Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Aircraft Maintenance and Inspections interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Aircraft Maintenance and Inspections Interview

Q 1. Explain the difference between preventative and corrective maintenance.

Preventative maintenance, as the name suggests, focuses on preventing issues before they arise. It’s proactive, involving scheduled inspections, lubrication, and component replacements based on manufacturer recommendations and flight hours. Think of it like regular car servicing – changing oil, rotating tires – to avoid bigger problems down the line. Corrective maintenance, on the other hand, addresses problems *after* they occur. This is reactive maintenance; you fix something that’s already broken. For example, replacing a faulty fuel pump after it malfunctions during a flight. The key difference lies in the timing and approach: preventative is proactive and scheduled, while corrective is reactive and unscheduled.

In aircraft maintenance, a robust preventative maintenance program is crucial for safety and operational efficiency. It minimizes unexpected downtime and reduces the risk of catastrophic failures. A good balance between preventative and corrective maintenance is essential for cost-effectiveness and safety.

Q 2. Describe your experience with aircraft logbook maintenance and record-keeping.

My experience with aircraft logbook maintenance and record-keeping is extensive. I’ve worked with both paper-based and digital systems, ensuring meticulous documentation of all maintenance activities. This includes recording inspections, repairs, part replacements, and any discrepancies found. Accurate logbook maintenance is not just a matter of compliance; it’s a critical safety aspect. A properly maintained logbook provides a complete history of the aircraft, allowing for informed decision-making regarding future maintenance needs and ensuring regulatory compliance. I am proficient in using various software programs for managing aircraft records, ensuring data integrity and easy accessibility for audits and investigations. In one instance, careful review of the logbook revealed a subtle trend in a specific component’s failure rate, leading to a preventative maintenance strategy that significantly reduced downtime and potential safety risks.

Q 3. What are the key components of a pre-flight inspection?

A pre-flight inspection is a critical safety check performed before each flight. It’s a visual and functional check of numerous systems to ensure the aircraft is airworthy. Key components include:

- External Inspection: Checking for damage to the airframe, control surfaces, and propellers; verifying fuel levels and absence of leaks; inspecting tires, brakes, and landing gear.

- Cockpit Check: Confirming the functionality of flight instruments, radios, lights, and other avionics; verifying fuel gauges, engine oil pressure, and other vital parameters.

- Engine Check: Inspecting for any leaks or damage around the engine; verifying oil levels and checking for any unusual noises or vibrations during a brief engine run-up.

- Control Surface Check: Verifying the smooth and proper operation of ailerons, elevators, and rudder.

The specifics vary depending on the aircraft type, but the overall goal is consistent: to identify any potential issues that could compromise safety before takeoff.

Q 4. How do you troubleshoot a malfunctioning aircraft system?

Troubleshooting a malfunctioning aircraft system is a systematic process. It starts with identifying the symptoms – what’s not working correctly. Then, using the aircraft’s systems schematics and troubleshooting manuals, I work through a series of logical steps:

- Gather Information: Collect data from pilot reports, flight data recorders, and any available diagnostic tools.

- Isolate the Problem: Determine which system is malfunctioning and the extent of the problem.

- Consult Documentation: Refer to maintenance manuals, troubleshooting guides, and relevant service bulletins for possible causes and solutions.

- Check Simple Things First: Often, the issue is something straightforward, such as a loose connection or a blown fuse, before moving to more complex issues.

- Perform Tests: Conduct specific tests to confirm or eliminate potential causes.

- Repair or Replace: Once the root cause is identified, the necessary repairs or component replacements are undertaken, always ensuring adherence to safety regulations and manufacturer guidelines.

Thorough documentation of every step is crucial, both for tracking the resolution and for future reference. For example, recently I resolved a hydraulic leak by systematically tracing the hydraulic lines, identifying a small crack in a fitting, and replacing the faulty component.

Q 5. Describe your experience with different types of aircraft maintenance documentation.

My experience encompasses a wide range of aircraft maintenance documentation, including:

- Maintenance Manuals: Comprehensive guides providing detailed information about aircraft systems, maintenance procedures, and troubleshooting steps.

- Service Bulletins: Notifications from manufacturers addressing specific problems or improvements to aircraft systems.

- Airworthiness Directives (ADs): Mandatory instructions from aviation authorities addressing safety concerns related to specific aircraft models or systems.

- Logbooks: Detailed records of all maintenance activities performed on the aircraft.

- Parts Manuals: Catalogs detailing all the aircraft’s parts and their specifications.

- Weight and Balance Reports: Documentation of the aircraft’s weight distribution, crucial for flight safety.

Understanding and effectively utilizing these diverse documents are fundamental to safe and compliant aircraft maintenance.

Q 6. What are the common causes of engine failure and how can they be prevented?

Engine failure can stem from various causes, broadly categorized as mechanical, operational, or environmental.

- Mechanical Failures: These include issues like fatigue cracking in components, bearing failure, compressor or turbine blade damage, fuel pump malfunction, and problems within the combustion system. Regular inspections, preventative maintenance, and adhering to maintenance schedules are key preventative measures.

- Operational Issues: Incorrect operating procedures, such as exceeding operational limits (e.g., exceeding RPM) or insufficient lubrication, contribute significantly to engine problems. Pilot training and adherence to operational manuals are vital.

- Environmental Factors: Ingestion of foreign objects (FOD) such as birds or debris can cause severe engine damage. Proper maintenance of engine intakes and adhering to operating procedures in known FOD-prone environments are crucial.

Preventing engine failures is a multifaceted approach relying on robust maintenance programs, strict adherence to manufacturer recommendations, meticulous pilot operation, and vigilant FOD awareness.

Q 7. Explain your understanding of FAA regulations and maintenance guidelines.

My understanding of FAA regulations and maintenance guidelines is comprehensive. I am intimately familiar with FAR Part 43 (Maintenance, Preventive Maintenance, Rebuilding, and Alteration), which governs aircraft maintenance in the United States. This includes understanding airworthiness standards, record-keeping requirements, and the processes for returning aircraft to service after maintenance. I also stay abreast of all applicable Airworthiness Directives (ADs) and service bulletins. Compliance with these regulations isn’t just a legal obligation; it’s a critical aspect of ensuring aviation safety. I regularly attend training courses and workshops to stay updated on regulatory changes and best practices. For example, I recently completed a course on the latest updates to FAR Part 43, which addressed changes in documentation requirements for major repairs.

Q 8. How do you ensure compliance with safety regulations during maintenance procedures?

Ensuring compliance with safety regulations during aircraft maintenance is paramount. It’s not just about following a checklist; it’s about a deeply ingrained safety culture. We achieve this through a multi-layered approach.

- Strict Adherence to Regulations: We meticulously follow all applicable regulations set by governing bodies like the FAA (Federal Aviation Administration) or EASA (European Union Aviation Safety Agency), including airworthiness directives (ADs) and maintenance manuals. These documents are our bible.

- Detailed Documentation: Every single task, from a simple oil change to a complex engine overhaul, is meticulously documented. This includes recording the parts used, the time spent, and any discrepancies encountered. This comprehensive record-keeping allows for traceability and ensures accountability.

- Regular Audits and Inspections: Internal and external audits are crucial. These audits verify that our procedures and documentation meet the required standards. Any discrepancies are promptly addressed with corrective actions.

- Continuous Training and Proficiency: Our team undergoes continuous training to stay updated on the latest regulations, techniques, and technologies. Regular competency checks ensure technicians maintain the necessary skills and knowledge.

- Risk Assessment and Mitigation: Before any maintenance task, we conduct a thorough risk assessment to identify potential hazards and implement appropriate safety measures. This could include specialized tools, personal protective equipment (PPE), or work area limitations.

- Quality Control Checks: Multiple layers of quality control are built into the process. This often involves peer reviews and cross-checks to ensure accuracy and prevent errors.

For example, if an AD mandates a specific repair on a certain component, we not only perform the repair but also meticulously document every step, ensuring complete compliance and traceability. Failure to comply can result in serious safety implications and legal repercussions.

Q 9. What is your experience with hydraulic systems maintenance?

I have extensive experience maintaining hydraulic systems, spanning various aircraft types. My work encompasses preventative maintenance, troubleshooting, and repairs. Hydraulic systems are critical for flight control, landing gear operation, and braking, so meticulous attention to detail is essential.

- Preventative Maintenance: This includes regular fluid sampling and analysis to detect contamination, inspections for leaks, and the timely replacement of components based on manufacturer’s recommendations or scheduled maintenance programs. I’m familiar with various types of hydraulic fluids and their properties.

- Troubleshooting: Identifying and resolving hydraulic system malfunctions involves systematic diagnosis. This might include checking pressure gauges, identifying leaks using dye penetrant inspection, testing components with specialized equipment, and tracing hydraulic lines for blockages or damage. One time, I successfully diagnosed a subtle leak in a hydraulic actuator by carefully listening for unusual sounds during system operation, something easily missed by a less experienced technician.

- Repairs: This can range from simple repairs like replacing seals and O-rings to more complex tasks like overhauling hydraulic pumps or actuators. I’m proficient in using specialized tools and equipment necessary for these repairs, always adhering to strict safety protocols.

I’m experienced with both conventional and advanced hydraulic systems, including those incorporating electro-hydraulic controls. I’m also familiar with various types of hydraulic components such as pumps, actuators, valves, and accumulators.

Q 10. How familiar are you with different types of aircraft engines?

My familiarity with different aircraft engines is comprehensive, encompassing both turbofan, turboprop, and piston engines. Understanding the nuances of each type is crucial for effective maintenance and troubleshooting.

- Turbofan Engines: I have extensive experience working with various turbofan engines, including those manufactured by Rolls-Royce, GE, and Pratt & Whitney. My knowledge covers their operation, maintenance procedures, and troubleshooting techniques. I’m familiar with engine health monitoring systems and performance analysis.

- Turboprop Engines: I’m proficient in maintaining turboprop engines, focusing on their unique characteristics, such as propeller systems and their interaction with the engine. This includes understanding propeller synchronization and balancing procedures.

- Piston Engines: I have experience maintaining piston engines, commonly found in smaller aircraft. This involves understanding carburetor systems, ignition systems, and the intricacies of reciprocating engine mechanics.

Regardless of the engine type, my approach is always systematic and thorough, ensuring the highest standards of safety and reliability. I constantly update my knowledge to stay abreast of new engine technologies and maintenance procedures.

Q 11. Explain your experience with troubleshooting electrical system issues.

Troubleshooting electrical system issues in aircraft requires a systematic and methodical approach, combining theoretical understanding with practical skills. It’s a complex system, and a small problem can lead to significant safety hazards.

- Systematic Approach: I use a structured approach, starting with a thorough understanding of the aircraft’s electrical system schematics. This helps in tracing the flow of electricity and isolating the fault.

- Testing Equipment: I’m proficient in using various testing equipment such as multimeters, oscilloscopes, and circuit testers to identify voltage, current, and resistance issues. Knowing the limits of each tool and when to use each is crucial.

- Component Level Diagnosis: This often involves testing individual components, such as circuit breakers, relays, and wiring harnesses, to pinpoint the faulty component. Sometimes a simple visual inspection can reveal a loose connection or damaged wire. One instance involved tracing a seemingly erratic electrical fault in the flight control system to a tiny crack in a wire harness, concealed beneath a layer of insulation.

- Fault Isolation: This is a critical part of the process, requiring careful analysis and elimination of potential causes. I’ve successfully employed fault trees and other diagnostic tools to isolate complex problems.

Safety is always a top priority. Working with aircraft electrical systems demands meticulous care and adherence to safety protocols to prevent electrical shock or fire.

Q 12. What is your experience with non-destructive testing (NDT) methods?

I’m experienced in various Non-Destructive Testing (NDT) methods employed in aircraft maintenance. NDT is crucial for detecting flaws and defects without damaging the aircraft structure.

- Dye Penetrant Inspection (DPI): This method effectively detects surface-breaking cracks and flaws in non-porous materials. I’m proficient in applying the penetrant, developer, and interpreting the results to identify any anomalies.

- Magnetic Particle Inspection (MPI): MPI is used to detect surface and near-surface flaws in ferromagnetic materials. I have experience magnetizing the component, applying magnetic particles, and interpreting the resulting patterns to locate flaws.

- Ultrasonic Testing (UT): UT uses high-frequency sound waves to detect internal flaws in materials. I’m skilled in operating ultrasonic equipment, interpreting the signals, and identifying flaws such as cracks, delaminations, or corrosion.

- Radiographic Inspection (RT): I have knowledge of RT techniques, although it is often handled by specialized personnel. Understanding the limitations and the ability to interpret radiographic images is vital for collaborating effectively.

Interpreting NDT results accurately requires training and experience. Misinterpreting the data can have serious consequences, so thorough training and continuing education in this area is essential.

Q 13. Describe your experience working with composite materials.

Working with composite materials is a significant part of modern aircraft maintenance. These materials, while offering high strength-to-weight ratios, require specialized handling and repair techniques. My experience covers various aspects of composite maintenance.

- Inspection and Repair: I can identify and assess damage to composite structures, including delaminations, impact damage, and corrosion. Repair techniques range from simple patching to more complex repairs involving layup and curing of new composite layers.

- Material Selection and Handling: Choosing the right materials for repairs is crucial. I’m familiar with different types of composites, resins, and fabrics, and I understand the importance of proper surface preparation and handling techniques to maintain the structural integrity.

- Specialized Tools and Equipment: Working with composites requires specialized tools and equipment, including drills, grinders, and curing ovens. Safety is paramount when using these tools.

- Understanding of Material Properties: A key aspect is understanding the mechanical properties of various composite materials. This allows for informed repair decisions and ensures the structural integrity of the repaired component.

One challenging repair involved a significant delamination in an aircraft wing. Using my knowledge of composite repair techniques, I successfully restored the structural integrity of the wing, ensuring its airworthiness.

Q 14. How do you handle a maintenance discrepancy that you are unfamiliar with?

Encountering an unfamiliar maintenance discrepancy is a situation I handle systematically and cautiously. Safety and correct diagnosis are paramount.

- Consult Documentation: The first step is to thoroughly review the aircraft’s maintenance manual, service bulletins, and airworthiness directives to see if the discrepancy is documented.

- Seek Assistance: If the documentation doesn’t provide a solution, I would consult with senior technicians, engineers, or other experts within the maintenance organization. This could involve contacting the aircraft manufacturer’s technical support team.

- Research and Learning: I would utilize reputable technical resources, such as online databases, technical publications, and industry best practices to gain a better understanding of the issue.

- Temporary Safe Actions: If the discrepancy poses a safety risk, temporary measures would be implemented to mitigate the risk while a permanent solution is being sought. These temporary measures would be documented carefully.

- Thorough Documentation: Every step of the process, including the initial discovery, research, and attempted solutions, would be carefully documented to ensure a clear record of the events.

This measured approach ensures that the aircraft remains safe and airworthy while the appropriate solution is found. It reflects a commitment to continuous learning and a responsible approach to aircraft maintenance.

Q 15. What is your experience with aircraft weight and balance calculations?

Aircraft weight and balance is crucial for safe flight. It involves calculating the aircraft’s center of gravity (CG) to ensure it remains within the approved limits specified in the aircraft’s flight manual. Incorrect weight and balance can lead to handling difficulties, reduced performance, and even catastrophic structural failure.

My experience includes performing these calculations manually using weight and balance forms and using specialized software. This involves meticulously recording the weight of fuel, passengers, cargo, and the aircraft itself. I’ve worked with both simple general aviation aircraft and more complex commercial jets, each requiring a different level of detail and software application. For example, I’ve handled situations where unexpectedly heavy baggage needed to be redistributed to maintain CG within limits before takeoff, preventing a potentially dangerous flight. I understand the importance of accounting for fuel burn throughout the flight and how this affects the CG over time. This requires an understanding of fuel consumption rates and the effects on weight distribution.

Furthermore, I’m proficient in using software like [Name of software 1] and [Name of software 2], which automate much of the process, reducing the risk of human error. These programs provide visual representations of the CG location and help identify potential issues proactively.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your understanding of corrosion control and prevention.

Corrosion control is paramount in aircraft maintenance. Corrosion, the deterioration of metals due to chemical reactions, can severely weaken airframe structures, compromising safety. My approach to corrosion control involves a multi-pronged strategy focusing on prevention, detection, and treatment.

- Prevention: This includes regular cleaning and washing of the aircraft to remove contaminants, the application of protective coatings like paints and sealants, and the use of corrosion inhibitors. Proper storage procedures, minimizing exposure to moisture and salt, are also essential. We use specialized cleaning agents that are compatible with the aircraft materials to avoid further damage.

- Detection: This involves regular visual inspections, using tools like boroscopes to access hard-to-reach areas, and employing non-destructive testing (NDT) methods such as dye penetrant inspection or eddy current testing to identify hidden corrosion. Documentation of all findings is crucial.

- Treatment: Once corrosion is detected, appropriate treatment is implemented. This might include removing the corroded material, cleaning the affected area, applying a primer, and repainting. Severe corrosion might necessitate more complex repairs or even part replacement. The type of repair is chosen depending on severity and location.

For instance, I’ve successfully addressed corrosion issues in an aircraft’s wing spars by using a combination of meticulous cleaning, the application of a specialized corrosion inhibitor, and detailed documentation for the repair log. Understanding the different types of corrosion – galvanic, crevice, stress corrosion cracking – is vital in determining the best course of action.

Q 17. Describe your proficiency in using aircraft maintenance software.

Proficiency in aircraft maintenance software is essential for efficient and accurate record-keeping. I’m experienced using several popular systems, including [Name of software 1], [Name of software 2], and [Name of software 3]. These programs allow for tracking maintenance schedules, recording inspections, managing parts inventory, and generating reports. They improve efficiency, reduce paperwork, and enhance traceability.

My skills include entering and managing maintenance data, generating reports for regulatory compliance, and utilizing the software’s search functions to quickly access relevant information on past maintenance activities for a specific aircraft. I can troubleshoot minor software issues and understand the importance of data integrity for safety and regulatory purposes. For example, I once used the software to track a specific part’s lifespan, allowing for proactive replacement before it reached its service limit, preventing a potential in-flight failure.

Q 18. How do you prioritize maintenance tasks based on urgency and importance?

Prioritizing maintenance tasks requires a systematic approach. I utilize a combination of the aircraft’s maintenance manual, airworthiness directives (ADs), and the aircraft’s operational history to determine the urgency and importance of tasks. A common method I employ is a risk-based approach.

- Urgency: Tasks with immediate safety implications, such as those identified by ADs or those impacting flight safety, have the highest urgency. These are addressed immediately.

- Importance: Tasks essential for maintaining airworthiness but without immediate safety implications are considered important. These tasks are scheduled according to the maintenance manual and regulatory requirements.

I use a system that combines urgency and importance into a matrix. Tasks are assigned to quadrants based on their urgency and importance. This allows me to prioritize tasks logically and efficiently. For example, a critical AD requiring immediate action would be prioritized over a scheduled inspection that can be delayed slightly without jeopardizing safety. I also factor in the impact on aircraft availability and operational costs when prioritizing tasks, ensuring a balance between safety and efficiency.

Q 19. What is your experience with different types of aircraft landing gear systems?

My experience encompasses various landing gear systems, including:

- Conventional Gear: This type uses a tailwheel or nosewheel configuration. I understand the intricacies of their operation, maintenance, and troubleshooting. I’m familiar with inspecting shock absorbers, brakes, and steering mechanisms, recognizing wear and tear or potential malfunctions.

- Tricycle Gear: The most common type, featuring a nosewheel and two main landing gear legs. I’m skilled in inspecting components like the nosewheel steering system, shock struts, brakes, and retraction mechanisms. I’ve handled issues involving hydraulic leaks and malfunctioning retraction systems.

- Tandem Gear: Two main gear located close to the aircraft’s center. I’ve worked with aircraft using this less common configuration, understanding its specific challenges and maintenance requirements, like potential for ground clearance issues.

Regardless of the type, I thoroughly inspect all components, including tires, brakes, shock absorbers, and linkages for wear, damage, and proper functioning. I am proficient in performing scheduled inspections, as well as troubleshooting and resolving malfunctions. I understand the importance of adherence to manufacturer’s guidelines and regulatory requirements for each system type.

Q 20. Describe your experience with fuel system maintenance and inspections.

Fuel system maintenance and inspections are critical for safe operation. Fuel leaks can be hazardous, and contaminated fuel can damage the engine. My experience includes inspecting fuel tanks, lines, pumps, filters, and other components for leaks, cracks, corrosion, and contamination. I’m proficient in performing fuel system pressure tests, checking fuel flow, and ensuring proper operation of fuel gauges and other instrumentation. I’ve also handled situations involving fuel contamination, tracing the source of the contamination and taking appropriate remediation actions.

For example, I’ve worked on various aircraft, from small single-engine aircraft to larger multi-engine planes, performing tasks ranging from simple fuel filter changes to more complex repairs of fuel tank seals and pump replacements. I always follow stringent safety procedures, including properly grounding the aircraft before any maintenance work and taking appropriate precautions to avoid ignition sources when handling fuel.

My experience also encompasses the understanding of different fuel types and their compatibility with the aircraft system, ensuring the right type of fuel is used and that procedures for handling different fuel grades are correctly followed.

Q 21. What safety measures do you always employ during maintenance procedures?

Safety is my paramount concern. I religiously adhere to a strict set of safety measures during all maintenance procedures. These include:

- Lockout/Tagout Procedures: I always use lockout/tagout procedures to prevent accidental energization of electrical systems or activation of hydraulic or pneumatic systems. This is crucial to prevent injuries from unexpected movement of equipment.

- Grounding Procedures: When working on any system involving electricity or fuel, grounding procedures are followed meticulously to prevent static electricity buildup and potential sparks.

- Personal Protective Equipment (PPE): I always wear appropriate PPE, including safety glasses, gloves, hearing protection, and protective clothing, based on the specific task.

- Tool Control: Tools are inspected before each use to ensure they’re in good working condition and correctly maintained. I employ best practices for tool control to prevent dropping tools, a significant risk factor during aircraft maintenance.

- Following Manufacturer’s Instructions: I adhere strictly to the aircraft manufacturer’s maintenance manuals and instructions for each task.

- Work Area Safety: I ensure the work area is clean, organized, and free from obstructions to prevent accidents.

Beyond these standard procedures, I always maintain situational awareness and exercise caution, taking extra precautions whenever working at heights or in confined spaces. I also regularly review safety procedures and participate in safety training to stay updated on best practices and hazard mitigation techniques.

Q 22. How do you manage your time effectively during maintenance tasks?

Effective time management during aircraft maintenance is crucial for safety and efficiency. It’s not just about working quickly, but working smartly. My approach involves several key strategies:

- Detailed Task Breakdown: Before starting any maintenance task, I meticulously review the relevant maintenance manual and break down the job into smaller, manageable steps. This prevents overlooking crucial details and allows for better time allocation.

- Prioritization: I prioritize tasks based on urgency and safety implications. Emergency repairs always take precedence. This often requires a quick assessment of the situation to determine the most critical repairs.

- Resource Management: I ensure all necessary tools, parts, and documentation are readily available before commencing work. This minimizes downtime spent searching or waiting.

- Regular Check-ins: I set regular checkpoints to monitor progress against the schedule. This allows for timely adjustments if unforeseen delays occur.

- Utilizing Technology: I leverage digital maintenance tracking systems and mobile apps to manage schedules, track progress, and access technical data quickly and efficiently. This also improves communication within the team.

For example, during a recent engine change, breaking the task down into stages – engine removal, inspection, installation of the new engine, and post-installation checks – allowed for better time allocation and facilitated smoother collaboration with the team.

Q 23. How do you work effectively within a team environment during maintenance?

Teamwork is paramount in aircraft maintenance. Safety and efficiency depend on effective communication and collaboration. My experience highlights the importance of:

- Clear Communication: I actively participate in pre-job briefings, ensuring everyone understands the scope of work, potential hazards, and assigned roles. Open communication throughout the process prevents misunderstandings and delays.

- Respectful Collaboration: I value the expertise of each team member and foster a supportive environment where everyone feels comfortable contributing their knowledge and raising concerns.

- Problem-Solving as a Team: When challenges arise, I actively participate in brainstorming sessions, offering suggestions and working collaboratively to find the best solutions. This fosters a sense of shared responsibility and promotes quicker problem-solving.

- Delegation and Support: I am comfortable delegating tasks based on team members’ skills and experience, providing guidance and support as needed. This allows for efficient task completion and skill development within the team.

During a complex landing gear overhaul, for instance, clear communication with the hydraulics specialist, the structural mechanic, and the quality control inspector ensured that every step of the process was correctly and safely executed.

Q 24. What is your experience with performing post-maintenance flight tests?

Post-maintenance flight tests are critical for verifying the effectiveness of repairs and ensuring the aircraft is airworthy. My experience includes participating in and leading these tests, adhering strictly to safety protocols. This involves:

- Pre-flight Checks: A thorough pre-flight inspection is conducted, verifying all systems are functioning correctly before flight.

- Flight Test Execution: I work closely with the pilot, executing a series of maneuvers designed to test the specific systems affected by the maintenance. These tests are carefully planned to avoid unnecessary risks.

- Data Recording and Analysis: Flight parameters are carefully monitored and recorded, often using specialized flight data recorders. This data is then analyzed to assess the aircraft’s performance.

- Post-flight Inspection: A post-flight inspection examines the aircraft for any signs of malfunctions or anomalies. Any detected issues are documented and addressed.

For example, after an engine replacement, I’ve participated in test flights to verify engine performance, fuel consumption, and overall aircraft handling characteristics. Ensuring the safe and successful completion of these flights requires meticulous planning and close collaboration between the maintenance team and the pilots.

Q 25. Describe a time you had to solve a complex maintenance problem.

During a routine inspection, we discovered a significant crack in a critical component of the aircraft’s flight control system. This was a complex problem as the component was difficult to access and the crack posed a serious safety risk. My problem-solving approach involved:

- Assessment: We thoroughly assessed the extent of the damage, consulting the aircraft’s maintenance manual and contacting the manufacturer for guidance.

- Research: We researched various repair solutions, considering factors like safety, cost, and the aircraft’s downtime.

- Solution Selection: After careful evaluation, we decided on a specialized repair technique using a composite patch, a solution that minimized aircraft downtime and ensured the highest level of safety.

- Repair Execution: The repair was carried out meticulously, with strict adherence to safety procedures and quality control checks at every stage.

- Verification: Following the repair, we conducted thorough inspections and functional tests to ensure the component’s integrity before returning the aircraft to service.

This situation highlighted the importance of thorough inspections, collaborative problem-solving, and the use of advanced repair techniques to maintain aircraft safety and operational efficiency.

Q 26. How familiar are you with the different types of aircraft instruments and their maintenance?

I am very familiar with various aircraft instruments and their maintenance. My experience spans a wide range, including:

- Flight Instruments: Altimeters, airspeed indicators, vertical speed indicators, and attitude indicators, including their associated sensors and systems.

- Navigation Instruments: GPS, VOR, ILS, and ADF systems, understanding their principles of operation and calibration procedures.

- Engine Instruments: Engine gauges, fuel flow meters, oil pressure indicators, and temperature gauges, understanding their significance in monitoring engine health.

- Electrical Systems: Various electrical components, including voltage regulators, circuit breakers, and warning lights, and their maintenance and troubleshooting.

I understand the importance of regularly calibrating and maintaining these instruments to ensure accurate readings and safe operation. For example, I’ve performed calibrations on various altimeters, ensuring they meet strict accuracy standards required for safe flight.

Q 27. What experience do you have with the use of specialized tools and equipment?

My experience with specialized tools and equipment is extensive, encompassing a wide range of tools used in aircraft maintenance, including:

- Hand Tools: Specialized wrenches, screwdrivers, pliers, and other hand tools specific to aircraft components.

- Power Tools: Drills, grinders, and other power tools used in various repair and maintenance tasks. Safety procedures are always paramount when using these tools.

- Test Equipment: Multimeters, oscilloscopes, and other electronic test equipment used for diagnostics and troubleshooting.

- Specialized Equipment: Hydraulic test equipment, specialized torque wrenches, and other sophisticated equipment needed for specific maintenance procedures.

I am proficient in using these tools safely and effectively, following all safety regulations and manufacturer guidelines. For instance, I’m experienced using specialized torque wrenches to ensure the proper tightening of critical fasteners, preventing potential structural damage.

Q 28. Describe your experience with aircraft scheduled maintenance programs (e.g., calendar-based or usage-based)

I have extensive experience with aircraft scheduled maintenance programs, both calendar-based and usage-based. Understanding the differences between these is key to ensuring airworthiness and optimizing maintenance costs:

- Calendar-Based: This involves performing maintenance at predetermined intervals, regardless of the aircraft’s usage. This is simpler to manage but might lead to unnecessary maintenance on lightly used aircraft.

- Usage-Based: This involves scheduling maintenance based on the aircraft’s actual usage, such as flight hours or flight cycles. This is more cost-effective for heavily used aircraft but requires a more sophisticated tracking system.

My experience includes working with both systems, utilizing computerized maintenance management systems (CMMS) to track maintenance schedules and ensure compliance with regulatory requirements. Understanding both approaches ensures I can tailor maintenance strategies to optimize costs and maintain aircraft airworthiness, regardless of operational intensity.

Key Topics to Learn for Aircraft Maintenance and Inspections Interview

- Aircraft Systems Knowledge: Understanding the intricacies of various aircraft systems (e.g., hydraulics, pneumatics, electrical, fuel, avionics) is crucial. Prepare to discuss their operation, maintenance procedures, and potential failure points.

- Maintenance Manuals & Regulations: Demonstrate familiarity with interpreting and applying maintenance manuals, FAA regulations (or equivalent international regulations), and airworthiness directives. Be ready to discuss how you ensure compliance.

- Troubleshooting & Problem-Solving: Practice explaining your approach to diagnosing aircraft malfunctions. Highlight your experience with systematic troubleshooting, using diagnostic tools, and documenting findings effectively.

- Inspection Techniques & Procedures: Describe your proficiency in conducting various inspections (e.g., pre-flight, routine, scheduled) according to established procedures. Showcase your attention to detail and ability to identify potential issues.

- Safety Regulations & Procedures: Emphasize your commitment to safety and your understanding of relevant safety regulations and best practices. Be prepared to discuss how you ensure a safe working environment and prevent accidents.

- Record Keeping & Documentation: Explain your experience with meticulous record-keeping, including maintenance logs, inspection reports, and other relevant documentation. Highlight your ability to maintain accurate and up-to-date records.

- Teamwork & Communication: Discuss your ability to work effectively in a team environment, communicate technical information clearly, and collaborate with other maintenance personnel.

- Continuous Learning & Professional Development: Show your commitment to staying current with industry advancements through training, certifications, and self-learning. This demonstrates your dedication to professional growth.

Next Steps

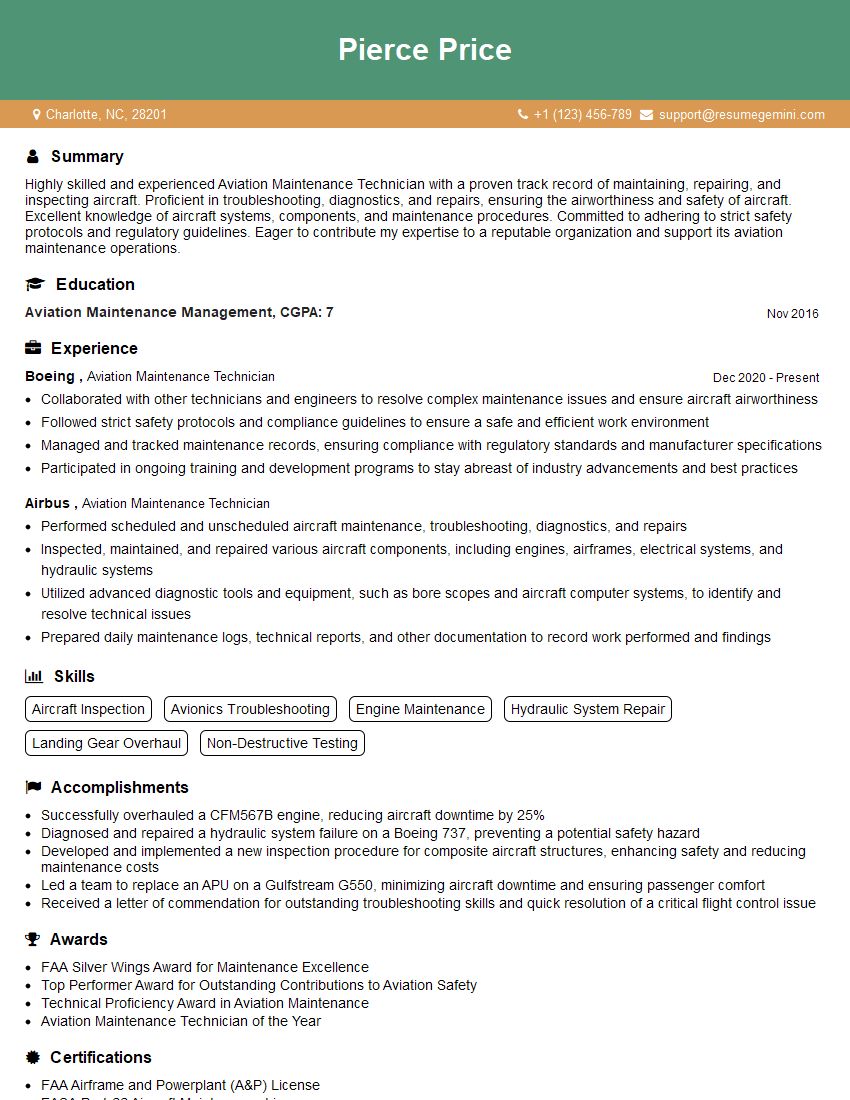

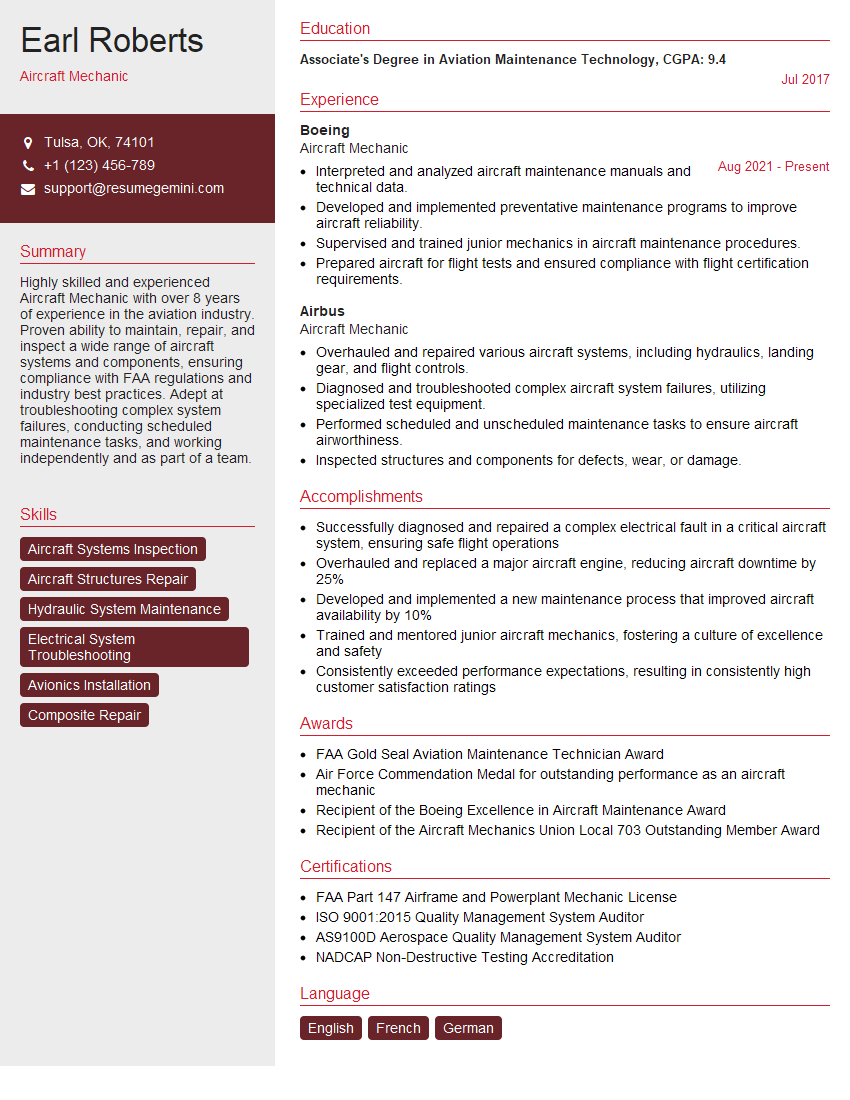

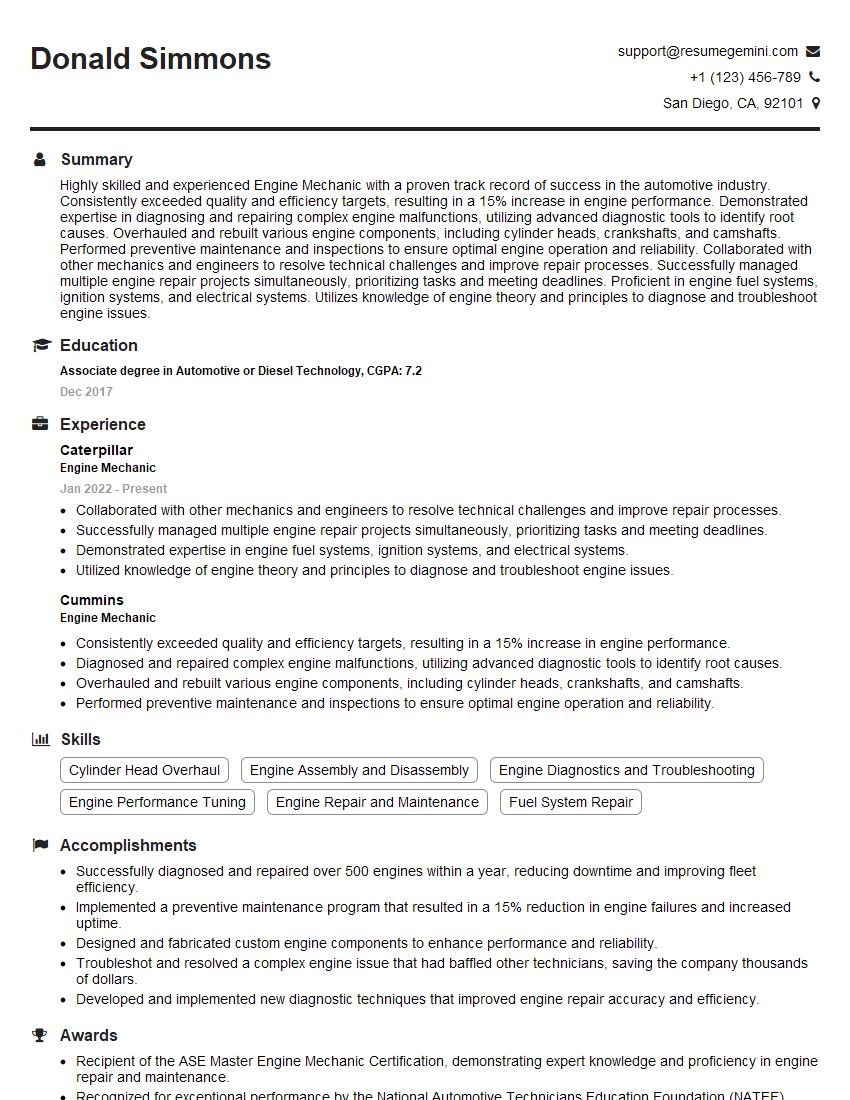

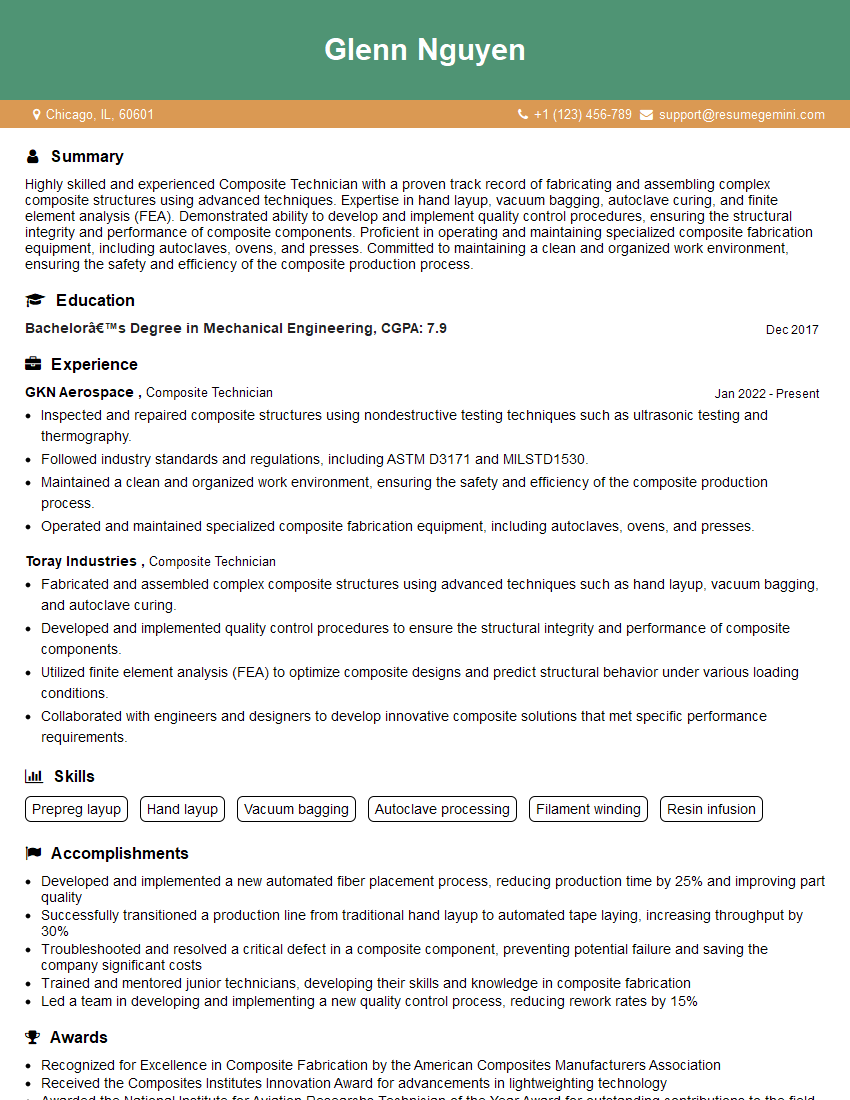

Mastering Aircraft Maintenance and Inspections opens doors to a rewarding and challenging career with excellent growth potential. To maximize your job prospects, it’s vital to present your skills effectively. Creating an ATS-friendly resume is key to getting your application noticed by recruiters. We strongly encourage you to leverage ResumeGemini, a trusted resource for building professional resumes that stand out. ResumeGemini provides examples of resumes tailored to Aircraft Maintenance and Inspections to help you craft a compelling application that highlights your qualifications.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good