Preparation is the key to success in any interview. In this post, we’ll explore crucial ANSI/ASNT Level II interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in ANSI/ASNT Level II Interview

Q 1. Explain the difference between Type I and Type II discontinuities.

In non-destructive testing (NDT), Type I and Type II discontinuities refer to the origin of flaws within a material. Think of it like this: Type I discontinuities are flaws that originated during the manufacturing process, such as inclusions or shrinkage porosity in a casting. They’re ‘born’ with the part. Type II discontinuities, on the other hand, are flaws that developed after manufacturing, perhaps due to fatigue cracking from use, corrosion, or improper welding. They happen *after* the part is made.

- Type I (Manufacturing): Examples include shrinkage cavities in castings, laminations in forgings, and inclusions in welds. These are inherent to the manufacturing process.

- Type II (Service-Induced): Examples include fatigue cracks from cyclic loading, stress corrosion cracking, and cracks from impact damage. These develop during the service life of the component.

Understanding this distinction is crucial for determining the cause of failure and implementing corrective actions. For instance, identifying numerous Type I discontinuities might suggest a problem with the manufacturing process itself, requiring changes in material selection or production techniques. Conversely, predominantly Type II discontinuities point toward issues related to service conditions or design limitations.

Q 2. Describe the principles of ultrasonic testing (UT).

Ultrasonic testing (UT) leverages high-frequency sound waves to detect internal flaws in materials. Imagine sending echoes into a material – similar to sonar used by ships. A transducer transmits ultrasonic waves into the material; these waves travel through the material and reflect (or echo) back when they encounter an interface, such as a discontinuity (crack, void, inclusion) or the back wall of the material.

The time it takes for the echo to return is directly proportional to the distance of the reflector from the transducer. By analyzing the amplitude, time of flight, and other characteristics of these echoes, we can determine the size, location, and nature of the discontinuity. Different types of waves (longitudinal, shear) are used depending on the material and type of flaw being sought.

In practice, this often involves applying a couplant (like gel) between the transducer and the test piece to ensure efficient sound wave transmission. The resulting signals are displayed on an oscilloscope or other recording device, enabling trained technicians to interpret the findings and assess material integrity.

Q 3. What are the limitations of radiographic testing (RT)?

Radiographic testing (RT), while a powerful NDT method, does have limitations. One major drawback is its inability to easily detect flaws oriented parallel to the X-ray beam; these flaws may be missed entirely. Furthermore, RT is less sensitive to small, shallow flaws or those with low density contrast compared to the surrounding material.

- Limited Sensitivity to Small Flaws: Very small cracks or porosity may not show up clearly on the radiograph.

- Geometry Limitations: It struggles with complex geometries or castings with heavy sections, which can lead to scattered radiation obscuring details.

- Safety Concerns: The use of ionizing radiation requires strict safety protocols and shielding, adding complexity and cost.

- Cost and Time: RT often involves specialized equipment, trained personnel, and film processing, making it a relatively expensive and time-consuming method.

- Interpretation Challenges: Interpretation of radiographs requires significant experience and training; variations in film density and other factors can make assessment challenging.

Despite these limitations, RT remains an important method for detecting internal flaws, especially in thick materials and welds. The choice of NDT method always depends on the specific application and the type of flaw expected.

Q 4. Explain the process of liquid penetrant testing (PT).

Liquid penetrant testing (PT) is a widely used method for detecting surface-breaking discontinuities. It’s like using a highly visible dye to highlight cracks or other surface defects. The process involves several steps:

- Cleaning: The surface must be thoroughly cleaned to remove any dirt, grease, or other contaminants that could block the penetrant.

- Penetrant Application: A liquid penetrant, which is a low-viscosity dye, is applied to the surface and allowed to dwell for a specified time to soak into any surface-breaking cracks.

- Excess Penetrant Removal: After the dwell time, excess penetrant is removed from the surface using a cleaning agent.

- Developer Application: A developer is then applied, which draws the penetrant out of any discontinuities, making them visible.

- Inspection: The surface is inspected for indications of discontinuities. These indications appear as a colored pattern on the developer.

PT is particularly useful for detecting very fine cracks that might be missed by other methods. However, it’s limited to detecting surface-breaking flaws and not subsurface flaws.

Q 5. Describe the process of magnetic particle testing (MT).

Magnetic particle testing (MT) is used to detect surface and near-surface discontinuities in ferromagnetic materials (materials that can be magnetized, like iron, steel, nickel). It works by magnetizing the part and then applying ferromagnetic particles (usually iron powder) to the surface. The particles are attracted to magnetic flux leakage fields created at discontinuities, allowing us to visualize the flaws.

The magnetization can be achieved using either a direct current (DC) or alternating current (AC) electromagnetic field. The choice depends on the type of discontinuity being sought; DC is better for detecting deep flaws, while AC is more effective for detecting surface cracks.

After applying the particles, the inspector visually examines the part for indications of discontinuities. These indications appear as a pattern of particles clinging to the leakage field above the flaw. The method is relatively simple, portable, and effective for detecting a range of surface and near-surface flaws.

Q 6. What are the different types of discontinuities detectable by MT?

Magnetic particle testing can detect a variety of discontinuities in ferromagnetic materials, including:

- Surface Cracks: These are cracks that extend to the surface of the part, such as fatigue cracks or grinding cracks.

- Near-Surface Cracks: These are cracks that are located just below the surface of the part.

- Inclusions: These are foreign particles embedded in the material.

- Lack of Fusion: This is a discontinuity in a weld where the weld metal did not properly fuse with the base metal.

- Porosity: This refers to small voids or holes in the material.

- Seams: These are thin laminations or separations within the material.

The effectiveness of MT in detecting a particular discontinuity depends on factors such as the size, orientation, and depth of the flaw, as well as the magnetization technique used.

Q 7. Explain the principles of eddy current testing (ET).

Eddy current testing (ET) uses electromagnetic induction to detect surface and subsurface flaws in conductive materials, such as metals. It works by placing an electromagnetic coil near the test piece; this coil generates an alternating magnetic field, inducing eddy currents (circular electrical currents) in the conductive material.

The presence of discontinuities alters the flow of these eddy currents, causing changes in the impedance of the coil. These changes are detected by the instrument, allowing for the identification and characterization of flaws. Different coil configurations and frequencies can be used to optimize detection of various types and depths of flaws. The method is non-contact, relatively fast, and can be used for both surface and subsurface flaw detection, making it a versatile NDT technique.

Think of it as a sophisticated metal detector, but instead of detecting buried treasure, it detects subtle changes in the material’s conductivity caused by defects. This technology is commonly used for inspecting tubing, wires, and other conductive materials.

Q 8. What are the advantages and disadvantages of UT compared to RT?

Ultrasonic Testing (UT) and Radiographic Testing (RT) are both crucial Non-Destructive Testing (NDT) methods, but they offer different advantages and disadvantages. Think of it like this: RT is like taking an X-ray of the object, while UT is like using sonar to explore its interior.

UT Advantages:

- Portability: UT equipment is generally more portable than RT equipment, allowing for on-site inspection in various locations.

- Speed: UT often provides faster inspection times, especially for large components.

- Depth information: UT provides detailed information about the depth of flaws, which RT struggles with.

- Electronic readout: Digital UT displays provide immediate results and data storage.

- Minimal surface preparation: While some surface preparation might be beneficial, UT often requires less than RT.

UT Disadvantages:

- Operator skill: Requires highly skilled technicians for accurate interpretation of results.

- Couplant needed: A coupling agent (e.g., gel) is needed to transmit ultrasonic waves efficiently.

- Difficulty with complex geometries: Inspection of complex shapes can be challenging.

- Surface roughness influence: Surface roughness can affect the accuracy of the test.

RT Advantages:

- Permanent record: RT produces a permanent image (film or digital) of the internal structure.

- Wide area coverage: Can detect flaws across a wide area in a single exposure.

- Suitable for a variety of materials: Applicable to a broad range of materials, including metals and composites.

RT Disadvantages:

- Radiation safety: Requires adherence to strict safety regulations to protect personnel from ionizing radiation.

- Limited depth information: Determining flaw depth is challenging.

- Setup time: Time-consuming to set up, especially for large components.

- Less portable: RT equipment is generally larger and less portable than UT equipment.

- High cost of consumables: Film, processing chemicals, and specialized equipment can be expensive.

In practice, the choice between UT and RT depends on factors such as the type of material, the size and complexity of the component, the type of flaw being sought, accessibility, and budget constraints. Often, a combination of both techniques provides the most comprehensive inspection.

Q 9. How do you interpret radiographic film?

Interpreting radiographic film involves carefully examining the image for indications of discontinuities within the test object. It’s like reading a map of the internal structure, where variations in density show up as different shades of gray.

Steps in interpreting a radiograph:

- Initial observation: Look for overall image quality, checking for proper exposure, density, and contrast.

- Identification of indications: Identify any areas of unusual density (darker or lighter areas), which might indicate flaws like cracks, porosity, or inclusions.

- Characterization of indications: Determine the size, shape, location, and distribution of indications. Use standard reference radiographs or comparison standards for assistance.

- Assessment of significance: Determine the significance of the indications according to relevant acceptance criteria specified in codes and standards. Some indications might be acceptable, while others might necessitate rejection of the part.

- Documentation: Carefully document all observations, including the location, size, type, and assessment of each indication. This could involve using a template to mark the flaws on the radiograph.

Examples of indications and their appearance:

- Cracks: Appear as thin, dark lines.

- Porosity: Appears as numerous small, dark spots.

- Inclusions: Appear as dark or light spots or streaks, depending on the composition.

- Lack of fusion: Appears as a dark line along a weld.

Experience and training are essential for accurate radiograph interpretation. Proper training, combined with the use of reference radiographs, aids in identifying and classifying different types of flaws. Remember, always follow established procedures and safety protocols while handling radiographic film.

Q 10. How do you interpret ultrasonic test results?

Interpreting ultrasonic test results involves analyzing the signals received by the transducer after it sends ultrasonic waves into the test material. Imagine it like sending sound waves into the object and listening for echoes that reveal internal structures or flaws. The ultrasonic signals are displayed as waveforms on an oscilloscope screen or in digital format.

Key aspects of interpreting ultrasonic test results:

- Amplitude: The height of the signal, which indicates the size and strength of the reflector (e.g., a crack or inclusion).

- Time of Flight: The time it takes for the ultrasonic wave to travel to the reflector and back, which determines the depth of the flaw. We calculate this depth based on the wave’s velocity in the material.

- Signal shape: The shape of the signal (e.g., sharp peak, long tail) provides information about the type of flaw.

- Calibration: Ensuring that the equipment is calibrated correctly is crucial for accurate interpretation of the data.

Interpretation process:

- Visual inspection of the waveform: Identify the echoes that represent the reflections from various interfaces, including the material’s back wall and any flaws.

- Measurement of amplitude and time of flight: Using the oscilloscope or digital display, measure the amplitude and time of flight of identified echoes.

- Calculation of flaw depth: Use the time of flight and the known velocity of sound in the material to determine the flaw’s depth.

- Evaluation and classification: Compare the measured characteristics of the indications to acceptance standards and other available information to assess the significance of the flaws.

- Documentation: Maintain a record of the results, including flaw location, size, type, and depth.

Sophisticated software can enhance interpretation by analyzing ultrasonic data automatically and generating reports. Proper training and experience are crucial for accurate interpretation and reliable flaw detection. For example, understanding different flaw types will help differentiate between a small, insignificant porosity and a larger, critical crack.

Q 11. Explain the importance of calibration in NDT.

Calibration in NDT is the process of verifying that the measurement equipment is providing accurate and reliable results. Think of it as regularly checking the accuracy of a measuring tape; you wouldn’t want to build a house using a tape that’s stretched or misaligned.

Importance of Calibration:

- Accuracy: Calibration ensures that the equipment is providing accurate measurements, leading to reliable inspection results. Without calibration, our measurements can be off, potentially leading to misinterpretations.

- Consistency: Calibration maintains consistency in test results over time, ensuring that the tests are comparable and repeatable.

- Traceability: Proper calibration allows traceability to national or international standards, providing assurance that the measurements meet acceptable quality levels. This helps with standardization across multiple facilities and industries.

- Reliability: Calibration helps to identify and address any equipment drift or malfunction, ensuring the reliability of the inspection process. Identifying a problem early prevents costly rework or repairs later on.

- Legal and regulatory compliance: Many industries have strict regulations requiring regular calibration of NDT equipment to comply with safety and quality standards. For instance, if a facility fails to properly calibrate its equipment, it might be unable to show that its products meet regulatory requirements.

Different NDT methods have specific calibration procedures. For example, in UT, the equipment is calibrated using standard blocks with known flaw sizes. In RT, the film processing and exposure parameters are calibrated to ensure consistent image quality. Failure to calibrate equipment appropriately can lead to inaccurate results, potentially causing safety risks or economic loss due to costly repairs or product failure.

Q 12. What are the safety precautions for performing RT?

Radiographic testing involves ionizing radiation, posing significant safety risks if not handled correctly. Safety precautions are paramount to protecting personnel and the environment.

Safety precautions for RT:

- Radiation safety training: All personnel involved in RT must undergo proper training on radiation safety and handling procedures. This training must be regularly updated and reinforced.

- Radiation monitoring: Use of radiation survey meters to monitor radiation levels in the area. This should be done routinely and especially after any modifications to the RT setup.

- Shielding: Using appropriate shielding (lead, concrete) to protect personnel from radiation exposure. This includes using lead aprons and other protective gear.

- Distance: Maximizing the distance from the radiation source reduces exposure. This could entail remote control operations whenever possible.

- Time minimization: Minimizing time spent in the radiation area. Time management is crucial to minimize exposure.

- Film handling: Following proper procedures for handling and processing radiographic film. This includes the safe handling of chemicals involved in processing the films.

- Area control: Controlling access to the radiation area, making sure only authorized personnel are present. This entails using barriers, signage, and locking mechanisms.

- Emergency procedures: Having well-defined emergency procedures in place in case of accidents or malfunctions. This includes knowing exactly where to find emergency shut-offs and radiation safety officers.

- Disposal of radioactive materials: Following proper procedures for the disposal of used radioactive sources. This is critical to ensure the safety of the environment and people.

These precautions are non-negotiable and must be strictly followed to ensure the health and safety of everyone involved. Failure to comply with radiation safety regulations can result in severe health consequences and legal penalties.

Q 13. What are the safety precautions for performing UT?

While UT doesn’t involve ionizing radiation like RT, several safety precautions are necessary to prevent accidents and ensure accurate results.

Safety precautions for UT:

- Proper training: Technicians must receive comprehensive training on the operation and safety procedures of ultrasonic equipment. This includes understanding the equipment’s functionalities and limitations.

- Equipment inspection: Inspecting ultrasonic equipment before each use to ensure proper functionality and safety. Look for damaged cables, transducers, or other parts.

- Safe handling of transducers: Handling transducers carefully to prevent damage. They are delicate and crucial to the test.

- Use of couplant safely: Selecting and using appropriate couplants and avoiding spills or skin contact. Some couplants are irritating or harmful.

- Eye protection: Using eye protection when working with some couplants or high-intensity ultrasonic beams. This is important to avoid eye injuries.

- Hearing protection: In some cases, using hearing protection as some equipment can be quite noisy.

- Electrical safety: Following all relevant electrical safety procedures. This includes operating the equipment according to the manufacturer’s instructions and avoiding damage to cables.

- Work area safety: Maintaining a clean, organized, and safe work area to prevent accidents and ensure accurate testing. This includes reducing risks of tripping and falling.

Adhering to these precautions minimizes the risks associated with UT, allowing for efficient and safe operation. Always remember that proper safety procedures are vital to both personal safety and the accuracy of test results.

Q 14. What are the different types of penetrants used in PT?

Penetrant testing (PT) uses various types of penetrants to detect surface-breaking flaws in components. The penetrant is drawn into these flaws and then made visible, allowing for easy detection.

Different types of penetrants:

- Visible (dye) penetrants: These penetrants contain a dye that is visible to the naked eye after the excess penetrant is removed and a developer is applied. This is the simplest and most common type of penetrant.

- Fluorescent penetrants: These penetrants contain a fluorescent dye that glows under ultraviolet (UV) light. They are more sensitive than visible penetrants and allow for the detection of smaller flaws.

- Water-washable penetrants: These penetrants are easily removed with water, simplifying the cleaning process and reducing environmental impact.

- Solvent-removable penetrants: These penetrants require a solvent for removal. They are often used for applications where water washing is not possible or desirable.

- Post-emulsifiable penetrants: This type requires an emulsifier to help remove the excess penetrant. The emulsifier breaks down the penetrant, making it easier to remove.

The choice of penetrant depends on various factors, including the material being tested, the type of flaw being sought, and environmental conditions. Fluorescent penetrants are particularly useful for detecting very small discontinuities, while water-washable penetrants are environmentally friendly and easier to use.

Q 15. Explain the different types of magnetic fields used in MT.

Magnetic particle testing (MT) utilizes two main types of magnetic fields: circular and longitudinal. The choice depends on the type of discontinuity being sought and the geometry of the part.

- Circular Magnetization: This is achieved by passing a current directly through the part. The resulting magnetic field flows in a circular pattern around the current’s path. This is effective for detecting surface and near-surface defects oriented parallel to the direction of the current. Think of it like the magnetic field around a wire carrying electricity – the field is concentric circles around the wire.

- Longitudinal Magnetization: This is produced using a solenoid or electromagnets. The magnetic field lines flow lengthwise through the part. This is best for detecting defects oriented perpendicular to the magnetic field lines. Imagine placing a bar magnet inside a long coil of wire; the magnetic field within the bar will be along its length.

It’s often necessary to use a combination of both methods, or to use specialized techniques like prod or yoke magnetization for specific situations. For instance, a circular field might be used for inspecting a small diameter shaft, while a longitudinal field is more suitable for a long bar. The choice is guided by the part geometry, the expected defect orientation, and the required sensitivity.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you select the appropriate NDT method for a specific application?

Selecting the right NDT method is crucial for efficient and reliable inspection. The process involves careful consideration of several factors:

- Material Type: Ferrous materials lend themselves well to magnetic particle testing, while non-ferrous materials are better suited for liquid penetrant testing or ultrasonic testing. Some materials might require specialized methods like eddy current testing.

- Component Geometry: Access to the component’s surface greatly influences the choice. Complex geometries might require techniques offering greater flexibility, like liquid penetrant testing or ultrasonic testing with specialized probes.

- Type of Discontinuity Expected: Surface cracks are easily detectable using liquid penetrant testing or magnetic particle testing. Subsurface flaws are better detected using ultrasonic testing or radiography.

- Sensitivity Requirements: The required level of detection for small discontinuities will influence the choice. Ultrasonic testing, for example, offers high sensitivity, while visual inspection might suffice for larger, more obvious defects.

- Cost and Time Constraints: Some NDT methods are more expensive or time-consuming than others. This is a significant factor in selecting the most practical approach.

Often, a combination of methods (multi-method inspection) provides the best approach. For example, initial visual inspection followed by liquid penetrant testing may be used before final acceptance of critical components.

Q 17. Explain the concept of acceptance criteria in NDT.

Acceptance criteria in NDT define the limits of acceptable flaws in a component. These criteria are based on factors like the component’s intended application, safety requirements, and industry standards. A flaw exceeding the acceptance criteria indicates that the component is considered non-compliant and may require repair or rejection.

These criteria usually specify allowable flaw size (length, depth, area, etc.), type of flaw, and location. For example, a weld may have specific acceptance criteria defined in a relevant welding code, limiting the size of cracks or porosity allowed based on its criticality. The criteria are not arbitrary; they are based on rigorous analysis and risk assessment to ensure structural integrity and safety.

Defining and applying appropriate acceptance criteria is a critical aspect of NDT. Incorrect acceptance criteria can lead to unsafe structures or costly rework, while overly stringent criteria might unnecessarily reject good parts.

Q 18. What are the common codes and standards used in NDT?

Numerous codes and standards govern NDT practices to ensure consistency and reliability. Some prominent examples include:

- ASME Section V: This section of the ASME Boiler and Pressure Vessel Code covers NDT methods and acceptance standards for pressure vessels and related components.

- ASTM Standards: ASTM International publishes numerous standards covering various NDT methods, including specific procedures and practices. For example, ASTM E1417 covers liquid penetrant testing.

- API Standards: The American Petroleum Institute publishes standards for NDT in the oil and gas industry.

- MIL-STD Standards: Military standards define NDT procedures for defense applications.

- EN Standards (European Norms): These standards provide guidelines for NDT in Europe.

Selecting the appropriate code and standard is vital to ensure compliance and to maintain consistent quality control. The choice depends on the industry, the component’s application, and relevant regulations.

Q 19. Describe the process of creating a NDT report.

The NDT report is a formal record of the inspection process and its findings. A well-structured report provides a clear and concise summary for stakeholders.

Creating an NDT report typically involves these steps:

- Identification of the Component and Material: Including details like part number, material type, and manufacturer.

- Description of the Inspection Method(s) Used: Specifying the techniques employed and relevant parameters.

- Scope of the Inspection: Defining the areas inspected and any limitations.

- Personnel Involved: Identifying the qualified NDT personnel who performed the inspection.

- Equipment Used: Documenting all equipment used and their calibration status.

- Results of the Inspection: Clearly stating the findings, including descriptions of any discontinuities detected, their locations, sizes, and orientations. Including relevant images or illustrations.

- Interpretation of Results: Comparing the findings to the applicable acceptance criteria.

- Conclusion: Summarizing the overall condition of the component and whether it meets the acceptance criteria. A statement of compliance or non-compliance is needed.

- Approvals and Signatures: Appropriate signatures and approvals from qualified personnel are crucial for the report’s validity.

The report should be clear, concise, and easy to understand for all readers. Accuracy and completeness are paramount to ensure reliable decision-making.

Q 20. How do you handle non-conformances during an inspection?

Handling non-conformances is a critical part of the NDT process. When a flaw is discovered that exceeds acceptance criteria, several actions are taken:

- Documentation: Meticulously document the non-conformances, including their location, size, type, and supporting evidence (e.g., photos, sketches).

- Verification: Independently verify the non-conformances to ensure accuracy. This may involve re-inspection using the same or a different NDT method.

- Assessment: Assess the significance of the non-conformance. This considers the flaw’s size, location, and potential impact on the component’s integrity and functionality.

- Corrective Actions: Decide on appropriate corrective actions, which could include repair, rework, or rejection of the component. This is often a collaborative effort between the NDT technician, engineers, and management.

- Reporting: Report the non-conformances to relevant parties, including engineers and management. This typically involves updating the NDT report and initiating any necessary corrective actions.

- Follow-up Inspection: If repair or rework is performed, a follow-up inspection verifies the effectiveness of the corrective actions.

Effective non-conformance management ensures that defects are addressed appropriately, mitigating potential risks and maintaining the quality of the inspected components.

Q 21. What are the different types of probes used in UT?

Ultrasonic testing (UT) employs various probes, each designed for specific applications and material characteristics:

- Normal Incidence Probes (Straight Beam Probes): These probes transmit ultrasonic waves perpendicular to the surface, ideal for detecting discontinuities parallel to the surface.

- Angle Beam Probes: These probes transmit ultrasonic waves at an angle to the surface, enabling the detection of discontinuities at different depths and orientations.

- Dual-Element Probes: These probes have separate transmitting and receiving elements, improving signal quality and reducing noise.

- Surface Wave Probes (Rayleigh Wave Probes): These probes generate surface waves that travel along the component’s surface, making them suitable for surface crack detection.

- Contact Probes: These probes require direct contact with the inspection surface, usually using a couplant (e.g., oil, gel) to improve sound transmission.

- Immersion Probes: These probes are used with an immersion tank where the part and probe are submerged in water, providing good coupling and enabling scanning of complex shapes.

Probe selection depends on factors such as the material being inspected, the expected type and orientation of the discontinuities, and the component’s geometry. The frequency of the probe also impacts the penetration depth and resolution.

Q 22. What are the different types of films used in RT?

Radiographic testing (RT) utilizes various films to capture the image produced by X-rays or gamma rays passing through a material. The film’s sensitivity to radiation dictates its suitability for different applications. Film selection depends largely on the material thickness, radiation energy, and the desired image contrast and detail.

- Industrial X-ray film: This is the most common type, available in various speeds (fast, medium, slow). Faster films require less exposure time but offer slightly less detail. Slower films provide greater detail with longer exposure times.

- Direct exposure film: This film directly interacts with the radiation. It’s generally used for simpler inspections.

- Screen-type film: This type uses intensifying screens that amplify the radiation signal, leading to shorter exposure times. The screens contain phosphors that emit light when exposed to radiation, which in turn exposes the film. This results in a faster exposure but can potentially reduce image sharpness depending on the screen type and thickness.

- Special films: There are specialized films designed for specific applications, such as those with double emulsion for enhanced sensitivity or those with higher contrast for highlighting specific features.

For example, when inspecting a thin aluminum weld, a fast film with intensifying screens might be used to reduce exposure time. However, for a thick steel casting, a slower film with possibly fine-grain screens would be preferred to achieve high resolution and detect small flaws. The choice is always a balance between sensitivity, resolution, and practical limitations of exposure time and radiation safety.

Q 23. Explain the principle of phased array UT.

Phased array ultrasonic testing (PAUT) employs multiple piezoelectric elements arranged in an array, allowing for the electronic steering and focusing of ultrasound beams. Unlike conventional UT which uses a single transducer, PAUT manipulates the timing and amplitude of signals sent to each element in the array. This creates a focused beam that can be electronically scanned across the material without physically moving the transducer.

The principle lies in the constructive and destructive interference of the ultrasonic waves emitted from the individual elements. By precisely controlling the phase and amplitude of each element’s signal, the ultrasound energy is focused at a specific location within the material. This focused beam can be electronically steered and focused in various directions, creating a slice or sector scan of the material. Different waveforms and delays can also be implemented to improve inspection capabilities, enhancing resolution and penetration depth. Imagine a spotlight: you can move it around electronically by adjusting the individual light sources without physically moving the whole spotlight. PAUT works similarly by manipulating the individual elements of the array to manipulate the sound beam.

This technique is significantly advantageous in terms of speed, data acquisition, and flaw characterization compared to conventional ultrasonic testing. For instance, in pipeline inspections, PAUT allows for rapid scanning of large areas, detecting and characterizing flaws more efficiently.

Q 24. Describe your experience with data acquisition and analysis in NDT.

My experience with data acquisition and analysis in NDT spans several techniques. I’m proficient in using various data acquisition systems for ultrasonic testing (UT), including both conventional and phased array systems. I’m comfortable with the software necessary for collecting, processing, and analyzing raw data such as amplitude, time-of-flight, and waveform characteristics. I have used software packages from Olympus and Zetec, proficiently interpreting A-scan, B-scan, C-scan and S-scan displays.

For radiographic testing (RT), I’m experienced in digitizing radiographic films using a dedicated film digitizer and interpreting the digital images. In addition to processing and analyzing the images using software, I’m also skilled in identifying and characterizing flaws like cracks, inclusions, and voids. I am able to develop and interpret reports adhering to strict specifications.

A specific example of a complex data analysis project I undertook involved the inspection of a large pressure vessel using PAUT. The sheer volume of data acquired necessitated advanced signal processing techniques. We employed automated flaw recognition software alongside manual interpretation to efficiently analyze the data and provide a comprehensive assessment of the pressure vessel’s integrity. This meticulous approach helped us identify critical flaws that might have otherwise been overlooked.

Q 25. How do you maintain your NDT equipment?

Maintaining NDT equipment is paramount for ensuring accurate and reliable inspection results. My approach follows a structured procedure encompassing preventive maintenance and calibration checks. This involves regular cleaning, inspecting for any physical damage, and verifying proper functionality. I maintain detailed records of all maintenance activities and calibration checks.

- Preventive Maintenance: This includes regular cleaning of transducers with appropriate solvents, checking cables for damage, ensuring proper transducer coupling, and visually inspecting equipment for wear and tear.

- Calibration: Calibration is crucial. Ultrasonic equipment requires regular calibration using standardized test blocks to ensure accurate measurements. I adhere strictly to manufacturer’s instructions and utilize traceable standards.

- Documentation: All maintenance and calibration activities are meticulously documented, including dates, details of the work performed, and the results of the calibration checks. This documentation ensures traceability and provides evidence of compliance with relevant standards.

For instance, I’ve developed a schedule for calibrating my ultrasonic equipment every six months, this schedule guarantees the equipment’s reliability. Any issues detected are immediately addressed and recorded, ensuring uninterrupted inspection operations.

Q 26. Explain your understanding of the ASNT Recommended Practice No. SNT-TC-1A.

ASNT Recommended Practice No. SNT-TC-1A is a widely recognized standard for personnel qualification and certification in nondestructive testing (NDT). It outlines the requirements for establishing and maintaining an effective personnel qualification and certification program. This includes establishing written practices, documenting training, and administering examinations to verify competence in specific NDT methods.

The standard covers various aspects, including:

- Establishing a written practice: This involves defining the specific NDT methods used, the types of materials inspected, and the relevant acceptance criteria.

- Training and experience requirements: SNT-TC-1A defines the minimum training and practical experience required to achieve different levels of certification, such as Level I, II, and III. This ensures that personnel possess the necessary skills and knowledge.

- Examination procedures: It details the procedures for conducting examinations to evaluate the knowledge and practical skills of the NDT personnel.

- Certification and recertification: The standard explains the process for issuing and renewing certifications, ensuring that personnel remain competent throughout their careers.

Understanding SNT-TC-1A is vital for ensuring consistent quality and safety in NDT operations. Compliance with the standard helps maintain a qualified workforce and promotes best practices in the industry. For example, our company strictly adheres to SNT-TC-1A in our personnel qualification program, ensuring that all our NDT inspectors are properly trained, certified, and updated on the latest industry standards.

Q 27. Describe your experience with different types of weld inspection techniques.

My experience encompasses a wide range of weld inspection techniques, including:

- Visual Inspection (VT): I’m proficient in conducting visual inspections of welds to identify surface defects such as cracks, porosity, undercut, and incomplete fusion. This often serves as the first step in any weld inspection process.

- Ultrasonic Testing (UT): I’ve performed UT on welds using both conventional and phased array techniques, detecting internal flaws like lack of fusion, cracks, and inclusions. My experience covers various weld geometries and materials.

- Radiographic Testing (RT): I am experienced in interpreting radiographs of welds to identify internal discontinuities. This includes understanding various radiographic techniques and the interpretation of image quality indicators (IQIs).

- Magnetic Particle Testing (MT): I have experience using MT to detect surface and near-surface flaws in ferromagnetic materials. This is particularly useful for detecting cracks in welds.

- Liquid Penetrant Testing (PT): I can use PT to detect surface-breaking defects in a wide range of materials. This is a highly sensitive method for identifying small surface cracks in welds.

I’ve worked on diverse projects ranging from inspecting simple butt welds in pipelines to complex welds in pressure vessels. For example, on a recent project involving the inspection of high-pressure piping, I utilized a combination of UT and RT to ensure complete and accurate assessment of the weld integrity.

Q 28. Explain the importance of continuing education in the field of NDT.

Continuing education in NDT is absolutely critical for several reasons. The field of NDT is constantly evolving with new techniques, technologies, and standards being developed. Staying updated ensures that inspectors remain proficient and employ the most efficient and reliable methods.

The importance of continuing education includes:

- Keeping up with advancements: New NDT methods and technologies are constantly emerging. Continuing education provides the opportunity to learn about these advancements and incorporate them into your inspection practices. For example, the increasing use of automated data acquisition and analysis systems necessitates ongoing training.

- Improving inspection skills: Continued learning refines your skills and enhances your ability to identify and characterize flaws more accurately and efficiently.

- Maintaining certifications: Many certification bodies mandate a certain amount of continuing education to maintain active certifications. This ensures that certified personnel remain current with the latest industry standards and best practices.

- Enhancing safety: New safety regulations and procedures are frequently introduced. Continuing education ensures inspectors are aware of and adhere to these safety protocols.

I personally attend workshops, seminars, and conferences regularly, actively participating in online courses to keep myself updated with the latest advancements in NDT technologies and methodologies. This dedication ensures that my inspection services remain at the highest professional standards.

Key Topics to Learn for Your ANSI/ASNT Level II Interview

Landing your dream ANSI/ASNT Level II role requires a solid understanding of both theory and practice. Focus your preparation on these key areas:

- Basic Nondestructive Testing (NDT) Principles: Understand the fundamental concepts behind various NDT methods, including their strengths, limitations, and applications. Be prepared to discuss the underlying physics and how each method detects flaws.

- Specific NDT Methods (Relevant to your certification): Deepen your knowledge of the specific NDT methods you’ve been certified in (e.g., Ultrasonic Testing, Radiographic Testing, Magnetic Particle Testing, Liquid Penetrant Testing). Practice explaining the procedures, equipment operation, and interpretation of results.

- Code and Standard Interpretation: Demonstrate a thorough understanding of relevant codes and standards (like ASME Section V) and how they relate to your NDT work. Be ready to discuss specific requirements and their practical implications.

- Calibration and Equipment Maintenance: Show you understand the critical role of proper calibration and routine maintenance in ensuring accurate and reliable test results. Be able to discuss common calibration procedures and troubleshooting techniques.

- Data Analysis and Reporting: Practice interpreting and presenting NDT data effectively. Know how to document findings, create clear reports, and communicate results to both technical and non-technical audiences.

- Safety Procedures and Regulations: Highlight your commitment to safety by demonstrating a thorough understanding of relevant safety protocols and regulations within the NDT field. This is crucial for any role.

- Problem-Solving and Critical Thinking: Be prepared to discuss how you approach challenges in NDT inspection. Use examples from your experience to showcase your problem-solving skills and ability to think critically.

Next Steps: Unlock Your Career Potential

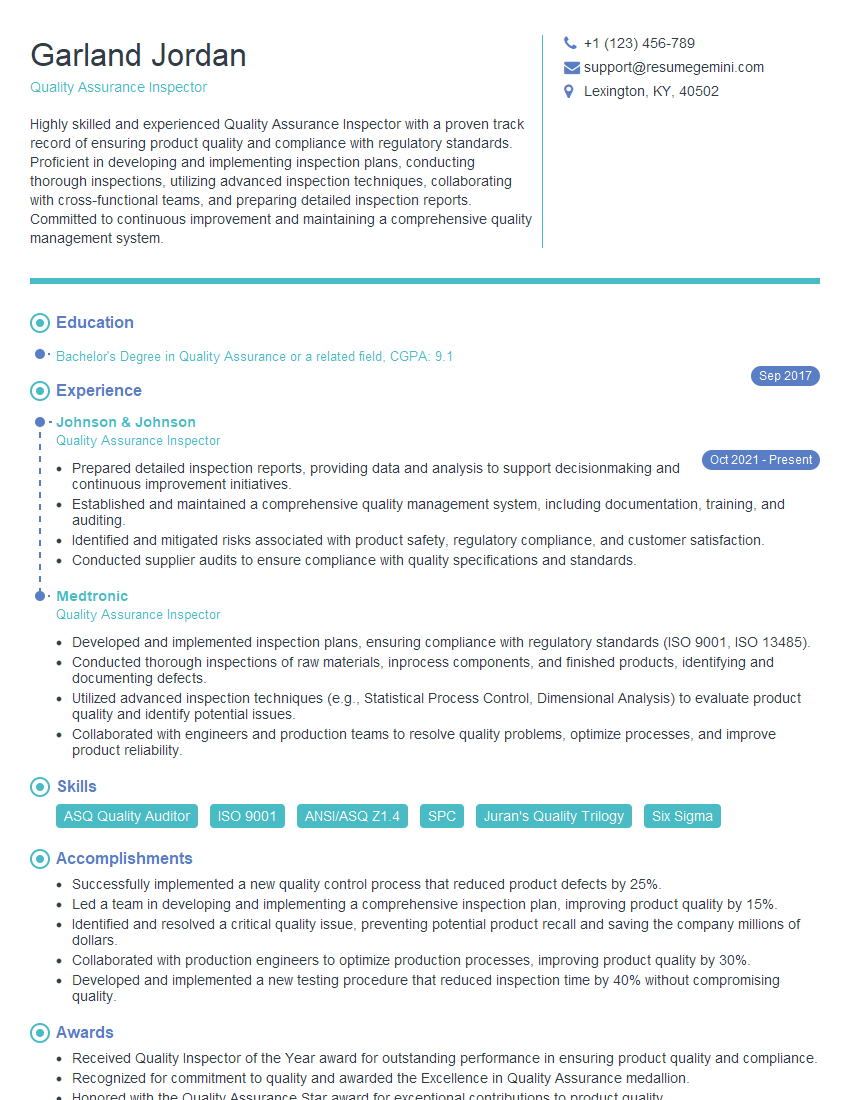

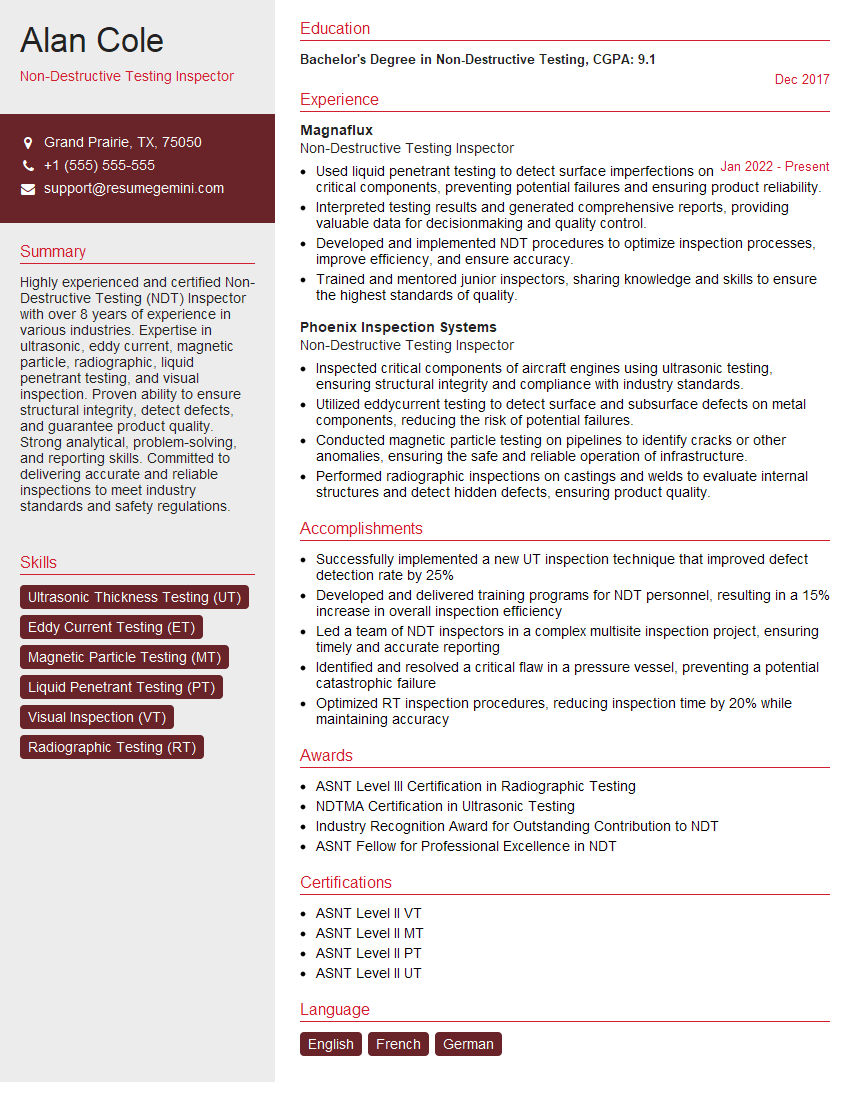

Mastering ANSI/ASNT Level II opens doors to exciting career opportunities and higher earning potential in various industries. To make the most of your qualifications, a strong resume is essential. Creating an ATS-friendly resume significantly improves your chances of getting noticed by recruiters. ResumeGemini is a trusted resource to help you build a professional, impactful resume tailored to the NDT field. We provide examples of resumes specifically designed for ANSI/ASNT Level II certified professionals to guide you. Take the next step towards your ideal career – build your best resume with ResumeGemini.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good