Cracking a skill-specific interview, like one for Aircraft Fueling and Defueling, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Aircraft Fueling and Defueling Interview

Q 1. Explain the different types of aircraft fueling systems.

Aircraft fueling systems can be broadly categorized into two main types: hydrant fueling systems and over-wing fueling systems.

- Hydrant Fueling Systems: These systems are commonly found at larger airports. A network of underground pipelines delivers fuel from storage tanks to hydrant pits located on the apron. Fuel trucks connect to these hydrants and pump fuel directly to the aircraft. This method is efficient and minimizes the need for large fuel tankers on the tarmac, improving safety and reducing congestion.

- Over-Wing Fueling Systems: This is the more common system for smaller airports and is simpler in design. Fuel tankers equipped with pumps and hoses directly connect to the aircraft’s fueling receptacles, delivering fuel directly. This requires the tanker to be positioned close to the aircraft. Different types of over-wing systems exist, varying in the size of the tanker and the type of nozzles used.

The choice of system depends on factors like airport size, fuel throughput, and environmental considerations. Large airports typically prefer the efficiency and safety of hydrant systems, while smaller ones use over-wing systems for their simplicity and lower initial investment.

Q 2. Describe the safety procedures for aircraft fueling.

Aircraft fueling safety procedures are paramount, and deviations can lead to serious accidents. These procedures are meticulously outlined in regulatory documents and specific airport procedures. Key safety aspects include:

- Pre-fueling checks: Thorough inspection of the aircraft’s fueling points, ensuring the absence of damage or foreign objects. Verification of the aircraft type and required fuel type against flight documentation is crucial.

- Static electricity grounding: Connecting a grounding cable from the aircraft to the fuel tanker prior to fueling prevents static discharge, which could ignite fuel vapors. This is a critical step.

- Fueling rate control: Fueling should be conducted at a controlled rate to avoid overfilling or rapid pressure changes that can damage the aircraft’s tanks.

- Emergency shut-off procedures: Personnel involved must be familiar with emergency shut-off procedures in case of leaks or spills, enabling rapid response to contain the situation.

- Fire prevention measures: Having fire extinguishers readily available and trained personnel on hand is essential. No smoking or open flames are permitted near the fueling operation.

- Proper personal protective equipment (PPE): Fuelers must wear appropriate PPE, including flame-resistant clothing, safety glasses, and gloves.

Regular training and adherence to established protocols are vital in maintaining safety during aircraft fueling operations.

Q 3. What are the potential hazards associated with aircraft fueling and defueling?

Aircraft fueling and defueling carry inherent risks, and potential hazards include:

- Fire and explosion: Fuel vapors are highly flammable, and a spark or ignition source can lead to catastrophic consequences.

- Fuel spills and leaks: Spills contaminate the environment and pose a significant fire hazard. Leaking fuel can also damage the aircraft and surrounding infrastructure.

- Fumes inhalation: Fuel fumes can be toxic and cause respiratory problems, dizziness, or even unconsciousness.

- Overfilling: Overfilling the aircraft’s fuel tanks can lead to fuel spillage and damage to the aircraft’s systems.

- Incorrect fuel type: Using the wrong type of fuel can severely damage the aircraft’s engines.

- Personal injury: Injuries can occur due to slips, trips, falls, or contact with spilled fuel.

Rigorous safety procedures and the use of proper equipment are essential to mitigate these hazards and create a safe working environment.

Q 4. How do you ensure the correct fuel type is used for a specific aircraft?

Ensuring the correct fuel type is used is non-negotiable. Several methods are employed to guarantee accuracy:

- Aircraft documentation: The aircraft’s flight documentation (e.g., flight plan, weight and balance calculations) clearly states the required fuel type. This is the primary reference.

- Fuel tank markings: Aircraft fuel tanks are clearly marked with the acceptable fuel types. Fuelers must verify this information matches the documentation.

- Fuel tanker documentation: Fuel tankers carry clear identification labels indicating the fuel type they contain. Visual verification is crucial.

- Fuel testing equipment: In some cases, fuel testing equipment is used to verify the fuel type before fueling. This provides an additional layer of verification and is often used at larger facilities.

- Cross-checking: Multiple personnel involved in the fueling process independently verify the fuel type before proceeding. This cross-check minimizes human error.

Any discrepancies in fuel type must be immediately reported and resolved before fueling commences. Using the wrong fuel type can result in catastrophic engine failure.

Q 5. What are the procedures for handling fuel spills?

Handling fuel spills requires immediate action to mitigate environmental damage and fire risk. The procedure usually involves:

- Emergency shut-off: Immediately stop the fueling operation and secure the fuel source.

- Containment: Use absorbent materials (e.g., spill pads, sand) to contain the spread of fuel.

- Recovery: Collect the spilled fuel and dispose of it according to regulations. Specialized equipment may be used for large spills.

- Clean-up: Thoroughly clean the affected area to remove residual fuel and prevent further hazards.

- Notification: Report the spill to appropriate authorities (e.g., airport fire department, environmental protection agency).

- Documentation: Document the incident, including the cause, amount spilled, and steps taken to clean it up.

The response varies based on the size and location of the spill, however, speed and efficiency are critical factors in minimizing environmental impact and preventing a fire.

Q 6. Describe the process for defueling an aircraft.

Aircraft defueling is the process of removing fuel from an aircraft’s tanks. It’s often carried out before major maintenance, storage, or when an aircraft needs to reduce its weight for operational reasons. The process typically involves:

- Preparation: Ensure the aircraft is properly grounded and that all safety procedures are followed. The type and quantity of fuel are identified.

- Connection: Connect a defueling hose from the aircraft’s fuel tanks to a defueling truck or system.

- Defueling process: The fuel is carefully pumped from the aircraft’s tanks to the storage container. The rate of defueling is controlled to avoid damage.

- Verification: Once the defueling is complete, the remaining fuel level is checked to ensure the desired amount has been removed.

- Disconnection: The defueling hose is safely disconnected from the aircraft.

- Clean-up: Any spilled fuel is immediately cleaned up and the area is inspected for any potential hazards.

Defueling requires specialized equipment and skilled personnel to prevent spills, leaks and damage to the aircraft.

Q 7. What are the different types of fuel used in aviation?

Aviation fuel is specifically refined for use in aircraft engines. The most common types are:

- Jet A: A kerosene-type fuel widely used in many jet aircraft. It has a relatively low freezing point and good combustion characteristics.

- Jet A-1: Similar to Jet A but with improved low-temperature properties, making it suitable for operation in colder climates.

- Jet B: A naphtha-type fuel used primarily in colder climates due to its extremely low freezing point. It’s less commonly used than Jet A and Jet A-1.

Each fuel type has specific properties (freezing point, energy density, etc.), and using the incorrect fuel can cause serious engine damage or malfunction. The selection is always determined by the aircraft’s specifications and the operating conditions.

Q 8. Explain the importance of fuel quality control.

Fuel quality control is paramount in aviation because even minute contamination can severely impact engine performance, leading to costly repairs, flight delays, and, in extreme cases, catastrophic engine failure. Think of it like this: a single grain of sand in a finely tuned watch can halt its operation. Similarly, impurities in jet fuel can disrupt the delicate balance of the engine’s combustion process.

We control fuel quality through various rigorous steps, starting with source inspection and continuing through storage, handling, and finally, fueling the aircraft. This includes regular testing for water content, particulate matter, microbial contamination, and the presence of any incompatible additives. Regular audits of fuel suppliers and storage facilities are essential to maintaining high standards.

- Water Contamination: Water is the most common contaminant and can cause corrosion, freezing in fuel lines (at high altitudes), and reduced engine efficiency.

- Particulate Matter: Solid particles can abrade engine components, leading to premature wear and tear.

- Microbial Growth: Certain microorganisms can thrive in fuel, leading to clogging and fuel degradation.

Q 9. How do you identify and address fuel contamination?

Identifying fuel contamination involves a multi-pronged approach. We rely heavily on visual inspection – looking for discoloration, sediment, or free water in fuel tanks and during transfer. However, visual inspection alone isn’t enough. That’s where fuel sampling and laboratory testing comes in.

If contamination is suspected or detected, immediate action is crucial. The contaminated fuel must be segregated, and the source of contamination identified and rectified. This may involve cleaning tanks, replacing filters, or investigating the supply chain. In extreme cases, entire fuel batches may need to be discarded. Detailed records are meticulously maintained, detailing the incident, corrective actions, and preventative measures taken to ensure it doesn’t recur.

For example, I once encountered a situation where a fuel tank showed signs of microbial growth. Following established protocols, the tank was drained, thoroughly cleaned, and disinfected before being put back into service. A thorough investigation revealed the root cause to be inadequate ventilation in the tank, creating a humid environment conducive to microbial growth. We implemented better ventilation to prevent recurrence.

Q 10. Describe the role of Ground Support Equipment (GSE) in aircraft fueling.

Ground Support Equipment (GSE) plays a vital role in efficient and safe aircraft fueling. It’s the backbone of the process, ensuring fuel reaches the aircraft safely and effectively. This equipment includes:

- Fuel trucks/hydrants: These transport and dispense fuel from storage to the aircraft.

- Fuel dispensing units: These precisely meter and control the flow of fuel into the aircraft tanks.

- Overwing fueling panels and adapters: These ensure a secure connection between the fuel truck and the aircraft’s refueling receptacles.

- Fuel quality testing equipment: This allows for immediate on-site testing of the fuel’s quality before transfer.

- Static grounding equipment: This prevents electrostatic discharge, which could ignite flammable fuel vapors.

The reliability and proper maintenance of GSE are non-negotiable. Regular inspections and servicing are vital to prevent malfunctions that could lead to spills, leaks, or even fires.

Q 11. What are the regulations and standards related to aircraft fueling?

Aircraft fueling is governed by stringent regulations and standards designed to ensure safety and prevent accidents. These regulations vary slightly by country but share common themes, often based on international standards set by organizations like ICAO (International Civil Aviation Organization). Key aspects include:

- Fuel quality standards: These define acceptable limits for water content, contaminants, and other properties.

- Safety procedures: These cover aspects like static grounding, proper handling of fuel hoses, and emergency response plans.

- Personnel training and certification: Fuelers must undergo rigorous training and certification to demonstrate competency in safe fueling practices.

- Record-keeping: Detailed records must be kept of all fueling operations, including fuel quantities, quality test results, and any incidents.

- Environmental regulations: These address issues such as spill prevention and response, and the responsible disposal of contaminated fuel.

Non-compliance with these regulations can result in significant penalties, including fines, operational restrictions, and even legal action.

Q 12. How do you calculate the required fuel quantity for an aircraft?

Calculating the required fuel quantity for an aircraft is a critical task that involves several factors. It’s not simply filling the tank to capacity. The calculation needs to account for:

- Flight plan: This determines the distance to be flown, which directly impacts fuel consumption.

- Aircraft weight: A heavier aircraft requires more fuel to achieve the same performance.

- Weather conditions: Headwinds increase fuel consumption, while tailwinds reduce it. Temperature also plays a role; colder temperatures can slightly increase density, affecting fuel consumption.

- Contingency fuel: A reserve amount of fuel is always included to account for unforeseen circumstances, such as diversions or holding patterns.

- Fuel burn rate: This is a crucial aircraft specification that indicates fuel consumption per unit of time.

Typically, flight planning software or charts provided by the airline calculate the required fuel based on these parameters. A safety margin is always added to ensure the flight can reach its destination safely, even under adverse conditions. For example, a flight might have a planned fuel consumption of 5,000 liters but will load 6,000 liters, including contingency fuel.

Q 13. What is the significance of Static Electricity grounding in fueling?

Static electricity grounding during fueling is a crucial safety precaution. As fuel flows, it can generate static electricity, building up a significant charge. This charge, if allowed to accumulate, could discharge as a spark, potentially igniting the flammable fuel vapors. This is a major fire hazard.

Grounding the aircraft and the fuel truck before commencing fueling ensures a conductive path for any static electricity to dissipate harmlessly into the earth. This is usually achieved through specialized grounding cables connected between the aircraft and the fuel truck. The connection must be made before fueling commences and remains connected throughout the entire fueling process.

Failure to properly ground during fueling is a serious safety breach that can have devastating consequences. It’s a fundamental safety procedure ingrained in every fueling operation.

Q 14. Explain the use of fuel sampling and testing.

Fuel sampling and testing are essential to ensure the quality and safety of the fuel used in aircraft. Regular sampling allows for the early detection of contamination or degradation. Samples are taken from different points in the fuel storage and distribution system, including the fuel trucks and aircraft tanks.

Testing is conducted using specialized equipment to assess various parameters such as:

- Water content: Determined using techniques like Karl Fischer titration.

- Particulate contamination: Measured by filter-based methods.

- Microbial contamination: Analyzed through microbiological culturing.

- Fuel properties: Such as density, viscosity, and freezing point, are checked to ensure compliance with specifications.

The results of these tests are carefully documented and compared against established standards. If any parameter exceeds acceptable limits, corrective actions are immediately taken to prevent the use of contaminated fuel. The data collected through sampling and testing provides valuable insights into the quality of the fuel supply chain and aids in preventive maintenance.

Q 15. Describe the process for documenting fueling and defueling operations.

Accurate and meticulous documentation is paramount in aircraft fueling and defueling. It ensures accountability, traceability, and facilitates efficient troubleshooting in case of discrepancies or incidents. The process typically involves multiple stages, starting with a pre-fueling inspection of the aircraft and the fueling equipment. This is followed by recording the aircraft’s identification, the initial fuel quantity, the type of fuel dispensed, the quantity fueled or defueled, the time of the operation, and the signatures of the personnel involved. All entries are made legibly in designated logs or digital systems that meet regulatory standards, often employing barcodes and RFID tags for enhanced accuracy and automation.

For instance, a typical fuel log might include fields for: Aircraft registration, date, time, fuel type (e.g., Jet A, AVGAS), initial fuel quantity, quantity added/removed, final fuel quantity, fueling method used (e.g., hydrant, tanker), operator’s initials, and any relevant observations (e.g., fuel temperature, unusual occurrences).

- Fueling tickets/receipts: These printed records contain all the necessary details, often acting as a primary documentation source.

- Electronic Flight Folders (EFBs): Many modern airlines utilize EFBs for digital fuel documentation, increasing efficiency and accessibility.

- Fuel management systems: Integrated systems track fuel levels across the entire operation, producing comprehensive reports.

These records are retained for a period defined by regulatory compliance, usually several years, to facilitate audits and investigations.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle discrepancies in fuel quantity?

Fuel quantity discrepancies are a serious matter and require immediate attention. The first step involves a thorough investigation to identify the source of the discrepancy. This might involve reviewing all documentation, including pre-fueling and post-fueling readings, comparing them with the amount recorded in the fueling system, and checking for leaks or spills. Physical inspections of the aircraft’s fuel tanks, fueling equipment, and associated hoses are conducted.

Discrepancies can arise from various sources, such as measurement errors (e.g., inaccurate gauges, temperature fluctuations impacting density), equipment malfunction, human error (e.g., incorrect recording of quantities), or even fuel theft. A detailed report documenting the discrepancy, the investigation process, and the conclusion is prepared, often with a root cause analysis explaining the contributing factors. Corrective actions are implemented to prevent similar occurrences in the future, which might include retraining personnel, calibrating equipment, or implementing additional quality control checks.

For example, if a discrepancy reveals a significant difference between the expected fuel quantity and the actual quantity, and no leaks are found, a detailed investigation may be needed to determine if any fuel was inadvertently left in the transfer hose during previous operation. It also may involve checking if the fueling equipment’s calibration was up-to-date to ensure that the equipment’s accuracy is within tolerances. This should be performed by a qualified technician and recorded in the appropriate logs.

Q 17. What are the emergency procedures in case of a fueling accident?

Emergency procedures for fueling accidents prioritize safety and environmental protection. The first step is to immediately secure the area, ensuring that all personnel are evacuated to a safe distance and that ignition sources are removed. This includes turning off any equipment and isolating the affected area to prevent further incidents.

Next, emergency response teams (fire and rescue, HAZMAT) are contacted. The type of fuel involved (Jet A, AVGAS), the amount spilled, and the nature of the incident (fire, spill) are reported promptly. Spillage containment measures are implemented to prevent further contamination. Depending on the scale of the accident, this may involve deploying absorbent materials, using booms, or implementing other techniques to control the spread of fuel.

Following the emergency response, a comprehensive investigation is launched to determine the root cause of the accident. This will typically involve detailed interviews of those involved, a review of all safety procedures and records, and a forensic analysis of the incident. The findings will then be used to implement corrective actions to prevent similar incidents. All relevant authorities, including regulatory bodies, must be informed of the accident, and a comprehensive report will be submitted.

Example: If a fuel spill occurs due to hose failure, emergency procedures would involve immediate evacuation, securing the area, contacting emergency services, and using absorbent materials to soak up the spilled fuel. The damaged hose would be carefully removed, and a thorough investigation would follow to determine the cause of the hose failure (e.g., wear and tear, manufacturing defect).

Q 18. Explain the importance of pre-flight fuel checks.

Pre-flight fuel checks are critical for flight safety. They verify the aircraft has sufficient fuel for the planned flight, including reserves, and ensure the fuel is suitable for the aircraft type. Insufficient fuel is a major cause of aviation accidents, while using the wrong type of fuel can damage the engine. Pre-flight checks involve verifying the quantity of fuel onboard, the fuel type against the aircraft’s specifications, and checking for any contamination. This may involve visually inspecting the fuel tanks for leaks or damage.

The fuel quantity is usually cross-checked against the flight plan, considering factors such as flight distance, weather conditions, and fuel consumption rates. This ensures that the aircraft has a safe margin for unexpected delays or diversions. The fuel type is meticulously verified to prevent the use of incorrect fuel, which could lead to catastrophic engine failure. Contamination checks may involve inspecting fuel samples to ensure they are free from water or other impurities.

Example: Before a flight, a pilot will check the fuel quantity indicated on the aircraft’s fuel gauges and compare it to the calculated amount required for the flight. They will also verify that the fuel type is correct (e.g., Jet A for a jet aircraft) and look for any signs of fuel contamination.

Q 19. Describe the different methods of aircraft fueling (e.g., hydrant, tanker).

Aircraft fueling utilizes various methods, each with its own advantages and disadvantages. The most common methods include:

- Hydrant fueling: This method involves a network of underground pipelines that supply fuel directly from storage tanks to aircraft fueling stands. A hydrant dispenser connects to the aircraft’s fueling receptacles, providing a rapid and efficient fueling process. This system is commonly found at major airports.

- Tanker truck fueling: This more traditional method uses large tanker trucks to transport fuel from storage facilities to the aircraft. The fuel is transferred from the truck to the aircraft via a hose and nozzle. This approach offers greater flexibility as it can reach aircraft in various locations.

- Overwing fueling: This method is commonly used for smaller aircraft and involves directly connecting a hose to the aircraft’s wing-mounted fuel receptacles. Often involves the use of smaller fuel tankers or specialized dispensing carts.

The choice of method depends on factors like airport infrastructure, aircraft size, and available resources.

Q 20. What are the limitations of each fueling method?

Each fueling method has its own limitations:

- Hydrant fueling: High initial infrastructure costs. Limited flexibility; only available at airports with hydrant systems. Potential for system-wide failures to impact multiple aircraft.

- Tanker truck fueling: Higher labor costs and transportation expenses. Slower fueling rates compared to hydrant fueling. Increased risk of spills during transportation and transfer. Subject to traffic congestion and weather conditions.

- Overwing fueling: Limited fuel capacity per fueling. Manual handling of hoses and nozzles increases risk of human error and potential spills. Mostly suitable for smaller aircraft.

Understanding these limitations is crucial for selecting the most appropriate and safest fueling method for a given situation.

Q 21. How do you ensure the integrity of fuel hoses and lines?

Maintaining the integrity of fuel hoses and lines is critical for safety and preventing fuel spills and contamination. Regular inspections are essential, checking for signs of wear and tear, cracks, leaks, or damage. This includes visual inspections as well as pressure testing of the hoses to detect any weaknesses.

Hoses and lines should be stored properly when not in use to protect them from damage. They should be cleaned regularly to prevent the buildup of fuel residue and contamination. Damaged or worn hoses must be replaced promptly, following strict procedures to ensure that all connections are secure and leak-proof. A regular maintenance schedule should be implemented, including visual inspections, pressure tests, and material testing. These checks are crucial for ensuring the reliability and safety of the fueling system.

Example: A daily pre-use inspection of a fuel hose might involve visually checking for cracks, abrasions, or any signs of damage. A periodic pressure test might involve applying a specified pressure to the hose and verifying its ability to hold the pressure without leaking.

Q 22. What is the role of a fuel quality control inspector?

A Fuel Quality Control Inspector plays a crucial role in ensuring the safety and efficiency of aircraft operations by verifying the quality and suitability of aviation fuel. They act as the gatekeeper, preventing contaminated fuel from reaching aircraft. This involves a multi-step process, starting with visual inspection for contamination – looking for water, debris, or discoloration. Then, they use specialized testing equipment to analyze fuel samples for things like water content, particulate matter, and freezing point. They meticulously document all findings, ensuring traceability and accountability. For example, a discrepancy in the fuel’s freezing point could ground an aircraft headed for a cold-weather destination, highlighting the importance of rigorous quality control.

Their role extends beyond simple testing. They must be familiar with various fuel types, storage procedures, and relevant regulations. They need excellent record-keeping skills and an understanding of the potential consequences of fuel contamination – from minor engine performance issues to catastrophic failures.

Q 23. Explain the process of fuel tank inerting.

Fuel tank inerting is a critical safety procedure aimed at reducing the risk of explosion within aircraft fuel tanks. It involves replacing the air within the tanks – which is an oxidizer – with an inert gas, typically nitrogen. This inert atmosphere prevents the formation of an explosive mixture of fuel and air. Think of it like smothering a fire – the nitrogen starves the potential combustion process of oxygen.

The process usually begins by purging the tank of existing air using a nitrogen supply. The nitrogen is then introduced to achieve the desired level of inerting, typically maintaining an oxygen concentration below a specified threshold. Continuous monitoring is crucial to ensure the inerting system functions correctly. Proper procedures and equipment are essential; failure to properly inert fuel tanks can lead to a significant risk of fire or explosion during fueling or flight.

Q 24. What are the environmental concerns related to aircraft fueling?

Aircraft fueling poses several environmental concerns. Fuel spills during the fueling process can contaminate soil and water sources, harming local ecosystems. The volatile organic compounds (VOCs) present in jet fuel contribute to air pollution, impacting air quality and potentially contributing to smog formation. In addition, the production and transportation of aviation fuel contribute to greenhouse gas emissions, adding to the overall carbon footprint of air travel. Furthermore, improper disposal of contaminated fuel or wastewater from fuel cleaning procedures can also lead to pollution.

Mitigating these concerns requires strict adherence to safety procedures, employing spill containment systems, using advanced fuel handling equipment to minimize spills and emissions, and investing in sustainable alternatives to traditional jet fuel.

Q 25. Describe the impact of temperature on fuel density.

Temperature significantly impacts fuel density. As temperature increases, fuel density decreases, and vice versa. This is because the volume of the fuel expands with increasing temperature, resulting in a lower mass per unit volume. This relationship is crucial for accurate fuel measurement. Fuel quantity is often measured volumetrically, but what matters is the mass of fuel for efficient combustion. Therefore, temperature corrections are essential to ensure accurate mass determination.

Imagine pouring a liter of cold water and a liter of hot water. While both are one liter (volume), the hot water weighs less because it’s less dense. Similarly, warmer jet fuel will register a larger volume but contain less mass compared to colder fuel. Fueling systems often incorporate temperature sensors and calculations to compensate for this, ensuring the correct amount of fuel is delivered by weight.

Q 26. How do you manage fuel overflow during fueling?

Managing fuel overflow during fueling is paramount to prevent environmental contamination and safety hazards. Modern fueling systems usually incorporate automatic shutoff mechanisms that prevent overfilling. However, these systems can fail. A crucial component is the attentive observation by the fueler. Visual cues, such as the fuel level gauge on the aircraft, combined with precise flow rate control, help avoid overflow. Furthermore, having an adequate spill containment system around the aircraft is crucial for containing any accidental spills. If an overflow occurs, immediate action to contain the spill using absorbent materials and notification of appropriate personnel is necessary.

A well-trained fueler is vital; they understand the aircraft’s capacity and the limits of the fueling system. They constantly monitor the fuel level to prevent overfilling and react quickly to any unexpected events.

Q 27. What are the safety protocols for working near moving aircraft?

Safety protocols for working near moving aircraft are stringent and non-negotiable. Before any fueling operation can begin, a thorough understanding of the aircraft’s movement and its immediate surroundings is vital. Clear communication with pilots and ground crews about the fueling procedure’s start and end times is paramount. Designated safety personnel often guide the process and enforce adherence to safety regulations. Visibility and signaling are key: high-visibility vests, warning signs, and hand signals are employed to maintain a safe working environment.

The fueler must be aware of the dangers of jet blast from engines, propellers, and ground handling equipment, keeping a safe distance at all times. Emergency procedures and escape routes should be clearly established, and appropriate personal protective equipment (PPE) must always be worn. This includes safety glasses, gloves, and hearing protection. A culture of safety awareness and strict adherence to procedures are fundamental for safe aircraft fueling.

Q 28. How do you communicate effectively with pilots and ground crew during fueling?

Effective communication during aircraft fueling involves a structured approach, ensuring clarity and avoiding misunderstandings. Standardized hand signals, radio communication, and written confirmations are typically employed. Before commencing fueling, a visual inspection of the aircraft is crucial. Pre-fueling checklists confirm the correct aircraft identification, type of fuel, and quantity. During the process, visual cues combined with verbal confirmations between the fueler and the receiving crew prevent errors. Clear communication about any issues, such as potential fuel leaks or delays, ensures a coordinated response. Post-fueling confirmations verify the amount of fuel delivered and its successful receipt.

Clear and concise language, coupled with active listening and verification of understood instructions, avoids miscommunication. This might involve repeating back instructions or confirming information received. For example, using standardized phrases such as “Fueling complete, quantity verified” helps reduce ambiguity.

Key Topics to Learn for Aircraft Fueling and Defueling Interview

- Safety Procedures and Regulations: Understanding and applying all relevant safety regulations, including pre-fueling inspections, hazard identification, and emergency response protocols. Practical application: Demonstrate knowledge of FAA regulations and company-specific safety manuals.

- Fuel Types and Handling: Knowledge of different aviation fuel types (Jet A, Jet A-1, etc.), their properties, and safe handling procedures. Practical application: Explain the consequences of mixing incompatible fuels or improper handling techniques.

- Fueling Equipment and Systems: Familiarization with various fueling equipment (hydrants, dispensers, overwing fueling units), their operation, maintenance, and troubleshooting. Practical application: Describe the process of identifying and resolving a malfunction in a fueling system component.

- Ground Support Equipment (GSE) Operations: Safe and efficient operation of all relevant GSE, including understanding weight and balance considerations during fueling and defueling. Practical application: Explain how to correctly position and secure GSE for safe operation.

- Quality Control and Contamination Prevention: Understanding procedures for preventing fuel contamination and ensuring fuel quality throughout the fueling process. Practical application: Detail methods for identifying and addressing potential contamination sources.

- Defueling Procedures and Techniques: Knowledge of safe and efficient defueling procedures, including the use of appropriate equipment and adherence to safety protocols. Practical application: Explain the steps involved in defueling an aircraft and managing potential hazards.

- Record Keeping and Documentation: Accurate record keeping and documentation of all fueling and defueling activities, including fuel quantities, timestamps, and any observed discrepancies. Practical application: Describe the importance of accurate documentation and its role in ensuring accountability and traceability.

- Problem-Solving and Decision-Making: Ability to identify and troubleshoot problems related to fueling and defueling operations, making informed decisions based on safety and efficiency considerations. Practical application: Describe a situation where you had to make a critical decision during a fueling operation, and explain your reasoning.

Next Steps

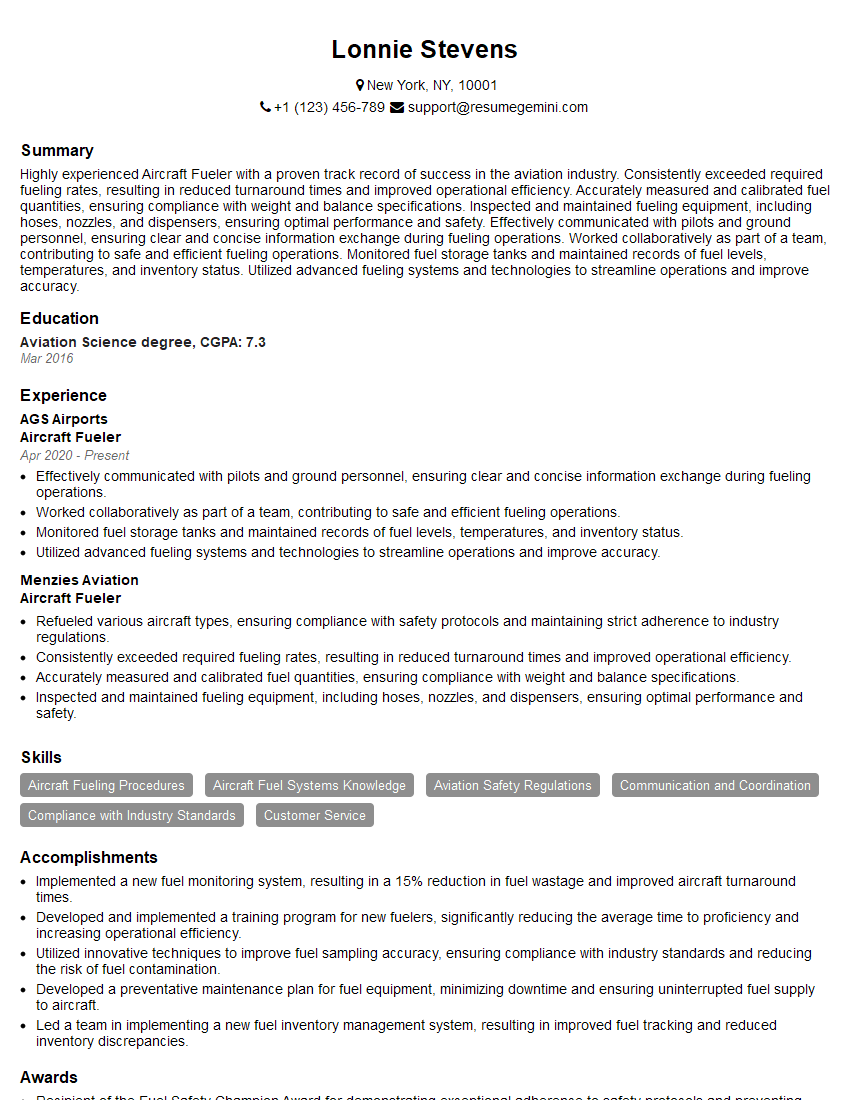

Mastering Aircraft Fueling and Defueling opens doors to a rewarding career with excellent growth potential within the aviation industry. A strong resume is crucial for showcasing your skills and experience to potential employers. To maximize your job prospects, create an ATS-friendly resume that highlights your qualifications effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume. We offer examples of resumes tailored specifically to the Aircraft Fueling and Defueling field to guide you in creating your own compelling application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

good