Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Avionics Maintenance and Modification interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Avionics Maintenance and Modification Interview

Q 1. Explain the process of troubleshooting an avionics system malfunction.

Troubleshooting an avionics system malfunction is a systematic process that requires a methodical approach. It’s like solving a detective mystery, where you gather clues to pinpoint the problem. The process typically begins with a thorough understanding of the reported malfunction. This involves documenting the symptoms, such as intermittent failures, complete system outages, or specific error messages displayed on the system’s indicator panels.

- Gather Information: The first step involves gathering all relevant information, including the aircraft type, system involved, the nature of the malfunction, and any preceding events. Pilot reports and maintenance logs are invaluable resources. For example, if the malfunction is a GPS navigation problem, you need to check the pilot’s reported issues – was there a loss of signal, inaccurate readings or a complete failure?

- Visual Inspection: A visual inspection of the affected avionics bay is often the next step. Look for loose connections, damaged wiring, or signs of overheating. This is akin to looking for obvious damage at the crime scene.

- System Tests: Built-in test equipment (BITE) provides initial diagnostic information. For instance, many transponders have internal tests that indicate a specific faulty component. Following the BIT guidance will often isolate the issue rapidly. We also utilize external test sets, such as signal generators and spectrum analyzers, to further isolate faults and confirm functionality.

- Schematic Diagrams and Troubleshooting Manuals: These are the keys to understanding the avionics system. They offer detailed information on the system’s architecture and common failure points, providing a roadmap for diagnosis. These act as the case files in our investigation.

- Component Replacement/Repair: After isolating the faulty component, it is either replaced (following strict procedures and utilizing only approved parts) or repaired, if feasible, according to the manufacturer’s instructions and relevant maintenance manuals. This is the ‘arrest and conviction’ stage of our investigation.

- Verification and Documentation: After repair or replacement, the system must be thoroughly tested to verify proper functionality. All maintenance performed is rigorously documented to maintain compliance with regulatory requirements. This forms our detailed case file for future reference.

For example, if a transponder is malfunctioning, I’d start by checking the power supply, signal integrity, and antenna connections. If these are all sound, I would then use specialized test equipment to probe deeper into the system’s functionality.

Q 2. Describe your experience with different avionics testing equipment.

My experience encompasses a wide range of avionics testing equipment. This includes both built-in test equipment (BITE) found within the avionics units themselves, and external test sets used for more comprehensive diagnostics. I am proficient in using:

- Multimeters: Essential for basic electrical measurements like voltage, current, and resistance.

- Oscilloscope: Used for analyzing analog and digital signals, helping to identify intermittent faults or signal integrity issues.

- Signal Generators: Crucial for simulating inputs to avionics systems and observing their responses, for example, testing the signal path of a GPS receiver.

- Spectrum Analyzers: Used for evaluating radio frequency signals, verifying transponder operation, and identifying interference issues.

- Aircraft Specific Test Sets: Many airframes have dedicated test sets designed to interface with specific avionics systems, providing detailed diagnostic capabilities.

- Specialized Software: Modern avionics often rely on sophisticated software for diagnostics and data logging. I have experience with various software packages, including those specific to different manufacturers’ avionics systems.

For instance, during a recent troubleshooting of a GPS receiver, I used a spectrum analyzer to confirm signal strength and identify potential interference, and an oscilloscope to inspect the timing signals and data output.

Q 3. How familiar are you with FAA regulations and maintenance documentation?

I am extremely familiar with FAA regulations, particularly those related to Part 43 (Maintenance, Preventive Maintenance, and Rebuilding) and Part 145 (Repair Stations). I understand the importance of adhering to these regulations and maintaining meticulous documentation. My experience involves:

- Compliance with ADs (Airworthiness Directives): I have a thorough understanding of ADs and their implications for avionics maintenance. I know how to correctly implement the ADs and document the required actions.

- Maintenance Records: I maintain accurate and detailed maintenance records, ensuring compliance with FAA requirements. This includes using approved forms and adhering to strict documentation procedures. This is crucial for demonstrating airworthiness and for tracing the history of any modifications or repairs.

- Interpreting Technical Publications: I am adept at interpreting complex technical publications, such as maintenance manuals, service bulletins, and manufacturer’s instructions. I can easily locate relevant sections and follow the procedures accurately and safely.

- Understanding Airworthiness Certificates: I have a good understanding of aircraft airworthiness certificates and how avionics maintenance impacts their validity.

For example, I have successfully managed the implementation of several Airworthiness Directives, ensuring that the required modifications were carried out flawlessly and documented meticulously, thus maintaining the aircraft’s airworthiness.

Q 4. What are your troubleshooting skills when dealing with complex avionics systems?

Troubleshooting complex avionics systems requires a blend of technical expertise, logical reasoning, and systematic problem-solving. I employ a multi-pronged approach:

- Structured Approach: I follow a step-by-step process, starting with the simplest checks and progressively moving towards more complex diagnostics. This prevents overlooking obvious problems and ensures efficient troubleshooting.

- Data Analysis: I meticulously analyze all available data, including system logs, error messages, and pilot reports, to identify patterns and clues that point towards the root cause. I am proficient in interpreting digital data logs to find subtle anomalies that may indicate problems.

- Isolation Techniques: I utilize various isolation techniques to pinpoint the faulty component or subsystem. This may involve disconnecting parts of the system to see how it affects the overall functionality.

- Knowledge of System Architecture: A deep understanding of the avionics system architecture is crucial. This allows me to anticipate the effects of potential failures and effectively isolate the source of the problem.

- Resourcefulness: I am resourceful and can adapt my troubleshooting methods based on the specific situation and available resources. This is especially important when dealing with unfamiliar systems or limited resources.

For instance, when troubleshooting a complex communication system failure, I used data analysis from the system’s logs to isolate the problem to a specific network interface card, rather than replace the whole system prematurely.

Q 5. Explain your experience with different types of avionics systems (e.g., GPS, transponders, radar).

My experience spans a variety of avionics systems, including:

- GPS (Global Positioning System): I have extensive experience working with GPS receivers, understanding their principles of operation, and troubleshooting signal acquisition, accuracy, and integrity issues.

- Transponders: I am familiar with various types of transponders (Mode S, ADS-B) and their operational characteristics. I have experience in troubleshooting transponder malfunctions, including antenna issues and internal component failures.

- Radars (Weather and Terrain): I understand radar principles and have experience working with weather and terrain avoidance radars, including their calibration, maintenance, and troubleshooting of signal processing units.

- Communication Systems: I possess extensive experience working with communication systems, including VHF radios, HF radios, and satellite communication systems. I am familiar with their maintenance, testing, and troubleshooting.

- Autopilots: I have experience working with autopilots, including their calibration, maintenance, and testing. I understand their interface with other flight control systems.

- Flight Management Systems (FMS): I have experience troubleshooting complex Flight Management Systems, including understanding the software and hardware interaction of this system.

In a real-world example, I recently worked on a situation where a faulty GPS antenna resulted in inaccurate navigation data. By utilizing specialized testing equipment, I successfully identified the faulty antenna, leading to its swift replacement and restoring accurate GPS functionality.

Q 6. Describe your experience with avionics system installations and modifications.

I have significant experience with avionics system installations and modifications. This includes:

- Installation Procedures: I am proficient in following installation manuals and adhering to strict wiring diagrams and procedures to ensure proper system integration and functionality.

- Wiring and Cabling: I am skilled in aircraft wiring techniques, including proper routing, termination, and shielding to avoid interference and ensure signal integrity. This includes using specialized tools and techniques to ensure reliable and safe connections.

- Testing and Verification: After an installation or modification, I conduct comprehensive testing and verification to ensure that the system operates as designed and meets all regulatory requirements. This includes rigorous functional and performance testing.

- Modification Kits: I have experience working with various modification kits, following manufacturer’s instructions, and ensuring compliance with regulatory standards.

- Documentation: All installations and modifications are meticulously documented, with accurate records maintained throughout the entire process. This documentation includes details of the work performed, parts used, and test results.

For example, I recently participated in the installation of a new weather radar system on a regional jet. I meticulously followed the manufacturer’s installation manual, ensuring all wiring was properly routed and terminated, and then conducted extensive testing to verify the system’s performance before the aircraft returned to service.

Q 7. How do you ensure compliance with safety regulations during avionics maintenance?

Ensuring compliance with safety regulations during avionics maintenance is paramount. My approach incorporates several key elements:

- Adherence to FAA Regulations: I strictly adhere to all applicable FAA regulations, including Part 43 and Part 145. This includes following approved procedures, using certified parts, and maintaining accurate and detailed records.

- Proper Use of Tools and Equipment: I use only approved tools and test equipment, ensuring they are properly calibrated and maintained. This prevents accidental damage and ensures accurate measurements and diagnoses.

- Safety Procedures: I strictly follow all safety procedures, including the use of proper personal protective equipment (PPE), grounding techniques, and lockout/tagout procedures to prevent electrical shocks or accidental damage. Safety is always my top priority.

- Quality Control: I meticulously perform quality control checks at each stage of the maintenance process. This helps prevent errors and ensures that the work meets the highest standards of quality and safety. This includes multiple checks and verification of work completed.

- Continuous Learning: I stay current with the latest FAA regulations and industry best practices through continuous professional development. This keeps my knowledge and skills up-to-date and allows me to effectively apply them to enhance safety measures.

For example, I always utilize lockout/tagout procedures before commencing any electrical work on the aircraft’s avionics system to prevent accidental energizing during maintenance and thus protect myself and others from potential harm.

Q 8. What is your experience with aircraft wiring diagrams and schematics?

Aircraft wiring diagrams and schematics are the blueprints of an aircraft’s electrical system. They’re crucial for understanding the complex network of wires, connectors, and components. My experience spans over 10 years, working with various aircraft types, from small general aviation planes to large commercial airliners. I’m proficient in interpreting both simple and highly complex schematics, identifying wire gauges, connector types, and circuit functions. For instance, I recently used a schematic to troubleshoot an intermittent fault in the GPS navigation system of a Cessna 172. By carefully tracing the wiring diagram, I pinpointed a loose connection in the power distribution bus, resolving the issue quickly and safely.

I’m familiar with both paper-based diagrams and digital versions using software like AutoCAD and specialized avionics design software. Understanding these schematics is not simply about reading lines and symbols; it’s about visualizing the electrical flow and anticipating potential problems before they occur.

Q 9. Explain your experience with using diagnostic software for avionics systems.

Diagnostic software is indispensable in modern avionics maintenance. My experience includes using various proprietary and open-source diagnostic tools, such as those provided by manufacturers like Honeywell and Rockwell Collins. I’m comfortable using these tools to perform fault isolation, data logging, and system testing. For example, I used a built-in diagnostic system on an Airbus A320 to pinpoint a malfunctioning air data computer. The system provided specific error codes and logged relevant sensor data, which allowed for precise diagnosis and efficient repair.

Furthermore, my expertise extends to interpreting the diagnostic data and correlating it with the relevant wiring diagrams and technical publications to determine the root cause of the problem. This involves understanding the various communication protocols and data formats used within the avionics system. I’m also experienced in utilizing specialized test equipment in conjunction with diagnostic software to validate repairs and ensure system integrity.

Q 10. How do you handle unexpected issues during an avionics repair?

Unexpected issues are a common occurrence in avionics repair. My approach involves a systematic and methodical troubleshooting process. First, I prioritize safety and ensure the aircraft remains secured. Next, I thoroughly document the unexpected issue, including the initial symptoms, relevant system indicators, and any immediate actions taken. This documentation forms the basis of my troubleshooting investigation.

Then I systematically review all relevant documentation: maintenance manuals, wiring diagrams, and service bulletins. I use diagnostic tools to gather data, narrowing down potential causes. If the problem remains unresolved, I consult with senior technicians or engineers, leveraging their expertise. Finally, I document all troubleshooting steps and the implemented solution. A recent example involved an unexpected power surge that affected several avionics systems. Through careful analysis and cross-referencing the data from multiple diagnostic tools, I traced the surge to a faulty power regulator, a problem that wasn’t initially apparent. This systematic approach prevented further damage and ensured a safe return to service.

Q 11. Describe your experience with performing preventative maintenance on avionics systems.

Preventative maintenance is crucial for ensuring the reliable operation of avionics systems. My experience includes performing a wide range of preventative maintenance tasks, such as inspections, cleaning, and lubrication of connectors, and conducting functional tests of various components. These tasks adhere strictly to the manufacturer’s recommendations and maintenance schedules, as outlined in the aircraft’s maintenance manual.

A typical preventative maintenance task would be inspecting the avionics bay for signs of corrosion, loose connections, or damaged wiring. This also involves verifying the proper operation of cooling systems and ensuring adequate ventilation. I’m meticulous in recording every inspection and maintenance action, ensuring complete traceability and compliance with regulatory requirements. Regular preventative maintenance significantly reduces the likelihood of unexpected failures and enhances the overall operational safety and reliability of the aircraft.

Q 12. How familiar are you with different types of avionics components?

My familiarity with avionics components is extensive. I’ve worked with a wide range of components, including:

- Navigation systems: GPS receivers, VOR/ILS receivers, inertial navigation systems

- Communication systems: VHF/UHF radios, transponders, satellite communication systems

- Flight management systems (FMS): Flight computers, navigation displays, and associated hardware

- Displays: Primary flight displays (PFDs), multi-function displays (MFDs), and electronic flight instrument systems (EFIS)

- Sensors: Air data computers, altimeters, and various sensors feeding the flight control system

- Power supplies: Transformers, inverters, and battery systems

This broad understanding allows me to quickly assess problems and determine effective repair strategies. Understanding the specific functionality and limitations of each component is vital for safe and efficient maintenance.

Q 13. Explain your understanding of avionics system architecture.

Avionics system architecture is essentially a complex network of interconnected components working together to provide vital information and control functions. My understanding includes knowledge of the different levels of the system architecture, from sensors and transducers at the bottom, through data processing and communication buses in the middle, to displays and control interfaces at the top. I understand the data flow between these different layers and the protocols that govern the communication between them (e.g., ARINC 429, Ethernet).

Understanding this architecture allows for efficient troubleshooting. For example, a problem in a specific component can be isolated and addressed without affecting the entire system. I understand the importance of redundancy and fail-operational designs that provide backup systems to ensure safety in case of failure. This knowledge is critical for ensuring the safety and reliability of aircraft avionics.

Q 14. How do you maintain accurate and detailed maintenance logs?

Maintaining accurate and detailed maintenance logs is paramount in avionics maintenance. It ensures traceability, accountability, and compliance with regulatory requirements. I utilize both electronic and paper-based logbooks, ensuring that all entries are made promptly and include all the necessary information, such as the date, time, type of maintenance performed, parts used (with serial numbers), and the technician’s signature.

Furthermore, I maintain a consistent and standardized format for my entries, making them easy to read and interpret. For electronic logbooks, I ensure the system’s security and data integrity, making regular backups to prevent data loss. Accurate maintenance logs are critical for tracking the aircraft’s maintenance history, ensuring compliance with regulatory standards, and for facilitating future maintenance and repairs.

Q 15. Describe your experience with working on different aircraft types.

Throughout my career, I’ve had the privilege of working on a diverse range of aircraft, from light single-engine aircraft like Cessnas to complex airliners such as Boeing 737s and Airbus A320s. This experience has provided me with a comprehensive understanding of different avionics systems, maintenance procedures, and troubleshooting techniques specific to each aircraft type. For instance, working on a Cessna 172 exposed me to the intricacies of basic analog systems, while working on a Boeing 737 required mastery of sophisticated integrated digital avionics suites. This broad experience allows me to adapt quickly to new aircraft models and systems, readily identifying similarities and differences to optimize efficiency and effectiveness.

For example, while the basic principles of troubleshooting a faulty transponder remain the same across different aircraft, the specific diagnostic procedures, access panels, and associated documentation vary significantly. My experience allows me to quickly navigate these differences and efficiently resolve issues.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with interpreting technical manuals and service bulletins?

Interpreting technical manuals and service bulletins is fundamental to my work. I’m proficient in deciphering complex schematics, wiring diagrams, and maintenance procedures outlined in these documents. My approach involves a multi-step process: first, I meticulously review the relevant sections to understand the problem or modification. Then, I cross-reference the information with the aircraft’s specific configuration and serial number to ensure applicability. Finally, I meticulously follow the prescribed steps, documenting each action taken.

Imagine a service bulletin detailing a modification to a GPS receiver. I’d first identify the aircraft’s specific model and its current GPS system. Then, I would follow the step-by-step instructions, ensuring I have the correct tools and parts. The process includes verifying the installation, testing the functionality, and documenting the completed work in accordance with regulatory requirements. I also pay close attention to any safety precautions or potential hazards detailed in the manual.

Q 17. How do you prioritize tasks during a busy maintenance schedule?

Prioritizing tasks during a busy maintenance schedule is crucial for efficient workflow and timely aircraft turnaround. My approach combines urgency, safety, and regulatory compliance. I utilize a system that prioritizes tasks based on several factors:

- Safety-critical issues: Items that directly impact flight safety, such as malfunctions in critical systems (flight controls, engines), take precedence.

- Airworthiness directives (ADs): These mandatory actions issued by aviation authorities must be completed within the specified timeframe.

- Scheduled maintenance: Tasks based on the aircraft’s maintenance program, flight hours, or calendar time are also prioritized.

- Operational needs: Urgent requests from flight operations or customers are considered within the context of safety and regulatory compliance.

I employ tools like maintenance tracking software to manage the workflow visually, ensuring transparency and accountability. This structured approach minimizes delays and ensures efficient use of resources.

Q 18. Describe your experience with communicating technical information to non-technical personnel.

Communicating technical information effectively to non-technical personnel is a critical skill. My approach focuses on simplifying complex technical jargon into easily understood language, using clear analogies and visual aids where appropriate. Instead of saying ‘the yaw damper actuator exhibited intermittent signal attenuation,’ I might explain: ‘Sometimes, the system that helps stabilize the aircraft during turns wasn’t working correctly.’

For example, when explaining a repair to a pilot, I’d highlight the impact on flight safety and the improved performance following the maintenance. When communicating with a customer, I’d focus on the overall functionality and the cost-effectiveness of the work done. Active listening and tailoring my communication style to the audience’s level of understanding are key to successful communication.

Q 19. How do you stay current with the latest advancements in avionics technology?

Staying current with the latest advancements in avionics technology is paramount. I actively engage in several methods to achieve this. I subscribe to industry journals and publications, attend workshops and conferences, participate in online forums and webinars, and actively seek out training courses offered by manufacturers and industry organizations.

For example, I recently completed a training course on the latest generation of ADS-B systems. Moreover, I maintain professional memberships with organizations that provide access to the latest updates and research in the field, furthering my professional development and keeping my knowledge relevant and up-to-date.

Q 20. What is your approach to problem-solving in avionics maintenance?

My problem-solving approach in avionics maintenance follows a systematic process:

- Problem definition: Clearly identifying the symptoms and gathering all available data is the first step. This includes reviewing maintenance logs, flight data, and conducting initial visual inspections.

- Hypothesis formation: Based on the initial assessment, I develop possible causes for the malfunction.

- Testing and verification: I systematically test each hypothesis, using appropriate diagnostic tools and procedures. This might involve checking wiring diagrams, using multimeters, or accessing built-in test equipment (BITE).

- Solution implementation: Once the root cause is identified, I implement the necessary repair or replacement, adhering to all safety protocols and regulatory requirements.

- Verification and documentation: After implementing the solution, I thoroughly test the system to verify its functionality and meticulously document all steps taken in the maintenance log.

This structured approach allows me to efficiently and effectively resolve avionics issues, minimizing downtime and ensuring aircraft safety.

Q 21. How do you ensure the quality of your work in avionics maintenance?

Ensuring the quality of my work involves meticulous attention to detail and adherence to strict industry standards. This includes several key aspects:

- Following procedures: I strictly adhere to the manufacturer’s maintenance manuals and service bulletins, following each step precisely.

- Using calibrated tools: All tools and test equipment used are properly calibrated and maintained to ensure accurate readings and measurements.

- Thorough testing: After completing any repair or maintenance task, I thoroughly test the system to ensure its proper functionality before returning the aircraft to service.

- Documentation: All maintenance work is meticulously documented in accordance with regulatory requirements, providing a clear and accurate record of the procedures followed.

- Quality checks: I conduct self-checks at various stages of the process and, when applicable, seek peer review to ensure the quality and accuracy of my work.

My commitment to quality is unwavering because it directly impacts the safety and reliability of the aircraft.

Q 22. Describe your experience with working in a team environment.

Teamwork is paramount in avionics maintenance, where complex tasks often require diverse skill sets. In my previous role at [Company Name], I consistently collaborated with engineers, technicians, and supervisors to troubleshoot and resolve intricate system failures. For instance, during a critical engine sensor malfunction, I worked alongside an electrical engineer to isolate the fault using specialized diagnostic equipment, while another technician coordinated the necessary parts replacement. Effective communication, active listening, and mutual respect were key to our success. We utilized a structured problem-solving methodology, assigning specific roles and responsibilities while maintaining open channels for updates and feedback. This collaborative approach ensured timely repairs and minimized aircraft downtime.

- Developed strong communication skills to effectively coordinate with multidisciplinary teams.

- Contributed to a collaborative environment that fostered problem-solving and efficient workflow.

- Successfully managed team dynamics to meet tight deadlines and complex project demands.

Q 23. Explain your experience with using specialized tools and equipment in avionics maintenance.

My experience encompasses a wide range of specialized tools and equipment, from sophisticated diagnostic software to precision hand tools. I’m proficient in using test equipment such as oscilloscopes, multimeters, and signal generators for diagnosing electrical and electronic faults within avionics systems. I’m also experienced in handling specialized tools for removing and installing components such as fiber optic connectors, pneumatic actuators, and integrated circuit boards. For example, during the maintenance of a flight control system, I used a specialized calibration tool to ensure accurate alignment and performance after repair. Safety is always the utmost priority. I’m rigorously trained and certified in the proper handling, maintenance, and calibration of all equipment I use.

- Proficient in the use of advanced diagnostic software and hardware, such as [mention specific software/hardware e.g., Avionics Maintenance Software, specific oscilloscope model].

- Expert in the safe handling and operation of specialized tools for avionics maintenance and repair.

- Experienced in calibration and maintenance of test equipment to ensure accurate and reliable measurements.

Q 24. How do you handle pressure and deadlines in a fast-paced environment?

The avionics maintenance environment is inherently fast-paced, often demanding immediate solutions to critical issues. I thrive under pressure. My approach involves prioritizing tasks, efficiently allocating resources, and maintaining clear communication. For instance, during an unexpected in-flight failure that necessitated a rapid turnaround, I expertly coordinated with my team to diagnose the problem, secure necessary parts, and complete the repair within the stringent deadline. My experience has equipped me with the ability to remain calm and focused during high-stress situations, ensuring the safety and efficiency of all operations. I use tools like Kanban boards or similar systems to visualize workflow and manage priorities effectively.

- Experienced in managing multiple tasks simultaneously and prioritizing effectively under pressure.

- Demonstrated ability to maintain composure and efficiency in high-stress environments.

- Effective in utilizing organizational tools to manage time and resources efficiently.

Q 25. Describe your understanding of the importance of safety in avionics maintenance.

Safety is the absolute cornerstone of avionics maintenance. Any lapse in safety procedures can have catastrophic consequences. I’m deeply committed to adhering to strict safety regulations and guidelines, including those laid out by the FAA (or relevant governing body). This commitment involves meticulously following all safety protocols, such as using lockout/tagout procedures when working on energized systems, conducting thorough pre-flight inspections, and accurately documenting all maintenance actions. I consider safety not only a responsibility but a personal ethos. This includes self-assessment and peer-to-peer reviews to identify and mitigate any potential hazards. A personal example is during a routine inspection, I noticed a loose wire that could have potentially led to a short circuit – my intervention prevented a potentially serious incident.

- Strict adherence to FAA regulations and safety protocols (or relevant governing body).

- Proactive identification and mitigation of potential safety hazards.

- Deep understanding and implementation of lockout/tagout procedures and other safety measures.

Q 26. What is your experience with conducting post-maintenance testing?

Post-maintenance testing is crucial to verify the effectiveness of repairs and modifications. My experience includes conducting both functional and performance testing. For example, after replacing a faulty transponder, I conducted comprehensive tests to ensure its proper functionality, verifying signal strength, accuracy, and response times. These tests are often done using sophisticated test equipment, and the results are meticulously documented, complying with regulatory requirements. Failure to meet specifications necessitates further investigation and corrective actions. In short, I treat post-maintenance testing as an indispensable quality control measure.

- Proficient in conducting functional and performance testing of avionics systems post-maintenance.

- Experienced in using specialized test equipment to verify system functionality.

- Meticulous in documenting test results and reporting any discrepancies.

Q 27. Explain your experience with troubleshooting communication systems on aircraft.

Troubleshooting aircraft communication systems requires a systematic and methodical approach. I’m experienced in diagnosing faults within VHF radios, HF radios, satellite communication systems, and aircraft intercoms. My troubleshooting methodology involves a combination of visual inspection, signal tracing, and the use of specialized diagnostic equipment. For example, when troubleshooting a faulty VHF radio, I would first visually inspect the connections and wiring. Then, I would use a signal generator and oscilloscope to trace the signal path and identify points of failure. Documentation is crucial, carefully recording each step, the findings, and corrective actions. This ensures traceability and aids in preventing future issues.

- Experience in troubleshooting a variety of aircraft communication systems, including VHF, HF, SATCOM, and intercoms.

- Proficient in using specialized test equipment and diagnostic software for communication system fault isolation.

- Systematic and methodical approach to troubleshooting, ensuring accurate diagnosis and effective repairs.

Q 28. Describe your experience with the maintenance of navigation systems on aircraft.

Maintenance of aircraft navigation systems demands precision and a deep understanding of their operation. I have experience maintaining various systems including GPS, VOR, ILS, and ADF. This involves periodic inspections, calibrations, and repairs as needed. For instance, during the maintenance of a GPS system, I’d verify the antenna integrity, check for proper signal reception, and calibrate the unit to ensure accurate positioning. I use specialized test equipment to assess the performance parameters and compare them against manufacturer specifications. Any discrepancies would trigger further diagnostic steps and corrective actions. Safety is paramount, ensuring the navigation system’s integrity for safe and efficient flight operations.

- Experienced in the maintenance and repair of various aircraft navigation systems, including GPS, VOR, ILS, and ADF.

- Proficient in using specialized test equipment to verify the performance and accuracy of navigation systems.

- Deep understanding of navigation system operational principles and regulatory requirements.

Key Topics to Learn for Avionics Maintenance and Modification Interview

- Avionics Systems Overview: Understanding the interconnectedness of various aircraft systems (navigation, communication, flight control) and their functionalities.

- Troubleshooting and Diagnostics: Practical application of fault isolation techniques, using schematics, and interpreting diagnostic data to pinpoint and rectify malfunctions.

- Maintenance Procedures and Regulations: Familiarity with FAA regulations (or equivalent international standards), maintenance manuals, and best practices for performing repairs and modifications.

- Avionics Components and their Functionality: In-depth knowledge of various components like GPS, transponders, radios, and their operational principles.

- Modification and Upgrade Procedures: Understanding the process of integrating new avionics systems, adhering to certification requirements, and ensuring compliance.

- Safety Regulations and Procedures: Demonstrating a strong commitment to safety by highlighting your knowledge of risk assessment, hazard identification, and safety protocols within the avionics maintenance environment.

- Testing and Quality Assurance: Understanding the importance of rigorous testing procedures to verify the functionality and reliability of repaired or modified avionics systems.

- Electrical Systems and Wiring: Understanding aircraft electrical systems, including wiring diagrams, circuit analysis, and troubleshooting electrical faults.

- Documentation and Record Keeping: Proficiency in accurately documenting maintenance activities, repairs, and modifications according to industry standards.

- Problem-solving and Analytical Skills: Ability to approach complex problems systematically, using analytical thinking and troubleshooting skills to resolve avionics malfunctions efficiently and effectively.

Next Steps

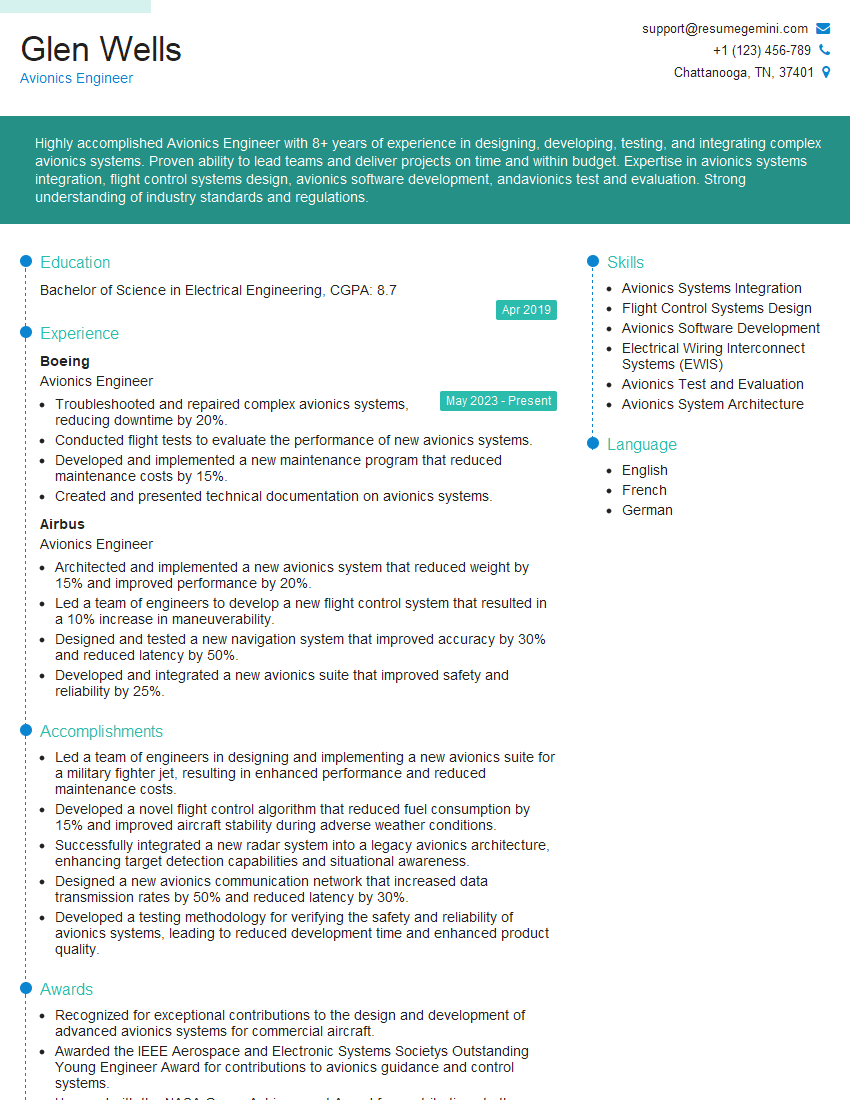

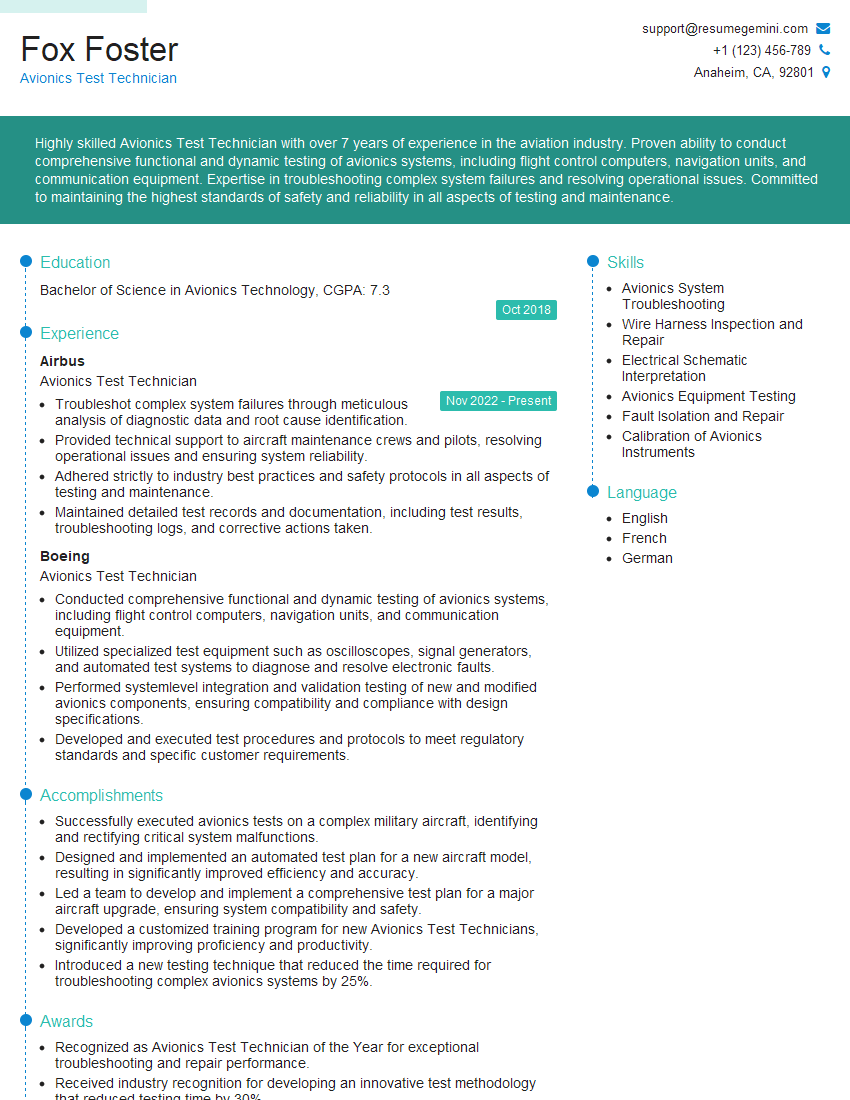

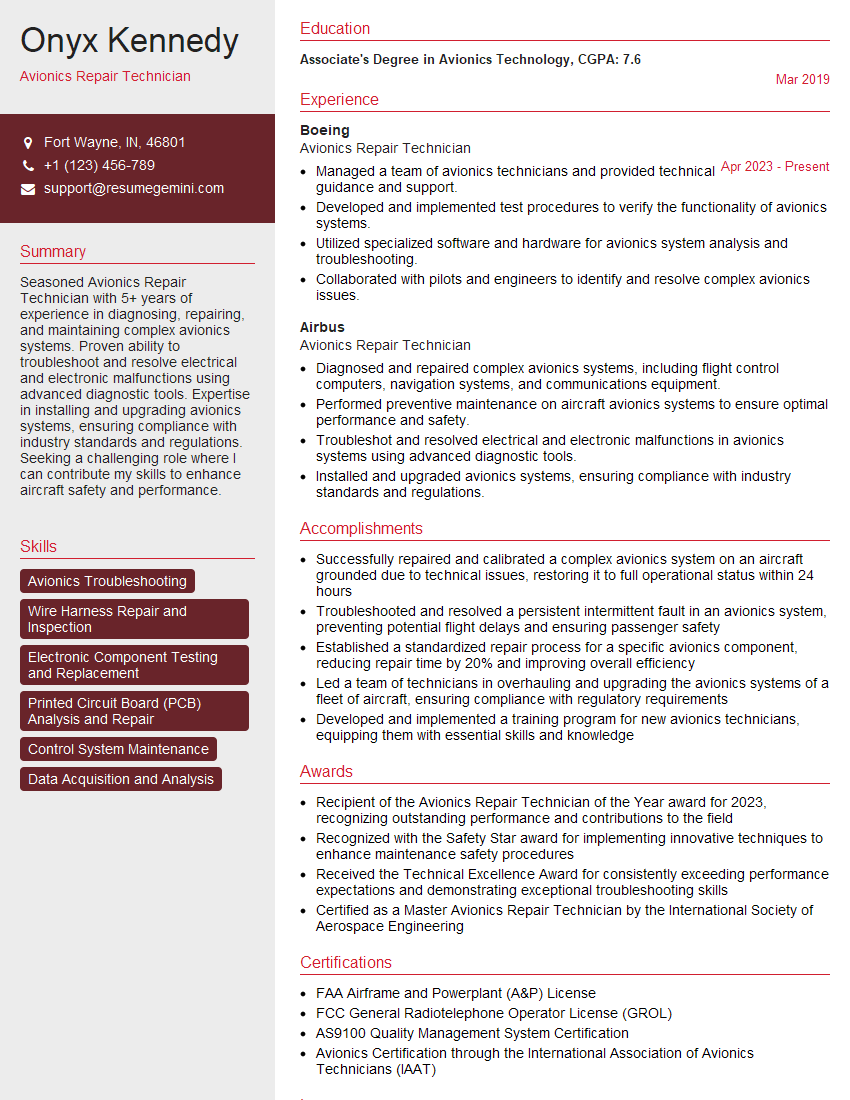

Mastering Avionics Maintenance and Modification opens doors to a rewarding career with excellent growth potential in the aviation industry. To maximize your job prospects, focus on building a strong, ATS-friendly resume that effectively showcases your skills and experience. ResumeGemini is a trusted resource that can help you create a compelling resume that gets noticed. They provide examples of resumes tailored to Avionics Maintenance and Modification, ensuring your application stands out from the competition. Take advantage of this valuable resource to build your best possible resume and land your dream job.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good