The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Assembling and disassembling products interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Assembling and disassembling products Interview

Q 1. Describe your experience with various hand tools used in assembly and disassembly.

My experience with hand tools spans over a decade, encompassing a wide range of applications in both assembly and disassembly. I’m proficient with tools like screwdrivers (Phillips, flathead, Torx), wrenches (open-end, box-end, socket), pliers (needle-nose, slip-joint), hammers, and various specialized tools depending on the project. For example, working on delicate electronics requires precision screwdrivers and anti-static tools, while assembling furniture might involve power drills and specialized bits. I’m also comfortable using torque wrenches to ensure fasteners are tightened to the correct specification, preventing damage. I understand the nuances of each tool and how to select the appropriate tool for a given task, ensuring both efficiency and safety.

- Screwdrivers: I understand the importance of selecting the right size and type (Phillips, flathead, Torx) to avoid cam-out and damage.

- Wrenches: Knowing when to use an open-end, box-end, or socket wrench is crucial for efficient and effective fastening.

- Pliers: I’m adept at using needle-nose pliers for reaching tight spaces and slip-joint pliers for a range of gripping tasks.

My experience extends to understanding tool maintenance – proper cleaning and storage to ensure longevity and optimal performance. A well-maintained toolset is essential for precise and efficient work.

Q 2. Explain the importance of following assembly instructions precisely.

Following assembly instructions precisely is paramount to ensuring the product functions correctly, safely, and meets the required specifications. Deviations from the instructions, even seemingly minor ones, can lead to malfunctions, damage to components, and even safety hazards. Think of building a house – skipping steps in the foundation would have disastrous consequences. Similarly, in assembling a complex mechanism, omitting a step or installing a component incorrectly can lead to complete failure or compromise its performance.

For instance, assembling an electronic device requires following the sequence of connections precisely. Connecting components in the wrong order might lead to short circuits or damage to sensitive components. Instructions often dictate the torque required for fasteners; ignoring this could lead to stripped threads or loose connections. In essence, accurate assembly instructions are the blueprint for a successful outcome.

Q 3. How do you identify and troubleshoot assembly errors?

Identifying and troubleshooting assembly errors requires a systematic approach. I typically begin by carefully reviewing the assembly instructions, comparing the current state of the assembly with the diagrams and instructions. This helps pinpoint the discrepancies. If an error is found, I carefully examine the faulty area, checking for bent or broken parts, incorrect component orientation or placement. I use visual inspection and, if necessary, measuring tools (e.g., calipers) to verify dimensions and alignments.

For instance, if a mechanical device is not functioning correctly, I might start by checking the connections of individual components, then examine individual parts for wear or damage. Sometimes, simple visual inspection suffices; other times, more advanced techniques or specialized tools may be required. If the problem persists, I consult schematics, diagrams, or technical documentation for further guidance. My methodical approach, combined with my experience, allows me to efficiently pinpoint and solve assembly errors.

Q 4. What safety precautions do you take when working with assembly tools and equipment?

Safety is my top priority. I always wear appropriate personal protective equipment (PPE), including safety glasses to protect my eyes from flying debris, gloves to protect my hands, and hearing protection when using power tools. Before starting any task, I inspect my tools for damage and ensure they are in good working order. I maintain a clean and organized workspace to minimize the risk of tripping or accidental injury. I am also conscious of potential hazards associated with specific materials – for example, handling chemicals requires additional precautions and protective gear.

When using power tools, I always follow manufacturer’s instructions, and I never operate them without proper training. I am aware of lockout/tagout procedures for equipment requiring power disconnection. I also prioritize proper posture and lifting techniques to avoid injuries. Safety is not just a protocol, but a fundamental aspect of my work process.

Q 5. Describe your experience with different types of fasteners (screws, bolts, rivets, etc.).

My experience encompasses a wide array of fasteners, including screws (machine screws, wood screws, self-tapping screws), bolts (hex bolts, carriage bolts, eye bolts), rivets, and other specialized fasteners. I understand the different types, their applications, and the tools required for their installation and removal. For example, I understand the importance of selecting the right screw type for a specific material – using wood screws for metal would likely result in damage. Similarly, using the wrong size or type of bolt can lead to stripped threads or insufficient strength.

I am familiar with various techniques for fastening, such as using torque wrenches to ensure proper tightening without damaging components, and using appropriate techniques for setting rivets. My knowledge extends to understanding different drive types (Phillips, flathead, Torx) and how to select the right bit for efficient and damage-free installation.

Q 6. How do you ensure the quality of your work during assembly?

Ensuring the quality of my work involves a multi-faceted approach. First, I meticulously follow assembly instructions, paying close attention to details and ensuring each step is performed correctly. I regularly inspect my work throughout the assembly process, using visual checks and, where appropriate, measuring instruments to verify dimensions, alignments, and functionality. This proactive approach allows me to catch and rectify minor errors before they escalate into major problems.

After the assembly is complete, I perform a thorough functional test, checking all aspects of the product’s operation to ensure it functions as intended. This may include measuring output parameters, checking for leaks, or testing various functionalities. This quality-focused approach ensures that the final product meets the highest standards of quality and reliability. Documenting each step and the results of my tests further enhances accountability and helps to maintain consistent quality standards.

Q 7. Explain your process for disassembling a complex product.

Disassembling a complex product demands a methodical and organized approach. My process begins with careful documentation – taking photos or creating diagrams of the product’s initial state and the location of each component before I start. This is crucial for reassembly. Next, I systematically remove components, starting with the most easily accessible parts. I work methodically, labeling and organizing parts as I go to prevent mixing them up. This usually involves working from the outside in, removing external panels and covers before moving to internal components. For example, when disassembling a computer, I would start by removing the side panels, then the hard drives, optical drives, and other components in a logical sequence.

Throughout the process, I use the appropriate tools for each task, avoiding unnecessary force to prevent damaging components. When encountering fasteners such as screws or bolts, I take note of their size, type, and orientation. This is crucial for reassembly. When faced with particularly challenging components, I consult schematics or service manuals to identify the most efficient disassembly procedure. Organized disassembly minimizes the risk of damage and ensures smoother reassembly.

Q 8. How do you handle damaged or defective components during assembly or disassembly?

Handling damaged or defective components is crucial for ensuring product quality and safety. My process begins with a thorough visual inspection. If a component shows any signs of damage – cracks, dents, discoloration, or irregularities – I immediately flag it. I then follow established protocols, which usually involve documenting the damage with photos and detailed notes, including the component’s part number and location in the assembly. This documentation is essential for traceability and potential warranty claims. Next, I segregate the defective component, keeping it separate from functional parts to prevent accidental use. The defective component is then reported to the appropriate supervisor or quality control personnel for further evaluation, replacement, or root cause analysis. This ensures that the problem is addressed and prevents the same issue from recurring. In some cases, I might attempt minor repairs, such as cleaning or realigning a slightly misaligned part, but only if authorized and if the repair doesn’t compromise the integrity of the component. This meticulous approach minimizes risks and maximizes efficiency.

Q 9. Describe your experience with different assembly techniques (e.g., hand assembly, automated assembly).

My experience spans both hand assembly and automated assembly techniques. Hand assembly requires precision, dexterity, and a keen eye for detail. I’ve worked extensively on projects involving intricate mechanical or electronic assemblies, where hand assembly is necessary to ensure proper alignment and secure connections. For example, I assembled high-precision instruments where even slight misalignments could compromise functionality. This involved using specialized tools, following strict assembly procedures, and meticulously checking each step for accuracy. Automated assembly, on the other hand, offers efficiency and consistency on a larger scale. I’ve worked with automated assembly lines involving robotic arms and conveyor systems. In these settings, my role involved programming, troubleshooting, and maintaining the automated systems, as well as monitoring the quality of the assembled products. This experience highlights my adaptability to various assembly methods, my ability to troubleshoot and maintain both manual and automated systems, and my focus on quality control regardless of the assembly technique.

Q 10. What is your experience with using torque wrenches and other precision tools?

Torque wrenches are essential for ensuring that fasteners are tightened to the correct specifications. Incorrect torque can lead to stripped threads, loose connections, or even component failure. I am proficient in using various types of torque wrenches, including click-type, dial-type, and digital torque wrenches. I understand the importance of calibrating torque wrenches regularly to maintain accuracy. Beyond torque wrenches, I have extensive experience with other precision tools, such as micrometers for precise measurements, dial indicators for alignment checks, and various specialized hand tools for delicate components. For instance, in assembling a complex gear mechanism, I used a micrometer to ensure the precise spacing between gears, while a dial indicator was used to verify proper alignment. My experience ensures components are assembled to manufacturer’s specifications, leading to reliable and safe products.

Q 11. How do you maintain your work area and tools during the assembly process?

Maintaining a clean and organized workspace is paramount for efficient and safe assembly. My approach involves a systematic organization of parts, tools, and documentation. I utilize shadow boards or designated areas for each tool, preventing loss or misplacement. I use appropriate containers to keep components sorted and easily accessible. Regularly cleaning the workspace, removing debris, and keeping surfaces clear is critical to prevent accidental damage or contamination. Tool maintenance is equally important; I regularly inspect tools for damage, cleanliness, and proper functionality, ensuring that they are stored properly after use. This organized approach enhances efficiency, reduces errors, and creates a safer working environment. It’s like a chef meticulously organizing their kitchen – you work more efficiently and produce better results.

Q 12. How do you manage time effectively during assembly tasks?

Effective time management in assembly requires careful planning and execution. Before starting, I review assembly instructions and schematics to understand the task’s scope and sequence. This allows me to pre-stage parts and tools, optimizing workflow. I prioritize tasks based on their criticality and dependencies, focusing on critical components first. I break down complex tasks into smaller, more manageable steps. I also utilize time-saving techniques, like batching similar tasks together, to maximize efficiency. Regularly checking my progress against the schedule helps identify potential delays and allows for timely adjustments. Consistent focus and minimizing distractions contribute significantly to efficient time management. Just like a skilled carpenter meticulously plans and executes each cut, I approach assembly tasks strategically to meet deadlines without compromising quality.

Q 13. Explain your experience working with schematics, diagrams, or blueprints.

Schematics, diagrams, and blueprints are essential for understanding the product’s design and assembly procedures. I’m proficient in reading and interpreting various types of technical documentation, including electrical schematics, mechanical drawings, and assembly instructions. I understand the symbology and conventions used in these documents. For example, I’ve used electrical schematics to trace circuits and identify component connections in electronic assemblies, and mechanical drawings to understand component dimensions and tolerances. My ability to interpret these documents allows me to assemble products accurately and efficiently. It’s like having a roadmap – it guides me step-by-step, ensuring that I assemble the product correctly.

Q 14. Describe a situation where you had to troubleshoot a complex assembly problem.

During the assembly of a complex robotic arm, I encountered a situation where the arm wouldn’t perform the programmed movements correctly. Initial troubleshooting focused on the programming, but the problem persisted. I systematically reviewed the assembly process, checking for any misalignments or improperly tightened components. After carefully inspecting the arm’s joints, I discovered a small, almost invisible, burr on a critical shaft that was causing friction and binding. This minor defect wasn’t apparent in the initial inspection. I carefully removed the burr using a deburring tool, reassembled the joint, and tested the arm. The problem was resolved. This experience highlighted the importance of meticulous attention to detail during assembly and the value of systematic troubleshooting, working methodically through each potential cause. The solution demonstrated my problem-solving skills and ability to identify even subtle issues that might impact functionality.

Q 15. How do you document your work during assembly and disassembly?

Thorough documentation is crucial for efficient assembly and disassembly. My approach involves a multi-layered system. First, I use high-quality photos at each stage, capturing both the overall assembly and close-ups of critical connections. Think of it like building a detailed visual instruction manual. Second, I maintain detailed written notes, including part numbers, torque specifications (where applicable), and any observations about unusual assembly techniques or potential points of failure. This is akin to creating a troubleshooting guide for future reference. Finally, for complex assemblies, I utilize annotated diagrams or 3D models, adding layers of information like component names, wiring diagrams, and even small videos of specific assembly steps. This method allows me to easily reconstruct the assembly or troubleshoot problems at a later date.

For example, when disassembling a computer, I would photograph the cable management before disconnecting any wires, note down the motherboard standoffs and their locations, and document the order in which I remove each component. This meticulous approach helps significantly when reassembling the machine.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What software or systems are you familiar with that support assembly or disassembly tasks?

My experience spans several software systems relevant to assembly and disassembly. I’m proficient in CAD software like SolidWorks and AutoCAD, which allows me to visualize assemblies, create exploded views (which are incredibly helpful for disassembly and reassembly), and generate documentation directly from the 3D model. For managing parts and processes, I’m familiar with ERP (Enterprise Resource Planning) systems like SAP and inventory management tools. These help track components and optimize workflows. Additionally, I’m comfortable using simple spreadsheet software like Microsoft Excel for creating bills of materials (BOMs) and documenting assembly processes. Finally, software for creating and editing digital manuals, such as Adobe InDesign, is also in my toolkit.

Q 17. How do you prioritize tasks when working on multiple assembly projects simultaneously?

Prioritizing multiple assembly projects requires a structured approach. I use a combination of methods, including the MoSCoW method (Must have, Should have, Could have, Won’t have), which helps categorize tasks by importance and urgency. This is coupled with a Kanban board or a similar visual task management system to track progress across all projects. Deadlines are factored into the prioritization, ensuring timely completion of critical tasks. Furthermore, I often break down larger projects into smaller, more manageable tasks. This allows for flexible task switching without losing overall project momentum. For example, if I have a tight deadline on one project, I may allocate more time to it, even if it means delaying certain tasks in less urgent projects.

Q 18. What are your strategies for handling repetitive assembly tasks?

Repetitive tasks can be optimized through a combination of techniques. First, I analyze the process for areas of improvement. Can anything be automated? Can I use jigs or fixtures to guide the assembly, making it quicker and less prone to errors? Secondly, I focus on ergonomic considerations. Improper posture or repetitive movements can lead to injuries. I use tools designed for efficient assembly, and I take breaks to avoid fatigue. In some cases, I work with teams, ensuring task distribution prevents burnout and enhances productivity. Think of it as an assembly line; dividing work improves efficiency and reduces monotony.

Q 19. How do you ensure the proper alignment and fit of components during assembly?

Ensuring proper alignment and fit is paramount. I start by carefully reviewing the assembly drawings and specifications, paying close attention to tolerances and mating surfaces. I use appropriate tools, like alignment pins, jigs, and fixtures, to guide components into their correct positions. For example, when installing a CPU into a motherboard, I use the alignment pins to ensure correct placement before lowering the CPU onto its socket. If precise alignment is critical, I’ll use measuring tools like calipers or micrometers to double-check the position and dimensions. A methodical approach and careful attention to detail is key in minimizing misalignments.

Q 20. Explain your understanding of different types of adhesives and their applications in assembly.

My understanding of adhesives includes various types and their applications. Cyanoacrylate (super glue) is great for small, quick-setting bonds. Epoxy resins are stronger and offer greater durability, suitable for structural applications. UV-curable adhesives are ideal for automated systems, where fast curing is necessary. Silicone-based adhesives provide flexibility and are good for applications where movement or vibration is expected. Anaerobic adhesives cure in the absence of air and are often used for thread locking and sealing. Choosing the right adhesive depends on the materials being joined, the required bond strength, and the environmental conditions. For example, when assembling a circuit board, I might use UV-curable adhesive to securely fix components, whereas in assembling a wooden frame, a strong epoxy resin would be more suitable.

Q 21. How do you prevent damage to components during disassembly?

Preventing component damage during disassembly involves a cautious and systematic approach. I always start by carefully reviewing the assembly drawings and any available disassembly instructions. If working with electronics, I always discharge any static electricity before touching sensitive components. I use the right tools for the job—the wrong tool can easily cause damage. For example, using a screwdriver that’s too large or applying excessive force can strip screws or scratch surfaces. I use heat where necessary to loosen adhesives without damaging the parts. Wherever possible, I use specialized tools, like plastic pry bars, to gently separate components. If I’m unsure about a step, I will always err on the side of caution and consult additional resources or experienced colleagues before proceeding.

Q 22. Describe your experience with soldering and other electronic assembly techniques.

My experience with soldering encompasses a wide range of techniques, from through-hole soldering of components onto PCBs (Printed Circuit Boards) to surface mount technology (SMT) soldering using various methods like reflow and wave soldering. I’m proficient with different solder types, including lead-free solder, and I understand the importance of proper flux application for clean and reliable joints. Beyond soldering, I’m experienced in other electronic assembly techniques such as crimping, wire harnessing, and connector assembly. For example, in a recent project involving the assembly of a complex sensor array, I successfully utilized a combination of reflow soldering for SMT components and through-hole soldering for larger connectors, ensuring all connections were robust and met the required specifications. My skills also extend to using specialized tools like hot air rework stations for removing and replacing components without damaging the PCB. I’m meticulous about cleanliness and adhere strictly to ESD (Electrostatic Discharge) precautions to prevent damage to sensitive electronic components.

Q 23. How do you identify and address potential safety hazards during assembly and disassembly?

Safety is paramount in assembly and disassembly. My approach involves a multi-layered strategy. Firstly, I always conduct a thorough risk assessment before starting any work, identifying potential hazards like sharp objects (e.g., component leads), electrical hazards (e.g., live circuits), chemical hazards (e.g., flux fumes), and ergonomic hazards (e.g., repetitive strain injuries). Based on this assessment, I implement appropriate control measures. This includes using proper personal protective equipment (PPE) such as safety glasses, gloves, and anti-static wrist straps. For electrical hazards, I always ensure power is completely disconnected before working on any live circuit. I also maintain a clean and organized workspace to minimize tripping hazards and prevent accidental damage to components. Furthermore, I’m trained in the safe handling and disposal of hazardous materials such as lead-containing solder and cleaning solvents. For instance, during the disassembly of an older device containing capacitors, I carefully discharged the capacitors using a resistor before handling them to prevent electric shock.

Q 24. What are the key differences between preventative and corrective maintenance in assembly?

Preventative maintenance focuses on preventing failures before they occur, while corrective maintenance addresses failures after they’ve happened. Think of it like this: preventative maintenance is like regular checkups at the doctor, aiming to catch potential problems early, whereas corrective maintenance is like going to the emergency room after you’ve fallen ill. In assembly, preventative maintenance involves regular cleaning of equipment, calibration of tools, and scheduled inspections for wear and tear. For example, regularly lubricating moving parts of automated assembly machines prevents premature failure. Corrective maintenance, on the other hand, involves repairing or replacing faulty components, machines, or tools after a breakdown. For instance, if a soldering iron malfunctions during assembly, corrective maintenance would involve either repairing it or replacing it with a new one. Effective preventative maintenance significantly reduces downtime, improves product quality, and minimizes overall costs compared to solely relying on corrective maintenance.

Q 25. How do you utilize quality control checks during the assembly process?

Quality control checks are integrated throughout the entire assembly process. I use a multi-stage approach:

- Incoming Inspection: Verifying the quality of components before they enter the assembly line.

- In-process Inspection: Performing checks at various stages of the assembly process to catch defects early.

- Final Inspection: Thorough examination of the finished product to ensure it meets all specifications.

Q 26. Describe your experience with lean manufacturing principles in assembly.

I have significant experience implementing lean manufacturing principles in assembly, focusing on reducing waste and improving efficiency. This includes utilizing techniques like 5S (Sort, Set in Order, Shine, Standardize, Sustain) to maintain a clean and organized workspace, thereby minimizing wasted time searching for tools and materials. I’m also experienced in Kaizen, continuous improvement, identifying and eliminating bottlenecks in the assembly process. In a previous role, we implemented a Kanban system to manage inventory and optimize workflow, resulting in a significant reduction in lead times and improved product flow. Value stream mapping helped us identify areas for improvement in our assembly process, allowing us to streamline operations and reduce waste. By focusing on these principles, we achieved significant gains in productivity and reduced manufacturing costs.

Q 27. How do you stay updated with the latest advancements in assembly techniques and technologies?

Staying updated in this rapidly evolving field is critical. I regularly attend industry conferences and workshops, read industry publications, and participate in online forums and communities dedicated to assembly techniques and technologies. I also actively seek out training opportunities on new tools and technologies, such as automated assembly systems and advanced soldering techniques. Subscription to relevant journals and online resources allows me to stay informed about the latest advancements in areas like robotics, automation, and new materials in manufacturing. My professional network is a valuable source of information, providing insights into emerging trends and best practices. Continuous learning is essential for maintaining my expertise and adapting to the ever-changing landscape of the assembly industry.

Q 28. What are your salary expectations for this role?

My salary expectations for this role are in the range of $X to $Y per year. This is based on my experience, skills, and the responsibilities associated with this position. I am flexible and open to discussing this further based on the details of the compensation package, including benefits.

Key Topics to Learn for Assembling and Disassembling Products Interview

- Understanding Technical Drawings and Schematics: Interpreting blueprints, diagrams, and assembly instructions to accurately understand the product’s components and their relationships.

- Tool Selection and Usage: Identifying the appropriate tools for specific tasks, demonstrating safe and efficient tool handling techniques, and understanding the limitations of each tool.

- Component Identification and Handling: Accurately identifying individual parts, understanding their functions, and handling them with care to avoid damage.

- Assembly Processes and Techniques: Mastering various assembly methods (e.g., fastening, joining, aligning), understanding the importance of proper sequence and torque specifications.

- Disassembly Procedures and Safety: Following safe disassembly practices, understanding the order of removal to avoid damage, and properly storing components.

- Quality Control and Inspection: Performing thorough inspections at each stage of assembly and disassembly to identify defects and ensure adherence to quality standards.

- Troubleshooting and Problem-Solving: Identifying and resolving common assembly and disassembly challenges, demonstrating effective problem-solving approaches.

- Ergonomics and Workplace Safety: Understanding and applying safe work practices, utilizing proper lifting techniques, and maintaining a clean and organized workspace.

- Material Handling and Storage: Proper handling and storage of components to prevent damage and ensure efficient workflow.

- Working with Different Materials: Demonstrating familiarity with various materials (e.g., plastics, metals, composites) and their specific handling requirements.

Next Steps

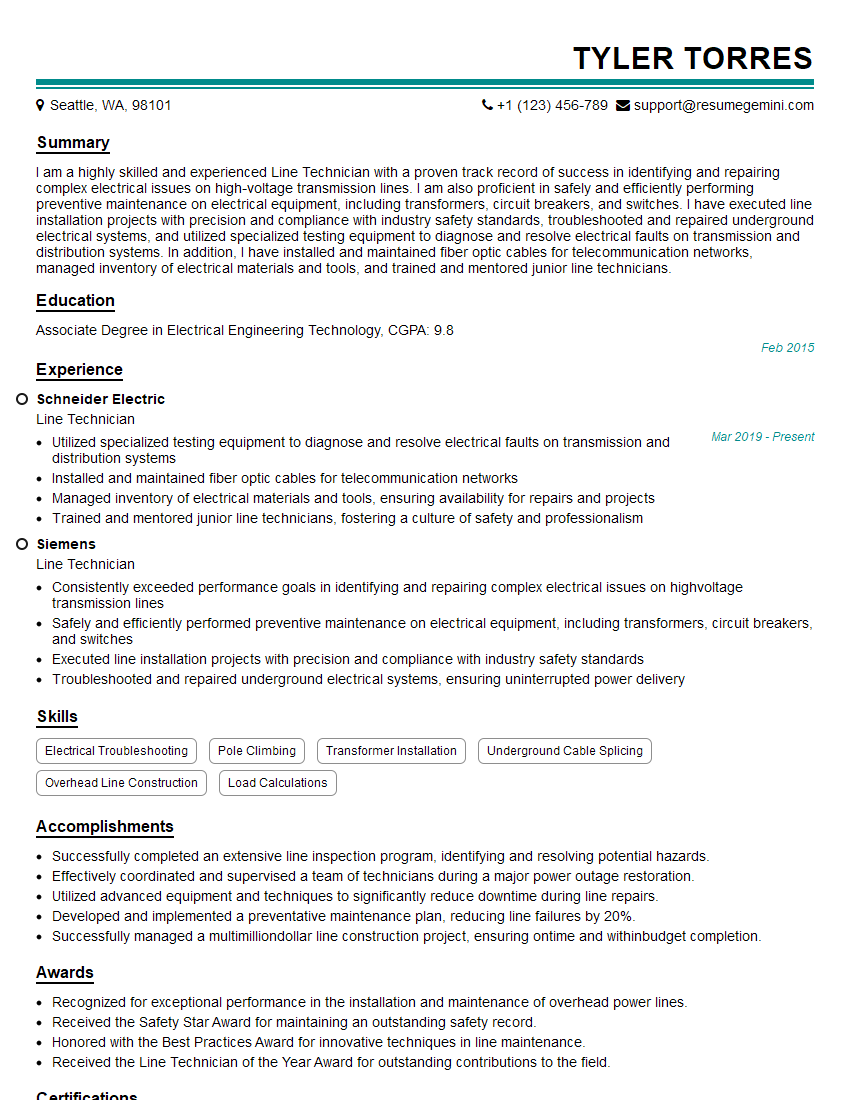

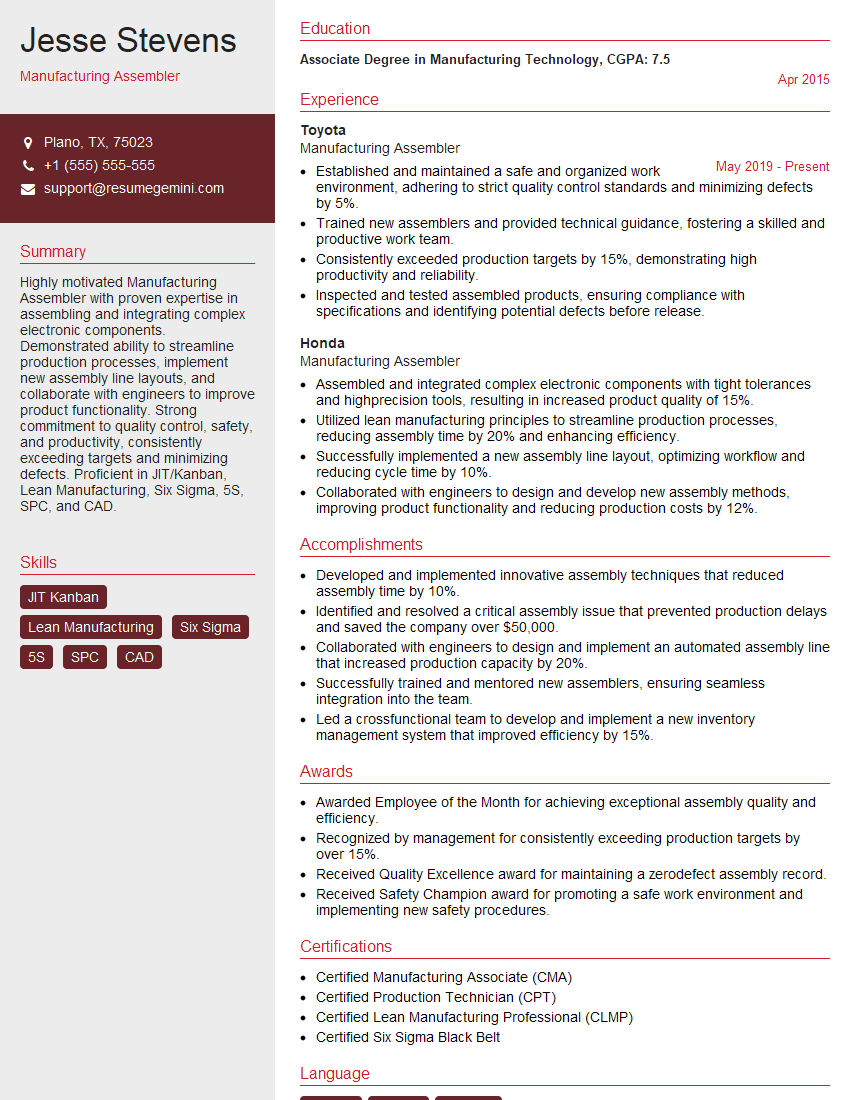

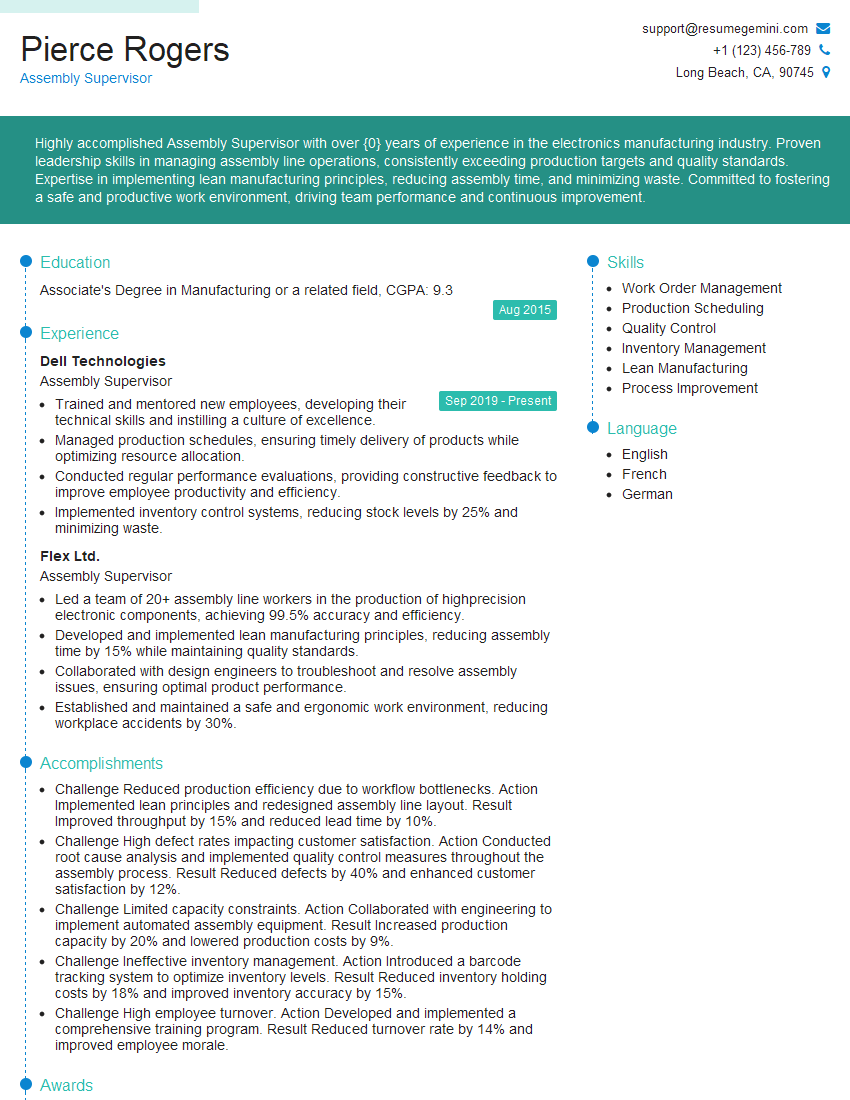

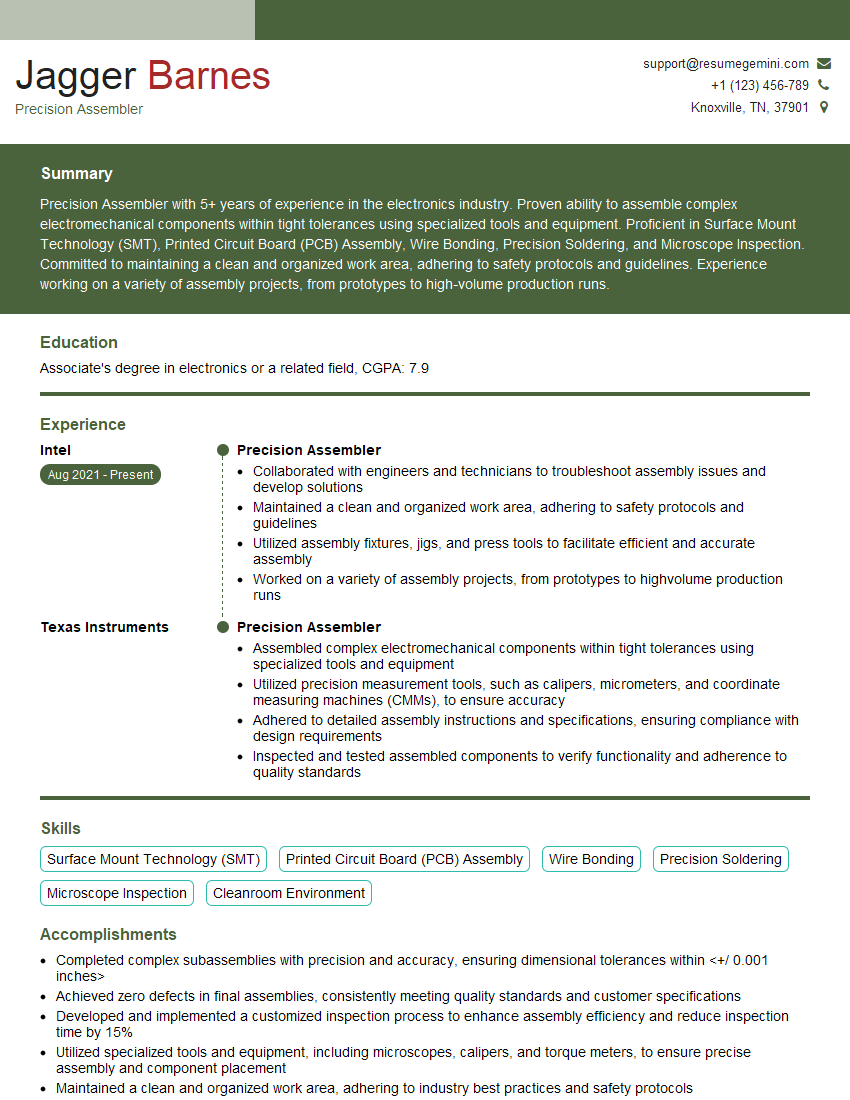

Mastering the art of assembling and disassembling products is crucial for a successful career in manufacturing, engineering, and related fields. It demonstrates key skills like precision, problem-solving, and attention to detail, all highly valued by employers. To significantly boost your job prospects, it’s essential to create a resume that highlights these skills effectively, using keywords that Applicant Tracking Systems (ATS) recognize. We strongly encourage you to use ResumeGemini to build a professional and ATS-friendly resume that showcases your abilities in assembling and disassembling products. ResumeGemini provides examples of resumes tailored specifically to this field, helping you craft a compelling application that gets noticed.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good