Are you ready to stand out in your next interview? Understanding and preparing for Automated Screen Printing interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Automated Screen Printing Interview

Q 1. Describe your experience with different types of automated screen printing machines.

My experience encompasses a wide range of automated screen printing machines, from single-color, manual-feed presses to highly sophisticated, multi-color carousel systems with automated pallet handling. I’ve worked extensively with manufacturers like M&R, Anatol, and Vastex, becoming proficient in their unique operating systems and capabilities. For instance, I’ve operated M&R’s Commander series, known for its precise registration and robust build, and Anatol’s high-volume rotary presses, which are ideal for large-scale production runs. Each machine presents its own set of advantages and disadvantages; a carousel system excels at high-throughput but might require more complex setup, while a smaller, single-color press is perfect for short runs and quick turnaround times. My expertise lies not just in operating these machines but also in optimizing their performance for different applications and substrates.

Q 2. Explain the process of setting up an automated screen printing machine for a new job.

Setting up an automated screen printing machine for a new job is a methodical process requiring precision. It begins with a thorough review of the artwork and the specifications of the print job, including the number of colors, the substrate type (e.g., t-shirts, mugs, posters), and the required print area. Next, we prepare the screens, ensuring they are properly tensioned and the emulsion is in good condition. The screens are then meticulously aligned using micro-registration systems, often involving the use of precision-engineered pins or laser alignment tools. Accurate alignment is crucial for perfect print registration. Once the screens are in place, we adjust the squeegee pressure, speed, and ink flow based on the ink viscosity and the desired print quality. Finally, we perform a test print to fine-tune the settings before beginning the full production run. Think of it like setting up a finely-tuned orchestra – each instrument (machine component) needs to be perfectly adjusted to produce a harmonious result (the perfect print).

Q 3. How do you ensure accurate registration in automated screen printing?

Accurate registration in automated screen printing is paramount to achieving high-quality prints. We use several methods to achieve this. Micro-registration systems, as mentioned, are crucial, ensuring the screens align precisely with each other and with the substrate. These systems often incorporate features like laser alignment, ensuring sub-millimeter accuracy. Additionally, we use precise screen clamps and sturdy press frames to minimize any movement or misalignment during the printing process. Regular calibration and maintenance of the registration system are critical, using specialized tools and procedures recommended by the machine manufacturer. Imagine it as building a skyscraper – the foundation (registration) must be perfectly level to ensure the whole structure (print) stands tall and true.

Q 4. What are the common causes of ink smearing or bleeding in automated screen printing, and how do you troubleshoot them?

Ink smearing or bleeding is a common issue in screen printing, often stemming from several factors. One frequent culprit is excessive ink viscosity – too thick an ink will not flow smoothly and can lead to smearing, while too thin an ink can seep under the stencil, causing bleeding. Improper squeegee pressure and speed can also contribute, with too much pressure forcing ink under the stencil and too little leaving an uneven print. Other causes include worn or damaged screens, improper screen tension, and even environmental factors like humidity. Troubleshooting involves systematically examining each variable. We would first assess the ink viscosity and adjust it accordingly. Next, we check the squeegee pressure and speed, making adjustments based on the type of ink and substrate. Examining the screen for damage, ensuring proper tension, and checking the print head for any debris complete the process. It’s a process of elimination, similar to diagnosing a car problem – you systematically check each part until you find the source.

Q 5. Explain your experience with different types of screen printing inks and their application.

My experience with screen printing inks is broad, encompassing plastisol, water-based, discharge, and specialty inks. Plastisol inks are known for their vibrancy and durability, commonly used on textiles. Water-based inks offer a more environmentally friendly option, though they generally have less vibrancy and durability. Discharge inks are used to remove color from a garment before printing a new design, while specialty inks might include glow-in-the-dark, metallic, or high-build varieties. The application method varies depending on the ink type. Plastisol inks often require higher-temperature curing, whereas water-based inks cure at lower temperatures. Knowing the properties of each ink and selecting the right one for the substrate and desired effect is crucial to achieving high-quality prints. It’s like choosing the right paint for a project – you wouldn’t use house paint for a delicate watercolor painting.

Q 6. How do you maintain and troubleshoot automated screen printing equipment?

Maintaining and troubleshooting automated screen printing equipment requires a proactive and systematic approach. Regular cleaning and lubrication of moving parts are essential, preventing wear and tear. We follow manufacturer-recommended maintenance schedules, including inspections of the squeegee blades, print heads, and registration systems. Troubleshooting involves a systematic diagnostic process. If a problem arises, I start by reviewing the print output and looking for patterns in defects. Then, I examine the machine components, checking for any loose connections, worn parts, or blockages. Detailed logs are kept to track issues and their resolutions, contributing to preventative maintenance and enhanced machine lifespan. This preventative approach prevents costly downtime and ensures consistent, high-quality printing.

Q 7. Describe your experience with different types of screens and mesh counts.

My experience includes working with a variety of screens and mesh counts, selecting the appropriate screen based on the design details and the desired print quality. Fine-mesh counts (e.g., 156, 230) are ideal for intricate designs requiring fine detail, while coarser mesh counts (e.g., 43, 61) are better suited for large, bold designs. The mesh count influences ink deposit, with finer meshes producing thinner, more detailed prints, and coarser meshes producing thicker, more opaque prints. I’ve worked with various screen materials, including polyester and nylon, each offering unique properties in terms of durability, tension, and ink release. Selecting the right combination of mesh count and material is crucial for achieving optimal results. It’s like choosing the right camera lens— you need a telephoto lens for zoomed-in shots, while a wide-angle lens is best for capturing a broad landscape.

Q 8. How do you ensure consistent print quality throughout a long production run?

Maintaining consistent print quality throughout a long production run is paramount in automated screen printing. It’s like baking a cake – you need the same ingredients and baking time for each cake to taste identical. In screen printing, this involves meticulous control over several factors.

Precise Ink Delivery: Automated systems allow for consistent ink flow, minimizing variations. Regular calibration of pumps and valves is crucial. Think of it as ensuring your cake batter dispenser is always dispensing the exact same amount.

Substrate Handling: Automated feeders and conveyors ensure uniform substrate movement and precise registration, preventing misalignment. It’s like having a perfectly synchronized conveyor belt in a bakery, delivering the cake pans to the oven at the same pace.

Environmental Control: Temperature and humidity affect ink viscosity and drying. A stable environment is essential for consistent results. Imagine baking cakes in a constantly fluctuating temperature oven – disaster!

Regular Maintenance: Preventative maintenance on the entire system (screens, squeegees, pumps) prevents inconsistencies caused by worn-out parts. Just like a baker needs to regularly clean and sharpen their tools, you need to maintain your automated system.

Operator Training: Well-trained operators can identify and address minor deviations before they impact print quality. A skilled baker immediately notices if the cake is browning too quickly or slowly.

Q 9. What are your methods for preventing and resolving screen clogging?

Screen clogging is a common challenge, significantly impacting productivity and print quality. Think of it as a clogged pipe hindering water flow. Prevention and resolution strategies include:

Proper Screen Preparation: Using high-quality emulsion, proper mesh tension, and careful coating are vital. This is the foundation. A baker would carefully choose their ingredients – proper preparation prevents issues later.

Ink Filtration: Filtering ink before use removes contaminants that can cause clogging. Imagine using a strainer to filter the batter for your cake.

Regular Cleaning: Thorough cleaning of the screen after each print run prevents ink buildup. This is akin to cleaning your baking tools after each use.

Proper Ink Viscosity: Maintaining the correct viscosity prevents clogging. If the ink is too thick it acts like molasses in a narrow pipe.

Squeegee Technique: The angle and pressure of the squeegee affect ink flow and should be optimized. A skilled baker knows how to properly spread and level their batter.

Chemical Cleaning: Using appropriate screen cleaning chemicals can effectively remove stubborn clogs. Think of this as using a specialized cleaning agent to unclog your pipes.

Q 10. Explain your understanding of color management in screen printing.

Color management in screen printing involves ensuring the printed colors accurately reflect the desired design. It’s like matching a paint swatch to a wall in real life. Achieving this requires a multi-faceted approach:

Color Separation: Breaking down the design into individual color separations (cyan, magenta, yellow, black – CMYK) is the first step. This is like separating the different colors in a painting for printing.

Ink Selection: Choosing inks with accurate color characteristics is crucial. This can include specialized inks for different substrates and applications.

Calibration: Regular calibration of the printing equipment and color profiles ensures consistency. A properly calibrated printing press produces consistent color.

Proofing: Creating accurate color proofs allows for comparison with the final print. This is critical for review and validation.

Color Matching Software: Utilizing software for color matching streamlines the process, assisting in achieving the desired color accurately. It’s a digital assistant to fine-tune the colors.

Q 11. How do you monitor and control ink viscosity?

Controlling ink viscosity is vital for consistent print quality and preventing clogging. It’s like adjusting the consistency of pancake batter – too thick, and it’s hard to spread; too thin, and it’s runny. Monitoring and controlling it involves:

Viscometer: Using a viscometer, a device that measures the viscosity of a liquid, allows for precise measurement.

Ink Additives: Adding viscosity reducers or thickeners, such as retarders or flow improvers, adjusts the consistency to the ideal range. This acts as flavoring or sweeteners in a recipe.

Temperature Control: Temperature impacts viscosity; maintaining a stable temperature is important. Imagine how chocolate changes consistency as it cools.

Regular Checks: Frequent viscosity checks throughout the print run ensure consistency. Regular checks on batter consistency will also produce consistent cakes.

Q 12. Describe your experience with different curing methods for screen printed products.

Curing methods solidify the ink onto the substrate. Different methods suit different materials and inks, much like choosing the right oven temperature for different types of bread. My experience includes:

Convection Oven: A widely used method, particularly for heat-set inks on various substrates. This is like using a standard oven for baking.

UV Curing: Fast and efficient, using ultraviolet light to instantly cure inks. This is a quicker method like using a microwave.

Infrared (IR) Curing: Uses infrared radiation to cure inks, often used for heat-sensitive substrates. This is gentler and slower, like letting a cake cool down to room temperature.

Q 13. How do you perform quality control checks throughout the printing process?

Quality control is ongoing, not just at the end. Think of it like tasting a cake at each stage of the process. My process involves:

Initial Screen Inspection: Checking the screen for defects before printing starts.

Ink Viscosity Checks: Regularly checking the ink viscosity throughout the run.

Print Samples: Taking samples at intervals to assess color accuracy and registration.

Visual Inspection: Regularly inspecting prints for defects such as pinholes, smears, and misregistration.

Automated Inspection Systems (if applicable): Utilizing automated systems to detect defects and ensure quality. This is like employing a quality control robotic system.

Q 14. Explain your experience with different types of substrates suitable for screen printing.

Screen printing accommodates a vast range of substrates. It’s like choosing the right canvas for a painting. My experience encompasses:

Textiles: Cotton, polyester, blends – requiring specific inks and curing methods. It is like painting on clothes or flags.

Paper and Cardboard: Different paper weights and coatings require adjustments to printing parameters. It’s like printing on posters or packaging.

Plastics: Various plastics (polypropylene, PVC, etc.) necessitate careful ink selection and curing processes. It’s similar to printing on signs or other plastic products.

Metals: Using specialized inks for adhesion to metals like aluminum or steel. It’s like marking product containers or other metal objects.

Wood: Requires inks that penetrate and adhere effectively. It’s akin to printing on custom wooden plaques.

Q 15. How do you handle different types of screen printing designs (e.g., halftones, fine lines)?

Handling different screen printing designs, like halftones and fine lines, requires a nuanced approach. The key is understanding how mesh count, emulsion thickness, and squeegee pressure interact to produce the desired result. For halftones, which create the illusion of gradation, a finer mesh (higher number, like 156 or higher) is necessary to reproduce the subtle variations in tone. A thicker emulsion layer ensures good dot definition and prevents ink bleed. Squeegee pressure needs to be carefully controlled to avoid smearing the delicate dots. For fine lines, you similarly need a high mesh count to create sharp, crisp detail. However, you may need a slightly thinner emulsion layer to help prevent clogging and ensure ink flow. The squeegee angle and pressure must be perfectly calibrated to avoid blurring or breaking the lines. Think of it like using different brushes for different painting techniques: a fine brush for intricate details, a broader brush for larger areas. In my experience, I’ve perfected this by experimenting with different mesh counts, emulsion types, and squeegee pressures for each specific design, meticulously documenting my findings to create a library of best practices for future projects.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What safety precautions do you take when operating automated screen printing machines?

Safety is paramount in automated screen printing. Our protocol begins with thorough machine inspections before each use, checking for any loose parts, damaged wiring, or leaks. Appropriate Personal Protective Equipment (PPE) is mandatory – safety glasses, gloves to protect against ink and solvents, and hearing protection due to the machinery’s noise. We also utilize a well-ventilated workspace to mitigate the effects of ink fumes and solvents. Emergency stop buttons are readily accessible, and all operators undergo extensive training on safe operating procedures, including emergency shutdowns and proper cleanup procedures. Additionally, we have regular safety audits and training sessions to reinforce these best practices. For example, we had a situation where a minor electrical malfunction occurred; thankfully, our operator’s quick response and knowledge of emergency procedures prevented a serious incident. This reinforced the importance of continuous training and proactive safety measures.

Q 17. Describe your experience with using different types of squeegees and their impact on print quality.

Different squeegees significantly impact print quality. The choice depends on the design, ink, and substrate. For example, a harder squeegee, typically made of polyurethane or steel, provides sharper, more defined prints, particularly useful for fine lines and detailed artwork. Softer squeegees, often made of rubber, are more suitable for softer prints or when working with delicate substrates to avoid damage. The squeegee’s durometer (hardness) is crucial; a harder squeegee requires more pressure for the same ink transfer as a softer one. We also consider the angle of the squeegee. A more aggressive angle (closer to 90 degrees) allows for a sharper print but can also lead to ink scraping. Conversely, a gentler angle (closer to 45 degrees) produces a softer, less defined print. The blade shape also matters – square blades for sharp prints and rounded blades for smoother ones. Through years of experience, I’ve developed a strong understanding of how each squeegee type interacts with various inks and substrates, ensuring consistent and high-quality results.

Q 18. How do you calculate the correct amount of ink needed for a specific job?

Calculating the correct ink amount involves several factors. Firstly, we determine the print area. This includes the dimensions of the design and the number of colors. Then, we consider the ink viscosity; thinner inks require less pressure and potentially less volume. The substrate also plays a role: porous materials like cotton absorb more ink than non-porous materials like polyester. Finally, the desired ink thickness and opacity influence the quantity. We typically calculate the total print area and then multiply it by a factor determined by the ink viscosity, substrate type, and desired ink thickness, which has been empirically determined through past jobs and our extensive knowledge base. For example, a job using a highly porous substrate and a low viscosity ink will require a higher ink-per-area multiplier compared to a job using a non-porous substrate and a high viscosity ink. This careful calculation helps us to avoid waste, control costs, and ensure consistent ink coverage.

Q 19. What is your experience with different types of screen printing emulsions?

My experience encompasses various screen printing emulsions, each with its strengths and weaknesses. Diazo-based emulsions are widely used and relatively affordable, offering good sensitivity and detail reproduction. Photopolymer emulsions provide higher resolution and are better suited for intricate designs, but are generally more expensive. I’ve also worked with capillary film emulsions that allow for extremely fine details. The choice depends on the specific job requirements – a simpler design might use a diazo emulsion, while a highly detailed design calls for a photopolymer emulsion. We consider factors like mesh count, desired image sharpness, and budget when selecting an emulsion. For example, on a recent project with intricate line art, the photopolymer emulsion proved crucial in achieving the required level of detail, highlighting the importance of selecting the appropriate emulsion for optimal print results.

Q 20. How do you troubleshoot issues related to substrate inconsistencies?

Substrate inconsistencies can cause significant print quality issues. Troubleshooting begins with identifying the source of the inconsistency – it could be variations in thickness, texture, or surface treatment. We then adjust the printing parameters accordingly. For instance, if the substrate is uneven, we might need to reduce squeegee pressure to avoid damaging the thinner areas and increase pressure to get proper ink coverage on the thicker areas. If the substrate is too absorbent, we may need to add a pretreatment to enhance its surface properties. If the problem stems from electrostatic issues, we address this by ensuring the substrate has been properly grounded and treated to mitigate potential static. Careful inspection of the substrate before printing and pre-treatment steps can help prevent many issues. I’ve learned to visually inspect every substrate to prevent production disruptions, catching inconsistent surfaces before they negatively impact the print runs.

Q 21. How do you handle production delays or unexpected issues?

Production delays or unexpected issues are handled proactively through a combination of meticulous planning, effective communication, and problem-solving skills. We maintain a robust inventory management system, minimizing the risk of supply chain disruptions. If a delay occurs, we immediately assess the impact and communicate it transparently to clients, proposing solutions to mitigate the delay. For unexpected issues, a systematic troubleshooting approach is employed, involving a team effort to identify the root cause, implement corrective actions, and prevent recurrence. Our well-documented processes and SOPs (Standard Operating Procedures) are essential in navigating such situations. We once encountered a critical machine malfunction during a large-scale production. Using our documented troubleshooting steps, we swiftly diagnosed the problem, and with a readily available spare part, we got the equipment functioning in under 3 hours, minimizing the impact on the production timeline. Our comprehensive risk management strategy and well-trained team allows for prompt response and effective solutions.

Q 22. Explain your experience with preventative maintenance on automated screen printing equipment.

Preventative maintenance is crucial for maximizing the lifespan and efficiency of automated screen printing equipment. My approach is proactive, focusing on scheduled maintenance and meticulous observation to catch potential issues before they escalate into costly downtime. This involves a multi-faceted strategy:

- Regular Inspections: Daily visual inspections check for loose components, leaks, unusual noises, or signs of wear on critical parts like squeegees, flood bars, and the print head itself. I maintain detailed checklists to ensure nothing is overlooked.

- Scheduled Maintenance: I follow a strict schedule for lubrication, cleaning, and part replacements based on manufacturer recommendations and historical performance data. This might include replacing worn squeegees every X number of prints, or cleaning the ink recirculation system weekly.

- Data Monitoring: Modern automated systems often provide real-time data on machine performance. I analyze this data to identify trends, predict potential failures (e.g., a gradual decrease in print pressure), and schedule maintenance accordingly. This proactive approach prevents unexpected breakdowns.

- Operator Training: Proper operator training is key. I regularly train operators on best practices for equipment usage, early detection of problems, and reporting malfunctions. A well-trained operator is the first line of defense against equipment damage.

For example, during one project, I noticed a slight decrease in print consistency over several weeks. By analyzing the machine’s data logs, I pinpointed a gradual wear on the print head bearings. Proactive replacement prevented a major production slowdown and ensured consistent print quality.

Q 23. Describe your experience with different types of drying systems used in screen printing.

Drying systems are critical for ensuring proper ink adhesion and preventing smearing or smudging in screen printing. I have experience with several types:

- Convection Dryers: These utilize heated air circulated by fans to evaporate the ink solvent. They are efficient and relatively inexpensive, suitable for many applications. I’ve worked extensively with these, adjusting air flow and temperature to optimize drying times for different inks and substrates.

- Infrared (IR) Dryers: These use infrared radiation to directly heat the ink, accelerating the drying process. They are particularly effective for thicker inks or heat-sensitive substrates. The challenge is balancing sufficient heat to dry without damaging the material; precise temperature control is essential.

- UV Dryers: These utilize ultraviolet light to cure UV-curable inks instantly. This is a fast, efficient method with minimal environmental impact. I have experience calibrating UV lamps and monitoring their intensity to maintain optimal curing.

- Hybrid Systems: Some systems combine different drying methods, such as combining convection and IR for a more efficient and versatile drying process. I have experience integrating and optimizing such systems to meet specific production needs.

Choosing the right drying system depends on factors like ink type, substrate, production speed, and budget. For instance, a high-volume production line with UV-curable inks would benefit from a fast-curing UV dryer, while a smaller operation printing on heat-sensitive materials might opt for a convection dryer with precise temperature control.

Q 24. How do you track and report production metrics?

Tracking and reporting production metrics is essential for evaluating performance, identifying areas for improvement, and making data-driven decisions. My approach involves a combination of automated data collection and manual monitoring:

- Automated Data Acquisition: Modern automated screen printing machines typically track various parameters, including print speed, number of prints, ink usage, downtime, and defect rates. I utilize this data, often exported to spreadsheets or databases, for detailed analysis.

- Manual Data Collection: While automated data is invaluable, manual tracking of specific quality parameters (e.g., visual inspection results, substrate defects) complements this. This helps to identify issues not captured by automated systems.

- Reporting & Analysis: I create regular reports that summarize key metrics, including daily/weekly production output, defect rates, downtime, and overall efficiency. I use charts and graphs to visualize data and identify trends. This information informs decisions about process improvements, equipment maintenance, and operator training.

- KPI Definition: I work closely with management to define key performance indicators (KPIs) that align with business objectives. These could include things like prints per hour, defect rate, or overall equipment effectiveness (OEE).

For example, by analyzing downtime data, I identified a recurring issue with a specific component, leading to preventative maintenance and a significant reduction in downtime and improved efficiency.

Q 25. What are your preferred methods for cleaning and maintaining screens?

Proper screen cleaning and maintenance are vital for maintaining print quality and extending screen lifespan. My methods are thorough and systematic:

- Immediate Cleaning: After each printing job, I clean the screen thoroughly to remove excess ink. This prevents ink buildup, which can affect subsequent prints.

- Emulsion Removal: When screens require re-coating, I carefully remove the old emulsion using appropriate chemicals and techniques to prevent damage to the mesh.

- Degreasing: I use degreasing agents to remove any oil, grease, or other contaminants that can interfere with ink adhesion and print quality. Safety precautions are always paramount when handling chemicals.

- Mesh Care: I handle screens with care to prevent damage to the delicate mesh. Proper storage, avoiding harsh bending, and using appropriate cleaning methods contribute to the longevity of the screen.

- Screen Storage: Clean screens are stored properly to prevent dust and other contaminants from settling.

For example, I use a specialized cleaning system that utilizes ultrasonic vibrations to thoroughly remove ink from fine mesh screens, significantly improving cleaning efficiency and reducing the risk of damage. This contributes to higher quality prints and extends screen life.

Q 26. Describe your experience with different types of automated screen printing software.

My experience encompasses various automated screen printing software solutions, including proprietary systems from machine manufacturers and industry-standard RIP (Raster Image Processor) software.

- Proprietary Software: Many automated screen printing machines have dedicated software that controls various aspects of the printing process, such as print speed, pressure, and ink flow. I’m proficient in configuring these systems to optimize print parameters for different jobs.

- RIP Software: RIP software processes digital artwork for printing, converting raster images into instructions for the screen printing machine. I’m experienced with various RIP software packages, adjusting color profiles and image settings for optimal output. This includes color correction, halftoning techniques, and ensuring proper resolution for high-quality prints.

- Integration with other Systems: I have experience integrating automated screen printing software with other production management systems, such as ERP (Enterprise Resource Planning) software or job tracking databases, allowing for seamless integration of print jobs within a larger production workflow.

One example includes optimizing a RIP software’s color profiles for a specific ink set. This involved careful calibration and testing to ensure accurate color reproduction across various substrates, significantly improving the consistency and quality of the final prints.

Q 27. How do you handle customer requests or feedback regarding print quality?

Addressing customer requests and feedback regarding print quality is a crucial aspect of my role. My approach involves a systematic investigation and collaborative solution:

- Understanding the Issue: First, I thoroughly understand the customer’s concerns, gathering detailed information about the specific print defects, including images and descriptions. Clear communication is essential.

- Root Cause Analysis: I systematically investigate the potential causes of the defects, considering factors such as ink formulation, screen preparation, printing parameters, drying conditions, and substrate quality.

- Testing & Experimentation: I might conduct test prints with variations in parameters to identify the root cause and develop a solution. This often involves collaborative work with the customer to replicate the issue and test potential solutions.

- Corrective Actions: Once the root cause is identified, I implement appropriate corrective actions, which may involve adjustments to printing parameters, ink formulation, or screen preparation techniques.

- Communication & Follow-up: I keep the customer informed throughout the process and follow up to confirm that the issue has been resolved to their satisfaction.

For example, a customer complained about inconsistent print opacity. By analyzing the data and running tests, I identified a slight variation in ink viscosity due to temperature fluctuations. Adjusting the ink temperature and adding a viscosity control agent solved the problem, maintaining consistent opacity and satisfying the customer.

Q 28. Explain your understanding of different print techniques (e.g., flood coating, underbase)

Screen printing employs various techniques to achieve different effects and optimize the printing process:

- Flood Coating: This involves applying a thin, even layer of ink across the entire screen before printing. This ensures uniform ink distribution and prevents ink from drying out prematurely, especially important for detailed designs.

- Underbase: This is a foundational layer of ink applied to the substrate before the main design. It can improve ink adhesion on specific materials (e.g., dark-colored fabrics), create a more vibrant or opaque print, or act as a color base for subsequent layers. Choosing the correct underbase is crucial for ensuring color fidelity and print quality.

- Multiple Passes/Layering: Achieving complex designs often requires multiple passes with different colors or inks, building up the desired effect layer by layer. Accurate registration (alignment) between passes is key for a crisp, professional look.

- Spot/Highlight Printing: This technique uses specific areas of ink to add highlights or details to a design. Masking or specialized screen preparation is needed for accurate placement of these highlights.

- Specialty Effects: Techniques like using specialty inks (e.g., metallic, glow-in-the-dark, puff inks) or textures to create unique visual effects are also part of the process.

The choice of printing technique depends on the specific design, substrate, and desired result. For instance, a design with intricate details would benefit from flood coating and possibly multiple passes, while printing on dark fabric may require a careful underbase selection. This requires a comprehensive understanding of ink chemistry and screen printing principles.

Key Topics to Learn for Automated Screen Printing Interview

- Screen Printing Fundamentals: Understanding the process, including mesh selection, emulsion coating, exposure, and reclaiming.

- Automated Screen Printing Machines: Familiarize yourself with different machine types (e.g., carousel, flatbed, rotary), their functionalities, and maintenance procedures. Practical application: Be prepared to discuss troubleshooting common machine malfunctions.

- Ink Selection and Application: Knowledge of various ink types (plastisol, water-based, UV-curable), their properties, and appropriate application techniques for different substrates.

- Color Management and Matching: Understanding color separation, halftoning, and achieving consistent color reproduction across print runs.

- Pre-press and Image Preparation: Experience with film positives, digital artwork, and preparing files for automated screen printing. Practical application: Discuss your experience with file formats and software used in this process.

- Quality Control and Inspection: Implementing quality control measures throughout the printing process and identifying and resolving print defects. Problem-solving approach: Describe your methodology for identifying the root cause of printing issues.

- Safety Procedures and Regulations: Understanding and adhering to safety protocols related to ink handling, machine operation, and waste disposal.

- Production Optimization and Efficiency: Strategies for maximizing throughput, minimizing waste, and improving overall production efficiency.

- Troubleshooting and Maintenance: Developing proactive maintenance strategies and efficiently troubleshooting common equipment problems.

Next Steps

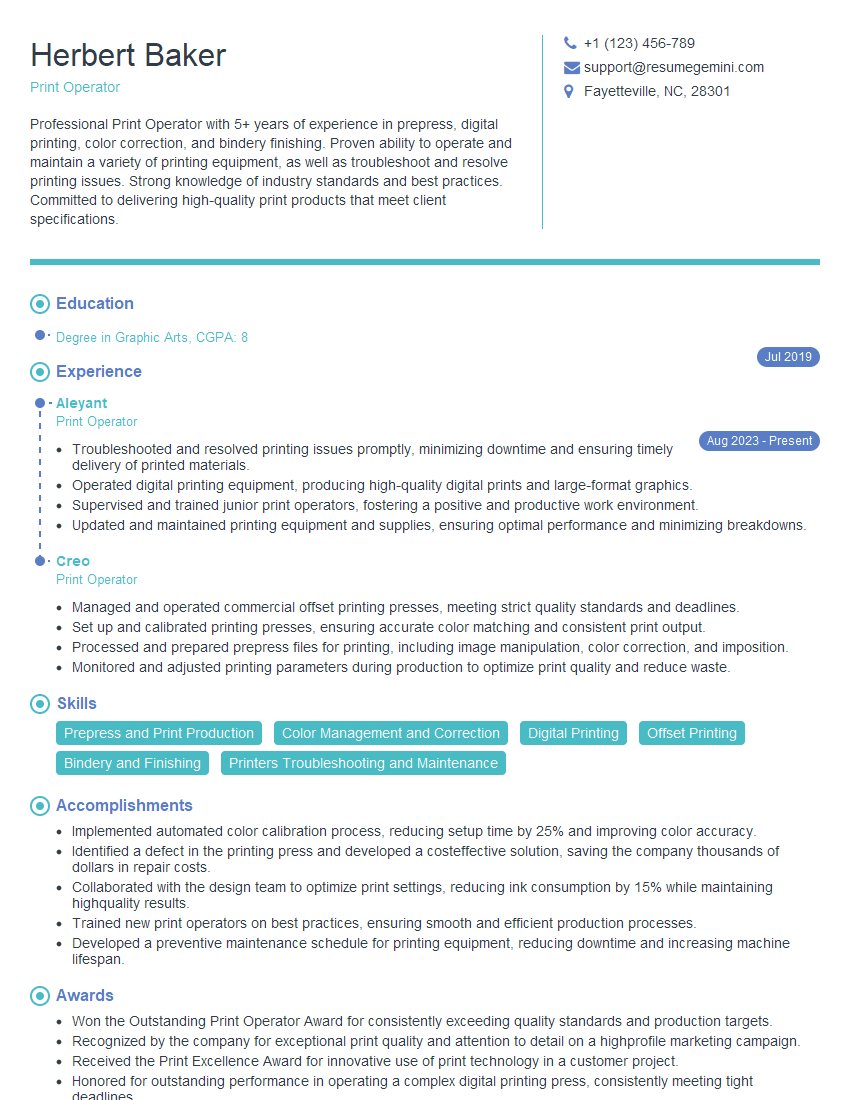

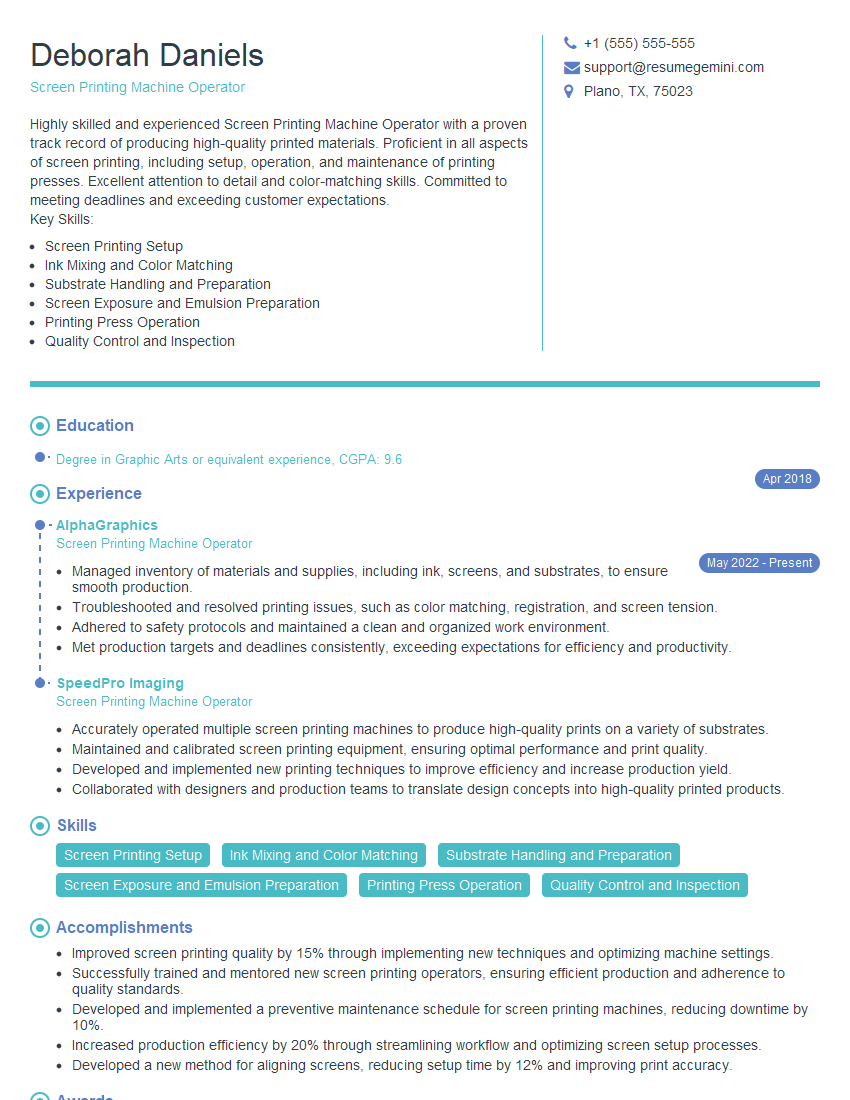

Mastering automated screen printing opens doors to exciting career opportunities in a dynamic industry. Companies highly value skilled professionals who can optimize production, troubleshoot equipment, and ensure high-quality output. To maximize your job prospects, creating a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional resume that highlights your skills and experience effectively. Examples of resumes tailored to Automated Screen Printing are provided to help you craft the perfect application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good