The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Assembling dies interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Assembling dies Interview

Q 1. Describe your experience with different types of dies (progressive, compound, etc.).

My experience encompasses a wide range of die types, focusing primarily on progressive, compound, and single-stage dies. Progressive dies, known for their efficiency in high-volume production, involve a series of operations completed in a single pass of the workpiece through the die. I’ve worked extensively on these, assembling intricate sequences of punches and dies, ensuring precise registration between operations. Compound dies, combining multiple operations within a single die set, often require more complex assembly procedures due to the close proximity and interaction of different components. My experience with these often involves intricate alignment and spring-load adjustments. Finally, single-stage dies, performing a single operation, while simpler in design, still demand precision assembly to ensure proper function and part quality. Each type presents unique challenges; progressive dies demand precision in sequencing and alignment, compound dies require careful management of multiple operations in a confined space, and single-stage dies need unwavering focus on achieving consistent results. For instance, in assembling a progressive die for a small electronic component, precise alignment was crucial to avoid damaging delicate features during multiple punch operations.

Q 2. Explain the process of assembling a progressive die.

Assembling a progressive die is a meticulous process requiring a systematic approach. It typically begins with a thorough inspection of individual components for damage or defects. Then, the process often starts with the installation of the stripper plates, ensuring they are accurately positioned and securely fastened. Next, punches and dies are carefully inserted, meticulously checking alignment with precision measuring tools. This step is crucial; any misalignment can cause significant problems, like part defects or tool damage. The alignment is often verified using a dial indicator or optical comparator. Following this, the die components, such as bushings and guide pins, are meticulously fitted to maintain correct tolerances. Finally, the assembled die undergoes a thorough testing process to confirm its functionality and accuracy, and adjust if necessary. Think of it like assembling a complex watch – each component plays a vital role, and even a minor error can significantly impact the final outcome.

Q 3. What are the critical tolerances you’ve worked with in die assembly?

Throughout my career, I’ve worked with critical tolerances ranging from ±0.0001 inches (0.0025 mm) to ±0.0005 inches (0.0127 mm) in die assembly, depending on the application and the materials used. These tight tolerances are especially critical in high-precision applications like micro-electronics and medical devices. For example, assembling dies for producing miniature connector parts required holding tolerances under ±0.0002 inches to maintain electrical connectivity. The use of precision measuring instruments and advanced techniques like laser alignment was crucial for achieving such tolerances. A small deviation can lead to part failure, scrap, or even damage to the machinery.

Q 4. How do you ensure the accuracy of die alignment during assembly?

Ensuring accurate die alignment is paramount. We use various techniques to achieve this. A common method is employing precision dowel pins and bushings during assembly. These act as guides, maintaining consistent alignment between different die components. Optical comparators and laser alignment systems are also used to verify alignment precisely. These tools project magnified images of the die components, enabling the detection of even minute misalignments. Dial indicators are indispensable for measuring the parallelism and perpendicularity of various die components. We also utilise shims to make minute adjustments to alignment during the final stages of the assembly process. Regular calibration of the measuring instruments is crucial to maintain accuracy and confidence in our measurements. I often use a ‘step-by-step’ approach, checking alignment after each component is installed to ensure early detection and correction of any errors.

Q 5. What tools and equipment are commonly used in die assembly?

Die assembly relies on a variety of specialized tools and equipment. These include precision measuring instruments like dial indicators, optical comparators, and laser alignment systems. We also use specialized wrenches, torque wrenches, and hand tools for fastening and adjusting components. Surface grinders and lapping machines are used to prepare components for assembly. Presses, both mechanical and hydraulic, are used for installing certain die components, and finally, specialized fixtures and jigs are crucial for holding components in place during assembly to ensure accuracy and prevent damage.

Q 6. Describe your experience with using precision measuring instruments.

My experience with precision measuring instruments is extensive. I’m proficient in using dial indicators to measure runout, parallelism, and perpendicularity with high accuracy. I’m also well-versed in using optical comparators to visualize and measure die components with high magnification. I understand the importance of proper instrument calibration and the application of various measurement techniques. I know how to interpret the data from these instruments and use them to fine-tune die components to meet the specified tolerances. For instance, while assembling a very complex progressive die, detecting a slight misalignment using an optical comparator prevented significant rework later on, saving both time and resources.

Q 7. How do you identify and resolve common issues during die assembly?

Identifying and resolving issues during die assembly often involves a systematic troubleshooting approach. We start by carefully inspecting the components and using precision measuring instruments to pinpoint the source of the problem. Common issues include misalignment of punches and dies, improper seating of components, or incorrect fastening of parts. For example, if a punch isn’t properly aligned, it might lead to burrs on the workpiece. In such a case, I would use a dial indicator to determine the extent and direction of misalignment, then use shims or other corrective actions to readjust it. If a component is damaged, it needs to be replaced. If the issue is due to incorrect assembly procedures, further training or review of the assembly drawings may be necessary. Documentation is key; noting the specific issue, its cause, and the corrective action taken is vital for preventing future recurrence. A methodical and precise approach is essential to identify and resolve these issues efficiently.

Q 8. What safety precautions do you follow while assembling dies?

Safety is paramount when assembling dies. My approach is multifaceted, starting with a thorough understanding of the specific hazards associated with each die and its components. This includes potential risks from sharp edges, heavy materials, and the use of specialized tools.

- Personal Protective Equipment (PPE): I always wear safety glasses, gloves appropriate for the materials being handled (e.g., nitrile for chemicals, cut-resistant for sharp components), and a lab coat to protect my clothing. Depending on the task, I might also utilize hearing protection or a respirator.

- Proper Tool Usage: I ensure that all tools are in good working condition and are used correctly according to their instructions. This includes regular maintenance and inspections of tools like presses, microscopes, and specialized handling equipment.

- Work Area Safety: The workspace is kept clean, organized, and well-lit to prevent accidents caused by tripping hazards or obscured vision. Components and tools are stored appropriately, following established protocols for hazardous materials.

- Emergency Procedures: I am familiar with and routinely practice emergency procedures, including the location of safety showers, eyewash stations, and fire extinguishers. I report any incidents, no matter how minor, to ensure a safe working environment.

For example, during the assembly of a large, heavy progressive die, I’d always use a die handling cart and ask a colleague for assistance, rather than risking a back injury by trying to move it alone. Safety is a shared responsibility.

Q 9. Explain your experience with different die materials and their properties.

My experience encompasses a wide range of die materials, each with unique properties that influence the assembly process and the final die’s performance. Material selection is crucial and depends heavily on the application.

- Tool Steel: This is the workhorse of die making, offering excellent hardness, wear resistance, and toughness. Different grades of tool steel (e.g., A2, D2, M2) offer varying properties, affecting the assembly method. For instance, tougher steels might require more careful handling to prevent cracking during installation.

- High-Speed Steel (HSS): While less hard than tool steel, HSS provides good wear resistance and is often used in punches and dies where high-speed operation is involved. Its ductility can be advantageous for certain assembly operations.

- Carbide: Carbide offers exceptional hardness and wear resistance, often used for applications requiring extreme durability and precision. However, its brittleness requires meticulous handling to avoid chipping or cracking during assembly. Specialized tools and techniques are necessary.

- Ceramics: For specific applications demanding high wear resistance and corrosion resistance, ceramic materials are used. Their brittle nature requires precise handling and alignment.

For instance, when assembling a die with carbide inserts, I use specialized fixtures and microscopic inspection to ensure perfect alignment to prevent premature wear or failure. Understanding the material’s limitations is just as important as its advantages.

Q 10. How do you handle damaged or defective components during assembly?

Handling damaged or defective components is a critical aspect of die assembly. Immediate action is crucial to prevent further damage and ensure the final product’s integrity.

- Identification and Isolation: Damaged or defective components are immediately identified and segregated from usable parts. Clear labeling is crucial to avoid accidental use.

- Documentation: I meticulously document the defect, including its type, location, and potential cause. This information is vital for analysis, preventing recurrence, and potentially informing design improvements.

- Replacement: Defective components are promptly replaced with verified good parts. This involves strict adherence to quality control standards and traceability.

- Root Cause Analysis: In cases of recurring defects, a root cause analysis is performed to identify systemic issues in the manufacturing or handling process. This could involve collaboration with other departments or suppliers.

Imagine finding a small crack in a critical die component. I would not attempt to repair it but would immediately document it, replace it with a new component, and then initiate a review to determine if there was a flaw in the manufacturing or supply chain process.

Q 11. Describe your process for inspecting an assembled die for quality.

Inspecting an assembled die for quality is a systematic process involving multiple stages. The objective is to ensure it meets the required specifications and will function as intended.

- Visual Inspection: A thorough visual inspection is performed under magnification, checking for any signs of damage, misalignment, burrs, or other defects. This often involves the use of a microscope or magnifying glass.

- Dimensional Measurement: Precision measuring tools, such as calipers, micrometers, and height gauges, are used to verify that critical dimensions are within specified tolerances.

- Functional Testing: Once the visual and dimensional checks are satisfactory, the die is tested functionally. This could involve trial runs with sample material to assess its performance, including verifying proper part geometry and identifying any potential issues.

- Documentation: All inspection findings are meticulously documented with photographs or sketches where necessary. This creates a permanent record for traceability and future reference.

For example, after assembling a progressive die for a stamping operation, I would perform a trial run to ensure the blanks are produced correctly and that there are no issues like binding or premature wear. Only after a successful trial run would the die be deemed ready for production.

Q 12. How do you document the assembly process?

Documentation of the die assembly process is essential for quality control, traceability, and future maintenance. A comprehensive system is crucial.

- Assembly Drawings and Instructions: I refer to detailed assembly drawings and instructions throughout the process, noting any deviations or modifications made.

- Work Instructions: Detailed work instructions outline the sequence of steps and the specific tools and materials required. Any deviations from standard procedures are documented.

- Inspection Reports: Inspection reports detail the results of each inspection stage, documenting any non-conformances and corrective actions.

- Digital Records: Digital records, including images and videos, are created to complement the written documentation, providing visual confirmation of the assembly process and the final product’s quality.

- Serial Numbers and Traceability: Each assembled die is assigned a unique serial number, enabling complete traceability through the entire lifecycle of the die.

Maintaining this comprehensive documentation system allows us to easily identify problems, replicate successful processes, and ensure consistent quality in the long term. It’s a crucial element of quality control in our shop.

Q 13. How do you maintain cleanliness and organization in your work area?

Maintaining a clean and organized work area is critical for both safety and efficiency in die assembly. It minimizes risks of accidents and speeds up the process.

- 5S Methodology: I utilize the 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain) to keep my workspace organized. This involves regularly removing unnecessary items, arranging tools and components logically, cleaning the area thoroughly, establishing standardized procedures for organization, and maintaining a consistent level of cleanliness.

- Designated Storage: Components and tools are stored in designated locations, utilizing appropriate containers and labels to ensure easy retrieval and prevent mix-ups.

- Regular Cleaning: The work area is cleaned regularly, removing debris, dust, and other contaminants that could affect the assembly process or introduce defects.

- Waste Management: Waste materials, such as scraps and packaging, are properly disposed of according to established safety protocols.

A clean and organized workspace is not just about aesthetics. It prevents accidental damage to components, improves efficiency by making tools and parts easily accessible, and significantly reduces the risk of workplace accidents.

Q 14. What is your experience with troubleshooting die assembly problems?

Troubleshooting die assembly problems requires a systematic approach, combining experience, observation, and analytical skills. It’s often a process of elimination.

- Identify the Problem: The first step is accurately defining the problem. What is malfunctioning? Is it a functional issue, a dimensional issue, or a safety concern?

- Review Documentation: I refer to assembly drawings, work instructions, and inspection reports to compare the assembled die to the specifications.

- Visual Inspection: A thorough visual inspection is performed to identify potential sources of the problem, such as misaligned components, damaged parts, or incorrect installation.

- Measurement and Testing: Precision measuring tools are used to verify critical dimensions, and functional testing is performed to assess the die’s performance.

- Systematic Elimination: I approach troubleshooting systematically, using a process of elimination. By methodically testing and checking each component and its installation, I narrow down the possible causes.

For example, if a die produces a part with incorrect dimensions, I would systematically check each component for misalignment, check the punch and die clearances, and verify the correct installation and setting of any adjustments. This step-by-step process often reveals the root cause of the problem.

Q 15. How do you handle conflicting priorities during die assembly?

Conflicting priorities in die assembly are a common challenge. Think of it like a tightrope walk – you need balance and precision. My approach involves a structured prioritization method. First, I assess the urgency and impact of each task. This often involves discussions with the project manager and the team to understand the overall project goals. We then use a prioritization matrix, considering factors like deadlines, critical path dependencies, and potential consequences of delays. For example, if a critical component requires a specialized process with a longer lead time, we’d prioritize that early to avoid holding up the entire assembly. Once priorities are established, I create a detailed schedule, carefully sequencing tasks to minimize conflicts and maximize efficiency. Regular progress reviews and proactive communication ensure we stay on track and adapt to any unforeseen issues.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with working under pressure to meet deadlines.

Working under pressure is an inherent part of die assembly. In my previous role, we faced a critical situation where a major automotive client needed a complex progressive die within a drastically shortened timeline – half the usual time, in fact. To meet this challenge, we implemented several strategies. We organized the team into smaller, specialized units, focusing on parallel processing of different die components. We also leveraged lean manufacturing principles, eliminating waste and streamlining processes. This included optimizing tool selection, reducing setup times, and implementing a rigorous quality control system at each stage. We held daily stand-up meetings to track progress, identify bottlenecks, and adjust our strategy as needed. By focusing on teamwork, efficient workflows, and effective communication, we successfully delivered the die on time and met the client’s exacting specifications. It was a testament to the team’s dedication and our ability to adapt under pressure.

Q 17. Explain your understanding of different die designs and their applications.

My understanding of die designs spans a wide range of applications and complexities. I’m familiar with progressive dies, which are highly efficient for mass production of parts with multiple operations in a single pass. Imagine a sophisticated machine performing multiple steps, like punching, blanking, and forming, all in one continuous sequence. Then there are compound dies, where multiple operations occur simultaneously, offering high speed but often requiring more intricate setup and tooling. For unique or low-volume parts, single-stage dies might be the most practical choice. I also have experience with specialized dies, such as those used for deep drawing, embossing, or coining. The choice of die design hinges on factors like production volume, part geometry, material properties, and desired tolerances. My expertise allows me to select and adapt the optimal die design for a given project, optimizing for speed, efficiency, and part quality.

Q 18. How do you work effectively within a team to assemble dies?

Effective teamwork is the backbone of successful die assembly. I believe in a collaborative approach where each team member contributes their unique skills and expertise. I always start with clear communication of roles and responsibilities. Before commencing assembly, we carefully review the design specifications and production plan. During assembly, open communication and regular check-ins ensure everyone is on the same page and potential issues are addressed proactively. We also foster a culture of mutual respect and support, where team members feel comfortable sharing ideas and offering help. For example, during the assembly of a large progressive die, I worked alongside a skilled machinist who had invaluable expertise in precise adjustments. By combining our skills and knowledge, we ensured the die met the highest quality standards.

Q 19. What is your experience with different types of die lubricants?

Die lubricants are crucial for smooth operation, reduced wear, and extended die life. My experience encompasses a variety of lubricants, each chosen based on specific application requirements. For example, water-soluble lubricants are commonly used for their environmental friendliness and ease of cleanup, but they might not be suitable for all materials or operations. In contrast, oil-based lubricants offer excellent lubrication and anti-corrosion properties, often preferred for high-speed operations or demanding materials. I’m also familiar with dry lubricants, such as graphite or molybdenum disulfide, which are valuable in certain situations but require careful selection to ensure compatibility with the die and workpiece material. The selection of lubricant involves careful consideration of factors like friction reduction, material compatibility, temperature stability, and environmental regulations. Incorrect lubricant selection can lead to poor surface finish, increased wear, and even die damage.

Q 20. Describe your experience with using specialized jigs and fixtures.

Specialized jigs and fixtures are essential tools in precise die assembly. These tools provide the necessary support, alignment, and clamping during assembly, preventing misalignment and ensuring accurate component placement. I have extensive experience using various jigs and fixtures, from simple clamping devices to complex, multi-axis positioning systems. For example, in assembling a complicated progressive die, we used a custom-designed fixture that precisely held all the components in alignment during the critical welding process. This fixture not only ensured consistent alignment but also significantly reduced assembly time and improved repeatability. My expertise extends to designing and modifying jigs and fixtures to optimize the assembly process for specific dies and applications. Selecting the correct fixture is key for maintaining tolerances and quality throughout the assembly process.

Q 21. How do you ensure the proper functioning of assembled dies?

Ensuring the proper functioning of assembled dies involves a multi-stage approach encompassing meticulous assembly, rigorous testing, and thorough inspection. After assembly, I conduct a thorough visual inspection for any signs of damage or misalignment. This is followed by a series of functional tests that simulate real-world operating conditions. These tests assess critical parameters such as part accuracy, repeatability, and die life. For progressive dies, this might involve running hundreds of parts and measuring key dimensions to verify conformance with specifications. We also utilize advanced measuring instruments, such as coordinate measuring machines (CMMs), to ensure dimensional accuracy. Throughout the process, I maintain detailed records of all procedures, inspections, and test results, enabling continuous improvement and troubleshooting if issues arise. This systematic approach guarantees the die meets the required specifications and delivers the intended functionality, leading to high-quality production and minimal downtime.

Q 22. What is your understanding of quality control procedures in die assembly?

Quality control in die assembly is paramount to ensure the manufactured parts meet the required specifications and are free from defects. It’s a multi-stage process that begins with incoming inspection of raw materials and components, verifying their dimensions, material properties, and surface finish. This is followed by in-process inspections at various stages of assembly, such as after component fastening, alignment checks, and functional tests. We use a combination of methods including visual inspection, dimensional measurements using CMMs (Coordinate Measuring Machines) or calipers, and specialized testing equipment to verify functionality and performance. Finally, a thorough final inspection is performed before the die is released for use. Statistical Process Control (SPC) charts are utilized to monitor key process parameters, enabling proactive identification and correction of potential problems. Non-conforming parts or assemblies are carefully documented and handled according to established procedures, which might involve rework, scrap, or further investigation to identify root causes.

For example, in assembling a progressive die, we might use a CMM to verify the precise alignment of punches and dies after each stage of assembly. Any deviation outside the acceptable tolerance would trigger a corrective action, potentially involving adjustment of the components or even replacement of faulty parts.

Q 23. How do you handle deviations from assembly instructions?

Deviations from assembly instructions are addressed through a structured problem-solving approach. First, I would thoroughly document the deviation, noting the specific instruction, the actual outcome, and any contributing factors. This detailed record is crucial for traceability and root cause analysis. Then, depending on the severity of the deviation, I’d follow established protocols. Minor deviations, within acceptable tolerances, might be addressed through minor adjustments or recalibration. More significant deviations may necessitate a consultation with senior engineers or supervisors, potentially requiring a change in the assembly procedure or a review of the design itself. If the deviation results in a non-conforming product, we would follow our established non-conformance procedures, which may include rework, scrap, or a thorough analysis to prevent recurrence.

For instance, if an instruction calls for a specific torque value for a screw, but the torque wrench shows a significant deviation, I would first verify the wrench’s calibration. If the wrench is accurate, then the deviation might indicate a problem with the component or the assembly process itself, necessitating further investigation. This could involve checking for burrs, misaligned components, or even examining the design for potential improvements.

Q 24. Explain your experience with different fastening methods in die assembly.

My experience encompasses a wide range of fastening methods in die assembly, including: mechanical fasteners like screws, bolts, and rivets; press fits; interference fits; and adhesive bonding. The choice of fastening method depends on several factors including the specific application, the materials involved, the required strength and durability, and the desired level of precision. I’m proficient in using various tools and techniques for each method, ensuring proper torque control for threaded fasteners, precise alignment during press fits, and proper surface preparation for adhesive bonding. I understand the importance of selecting the appropriate fastener material to prevent galvanic corrosion and ensure compatibility with the components being joined. I also have experience with specialized fastening techniques like welding or brazing in certain applications, always adhering to safety protocols.

For instance, when assembling a blanking die, I might use high-strength bolts with precise torque specifications to secure the punch and die plates, while for assembling a smaller, more delicate component, I might utilize an adhesive bonding technique, ensuring the surface is thoroughly cleaned before application.

Q 25. How do you stay updated with the latest advancements in die assembly technology?

Staying updated on the latest advancements in die assembly technology is an ongoing process. I actively participate in industry conferences and workshops, attending seminars and training sessions offered by manufacturers of die components and assembly equipment. I regularly review technical publications, journals, and industry websites to keep abreast of new materials, processes, and automation technologies. Networking with colleagues and peers within the industry is also invaluable in sharing best practices and learning about new developments. I also actively seek opportunities to learn about and implement new techniques and technologies within my own workplace, contributing to process improvements and enhancing overall efficiency.

Specifically, I follow leading journals in manufacturing engineering and actively search for updates on new materials like advanced ceramics or composites that improve die life and performance. I also investigate new automation methods, like robotic assembly systems that improve efficiency and precision.

Q 26. Describe a time you had to solve a complex problem in die assembly.

In one instance, we faced a significant challenge with a progressive die used for stamping intricate automotive parts. The die consistently produced parts with burrs on one specific edge, leading to rejects and significant production downtime. Initial troubleshooting focused on the die itself, checking for wear and tear, misalignment, and incorrect clearances. However, the problem persisted. A thorough investigation eventually revealed that the problem wasn’t with the die’s physical construction, but rather with the coil feed system that supplied the metal sheet. The inconsistent feeding of the material was causing the metal to buckle slightly before stamping, resulting in the burrs. By improving the coil feed system’s tension and alignment, we were able to resolve the issue, demonstrating the importance of considering the entire manufacturing process when troubleshooting.

This experience highlighted the importance of systematic troubleshooting, starting with the most likely causes and gradually investigating more complex possibilities. It also emphasized the collaborative nature of problem-solving; the solution involved input from mechanical and electrical engineers, showcasing the value of interdisciplinary teamwork.

Q 27. What is your experience with preventative maintenance of dies?

Preventative maintenance of dies is crucial for maximizing their lifespan and minimizing downtime. Our maintenance program is proactive and systematic, incorporating regular inspections, cleaning, lubrication, and component replacement as needed. We use checklists and documented procedures to ensure consistency and thoroughness. Regular inspections include checking for wear and tear on punches and dies, verifying alignment, and assessing the condition of guide pins and bushings. Cleaning involves removing debris and chips to prevent damage and ensure smooth operation. Lubrication is vital to reduce friction and wear, using appropriate lubricants based on the die’s materials and operating conditions. Component replacement is scheduled proactively, based on wear patterns and manufacturers’ recommendations, preventing unexpected failures.

For example, we might schedule a preventative maintenance check of a stamping die every 50,000 parts, during which we’d visually inspect the die components, measure critical dimensions, lubricate moving parts, and replace any worn-out components, all carefully documented for traceability.

Q 28. How do you contribute to a safe and efficient working environment?

Contributing to a safe and efficient working environment is a top priority. I strictly adhere to all safety regulations and procedures, using appropriate personal protective equipment (PPE) such as safety glasses, gloves, and hearing protection. I actively participate in safety training and promote a culture of safety awareness among colleagues, reporting any potential hazards immediately. I maintain a clean and organized workspace, ensuring that tools and equipment are properly stored and that materials are handled safely. By following standardized procedures and using proper techniques, I contribute to efficient workflow, minimizing the risk of accidents and maximizing productivity. I also actively participate in discussions regarding workplace improvements, suggesting solutions that enhance both safety and efficiency.

For instance, I might suggest improvements to the layout of a workstation to reduce the risk of repetitive strain injuries, or propose the implementation of a new tool to improve the efficiency and safety of a particular assembly task.

Key Topics to Learn for Assembling Dies Interview

- Die Design Fundamentals: Understanding different die types (progressive, compound, etc.), their components, and their functionalities. Explore the relationship between die design and the final product’s quality.

- Assembly Processes: Mastering the practical steps involved in assembling dies, including tool selection, precision alignment, and securing components. Consider the impact of different assembly methods on efficiency and accuracy.

- Material Selection and Properties: Understanding the properties of various materials used in die construction (steels, carbides, etc.) and their suitability for different applications. Analyze how material choice affects die lifespan and performance.

- Quality Control and Inspection: Learn about different inspection techniques used to ensure die quality and identify potential defects. Understand the importance of documentation and record-keeping throughout the assembly process.

- Troubleshooting and Problem-Solving: Develop your skills in identifying and resolving common assembly issues, such as misalignment, component failure, and dimensional inaccuracies. Practice applying systematic troubleshooting methodologies.

- Safety Procedures and Regulations: Familiarize yourself with relevant safety protocols and industry regulations related to die assembly and handling. Demonstrate your commitment to a safe working environment.

- Automation and Robotics in Die Assembly: Explore the role of automation in modern die assembly processes, including the use of robotics and automated assembly systems. Discuss the advantages and limitations of automation.

Next Steps

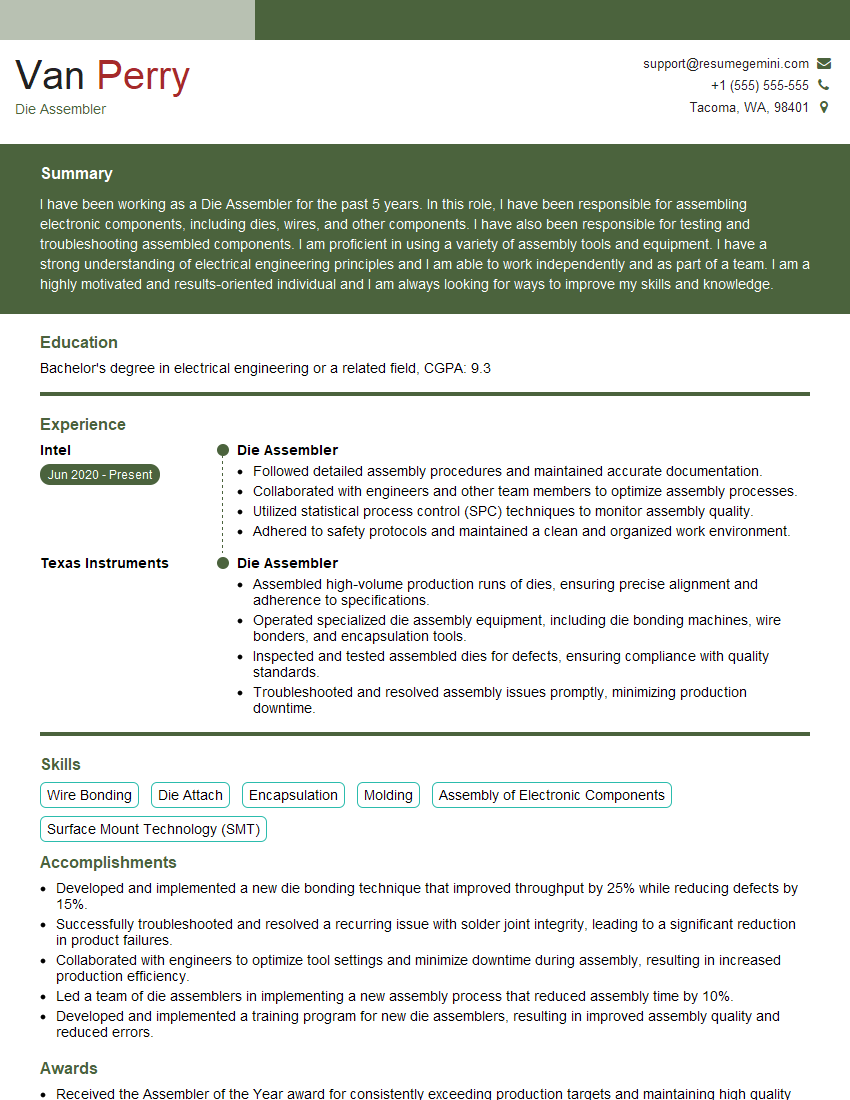

Mastering the art of assembling dies opens doors to exciting career opportunities in manufacturing and engineering, offering rewarding challenges and significant growth potential. To maximize your job prospects, it’s crucial to present your skills effectively. Create an ATS-friendly resume that highlights your technical abilities and experience. ResumeGemini is a trusted resource to help you build a professional and impactful resume that gets noticed by recruiters. Examples of resumes tailored to Assembling Dies are available to help guide your process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good