Unlock your full potential by mastering the most common Aircraft Handling and Damage Control interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Aircraft Handling and Damage Control Interview

Q 1. Describe the procedures for pre-flight inspection of an aircraft.

A pre-flight inspection is a crucial safety procedure ensuring the aircraft is airworthy before takeoff. It’s a systematic visual check, often following a checklist, covering all critical systems and components. Think of it like a thorough health check-up before a long journey.

- Exterior Inspection: This includes examining the fuselage, wings, tail surfaces, and control surfaces for any damage, dents, cracks, or loose parts. We check for proper functioning of flaps, ailerons, and elevators. We also inspect landing gear, tires, and brakes.

- Engine Inspection: This involves checking engine oil levels, inspecting for leaks or damage, and verifying the proper operation of all engine-related components. We may visually inspect for debris build up.

- Cockpit Check: This includes verifying the functioning of all instruments, flight controls, communication systems, and safety equipment. This often involves a system test to ensure all readouts are accurate.

- Documentation: All findings, including any discrepancies or defects, are meticulously recorded. This record serves as a crucial part of the aircraft’s maintenance log.

For instance, during a pre-flight inspection, I once discovered a small crack in a wing’s leading edge. This was immediately reported, preventing a potentially dangerous situation during flight. The aircraft was grounded until repairs were completed, showcasing the importance of meticulous pre-flight checks.

Q 2. Explain the different types of aircraft tow bars and their usage.

Aircraft tow bars are essential for moving aircraft on the ground, especially large ones that can’t be easily maneuvered by hand. There are several types, each designed for specific aircraft and situations.

- Conventional Tow Bar: This is the most common type, with a rigid structure connecting to the aircraft’s nose gear. It’s suitable for most aircraft and relatively straightforward to operate. Think of it as a simple, sturdy push cart for an airplane.

- Electric Tow Bar: These offer power-assisted steering and speed control, making them easier and safer to handle, especially for larger aircraft in busy environments. They’re like a power steering system for towing.

- Pushback Tow Bar: Designed for pushing aircraft backwards, particularly during taxiing, where it can be safer than traditional towing. These bars often have better visibility to assist the pilot during maneuver.

- Specialized Tow Bars: Certain aircraft, such as those with unusual nose gear configurations, might require specialized tow bars designed to accommodate their specific requirements. These are tailored to particular aircraft designs.

The choice of tow bar depends on the aircraft’s size, weight, and the specific operational needs of the airport or hangar. Safety protocols, such as ensuring proper attachment to the aircraft and correct operating procedures, are always strictly adhered to.

Q 3. How do you handle a bird strike incident?

A bird strike, or bird ingestion into an engine, is a serious incident requiring immediate and decisive action. The severity depends on the size of the bird, the speed of the aircraft, and the location of the impact.

- Assess the Damage: Immediately after the incident, the pilot makes a preliminary assessment of any damage to the aircraft, primarily focusing on engine performance and airframe integrity.

- Emergency Landing: Depending on the severity and the capability of the aircraft to maintain flight, an emergency landing may be required. Prioritizing safety is paramount in this situation.

- Post-Flight Inspection: After the aircraft has safely landed, a thorough inspection by maintenance personnel is carried out. This includes checking for damage to engines, wings, fuselage, and other components. We may take photos and write a full report.

- Reporting: The incident needs to be fully documented and reported to relevant authorities, such as the airport management and the aviation safety authorities. Details regarding the incident, the damage, and the steps taken must be included.

- Repairs/Replacement: Any necessary repairs or component replacements are made under strict maintenance procedures, ensuring the aircraft is deemed airworthy before returning to service.

One memorable incident involved a large bird striking the windshield of a small aircraft. While the damage wasn’t catastrophic, the impact caused significant distortion, necessitating a prompt inspection and a windshield replacement before the aircraft was cleared for flight.

Q 4. What are the safety protocols for aircraft refueling?

Aircraft refueling is a high-risk operation requiring strict adherence to safety protocols to prevent fire and other hazards. The core principles revolve around minimizing static electricity buildup, preventing spills, and ensuring proper grounding.

- Grounding: Both the aircraft and the refueling vehicle must be properly grounded to prevent static electricity discharge, using designated grounding points and equipment.

- Spill Prevention: Procedures are followed to minimize the risk of fuel spills, including using appropriate nozzles and controlling the flow rate of fuel. Spills are cleaned immediately and properly.

- Fire Prevention: No smoking or open flames are permitted in the vicinity of the refueling operation. Fire extinguishers are readily available, and personnel are trained in their use.

- Personnel Training: All personnel involved in refueling must undergo appropriate training, including safety procedures and emergency response. This is a crucial element.

- Communication: Clear and effective communication between the refueling crew and the aircraft crew is essential to coordinate the operation and address any unexpected issues.

For example, a failure to properly ground an aircraft could lead to static discharge igniting fuel vapors during refueling, resulting in a fire. The safety protocols are designed to prevent such scenarios.

Q 5. Outline the steps involved in securing an aircraft for inclement weather.

Securing an aircraft for inclement weather involves taking measures to protect it from damage caused by high winds, rain, snow, or ice. This often involves a combination of physical restraints and protective coverings.

- Wheel Chocks: Wheel chocks are used to prevent the aircraft from rolling. We use chocks under all wheels.

- Tie-Downs: Strong tie-downs are connected to the aircraft’s designated tie-down rings and anchored securely to the ground. These need to be appropriately rated.

- Protective Covers: Aircraft covers or hangars are used to shield the aircraft from rain, snow, and ice. We choose covers that are sufficiently large to avoid damage during high winds.

- Pitot-Static Covers: Pitot-static tubes are covered to prevent damage caused by ice accumulation, especially in freezing conditions. These are crucial for precise flight readings.

- Flight Controls: In extreme conditions we may consider locking the flight controls to protect them from wind damage.

Imagine a severe thunderstorm. Without proper tie-downs, the aircraft could be overturned by strong winds causing significant damage. The securing measures are critical to prevent such a scenario.

Q 6. Describe your experience with damage assessment on aircraft.

My experience in aircraft damage assessment involves systematically evaluating the extent and nature of damage to an aircraft following an incident or during routine inspections. This includes both external and internal assessments.

I’ve assessed damage ranging from minor scratches and dents to significant structural damage caused by bird strikes, ground collisions, or hard landings. My approach involves a careful visual inspection using checklists, aided by specialized tools when necessary. Photographs and detailed reports documenting the damage and recommended repair actions are created for the maintenance team.

One instance involved a significant hail storm damaging several aircraft. My assessment included identifying the extent of hail damage to the fuselage, wings, and control surfaces. The report facilitated the prioritization of repair works and ensured that all affected aircraft were correctly and safely restored to airworthiness. The damage ranged from superficial paint damage to significant pitting and dents requiring panel replacement.

Q 7. How do you identify and report potential aircraft damage?

Identifying and reporting potential aircraft damage is a continuous process relying on vigilance and a thorough understanding of aircraft systems.

- Routine Inspections: Regular inspections are carried out by ground crews and pilots, focusing on visual checks of the aircraft’s exterior and interior.

- Post-Flight Checks: Pilots conduct thorough post-flight checks, noting any irregularities in flight performance or system function that might indicate damage.

- Maintenance Logs: All identified issues are logged meticulously in the aircraft’s maintenance log. This record-keeping is essential.

- Reporting Procedures: A standardized reporting procedure is followed, providing detailed descriptions of the damage, its location, and any potential impact on aircraft operation.

- Photography/Documentation: Photographs or videos are often utilized to document the damage, facilitating the assessment and repair process. This is vital for insurance claims.

For example, during a routine inspection, a mechanic might notice a small dent in the aircraft’s skin. This would be documented immediately, and an assessment made to determine if the damage is significant enough to warrant repair.

Q 8. What are the different types of aircraft damage and their repair procedures?

Aircraft damage can range from minor scratches to significant structural failures. Categorizing damage helps determine the appropriate repair procedure. We can broadly classify damage as:

- Minor Damage: Scratches, dents, minor paint chips. Repair typically involves cleaning, polishing, and potentially repainting depending on the severity and location of the damage. For example, a small dent in the fuselage skin might just need a careful dent removal and repainting.

- Moderate Damage: Dents exceeding a certain depth, punctures, delamination of composite materials, damage to control surfaces. Repairs could include dent filling, patching, composite repairs requiring specialized bonding techniques and ovens, or replacement of damaged components. A punctured wing fuel tank, for instance, requires careful leak detection, repair patching, and pressure testing.

- Major Damage: Significant structural damage impacting the airworthiness of the aircraft, such as fuselage cracks, wing damage affecting the load-bearing capacity, or engine damage. This often necessitates extensive repairs involving specialized tooling, structural analysis, and potentially major component replacements. A major crack in the fuselage, for example, requires careful inspection, potential strengthening of surrounding areas, and possibly replacement sections. This often involves extensive documentation and approval from regulatory bodies.

Repair procedures always adhere to the aircraft manufacturer’s maintenance manual and applicable regulatory guidelines (like those from the FAA or EASA). They include thorough damage assessment, selection of appropriate repair techniques, documentation of all steps taken, and post-repair inspections and testing to ensure airworthiness.

Q 9. Explain your knowledge of aircraft weight and balance principles.

Aircraft weight and balance is crucial for safe flight. It involves determining the aircraft’s center of gravity (CG) location relative to its reference datum. The CG must remain within defined limits throughout the flight. An improperly balanced aircraft can be difficult to control and may even be dangerous.

We use weight and balance calculations to ensure the aircraft’s CG is within the operational limits defined in the aircraft’s flight manual. These calculations consider:

- Basic Empty Weight (BEW): Weight of the aircraft without fuel, oil, or payload.

- Payload: Weight of passengers, cargo, and equipment.

- Fuel Weight: Weight of the fuel onboard.

The CG location is calculated using the arm of each component (distance from the reference datum). These calculations are usually performed using specialized software or by hand via established formulas. If the CG is outside the permitted limits, adjustments must be made by shifting the cargo or fuel. Imagine a seesaw – if the weight isn’t balanced, it won’t work correctly. Similarly, an unbalanced aircraft can lead to handling difficulties and potential instability.

A weight and balance form or manifest is essential to ensure these calculations are accurate and consistently updated with any changes.

Q 10. How do you handle a situation involving a damaged aircraft component?

Handling a damaged aircraft component starts with a thorough assessment of the damage’s extent and severity. Safety is paramount; we must ensure the area is secure and appropriately cordoned off to prevent further damage or injury to personnel.

The steps involved are:

- Assess the Damage: Visually inspect the component and the surrounding area to determine the extent of the damage and potential impact on flight safety. Photograph and document all aspects of the damage.

- Secure the Area: Erect safety barriers and warning signs to protect personnel from potential hazards, such as exposed wires or sharp edges.

- Consult the Maintenance Manual: Refer to the aircraft maintenance manual for guidance on handling the specific damaged component. This usually includes temporary repair procedures to make the aircraft safe.

- Report the Damage: Report the incident to the appropriate authorities and maintenance personnel. This initiates the repair or replacement process.

- Implement Temporary Repairs (if necessary): Implement temporary repairs as per the maintenance manual, ensuring it does not further compromise the aircraft’s safety. This might involve covering exposed parts or stabilizing loose components.

- Ground the Aircraft: Unless deemed otherwise safe by maintenance, ground the aircraft until the damage is assessed and repaired by qualified personnel.

For example, if a leading-edge slat is damaged, we would cordon off the area, photograph the damage, and then potentially use temporary bracing to prevent further damage until it can be professionally repaired. This process emphasizes a safety-first approach at all times.

Q 11. Describe your experience with troubleshooting aircraft systems.

Troubleshooting aircraft systems requires a systematic approach, combining theoretical knowledge with practical experience. I approach it using a structured methodology, much like a detective solving a case.

My approach typically involves:

- Gather Information: Collect information about the malfunction, including any error messages, indications, and witness reports. I start with the most obvious symptoms and move towards less obvious ones.

- Consult Documentation: Consult the aircraft’s maintenance manual, schematics, and troubleshooting guides to identify potential causes.

- Visual Inspection: Perform a thorough visual inspection of the affected system, looking for visible damage, loose connections, or other irregularities.

- Perform Tests: Using built-in test equipment (BITE), multimeters, and other diagnostic tools, run appropriate tests to isolate the fault. This could include checking voltages, resistances, and continuity.

- Isolating the Fault: Through a process of elimination, identify the component or system causing the malfunction.

- Repair or Replacement: Once the fault is identified, undertake the necessary repair or replacement according to the maintenance manual. Ensure all steps are documented in accordance with maintenance records.

- Verification: After the repair or replacement, perform a functional test to verify that the system is operating correctly and the issue is resolved.

For example, if an engine fails to start, I would first check the fuel supply, battery voltage, starter motor operation, and then investigate other possible reasons based on symptoms and maintenance documentation. I have experience troubleshooting hydraulic, electrical, pneumatic, and fuel systems.

Q 12. What are the regulations and safety procedures for aircraft towing?

Aircraft towing procedures are strictly regulated to ensure safety. These regulations often vary slightly depending on the governing authority (e.g., FAA, EASA).

Key safety procedures include:

- Pre-Tow Inspection: A thorough inspection of the aircraft and towing equipment is essential before commencing any towing operation to ensure everything is in good working order. This includes checking brakes, lights, and the towbar connection.

- Authorized Personnel: Only qualified and authorized personnel should be involved in the towing operation. Proper training and certifications are required for individuals operating towing equipment.

- Communication: Clear communication between the tow vehicle driver and the aircraft marshal (spotter) is vital. Hand signals and/or two-way radios are generally utilized. This ensures the safety of personnel and prevents damage to the aircraft.

- Tow Bar Selection: The appropriate tow bar must be selected based on the aircraft type. The tow bar must be properly attached and secured before starting the tow.

- Speed Restrictions: Towing speeds are strictly limited to prevent damage to the aircraft or injury to personnel. The speed depends on the aircraft and environment.

- Emergency Procedures: Procedures for handling emergencies, such as tow bar failure, must be in place. This includes emergency stops and other safety protocols.

- Documentation: All towing operations should be documented to maintain a record of aircraft movements. This information may be essential for accident investigation and maintenance planning.

Ignoring any of these can lead to accidents resulting in damage to aircraft or injury to the personnel. It is all about following procedures and training.

Q 13. How do you ensure the safety of personnel during aircraft handling operations?

Safety of personnel is paramount during aircraft handling. A multi-layered approach is vital:

- Risk Assessment: Before any operation, conduct a thorough risk assessment to identify potential hazards and implement appropriate control measures. This would involve identifying potential hazards like sharp edges on the aircraft, propellers, and moving ground support equipment.

- Training: All personnel involved must receive adequate training in aircraft handling procedures, safety regulations, and emergency response. This includes understanding the use of safety equipment and emergency signals.

- Safety Equipment: Provide and ensure the use of appropriate personal protective equipment (PPE), such as safety helmets, high-visibility vests, gloves, and safety shoes.

- Clear Communication: Maintain clear and effective communication between all personnel involved in the operation. This might include standard hand signals and use of radios.

- Emergency Procedures: Establish clear emergency procedures and ensure everyone understands their roles and responsibilities in case of an emergency.

- Supervision: Experienced supervisors should oversee all aircraft handling operations to ensure safety procedures are followed.

- Signage and Warning Systems: Employ clear signage, warning lights, and barriers to delineate safe zones and alert personnel to potential hazards.

An example of ensuring personnel safety is the implementation of a ‘no-go’ area around the aircraft engines during operations to prevent accidental contact with moving parts. It is a constant effort that involves all personnel.

Q 14. Explain your understanding of aircraft ground handling equipment.

Aircraft ground handling equipment encompasses various specialized vehicles and tools used for the safe and efficient movement and servicing of aircraft on the ground. This equipment is essential for airport operations.

Examples include:

- Tow Tractors: Used for towing aircraft from gates to runways and vice versa.

- Pushback Tractors: Specifically designed to push back aircraft from the gate.

- Aircraft Stairs: Provide access to aircraft for passengers and crew.

- Baggage Tractors: Transport luggage and cargo to and from aircraft.

- Fuel Trucks: Refuel aircraft.

- Ground Power Units (GPU): Provide electrical power to aircraft on the ground.

- Air Start Units (ASU): Provide compressed air to start aircraft engines.

- Belt Loaders: Load and unload cargo efficiently.

- Passenger Steps: Allow passengers to board and disembark from aircraft.

The selection of appropriate ground handling equipment depends on factors such as the size and type of aircraft and the specific task. Each piece of equipment has its own safety regulations and operating procedures that must be carefully followed. Regular maintenance is vital to prevent failures and potential accidents.

Q 15. Describe your experience with aircraft de-icing and anti-icing procedures.

Aircraft de-icing and anti-icing are crucial for safe operations in cold weather conditions. De-icing removes existing ice and snow, while anti-icing prevents the formation of ice. My experience encompasses both Type I and Type IV de-icing fluids, applied according to the aircraft manufacturer’s specifications and prevailing weather conditions. I’m proficient in using various ground support equipment like de-icing trucks and ensuring complete coverage of the aircraft’s critical surfaces – wings, tail, engines, and control surfaces. For example, I’ve managed de-icing operations for Boeing 737s and Airbus A320s in heavy snow, employing careful fluid application to avoid run-off and ensuring the aircraft’s readiness for takeoff within the prescribed holding times.

Anti-icing involves applying a fluid that prevents ice adhesion. This is often crucial for pre-emptive protection, particularly during periods of freezing rain or prolonged exposure to low temperatures. I’m trained in assessing the risk of ice accretion based on weather reports and selecting the appropriate anti-icing fluid and application techniques. Proper documentation of the process, including fluid type, application time, and ambient temperature, is always meticulously maintained for traceability and regulatory compliance.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with using aircraft maintenance manuals?

Aircraft maintenance manuals (AMMs) are my bible. They’re the definitive source of information for all maintenance, repair, and operational procedures. My experience involves using AMMs daily to troubleshoot issues, perform inspections, and ensure compliance with regulatory requirements. I’m familiar with both the digital and hardcopy versions and adept at navigating their complex structures, including the use of illustrated parts catalogs, schematics, and troubleshooting flowcharts. For instance, when faced with a hydraulic leak on an aircraft, I’d consult the relevant section of the AMM to identify the probable cause, locate the affected component, and follow the prescribed procedure for repair or replacement, ensuring all steps are documented accurately.

Beyond simple repairs, AMMs are vital for understanding the aircraft’s limitations and operational procedures. They provide critical information on weight and balance calculations, loading restrictions, and emergency procedures. Effective use of the AMM requires attention to detail, a methodical approach, and an understanding of the underlying engineering principles.

Q 17. How do you handle emergency situations during aircraft handling?

Handling emergencies during aircraft handling demands quick thinking, clear communication, and a calm demeanor. My training emphasizes risk assessment, immediate action, and efficient coordination with other ground support personnel and air traffic control. Procedures are dictated by the nature of the emergency. For example, a fuel spill necessitates immediate containment and cleanup, calling for absorbent materials, emergency response teams, and potentially, notifying environmental authorities. A fire necessitates immediate evacuation of personnel, deployment of fire extinguishers, and summoning the airport fire department.

In all cases, my first priority is personnel safety. I ensure everyone is clear of the danger zone before addressing the emergency itself. Clear communication with the aircraft crew and ground personnel is vital to coordinate efforts effectively and ensure the safety of both aircraft and personnel. Post-incident reporting and investigation are critical for learning from mistakes and preventing similar occurrences in the future.

Q 18. Describe your understanding of aircraft loading procedures.

Aircraft loading procedures are critical for maintaining aircraft stability and safety. My experience covers weight and balance calculations, cargo securement, and passenger boarding procedures. I am proficient in using specialized software for weight and balance calculations, considering factors like passenger weight, cargo weight and distribution, fuel load, and aircraft’s empty weight. I understand the concept of Center of Gravity (CG) and its influence on aircraft stability.

Cargo securement is equally important. I’m familiar with various methods of securing different types of cargo to prevent shifting during flight, potentially causing imbalance. This includes using appropriate tie-downs, netting, and blocking. Compliance with regulations concerning hazardous materials transport is paramount, requiring specialized handling procedures and documentation. I ensure that all loading procedures are documented according to regulatory requirements.

Q 19. What are the safety precautions for working around moving aircraft?

Safety around moving aircraft is paramount. I always maintain a safe distance from moving aircraft and obey the instructions of the ground crew and pilots. High-visibility clothing is essential, ensuring I’m easily seen by pilots and other personnel. I never enter an area without first confirming its safety through proper communication channels. Awareness of the aircraft’s movement, including its turning radius and potential blind spots, is essential. I understand and follow the designated signaling procedures to communicate with pilots and ground handlers. In short, my safety procedures involve consistent vigilance, clear communication, and strict adherence to established safety protocols.

Furthermore, I understand and follow all designated safety areas and signage, as well as appropriate use of hearing and eye protection where required. Proactive risk assessment is crucial, anticipating potential hazards and avoiding them completely.

Q 20. Explain your experience with different types of aircraft.

My experience spans a variety of aircraft types, including narrow-body aircraft like the Boeing 737 and Airbus A320 family, wide-body aircraft such as the Boeing 777 and Airbus A330, and regional jets like the Embraer 170. Each aircraft type has its unique handling characteristics, weight and balance considerations, and operational procedures.

I’ve worked with both passenger and cargo aircraft, understanding the differences in loading requirements and safety precautions for each. This experience has allowed me to adapt quickly to new aircraft types, learning their specific procedures and safety protocols efficiently. Understanding the differences in size, weight, and handling characteristics between these aircraft is crucial for ensuring safe and efficient operations.

Q 21. How do you prioritize tasks during a busy aircraft handling operation?

Prioritizing tasks during busy aircraft handling operations requires a systematic approach and clear understanding of operational priorities. I use a combination of techniques, including urgency and importance matrices, to rank tasks based on their impact on flight schedules and safety. Safety-critical tasks always take precedence, such as de-icing in icy conditions or addressing a potential mechanical issue. Flight schedule adherence is another important factor, ensuring timely turnaround to minimize delays.

Effective communication with colleagues and air traffic control is crucial for coordinating efforts and allocating resources efficiently. I leverage my experience to anticipate potential bottlenecks and develop proactive solutions to prevent delays. Regularly reviewing the schedule and making adjustments based on real-time information allows for efficient handling of unexpected events. Flexibility and adaptability are crucial to successfully navigate the challenges of a busy operation.

Q 22. Describe your experience with aircraft documentation and record-keeping.

Aircraft documentation is the backbone of safe and efficient operations. My experience encompasses meticulous record-keeping, adhering to both regulatory requirements and company-specific procedures. This includes maintaining accurate logs for maintenance, repairs, flight hours, and any incidents or discrepancies. I’m proficient in using various digital and paper-based systems, ensuring all records are easily accessible, auditable, and compliant. For instance, I’ve been responsible for managing the technical logbooks for multiple aircraft types, including meticulously tracking maintenance actions according to the manufacturer’s instructions and regulatory mandates, like those stipulated by the FAA or EASA. This involved ensuring all entries were clear, concise, and dated correctly, along with proper signature verification.

Furthermore, I’m experienced in handling weight and balance documentation, ensuring accurate calculations for every flight to optimize fuel efficiency and flight safety. This includes using specialized software to input data and generate reports that are essential for pre-flight checks. Finally, I’m adept at managing the associated paperwork for aircraft inspections, ensuring timely completion and proper archiving of all documentation.

Q 23. How do you communicate effectively during aircraft handling operations?

Effective communication during aircraft handling is paramount for safety. I utilize a multi-faceted approach, employing standardized terminology and clear, concise language. This includes the use of established hand signals, radio communication protocols, and detailed checklists. Think of it like a well-orchestrated symphony; everyone needs to understand their role and communicate effectively to avoid any dissonance. For instance, during pushback procedures, clear communication with the ground crew is critical. Using standard phrases and avoiding jargon ensures everyone understands the instructions, such as “Pushback confirmed,” or “Clear of obstacles.” This clarity prevents misinterpretations and potential accidents.

Beyond verbal and visual communication, I ensure that all team members have a shared understanding of the operational plan, the aircraft’s specific requirements, and any potential risks involved. This pre-emptive planning and communication fosters a team environment where everyone is on the same page, ultimately leading to smoother and safer operations.

Q 24. Explain your understanding of aircraft emergency exits and evacuation procedures.

Understanding aircraft emergency exits and evacuation procedures is a critical aspect of my role. My knowledge extends beyond simply knowing the location of exits; it encompasses a comprehensive understanding of emergency response plans, including passenger briefing procedures and the use of emergency equipment. I’m trained in several different aircraft types and their unique exit configurations, considering factors like the location of emergency slides, the potential for obstacles, and the number of passengers onboard.

I understand the significance of rapid and orderly evacuation, and I’m familiar with various evacuation techniques, including assisting passengers with disabilities or those who may require extra support. During training, I’ve practiced emergency evacuation scenarios, incorporating realistic challenges like smoke or limited visibility, to ensure that my responses are efficient and effective under pressure. This includes familiarity with emergency lighting systems, knowing how to communicate with emergency responders, and understanding the post-evacuation procedures, such as passenger accountability.

Q 25. How do you ensure compliance with relevant safety regulations?

Compliance with safety regulations is non-negotiable in aviation. My approach to ensuring compliance involves a multi-pronged strategy. First, I actively stay updated on all relevant regulations, both at the national and international levels, through regular training, publications, and online resources. Second, I meticulously follow all documented procedures and protocols set by the company and regulatory bodies. This includes thorough pre-flight and post-flight inspections, adhering strictly to maintenance schedules, and ensuring that all documentation is correctly completed and filed. Think of it as a checklist that’s always updated and followed to the letter.

Finally, I proactively identify and report any potential safety hazards or non-compliance issues immediately. I believe that a proactive approach to safety is more effective than reacting to problems after they occur. If I identify a discrepancy, I will report it according to established procedures and work collaboratively with the relevant team members to address the issue swiftly and efficiently.

Q 26. Describe your problem-solving skills in relation to aircraft handling challenges.

Problem-solving in aircraft handling often involves quick thinking and decisive action. My approach focuses on a structured, methodical process. First, I clearly define the problem, gathering all relevant information and assessing the situation’s urgency. Then, I systematically evaluate possible solutions, considering their feasibility, safety implications, and potential impact on operations. This may involve consulting colleagues, referring to technical manuals, or utilizing troubleshooting guides.

For example, if an aircraft experiences a ground power failure during a pre-flight check, my problem-solving process would begin by assessing the severity (is it a minor glitch or a major system failure?), then evaluating potential solutions (using auxiliary power, contacting maintenance, etc.), and finally, selecting the most appropriate and safest course of action, ensuring all personnel are informed and safe.

Q 27. What is your experience with risk assessment in aircraft handling?

Risk assessment is integral to every aircraft handling operation. My experience involves conducting thorough risk assessments prior to any operation, identifying potential hazards and evaluating their likelihood and severity. This often involves using established methodologies and frameworks, such as HAZOP (Hazard and Operability Study), to identify potential hazards and develop mitigation strategies. This isn’t about eliminating risks entirely, which is practically impossible, but rather about managing them effectively.

For example, during winter operations, risks such as snow and ice accumulation on the aircraft or runways are major concerns. The risk assessment would identify these, assess their likelihood (high during winter months), evaluate their severity (potential for accidents), and then propose mitigation strategies (de-icing procedures, runway clearing, and adjustments to handling procedures).

Q 28. How do you stay current with changes in aviation safety regulations?

Staying current with changes in aviation safety regulations is an ongoing process requiring continuous effort and commitment. I leverage several methods to ensure I’m always up-to-date. This includes regularly reviewing official publications from aviation authorities such as the FAA or EASA, participating in industry conferences and training courses, and actively engaging with professional networks and online resources. I also subscribe to relevant newsletters and journals, and I actively seek out information on any changes related to the aircraft types I handle.

Moreover, I participate in regular internal training sessions and updates organized by my company to ensure alignment with the latest safety protocols. Staying current isn’t just about compliance; it’s about enhancing safety, improving efficiency, and ensuring the continual development of my expertise in this ever-evolving field.

Key Topics to Learn for Aircraft Handling and Damage Control Interview

- Aircraft Ground Handling Procedures: Understanding pushback procedures, towing techniques, weight and balance calculations, and safe movement of aircraft on the ground. Consider the practical application of these procedures in various weather conditions and airport environments.

- Damage Assessment and Reporting: Learn to accurately identify and document aircraft damage, utilizing appropriate reporting systems and documentation methods. Practice describing damage scenarios and the steps taken to mitigate further damage or risk.

- Safety Regulations and Compliance: Familiarize yourself with relevant aviation safety regulations (e.g., FAA, EASA) concerning aircraft handling and damage control. Understand how these regulations are practically implemented in your daily tasks.

- Emergency Response Procedures: Understand procedures for responding to various aircraft emergencies, including fire, fuel spills, and other incidents. Consider the practical application of emergency response plans and the importance of teamwork in these situations.

- Aircraft Structure and Systems: Develop a foundational understanding of aircraft structure and key systems relevant to handling and damage control. This will help you understand the potential impact of damage on aircraft operations.

- Material Science and Repair Techniques: Familiarize yourself with common aircraft materials and appropriate repair techniques. Consider the practical implications of choosing the correct repair method based on the type and extent of the damage.

- Risk Assessment and Mitigation: Learn to identify and assess potential risks associated with aircraft handling and damage control, and develop strategies for mitigating these risks effectively.

Next Steps

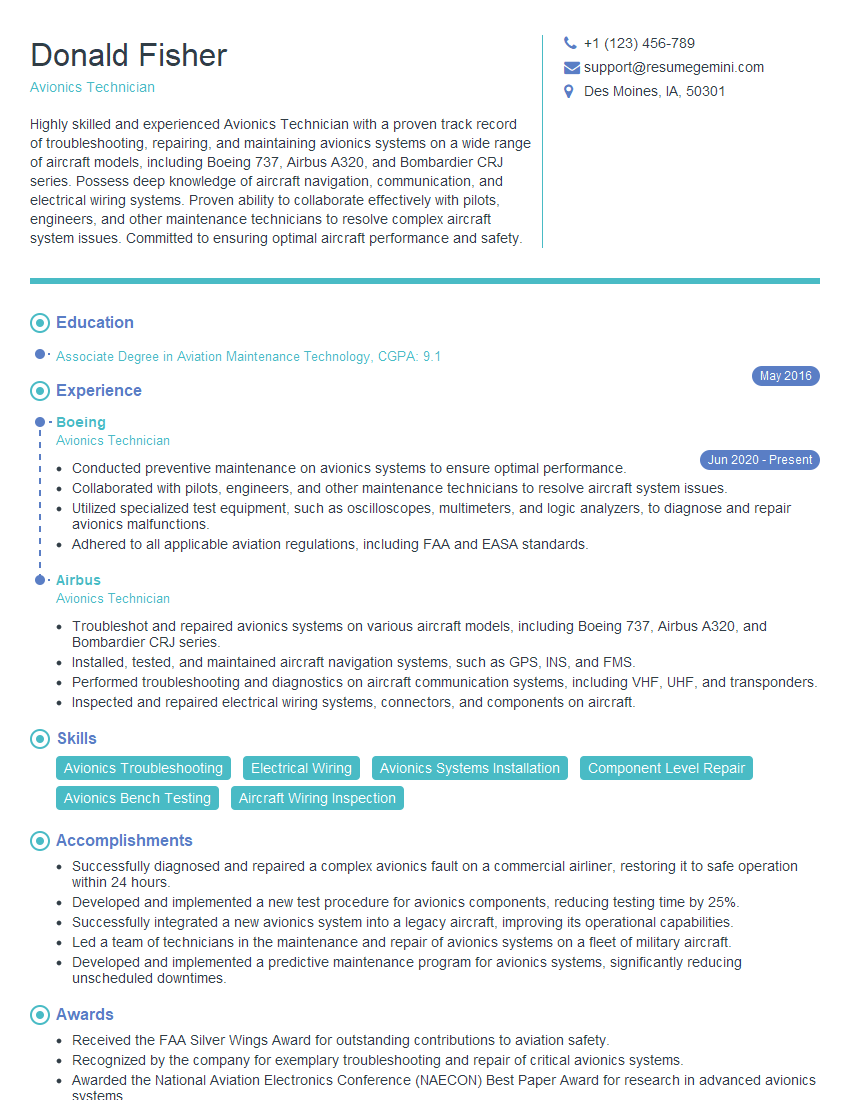

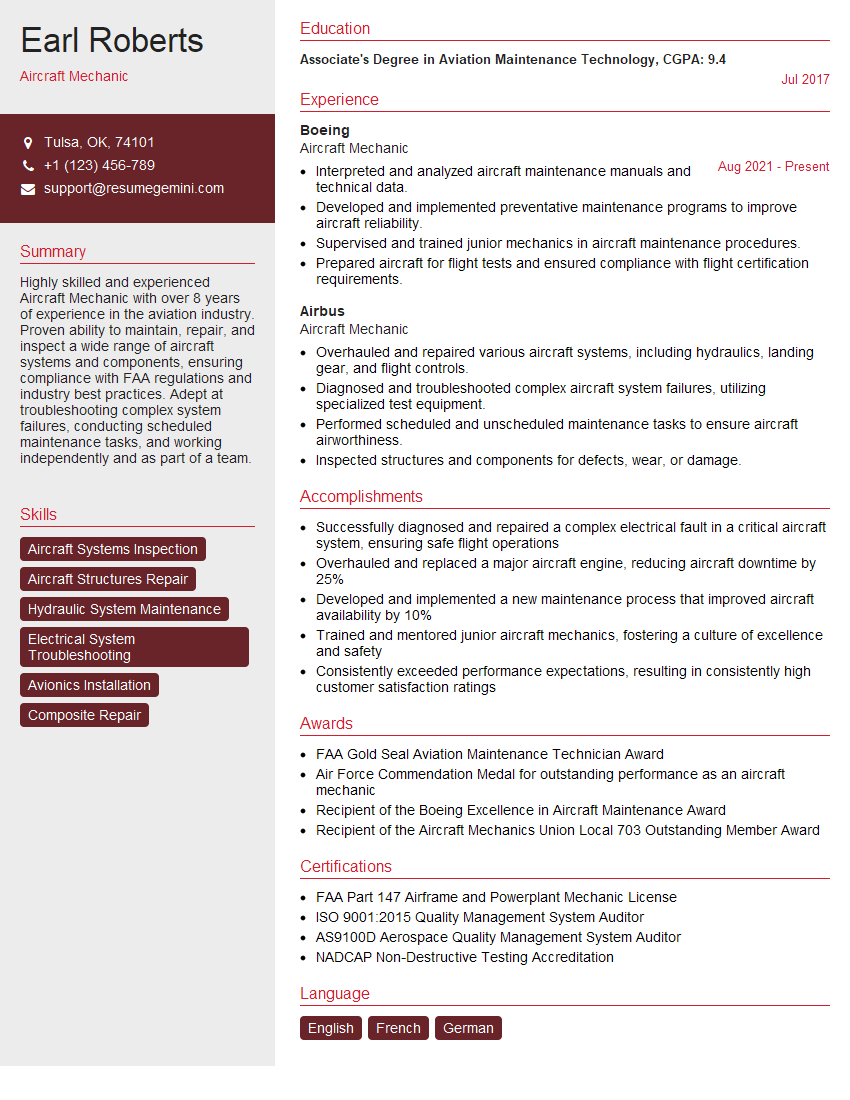

Mastering Aircraft Handling and Damage Control is crucial for a successful and rewarding career in aviation. It demonstrates a commitment to safety, precision, and problem-solving – highly valued skills in this demanding field. To maximize your job prospects, creating a strong, ATS-friendly resume is essential. ResumeGemini can help you build a professional and impactful resume that highlights your skills and experience effectively. We provide examples of resumes tailored to Aircraft Handling and Damage Control to guide you through the process. Invest in your future – invest in a compelling resume with ResumeGemini.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good