Unlock your full potential by mastering the most common Bag Forming and Heat Sealing interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Bag Forming and Heat Sealing Interview

Q 1. Explain the different types of bag forming machines.

Bag forming machines are categorized primarily by their forming method and the type of film they handle. Let’s explore some common types:

- Vertical Form Fill Seal (VFFS) machines: These are the workhorses of the industry, forming, filling, and sealing bags in a continuous vertical motion. They’re highly versatile, handling various bag styles (e.g., pillow pouches, gusseted bags) and film types. Think of the snack bags you see at the grocery store—most are likely made by a VFFS machine.

- Horizontal Form Fill Seal (HFFS) machines: These machines form bags horizontally, often ideal for larger or heavier products, or those requiring a more robust seal. They are typically used for industrial applications packaging items such as cement or pet food.

- Pre-made pouch machines: These machines don’t form bags from film rolls; instead, they fill and seal pre-made pouches. This is efficient for high-speed production lines when consistent pouch quality is critical, such as in pharmaceutical packaging.

- Side-weld machines: These create bags by sealing film along the side, then forming and sealing the top. Often utilized for creating bags with a flat bottom, suitable for items needing good stability on shelves.

The choice of machine depends on factors like production volume, bag style, product characteristics, and budget. For instance, a small bakery might use a simple side-weld machine, while a large food manufacturer would opt for a high-speed VFFS machine.

Q 2. Describe the heat sealing process and its parameters.

Heat sealing is a crucial step in bag forming, creating a hermetic seal that protects the product. The process involves applying heat and pressure to a thermoplastic film, causing the polymer chains to soften and fuse, forming a strong bond. Key parameters include:

- Temperature: This is crucial; too low, and the seal won’t fuse properly; too high, and you risk burning or damaging the film. It’s film-specific and needs adjustment based on the film’s melting point and thickness. Think of it like cooking—you need the right temperature to achieve the perfect outcome.

- Dwell Time (Heat Sealing Time): The length of time the heat and pressure are applied. Sufficient dwell time allows for complete fusion of the film layers. Too short, and the seal will be weak; too long, and you risk excess heat damage. This is closely linked to the film type and the thickness of the seal being created.

- Pressure: Ensures good contact between the film layers during the heating process. Insufficient pressure leads to weak seals, often appearing as an incomplete fusion or air gaps along the seal. The pressure varies based on the film thickness.

- Seal Width: The width of the heat seal affects its strength. A wider seal usually provides more strength, but consumes more material.

These parameters must be carefully controlled and adjusted based on the specific film being used and the desired seal strength and appearance. Incorrect settings can lead to significant seal failures, as shown in question 3.

Q 3. What are the common causes of heat seal failures?

Heat seal failures are frustrating but common. Understanding their causes is key to prevention. Here are some major culprits:

- Incorrect Heat Seal Parameters: This is the most frequent cause. Incorrect temperature, dwell time, or pressure leads to weak or incomplete seals. Imagine trying to weld two pieces of metal without sufficient heat or pressure.

- Film Contamination: Dust, dirt, or moisture on the film surface can prevent proper fusion. Think of it like trying to stick two wet pieces of paper together.

- Film Degradation: Old or improperly stored film can lose its heat-sealability, resulting in weak seals. This is similar to using old or damaged welding rods, which would not result in a proper weld.

- Faulty Heating Elements: Worn or malfunctioning heating elements in the machine can cause inconsistent heat distribution, leading to weak or uneven seals. This relates to using equipment that is not properly maintained or calibrated.

- Improper Film Alignment: If the film isn’t properly aligned, the seal won’t form consistently across its width. It’s like trying to join two pipes that aren’t perfectly aligned, the weld will be weaker.

Q 4. How do you troubleshoot a faulty heat seal?

Troubleshooting a faulty heat seal involves a systematic approach:

- Visual Inspection: Carefully examine the faulty seal. Look for inconsistencies such as open areas, weak spots, or discoloration. Does the seal appear thin, brittle, or uneven? This gives clues about the underlying cause.

- Check Machine Parameters: Verify temperature, dwell time, and pressure settings. Are they within the recommended range for the film being used? Refer to the machine’s manual and the film manufacturer’s specifications.

- Inspect the Film: Ensure the film is clean, dry, and hasn’t expired. Check for any visible damage or contamination that might affect seal integrity.

- Examine Heating Elements: If the problem seems widespread, check the heating elements for wear, tear, or malfunction. This often requires a professional technician.

- Test the Seal Strength: Using a seal strength tester (if available), measure the strength of the seal to objectively assess its quality. This provides quantifiable data to evaluate improvements after parameter adjustments.

- Adjust Parameters Incrementally: If parameters are off, make small adjustments (e.g., increase the temperature by 5°C) and test again. Note down each adjustment and its impact. This approach avoids drastic changes that could worsen the problem.

Remember to always prioritize safety during troubleshooting. Never work on the machine when it’s powered on.

Q 5. What are the safety precautions when operating bag forming and heat sealing equipment?

Safety is paramount when working with bag forming and heat sealing equipment. Here are essential precautions:

- Lockout/Tagout Procedures: Always lock out and tag out the power supply before performing any maintenance or cleaning tasks. This prevents accidental activation of the machine.

- Personal Protective Equipment (PPE): Use appropriate PPE, including safety glasses to protect against debris, heat-resistant gloves to prevent burns, and hearing protection for noisy machines.

- Emergency Shut-off Awareness: Locate and familiarize yourself with the emergency stop buttons and their operation. This enables quick response in case of an emergency.

- Regular Maintenance: Preventative maintenance is essential. Regularly inspect the machine for wear and tear and follow the manufacturer’s recommendations for routine checks and cleaning. Proper maintenance ensures safety and reduces the risk of malfunction.

- Proper Training: Ensure operators receive adequate training on the safe operation, maintenance, and troubleshooting of the machine. This is paramount to avoiding incidents.

- Clear Work Area: Keep the work area clean and free from clutter. A tidy environment reduces the risk of trips, falls, and other accidents.

Following these precautions is crucial to maintaining a safe working environment and avoiding injury.

Q 6. Explain the importance of proper film selection for bag forming.

Proper film selection is critical for successful bag forming and heat sealing. The film’s properties directly impact the seal’s strength, the bag’s appearance, and the product’s protection. Key considerations include:

- Heat Sealability: The film must have good heat-sealability, meaning it should fuse effectively under the application of heat and pressure. The film’s material composition determines this, and specifications are usually provided by the film manufacturer.

- Thickness: The film’s thickness affects the seal strength and the bag’s overall durability. Thicker films generally create stronger seals but might require adjustments in machine settings.

- Material Type: Different materials (e.g., polyethylene, polypropylene, polyester) offer different properties. Polyethylene is popular for its flexibility and heat-sealability, while polypropylene provides better clarity and stiffness.

- Barrier Properties: The film’s barrier properties determine its ability to protect the product from moisture, oxygen, and other environmental factors. This is particularly important for products with sensitive properties or long shelf lives.

- Product Compatibility: The film should be compatible with the product being packaged. For example, certain films might interact poorly with fatty or oily products, leaching chemicals into the product.

Choosing the right film is a balancing act between cost, performance, and product needs. For instance, a bakery might use a more economical film for bread, while a pharmaceutical company would require a film with excellent barrier properties to ensure drug stability.

Q 7. How do you adjust the heat sealing temperature and pressure?

Adjusting heat sealing temperature and pressure requires careful consideration and typically involves using the machine’s control panel. The specific methods vary depending on the machine’s model, but the general principles remain the same:

- Temperature Adjustment: Most machines have a digital display showing the current temperature and controls to increase or decrease it. Adjustments should be incremental (e.g., 2-5°C at a time) to avoid drastic changes and ensure that the adjustments are properly integrated into the machine’s control loop. Always consult the machine’s manual for the correct setting range for the specific film being used. Trial and error is sometimes necessary for fine tuning; keep detailed records of temperature adjustments and the associated seal quality.

- Pressure Adjustment: Similar to temperature, pressure is adjusted through machine controls. The method for adjustment varies by machine; some may use a dial, others a digital interface. It’s important to understand how the pressure is being measured (e.g., pneumatic pressure, mechanical pressure) to make effective adjustments. Again, small adjustments are recommended, and careful monitoring of the seal quality is vital.

Monitoring seal quality after each adjustment is crucial. Use a seal strength tester, if available, or visually inspect the seals. Record the settings and corresponding seal quality to optimize the process for the specific film and product.

Q 8. Describe the different types of heat sealing techniques.

Heat sealing, a crucial step in bag forming, utilizes heat to fuse thermoplastic materials, creating a strong, airtight seal. Several techniques exist, each with its advantages and disadvantages.

Impulse Sealing: This common method uses a short burst of heat from a heated element to seal a localized area. It’s efficient for smaller bags and offers low energy consumption. Think of it like briefly touching a hot iron to fabric.

Continuous Band Sealing: A heated band continuously seals the bag along its length, ideal for high-speed production lines. Imagine a conveyor belt with a constantly heated metal bar pressing against the bag material.

Rotary Sealing: This method involves a heated roller that seals the bag as it rotates. It’s best for flexible materials and achieving uniform seals, even at high speeds. It’s like using a heated rolling pin to seal a pastry.

Ultrasonic Sealing: This technique utilizes high-frequency vibrations to generate heat and fuse materials. It’s known for its clean seal and suitability for delicate materials and is often preferred in the food industry for its hygienic properties.

Hot Air Sealing: A stream of hot air fuses materials, often used in combination with other techniques, like a hairdryer drying paint before baking.

Q 9. How do you ensure consistent bag formation and sealing?

Consistent bag formation and sealing are paramount for efficient and reliable production. This requires a multi-faceted approach:

Precise Film Feeding: The film needs to be fed at a consistent speed and tension to avoid wrinkles or stretching that affects bag formation. Sensors and automated tension control systems play a vital role here.

Accurate Temperature Control: The heat sealing temperature needs precise control to achieve the ideal seal strength without damaging the film. Thermostats, thermocouples, and PID controllers are used to maintain consistent temperatures. Too low, and the seal won’t hold; too high, and the film will melt or burn.

Optimized Sealing Time (Dwell Time): Sufficient time must be allowed for the heat to properly fuse the materials and form a seal. This dwell time is adjustable based on the film type and sealing method.

Regular Calibration and Maintenance: Frequent checks and maintenance are necessary to keep equipment running efficiently and accurately. This includes cleaning, replacing worn parts, and calibrating sensors and controls.

Proper Film Selection: Choosing the right film material for the application is crucial. Film properties including thickness, heat sealability, and strength directly impact bag formation and seal integrity.

Q 10. What are the common maintenance procedures for bag forming and heat sealing machines?

Regular maintenance is key to preventing downtime and ensuring consistent performance. This includes:

Daily Cleaning: Removing accumulated film scraps, dust, and debris from the sealing jaws, belts, and other components.

Weekly Inspections: Checking for wear and tear on seals, belts, and other moving parts. This could involve lubricating moving parts and tightening loose screws or bolts.

Monthly Calibration: Checking and calibrating temperature sensors, film feed systems, and sealing pressure controls to ensure accuracy.

Periodic Overhaul: More extensive maintenance including replacing worn parts like sealing elements, belts, and rollers. The frequency of this depends on machine usage and the manufacturer’s recommendations.

Safety Checks: Regularly inspecting safety guards and interlocks to ensure the equipment operates safely and according to regulatory standards.

Q 11. How do you identify and resolve issues with bag size or shape?

Incorrect bag size or shape often stems from problems with the machine’s settings or components.

Check Film Feed Settings: Ensure correct film width and tension. Incorrect settings can lead to distorted bags.

Examine Forming Tubes and Jaws: Wear or damage in these parts can cause inconsistent bag dimensions. Replace or repair as needed.

Inspect Sealing Jaws Alignment: Improper alignment can create uneven seals or misshapen bags.

Review Temperature and Pressure Settings: Improper heat sealing parameters can lead to weak seals or distorted bags.

Check for Obstructions: Any blockages in the film path can affect bag formation.

Review Program Settings: If the machine is programmable, review and adjust the settings as needed, referencing the machine’s operational manual.

Q 12. Explain the role of dwell time in heat sealing.

Dwell time refers to the duration the heated sealing elements are in contact with the film during the sealing process. It’s crucial for achieving a strong, hermetic seal.

Insufficient dwell time results in a weak seal prone to leakage. Conversely, excessive dwell time can scorch or damage the film, leading to bag defects or weakening the seal. The ideal dwell time depends on factors like film thickness, material type, sealing temperature, and sealing pressure. Finding the optimal dwell time is typically done through experimentation and adjustments on the machine’s settings.

Q 13. What are the key performance indicators (KPIs) for bag forming and heat sealing operations?

Key Performance Indicators (KPIs) for bag forming and heat sealing operations should focus on efficiency, quality, and cost-effectiveness:

Output (bags/minute or hour): Measures the production speed and efficiency of the line.

Seal Strength: A crucial quality indicator; typically tested by measuring the force required to separate the sealed layers.

Defect Rate: Percentage of bags with imperfections, such as leaks, incomplete seals, or improper shape.

Downtime: Time the machine is not producing due to maintenance, repairs, or malfunctions.

Film Consumption: Monitoring the amount of film used per unit of output helps identify waste and optimize efficiency.

Energy Consumption: Tracking energy usage helps reduce operational costs and identify areas for improvement.

Maintenance Costs: Monitoring costs associated with maintenance and repair can help optimize maintenance strategies.

Q 14. How do you calculate the efficiency of a bag forming and heat sealing line?

Efficiency of a bag forming and heat sealing line is typically calculated as the ratio of actual output to the maximum possible output over a given period.

Efficiency (%) = (Actual Output / Maximum Possible Output) x 100

For example: If a machine has a maximum capacity of 10,000 bags per hour, but produced 8,000 bags in an hour due to planned or unplanned downtime, the efficiency would be:

Efficiency (%) = (8000 / 10000) x 100 = 80%

This calculation highlights the importance of minimizing downtime and optimizing machine settings to maximize efficiency. Analyzing downtime reasons and making process improvements are crucial to increase the overall line efficiency.

Q 15. Describe your experience with different types of packaging films.

My experience encompasses a wide range of packaging films, each with its unique properties impacting bag formation and heat sealing. I’ve worked extensively with films categorized by their material composition, including polyethylene (PE), polypropylene (PP), polyester (PET), and various laminates combining these materials. For example, PE films are known for their flexibility and cost-effectiveness, often used for simpler applications like pillow pouches for snacks. PP films offer superior strength and heat resistance, making them ideal for heavier products or those requiring microwaveable packaging. Laminated films, combining layers like PET/PE, provide barrier properties against moisture, oxygen, and aroma, crucial for preserving sensitive products like coffee or tea. Understanding these material properties is critical; a film’s thickness, clarity, and heat sealability directly influence the machine settings and overall bag quality.

- Polyethylene (PE): Common, cost-effective, good for flexible packaging.

- Polypropylene (PP): Stronger, heat resistant, suitable for heavier products.

- Polyester (PET): Excellent barrier properties, often used in laminates.

- Laminates (e.g., PET/PE): Combine properties of different materials for superior performance.

Career Expert Tips:

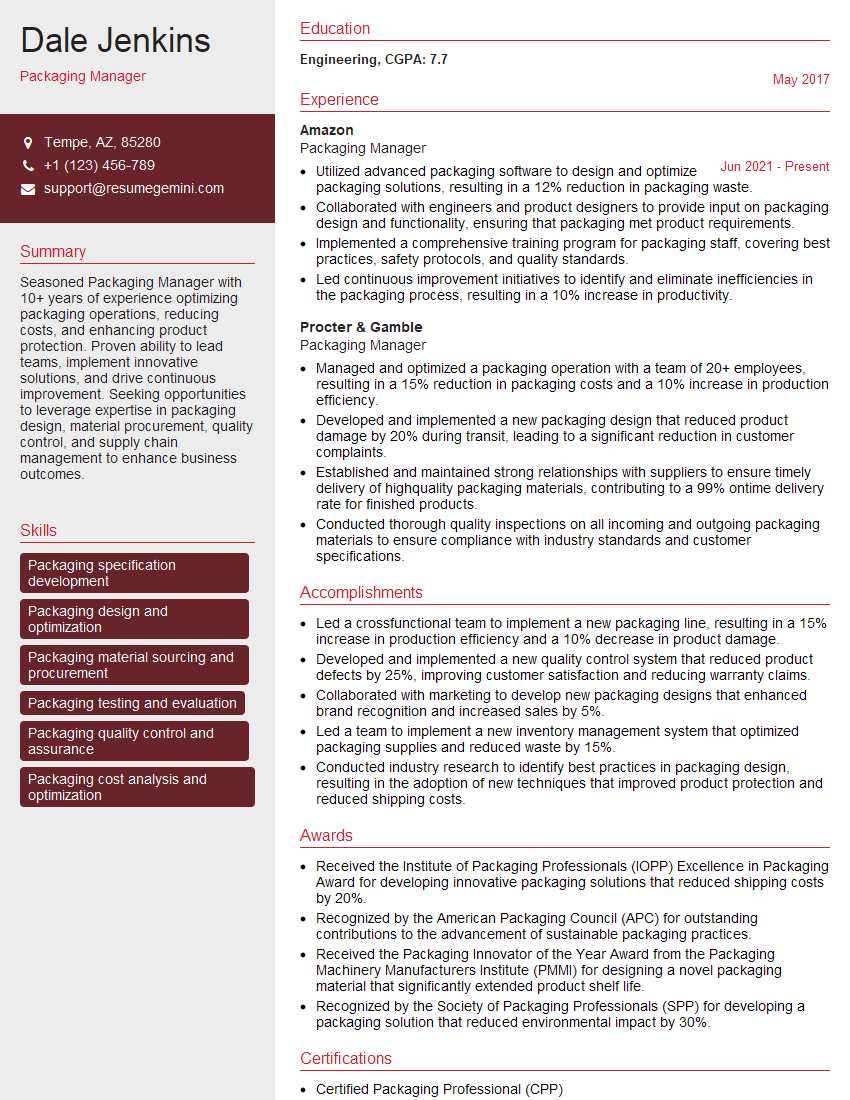

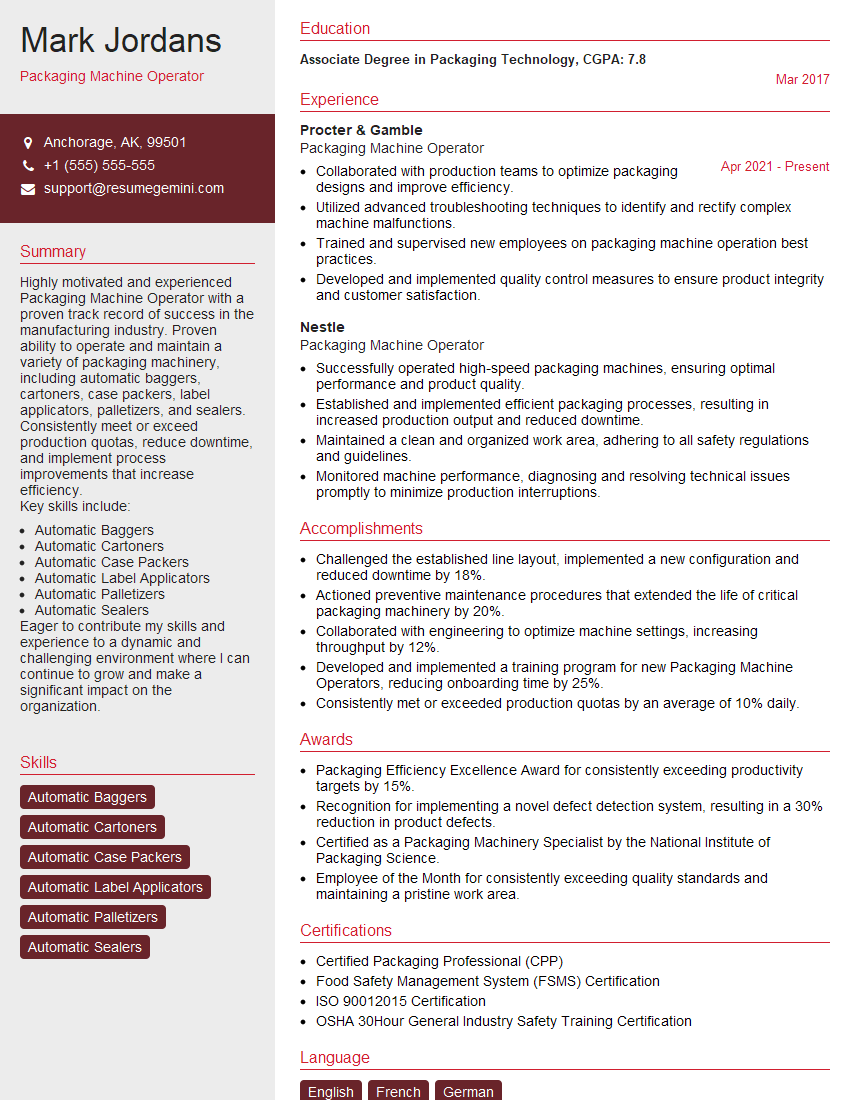

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle different bag styles (e.g., pillow pouches, stand-up pouches)?

Handling diverse bag styles requires adaptability in machine configuration and settings. Pillow pouches are relatively straightforward, requiring a simple sealing operation across the top. Stand-up pouches, however, demand more complex setups. These require forming the pouch shape, often involving gusseting (creating side folds) and then sealing three or even four sides. This necessitates precise control over film feed, jaw positioning, and sealing parameters. I’m proficient in configuring machines for various bag styles, including three-side seal, quad seal (four-side seal), and gusseted pouches. For example, when switching from pillow pouches to stand-up pouches, I’d adjust the film path, activate the gusseting mechanism, and modify the sealing jaw configuration and timing settings on the PLC to ensure proper formation and sealing.

Adapting to different sizes within each style is also crucial. I’ve worked with machines capable of accommodating a wide range of dimensions, requiring adjustments to the film unwind, bag length, and sealing jaw settings. Accurate calibration is key to preventing defects like short seals or poorly formed pouches.

Q 17. What is your experience with PLC programming related to bag forming and heat sealing?

My PLC programming experience is extensive, primarily using Siemens and Allen-Bradley platforms. I’m adept at designing and modifying PLC programs to control various aspects of the bag-forming and heat-sealing process. This includes managing film feed, sealing temperature, jaw pressure, bag length, and overall machine sequencing. I have experience with troubleshooting existing programs and implementing modifications based on production requirements, optimizing production speeds, or resolving recurring issues. For example, I’ve written programs to incorporate sensor feedback, enabling real-time adjustments based on film thickness variations or to detect and reject defective seals using quality control sensors. I use ladder logic to create functional programs that meet specific machine requirements and integrate various safety features.

Example code snippet (Illustrative - Specific syntax depends on the PLC platform):IF Film Sensor = ON THEN Start Film FeedEND IFQ 18. Explain your experience with preventative maintenance on packaging machinery.

Preventative maintenance (PM) is critical for maximizing uptime and minimizing costly breakdowns. My PM routine follows a structured approach, encompassing regular cleaning, lubrication, and inspection of key components. This includes checking the condition of the heat sealing jaws, inspecting the film path for wear and tear, lubricating moving parts like rollers and motors, verifying the accuracy of sensors, and cleaning debris buildup from the machine. I maintain detailed records, tracking maintenance activities and noting any anomalies observed during inspections. Adopting a preventative approach has helped avoid costly downtime and significantly extended the lifespan of several packaging machines I’ve overseen.

I also conduct performance checks, such as measuring seal strength and consistency, to ensure that the machine is operating within its specifications. We also schedule periodic calibration checks on critical parameters like temperature and pressure sensors to ensure accuracy, and implement a system for tracking spare parts and consumables.

Q 19. How do you ensure the quality of the sealed bags?

Ensuring quality sealed bags is paramount. My approach involves a multi-faceted strategy focusing on machine settings, quality control checks, and statistical process control (SPC). I meticulously control the heat sealing parameters—temperature, time, and pressure—to ensure consistent seal strength. Regular monitoring and adjustment are key. Furthermore, I use a seal strength tester to perform random sample checks throughout the production run, verifying that seals meet pre-defined specifications. Any deviations trigger an investigation into the root cause and immediate corrective actions. I’ve implemented automated systems to perform these checks inline, allowing for real-time quality monitoring and automatic rejection of bags with defective seals. Statistical process control (SPC) helps track seal strength variations over time to identify trends and prevent potential issues before they escalate into significant problems.

Q 20. Describe your experience with different types of heat sealing jaws.

My experience spans several types of heat sealing jaws, each suited for specific applications. I’ve worked with smooth jaws for general-purpose applications, requiring careful adjustment of the sealing temperature and pressure. For more specialized applications, I’ve used textured jaws, which provide a better seal on films with low surface energy. These create a larger surface area for heat transfer. I’ve also utilized jaws with different shapes and sizes, tailored to handle specific bag styles and dimensions. Furthermore, I have expertise in choosing the right jaw material (e.g., Teflon-coated for non-stick properties) based on the film type and the product being packaged. Regular maintenance, including cleaning and replacement of worn jaws, is crucial for consistent seal quality and machine longevity.

Q 21. How do you troubleshoot a jam in the bag forming machine?

Troubleshooting a jam in the bag forming machine requires a systematic approach. My first step is to safely stop the machine and assess the situation. I then visually inspect the film path, checking for any obvious obstructions such as wrinkles, folds, or foreign objects. Next, I would check the film tension and unwind system, as inconsistent film feeding can cause jams. I would then inspect rollers and guide systems ensuring smooth film movement. If the jam is within the forming area, I check for problems with the bag forming mechanism itself, such as a malfunctioning gusseting mechanism or misalignment. Finally, I would check the PLC program for any logic errors or faulty sensors that might contribute to the problem. The troubleshooting process often involves checking sensor readings, analyzing PLC program logs, and testing individual components to pinpoint the root cause and implement an effective solution. This often includes carefully removing the jammed material without damaging the machine. Detailed documentation of the problem and the corrective actions is critical for preventing future occurrences.

Q 22. What are the different types of sensors used in bag forming and heat sealing machines?

A variety of sensors are crucial for efficient and reliable bag forming and heat sealing. These sensors monitor various parameters throughout the process, ensuring quality and preventing errors. Let’s look at some key examples:

- Photoelectric Sensors: These are used for detecting the presence or absence of film, ensuring the machine doesn’t run without material. Think of it like a light switch – if no film is present, the light beam isn’t broken, and the machine stops.

- Proximity Sensors: These sensors detect the proximity of objects without physical contact, often used to monitor the position of the film or the jaws of the sealing unit. They are vital in precise alignment of the sealing elements.

- Temperature Sensors (Thermocouples or RTDs): These are critical for monitoring and controlling the heat sealing temperature. Accurate temperature control is essential to achieve a strong, reliable seal without damaging the film or the product.

- Tension Sensors: These measure the tension of the film as it’s fed into the machine. Maintaining consistent tension prevents wrinkles and ensures uniform seal formation.

- Length Sensors: These sensors accurately measure and control the length of the bag being formed, ensuring consistent bag sizes and preventing waste.

The specific sensors used vary depending on the machine’s complexity and the type of packaging material being used. For instance, a high-speed machine for flexible packaging might incorporate all of the above, while a simpler machine for heavier-duty bags may only require a few key sensors.

Q 23. Explain your experience with different types of bag closure systems.

My experience encompasses a wide range of bag closure systems, each with its own advantages and disadvantages. The choice often depends on the product, packaging material, and desired level of protection.

- Heat Sealing: This is the most common method, creating a seal by melting the film together using heat. I have extensive experience with various heat sealing techniques, including impulse sealing (for single-use seals) and continuous sealing (for high-speed applications). I’ve worked with different sealing jaw configurations optimized for different film thicknesses and types.

- Ultrasonic Sealing: This method uses high-frequency sound waves to create a seal without heat. It’s particularly suitable for heat-sensitive materials and offers a strong, hermetic seal. I’ve been involved in the setup and maintenance of ultrasonic sealing systems, troubleshooting issues related to sound wave penetration and seal integrity.

- Tape Sealing: While simpler than heat sealing, tape offers good protection and is often used for heavier bags or those requiring a more robust closure. I’ve worked with automatic tape application systems, ensuring proper alignment and adhesion.

- Crimped Seals: This method utilizes a crimping mechanism to create a strong seal, often seen in metallized or foil pouches. My experience includes working with various crimping tools and ensuring proper settings to avoid damage to the bag.

In my previous role, I successfully implemented an ultrasonic sealing system to replace heat sealing for a product sensitive to high temperatures, resulting in a significant improvement in product quality and reduced material waste.

Q 24. How do you minimize material waste in bag forming and heat sealing?

Minimizing material waste is a critical aspect of efficient bag forming and heat sealing. It’s both environmentally responsible and cost-effective.

- Precise Film Feeding: Ensuring precise control of film feeding through accurate sensor readings and adjustments minimizes waste caused by incorrect film length or misalignment.

- Optimized Machine Settings: Proper adjustment of sealing parameters (temperature, pressure, and time) is crucial. Incorrect settings can lead to seals that are too weak (requiring remakes) or seals that damage the film.

- Regular Maintenance: Consistent machine maintenance is key. A well-maintained machine operates efficiently, reducing defects and preventing unexpected stoppages that lead to material waste.

- Statistical Process Control (SPC): Implementing SPC helps identify trends and patterns of waste, enabling proactive adjustments and preventions.

- Waste Reduction Programs: Implementing systematic programs to track and analyze waste generation, identifying and rectifying root causes, are vital for continuous improvement.

- Efficient Scrap Management: Having a system in place to collect, sort, and possibly recycle scrap material is also vital for waste reduction.

For instance, by implementing a new film feeding system with improved sensor accuracy, my team reduced material waste by 15% in a single quarter.

Q 25. How do you handle production line malfunctions during peak production periods?

Malfunctions during peak production are a serious concern, requiring a rapid and effective response. My approach involves a structured problem-solving process:

- Immediate Assessment: Quickly determine the nature and severity of the malfunction. Is it a minor issue, or does it require immediate shutdown?

- Safety First: Prioritize the safety of personnel. If necessary, shut down the line to ensure safety.

- Troubleshooting: Based on my experience and understanding of the machine, I’ll systematically troubleshoot the problem, checking sensors, power supply, and other components.

- Root Cause Analysis: Once the issue is resolved, a thorough root cause analysis is conducted to prevent future occurrences. This often includes documenting the issue, corrective action, and preventative measures.

- Teamwork: I actively involve the maintenance team and other relevant personnel to expedite repairs and minimize downtime.

- Communication: Keeping stakeholders (management, production supervisors) informed about the situation and progress is crucial.

In one instance, during a critical peak season, a sensor malfunction caused a significant production delay. By quickly identifying and replacing the faulty sensor, and involving the maintenance team in a collaborative effort, we were able to resume production within 30 minutes, minimizing production disruption.

Q 26. Describe your experience with lean manufacturing principles in a packaging environment.

Lean manufacturing principles are central to efficient and effective packaging operations. My experience includes implementing and optimizing various lean methodologies:

- 5S Methodology: I’ve been involved in implementing 5S (Sort, Set in Order, Shine, Standardize, Sustain) in the packaging area, improving workplace organization and efficiency.

- Value Stream Mapping: I’ve used value stream mapping to identify and eliminate waste throughout the packaging process, focusing on reducing lead times and improving overall flow.

- Kaizen Events: I’ve actively participated in Kaizen events, focusing on continuous improvement initiatives. These events involve cross-functional teams working to identify and solve problems related to efficiency and waste reduction.

- Kanban Systems: Implementing Kanban systems to manage inventory levels and improve material flow, avoiding excessive stockpiles and reducing waste.

For example, by applying value stream mapping to our bag-forming process, we identified a bottleneck in the film-feeding stage. We implemented improvements to that stage, leading to a 10% reduction in lead time and a reduction in material waste.

Q 27. What is your experience with quality control documentation and reporting?

Quality control documentation and reporting are essential for maintaining consistent product quality and meeting regulatory requirements. My experience includes:

- Maintaining detailed records of machine settings and operational parameters: This data is crucial for tracking performance and identifying trends.

- Implementing and managing quality control checkpoints throughout the production process: This involves regularly inspecting bags for defects (seal integrity, dimensions, etc.).

- Generating regular quality control reports, including statistical data on defect rates, and material waste: These reports are vital for tracking performance and identifying areas for improvement.

- Maintaining a robust system for tracking and resolving quality issues: This includes documenting corrective and preventative actions (CAPA).

- Ensuring compliance with relevant industry standards and regulations: Understanding and adhering to Good Manufacturing Practices (GMP) and other standards is a priority.

In my previous role, I implemented a new quality control system that reduced defect rates by 12%, demonstrably improving product quality and customer satisfaction. The system included detailed reporting and tracking of all quality metrics, providing valuable data for continuous improvement.

Q 28. How do you maintain a clean and safe work environment in the packaging area?

Maintaining a clean and safe work environment is paramount. My approach is multi-faceted:

- Regular Cleaning and Sanitation: Implementing a regular cleaning schedule, using appropriate cleaning agents, and ensuring proper disposal of waste materials.

- Proper Housekeeping: Maintaining an organized workspace, minimizing clutter, and ensuring proper storage of materials and equipment.

- Safety Training: Providing regular safety training to all personnel on safe operating procedures, lockout/tagout procedures, and emergency response.

- Personal Protective Equipment (PPE): Ensuring that all personnel use appropriate PPE, including safety glasses, gloves, and hearing protection.

- Machine Guarding: Ensuring all machinery is properly guarded to prevent accidents.

- Regular Inspections: Conducting regular safety inspections of the equipment and the workplace to identify and rectify potential hazards.

By focusing on these aspects, I’ve consistently contributed to a safe and efficient work environment, improving employee morale and reducing the risk of workplace incidents.

Key Topics to Learn for Bag Forming and Heat Sealing Interview

- Film Selection and Properties: Understanding different film types (e.g., polyethylene, polypropylene), their properties (e.g., thickness, heat sealability, strength), and suitability for various applications. Consider the impact of film selection on the final bag quality and production efficiency.

- Machine Operation and Maintenance: Familiarize yourself with the mechanics of bag forming and heat sealing machines. This includes understanding the various components (e.g., jaws, heat seals, cutting mechanisms), their functions, and common troubleshooting procedures. Practical experience is highly valuable here.

- Heat Sealing Principles: Grasp the fundamental principles of heat sealing, including the role of temperature, pressure, and dwell time in creating strong and reliable seals. Be able to explain how these parameters affect seal integrity and production output.

- Quality Control and Assurance: Understand the importance of quality control in bag forming and heat sealing. Learn about different inspection methods, defect identification, and implementing corrective actions to maintain consistent product quality. This includes understanding relevant industry standards and regulations.

- Safety Procedures and Regulations: Demonstrate a thorough understanding of workplace safety protocols associated with machinery operation, including lockout/tagout procedures, personal protective equipment (PPE) usage, and hazard identification.

- Troubleshooting and Problem-Solving: Be prepared to discuss your approach to troubleshooting common issues encountered during production, such as seal failures, film jams, or machine malfunctions. Highlight your analytical and problem-solving skills.

- Production Optimization and Efficiency: Discuss strategies for improving production efficiency, such as optimizing machine settings, minimizing downtime, and improving material handling procedures. Quantifiable examples of improvements will impress interviewers.

Next Steps

Mastering bag forming and heat sealing opens doors to rewarding careers in packaging, manufacturing, and related industries. A strong understanding of these processes significantly enhances your employability and positions you for advancement. To maximize your job prospects, creating a compelling and ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional resume that highlights your skills and experience effectively. Examples of resumes tailored to Bag Forming and Heat Sealing are available to help guide your creation process. Invest the time to craft a resume that truly showcases your potential; it’s an investment in your future success.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good