Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Avionics System Installation and Configuration interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Avionics System Installation and Configuration Interview

Q 1. Describe your experience with installing and configuring different types of avionics systems.

My experience encompasses a wide range of avionics systems installations and configurations, from basic GPS and transponders to advanced flight management systems (FMS) and weather radar. I’ve worked on various aircraft types, including both fixed-wing and rotary, and have hands-on experience with both new installations and retrofits. For example, I recently completed a project involving the integration of a new ADS-B system into a fleet of Cessna 172s. This required careful planning to ensure compatibility with existing equipment and adherence to FAA regulations. Another significant project involved the installation and configuration of a sophisticated glass cockpit in a King Air, a task that required extensive knowledge of ARINC communication protocols and intricate wiring diagrams.

I’m proficient in all phases of the installation process, from initial planning and system design, through physical installation, testing and commissioning, and finally the delivery and training of the end-users. I understand the critical safety implications of avionics installations and am committed to maintaining the highest standards of quality and safety.

Q 2. Explain the process of troubleshooting a faulty avionics system.

Troubleshooting a faulty avionics system is a systematic process that requires a methodical approach. It often begins with a thorough review of the symptoms reported by the pilot or maintenance crew. Next, I’d consult the aircraft’s maintenance manuals and system schematics to understand the system architecture and identify potential points of failure.

- Initial Assessment: This includes checking power supply, fuses, and circuit breakers. Often, a simple power issue solves the problem.

- Data Analysis: I would use diagnostic tools like built-in test equipment (BITE), multimeters, and specialized avionics test sets to isolate the fault. Analyzing data logged by the system can provide valuable clues.

- Component Testing: Once a suspect component is identified, I would conduct thorough testing to confirm its malfunction. This may involve removing the component and performing bench testing or using specialized diagnostic software.

- Replacement and Verification: Once the faulty component is replaced, a thorough system check is critical to ensure the proper function of the repaired system. This includes functional testing and verifying all system parameters conform to specifications.

For instance, I once encountered a transponder malfunction where the system failed to respond to ATC interrogation. After systematic testing, I discovered a faulty amplifier within the transponder unit. Replacing it resolved the issue.

Q 3. How familiar are you with various avionics communication protocols (e.g., ARINC 429, Ethernet)?

I possess a strong understanding of various avionics communication protocols, including ARINC 429, ARINC 629, ARINC 708 (AFDX), and Ethernet (10BASE-T, 100BASE-TX). ARINC 429 is a widely used data bus that uses a high-speed, serial, digital method to transmit information between avionics components. I’m familiar with its word formats and error detection mechanisms. ARINC 629 provides a higher data rate than 429 and is utilized in systems requiring greater bandwidth. AFDX, a switched Ethernet protocol based on ARINC 708, offers increased bandwidth and redundancy, crucial for modern, integrated systems. Understanding the nuances of each protocol is critical to successfully integrating new avionics into an existing architecture.

Furthermore, I understand the importance of data integrity and the challenges of real-time communication in an aviation context, especially the need for protocols that handle data transmission with low latency and high reliability.

Q 4. Describe your experience with aircraft wiring diagrams and schematics.

I’m highly proficient in interpreting and utilizing aircraft wiring diagrams and schematics. These documents are essential for any avionics installation or repair work. I can effectively trace signal paths, identify wire gauges, and understand connector pinouts using wiring diagrams. My experience includes working with both paper and electronic versions of schematics, and I’m comfortable using software to navigate and interpret complex diagrams.

For example, when working on a recent avionics upgrade, I used the wiring diagram to identify the appropriate power and data lines for the new equipment, ensuring proper connections and avoiding any potential short circuits or conflicts with existing systems. Understanding the logic behind how the system is wired is crucial to avoid costly mistakes and guarantee safe operations.

Q 5. How do you ensure compliance with FAA regulations during avionics installation?

Ensuring compliance with FAA regulations is paramount in avionics installation. This involves meticulous documentation, adherence to approved data sheets and manuals (e.g., STC, PMA), and rigorous testing and inspection. Every step of the installation must be meticulously documented, and all modifications must be properly recorded in the aircraft’s maintenance logbooks. We use FAA-approved parts and tools and ensure all work conforms to the applicable Advisory Circulars and regulations.

Before any new avionics system can be certified for flight, a thorough inspection by a qualified mechanic and, if necessary, a Designated Engineering Representative (DER), must be completed. This ensures that the system is properly installed, functioning correctly, and does not compromise the aircraft’s safety and airworthiness. Following FAA guidelines and maintaining precise records allows us to maintain consistent high-quality work and ensure regulatory compliance.

Q 6. What are your skills in using diagnostic tools for avionics systems?

My proficiency extends to a variety of diagnostic tools, including multimeters, oscilloscopes, spectrum analyzers, and specialized avionics test sets. I’m experienced in using built-in test equipment (BITE) which are self-diagnostic systems within avionics components themselves. I’m also skilled at using manufacturer-specific software tools for configuration and troubleshooting. Properly using these tools allows for precise identification and resolution of avionics faults.

For example, I use an oscilloscope to analyze signal integrity on data buses like ARINC 429, helping to pinpoint communication errors. Manufacturer-specific software is key for configuring complex FMS systems and ensuring proper data exchange between different components.

Q 7. How do you handle discrepancies between installation manuals and actual aircraft configurations?

Discrepancies between installation manuals and actual aircraft configurations are a common challenge. When such discrepancies arise, I follow a well-defined procedure to resolve them. First, I thoroughly document the differences with photographs and detailed notes. Second, I consult with experienced colleagues or the aircraft manufacturer’s engineering support to understand the root cause of the discrepancy and determine the best course of action.

This often involves verifying the aircraft configuration with historical records and potentially modifying the installation plan. In some cases, a DER might be needed to approve a deviation from the original installation plan. Safety and airworthiness are always the top priorities, and any change must be properly documented and approved. Thorough documentation and careful consideration are crucial for addressing such situations effectively and maintaining the safety of the aircraft.

Q 8. Explain your experience with different types of avionics components (e.g., GPS, transponders, radios).

My experience encompasses a wide range of avionics components, from core navigation and communication systems to more specialized equipment. I’ve worked extensively with GPS systems, including WAAS/EGNOS enabled units, ensuring accurate navigation data acquisition and integration with flight management systems. This involves understanding the intricacies of satellite signal reception, data processing, and error correction. With transponders, my experience extends to both Mode S and ADS-B systems, focusing on ensuring proper communication with air traffic control. I’m proficient in troubleshooting signal interference and ensuring accurate transmission of aircraft identification and position. Finally, my work with various communication radios, including VHF, HF, and satellite communications, ensures clear and reliable voice and data links, vital for safe and efficient flight operations. I’ve managed installations involving diverse configurations – from simple single-frequency radios to sophisticated multi-channel systems requiring careful antenna placement and power distribution.

- GPS Example: Troubleshooting a GPS antenna installation that resulted in intermittent signal loss, identifying the issue as faulty grounding, and implementing a successful fix.

- Transponder Example: Configuring a Mode S transponder to comply with specific airspace regulations, ensuring accurate and reliable communication with ATC.

- Radio Example: Integrating a new VHF radio system, including careful antenna placement to minimize interference and ensure optimal signal strength.

Q 9. How do you manage your time effectively when working on multiple avionics installations simultaneously?

Managing multiple avionics installations simultaneously requires a structured approach. I utilize project management techniques such as creating detailed schedules for each installation, prioritizing tasks based on criticality and deadlines, and allocating resources effectively. A critical path method helps identify potential bottlenecks. Regular progress meetings ensure communication with clients and the team, facilitating adjustments as needed. I also utilize specialized software for project tracking and resource allocation. A key aspect is meticulous documentation, ensuring all tasks, modifications, and testing are thoroughly recorded. This avoids confusion and ensures efficient handover between team members. Imagine it as an orchestra – each section (installation) needs to be rehearsed separately and then brought together harmoniously. My role is the conductor, ensuring everyone plays their part at the right time.

Q 10. What is your experience with testing and validating avionics installations?

Testing and validating avionics installations is crucial for ensuring safety and operational effectiveness. My approach involves several stages, beginning with pre-installation checks to verify component integrity and compatibility. During installation, meticulous wiring checks are performed to prevent shorts or misconnections. Post-installation, comprehensive testing includes functional checks of each component, followed by integrated system tests to ensure seamless interaction. This often involves using specialized test equipment to verify signal quality, data accuracy, and overall system performance. I meticulously document each test, recording results and addressing any anomalies. Further, I leverage existing test procedures and checklists, adapting them as needed for specific aircraft types and avionics configurations. Finally, I often work closely with regulatory authorities to ensure compliance with all safety standards.

- Example: Using a dedicated test set to verify the integrity of the communication links between the avionics systems and the flight management computer.

Q 11. Describe your understanding of avionics power systems and their integration.

Avionics power systems are critical for the safe operation of aircraft. I have experience with various architectures, including DC and AC power distribution, as well as redundant power systems to ensure continued operation in case of failures. Understanding the specific voltage and current requirements of each component is crucial for correct integration. This includes careful consideration of power bus configurations, circuit protection devices (fuses, circuit breakers), and proper grounding techniques to prevent electrical interference. I’m familiar with various power management techniques, such as load shedding, which ensures the availability of power to essential systems in case of power surges or faults. Furthermore, careful planning and installation prevent overheating and potential fire hazards. Think of it as the circulatory system of the aircraft – every component needs the right amount of ‘blood’ (power) at the right time to function properly.

Q 12. How do you ensure the safety of aircraft systems during avionics installation?

Ensuring aircraft safety during avionics installation is paramount. My procedures adhere strictly to safety regulations and best practices. This starts with a thorough risk assessment identifying potential hazards, followed by the implementation of appropriate safety measures. Strict adherence to manufacturer’s guidelines for installation and maintenance is essential. This includes the use of appropriate tools and equipment, proper grounding techniques to prevent electrostatic discharge, and the use of protective clothing and equipment. Furthermore, regular safety briefings for the team reinforce procedures and ensure everyone is aware of potential risks. Throughout the process, meticulous documentation of every step, including any deviations from standard procedures, is maintained. Post-installation, rigorous testing and verification processes ensure the system is functioning safely and as intended. Think of it as a surgical procedure—precision and attention to detail are non-negotiable.

Q 13. What experience do you have with different aircraft types and their unique avionics requirements?

My experience spans several aircraft types, including general aviation aircraft, commercial airliners, and helicopters. Each aircraft presents unique challenges due to variations in airframe design, avionics bays, and power systems. For instance, the installation process for a Cessna 172 is vastly different from that of a Boeing 737. General aviation aircraft often involve simpler systems with less stringent regulatory requirements, whereas commercial airliners demand meticulous adherence to complex safety and certification protocols. Helicopters require a specialized understanding of their unique flight dynamics and avionics needs. I tailor my approach to each aircraft type, always referencing manufacturer’s documentation and industry best practices to ensure compatibility and regulatory compliance. This includes understanding the specific weight and balance considerations of each aircraft and the impact of additional avionics installations.

Q 14. How familiar are you with different types of avionics software and their configuration?

I’m proficient with various avionics software packages, including those used for flight management systems, communication systems, and data acquisition and management. My experience extends to both legacy systems and the latest generation of software, including those that leverage advanced technologies such as ARINC 661 and AFDX. I’m familiar with the software configuration process, including loading software, performing database updates, and configuring parameters to meet specific operational requirements. This involves understanding the software’s architecture, functionalities, and interdependencies within the overall avionics system. Furthermore, I’m capable of troubleshooting software-related issues, including resolving conflicts, debugging code, and implementing software updates. My experience with software configuration also involves using specialized tools and software to communicate with avionics units and access relevant parameters. Ensuring compatibility between software versions and hardware is crucial.

Q 15. Explain your understanding of electromagnetic compatibility (EMC) in avionics systems.

Electromagnetic Compatibility (EMC) in avionics is crucial for ensuring that all systems within an aircraft operate reliably without causing interference with each other or with external sources. It’s essentially about managing electromagnetic energy to prevent malfunctions and maintain safety. This involves controlling emissions (radiated and conducted) from the avionics systems, and ensuring that the systems are immune to electromagnetic interference (EMI) from both internal and external sources, such as weather, other aircraft, and ground-based equipment.

For example, a poorly shielded wire harness could radiate electromagnetic energy, potentially interfering with a sensitive GPS receiver, leading to inaccurate navigation data. Similarly, a powerful radar system could generate strong emissions that disrupt the operation of other less robust systems. To address this, avionics installations employ various EMC techniques including shielding, filtering, grounding, and careful cable routing to minimize the impact of emissions and improve immunity to interference. Compliance with stringent regulatory standards like DO-160 is paramount, ensuring that installed systems meet specified EMC performance levels.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you document your work during avionics installation and configuration?

Documentation is paramount in avionics installation and configuration. It ensures traceability, facilitates maintenance, and supports future upgrades. My documentation process incorporates several key elements:

- Installation Drawings: Detailed diagrams showing the precise location and wiring of each component, referencing manufacturer part numbers and specifications.

- Wiring Diagrams: Comprehensive schematics illustrating the interconnection of all wires and connectors, ensuring continuity and identifying wire gauges and insulation types.

- Test Procedures and Results: A comprehensive record of all tests performed during and after installation, including pre-flight checks, functional tests, and EMC verification. Detailed records of results, including any discrepancies or corrective actions, are maintained.

- Configuration Management Database: Using software to centralize all documentation and track revisions, ensuring consistency and traceability across the aircraft’s lifespan. This database would include software versions installed in each avionics unit.

- Non-Conformance Reports (NCRs): Formal documentation of any deviations from the specifications, including root cause analysis and corrective actions implemented.

Maintaining meticulously detailed and organized records is critical for both safety and compliance.

Q 17. What are your skills in using specialized avionics tools and equipment?

My skills encompass a broad range of specialized avionics tools and equipment. This includes:

- Test Equipment: Oscilloscopes, spectrum analyzers, multimeters, and other instruments for verifying signal integrity, power levels, and electromagnetic emissions.

- Aircraft Wiring Tools: Crimping tools, wire strippers, specialized connectors, and soldering equipment for meticulous wire harness assembly and repair.

- Avionics Software Tools: Experience with various diagnostic software packages for troubleshooting and configuring avionics systems. This includes software for flight management systems, communication systems, and other specialized avionics suites.

- Specialized Test Sets: Knowledge and practical experience using manufacturer-specific test sets for validating the functionality and performance of avionics units, often involving sophisticated communications protocols.

- Handheld Diagnostic Tools: Proficiency with various handheld diagnostic tools for quick troubleshooting and fault identification.

I’m adept at selecting and using the appropriate tools for specific tasks, ensuring efficient and accurate work within the confines of safety regulations.

Q 18. Describe your problem-solving approach when dealing with complex avionics issues.

My problem-solving approach to complex avionics issues is systematic and thorough. I follow a structured process that involves:

- Problem Definition: Clearly defining the symptoms, the affected systems, and any contributing factors. This includes gathering all available data, including error messages and system logs.

- Hypothesis Generation: Developing potential causes based on my knowledge and experience. This often involves considering multiple possibilities.

- Testing and Verification: Systematically testing each hypothesis using appropriate tools and techniques, isolating the faulty component or configuration.

- Root Cause Analysis: Identifying the underlying cause of the problem, not just the symptoms. This might involve examining wiring diagrams, schematics, or reviewing maintenance logs.

- Solution Implementation: Implementing the necessary repairs or modifications to resolve the issue. This may involve replacing faulty components, reconfiguring settings, or modifying wiring.

- Verification and Documentation: Thoroughly testing the system to verify the fix and documenting all steps of the process, including the solution, root cause, and preventive measures.

This structured approach ensures efficient and effective troubleshooting, minimizing downtime and improving aircraft safety.

Q 19. How do you stay current with the latest advancements in avionics technology?

Staying current in avionics is vital. I actively pursue continuous learning through several avenues:

- Industry Publications and Journals: Regularly reading trade publications and journals to keep abreast of new technologies and industry best practices.

- Conferences and Workshops: Attending industry conferences and workshops to learn from experts and network with peers. This provides exposure to real-world applications and emerging technologies.

- Manufacturer Training: Participating in manufacturer-provided training courses to stay updated on specific avionics systems and software updates.

- Online Courses and Webinars: Utilizing online platforms to access tutorials and webinars covering new technologies and maintenance procedures. This provides flexible, targeted learning experiences.

- Professional Organizations: Participating in professional organizations like the SAE International to access their resources and networking opportunities.

This multifaceted approach allows me to adapt to evolving technologies and maintain proficiency in the field.

Q 20. What is your experience with working in a team environment during avionics installations?

I have extensive experience working in collaborative team environments during avionics installations. I believe in open communication and clear roles. My strengths include:

- Effective Communication: Clearly conveying information to team members, ensuring everyone understands their roles and responsibilities.

- Collaboration and Teamwork: Working effectively with engineers, technicians, and other specialists to achieve common goals. This includes actively listening to different perspectives and valuing diverse contributions.

- Conflict Resolution: Addressing disagreements professionally and constructively, ensuring a harmonious and productive work environment.

- Mentorship and Guidance: Supporting less experienced team members through training and guidance, fostering a culture of knowledge sharing.

I value a team-oriented approach, believing that collective expertise and collaboration lead to the most effective and safest avionics installations.

Q 21. Describe a situation where you had to troubleshoot a difficult avionics problem. How did you solve it?

During the installation of a new flight management system (FMS) on a regional jet, we encountered a persistent communication error between the FMS and the air data computer (ADC). Initial troubleshooting steps, including checking wiring and power connections, yielded no results. The error message was vague, only indicating a ‘communication failure.’

My approach involved the following steps:

- Detailed System Analysis: We meticulously reviewed the FMS and ADC communication protocols, checking for discrepancies in data formatting or transmission rates.

- Data Logging: We implemented data logging to capture detailed communication traffic between the two units, looking for patterns or anomalies.

- Signal Tracing: Using an oscilloscope, we carefully traced the signals along the communication pathway, checking for signal degradation or noise.

- Software Diagnostics: We accessed the onboard diagnostic software for both the FMS and ADC, checking for internal errors or fault codes.

- Component Replacement: Ultimately, our investigation revealed a faulty communication interface card within the ADC. Replacing this component resolved the communication issue.

This case highlighted the importance of a systematic and multifaceted approach to avionics troubleshooting. The resolution involved collaboration, careful attention to detail, and using various diagnostic tools to pinpoint the problem.

Q 22. Explain your experience with pre-flight inspections involving avionics systems.

Pre-flight avionics inspections are crucial for ensuring safe and efficient flight operations. They involve a systematic check of all avionics systems to verify their functionality and identify any potential issues before takeoff. My experience includes visually inspecting all components for damage, checking for proper connections and securing of wiring harnesses, and verifying the operational status of each system through built-in test equipment (BITE) or external testing tools.

For example, I would meticulously check the navigation system, ensuring the GPS is receiving satellites and providing accurate position data. I’d also verify the functionality of the transponder, ensuring it correctly transmits the aircraft’s identification and altitude. Any discrepancies are documented and addressed before the flight is authorized. This process is guided by the aircraft’s specific checklist and maintenance manual.

Beyond visual inspections, I also verify the proper functioning of the communication systems, including radios and interphones. I would test all frequencies and ensure clear communication with air traffic control. Finally, I’d check the status of the flight data recorder (FDR) and cockpit voice recorder (CVR), confirming that both are operational and recording data.

Q 23. What are the safety protocols you follow while working on live aircraft avionics?

Safety is paramount when working on live aircraft avionics. My adherence to safety protocols is unwavering. These protocols encompass several key aspects, starting with proper lockout/tagout procedures to prevent accidental power application. Before commencing any work, I ensure the aircraft’s power is switched off and the system is isolated, using appropriate safety tags and locks. This prevents accidental energization and potential harm.

Beyond power isolation, I meticulously follow the manufacturer’s instructions and use appropriate safety equipment, such as anti-static wrist straps to prevent electrostatic discharge (ESD) damage to sensitive electronic components. I also employ appropriate personal protective equipment (PPE), including safety glasses, gloves, and hearing protection as necessary.

Furthermore, I work closely with the flight crew and ground personnel to ensure a coordinated and safe working environment. Open communication regarding tasks and potential hazards is critical. Before any work is completed, I conduct a thorough inspection to confirm that all safety measures have been followed and that the system is in a safe condition. Think of it like performing surgery – precision, attention to detail, and safety are non-negotiable.

Q 24. How do you handle pressure and tight deadlines during critical avionics installation projects?

Avionics installations often involve tight deadlines and considerable pressure. To manage this effectively, I employ a structured approach combining meticulous planning, efficient task management, and effective communication. I start by breaking down the project into smaller, manageable tasks with clearly defined milestones. This allows for better tracking of progress and identification of potential delays early on.

I utilize project management tools to track deadlines, allocate resources, and monitor progress. Prioritization is key. Identifying critical path tasks and focusing resources on those ensures timely project completion. I actively communicate with the project team and stakeholders to keep everyone informed about progress, challenges, and potential solutions.

When facing unexpected issues or delays, I immediately assess the situation, develop contingency plans, and promptly communicate the situation and proposed solutions to relevant parties. I also believe in proactively seeking help when needed; leveraging the expertise of other team members can often accelerate problem-solving and mitigate delays. Remember, asking for help isn’t a weakness; it’s a sign of strength and commitment to project success.

Q 25. Describe your experience with the use of technical manuals and documentation during avionics installations.

Technical manuals and documentation are my indispensable tools. They provide the crucial information needed for correct installation, configuration, and troubleshooting of avionics systems. My experience involves navigating complex schematics, wiring diagrams, and maintenance manuals to understand system architecture and component interactions.

For example, I regularly use Illustrated Parts Catalogs (IPCs) to identify specific parts and their locations within the aircraft system. Wiring diagrams guide me through the intricate network of cables and connectors, ensuring proper routing and connections. Troubleshooting guides help me diagnose and resolve issues by providing step-by-step procedures and potential solutions.

Furthermore, I diligently follow all manufacturer’s recommendations and specifications outlined in these documents. Adherence to these standards ensures that the avionics system is installed correctly, functions reliably, and meets all safety regulations. Maintaining accurate records of all work performed, including parts used and procedures followed, is critical for compliance and traceability.

Q 26. How familiar are you with the principles of aircraft weight and balance as it relates to avionics installations?

Understanding aircraft weight and balance is fundamental to avionics installations. Adding new avionics equipment alters the aircraft’s center of gravity, potentially impacting its stability and handling characteristics. My experience includes calculating the weight and center of gravity shifts resulting from avionics installations, using specialized software and weight and balance calculation methods.

This process involves precisely weighing each new component, determining its location within the aircraft, and then using appropriate formulas to calculate the effect on the aircraft’s overall weight and balance. The results are then compared against the aircraft’s certified limits to ensure compliance with safety regulations. Any deviations require adjustments, which may include weight shifting or other compensatory measures.

For example, a heavy avionics unit installed too far aft might shift the center of gravity beyond acceptable limits. This could lead to handling difficulties, particularly during takeoff and landing. Careful weight and balance calculations prevent such issues and maintain the aircraft’s safe flight characteristics.

Q 27. What is your experience with the use of specialized software for avionics system configuration?

I’m proficient in using various specialized software for avionics system configuration. This software ranges from simple diagnostic tools to complex configuration and programming applications. I have experience with software used to program and test flight management systems (FMS), communication systems, and other avionics equipment. This typically involves connecting to the avionics system via data bus interfaces, inputting specific configuration parameters and testing for proper functionality.

For example, I’ve used software to upload navigation databases into the aircraft’s GPS, program communication frequencies into radios, and configure the aircraft’s transponder for appropriate operational modes. These programs often have robust diagnostic capabilities, allowing me to identify and correct configuration errors or faults.

Proficiency with these tools is critical for efficient and accurate avionics installations. It is essential to be familiar with the specific software used for each type of avionics equipment to ensure proper configuration and compliance with regulatory standards. This is achieved through continuous training and hands-on experience.

Q 28. Explain your understanding of the certification processes for avionics installations.

Avionics installations are subject to stringent certification processes to ensure airworthiness and safety. My understanding of these processes is comprehensive, encompassing both the technical aspects and regulatory compliance requirements. These processes vary depending on the type of aircraft and the modifications being made, but they generally involve several stages.

Firstly, the installation must comply with all relevant airworthiness regulations, such as those defined by the FAA (Federal Aviation Administration) or EASA (European Union Aviation Safety Agency). This involves rigorous documentation of all modifications, including detailed drawings, schematics, and test results. The installation itself must follow strict procedures and quality control standards.

After the installation is complete, a series of tests and inspections are performed to verify the functionality and safety of the modified avionics system. This may involve functional testing of the installed equipment and integration testing to ensure that all systems are working correctly together. Finally, depending on the complexity of the installation, a certification authority will review all documentation and test results before approving the modification and issuing the necessary airworthiness certificates. This entire process ensures that all safety standards are met before the aircraft returns to service.

Key Topics to Learn for Avionics System Installation and Configuration Interview

- System Integration: Understanding the interconnectedness of various avionics systems (navigation, communication, flight control, etc.) and their seamless operation. Practical application includes troubleshooting integration issues and ensuring data compatibility.

- Wiring and Cabling: Knowledge of aircraft wiring diagrams, proper installation techniques, and adherence to safety regulations. Practical application includes identifying and resolving wiring faults, ensuring proper grounding and shielding.

- Testing and Verification: Mastering the use of test equipment to verify proper system functionality and performance after installation. Practical application involves conducting pre-flight and post-installation checks, interpreting test results, and documenting findings.

- FAA Regulations and Certifications: Familiarity with relevant FAA regulations and certifications pertaining to avionics installations. Practical application involves ensuring compliance with all applicable rules and documenting all work meticulously.

- Troubleshooting and Problem Solving: Developing a systematic approach to diagnose and resolve avionics system malfunctions. Practical application includes using diagnostic tools, interpreting error codes, and applying logical reasoning to pinpoint the root cause of problems.

- Software Configuration and Updates: Understanding how to configure avionics software, perform updates, and manage data within the system. Practical application involves utilizing software tools to modify system parameters, install updates, and manage databases.

- Safety Procedures and Best Practices: Adherence to strict safety protocols throughout the installation and configuration process. Practical application includes following established procedures, using appropriate safety equipment, and prioritizing safety in all actions.

Next Steps

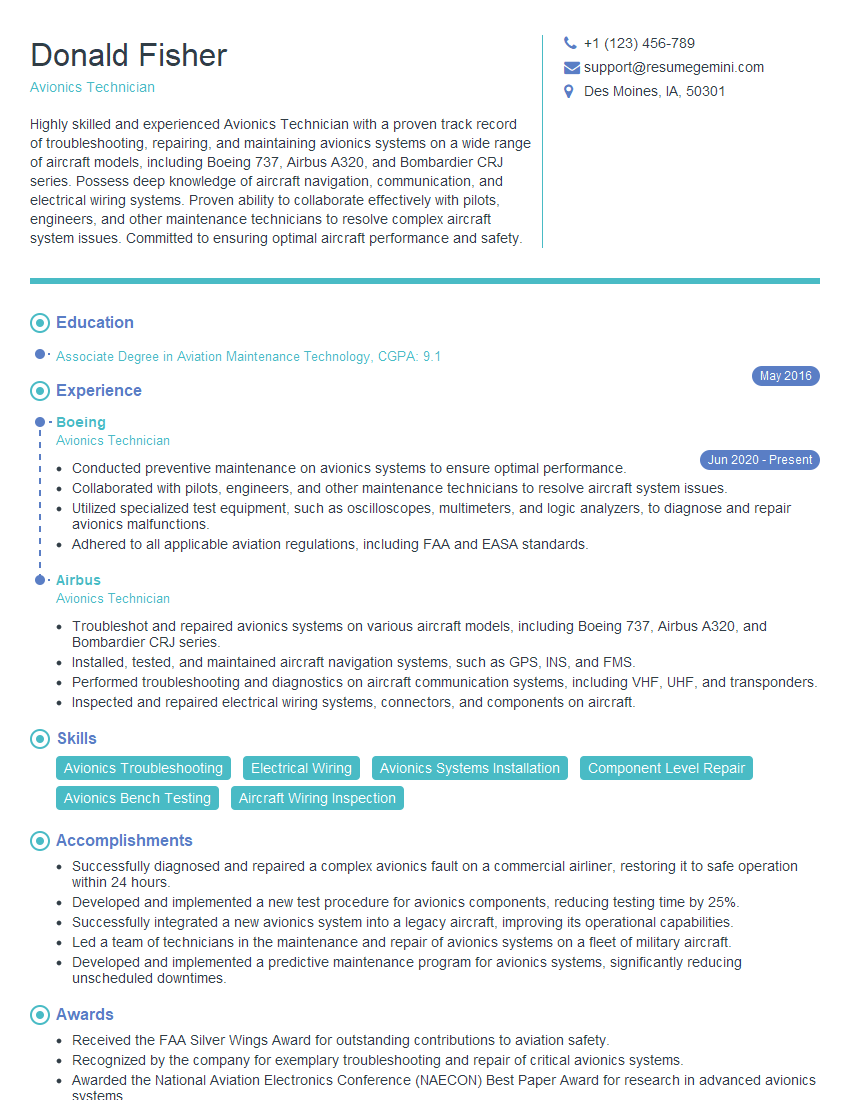

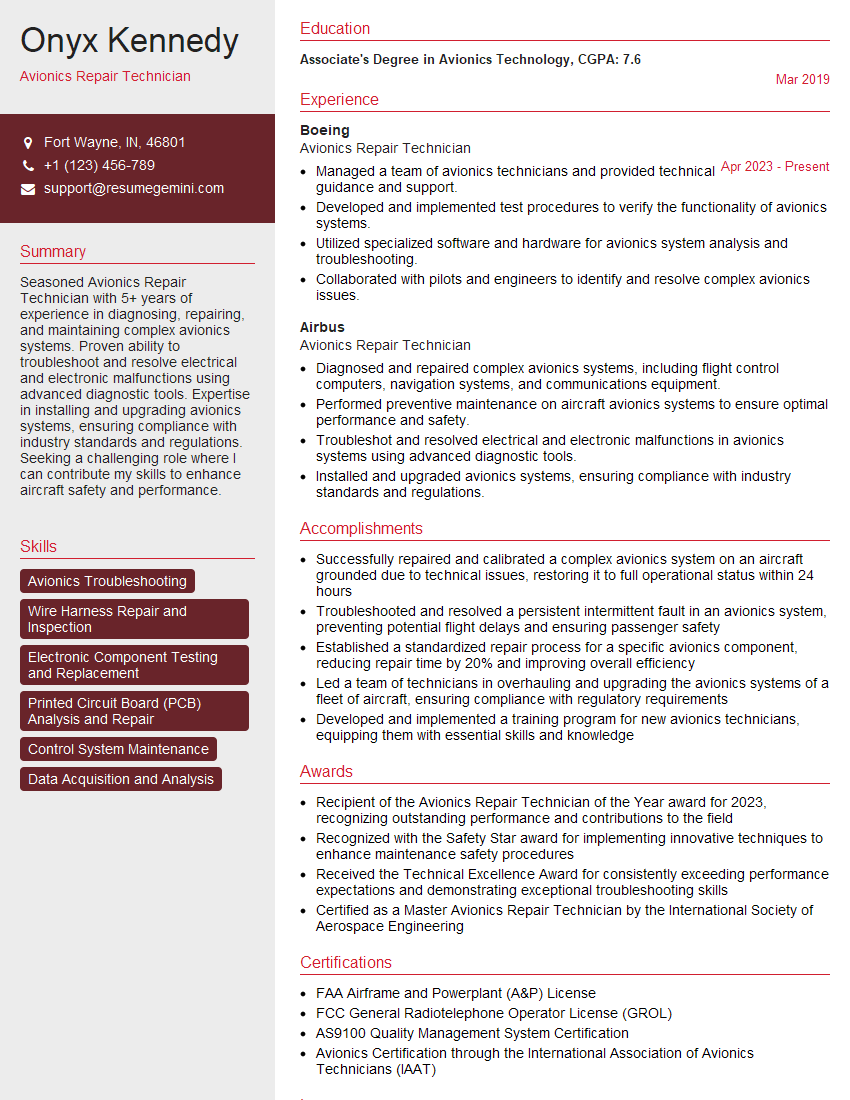

Mastering Avionics System Installation and Configuration opens doors to exciting and rewarding careers in the aviation industry, offering opportunities for professional growth and specialization. To maximize your job prospects, creating a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional resume tailored to highlight your skills and experience. Examples of resumes specifically designed for Avionics System Installation and Configuration professionals are available to help guide your resume creation process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good