The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Avionics Troubleshooting and Fault Isolation interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Avionics Troubleshooting and Fault Isolation Interview

Q 1. Explain the process of troubleshooting a failed transponder.

Troubleshooting a failed transponder involves a systematic approach combining visual inspection, utilizing built-in test equipment (BITE), and employing specialized test sets. First, we visually inspect the transponder unit for any obvious damage, loose connections, or burned components. This might involve checking for proper seating of cards and connectors. Next, we’ll utilize the aircraft’s BITE system, if available, to identify any fault codes or indications pointing towards a specific problem. These codes often provide a starting point for investigation. For example, a code might indicate a problem with the transmitter, receiver, or power supply. If the BITE is inconclusive, or if the transponder is entirely unresponsive, we’ll move to more advanced testing using a specialized transponder test set. This equipment allows us to send simulated interrogation signals and measure the transponder’s response, checking parameters like pulse width, coding accuracy, and signal strength. This detailed analysis helps pinpoint the faulty component, which might be a specific integrated circuit, a faulty antenna, or even a problem within the aircraft’s wiring harness. We always follow the aircraft’s maintenance manual during the whole process.

For example, during a recent troubleshooting of a transponder failure on a Cessna 172, the BITE indicated a problem with the power supply. Initial visual inspection revealed a loose connection to the power input. After securing the connection, the transponder was restored to full functionality. In another instance, a faulty integrated circuit within the transponder was identified only after using a specialized test set, and replacing this component solved the issue.

Q 2. Describe your experience with using built-in test equipment (BITE).

My experience with Built-In Test Equipment (BITE) is extensive. I’ve worked with various avionics systems, from simpler general aviation aircraft to complex airliners, and have relied heavily on BITE systems to expedite fault isolation. BITE systems are invaluable because they provide immediate feedback, often pinpointing the location of a malfunction. This reduces the time and effort spent on manual testing. For example, many modern systems use self-test routines that run at power-up or on demand. These routines provide basic health checks and flag potential problems. I’ve used BITE outputs to rapidly identify faults ranging from simple loose connectors to complex circuit board failures. The interpretation of BITE codes often involves consulting the aircraft’s maintenance manual, which contains detailed descriptions of each code and the associated troubleshooting steps. I am proficient in navigating these manuals and using the data provided by the BITE system to quickly and efficiently resolve issues. In more advanced systems, BITE data is often integrated into a central maintenance system allowing for more efficient analysis of recurring problems across multiple aircraft.

One instance involved a failure in the aircraft’s air data computer. The BITE indicated a faulty pressure sensor. A quick swap of the sensor confirmed the diagnosis, and the system returned to normal operation. In other cases, BITE has revealed more complex issues requiring more in-depth troubleshooting, but it always provided a crucial starting point.

Q 3. How do you diagnose intermittent faults in avionics systems?

Diagnosing intermittent faults in avionics is challenging because they are unpredictable and don’t always appear consistently. My approach involves a combination of techniques aiming to reproduce and isolate the fault. First, I gather as much information as possible about the circumstances surrounding the fault. This includes noting the conditions under which it occurs (e.g., specific flight phases, ambient temperature, or aircraft maneuvers). This information aids in developing a hypothesis of the potential cause. Next, I’ll use monitoring tools like oscilloscopes and logic analyzers to observe signals during operation, looking for anomalies that only appear when the fault is active. This often necessitates conducting numerous test flights or simulations to observe the issue. Sometimes, strategically applying stress to the system – such as vibration or temperature cycling – can help trigger the intermittent fault, making it easier to isolate the root cause. Furthermore, advanced diagnostic tools like data acquisition systems can log relevant parameters throughout flight, identifying patterns and correlating events related to the intermittent failure. Using these log files I can then reconstruct the conditions that trigger the fault. Finally, careful inspection of the suspect components is necessary. Look for signs of fatigue, loose connections, or any physical damage which can cause intermittent behaviour.

For instance, an intermittent GPS receiver failure I investigated was traced to a loose connection on the antenna. The vibration of flight would periodically interrupt the signal. Once the connection was secured the problem resolved permanently. In a more complex case, an intermittent malfunction in a flight control computer was tracked to a specific integrated circuit that was failing intermittently due to temperature changes during flight.

Q 4. What are the common causes of GPS receiver malfunctions?

GPS receiver malfunctions can stem from several sources. Common causes include:

- Antenna problems: Obstructions, damage, or poor connection to the receiver can severely degrade or completely block the GPS signal. This can be due to ice accumulation, physical damage, loose connectors, or even incorrect positioning of the antenna.

- Receiver internal faults: Component failure within the receiver itself, such as a faulty oscillator, processor, or memory, can result in inaccurate positioning or a complete loss of signal.

- Interference: Radio frequency (RF) interference from other electronic devices or sources can disrupt the GPS signal, leading to errors or signal loss. This is often seen in aircraft with poorly shielded avionics systems or near powerful radio sources.

- Satellite availability: Although rare, issues with the number of visible satellites or poor satellite geometry can affect accuracy and availability of the signal. This is commonly related to high latitudes or atmospheric interference.

- Software issues: Software bugs or glitches in the GPS receiver’s firmware can cause inaccurate readings or system crashes. This typically requires a firmware update.

Troubleshooting involves systematically checking each of these potential sources, often starting with a visual inspection of the antenna and its connection, followed by checks for interference, signal strength verification, and finally, running diagnostic tests on the receiver itself, using appropriate test equipment.

Q 5. Explain your understanding of fault trees and their application in avionics troubleshooting.

Fault trees are powerful tools for analyzing and representing potential failure modes in complex systems like avionics. They visually depict the combination of events that could lead to a top-level system failure. They use a hierarchical structure, starting with the undesired event (top event) at the top of the tree and working downwards to identify the contributing factors (basic events) and their relationships. The gates represent logical relationships (AND, OR) between events, describing how multiple events need to occur for the top event to happen. For example, an AND gate implies all events connected to it must occur for the top event to happen, whereas an OR gate requires only one of the connected events to trigger the top event. Fault trees are invaluable during design reviews, allowing for proactive identification and mitigation of potential failure paths. During troubleshooting, a fault tree can guide the diagnosis process by systematically exploring the potential causes, prioritizing those with higher probabilities, and directing testing efforts. This systematic approach minimizes guesswork and ensures efficiency in locating the root cause of a system failure.

Imagine a fault tree for a loss of navigation data. The top event would be “Loss of Navigation Data.” This might branch down to contributing factors like “GPS Receiver Failure,” “INS Failure,” “FMS Software Glitch,” etc. Each of those further branches into sub-causes, finally reaching specific component failures. Using the fault tree during troubleshooting helps streamline the process by systematically investigating each branch and identifying the specific cause of the top-level failure.

Q 6. How would you troubleshoot a loss of communication between the flight management system (FMS) and the autopilot?

Troubleshooting a loss of communication between the Flight Management System (FMS) and the autopilot involves a systematic approach encompassing multiple diagnostic avenues. Initially, I would verify basic power and data bus health for both the FMS and the autopilot. This might involve checking the data bus voltages, checking for any communication errors in the FMS’s and autopilot’s logs, and verifying that both are receiving power. Then, I would assess the communication link itself. This includes verifying the integrity of the data bus wiring and connectors, checking for any physical damage or corrosion. It is important to check the communication protocol, as problems in this area can cause an interruption of data between the systems. Often, a communication link involves ARINC 429 data buses – examining the messages on the bus using appropriate tools is crucial. Each message will have its own error detection and correction method which can be used to diagnose the issue. Further investigation would involve isolating the communication failure to a specific aspect of the databus – potentially a physical cable, a faulty transmitter/receiver, or a problem with the software handling the communication. If the problem is software related, it might necessitate a deeper dive into code analysis. The troubleshooting will require testing the functionality of the communication link to make sure data transfers are successful.

In a real-world scenario, I once encountered a loss of communication between the FMS and autopilot due to a faulty ARINC 429 transceiver on the autopilot side. After replacing the transceiver, communication was restored, illustrating the importance of checking the components in the communication path.

Q 7. Describe your experience with troubleshooting analog and digital circuits in avionics.

My experience encompasses troubleshooting both analog and digital circuits in avionics. Troubleshooting analog circuits often involves using oscilloscopes, multimeters, and signal generators to measure voltages, currents, and waveforms. Understanding the fundamental principles of analog electronics is crucial – this is crucial to identifying problems such as component failures, mismatched impedances, or signal degradation. Troubleshooting often starts with visual inspections, looking for any visible signs of damage or loose connections. Then, using multimeters to measure voltages and currents at different points in the circuit helps identify faulty components or areas with abnormal voltage drops. Oscilloscopes allow observation of waveforms for anomalies such as distortion or noise. Careful tracing of signals through the circuit helps identify the source of the problem.

Digital circuit troubleshooting often leverages logic analyzers, bus analyzers, and digital multimeters. Understanding digital logic gates, timing diagrams, and data protocols is essential. Logic analyzers capture digital signals and display their timing relationships, enabling identification of timing violations or incorrect data patterns. Digital multimeters can check voltage levels, and bus analyzers can decode communication protocols on various data buses. Identifying a faulty gate, a short circuit, or a problem with clock signals would help isolate the root cause. Using diagnostic software combined with these tools gives insight into internal microprocessor states for more complex systems.

For example, I once diagnosed a faulty analog sensor by analyzing its output voltage using an oscilloscope, which revealed a significant amount of noise. The solution was replacing the sensor with a properly shielded replacement. On a different occasion, a digital circuit fault was isolated using a logic analyzer, which pinpointed a timing error in a specific gate, solved by replacing the faulty integrated circuit.

Q 8. Explain the difference between preventive and corrective maintenance in avionics.

Preventive and corrective maintenance are two crucial aspects of avionics maintenance, aiming to ensure the safe and reliable operation of aircraft systems. Preventive maintenance focuses on preventing failures before they occur, while corrective maintenance addresses failures after they have happened.

- Preventive Maintenance: This involves scheduled inspections, servicing, and replacements of components based on manufacturers’ recommendations and service bulletins. Think of it like regular oil changes for your car – it keeps the engine running smoothly and prevents major problems down the line. Examples include scheduled inspections of wiring harnesses, lubrication of moving parts, and replacing components nearing their lifespan. This proactive approach minimizes unscheduled downtime and increases the overall lifespan of the avionics systems.

- Corrective Maintenance: This is troubleshooting and repairing avionics systems after a malfunction or failure has occurred. It’s like fixing a flat tire – you deal with the problem after it’s happened. This can range from simple repairs, such as replacing a faulty circuit breaker, to complex repairs requiring specialized tools and expertise. Corrective maintenance requires meticulous fault isolation techniques to pinpoint the root cause of the failure and prevent recurrence.

In essence, preventive maintenance is about avoiding problems, while corrective maintenance is about fixing them. A well-balanced maintenance program uses both approaches to maximize safety and efficiency.

Q 9. How familiar are you with various avionics communication protocols (e.g., ARINC 429, Ethernet)?

I’m highly familiar with various avionics communication protocols. My experience includes extensive work with both legacy and modern systems. Let’s delve into a few examples:

- ARINC 429: This is a widely used data bus in older and some modern aircraft. It’s a high-speed, reliable, and relatively simple protocol. I’m proficient in interpreting its data words, understanding its error detection mechanisms, and troubleshooting communication issues related to word count, data validity, and label decoding. I’ve worked on numerous occasions isolating problems where a faulty data word was causing an incorrect indication in the cockpit, requiring meticulous analysis of the data stream.

- Ethernet (AFDX): This is becoming increasingly prevalent in modern aircraft, offering high bandwidth and flexibility. My expertise extends to understanding its packet structure, network topology, and troubleshooting techniques for issues like network congestion, packet loss, and switch failures. I’m familiar with using network analyzers to diagnose network problems, and possess practical experience resolving network issues that caused intermittent communication failures.

- Other Protocols: My experience also covers other protocols like CAN bus (Controller Area Network), RS-232/422/485 serial communication, and various proprietary protocols. The specific protocol employed is often dependent on the system being maintained.

Understanding these protocols is crucial for effective fault isolation. Knowing the communication architecture allows for a systematic approach to pinpointing faulty components within the complex network of avionics systems.

Q 10. Describe your experience using diagnostic software for avionics systems.

I have extensive experience using various diagnostic software packages for avionics systems. My experience includes both built-in test equipment (BITE) and external diagnostic tools. For example, I’m proficient with tools that interface with aircraft data buses to monitor and log data from various avionics systems. This enables me to collect real-time data and historical logs for analysis.

One example includes using a specialized software package to diagnose an intermittent GPS navigation failure. By analyzing data logs, I was able to identify sporadic signal dropouts correlating with high G-forces, leading to the identification of a loose connection within the GPS antenna assembly. This illustrates how diagnostic software can dramatically speed up the troubleshooting process.

I’m also familiar with various manufacturer-specific diagnostic tools, offering in-depth access to system parameters and internal diagnostics. My experience extends to utilizing software packages that allow remote access to aircraft systems for real-time diagnostics, enabling rapid response to issues and reducing maintenance time.

Q 11. How do you ensure safety and compliance with regulations during avionics troubleshooting?

Safety and regulatory compliance are paramount in avionics troubleshooting. Every action I take is guided by adherence to strict safety procedures and regulations, such as those defined by the FAA (Federal Aviation Administration) and EASA (European Union Aviation Safety Agency).

- Strict adherence to maintenance manuals: All troubleshooting follows the manufacturer’s maintenance manuals, ensuring procedures are performed correctly and safely.

- Lockout/Tagout procedures: Before any work is performed, proper lockout/tagout procedures are followed to prevent accidental energization of circuits and ensure the safety of personnel.

- Proper documentation: All work performed, including troubleshooting steps, findings, and repairs, are meticulously documented. This ensures traceability and accountability, crucial for regulatory compliance and future maintenance.

- Calibration and testing: After repairs, thorough testing and recalibration are conducted to ensure the system functions correctly and within specified limits. This helps to prevent recurrence of the issue and assure continued airworthiness.

- Use of approved parts: Only approved and certified parts are used during repairs. This guarantees the integrity and reliability of the avionics system.

Neglecting safety procedures can have catastrophic consequences. My commitment to following these regulations rigorously is fundamental to my approach to avionics troubleshooting.

Q 12. How would you handle a situation where a critical avionics system fails during flight?

A critical avionics system failure during flight necessitates immediate and decisive action. The exact response depends on the specific system and its impact on flight safety.

- Immediate assessment of the situation: The first step is to quickly assess the nature of the failure and its impact on flight safety. This includes understanding the specific system affected and the available backup systems (if any).

- Follow established emergency procedures: Adherence to established emergency procedures for the specific failure is paramount. These procedures outline the steps necessary to mitigate the risk and ensure safe flight continuation or landing.

- Communication with air traffic control (ATC): Immediately communicate the emergency situation to ATC, providing them with the necessary information for guidance and assistance.

- Utilize available backup systems: If available, switch to backup systems to maintain essential functions. This requires proficiency with the aircraft systems and understanding of the limitations of the backup systems.

- Prioritize safe landing: The primary goal is a safe landing. This might involve diverting to a nearby airport or executing emergency procedures to ensure a safe return to the ground.

- Post-flight analysis: After a safe landing, a thorough post-flight analysis of the failure must be performed to determine the root cause, implement corrective actions, and prevent future occurrences.

In such critical situations, calm, methodical thinking, and accurate execution of established procedures are essential to ensuring the safety of the aircraft and its occupants.

Q 13. Explain your understanding of Human Factors and their impact on troubleshooting.

Human factors play a significant role in avionics troubleshooting. It encompasses the physical and cognitive aspects of human interaction with the system, encompassing the interaction between the technician and the equipment during troubleshooting.

- Cognitive factors: Stress, fatigue, time pressure, and lack of proper training can all negatively impact a technician’s ability to diagnose and resolve a problem accurately. Effective troubleshooting requires focus, clear thinking, and a methodical approach.

- Physical factors: Ergonomics, workspace layout, and the design of the diagnostic tools can also impact a technician’s ability to perform efficiently and safely. A poorly designed workspace or uncomfortable tools can contribute to errors.

- Decision-making: Troubleshooting often involves making decisions under uncertainty. Utilizing a structured troubleshooting methodology, such as a decision tree or fault isolation flowchart, can help mitigate errors and improve efficiency.

- Teamwork: Many troubleshooting scenarios involve teamwork. Clear communication, collaboration, and a shared understanding of procedures are vital for success.

Understanding human factors is essential for designing safe and efficient troubleshooting processes and for training technicians to perform their duties effectively. A good technician is aware of their own limitations and actively manages the human factors that can impact their work.

Q 14. Describe your experience with interpreting fault codes and logs.

Interpreting fault codes and logs is a fundamental skill in avionics troubleshooting. Fault codes provide valuable clues about the nature of a malfunction, while logs offer a historical record of system behavior. My experience spans interpreting a wide range of codes and log formats from various avionics manufacturers.

For instance, I recently worked on a system that generated a fault code indicating a communication error between the air data computer (ADC) and the flight management system (FMS). The associated log data revealed intermittent communication dropouts at specific altitudes. By meticulously analyzing the timing and sequence of these dropouts, I identified a faulty connector within the aircraft’s wiring harness that was failing under specific pressure conditions.

I’m skilled in utilizing various diagnostic software to decode fault codes, convert hexadecimal or binary representations into human-readable formats, and correlate this information with system schematics and technical documentation. My experience extends to interpreting both numerical fault codes and alphanumeric codes, and understanding how they relate to the system’s overall health. The ability to extract useful information from fault codes and logs is paramount for effective and efficient troubleshooting.

Q 15. How do you prioritize troubleshooting tasks based on safety and operational criticality?

Prioritizing troubleshooting tasks in avionics hinges on a critical understanding of safety and operational impact. We use a risk-based approach, employing techniques like Failure Modes and Effects Analysis (FMEA) to systematically assess the potential consequences of each malfunction.

For instance, a failure in the flight control system commands immediate attention, as it directly impacts flight safety and takes precedence over a malfunction in the in-flight entertainment system. We prioritize tasks based on a tiered system:

- Critical: Immediate attention required; impacts flight safety or critical flight operations (e.g., engine failure indications, loss of navigation data).

- High: Requires prompt attention; may affect flight operation but doesn’t immediately endanger safety (e.g., malfunctioning autopilot, loss of non-essential communication).

- Medium: Can be addressed during routine maintenance or next scheduled inspection; minimally impacts operation (e.g., minor discrepancies in the weather radar display).

- Low: Can be deferred to a later date without compromising safety or operations (e.g., minor cosmetic issues in the cockpit).

This tiered approach ensures that the most pressing issues—those directly affecting safety—are addressed first, while less critical issues are handled according to their operational importance.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the common sources of electromagnetic interference (EMI) affecting avionics and how do you mitigate them?

Electromagnetic Interference (EMI) is a significant concern in avionics, as it can disrupt the operation of sensitive electronic systems. Common sources include:

- Other Avionics Systems: Interference can occur between different systems within the aircraft due to poorly shielded wiring or inadequate filtering.

- Electrical Systems: High-power electrical components such as generators and starter motors can generate significant EMI.

- External Sources: Ground-based radar, radio transmissions, and lightning strikes can all cause significant interference.

- Internal Components: Faulty or improperly functioning components within avionics systems themselves can generate EMI.

Mitigation strategies involve careful design and implementation:

- Shielding: Using conductive materials to isolate sensitive circuits from EMI sources.

- Filtering: Employing filters to suppress unwanted frequencies.

- Grounding: Providing a low-impedance path to ground to prevent current build-up and reduce noise.

- Cable Management: Routing cables properly and using shielded cables to minimize coupling.

- EMC Testing: Performing thorough electromagnetic compatibility testing to verify that the system is robust against EMI.

For example, during an investigation of an erratic autopilot behavior, we discovered that the source of interference was a poorly shielded power cable running adjacent to the autopilot’s control lines. Re-routing the power cable and adding shielding resolved the issue.

Q 17. What is your experience with the use of schematics, wiring diagrams, and technical manuals?

Schematics, wiring diagrams, and technical manuals are essential tools in avionics troubleshooting. My experience with these documents is extensive, ranging from simple circuit analysis to complex system-level diagnostics.

Schematics provide a detailed illustration of the circuit’s components and their interconnections. They are crucial for understanding signal flow and identifying potential points of failure. Wiring diagrams, on the other hand, show the physical layout of the wiring and connectors in the aircraft. This is critical for tracing wires and identifying the exact location of components. Technical manuals offer comprehensive information about system operation, fault diagnosis, and maintenance procedures, guiding the troubleshooting process.

I’m proficient in using these documents in conjunction with diagnostic equipment to isolate faults. For example, during a recent troubleshooting event involving a malfunctioning transponder, I utilized the schematic to identify the faulty integrated circuit and then the wiring diagram to trace the associated wiring harness. The technical manual guided me through the detailed removal and replacement procedure, ensuring that the installation complied with all safety and regulatory standards.

Q 18. Explain your understanding of various avionics sensors and their troubleshooting.

Avionics sensors are critical for providing real-time data for flight operations. Understanding their operation and troubleshooting techniques is vital. I have extensive experience with various sensors, including:

- Air Data Sensors (ADS): These measure airspeed, altitude, and outside air temperature. Troubleshooting often involves checking sensor calibration, verifying the integrity of pneumatic lines, and checking for obstruction.

- Attitude and Heading Reference Systems (AHRS): These provide aircraft orientation data. Troubleshooting typically involves checking the power supply, verifying sensor alignment, and performing self-test procedures.

- Inertial Navigation Systems (INS): These provide navigation data using inertial sensors. Troubleshooting requires verifying alignment, checking for sensor drift, and inspecting the gyroscopes and accelerometers.

- GPS Receivers: These receive navigation signals from satellites. Troubleshooting generally involves checking antenna integrity, signal strength, and software updates.

Troubleshooting avionics sensors often involves a combination of visual inspection, utilizing built-in test equipment (BITE), and using specialized diagnostic tools. For instance, during a case involving an inaccurate airspeed reading, I used a calibrated airspeed indicator to cross-reference the sensor output, identifying a faulty pitot tube that needed replacement.

Q 19. Describe your experience with replacing and installing avionics components.

I have extensive experience replacing and installing various avionics components, ranging from simple instruments to complex integrated systems. This includes adhering to strict safety procedures and following manufacturer’s instructions.

The process typically involves:

- Disconnection: Carefully disconnecting power and data lines, ensuring all power is removed before handling any component.

- Removal: Removing the component using appropriate tools and techniques.

- Installation: Carefully installing the new component, ensuring correct orientation and secure connections.

- Testing: Thoroughly testing the newly installed component, verifying its proper functionality.

- Documentation: Documenting all the steps involved, including any part numbers replaced.

I have worked on various aircraft types, ensuring compliance with regulatory requirements and aircraft maintenance manuals. A recent example involved the replacement of a faulty flight control computer. This was a complex procedure requiring meticulous attention to detail. Before starting, I reviewed the maintenance manual and relevant schematics. After installation, extensive system tests were performed to ensure proper functionality before returning the aircraft to service.

Q 20. How do you document your troubleshooting process and findings?

Meticulous documentation is crucial in avionics troubleshooting. It ensures consistency, traceability, and accountability. My documentation process typically involves:

- Initial Report: Describing the initial malfunction, symptoms, and initial observations.

- Troubleshooting Steps: Detailing all the steps taken during the troubleshooting process, including tests conducted and results obtained.

- Component Identification: Clearly identifying all components inspected, tested, or replaced, including part numbers.

- Diagram and Schematics: Marking diagrams and schematics with notes and observations.

- Corrective Actions: Documenting the corrective actions taken, such as replacing components or adjusting settings.

- Verification: Recording the verification process and confirmation that the fault has been resolved.

I use a combination of digital and paper-based documentation depending on the specifics of the task. The documentation is always complete, accurate, and easily understandable by others. This meticulous record-keeping is essential for maintaining a comprehensive history of the aircraft’s maintenance and repair actions.

Q 21. What safety procedures do you follow during avionics troubleshooting?

Safety is paramount in avionics troubleshooting. My adherence to strict safety procedures is unwavering. These include:

- Lockout/Tagout: Utilizing lockout/tagout procedures to prevent accidental activation of power systems.

- Grounding: Ensuring proper grounding to prevent static discharge and electrical shock.

- Safety Equipment: Using appropriate personal protective equipment (PPE), such as safety glasses, gloves, and anti-static wrist straps.

- Awareness of Hazards: Maintaining awareness of potential hazards, such as high voltage, moving parts, and hazardous materials.

- Compliance with Regulations: Strict adherence to all relevant safety regulations and aircraft maintenance manuals.

- Risk Assessment: Conducting a thorough risk assessment before commencing any task.

For example, before working on any system with high voltage, I always follow the lockout/tagout procedure to ensure that power is completely disconnected and locked out. This rigorous adherence to safety protocols significantly minimizes the risk of accidents and ensures the safety of both myself and the aircraft.

Q 22. Explain your experience with performing functional checks and tests after repairs.

After any repair on an avionics system, rigorous functional checks and tests are paramount to ensure airworthiness and safety. This isn’t just about verifying the immediate repair; it’s about confirming the overall system integrity hasn’t been compromised. My approach involves a multi-step process.

- Pre-Flight Checks: I start with visual inspections, checking for proper cable routing, connector security, and any signs of damage. This is like a pre-flight check on an aircraft itself – you wouldn’t take off without visually inspecting the wings!

- Built-In Test Equipment (BITE) Utilization: Next, I leverage the aircraft’s BITE system. This built-in self-diagnostic system provides initial indications of system health. I’ll meticulously review all BITE reports and cross-reference them with the repair documentation.

- System-Specific Tests: Following the BITE, I perform system-specific tests according to the relevant maintenance manuals. This might involve using specialized test equipment to verify signal integrity, power levels, and communication protocols within the system. For example, testing an air data computer would involve checking for accurate airspeed, altitude, and outside air temperature readings.

- Functional Checks: Finally, I carry out functional checks that simulate real-world operating conditions. This could be anything from checking the functionality of a radio communication system through actual transmissions to verifying the correct operation of a flight control system in a simulated environment, always prioritizing safety.

- Documentation: Throughout this process, detailed records of each step, including test results and observations, are meticulously documented in accordance with regulatory requirements.

For example, after repairing a faulty GPS receiver, I wouldn’t just assume it’s working correctly after replacing a component. I would verify the GPS signal acquisition, accuracy, and integrity using a dedicated GPS test set and check it against known reference points before clearing the aircraft for flight.

Q 23. How do you stay updated with the latest technologies and advancements in avionics?

Staying current in the rapidly evolving field of avionics requires a proactive and multi-faceted approach. It’s not a passive process; it requires deliberate effort.

- Industry Publications and Conferences: I regularly subscribe to leading aviation publications like Aviation Week & Space Technology and actively participate in industry conferences and workshops. These provide insights into the newest technologies and emerging trends.

- Manufacturer Training: I actively seek out and participate in manufacturer-provided training courses on specific avionics systems and equipment. These courses often include hands-on training with the latest technologies and troubleshooting techniques.

- Online Resources and Webinars: I leverage online resources like technical forums, webinars, and manufacturer websites to access the latest service bulletins, technical notes, and updates.

- Continuing Education: I actively pursue continuing education units (CEUs) to maintain and enhance my certifications and technical expertise. This may involve formal courses or self-directed learning through online platforms.

- Networking: Building and maintaining a strong network within the avionics community is also crucial. Sharing knowledge and experiences with other professionals helps to stay informed about the latest developments.

Staying updated isn’t just about reading manuals; it’s about understanding the underlying principles and anticipating potential challenges. For instance, understanding the shift towards data-driven maintenance and the integration of advanced analytics requires a broader understanding than just the mechanical aspects of the systems.

Q 24. Describe your approach to troubleshooting a problem with unknown root cause.

Troubleshooting a problem with an unknown root cause demands a systematic and logical approach. Rushing to conclusions is a recipe for wasted time and potential safety hazards.

- Gather Information: The first step is always thorough information gathering. This involves interviewing pilots or maintenance personnel to understand the symptoms, when the problem occurred, and any preceding events. Think of it as a detective gathering clues at a crime scene.

- Initial Inspection: A visual inspection of the suspect system is crucial. Look for obvious signs of damage, loose connections, or anything out of the ordinary.

- BITE and System Logs: Check the BITE system and any relevant system logs for error codes or anomalies. These logs often offer valuable clues. Think of them as the aircraft’s “black box”.

- Schematic Review: Consult the system schematics and wiring diagrams to understand the system’s architecture and component interconnections. This helps pinpoint the potential areas of failure.

- Isolate the Problem: Use a process of elimination to isolate the faulty component. Start with the most likely causes based on the symptoms and available data. This might involve performing various tests using specialized test equipment.

- Hypothesis Testing: Develop hypotheses about the root cause based on observations and test results. Then, conduct further tests to verify or refute these hypotheses. This is an iterative process.

- Documentation and Reporting: Throughout this process, maintain detailed records of all steps, tests, and observations. This is essential for accurate reporting and preventing future issues.

For instance, if an aircraft experienced a sudden loss of communication, I wouldn’t immediately assume a radio failure. I would systematically check antennas, power supplies, and wiring harnesses before concluding the radio itself is the culprit. A methodical approach is key.

Q 25. How do you collaborate effectively with other technicians and engineers during troubleshooting?

Effective collaboration is essential in avionics troubleshooting, especially given the complexity of modern systems. My approach centers on clear communication, shared understanding, and mutual respect.

- Clear Communication: I use precise and unambiguous language to describe the problem and my findings to other technicians and engineers. I avoid jargon where possible and ensure everyone is on the same page.

- Shared Understanding: I make sure everyone involved understands the system architecture and the potential impact of the problem. I may use diagrams or visual aids to help illustrate complex concepts.

- Open Dialogue: I actively encourage open discussion and brainstorming, valuing the input and expertise of others. Different perspectives can often lead to creative solutions.

- Regular Updates: I provide regular updates on the troubleshooting progress and any significant findings. This keeps everyone informed and prevents delays.

- Respectful Collaboration: I respect the expertise of others, recognizing that everyone brings unique skills and knowledge to the team. A collaborative environment fosters better problem-solving.

For example, in a situation involving a complex flight management system issue, I’d collaborate closely with software engineers and other technicians, sharing diagnostic data and working together to identify the root cause. Effective communication ensures a quick and accurate resolution.

Q 26. Describe a challenging avionics troubleshooting experience and how you overcame it.

One challenging experience involved troubleshooting an intermittent failure in a flight control system. The problem was sporadic, making it difficult to pinpoint the cause. The aircraft would experience unusual pitch oscillations at random intervals.

Initially, the BITE system provided no specific fault codes. We systematically checked sensors, actuators, and the entire wiring harness. We replaced several components based on initial suspicions, but the problem persisted. The challenge was not only the intermittent nature of the problem but also the safety-critical nature of the flight control system. A single, undetected failure could have catastrophic consequences.

The breakthrough came when we decided to monitor the system’s electrical signals using an oscilloscope during a flight simulation. We discovered a subtle, intermittent noise in the power supply that was only apparent under specific load conditions. This noise was causing the flight control computer to malfunction sporadically. Replacing the power supply resolved the issue permanently.

This experience highlighted the importance of thorough investigation, creative problem-solving, and the use of specialized test equipment beyond basic BITE analysis. The success relied on a collaborative effort, meticulous data collection, and the willingness to explore alternative diagnostic methods when conventional approaches failed. It reinforced the critical need for precise documentation and a systematic approach to troubleshooting, especially when dealing with safety-critical systems.

Q 27. What are the limitations of using built-in test equipment (BITE)?

While Built-In Test Equipment (BITE) is a valuable tool in avionics troubleshooting, it does have limitations.

- Limited Scope: BITE systems are usually designed to detect common faults. They may not be able to detect subtle or intermittent problems, or those outside of their pre-programmed diagnostic routines.

- False Positives and Negatives: BITE systems are not foolproof. They can sometimes report false positives (indicating a fault when none exists) or false negatives (failing to detect an actual fault).

- Lack of Granularity: BITE often provides a general indication of a problem rather than pinpointing the exact faulty component. This requires further investigation using specialized test equipment.

- System Complexity: Modern avionics systems are incredibly complex. The BITE system might not be able to cover every potential point of failure in the system. For example, a complex software interaction may not be easily diagnosed by BITE.

Therefore, BITE should be considered as a starting point in the troubleshooting process, not the sole diagnostic tool. It’s crucial to use other techniques and specialized equipment to confirm BITE findings and diagnose problems that BITE may miss.

Q 28. How familiar are you with different types of aircraft avionics systems?

My experience encompasses a wide range of aircraft avionics systems, including those found on both commercial and general aviation aircraft.

- Flight Management Systems (FMS): I’m proficient in troubleshooting various FMS architectures and functionalities, including navigation, flight planning, and performance calculations. I understand the interplay between different components within the FMS, such as the GPS receivers, inertial reference units, and flight computers.

- Communication Systems: My expertise includes VHF and HF communication systems, transponders, and satellite communication equipment. I’m familiar with troubleshooting signal strength issues, antenna problems, and communication protocol malfunctions.

- Navigation Systems: I’m well-versed in the operation and troubleshooting of various navigation systems, including VOR, ILS, GPS, and inertial navigation systems. I understand the principles of these systems and can diagnose problems relating to sensor accuracy and data processing.

- Flight Control Systems: I possess a strong understanding of flight control systems, including both analog and digital architectures. I’m experienced in troubleshooting problems related to flight control actuators, sensors, and the flight control computer. Safety is paramount in this domain and requires a highly meticulous approach.

- Electrical Power Systems: I understand the various components of aircraft electrical power systems and how to troubleshoot problems related to power generation, distribution, and management. This involves understanding the critical need for reliable power distribution to maintain the operation of other avionics systems.

My knowledge spans multiple manufacturers’ systems, emphasizing a strong understanding of the underlying principles and operational methodologies. This is essential for providing efficient and effective troubleshooting across a variety of aircraft models.

Key Topics to Learn for Avionics Troubleshooting and Fault Isolation Interview

Ace your Avionics Troubleshooting and Fault Isolation interview by mastering these key areas. Remember, practical application and understanding the “why” behind the concepts are as crucial as theoretical knowledge.

- Systems Understanding: Develop a strong grasp of aircraft electrical systems, including power distribution, communication networks (e.g., ARINC), and data bus architectures. Understand how these systems interact and their dependencies.

- Fault Diagnosis Techniques: Familiarize yourself with various troubleshooting methodologies, including the systematic approach (e.g., top-down, bottom-up), using schematics and wiring diagrams effectively, and employing logical reasoning to isolate faults.

- Instrumentation and Test Equipment: Gain proficiency in using common avionics test equipment, such as multimeters, oscilloscopes, and specialized avionics test sets. Understand their limitations and how to interpret their readings accurately.

- Safety Regulations and Procedures: Demonstrate a thorough understanding of relevant safety regulations and procedures related to avionics maintenance and troubleshooting. This includes adhering to safety protocols and documentation practices.

- Troubleshooting Specific Avionics Systems: Focus your preparation on common avionics systems like GPS, transponders, navigation systems, and flight management systems. Understand their operational principles and common failure modes.

- Problem-Solving and Analytical Skills: Practice applying your knowledge to real-world scenarios. Develop strong analytical and problem-solving skills to efficiently identify and resolve complex issues.

- Communication and Teamwork: Prepare to discuss your collaborative approach to troubleshooting, effectively communicating technical information to both technical and non-technical audiences.

Next Steps

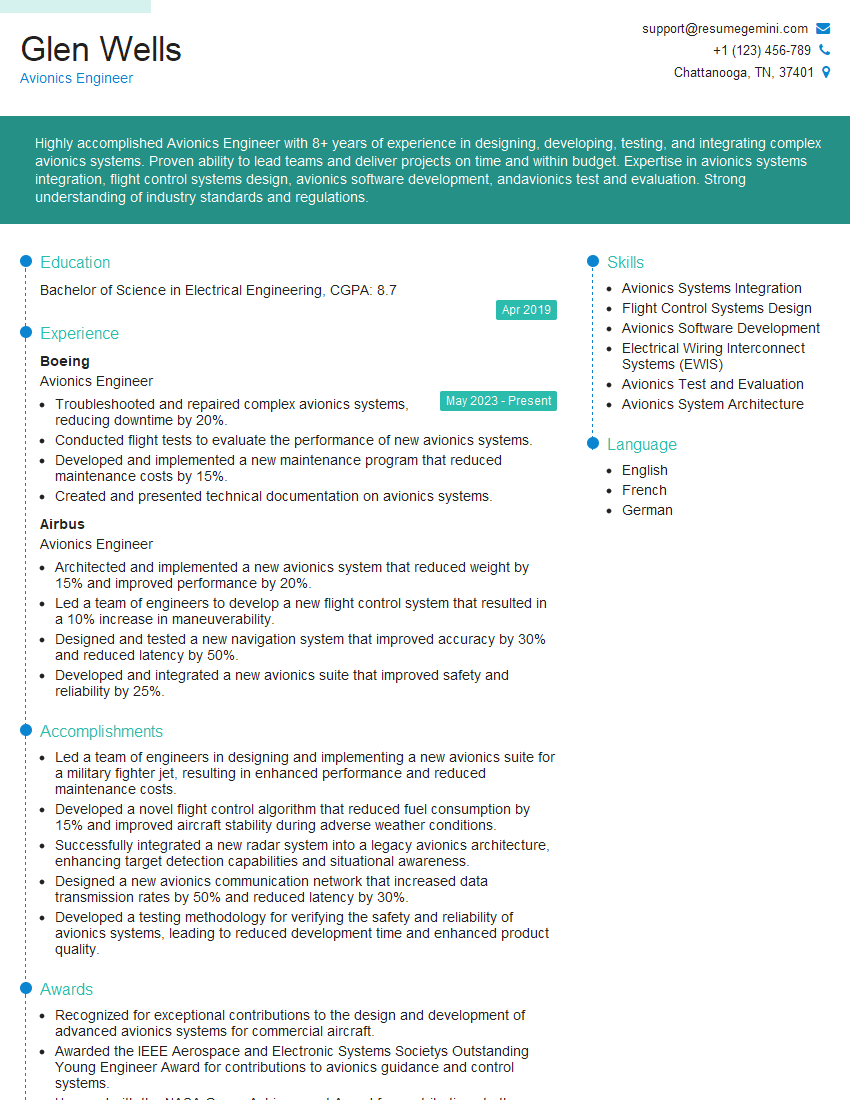

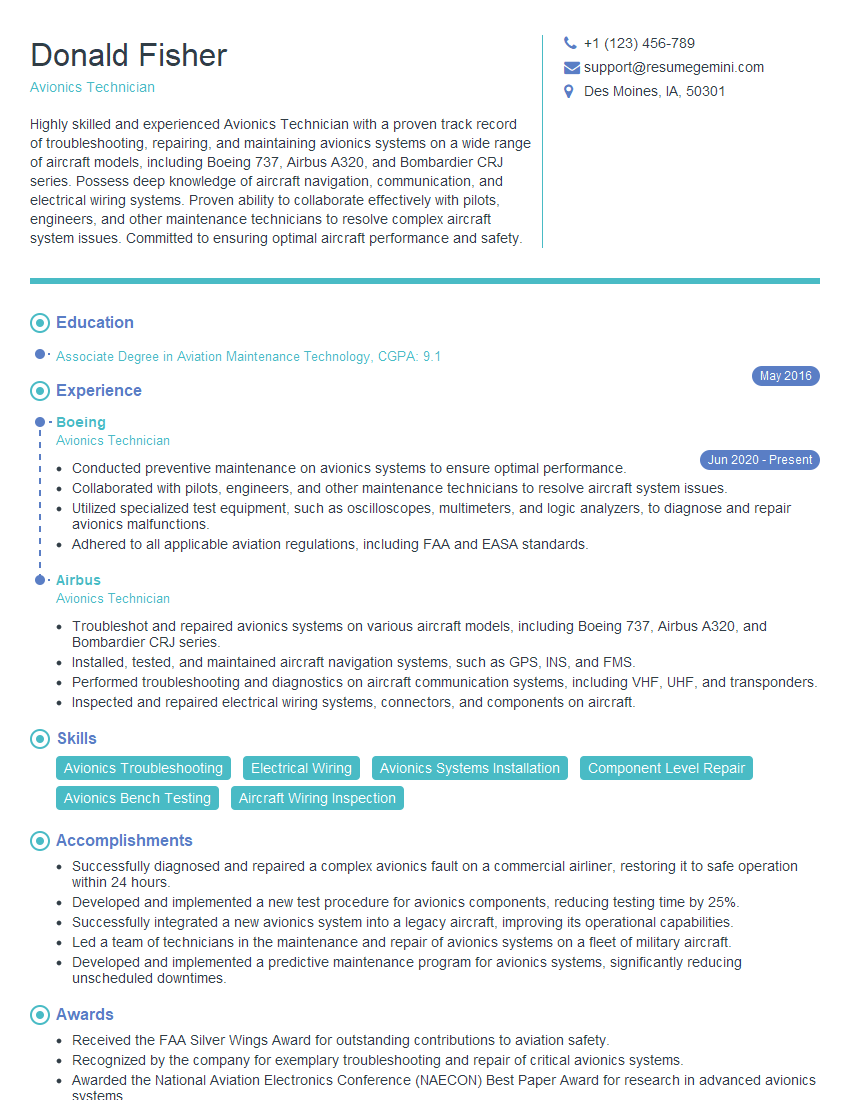

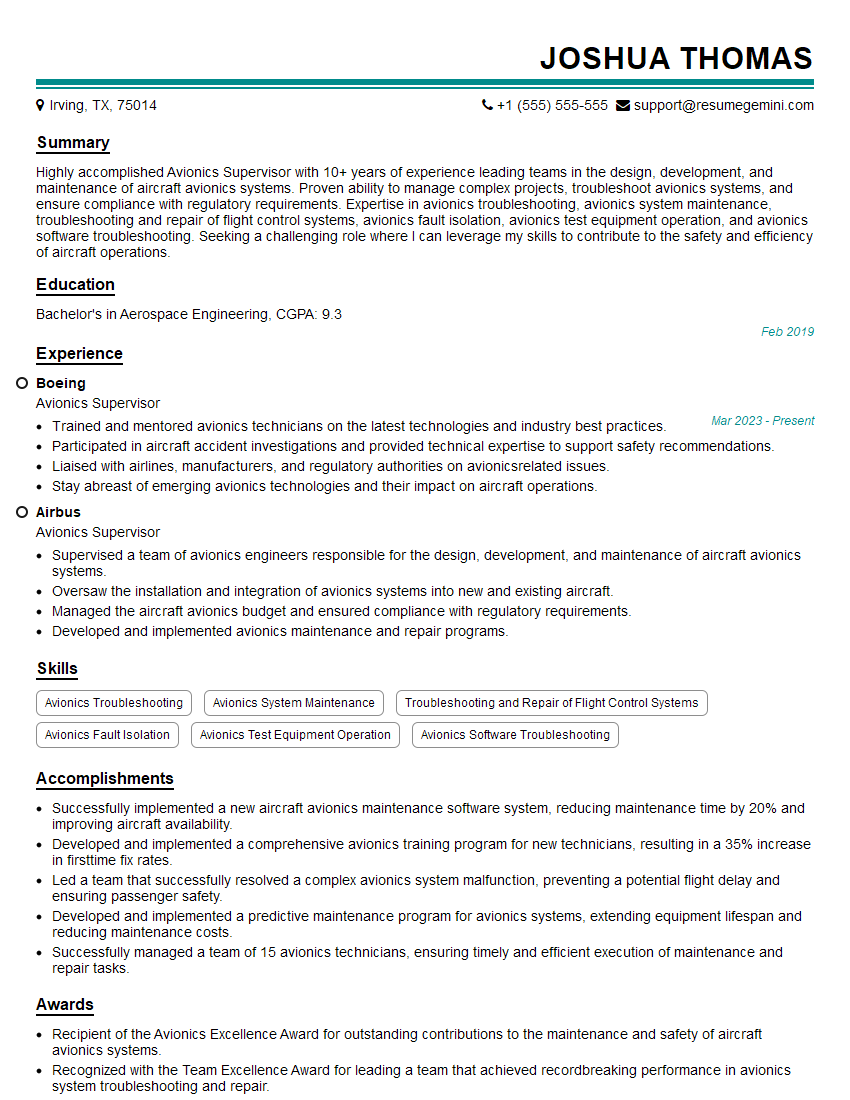

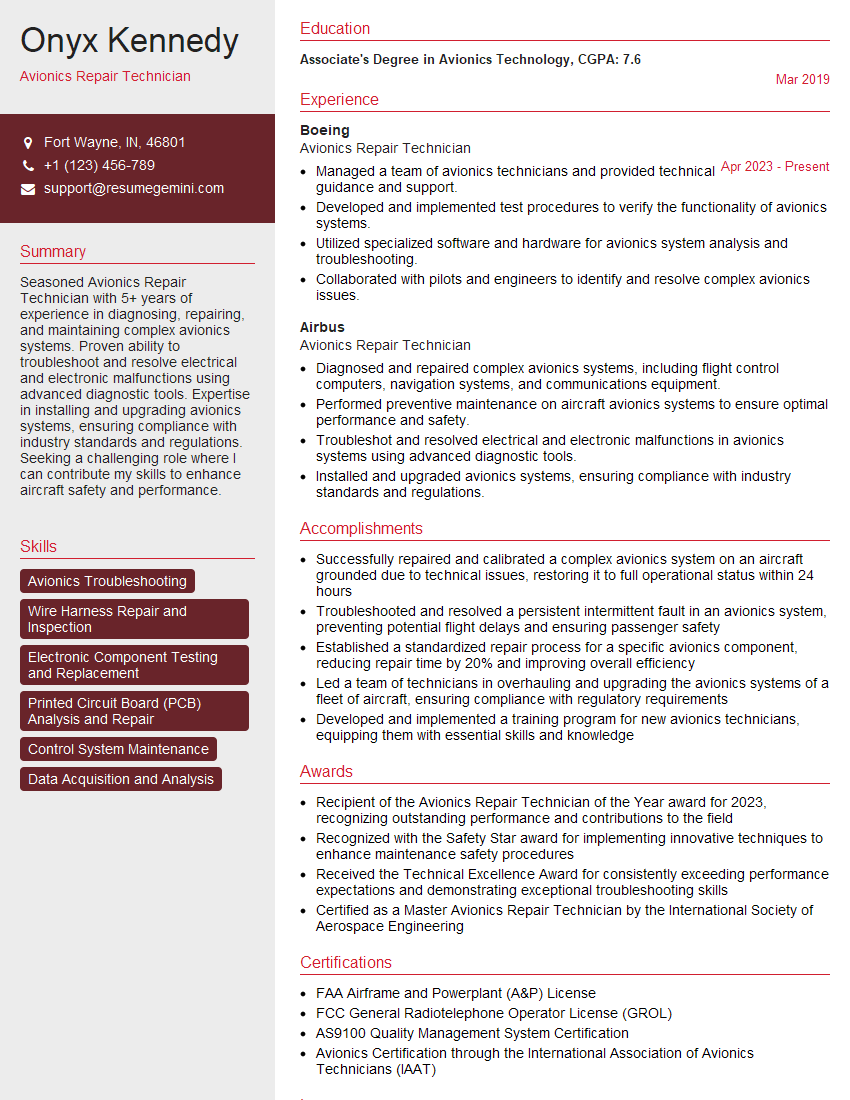

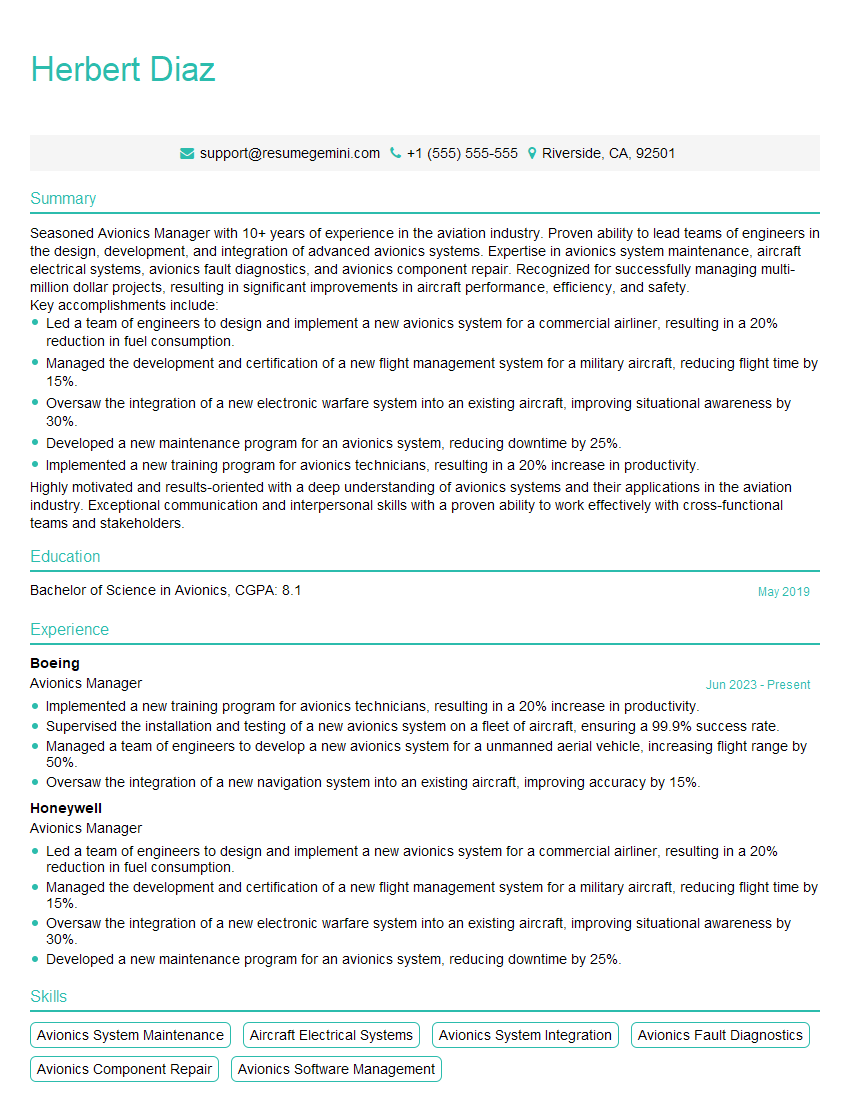

Mastering Avionics Troubleshooting and Fault Isolation opens doors to exciting and rewarding career opportunities in the aviation industry, offering excellent growth potential and challenging projects. To maximize your chances of landing your dream job, a well-crafted resume is essential. An ATS-friendly resume, optimized for Applicant Tracking Systems, significantly increases your visibility to potential employers.

We highly recommend using ResumeGemini to build a professional and effective resume. ResumeGemini provides a user-friendly platform and offers examples of resumes tailored to Avionics Troubleshooting and Fault Isolation roles, giving you a head start in showcasing your skills and experience. This will significantly improve your chances of getting noticed and landing an interview.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good