The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Avionics Component Level Repair interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Avionics Component Level Repair Interview

Q 1. Explain the process of troubleshooting a faulty avionics component.

Troubleshooting a faulty avionics component is a systematic process that combines technical knowledge with meticulous attention to detail. It begins with a thorough understanding of the system’s operational characteristics and the component’s function within that system. Think of it like diagnosing a car problem – you wouldn’t start by replacing the engine without checking simpler things first.

The process typically follows these steps:

- Symptom Identification: Precisely define the malfunction. Is it a complete failure, intermittent fault, or a degradation in performance? Document everything.

- System Review: Analyze the overall system’s health. Are other components exhibiting unusual behavior? This helps determine if the problem is isolated or part of a larger issue.

- Schematic & Diagram Review: Consult the relevant schematics and wiring diagrams to understand the component’s connections and signal paths. This is your roadmap.

- Visual Inspection: Carefully examine the component for any obvious physical damage, loose connections, or burnt components. Sometimes, a visual cue can lead you straight to the culprit.

- Testing & Measurements: Employ various testing techniques, including multimeter readings, signal tracing, and specialized avionics test equipment, to verify the component’s functionality against its specifications. Accurate measurements are crucial here.

- Fault Isolation: Use techniques like signal tracing and component substitution to pinpoint the exact faulty part. This is where experience and intuition come in handy.

- Repair or Replacement: Once the fault is identified, the component can be repaired (if feasible and permissible) or replaced with a certified equivalent.

- Verification & Testing: After repair or replacement, thoroughly test the system to ensure the problem has been resolved and the avionics system is functioning correctly and within safety limits.

For example, if a transponder is malfunctioning, I would first check for power and ground connections, then test the antenna and signal path before considering internal component failure.

Q 2. Describe your experience with different types of soldering techniques used in avionics repair.

My experience encompasses various soldering techniques crucial for avionics repair, each demanding precision and adherence to stringent quality standards. The choice of technique depends on the component’s size, type of connection, and the material being soldered. Improper soldering can lead to catastrophic failures.

- Through-hole soldering: This classic technique involves soldering leads directly into through-holes on a printed circuit board (PCB). It requires a steady hand and good control of the soldering iron temperature to prevent damage to the components or PCB.

- Surface mount technology (SMT) soldering: SMT soldering involves soldering smaller components directly onto the surface of a PCB. This requires specialized equipment like a hot air rework station for removing and replacing components, along with fine-tipped soldering irons for precise work. I’m proficient in both manual and automated SMT soldering techniques.

- Wire wrapping: This technique involves wrapping wires around terminals, providing robust and reliable connections, particularly useful in high-vibration environments often encountered in avionics. It’s critical to use the correct gauge wire and ensure the wrap is secure and consistent.

- Ultrasonic soldering: Used for delicate components or specialized alloys, ultrasonic soldering uses ultrasonic vibrations to create a strong bond without excessive heat, minimizing the risk of component damage. This technique requires specialized equipment and training.

In all cases, I meticulously adhere to the manufacturer’s instructions and use appropriate fluxes and solders approved for aerospace applications. Each solder joint is inspected under magnification to ensure a clean, strong, and reliable connection – this is paramount for flight safety.

Q 3. How do you identify and interpret schematics and wiring diagrams?

Interpreting schematics and wiring diagrams is fundamental to avionics repair. They act as blueprints, providing a visual representation of the electrical connections and signal flow within a system. Proficiency in this area is non-negotiable.

I approach this by:

- Understanding Symbols: A solid grasp of standard electronic symbols is essential. This allows quick identification of components (resistors, capacitors, transistors, integrated circuits), connectors, and other elements on the schematic.

- Tracing Signal Paths: I systematically trace signal paths from input to output, identifying all critical points and potential points of failure. I often use a highlighter to trace the specific signal path under investigation.

- Identifying Component Values: I accurately interpret component values (resistance, capacitance, inductance, etc.) to understand their function in the circuit. Incorrect interpretation here can be disastrous.

- Analyzing Circuit Topology: I determine the type of circuit (e.g., series, parallel, feedback) to understand its operational principles. This provides context for the functionality of the individual components.

- Cross-referencing Diagrams: I often cross-reference multiple diagrams – the schematic, wiring diagram, and parts lists – to get a complete picture of the system. This can be particularly crucial in complex systems.

For instance, when troubleshooting a faulty navigation system, I can utilize the schematic to trace the signal path from the GPS receiver to the display unit, identifying potential points of signal degradation or failure along the way.

Q 4. What are the common causes of failure in avionics components?

Avionics component failures stem from a variety of causes, ranging from environmental factors to manufacturing defects. Understanding these causes is vital for preventative maintenance and effective troubleshooting.

- Environmental Factors: Extreme temperatures, humidity, vibration, and electromagnetic interference (EMI) can significantly degrade components over time, leading to failure. This is particularly critical in aircraft where harsh environmental conditions are commonplace.

- Component Aging: Capacitors, resistors, and other components can degrade naturally over time due to material breakdown or drift in their electrical properties. This can lead to gradual performance deterioration or sudden failure.

- Manufacturing Defects: Manufacturing flaws, such as solder bridges, cold solder joints, or damaged components, can cause immediate or eventual failures. This highlights the importance of using certified and rigorously tested parts.

- Power Surges and Transients: Unexpected power surges or electrical transients can damage sensitive components, potentially causing immediate failure or latent issues that appear later. Proper surge protection is a crucial part of avionics system design.

- Mechanical Stress: Vibration and impact stresses from flight can damage components, particularly those with fragile connections or delicate internal structures. Proper mounting and shock absorption are essential.

Identifying the root cause is paramount for not only repairing the immediate issue but also preventing similar issues in the future. This requires careful analysis of failure modes and implementation of preventative measures.

Q 5. How do you ensure compliance with FAA regulations during component repair?

Ensuring compliance with FAA regulations is an absolute necessity in avionics component repair. This involves adhering to strict standards related to safety, quality control, and documentation. Negligence can lead to serious consequences.

Compliance is achieved by:

- Using Approved Parts: Only using parts approved by the FAA or equivalent regulatory bodies. This ensures that the replaced components meet the stringent safety and reliability requirements for aerospace applications.

- Following Repair Manuals: Strictly adhering to the manufacturer’s repair manuals and procedures. This guarantees that repairs are performed correctly and safely.

- Maintaining Accurate Records: Keeping meticulous records of all repair activities, including part numbers, serial numbers, dates, and detailed descriptions of the work performed. These records are critical for traceability and audit purposes.

- Performing Thorough Testing: Conducting comprehensive testing to ensure the repaired component functions correctly and meets all required performance standards. This involves functional tests as well as environmental testing.

- Obtaining Necessary Certifications: Holding the necessary certifications and licenses to perform the repairs, demonstrating competence and adherence to industry best practices.

- Adhering to Quality Control Procedures: Implementing rigorous quality control procedures throughout the repair process. This involves regular inspections and audits to identify and correct potential issues.

Failure to comply with these regulations can lead to serious repercussions, including grounding of aircraft, loss of certification, and potential legal liabilities.

Q 6. What experience do you have with specific avionics components such as gyros, accelerometers, or GPS receivers?

I have extensive experience working with various avionics components, including gyros, accelerometers, and GPS receivers. Each component presents unique challenges and requires specialized knowledge and tools for repair.

- Gyroscopes: I’m proficient in troubleshooting and repairing various types of gyroscopes, including rate gyros and attitude and heading reference systems (AHRS). This includes diagnosing issues related to sensor drift, bias errors, and mechanical failures. Alignment and calibration are critical aspects of gyro repair.

- Accelerometers: My experience includes working with accelerometers used in inertial navigation systems (INS) and other flight control systems. I can diagnose and repair problems related to sensor bias, scale factor errors, and noise. Testing requires specialized equipment capable of measuring minute changes in acceleration.

- GPS Receivers: I’m skilled in repairing and testing GPS receivers used for navigation and position determination. Troubleshooting issues involves checking antenna connections, signal integrity, and processing unit functionality. Knowledge of GPS signal structure and protocols is essential.

In each case, I adhere to strict quality control protocols, ensuring the repaired or replaced components meet the required specifications and performance standards before being re-integrated into the avionics system. The safety implications are too significant for anything less than perfection.

Q 7. Describe your experience with fault isolation techniques.

Fault isolation is the art of systematically identifying the root cause of a malfunction. It’s a blend of technical skills, problem-solving abilities, and experience. Imagine it as detective work, but for avionics.

My approach to fault isolation incorporates:

- Signal Tracing: Using oscilloscopes and multimeters to trace signals throughout the system, identifying points of deviation from expected behavior. This helps to narrow down the location of the fault.

- Component Substitution: Replacing suspected faulty components with known good parts to verify their functionality. This helps to isolate the specific component causing the issue.

- Logical Deduction: Using knowledge of circuit operation and component functionality to deduce the most likely cause of the fault. This involves careful consideration of the symptoms and potential failure modes.

- Systematic Elimination: Methodically eliminating possible causes one by one until the root cause is identified. This is a highly organized approach, avoiding guesswork.

- Diagnostic Software & Equipment: Utilizing specialized diagnostic software and equipment to run tests and isolate faults. This can range from simple multimeter tests to complex systems-level diagnostics.

For example, during the troubleshooting of a malfunctioning flight control system, I would use signal tracing to analyze the signals between the sensors and actuators, then utilize component substitution to verify faulty parts, ensuring a precise and efficient resolution.

Q 8. Explain your proficiency in using test equipment such as oscilloscopes, multimeters, and signal generators.

My proficiency with test equipment like oscilloscopes, multimeters, and signal generators is paramount to my work. I’m adept at using these tools not just to diagnose faults, but also to thoroughly test repaired components to ensure they meet stringent aviation standards.

For instance, using an oscilloscope, I can analyze waveforms to pinpoint issues like signal distortion or timing problems within a circuit. This is crucial when dealing with complex avionics systems where even a minor timing error can have significant consequences. I can accurately measure voltage, current, and resistance using a multimeter to identify component failures like open circuits or shorts. Finally, signal generators allow me to simulate various input signals to stress test repaired components and ensure proper functionality across a range of operating conditions.

One recent example involved a faulty air data computer. Using an oscilloscope, I observed distorted signals on the pressure sensor lines. This led me to identify a faulty capacitor causing the signal degradation. Replacing the capacitor and verifying the waveform’s return to normal using the oscilloscope confirmed the successful repair.

Q 9. How do you document your repair procedures and findings?

Thorough documentation is key to ensuring traceability and repeatability in avionics repair. My documentation meticulously follows industry best practices and regulatory requirements. It includes detailed step-by-step procedures, test results, and component part numbers. I use a combination of digital and physical records.

My digital records typically involve a comprehensive report containing images of the damaged component, schematics showing the repair location, and tables detailing test results before and after repair. This is often supplemented with software-generated reports from automated test equipment. Physical records include signed-off repair tags affixed to the repaired unit, which tracks the repair and allows for easier auditing.

Imagine a situation where a faulty transponder needs repair. My documentation would begin with a detailed description of the malfunction, including error codes. Then, the repair procedure with component replacements and associated part numbers would be clearly listed. Finally, post-repair tests, using the relevant test equipment, would be recorded showing the transponder is functioning within its specified parameters.

Q 10. Describe your experience with different types of avionics systems.

My experience encompasses a broad range of avionics systems, including but not limited to flight control systems, navigation systems (like GPS and INS), communication systems (radios and transponders), and air data computers. I’ve worked on both legacy systems using older technologies and modern systems incorporating advanced digital signal processing techniques. My work has involved various aircraft types, from small general aviation aircraft to larger commercial airliners.

For example, I’ve repaired sophisticated inertial navigation systems that rely on highly sensitive gyroscopes and accelerometers. This requires a deep understanding of the underlying physics and precise calibration techniques. I’ve also tackled problems in more commonplace systems like radio altimeters, where a thorough understanding of RF principles is essential. This diversity in experience equips me with the versatility necessary to troubleshoot and repair a vast array of avionics components.

Q 11. How do you handle situations where a repair is beyond your expertise?

When faced with a repair beyond my expertise, my first step is a thorough assessment to define the problem’s scope. This involves consulting schematics, technical manuals, and potentially, more senior engineers or specialized repair facilities.

Safety is paramount in avionics repair. Therefore, I would never attempt a repair that I’m not confident in performing correctly. Instead, I would escalate the issue to the appropriate authority, detailing my findings and recommendations. This might involve sending the component to a specialized repair center or engaging a more senior technician with the necessary expertise. Comprehensive documentation of this escalation process is, of course, also critical. Transparency and accountability are vital when dealing with safety-critical systems.

Q 12. Explain your understanding of ESD (Electrostatic Discharge) safety procedures.

ESD, or electrostatic discharge, is a significant threat to sensitive avionics components. Understanding and adhering to ESD safety procedures is non-negotiable. I’m rigorously trained in ESD control methods and consistently apply them in my work. This includes using anti-static wrist straps, conductive mats, and proper grounding techniques. All work surfaces are ESD-safe, and I regularly inspect my equipment and tools to ensure they are properly grounded.

Imagine working on a circuit board with microprocessors and memory chips. Even a small electrostatic discharge can cause latent damage, which may not be immediately apparent but could lead to catastrophic failure in flight. Therefore, using ESD-safe tools and procedures isn’t just a good practice; it’s essential to the safe operation of the aircraft.

Q 13. What is your experience with different types of circuit boards?

My experience encompasses various types of circuit boards, from simple single-layer PCBs to complex multi-layer boards with embedded components and surface-mount technology (SMT). I’m comfortable working with high-density boards and handling delicate components requiring specialized soldering techniques.

Working with different circuit board types requires adapting techniques and tools. For example, repairing surface-mount components often requires specialized soldering irons with fine tips and magnification to ensure accurate placement and avoid damage to surrounding components. Multi-layer boards require a detailed understanding of the board’s layers and tracing to accurately identify faulty components and connections. The repair approach is always tailored to the specific type and complexity of the circuit board.

Q 14. How do you ensure the quality of your repairs?

Quality assurance is paramount in avionics repair. My approach is multifaceted and ensures the repaired component meets or exceeds original specifications. This starts with a thorough diagnostic process to accurately identify the fault and proceeds with a carefully executed repair, followed by rigorous testing.

Post-repair testing uses specialized test equipment, often calibrated to industry standards, to ensure that the component functions within its defined parameters. This includes functional tests, environmental tests to check for temperature and vibration tolerance and often, burn-in tests to identify any latent failures. All test results are meticulously documented, creating a verifiable audit trail that guarantees the quality and reliability of my work. Adherence to these procedures ensures the safety and operational integrity of the avionics system.

Q 15. What is your understanding of IPC-A-610 standards?

IPC-A-610 is the globally recognized standard for the acceptability of printed boards. It defines the criteria for inspecting and accepting printed circuit boards (PCBs) across various aspects, including workmanship, visual inspection, and solder quality. Think of it as the ‘rulebook’ for ensuring a PCB is built to a high standard and will function reliably. In avionics, where reliability is paramount, adherence to IPC-A-610 is crucial. It ensures that repaired boards meet the stringent quality and safety requirements of the aerospace industry. The standard covers various aspects such as:

- Component placement and orientation: Ensuring components are correctly positioned and aligned.

- Soldering quality: Defining acceptable solder joint characteristics, including lack of bridging, cold solder joints, and proper wetting.

- Cleanliness: Specifying acceptable levels of flux residue and other contaminants.

- Visual inspection criteria: Providing detailed guidelines for identifying defects during visual examination.

Failure to adhere to IPC-A-610 can lead to board failure in flight, resulting in potentially catastrophic consequences. Therefore, it’s a critical part of our repair process.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe a challenging avionics repair you successfully completed.

One particularly challenging repair involved a faulty Air Data Computer (ADC) from a regional jet. The ADC had suffered multiple intermittent failures, making diagnosis extremely difficult. Initial testing revealed erratic sensor readings and intermittent power supply issues. We isolated the problem to a specific integrated circuit (IC) responsible for signal processing. However, this IC was surface-mount and densely packed, making it very difficult to replace without damaging surrounding components. I utilized a combination of advanced diagnostic equipment, including a high-resolution microscope and precision rework station, along with meticulous manual dexterity. I systematically removed the faulty IC using a hot air rework station, taking extreme care not to lift adjacent components. After cleaning the pads and installing the replacement IC, rigorous testing ensured the ADC operated within its specifications.

The success hinged on patience, precision, and a thorough understanding of both the ADC’s functionality and the intricacies of surface mount technology repair. The entire process took several days due to the delicate nature of the components and the necessity for extremely careful verification at each step.

Q 17. What tools and equipment are essential for avionics component level repair?

A comprehensive avionics component-level repair facility needs a diverse range of tools and equipment. The essential items can be broadly categorized:

- Diagnostic Equipment: This includes oscilloscopes, multimeters, logic analyzers, and specialized test equipment specific to the avionics components being repaired. For example, we might use a specific test set for an Air Data Computer or a dedicated programmer for certain microcontrollers.

- Rework Stations: These are crucial for removing and installing surface-mount components. Hot air rework stations, soldering irons (with various tips), and vacuum tweezers are indispensable for precise manipulation of delicate components.

- Microscopes: High-magnification microscopes are vital for inspecting fine solder joints, identifying micro-cracks, and detecting other minute defects.

- Clean Room Environment: Maintaining a clean environment is paramount to prevent contamination during repair. A clean room with appropriate air filtration is therefore essential.

- Specialized Hand Tools: This category includes precision screwdrivers, pliers, and tweezers for handling sensitive components.

- Component Identification and Datasheet Access: Accurate component identification and access to manufacturer datasheets are critical to ensure correct component replacement and repair procedures.

The specific tools and equipment will vary depending on the type of avionics component being repaired, but this list represents a core set of essentials.

Q 18. How do you stay current with advancements in avionics technology?

Staying current in the rapidly evolving field of avionics requires a multi-pronged approach:

- Industry Publications and Conferences: Regularly reading specialized publications like Aviation Week & Space Technology and attending industry conferences keeps me informed of the latest advancements and emerging technologies.

- Manufacturer Training and Webinars: Many manufacturers offer training programs and webinars on their latest products and troubleshooting techniques. Participation in these programs ensures I’m up-to-date on the specifics of the components we work with.

- Online Courses and Certifications: Online platforms offer valuable courses and certifications to enhance my knowledge and skills in specific areas of avionics repair.

- Professional Networks: Engaging with other professionals through online forums, professional organizations, and industry events provides opportunities for knowledge sharing and staying abreast of industry trends.

Continuous learning is essential in this dynamic field to maintain my expertise and ensure we utilize the best repair techniques and technologies.

Q 19. What is your experience with integrated circuits repair and testing?

My experience with integrated circuit (IC) repair and testing is extensive. I’ve worked on a wide range of ICs, from simple logic gates to complex microprocessors and memory chips. The repair process typically involves:

- Fault Isolation: Using diagnostic tools to pinpoint the malfunctioning IC.

- Component Removal and Replacement: Employing appropriate rework techniques to remove the faulty IC and install a new one, ensuring proper soldering and minimizing stress on surrounding components.

- Testing and Verification: Rigorous testing using specialized equipment to verify the functionality of the repaired circuit and the overall system.

Testing of ICs often includes functional testing, using dedicated testers to verify the functionality of the pins, and parametric testing, measuring the electrical characteristics of the device to make sure it’s within its specifications. Dealing with surface mount devices (SMD) ICs requires specialized expertise and equipment, as damage to neighboring components is a significant risk. I’m highly skilled in managing this risk and utilizing the necessary tools and techniques.

Q 20. Describe your experience with power supply repair in avionics systems.

Power supply repair in avionics systems requires a deep understanding of electronics, safety regulations, and the specific characteristics of aircraft power systems. My experience spans several areas, including:

- Troubleshooting: Isolating faults using oscilloscopes, multimeters, and specialized power supply testers. This often involves analyzing voltage, current, and frequency characteristics.

- Component-Level Repair: Replacing faulty components such as capacitors, transistors, diodes, and integrated circuits within the power supply circuitry. This often requires precision soldering and desoldering skills.

- Board-Level Repair: Repairing damaged traces and vias on the power supply PCB using appropriate techniques.

- Testing and Verification: Testing the repaired power supply under load to verify its output voltage, current, and ripple characteristics, ensuring it meets the stringent requirements of the aircraft system.

Safety is paramount in power supply repair. All work is done in accordance with relevant safety standards and procedures to prevent electric shock and potential damage to other system components. Any repaired power supply undergoes thorough testing before re-integration into the aircraft to ensure safe and reliable operation.

Q 21. How do you handle working under pressure and strict deadlines?

Working under pressure and strict deadlines is a regular part of this job. I manage this by implementing several key strategies:

- Prioritization and Time Management: I meticulously prioritize tasks based on urgency and complexity. Utilizing project management tools and techniques helps ensure efficient allocation of time and resources.

- Effective Communication: Maintaining clear and concise communication with supervisors and colleagues is crucial to manage expectations and address any potential roadblocks promptly.

- Methodical Approach: I adopt a structured and methodical approach to repair tasks, ensuring each step is executed accurately and efficiently. This prevents errors and reduces the need for rework.

- Stress Management Techniques: I utilize stress-management techniques such as regular breaks, deep breathing exercises, and maintaining a positive work-life balance to prevent burnout and maintain focus under pressure.

My experience has taught me that a calm and systematic approach is the most effective way to handle high-pressure situations and meet stringent deadlines while ensuring the highest quality of work.

Q 22. Explain your understanding of the different types of connectors used in avionics?

Avionics connectors are critical for ensuring reliable signal transmission and power distribution within aircraft systems. They must withstand extreme conditions like vibration, temperature fluctuations, and potential exposure to fluids. Several connector types are commonly used, each chosen based on specific application needs.

- Circular Connectors: These are robust and often used for high-current applications or where environmental sealing is crucial. Examples include MIL-DTL-38999 and similar military-spec connectors. They offer excellent protection against harsh environments. I’ve extensively worked with these during repairs on flight control systems.

- Rectangular Connectors: These are frequently employed for data busses and digital signals. They may have a higher pin count than circular connectors, facilitating more complex signal routing. Specific examples include D-Subminiature connectors and various proprietary designs. I’ve used these often in repairing aircraft communication systems.

- Fiber Optic Connectors: For high-bandwidth data transmission, fiber optic connectors are essential. SC, ST, and LC connectors are examples I’ve used, particularly in modern aircraft where data rates are very high. Careful cleaning and alignment are critical for ensuring reliable signal integrity.

- Coaxial Connectors: Used for RF and microwave signals, these connectors ensure impedance matching for minimal signal loss. Examples include BNC, TNC, and SMA connectors, crucial for components such as transponders and radar systems. Improper connection can lead to significant signal degradation.

Selecting the right connector for a particular application requires a thorough understanding of the signal characteristics, environmental conditions, and reliability requirements. A wrong choice can lead to costly failures or even safety hazards.

Q 23. What is your experience with conformal coating and its application in avionics?

Conformal coating is a protective layer applied to printed circuit boards (PCBs) and other electronic components to enhance their reliability in harsh environments. In avionics, this is crucial due to the extreme conditions experienced during flight.

My experience includes applying various types of conformal coatings, including acrylics, urethanes, and silicones, each offering unique properties like flexibility, temperature resistance, and chemical resistance. The selection process depends on factors like operating temperature, humidity, and the specific chemicals the component might be exposed to.

The application process itself is quite meticulous and requires careful attention to detail. Improper application can lead to pinholes, which compromise the protection, or to coating buildup, which can hinder functionality. I’ve used both spray and brush application techniques depending on the complexity of the PCB. Before coating, thorough cleaning is vital to ensure the coating adheres properly. After application, curing the coating according to the manufacturer’s specifications is essential to achieve the desired protection level.

One instance I recall vividly involved repairing a flight control computer where a faulty conformal coating had led to a short circuit. After carefully removing the old, damaged coating, cleaning the board meticulously, and applying a new layer according to strict procedure, we restored full functionality. The whole process emphasized the importance of proper technique in avoiding future failures.

Q 24. How do you interpret component datasheets and specifications?

Component datasheets and specifications are the bible for avionics technicians. They provide critical information on a component’s characteristics, operating parameters, and environmental limits. My experience involves interpreting these documents to ensure that a component meets the required standards for its application within an aircraft system.

I approach interpreting datasheets systematically: First, I identify the key parameters like operating voltage, current draw, power dissipation, and temperature range. Then, I compare these values to the actual operating conditions within the aircraft system to ensure compatibility. Next, I check for any relevant certifications or approvals, especially those pertaining to aviation standards like DO-160 or other relevant industry specifications. This step is crucial for ensuring airworthiness.

For example, when repairing a power supply unit, I would meticulously examine the datasheet for information on the input voltage range, output voltage, efficiency, and protection mechanisms. Any deviation from these specifications could indicate a potential fault. Matching these specifications to the system requirements helps me select the right replacement part and avoid cascading failures.

Often, I also refer to the manufacturer’s application notes and troubleshooting guides for additional context. These guides often contain valuable hints on common problems and their solutions, shortening my debugging process and ensuring correct repair procedures.

Q 25. Describe your experience with different types of soldering irons and their applications.

Soldering is a fundamental skill in avionics repair. The choice of soldering iron depends on the type of components and the required precision. I’ve worked with a variety of soldering irons over the years.

- Pencil Irons: These are versatile and commonly used for general-purpose soldering. Their temperature is easily adjustable, allowing for precise control during the soldering process. I regularly use these for working with through-hole components and smaller surface-mount components.

- Temperature-Controlled Soldering Stations: These offer much finer control over the soldering iron’s temperature, a crucial factor in soldering sensitive surface-mount components. The ability to preset the temperature is essential for avoiding damage to components. They are vital for intricate repairs and delicate work.

- Hot Air Rework Stations: Used for removing surface-mount components or for reflowing solder, these stations utilize heated air to efficiently remove or apply solder. I frequently use this tool for removing integrated circuits and other surface mount devices without causing damage.

Proper soldering technique is critical to ensure a reliable and durable joint. This involves using the correct amount of solder, ensuring sufficient heat, and avoiding overheating components. I also emphasize the importance of using appropriate fluxes to aid in the soldering process and cleaning the joint after soldering to remove any flux residue.

For instance, I recently had to replace a surface mount capacitor on a very dense PCB. Using a temperature-controlled station with a fine-tipped iron, and careful use of flux, I avoided damaging the surrounding components – a testament to the impact of using the right tool and possessing precise soldering skills.

Q 26. How do you maintain a clean and organized workspace?

Maintaining a clean and organized workspace is paramount for efficient and safe avionics repair. A cluttered workspace increases the risk of errors, damage to components, and even workplace injuries. My approach emphasizes a structured workflow and preventative measures.

My workspace is organized using a modular system. I have designated areas for tools, components, work-in-progress, and completed repairs. Tools are organized according to type and frequency of use. Components are stored in labeled containers or anti-static bags to prevent damage and static discharge. I use a magnetic mat to hold small screws and other easily lost parts, and I always clean my workspace before and after each repair.

Furthermore, I utilize anti-static mats and wrist straps to protect sensitive electronic components from electrostatic discharge (ESD). Regular cleaning with appropriate solvents helps remove any flux residue or contaminants from tools and work surfaces. This helps prevent potential short circuits, component damage, and ensures optimal soldering quality.

The 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain) guides my organization. It’s not just about tidiness, but a framework to consistently improve efficiency and reduce errors. A clean workspace directly translates to improved accuracy and reduced repair times, leading to better overall quality of the repair and increased safety.

Q 27. Explain your understanding of the importance of traceability in avionics repair.

Traceability in avionics repair is non-negotiable for safety and regulatory compliance. It ensures that every action taken during the repair process is documented, allowing for a complete audit trail. This is vital for tracking the history of a component, verifying its airworthiness, and ensuring accountability for repairs.

My experience emphasizes the importance of meticulously documenting each step. This includes recording the component’s serial number, the type of repair performed, the date and time of the repair, the technician’s identification, and the parts used. All this information is typically recorded using detailed work orders and/or electronic tracking systems. Often we utilize barcodes or RFID tags to automate tracking and minimize manual data entry.

Consider a scenario where a repaired component needs to be traced back. The documentation allows us to immediately identify the technicians involved, the procedures followed, and the parts used. This is especially crucial if there is a later issue, allowing for a thorough investigation without guesswork. Accurate traceability significantly reduces the risk of a repeat failure, helps to improve repair processes, and greatly aids in compliance audits.

Maintaining complete traceability is more than just record-keeping. It’s a commitment to safety and a reflection of professionalism. The consequences of poor traceability can be catastrophic, so it’s always a top priority in our repair processes.

Q 28. What is your experience with using specialized software for avionics diagnostics?

Specialized software plays a significant role in modern avionics diagnostics and repair. I have experience using various diagnostic tools and software packages, including those provided by the original equipment manufacturers (OEMs).

These software packages often provide detailed schematics, component information, and diagnostic routines. They allow me to isolate faults more effectively, interpret error codes, and access component-level information without needing to consult multiple manuals. This significantly reduces diagnosis time and improves repair efficiency.

For example, I’ve used software that allows for in-circuit testing of various components, identifying potential faults early in the repair process. Other software packages provide interactive troubleshooting guides, walking me through various diagnostic steps. This is particularly beneficial when dealing with complex systems.

Data logging and analysis capabilities are also valuable features. Some software packages can record operational parameters of the system, helping to identify recurring issues or trends. This proactive approach to problem-solving is critical in ensuring the long-term reliability of the repaired system. These software tools aren’t just diagnostic aids; they’re integral parts of a modern, efficient, and safe avionics repair workflow.

Key Topics to Learn for Avionics Component Level Repair Interview

- Digital Circuit Analysis: Understanding digital logic gates, Boolean algebra, and troubleshooting digital circuits within avionics systems. Practical application: Diagnosing faults in a faulty flight control computer.

- Analog Circuit Analysis: Proficiency in analyzing and troubleshooting analog circuits, including operational amplifiers, filters, and signal conditioning circuits. Practical application: Repairing a malfunctioning altimeter.

- Power Supply Design and Repair: Knowledge of various power supply topologies and their applications in avionics systems. Understanding power supply regulation, protection circuits, and troubleshooting techniques. Practical application: Fixing a faulty power supply in a navigation system.

- Soldering and Desoldering Techniques: Mastery of surface mount technology (SMT) soldering and desoldering techniques, including rework and repair of delicate components. Practical application: Replacing a damaged integrated circuit on a flight instrument panel.

- Schematic Reading and Interpretation: Ability to read and interpret complex avionics schematics and identify component locations, signal paths, and interconnections. Practical application: Tracing a signal to identify a fault in a communication system.

- Troubleshooting and Diagnostics: Employing systematic troubleshooting methodologies, using test equipment (e.g., oscilloscopes, multimeters) to isolate and repair faults. Practical application: Diagnosing intermittent faults in a transponder.

- Avionics Regulations and Standards: Familiarity with relevant aviation regulations and industry standards (e.g., FAA, EASA) impacting repair procedures and documentation. Practical application: Ensuring compliance with safety regulations during component repair.

- Component Identification and Selection: Ability to identify and select appropriate replacement components, understanding datasheets and component specifications. Practical application: Sourcing and replacing a faulty integrated circuit with the correct part number.

Next Steps

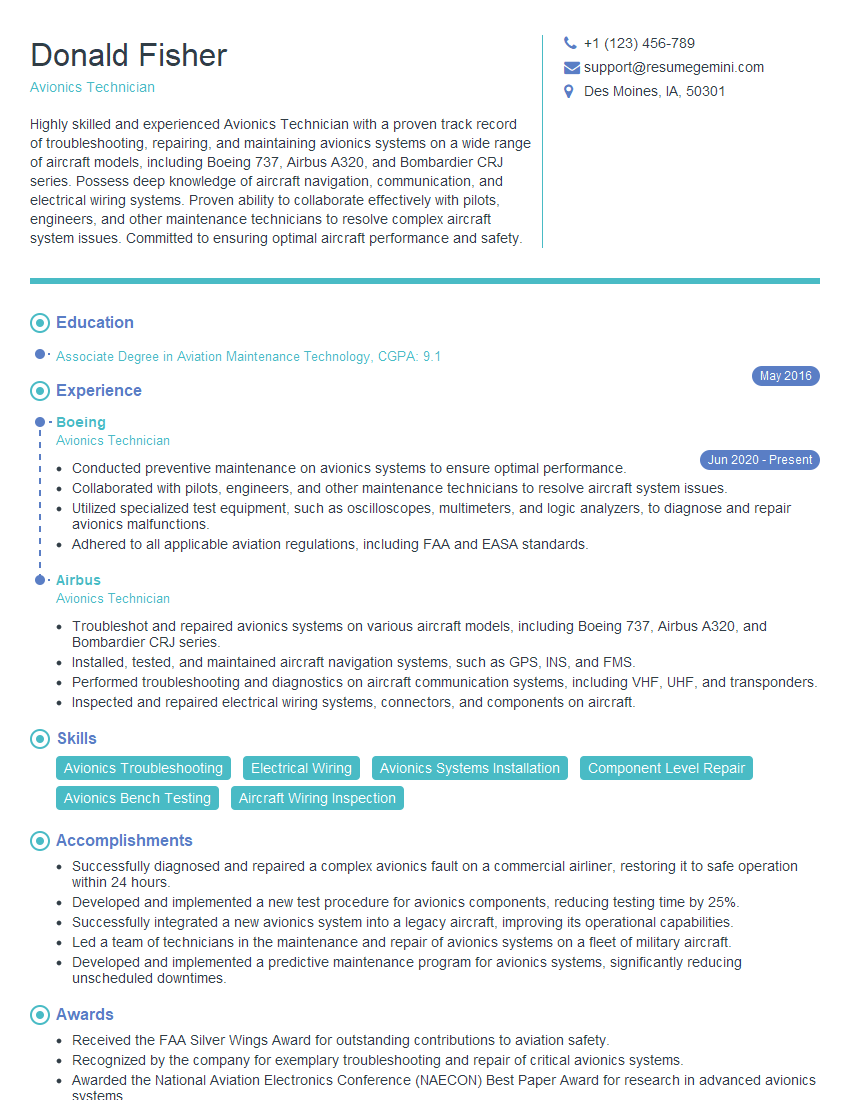

Mastering Avionics Component Level Repair opens doors to a rewarding career with excellent growth potential within the aerospace industry. To maximize your job prospects, crafting an ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional and impactful resume, ensuring your skills and experience shine. Examples of resumes tailored to Avionics Component Level Repair are available to help guide you. Invest in your future and create a resume that reflects your expertise!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good