Preparation is the key to success in any interview. In this post, we’ll explore crucial Automotive Restoration interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Automotive Restoration Interview

Q 1. Describe your experience with different types of paint finishes used in automotive restoration.

Choosing the right paint finish is crucial for a successful automotive restoration. The finish not only impacts the car’s appearance but also its durability and longevity. I’ve worked extensively with several types, each with its own characteristics and application techniques.

- Single-Stage Urethane: This is a popular choice for its ease of application and durability. It combines color and clear coat in a single layer, requiring less time and skill than a multi-stage system. Think of it like a simpler, all-in-one solution for a solid, lasting color.

- Basecoat/Clearcoat: This is the industry standard for its superior depth, shine, and protection. The basecoat provides the color, while the clear coat adds protection from UV rays and environmental damage. It offers greater flexibility in achieving custom colors and effects like metallics or pearls. This is like adding a protective shield on top of your perfectly applied color.

- Acrylic Lacquer: A classic choice, often used in concours restorations, it offers a beautiful, deep shine but is less durable and more susceptible to chipping and fading compared to urethanes. It’s a bit like a finely tailored suit – elegant, but requires more care and attention.

- Epoxy Primer: While not a finish itself, epoxy primer is essential for proper surface preparation. It provides a superior bond between the metal and the paint, filling in imperfections and promoting a smooth, even finish. This is the foundation for a flawless paint job – like building a strong base before constructing a house.

My experience spans from applying single-stage urethanes on everyday classics to meticulously layering basecoat/clearcoat systems on concours-ready show cars. The choice of finish depends heavily on the vehicle, the desired outcome, and the budget.

Q 2. Explain the process of restoring a classic car’s engine.

Restoring a classic car engine is a meticulous process that requires a thorough understanding of mechanical systems and precision. It’s not just about making it run, but bringing it back to its original glory, or at least a faithfully restored version of its former self. It’s a bit like performing open-heart surgery on a very old machine.

- Disassembly: The engine is completely disassembled, carefully documenting the location and order of each component. Every part, nut, bolt, and gasket is catalogued – think of it like taking apart a complex clock and keeping meticulous notes.

- Cleaning: All parts are meticulously cleaned using various methods, including chemical degreasing, ultrasonic cleaning, and media blasting (sand or soda blasting) to remove years of grime and corrosion. The goal is to inspect every nook and cranny for any damage.

- Inspection and Repair: Each part is carefully inspected for wear, damage, or cracks. Repairs may include honing cylinders, replacing worn bearings, and resurfacing cylinder heads. This is where experience and a keen eye for detail are essential.

- Rebuilding: The engine is reassembled using new gaskets, seals, and any necessary replacement parts. Precision tolerances are crucial, ensuring proper fit and function. Think about putting the clock back together, making sure each gear meshes perfectly.

- Testing: The rebuilt engine is thoroughly tested on a dynamometer to ensure it meets performance specifications and is free of any leaks or malfunctions. This step is essential before reinstalling it in the vehicle.

Throughout the process, I prioritize using correct OEM (Original Equipment Manufacturer) or high-quality replacement parts to maintain the engine’s originality and performance. Each step is carefully documented with photographs and notes to preserve the history of the restoration.

Q 3. What are the common challenges faced during bodywork restoration?

Bodywork restoration presents numerous challenges, often stemming from the age and condition of the vehicle. These challenges often require a combination of technical skill, artistry, and problem-solving.

- Rust Repair: Addressing rust is a major hurdle. It can range from surface rust to deep penetration, necessitating techniques like rust removal, metal repair, welding, and filler application. Rust is like a cancer to a car’s body. You have to completely remove it to prevent it from returning.

- Dent and Damage Repair: Years of use and accidents leave their marks. Repairs range from minor dent removal using techniques like PDR (Paintless Dent Repair) to major collision repairs requiring welding, panel replacement, and body filler application.

- Panel Alignment: Ensuring all body panels align perfectly requires precision and experience. Small misalignments can significantly impact the car’s appearance. This is a precision craft, similar to aligning wood for fine furniture making.

- Matching Paint: Achieving a perfect paint match, especially on older vehicles with faded or weathered paint, can be tricky. This requires careful color matching and blending techniques.

- Finding Replacement Parts: Sourcing original or high-quality reproduction panels can be challenging, especially for rarer vehicles. This often necessitates fabricating parts or adapting aftermarket components.

Overcoming these challenges requires a multifaceted approach that combines skillful metalworking, precise measuring, and a deep understanding of automotive body construction.

Q 4. How do you identify and address rust damage in a vehicle?

Identifying and addressing rust is paramount in automotive restoration. Early detection and proper treatment are crucial to prevent further damage and preserve the vehicle’s structural integrity.

- Visual Inspection: A thorough visual inspection is the first step. This involves carefully examining the vehicle’s exterior and interior for signs of rust, including surface rust, bubbling paint, and rust-colored stains. This is like a doctor’s examination, looking for any symptoms.

- Probe for Extent: Use a probe or screwdriver to assess the depth and extent of rust damage. This helps determine the necessary repair method.

- Rust Removal: Surface rust can often be removed using wire brushing, sanding, or chemical rust converters. For deeper rust, it might require more aggressive methods such as media blasting (sand or soda blasting) or cutting out and replacing the affected sections.

- Repair and Protection: After rust removal, any holes or damaged areas need to be repaired using welding, metal patching, or body filler. A rust-preventative primer and multiple layers of paint are applied to protect the repaired areas from future rust.

The key is to address rust comprehensively. Failing to completely remove all rust will result in its return, often with more extensive damage in the long run. Prevention is better than cure; rustproofing and regular inspections are highly recommended to protect your classic car.

Q 5. What methods do you use to source rare or discontinued parts for restoration projects?

Sourcing rare or discontinued parts is a significant challenge in automotive restoration. It requires a resourceful and strategic approach. Think of it like a treasure hunt, combining skill and perseverance.

- Online Marketplaces: Websites specializing in classic car parts, online auction sites (e.g., eBay), and specialized forums are excellent starting points. This is like browsing a massive online catalogue of automotive treasures.

- Classic Car Parts Suppliers: Many specialized suppliers focus on specific makes and models, often carrying hard-to-find parts. These are the experts, often holding a goldmine of rare components.

- Junkyards and Salvage Yards: These can be a treasure trove of usable parts, although they require extensive searching and patience. You need a good eye and patience, it’s like searching through a jumble sale hoping to unearth a gem.

- Parts Clubs and Forums: Connecting with enthusiasts and owners of the same make and model can lead to valuable leads. The car community is often a valuable source of information and support.

- Part Reproduction Specialists: If all else fails, consider contacting companies specializing in reproducing classic car parts. This is the ultimate resort, where you can commission a reproduction of the missing piece.

Finding rare parts is a combination of research, networking, and persistence. Often, success comes from multiple avenues explored concurrently.

Q 6. Describe your experience with upholstery repair and restoration.

Upholstery repair and restoration is an art form in itself, blending technical skill with an eye for detail and a passion for preserving originality. It’s a delicate dance of craftsmanship and artistry.

- Assessment and Planning: The process begins with a thorough assessment of the condition of the existing upholstery, including identifying damage, wear, and tear. Then, a plan is developed for repair or replacement, taking into account the original design and materials. This is like creating a blueprint for a renovation.

- Material Selection: Choosing the correct materials is crucial. This may involve sourcing original or high-quality reproduction materials that match the original specifications. This is where knowledge of original materials and modern equivalents is critical.

- Repair Techniques: Repair techniques range from simple stitching and patching to more complex processes like re-covering panels and replacing foam. Specialized tools and techniques are used, depending on the condition and type of upholstery.

- Installation: Once repairs are complete, the new or repaired upholstery is carefully installed, ensuring a proper fit and a professional finish. Every stitch matters, like constructing a fine garment.

My experience includes restoring everything from simple vinyl seats to complex leather interiors with intricate stitching and patterns. The goal is to preserve the original design while ensuring durability and comfort.

Q 7. How do you determine the authenticity of parts during a restoration project?

Authenticity is paramount in automotive restoration. Using non-authentic parts can significantly devalue a vehicle and compromise its historical integrity. Therefore, meticulous verification is essential.

- Part Number Identification: Compare the part number stamped or cast on the part with original part number lists or catalogs from the manufacturer. This is like checking the serial number on a valuable painting.

- Visual Inspection: Compare the part with original photos, drawings, or known good examples. Look for subtle details in casting marks, stampings, and material composition. This requires a keen eye and understanding of original manufacturing techniques.

- Material Analysis: In some cases, material analysis can be used to verify the composition of the part, confirming its age and origin. Think of it like using carbon dating on an artifact.

- Expert Consultation: Consulting with experienced restorers, historians, or parts specialists can provide additional insights and guidance in verifying authenticity. This is like getting a second opinion from a specialist.

- Documentation: Maintain thorough documentation of all parts used in the restoration, including sources, part numbers, and any verification performed. This provides a verifiable history of the restoration and increases the value of the vehicle.

Determining authenticity requires a combination of knowledge, research, and a keen eye for detail. The ultimate goal is to preserve the historical integrity of the vehicle.

Q 8. What safety precautions do you follow when working with automotive chemicals and tools?

Safety is paramount in automotive restoration. Working with chemicals and tools requires a meticulous approach. Think of it like being a surgeon – precision and safety protocols are non-negotiable.

- Personal Protective Equipment (PPE): This is fundamental. I always wear safety glasses, gloves appropriate for the chemical (nitrile for most solvents, neoprene for acids), a respirator for spray painting and working with dust, and appropriate clothing to protect my skin.

- Ventilation: Working in a well-ventilated area is critical when using solvents, paints, and other volatile compounds. I often use respirators with organic vapor cartridges for added protection and ensure adequate air circulation using fans or exhaust systems.

- Chemical Handling: I carefully read and follow the safety data sheets (SDS) for every chemical I use. This includes understanding storage requirements, disposal procedures, and first-aid measures. I always store chemicals in properly labeled containers, away from ignition sources.

- Tool Safety: Regular maintenance of tools is vital, and before using any power tool I always inspect it for damage and ensure it’s properly grounded. I use the correct tool for the job and always follow manufacturer instructions. For example, I never use a grinder without a safety guard.

- Emergency Preparedness: Having a first-aid kit readily available and knowing how to use it is crucial. I also make sure I have appropriate fire extinguishers on hand and understand the procedures for dealing with chemical spills.

For example, when working with fiberglass, I always wear a respirator to avoid inhaling the fine particles, and I make sure the area is well-ventilated to prevent buildup of potentially harmful dust.

Q 9. Explain your experience with different types of welding techniques used in automotive restoration.

Welding is a crucial skill in automotive restoration, and I’m proficient in several techniques. Each has its strengths and weaknesses depending on the project’s needs and the material being welded.

- MIG (Metal Inert Gas) Welding: This is my go-to for sheet metal repair. It’s relatively fast, produces a clean weld, and is suitable for a range of thicknesses. I use it frequently for repairing rust damage and patching holes in body panels.

- TIG (Tungsten Inert Gas) Welding: For high-precision work and where a visually flawless weld is crucial, TIG is unbeatable. It’s ideal for repairing valuable chrome parts, exhaust systems, or delicate chassis components. It requires more skill and patience than MIG welding but offers unparalleled control.

- Stick Welding (SMAW): This method is very robust and can be used in more challenging environments (e.g., outdoor restoration). I use it for thicker materials and where access may be limited. It’s less precise than MIG or TIG, but its versatility makes it valuable.

- Brazing: While not technically welding, brazing is a crucial technique for joining dissimilar metals. I use it for joining components where a high-strength, visually seamless joint is required without excessive heat input. This is often required for radiator repair.

Choosing the right welding technique depends on the specific needs of the project. For instance, on a classic car’s frame, stick welding might be ideal for its strength, whereas repairing a fender would likely call for MIG welding for its speed and precision.

Q 10. How do you manage the budget and timeline of a restoration project?

Budget and timeline management are critical aspects of any successful restoration project. I use a structured approach that involves several key steps.

- Detailed Estimate: Before starting, I create a comprehensive breakdown of all costs, including parts, materials, labor, and any unforeseen expenses (a contingency of 10-15% is usually included). This forms the basis of the project budget.

- Phased Approach: I break down the project into manageable phases, each with its own timeline and budget. This allows for better tracking of progress and easier identification of potential delays or cost overruns.

- Regular Monitoring: I regularly track expenses against the budget and progress against the timeline. This helps to identify any discrepancies early on. I use specialized software to track progress and costs, which allows for reporting to the client.

- Communication: Open communication with the client is key. I provide regular updates on the progress, highlighting any potential issues and proposing solutions. This ensures the client is informed and involved throughout the process.

- Contingency Planning: Unexpected issues always arise in restoration. I build a contingency into both the budget and timeline to address these. This helps to prevent significant delays or cost overruns.

For instance, during a recent Jaguar XK120 restoration, we discovered extensive rust damage not initially apparent. Thanks to the contingency plan, we were able to adjust the budget and timeline without causing major disruption to the project.

Q 11. Describe your experience working with different types of wood used in classic car interiors.

Classic car interiors often feature beautiful woodwork, requiring knowledge of various wood types and their properties. The choice depends on factors such as durability, aesthetics, and historical accuracy.

- Walnut: A popular choice for its rich color and distinctive grain pattern. It’s relatively durable but can be susceptible to scratches and dents.

- Mahogany: Another classic choice known for its reddish-brown hue and lustrous finish. It’s strong and relatively easy to work with.

- Birch: A harder, more durable wood often used for less visible components due to its lighter color and tighter grain.

- Oak: A very strong and durable wood. However, its open grain can require more careful finishing to achieve a smooth surface.

I always consider the historical accuracy of the wood used in a restoration. If restoring a 1950s car, I would research period-correct woods to ensure authenticity. Beyond the type of wood, the finishing techniques are also crucial—applying multiple coats of lacquer or varnish, sanding between coats, and achieving the correct sheen are essential steps for preserving the wood and ensuring a lasting, beautiful result.

Q 12. What are the different types of metal finishing techniques you are familiar with?

Metal finishing is a crucial element in automotive restoration, influencing both the look and the longevity of the car. I’m familiar with many techniques.

- Polishing: This process uses abrasives to create a smooth, shiny surface, removing minor imperfections. Various grades of polishing compounds are used, starting with coarser grades to remove scratches and ending with finer grades for a high gloss.

- Buffing: Similar to polishing but uses softer compounds and rotating buffs to achieve a mirror-like finish. It’s often used as a final step after polishing to enhance the shine.

- Chroming: A complex electroplating process that deposits a layer of chromium onto metal parts, providing a highly reflective and corrosion-resistant surface. I work with specialized chrome plating shops to ensure high quality.

- Powder Coating: A durable and environmentally friendly finish that involves applying a powdered coating to metal parts and then curing it in an oven. It’s very tough and resistant to chipping.

- Painting: While often considered separately, the proper surface preparation and application of paint are crucial aspects of metal finishing. It must be done correctly to ensure the paint adheres properly and provides long-lasting protection.

The choice of metal finishing technique depends on the metal, the desired finish, and the budget. For instance, while chroming provides an exceptional finish, it is relatively expensive compared to polishing or powder coating.

Q 13. How do you ensure the accuracy of color matching during a paint restoration?

Color matching is critical for preserving the authenticity and visual appeal of a classic car. Inaccurate color matching can significantly detract from the restoration. I employ a multi-step process to ensure accuracy.

- Original Paint Analysis: If possible, I analyze a small, inconspicuous section of original paint using a spectrophotometer. This device measures the exact color composition and provides a precise formula.

- Reference Chips: If the original paint is unavailable, I use reference chips from paint manufacturers or archival sources. These provide a color reference close to the original shade.

- Test Panels: Before applying the final paint, I always create test panels using the chosen paint to ensure the color matches under various lighting conditions. This allows for adjustments if necessary.

- Multiple Coats: Paint is applied in multiple thin coats, allowing ample time for drying and ensuring consistent color throughout. This is often supplemented with a clear coat for protection and enhancement of gloss.

- Experienced Eye: While technology is helpful, my own trained eye plays a crucial role in ensuring the final color is accurate and pleasing. Years of experience allow me to judge slight color variations and determine any adjustments needed.

For example, in restoring a vintage Porsche 356, we used a spectrophotometer analysis of a small, hidden section of original paint to accurately replicate the color. The use of test panels allowed minor adjustments for variations in light, leading to a perfect final finish.

Q 14. Describe your experience with diagnosing and repairing electrical systems in classic cars.

Classic car electrical systems can be challenging to diagnose and repair due to their age and complexity. It often requires a systematic approach combined with a deep understanding of vintage electrical systems.

- Visual Inspection: I begin by thoroughly inspecting the wiring harness, looking for broken wires, corrosion, and loose connections. Often, visual inspection helps to pinpoint issues quite quickly.

- Testing with a Multimeter: A multimeter is my most valuable tool for testing voltage, current, and resistance. This helps identify faulty components or circuits.

- Wiring Diagrams: I rely heavily on wiring diagrams specific to the car model and year. These diagrams provide invaluable guidance for tracing circuits and identifying components.

- Component Testing: I test individual components like switches, relays, and fuses to determine if they’re functioning correctly.

- Systematic Troubleshooting: If the problem is not immediately apparent, I use a systematic troubleshooting approach, working my way through the system, testing each component to isolate the fault.

For instance, recently I worked on a classic Ford Mustang with intermittent electrical problems. Using a multimeter and a wiring diagram, I traced the problem to a corroded connection in the fuse box. Replacing the affected section of the wiring harness resolved the issue, demonstrating the importance of a thorough inspection and understanding of the system’s layout. A simple corroded connection can cause significant and complex problems.

Q 15. What is your experience with chassis repair and straightening?

Chassis repair and straightening is a crucial aspect of automotive restoration, focusing on correcting frame damage and ensuring the vehicle’s structural integrity. My experience spans over 15 years, encompassing work on various makes and models, from classic muscle cars to vintage European sports cars. This involves a detailed assessment of the chassis using specialized measuring tools to identify areas of damage, such as bends, twists, or rust-induced weakening.

The repair process might include techniques like frame pulling using hydraulic rams and specialized jigs to carefully realign the chassis. For severe damage, sectioning and welding might be necessary, requiring precise measurements and skillful welding to maintain the original dimensions and strength. Rust repair is often a significant part of the process; this involves cutting out compromised sections and replacing them with new metal, ensuring smooth transitions and proper welding to prevent future corrosion.

For example, I recently restored a 1967 Mustang that had significant damage to its unibody. Using a combination of frame-pulling equipment and precise measurements, I was able to restore the chassis’s structural integrity, ensuring the car was safe and handled correctly. Post-repair, a thorough inspection and alignment are conducted to validate the restoration’s success.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle customer expectations and potential project delays?

Managing customer expectations and potential delays is paramount in automotive restoration. Transparency and proactive communication are key. Before starting a project, I conduct a thorough assessment and provide a detailed estimate, including a realistic timeline. This estimate accounts for potential unforeseen issues, such as hidden damage or parts sourcing difficulties. I emphasize that restoration is a meticulous process and unexpected complications can arise.

Regular updates are crucial. I use a combination of email, phone calls, and progress photos to keep customers informed every step of the way. If delays occur—and they inevitably do sometimes—I immediately communicate the reason, offering alternative solutions where possible and keeping the customer informed of revised timelines. Building a strong relationship based on trust and open communication minimizes misunderstandings and maintains client satisfaction, even when facing challenges. For instance, if a specific part is difficult to source, I will actively explore alternatives and discuss them with the client to reach a mutually agreeable solution.

Q 17. What is your experience working with different types of automotive fabrics?

My experience with automotive fabrics encompasses a wide range of materials, including leather, vinyl, cloth, and even specialized materials like headliner fabric. I understand the properties of each material and the appropriate techniques for its installation. Leather requires specific cleaning, conditioning, and stitching techniques to maintain its integrity and luxurious appearance. Vinyl, while durable, needs careful handling to avoid cracking or tearing during installation. Cloth fabrics, especially those used in classic cars, might require specialized cleaning and repair methods, such as re-weaving or patching.

The selection of fabric is critical. Understanding the original material used in the vehicle is important for maintaining historical accuracy. Replicating the original material is often challenging; sometimes, finding suitable replacements requires extensive research and sourcing. I’ve worked with numerous types of original and reproduction materials, developing expertise in their specific properties and installation processes to ensure a quality and historically accurate restoration.

Q 18. Explain your process for documenting a restoration project.

Comprehensive documentation is essential for any restoration project. My process begins with a detailed initial assessment, including photographic documentation of the vehicle’s condition before any work begins. This includes close-up shots highlighting damage, existing components, and unique features. I maintain a detailed log of all parts used, their sources, and any modifications made. Every step of the restoration is documented, from disassembly to reassembly, with accompanying photographs and notes.

I also utilize digital tools. A project-specific folder on my computer stores all documentation, including invoices, parts specifications, and communication with the client. This detailed documentation is not only beneficial for tracking progress but also acts as a valuable reference for future maintenance or repair. In case of future disputes or insurance claims, these records can provide an irrefutable record of the completed work.

Q 19. What software or tools do you use for project management in restoration?

For project management, I rely on a combination of software and tools. I utilize a project management software, such as Asana or Trello, to create a detailed timeline and track progress on various tasks, assigning deadlines and monitoring their completion. This helps me organize the many components involved in a restoration, ensuring tasks are completed in a timely and efficient manner.

Spreadsheet software like Excel or Google Sheets is used to track parts inventory, costs, and labor hours. This aids in budget management and provides a clear financial overview of the project. Beyond software, I utilize a physical notebook to record daily progress and any unforeseen issues that arise during the process. A combination of digital and physical tracking ensures a holistic approach to project management.

Q 20. Describe your knowledge of different types of automotive glass and its restoration.

Automotive glass restoration requires knowledge of different types of glass, including laminated, tempered, and flat glass. Laminated glass, commonly used in windshields, consists of two layers of glass bonded together with a layer of plastic. Tempered glass, used in side and rear windows, is heat-treated for increased strength. Flat glass, often found in older vehicles, is simply a single pane of glass. Understanding the properties of each glass type is crucial for choosing the right restoration technique.

Restoration can involve repairing minor chips or cracks using specialized resins, replacing damaged glass with new OEM-equivalent glass, or carefully restoring existing glass if it’s a particularly rare or valuable piece. For example, replacing a windshield requires precise measurements to ensure a proper fit. Furthermore, understanding the subtleties of different glass types, such as slight variations in tint or curvature from era to era, allows for historically-accurate restorations.

Q 21. How do you handle unexpected issues that arise during a restoration?

Unexpected issues are inevitable in automotive restoration. My approach involves careful assessment, documentation, and communication. When an unforeseen problem arises—such as discovering hidden rust damage or encountering a difficult-to-source part—I immediately document the issue, photograph it, and evaluate its impact on the project’s timeline and budget.

I then explore solutions, seeking alternative parts if necessary or adjusting my approach to address the unexpected damage. This evaluation involves open communication with the client, discussing potential solutions, and obtaining their approval before proceeding with repairs. Transparency throughout the entire process minimizes misunderstandings and maintains trust, even when facing unexpected complications. For example, if a structural problem is discovered, I will provide multiple repair solutions, along with cost and time implications for each option, allowing the client to make an informed decision.

Q 22. Explain your experience with engine rebuilding and performance tuning in classic cars.

Engine rebuilding and performance tuning in classic cars is a meticulous process demanding a deep understanding of internal combustion engines. It’s not just about replacing parts; it’s about optimizing performance while maintaining the car’s historical integrity. My experience spans decades, working on a variety of engines, from inline-sixes to V8s. I start by thoroughly disassembling the engine, meticulously inspecting each component for wear and tear. This includes carefully measuring tolerances using precision tools like micrometers and dial indicators. I then determine the necessary repairs or replacements, focusing on sourcing parts that meet or exceed original specifications. For performance tuning, I consider factors like camshaft profile, carburetor or fuel injection system calibration, and exhaust system modifications. For example, I recently rebuilt a 1967 Ford Mustang’s 289 cubic inch V8. The original engine was tired, exhibiting low compression and power loss. After a complete rebuild, including replacing worn pistons and rings, honing the cylinder bores, and meticulously setting the valve timing, we significantly improved horsepower and torque. Furthermore, I tailored the carburetor jetting and implemented a performance exhaust system, resulting in a substantial increase in performance while retaining the authentic feel of the classic engine. Each engine presents unique challenges, demanding a tailored approach and a keen eye for detail.

Q 23. What is your familiarity with different types of suspension systems and their restoration?

Suspension systems are critical for a car’s handling, ride comfort, and overall safety. I’m familiar with various types, including leaf springs, coil springs, torsion bars, and air suspensions. Restoration involves assessing the condition of each component – springs, shocks, bushings, control arms, etc. – often requiring replacement or refurbishment. For instance, leaf springs might need to be re-arched or replaced, while coil springs may require testing to ensure they meet the correct spring rate. Bushings, often overlooked, are vital for proper suspension geometry and should always be replaced with high-quality polyurethane or original-equipment-manufacturer (OEM) parts. I’ve worked extensively on restoring various suspension systems. A recent project involved a 1957 Chevrolet Bel Air, whose original leaf springs were sagging and the shock absorbers were completely worn out. Replacing the springs and shocks dramatically improved the car’s handling and ride quality, restoring it to its original driving experience. Understanding the nuances of each system and its impact on the car’s overall performance is paramount in achieving a successful restoration.

Q 24. What are your experience with different types of brake systems and their restoration?

Brake systems are crucial for safety. My experience encompasses drum brakes, disc brakes, and power brake systems. Restoration focuses on ensuring safe and reliable stopping power. This involves inspecting brake lines for leaks, calipers or wheel cylinders for proper operation, and brake pads or shoes for wear. I often replace brake components with high-quality, modern equivalents to ensure safety, while maintaining a period-correct appearance where possible. For example, a recent restoration of a 1970s British sports car required a complete overhaul of the disc brake system. This included replacing worn brake calipers, resurfacing the brake rotors, replacing brake pads, and bleeding the brake lines to remove any air bubbles. Maintaining original brake master cylinder and booster units (when possible) is crucial to ensure the braking system’s integrity. I always test and verify brake operation after restoration to ensure the safety and reliability of the braking system.

Q 25. How do you ensure the structural integrity of a vehicle after bodywork restoration?

Ensuring structural integrity after bodywork is paramount. This is often the most demanding aspect of a restoration. I use a combination of techniques to achieve this. Firstly, thorough rust repair is critical. This might involve media blasting to remove rust and old paint, followed by welding in new metal panels or patching existing sections. The repaired sections are then carefully shaped and smoothed using techniques like body filler application and metal finishing. Finally, to reinforce the structural integrity after major bodywork, I frequently incorporate techniques like adding extra bracing or welding in additional reinforcement plates in areas that have been heavily repaired. Once the bodywork is complete, I carefully check for alignment issues using specialized tools and techniques. I also might employ frame straightening equipment to correct any distortions. Finally, a thorough inspection is essential to identify any underlying weaknesses before the car is repainted or reassembled.

Q 26. How familiar are you with the history and evolution of different automotive makes and models?

My familiarity with automotive history is extensive. I have a deep appreciation for the evolution of automotive design and engineering across various makes and models. This knowledge is invaluable in accurately restoring a vehicle to its original specifications. I’m proficient in identifying subtle differences between various model years and trim levels. This includes understanding the variations in engine specifications, chassis construction, interior appointments, and exterior styling. For example, I know the subtle differences between a 1965 Mustang fastback and a 1966 model, or the intricacies of the evolution of the Porsche 911’s body style over its many generations. This detailed knowledge of automotive history allows me to provide informed advice to clients and ensure the integrity of their restoration project.

Q 27. Explain your experience with environmental regulations related to automotive restoration.

Environmental regulations play a significant role in automotive restoration. I’m aware of the regulations concerning the handling and disposal of hazardous materials like lead-based paint, asbestos, and refrigerants. I follow strict protocols for the proper disposal of these materials, adhering to all local and national environmental regulations. This includes using certified disposal facilities for hazardous waste and employing safe handling practices during the restoration process. Furthermore, I’m knowledgeable about emissions regulations for vehicles, understanding the requirements for compliance in terms of exhaust systems and emissions controls. For projects where emissions compliance is required, I’ll make sure to use parts and components that meet the current regulations while also respecting the vehicle’s originality.

Q 28. Describe your experience with the use of specialized tools and equipment in automotive restoration.

I have extensive experience using a wide range of specialized tools and equipment in automotive restoration. My workshop is equipped with advanced tools such as engine lifts, chassis stands, precision measuring instruments (micrometers, dial indicators), welding equipment (MIG, TIG), media blasting equipment, and paint spray booths. I also utilize specialized tools specific to certain makes and models. For example, I own specialized engine-building tools for certain engines, and various bodywork tools and techniques for different types of metalwork. Moreover, diagnostic equipment like engine analyzers is important for identifying and solving engine problems after reassembly. The use of correct tools and equipment is critical in achieving high-quality results while maintaining the safety of the restoration process. Proper use of this equipment is crucial in getting the job done properly.

Key Topics to Learn for Your Automotive Restoration Interview

- Vehicle History & Assessment: Understanding a vehicle’s history, identifying its make, model, and year, and conducting a thorough assessment of its condition (including rust, damage, and mechanical issues) are crucial first steps. Practical application includes documenting findings and creating a restoration plan.

- Mechanical Systems: A deep understanding of engine repair, transmission systems, braking systems, electrical systems, and suspension is vital. Practical application includes diagnosing problems, sourcing parts, and performing repairs or overseeing their execution.

- Bodywork & Paint: Mastering metalwork techniques (dent repair, panel replacement), primer application, paint preparation, and final paint finishes is essential for achieving a high-quality restoration. Practical application involves understanding different paint types, color matching, and achieving a flawless finish.

- Interior Restoration: This includes upholstery repair and replacement, carpet installation, and the restoration of interior trim pieces. Practical application involves sourcing correct materials and utilizing period-correct techniques.

- Parts Sourcing & Procurement: Knowing where to find original or reproduction parts, understanding part numbers, and managing a budget effectively is crucial. Practical application involves researching parts, negotiating prices, and managing inventory.

- Project Management & Budgeting: Successfully managing a restoration project requires strong organizational skills, attention to detail, and effective budget management. Practical application includes creating a detailed timeline, tracking expenses, and managing client expectations.

- Safety Regulations & Compliance: Understanding relevant safety regulations and compliance requirements for vehicle restoration is critical. Practical application includes ensuring the restored vehicle meets all legal standards.

Next Steps

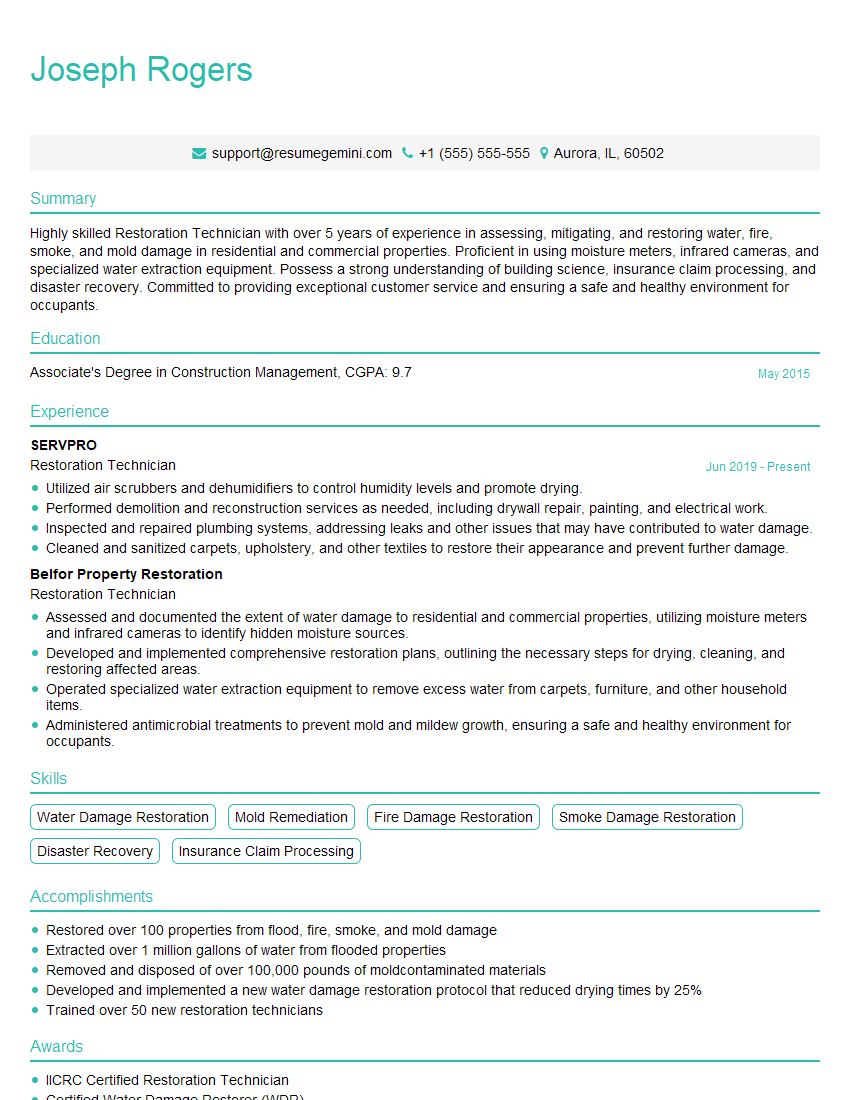

Mastering automotive restoration opens doors to a rewarding career with opportunities for growth and specialization. To maximize your job prospects, creating a strong, ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you build a professional resume that highlights your skills and experience effectively. Examples of resumes tailored to the Automotive Restoration field are available to guide you. Invest time in crafting a compelling resume – it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good