Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Bag Press Operation interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Bag Press Operation Interview

Q 1. Explain the principle of operation of a bag press.

A bag press, also known as a filter press, is a mechanical device used for solid-liquid separation. Its principle of operation relies on forcing a slurry (a mixture of solids and liquids) through a filter medium, typically a fabric bag, under pressure. The liquid passes through the filter medium, leaving behind a concentrated mass of solids known as the filter cake. This process effectively separates the solids from the liquid, resulting in a drier, more concentrated solid product and a clarified liquid effluent.

Imagine squeezing a wet sponge: the water (liquid) is squeezed out, leaving the sponge (solid) behind. A bag press operates on a similar principle, but on a much larger scale and with greater control over the process.

Q 2. Describe the different types of bag presses and their applications.

Bag presses come in several configurations, each suited for different applications. The most common types include:

- Chamber Bag Presses: These use individual filter chambers, each containing a filter bag. They are versatile and offer good cake dryness. They’re ideal for applications requiring high cake dryness and where the processed material has a diverse particle size distribution.

- Recessed Chamber Bag Presses: These have filter bags recessed into the press plates. This design offers easier bag changing and improved efficiency.

- Plate and Frame Filter Presses: While technically not ‘bag’ presses, they are frequently used for similar purposes. They use plates with recessed filter cloths instead of bags. They are robust and good for higher volume applications but typically achieve less cake dryness than chamber bag presses.

Applications vary widely depending on the industry. Common examples include:

- Wastewater treatment: Removing sludge and solids from wastewater streams.

- Chemical processing: Separating solids from chemical solutions.

- Mining: De-watering mineral concentrates.

- Food processing: Separating solids from fruit juices or other food products.

- Pharmaceutical industry: Removing solids from various production processes.

Q 3. How do you determine the optimal cycle time for a bag press?

Determining the optimal cycle time for a bag press is crucial for maximizing efficiency and cake dryness. It involves a balance between several factors:

- Filtration rate: A slower filtration rate may lead to longer cycle times but potentially drier cakes. A faster rate may reduce cycle time but compromise dryness.

- Cake properties: The characteristics of the solid material, including particle size and compressibility, significantly influence filtration rate and optimal cycle time.

- Pressure: Higher pressure generally speeds up filtration, but excessively high pressure might damage the bags or equipment.

- Desired cake dryness: The required dryness of the final cake dictates the minimum cycle time needed.

Optimizing cycle time often involves experimentation and data analysis. Starting with a conservative cycle time and progressively adjusting based on cake dryness and filtration rate data is a common approach. Regular monitoring of the process is key. Software and data acquisition systems are now frequently utilized to capture this data and assist in optimization.

Q 4. What are the common causes of bag press leaks and how do you troubleshoot them?

Bag press leaks can stem from various issues, significantly impacting efficiency and potentially causing safety hazards.

- Bag damage: Tears, punctures, or deterioration of the filter bags are common culprits. This may be caused by excessive pressure, sharp particles in the slurry, or simply the bag reaching its end of life.

- Improper bag installation: Incorrect seating of the bags can lead to leaks at the seals.

- Plate misalignment: Misaligned plates can create gaps where leakage can occur.

- Seal failure: Damaged or worn-out seals between plates and the bag housing can cause leakage.

- Cracked plates or housing: Physical damage to the press components themselves can result in leaks.

Troubleshooting involves a systematic approach:

- Visual inspection: Carefully examine the bags, plates, and seals for any visible damage.

- Pressure testing: Conduct a pressure test on the system to identify the location of the leak.

- Replace damaged components: Replace any damaged or worn-out bags, seals, or plates.

- Re-align plates: Ensure all plates are properly aligned.

- Check slurry consistency: Ensure the slurry doesn’t contain excessively abrasive materials that can damage bags.

Q 5. Explain the importance of proper cake discharge in a bag press.

Proper cake discharge is vital for efficient bag press operation and prevents several problems.

- Reduced downtime: Efficient discharge minimizes the time spent on removing the filter cake, increasing overall productivity.

- Prevents damage to equipment: Forcing cake removal can damage the bags or the press structure. A proper discharge mechanism minimizes this risk.

- Ensures consistent cake quality: Proper cake removal ensures a consistent, uniform cake, and prevents residual material from contaminating subsequent batches.

- Improved safety: Manual removal of tightly packed cake can be hazardous. Automated systems greatly improve safety.

Several methods assist in cake discharge, including automated systems (pneumatic or hydraulic cake ejection), cake loosening mechanisms (vibrators), or a combination thereof.

Q 6. How do you monitor the pressure and flow rate during bag press operation?

Monitoring pressure and flow rate during bag press operation is crucial for maintaining optimal performance and detecting potential problems.

- Pressure gauges: Pressure gauges at various points in the system (e.g., inlet, outlet, chamber pressure) provide vital information about filtration progress and identify potential blockages.

- Flow meters: Flow meters measure the rate of filtrate (liquid) leaving the press, providing insights into filtration efficiency. A sudden drop in flow might indicate clogging or other issues.

- Data acquisition systems (DAS): Modern bag presses often incorporate DAS, which automatically record pressure and flow data, aiding in process optimization and troubleshooting. This data can be used for predictive maintenance purposes.

Regular monitoring of these parameters allows for timely intervention to prevent problems such as bag ruptures, reduced filtration rate or equipment damage. Threshold alarms can be set to alert operators of any unusual changes.

Q 7. Describe the safety procedures you follow when operating a bag press.

Safety is paramount when operating a bag press. Procedures should include:

- Lockout/Tagout procedures: Before any maintenance or repair work, always follow proper lockout/tagout procedures to prevent accidental startup.

- Personal Protective Equipment (PPE): Wear appropriate PPE, including safety glasses, gloves, and hearing protection.

- Proper handling of materials: Exercise caution when handling the slurry and filter cake, as some materials may be hazardous.

- Regular inspections: Regularly inspect the bag press for leaks, wear, and tear to prevent accidents.

- Emergency shutdown procedures: All personnel must know how to operate the emergency shutdown switches in case of an emergency.

- Training: All operators must receive proper training on safe operating procedures before operating the equipment.

A thorough understanding of the machine’s functionality and adherence to standard safety practices are crucial to ensure a safe and efficient operating environment.

Q 8. How do you identify and address filter cloth clogging?

Identifying filter cloth clogging in a bag press often involves observing operational changes and conducting visual inspections. Reduced filtration efficiency, indicated by a decrease in the dryness of the dewatered solids or an increase in filtrate turbidity (cloudiness), is a primary indicator. Increased pressure in the press cycle is another key sign, as the clogged cloth resists the flow of liquid.

Addressing the clog depends on its severity and cause. For minor clogging, a simple backwash – reversing the flow of filtrate – can be effective. This dislodges loosely bound solids. For more serious clogs, chemical cleaning with appropriate detergents may be necessary, followed by a thorough rinse. In extreme cases where the cloth is severely damaged or beyond cleaning, replacement is essential. Imagine it like trying to squeeze water through a sponge; if the sponge is full of dirt, the water flow slows – replacing the sponge is the solution.

Regular preventative maintenance, such as proper pre-treatment of the feed slurry to remove large particles, contributes significantly to reducing the frequency of clogging.

Q 9. What are the maintenance procedures for a bag press?

Bag press maintenance is crucial for optimal performance, longevity, and safety. A comprehensive maintenance program includes:

- Regular inspections: Check for leaks, wear and tear on the filter cloths, and the condition of seals and other components.

- Cleaning: Regular cleaning of the press, including the chamber and the filter cloths, prevents the buildup of solids and contaminants.

- Lubrication: Proper lubrication of moving parts, such as hydraulic cylinders and mechanisms, ensures smooth operation and prevents premature wear.

- Filter cloth care: Proper cleaning, storage, and replacement of filter cloths are vital. Using the right cleaning agents and avoiding excessive abrasion will extend cloth lifespan.

- Hydraulic system checks: Regularly check oil levels, pressure, and for leaks in the hydraulic system. This is paramount for the press’s smooth operation and safety.

- Electrical system checks: Inspect wiring, connectors, and control panels for any damage or wear.

A well-maintained bag press significantly reduces downtime and operational costs, ensuring consistent and high-quality performance.

Q 10. How often should filter cloths be changed or cleaned?

The frequency of filter cloth changes or cleaning depends on several factors, including the type of filter media, the characteristics of the material being processed, and the desired level of filtration. In general, frequent monitoring and prompt action are crucial.

For example, in applications processing high-solids content slurries or those with abrasive particles, more frequent cleaning or replacement might be required, potentially every few days or even daily. On the other hand, applications with cleaner slurries might allow for longer intervals, perhaps every week or even several weeks.

Establishing a scheduled maintenance program with regular inspections and condition assessments will allow for the most efficient and cost-effective approach to filter cloth management.

Q 11. What are the signs of a failing bag press?

Several signs indicate a failing bag press. Decreased filtration efficiency (producing wetter cake or cloudier filtrate), increased cycle times, higher operating pressures, frequent filter cloth clogging, and unusual noises or vibrations during operation are all warning signs.

Leaks from the hydraulic system, damaged seals, or broken components are more serious and require immediate attention. A failing press not only reduces efficiency but can also pose safety risks, therefore prompt investigation and repairs are crucial. Think of it like a car – strange noises, poor performance, or leaks are all indicators of potential problems that need immediate attention.

Q 12. How do you handle a bag rupture during operation?

Bag rupture during operation is a serious event that requires immediate action to prevent further damage and ensure safety. The first step is to safely shut down the press, isolating it from power and hydraulic sources.

Once the press is safely secured, the damaged bag should be carefully removed and replaced. This often requires draining the chamber and possibly removing other bags for accessibility. The cause of the rupture should be investigated to prevent recurrence. This could involve examining the material being processed, the pressure levels, or the condition of the filter cloth itself. A ruptured bag is like a burst pipe – it requires immediate attention and investigation into the root cause of the failure.

Q 13. What are the different types of filter media used in bag presses?

Various filter media are used in bag presses, each with unique properties suitable for different applications. Common types include:

- Woven fabrics: These offer good strength and permeability, suitable for many applications.

- Non-woven fabrics: These have a wider range of pore sizes and are often more cost-effective.

- Felt fabrics: These are particularly suitable for applications requiring high filtration efficiency.

- Synthetic fabrics: These offer resistance to chemicals and high temperatures, making them ideal for various industrial processes.

The choice of filter media depends on factors such as the particle size distribution of the solids, the chemical compatibility with the slurry, the desired cake dryness, and the overall cost-effectiveness. Just as choosing the right filter for your coffee depends on your preferences, so too does choosing the right filter media in a bag press.

Q 14. How do you select the appropriate filter media for a specific application?

Selecting the appropriate filter media involves considering several key factors:

- Particle size distribution: The filter media should have a pore size suitable for retaining the solids while allowing the filtrate to pass through.

- Chemical compatibility: The filter media must be resistant to the chemicals present in the slurry.

- Temperature resistance: The filter media should withstand the operating temperature.

- Filtrate clarity requirements: The chosen media should deliver the desired level of filtrate clarity.

- Cake dryness requirements: The media’s ability to dewater the solids will impact the final product’s dryness.

- Cost considerations: Balancing cost and performance is crucial.

A thorough understanding of the slurry’s properties and the desired outcome is essential. Often, pilot testing different media with the actual slurry is necessary to determine the best option. It’s similar to choosing the right paint for a project – you wouldn’t use exterior paint for interior walls; similarly, the wrong filter media will lead to poor performance.

Q 15. Explain the concept of cake dryness and its importance.

Cake dryness, in the context of bag press operation, refers to the moisture content remaining in the solid material after dewatering. It’s expressed as a percentage of dry solids. A higher cake dryness indicates more efficient dewatering, meaning less liquid remains in the solid cake. This is crucial because a drier cake translates to lower transportation and disposal costs, reduced sludge volume, and potentially easier handling and processing downstream.

For example, imagine squeezing a wet sponge. The drier you get the sponge, the less water remains. Similarly, in a bag press, a higher cake dryness means the process has successfully removed more water from the sludge.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you measure and control the cake dryness?

Measuring cake dryness involves determining the weight of the wet cake and then drying a representative sample to constant weight to find the weight of dry solids. The percentage of dry solids is calculated using the formula: (Weight of dry solids / Weight of wet cake) * 100.

Controlling cake dryness involves manipulating several process parameters. These include:

- Filtration pressure: Increasing pressure generally increases dryness but can also reduce filtration rate and increase energy consumption. It’s a balancing act.

- Filtration time: Longer filtration times allow for more water extraction, leading to increased cake dryness. However, prolonged operation means higher costs.

- Polymer dosage: Adding flocculants or other conditioning agents before filtration helps solids settle, leading to better dewatering and higher cake dryness.

- Cake consolidation methods: Techniques such as pre-coating or using membrane filters can impact cake structure and improve dewatering.

Regular monitoring of cake dryness through sample testing and adjusting the mentioned parameters allows for optimization of the process.

Q 17. What are the environmental considerations related to bag press operation?

Environmental considerations in bag press operation are significant, focusing primarily on minimizing waste and emissions. The liquid filtrate generated needs careful management. Potential contaminants require treatment before discharge to comply with environmental regulations. This might involve processes like settling, filtration, or biological treatment to reduce pollutants.

Furthermore, the disposal of the dewatered cake itself is a key environmental concern. If the cake contains hazardous materials, specialized disposal methods are necessary. The operation should aim to reduce the volume of waste produced by optimizing cake dryness.

Noise pollution and energy consumption are other aspects to consider. Well-maintained equipment and sound-proofing measures can minimize noise, while efficient energy use mitigates the environmental impact of the operation.

Q 18. How do you ensure efficient energy consumption during bag press operation?

Efficient energy consumption during bag press operation involves a multi-pronged approach. First, optimizing the filtration process to achieve the desired cake dryness in the shortest possible time is essential. Overly long cycles waste energy.

Secondly, selecting energy-efficient equipment, including pumps and motors with high efficiency ratings, is vital. Regular maintenance of these components ensures optimal performance and prevents energy loss through friction or leakage.

Thirdly, implementing a process control system that monitors and adjusts parameters in real time can lead to significant energy savings. For instance, automatically adjusting the filtration pressure based on the cake dryness can prevent unnecessary energy use.

Finally, employing techniques like pre-coating the filter media can reduce the cycle time and improve energy efficiency. It’s about optimizing the whole process, not just individual components.

Q 19. Describe your experience with different types of automation systems in bag presses.

I have extensive experience with various automation systems in bag presses, ranging from basic programmable logic controllers (PLCs) to advanced supervisory control and data acquisition (SCADA) systems. In one project, we implemented a PLC-based system to control the entire bag press cycle, from filling and pressing to cake discharge. This system automated the process, reduced manual intervention, and improved consistency.

In another project, we integrated a SCADA system to monitor and control multiple bag presses across the plant. The SCADA system provided real-time data visualization, allowing for remote monitoring and improved process optimization. I’ve also worked with systems incorporating advanced analytics, allowing predictive maintenance and process optimization based on historical data and real-time insights. The choice of system depends heavily on the scale and complexity of the operation.

Q 20. How do you troubleshoot a malfunctioning PLC or control system on a bag press?

Troubleshooting a malfunctioning PLC or control system on a bag press begins with a systematic approach. First, I would consult the system’s documentation and check for any error codes or alarms displayed. This often provides clues to the problem’s location.

Next, I’d verify power supply to the PLC and all associated components. A simple power outage or loose connection can be the cause. Then, I’d check the input/output (I/O) signals to ensure they are consistent with the expected operation. For example, are the pressure sensors reporting correct readings? Are the motor control signals functioning correctly?

If the problem persists, I would use diagnostic tools such as a PLC programming software to examine the PLC’s program logic. Tracing the execution flow can identify faulty logic or programming errors. In some cases, replacing faulty components might be necessary. A methodical approach, coupled with solid knowledge of PLC programming and troubleshooting, is crucial for efficient resolution.

Q 21. What are the common causes of reduced filtration rate?

Reduced filtration rate in a bag press can stem from several sources. One common cause is filter media blinding or clogging. This occurs when fine particles accumulate on the filter surface, reducing permeability. Regular cleaning or replacement of the filter media can resolve this.

Another cause is poor cake structure, resulting from inadequate flocculation or conditioning of the sludge. Adjusting the polymer dosage or using a more effective flocculant can remedy this. High solids concentration in the feed can also lead to reduced filtration rates. Diluting the feed or optimizing the pre-treatment process can address this issue.

Finally, issues with the bag press itself, such as blockages in the piping or malfunctioning pumps, can also impact filtration rates. Regular maintenance and inspections are crucial to identify and address these mechanical problems. The key is methodical investigation and consideration of all potential causes.

Q 22. How do you optimize the performance of a bag press?

Optimizing bag press performance involves a multi-faceted approach focusing on maximizing dewatering efficiency while minimizing downtime and operational costs. It’s like fine-tuning an engine – each component needs to work harmoniously.

Proper Conditioning: Ensuring the sludge entering the bag press has the optimal solids content and chemical conditioning (polymers) is crucial. Too much or too little solids can negatively impact cake dryness and filter media life. We often adjust flocculants and polymers based on real-time data and sludge characteristics. For example, a higher solids concentration might require a slightly different polymer dosage to achieve the desired cake consistency.

Filter Media Selection: Choosing the right filter media is paramount. Different media (e.g., woven, non-woven) offer varying permeability and solids retention capabilities. The selection depends on the sludge type and desired cake dryness. We’ve seen significant improvements by switching from a standard woven media to a high-performance non-woven option in a specific application with very fine particles.

Pressure Management: Maintaining the appropriate pressure during the pressing cycle is essential. Too little pressure results in insufficient dewatering, while excessive pressure can damage the filter media or the bag press itself. Regular monitoring and adjustment of pressure settings are necessary. I often use pressure-time curves to visually assess the effectiveness of the press cycle and identify areas for optimization.

Regular Maintenance: Preventive maintenance is vital. This includes inspecting and cleaning the filter bags, checking for leaks in the system, and lubricating moving parts. A well-maintained bag press will operate more efficiently and last longer. We implemented a preventative maintenance schedule with specific checklists and timelines, resulting in a significant reduction in unplanned downtime.

Cycle Optimization: Fine-tuning the press cycle parameters (e.g., fill time, press time, drain time) can significantly improve performance. Data logging and analysis are essential for identifying areas for improvement. We used data analysis to reduce the press cycle time by 15% without compromising cake dryness.

Q 23. What are your experiences with different types of polymers used in sludge dewatering?

My experience spans a wide range of polymers used in sludge dewatering, each with unique properties impacting cake dryness, chemical costs, and environmental implications. The choice depends on factors like sludge characteristics, desired cake dryness, and budget constraints.

Anionic Polyacrylamides: These are widely used due to their effectiveness and relatively low cost. Their performance is influenced by factors such as molecular weight and charge density. We’ve successfully used them on a variety of sludges, adjusting the dosage based on sludge characteristics.

Cationic Polyacrylamides: Often used for sludges with high clay content, as they effectively condition negatively charged particles. However, they can be more expensive than anionic polymers. In one project with highly clay-rich sludge, cationic polymers resulted in a significant improvement in dewatering.

Non-ionic Polymers: These are sometimes used in combination with anionic or cationic polymers to enhance performance or improve handling. They can be particularly useful in certain applications where better dewatering is required. One example is a project where we combined a non-ionic polymer with an anionic polymer to improve cake solids.

Polymeric blends: To achieve optimal dewatering performance, I’ve often utilized carefully formulated blends of different polymers, often tailoring them to specific sludge characteristics. This approach requires a strong understanding of polymer chemistry and sludge properties.

Polymer selection is a critical aspect of bag press optimization. It’s not a one-size-fits-all approach – careful testing and analysis are essential to finding the best polymer or blend for a particular sludge.

Q 24. How do you interpret pressure and flow rate data to diagnose bag press issues?

Pressure and flow rate data are crucial for diagnosing bag press issues. Think of them as vital signs of the system. Changes in these parameters can indicate problems ranging from simple clogs to major mechanical failures.

Low Pressure/High Flow Rate: This might indicate a leak in the system or a problem with the filter media (e.g., tears or excessive wear). A visual inspection of the bag press and filter media is typically the first step in troubleshooting. Repairing leaks or replacing worn filter media should resolve the problem.

High Pressure/Low Flow Rate: This suggests a blockage somewhere in the system, possibly a clogged filter bag or a problem with the filter cake itself (e.g., overly thick or dense cake). Checking the filter bags and potentially adjusting the chemical conditioning can usually resolve this.

Fluctuating Pressure/Flow Rate: This can be caused by a variety of factors, including inconsistent sludge feed, airlocks in the system, or mechanical issues with the press itself. A step-by-step process of eliminating each possible cause can identify the root of the problem.

Interpreting this data requires a keen understanding of the bag press’s operational characteristics. I often use data logging and trend analysis software to identify patterns and anticipate potential problems. For example, a gradual decrease in flow rate over time might indicate a slow build-up of solids in the system, allowing for preventative maintenance before a major issue occurs.

Q 25. Explain your knowledge about different types of bag press designs (e.g., chamber, recessed chamber)?

Bag presses come in various designs, each with its own advantages and disadvantages. The choice of design depends on factors like sludge characteristics, throughput requirements, and budget constraints.

Chamber Bag Presses: These presses use individual filter chambers, each containing a filter bag. They’re known for their ease of maintenance and relatively low capital cost. The individual chambers allow for easier access to bags for cleaning or replacement and can accommodate different sludge types within one unit.

Recessed Chamber Bag Presses: These presses have recessed chambers, providing better sealing and potentially higher pressure. This allows for higher dewatering capacity but can be more complex to maintain. Recessed chambers offer improved sealing compared to the chamber design, therefore resulting in better dewatering efficiency.

Roll Bag Presses: These use continuously rotating rolls to squeeze the sludge, and the sludge continuously passes through, and the filter media is continuous as well. These are higher capacity machines, often suitable for very large sludge volumes, but they can be costly and more complex. They are highly automated and efficient for large scale projects.

Understanding the nuances of each design is crucial for selecting the right type of bag press for a specific application. For instance, a plant with limited maintenance resources might opt for a simpler chamber press, while a large-scale facility might prefer the higher capacity of a roll bag press.

Q 26. What are the key performance indicators (KPIs) for a bag press?

Key Performance Indicators (KPIs) for a bag press are essential for monitoring efficiency and identifying areas for improvement. They provide a quantitative measure of performance and guide optimization efforts.

Cake Dryness (Solids Content): This is arguably the most important KPI, representing the effectiveness of the dewatering process. It is typically measured as a percentage of solids in the dewatered cake. A higher solids content indicates better dewatering efficiency.

Throughput (tons/hour or m³/hour): This measures the volume of sludge processed per unit of time, indicating the system’s processing capacity.

Specific Energy Consumption (kWh/ton): This KPI shows the energy efficiency of the dewatering process, reflecting operational costs. We always aim to minimize energy consumption without compromising cake dryness.

Filter Media Life (cycles/media): This reflects the longevity and performance of the filter media, representing maintenance costs and downtime.

Downtime (hours/year): Minimizing downtime is essential for maintaining operational efficiency. This KPI shows the percentage of time the machine is not functional.

Polymer Consumption (kg/ton): This KPI tracks the amount of polymer needed per ton of sludge, indicating the efficiency of the chemical conditioning process. Reducing polymer consumption reduces operational costs and the environmental impact.

Regular monitoring of these KPIs allows for proactive adjustments to maximize efficiency and reduce operational costs.

Q 27. How do you contribute to a safe and efficient work environment when operating a bag press?

Safety and efficiency go hand-in-hand in bag press operation. A safe work environment is a productive work environment.

Lockout/Tagout Procedures: Strict adherence to lockout/tagout procedures is crucial before any maintenance or repair work. This prevents accidental start-ups and potential injuries. We conduct regular training sessions to reinforce these procedures.

Personal Protective Equipment (PPE): Providing and ensuring the use of appropriate PPE (e.g., gloves, safety glasses, hearing protection) is non-negotiable. This protects workers from potential hazards associated with the operation and maintenance of the bag press.

Regular Inspections: Regular visual inspections of the equipment and surrounding area identify potential hazards (e.g., leaks, worn parts, tripping hazards) before they become major issues. We have a checklist that is filled out daily by the operators.

Emergency Procedures: Well-defined emergency procedures, including clear communication channels and appropriate training, are essential for responding to unexpected events. Regular drills ensure everyone is prepared.

Ergonomic Design: Designing the work area with ergonomic considerations in mind minimizes worker strain and fatigue, leading to improved safety and productivity. We’ve made adjustments to workstation layouts to make tasks easier and safer.

Cleanliness and Organization: Maintaining a clean and organized work area reduces the risk of accidents and improves efficiency. We emphasize the importance of a clean and tidy work area during every shift.

Safety is not just a policy, it’s a culture. By integrating safety into every aspect of bag press operation, we create a work environment where efficiency and safety thrive together.

Key Topics to Learn for Bag Press Operation Interview

- Machine Operation & Maintenance: Understanding the mechanical components, hydraulic systems, and electrical controls of a bag press. This includes preventative maintenance procedures and troubleshooting common malfunctions.

- Bagging Processes & Techniques: Mastering the efficient and safe handling of various bag types, filling methods, and sealing techniques. This involves understanding optimal bagging speeds and minimizing waste.

- Safety Procedures & Regulations: Familiarity with OSHA regulations and company-specific safety protocols related to operating heavy machinery, handling materials, and maintaining a clean and organized workspace. This includes lockout/tagout procedures and proper personal protective equipment (PPE) usage.

- Quality Control & Assurance: Understanding the importance of consistently producing high-quality bagged products that meet specified weight, seal integrity, and appearance standards. This includes identifying and resolving defects efficiently.

- Production Optimization: Analyzing production data to identify areas for improvement in speed, efficiency, and waste reduction. This involves understanding key performance indicators (KPIs) and implementing strategies to meet production targets.

- Troubleshooting & Problem Solving: Developing the ability to diagnose and resolve mechanical, electrical, or operational issues quickly and effectively, minimizing downtime and production losses. This includes using diagnostic tools and following established troubleshooting procedures.

- Material Handling & Storage: Safe and efficient handling of raw materials and finished products, including proper storage and inventory management techniques. This involves understanding the importance of FIFO (First-In, First-Out) methods.

Next Steps

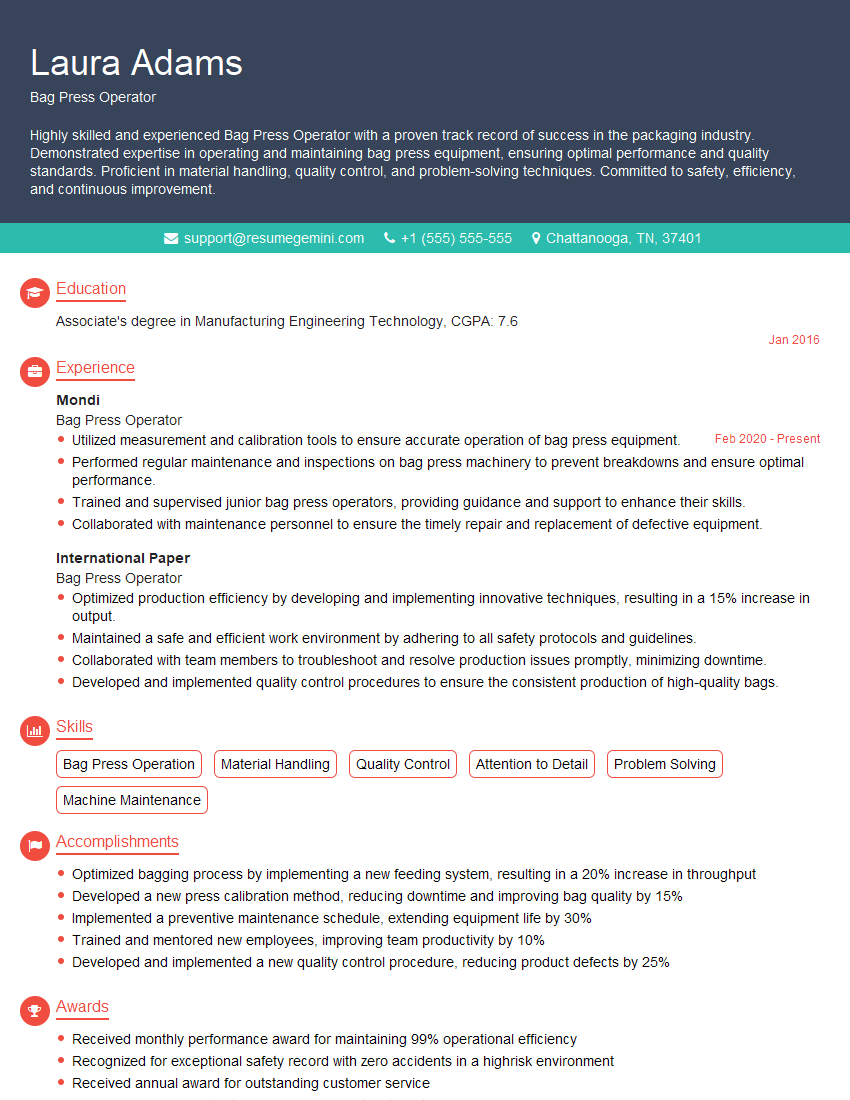

Mastering Bag Press Operation opens doors to a rewarding career with opportunities for advancement and increased responsibility. A strong understanding of these key concepts will significantly enhance your interview performance and showcase your skills to potential employers. To further strengthen your job application, crafting an ATS-friendly resume is crucial for getting noticed by recruiters. ResumeGemini is a trusted resource that can help you build a professional and effective resume tailored to highlight your Bag Press Operation expertise. Examples of resumes specifically tailored for Bag Press Operation positions are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good