed site and revisions to the design plans. The review process can take several weeks or months, depending on the complexity of the project.

- Permit Issuance: Once the application is approved, the permitting authority issues the necessary building permits.

- Construction and Inspections: Construction can commence once the permits are issued. The permitting authority will conduct inspections at various stages of construction to ensure compliance with approved plans and codes.

- Final Inspection and Certificate of Occupancy: Upon completion of construction, a final inspection is conducted. If the structure meets all requirements, a certificate of occupancy is issued, authorizing the use of the building.

Navigating this process requires careful planning and attention to detail. Consulting with a qualified architect or engineer familiar with local regulations can significantly streamline the process.

Q 14. What are some common problems encountered during the construction of agricultural structures?

Several common problems can arise during the construction of agricultural structures:

- Soil Issues: Unexpected soil conditions, such as unstable soils or high water tables, can lead to foundation problems and delays. Thorough geotechnical investigations are crucial to avoid these issues.

- Material Shortages or Delays: Delays in material delivery can disrupt the construction schedule and increase costs. Careful planning and procurement are necessary to mitigate this risk.

- Poor Weather Conditions: Adverse weather can significantly impact construction progress, causing delays and increasing costs. Contingency planning is vital to address potential weather-related disruptions.

- Inadequate Site Preparation: Inadequate site preparation, such as poor drainage or lack of access, can lead to delays and complications. Proper site preparation is essential before construction begins.

- Lack of Skilled Labor: Shortage of skilled labor can affect the quality of construction and increase the project timeline. Ensuring access to skilled workers is crucial.

- Changes in Design or Specifications: Changes to the original design or specifications during construction can lead to delays and increased costs. Thorough planning and clear communication are essential to avoid such issues.

Proactive planning, careful site investigation, and clear communication throughout the construction process can minimize the likelihood of encountering these common problems. Working with experienced contractors who are familiar with agricultural construction can also significantly reduce the risk.

Q 15. How do you manage risks associated with agricultural construction projects?

Managing risks in agricultural construction is crucial for project success and safety. It involves a proactive approach encompassing several key strategies. Think of it like building a strong foundation for a house – you wouldn’t skip steps, would you?

- Thorough Site Assessment: Before construction begins, a detailed site analysis is essential. This includes soil testing, assessing drainage, considering environmental factors (like potential flooding or extreme weather), and evaluating potential hazards like underground utilities. For example, discovering unstable soil early on prevents costly foundation issues later.

- Detailed Planning & Design: A well-defined plan, including detailed blueprints and specifications, minimizes errors and unforeseen challenges. This also includes selecting appropriate materials and construction methods suitable for the local climate and soil conditions. Think of it as having a roadmap before embarking on a long journey.

- Risk Assessment & Mitigation: Identifying potential risks – like equipment malfunctions, worker injuries, or material shortages – and developing mitigation strategies is paramount. This might involve procuring insurance, implementing safety protocols, and establishing contingency plans for material delays.

- Regular Monitoring & Inspections: Consistent monitoring of the construction progress ensures adherence to plans and identifies potential problems early. Regular inspections by qualified professionals ensure quality control and address any emerging risks promptly.

- Communication & Collaboration: Open communication among contractors, engineers, and clients is vital. Regular meetings and progress reports ensure everyone is on the same page and issues are addressed collaboratively.

Ignoring these steps can lead to cost overruns, delays, and even safety hazards. A comprehensive risk management plan is the cornerstone of a successful agricultural construction project.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with different types of agricultural equipment used in construction.

My experience encompasses a wide range of agricultural equipment used in construction. I’ve worked extensively with:

- Earthmoving Equipment: This includes excavators, bulldozers, and loaders for site preparation, excavation, and grading. For instance, an excavator is vital for digging foundations and trenches for irrigation systems. The efficiency and precision of these machines directly impact project timelines.

- Material Handling Equipment: Forklifts, cranes, and telehandlers are essential for moving materials such as concrete, timber, and steel. The right choice of equipment ensures safe and efficient material handling, reducing the risk of accidents.

- Specialized Agricultural Machinery: I’ve worked with equipment specifically designed for agricultural structures, like post-hole diggers, concrete mixers, and specialized spreaders for fertilizers and soil amendments. The use of such equipment optimizes efficiency and minimizes manual labor.

- Precision Agricultural Technology: Increasingly, GPS-guided machinery and laser leveling systems are used to ensure precise construction and improve efficiency. These technologies guarantee accuracy in tasks such as land leveling for barns or creating irrigation canals, minimizing waste and ensuring optimized functionality.

My familiarity with these machines extends beyond basic operation; I understand their maintenance requirements, safety procedures, and limitations. This knowledge helps me optimize project schedules and ensure the safe and effective execution of each phase of construction.

Q 17. What are the safety considerations for workers during the construction of agricultural structures?

Safety is paramount in agricultural construction. It’s not just about complying with regulations; it’s about safeguarding the well-being of the entire team. We employ a multi-layered approach, focusing on:

- Site Safety Plans: Before work starts, a detailed safety plan is developed, outlining potential hazards, appropriate personal protective equipment (PPE), emergency procedures, and safety training requirements.

- PPE Provision and Use: Providing and enforcing the correct PPE, including hard hats, safety glasses, gloves, and high-visibility clothing, is crucial. Regular checks ensure everyone is using their PPE correctly. A simple example: Requiring steel-toed boots to prevent foot injuries from dropped objects.

- Hazard Control Measures: Implementing measures to control specific hazards – like fall protection for elevated work, machine guarding to prevent entanglement, and proper signage to delineate hazardous areas – is crucial. For example, using barricades to prevent workers from entering unstable areas.

- Regular Safety Training: Workers receive regular safety training on equipment operation, hazard recognition, and emergency response procedures. Refresher courses and on-site training ensure knowledge stays current.

- Emergency Response Plan: Having a clear emergency response plan with designated personnel and communication protocols is vital for quick response in case of accidents or emergencies.

Neglecting safety can lead to serious injuries, delays, and legal ramifications. A strong safety culture, backed by clear procedures and regular training, is fundamental to any successful agricultural construction project.

Q 18. How do you ensure the structural integrity of existing agricultural buildings?

Ensuring the structural integrity of existing agricultural buildings requires a thorough assessment and proactive maintenance strategy. It’s like regular check-ups for your health – preventative care is better than a major repair.

- Regular Inspections: Visual inspections, both internal and external, identify signs of deterioration such as cracks in walls, rotting timber, or rusting metal. This is similar to regularly checking your car’s tires to prevent flat tires.

- Structural Assessments: For older or damaged structures, a professional structural engineer can perform a more in-depth assessment to determine the extent of any damage and recommend appropriate remediation.

- Load Capacity Analysis: Assessing the building’s capacity to withstand current and projected loads (e.g., stored materials, snow) is vital. Overloading can cause structural failure.

- Material Testing: Samples of materials (wood, concrete, steel) can be tested to determine their strength and degradation level. This helps determine the need for repairs or replacements.

- Preventative Maintenance: Regular maintenance, such as roof repairs, pest control, and gutter cleaning, prevents small problems from escalating into larger, more costly issues.

A proactive approach, combining regular inspections and preventative maintenance, helps extend the lifespan of agricultural buildings and prevents costly and potentially dangerous failures.

Q 19. What methods do you use to assess the condition of aging agricultural structures?

Assessing the condition of aging agricultural structures involves a systematic approach, combining visual inspection with more detailed investigations where necessary. It’s like a doctor diagnosing a patient – we need to gather sufficient evidence.

- Visual Inspection: This is the initial step, involving a thorough examination of the building’s exterior and interior, noting any visible signs of deterioration (cracks, rot, rust, settlement). Photographs and detailed notes document the findings.

- Non-Destructive Testing (NDT): Techniques like ultrasonic testing, ground-penetrating radar, and infrared thermography can be used to assess the condition of materials without causing damage. These methods help identify internal flaws or structural weaknesses.

- Load Testing: In some cases, controlled load testing may be necessary to determine the building’s ability to withstand its intended load. This is usually done by professional structural engineers.

- Material Sampling: Taking samples of materials (wood, concrete, steel) for laboratory testing determines their strength and degradation levels.

- Historical Records: Reviewing the building’s construction history, maintenance records, and previous inspections can provide valuable context and insights into potential problems.

The combination of these methods provides a comprehensive picture of the structure’s condition, allowing for informed decisions regarding repairs, renovations, or demolition.

Q 20. Describe your experience with structural repairs and renovations of agricultural buildings.

My experience in structural repairs and renovations of agricultural buildings is extensive. I’ve managed projects ranging from minor repairs to complete renovations. Each project requires a tailored approach based on the specific needs and challenges.

- Repairing Damaged Structures: This might involve repairing cracked walls, replacing rotten timbers, or fixing damaged roofing. We prioritize using materials and techniques compatible with the existing structure.

- Renovating Existing Buildings: Renovations often involve upgrading insulation, improving ventilation, and incorporating modern building technologies to enhance energy efficiency and functionality. For example, we might replace old windows with energy-efficient ones.

- Strengthening Existing Structures: Adding structural supports, such as steel beams or reinforced concrete foundations, strengthens older or weakened structures, increasing their lifespan and load-bearing capacity.

- Adapting Existing Structures: We often adapt existing structures for new purposes. For instance, converting an old hay barn into a workshop or storage facility.

- Modernization: Integrating modern technologies, like automated ventilation systems or smart climate control, improves efficiency and reduces operational costs.

Successful repairs and renovations require careful planning, attention to detail, and adherence to building codes and safety regulations. My experience ensures projects are completed on time, within budget, and meet the client’s specific needs.

Q 21. Explain your understanding of different types of irrigation systems.

Irrigation systems are critical for efficient and productive agriculture. Different systems cater to varying needs and conditions. Think of it like choosing the right tool for the job.

- Surface Irrigation: This involves flooding or furrow irrigation, where water flows over the land surface. It’s simple and cost-effective but can be inefficient and lead to waterlogging. Suitable for flat, level fields.

- Sprinkler Irrigation: Water is sprayed onto the field using sprinklers, mimicking natural rainfall. This method is efficient and versatile, suitable for various terrains and crops. Different sprinkler types (e.g., center pivot, lateral move) exist, each with advantages and disadvantages.

- Drip Irrigation (Micro-Irrigation): Water is delivered directly to the plant roots through a network of tubes and emitters. This is the most water-efficient method, minimizing water waste and runoff. Ideal for orchards, vineyards, and high-value crops.

- Subsurface Irrigation: Water is applied below the soil surface through buried pipes. This method conserves water, reduces weed growth, and minimizes evaporation. However, it requires a higher initial investment.

- Subsurface Drip Irrigation (SDI): Combining the benefits of drip irrigation and subsurface application, SDI offers high water use efficiency and reduced evaporation losses. It also minimizes weed growth and requires less maintenance than surface systems.

Choosing the right irrigation system depends on factors such as topography, soil type, crop type, water availability, and budget. A proper assessment of these factors is crucial for selecting the most efficient and effective system.

Q 22. How do you design an efficient irrigation system for a specific crop?

Designing an efficient irrigation system starts with understanding the crop’s specific water needs. We need to consider factors like the crop type, its growth stage, soil type, climate, and available water resources. This involves a multi-step process:

- Crop Water Requirements: Determining the evapotranspiration (ET) rate – the amount of water lost to the atmosphere through evaporation and transpiration – is crucial. This varies greatly depending on the crop, its growth stage, and environmental factors. We often use weather data, soil moisture sensors, and crop coefficients to estimate ET.

- Irrigation Method Selection: Choosing the right method – drip, sprinkler, furrow, or subsurface – depends on factors like topography, soil type, water availability, and the crop’s sensitivity to water stress. For instance, drip irrigation is highly efficient for high-value crops like fruits and vegetables, minimizing water waste and maximizing water delivery to the roots. Sprinkler irrigation is more suitable for large fields with uniform topography.

- System Design and Layout: This involves creating a detailed plan showing the location of water sources, pumps, pipes, valves, and emitters. We utilize computer-aided design (CAD) software to create precise maps and ensure optimal water distribution. The design needs to consider pressure, flow rates, and the uniformity of water application to prevent over or under-watering.

- Monitoring and Control: Incorporating sensors and automated control systems allows for real-time monitoring of soil moisture, water pressure, and flow rates. This allows for adjustments to irrigation schedules based on actual conditions, improving efficiency and minimizing water waste. For example, we might use soil moisture sensors to trigger irrigation only when necessary.

For example, in a project involving a vineyard, we might opt for a drip irrigation system to deliver water directly to the roots, minimizing water loss and preventing fungal diseases. Conversely, a large-scale wheat farm might benefit more from a center-pivot sprinkler system for its cost-effectiveness and coverage.

Q 23. Discuss the importance of precision agriculture in optimizing resource use.

Precision agriculture significantly optimizes resource use by allowing farmers to precisely target inputs like water, fertilizers, and pesticides based on the specific needs of individual areas within a field. This reduces waste and improves environmental sustainability while boosting yields and profitability.

- Variable Rate Technology (VRT): VRT enables the application of inputs at varying rates across a field based on real-time data. For example, a GPS-guided fertilizer spreader can apply more fertilizer to areas with lower nutrient levels, optimizing nutrient use and reducing environmental impact.

- Remote Sensing and GIS: Satellite imagery, drones, and sensors provide valuable data on crop health, soil conditions, and water stress. This information is used to create detailed maps and guide decisions about input application. For example, detecting areas of water stress from satellite imagery allows for targeted irrigation, conserving water and preventing crop loss.

- Data Analytics and Modeling: Sophisticated software analyzes the collected data to generate predictive models and optimize resource management strategies. This enables farmers to make informed decisions about planting, irrigation, fertilization, and pest control, maximizing efficiency and profitability.

Consider a large cornfield. Using precision agriculture, farmers can identify areas of nutrient deficiency via soil sensors and aerial imagery. This allows for precise application of fertilizers only where needed, unlike traditional blanket application, which leads to substantial waste and potential environmental pollution.

Q 24. Explain your familiarity with various types of agricultural software and tools.

My familiarity with agricultural software and tools is extensive. I’m proficient in various GIS software packages like ArcGIS and QGIS for spatial data analysis and mapping. I use precision agriculture software like AgLeader, John Deere Operations Center, and Climate FieldView for data collection, analysis, and prescription generation. I also utilize CAD software, such as AutoCAD, for designing agricultural structures and irrigation systems. Furthermore, I’m experienced with farm management software that helps track yields, expenses, and other key metrics, improving overall farm efficiency.

For example, in a recent project, we used ArcGIS to map soil nutrient levels and create variable rate fertilizer prescriptions, optimizing fertilizer usage and reducing environmental impact. We then used AgLeader to control the application of fertilizers according to the prescription, ensuring precise and efficient application.

Q 25. What is your experience with cost estimation and budgeting for agricultural construction projects?

Cost estimation and budgeting are critical aspects of successful agricultural construction projects. My experience involves developing detailed cost breakdowns encompassing materials, labor, equipment rental, permits, and contingency costs. I utilize various cost estimation methods like parametric estimating, unit pricing, and bottom-up estimating, depending on the project’s complexity and available data. I create comprehensive budgets, tracking expenses against the baseline budget and adjusting as needed throughout the project life cycle. This includes regular reporting to stakeholders, ensuring transparency and effective financial management.

In a recent greenhouse project, for instance, I developed a detailed cost estimate by breaking down the expenses for materials (steel, glass, insulation), labor (skilled and unskilled), equipment (cranes, excavators), permits, and a contingency buffer of 10% to account for unforeseen circumstances. This helped the client effectively manage their budget and avoid financial overruns.

Q 26. Describe your experience with project management software for agricultural construction.

I have extensive experience using various project management software solutions for agricultural construction, including Microsoft Project, Primavera P6, and Asana. These tools enable effective task scheduling, resource allocation, progress tracking, and risk management. The software helps streamline communication, collaboration, and documentation, ensuring projects are delivered on time and within budget. I tailor my software selection to the project’s specific needs and complexity.

For example, in a large-scale barn construction project, we used Primavera P6 to create a detailed project schedule, assigning tasks to teams, tracking progress against milestones, and identifying potential schedule conflicts. This ensured the project was completed efficiently and on schedule.

Q 27. How do you manage conflicts and disagreements among stakeholders in an agricultural construction project?

Managing conflicts among stakeholders in an agricultural construction project requires proactive communication, clear expectations, and a collaborative approach. I foster open dialogue, facilitating discussions where all stakeholders can express their concerns and perspectives. I prioritize active listening and strive to understand the root causes of disagreements. When conflicts arise, I employ conflict resolution techniques such as mediation and negotiation, aiming for mutually agreeable solutions that balance competing interests. Maintaining clear documentation of agreements and decisions is critical to avoid future misunderstandings.

In one instance, a disagreement arose between the farmer and the contractor regarding the timeline for completing a silo construction. Through facilitated discussions, I helped identify the reasons for the delay (unexpected weather conditions), and together, we developed a revised schedule acceptable to both parties, preserving the collaborative relationship.

Q 28. Describe your approach to problem-solving in a complex agricultural structure project.

My approach to problem-solving in complex agricultural structure projects involves a systematic and analytical process. I begin by thoroughly defining the problem, gathering relevant data, and identifying contributing factors. This often involves on-site inspections, data analysis, and consultations with specialists. I then generate multiple potential solutions, evaluating their feasibility, cost-effectiveness, and impact on project goals. This evaluation often involves using decision-making matrices and risk assessments. Once a solution is selected, I develop an implementation plan, clearly defining responsibilities and timelines. Finally, I monitor the solution’s effectiveness and make necessary adjustments based on progress and feedback.

For example, when facing unexpected soil instability during a greenhouse foundation construction, I first gathered geotechnical data to understand the nature of the problem. This led to exploring solutions like soil stabilization techniques and foundation redesign. After analyzing costs and timelines, we opted for soil stabilization, which proved to be a cost-effective and timely solution that prevented project delays.

Key Topics to Learn for Agricultural Structures Interview

- Design Principles: Understanding structural mechanics, load bearing, and material selection specific to agricultural environments (e.g., wind loads, snow loads, seismic activity).

- Building Materials: Knowledge of various materials used in agricultural structures (wood, steel, concrete, composites) – their properties, advantages, disadvantages, and appropriate applications.

- Environmental Considerations: Analyzing the impact of agricultural structures on the environment, including sustainability, energy efficiency, and waste management.

- Livestock Housing: Designing and managing structures for various animal species, considering factors like climate control, hygiene, and animal welfare.

- Storage Structures: Understanding the design and construction of grain silos, barns, and other storage facilities, including considerations for pest control and moisture management.

- Precision Agriculture: Incorporating technology into agricultural structures, such as automated climate control, sensor networks, and data acquisition systems.

- Structural Analysis & Calculations: Ability to perform basic structural calculations, analyze load paths, and ensure structural integrity using relevant software or hand calculations.

- Construction Methods & Practices: Familiarity with different construction techniques and best practices specific to agricultural structures, including safety regulations.

- Cost Estimation & Budgeting: Experience in estimating project costs, creating budgets, and managing resources effectively.

- Troubleshooting & Maintenance: Ability to identify and resolve common problems in agricultural structures, and develop preventative maintenance plans.

Next Steps

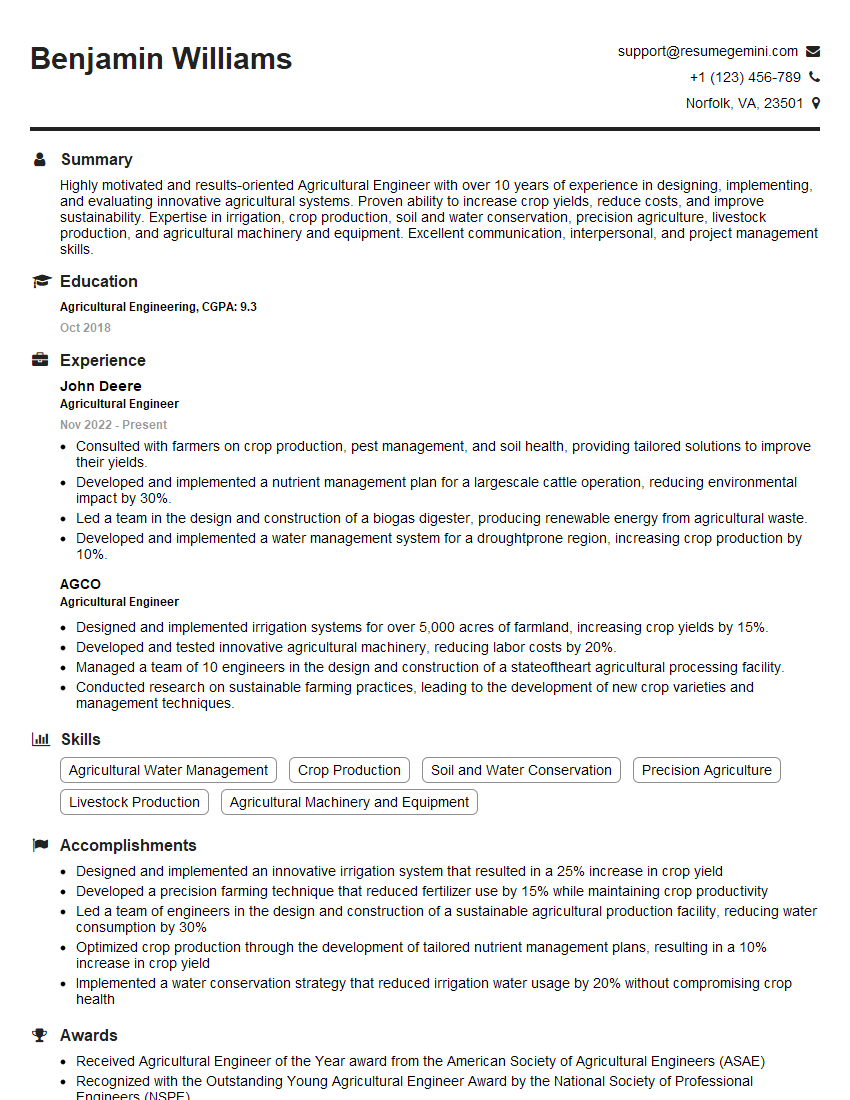

Mastering Agricultural Structures is crucial for a successful and rewarding career in this vital field. A strong understanding of these principles opens doors to exciting opportunities in design, construction, and management within the agricultural sector. To significantly enhance your job prospects, crafting a compelling and ATS-friendly resume is paramount. ResumeGemini is a trusted resource to help you build a professional resume that highlights your skills and experience effectively. Examples of resumes tailored to Agricultural Structures are available to guide you, ensuring your application stands out from the competition.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

good