Preparation is the key to success in any interview. In this post, we’ll explore crucial Balers Operation interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Balers Operation Interview

Q 1. What are the different types of balers?

Balers are categorized primarily by the type of bale they produce and the mechanism used to compress the material. There are several main types:

- Horizontal Balers: These balers compress material horizontally, creating rectangular bales that are often easier to handle and transport. They’re common in recycling centers and waste management facilities. Think of the large balers you see compacting cardboard.

- Vertical Balers: These balers compress material vertically, producing bales that are typically denser and more compact than horizontal bales. They are frequently used in the textile industry and for processing high-density materials like plastics.

- Self-Tied Balers: These balers automatically tie the bales using wire or twine, streamlining the process and reducing manual labor. This is a significant advantage in high-volume applications.

- Two-Ram Balers: These balers utilize two rams for increased compression force, often resulting in denser bales and faster cycle times. They are well-suited for exceptionally dense materials.

- Stationary vs. Mobile Balers: Balers can also be classified by their mobility. Stationary balers are fixed in place, whereas mobile balers are designed for transport and use in various locations.

The best type of baler depends entirely on the material being processed, the desired bale size and density, and the available space and budget.

Q 2. Describe the safety procedures for operating a baler.

Safety is paramount when operating a baler. A comprehensive safety procedure should always be followed, including:

- Lockout/Tagout Procedures: Before any maintenance or repair, the baler must be completely shut down and locked out to prevent accidental start-up. This is critical to prevent serious injury.

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including safety glasses, gloves, hearing protection, and steel-toed boots. The specific PPE requirements depend on the material being baled.

- Proper Training: Only trained and authorized personnel should operate the baler. Training should cover all aspects of operation, maintenance, and safety procedures.

- Clear Work Area: Ensure the area surrounding the baler is free of obstructions to prevent accidents. Proper lighting is also crucial.

- Regular Inspections: Before each use, inspect the baler for any damage or malfunctions. Never operate a damaged machine.

- Emergency Stop Button: Familiarize yourself with the location and operation of the emergency stop button and use it if necessary.

- Never Reach into a Running Baler: This is perhaps the most important rule. Serious injury can result from reaching into the machine while it’s operating.

Following these safety procedures is not just a recommendation; it’s a necessity for preventing accidents and ensuring a safe working environment.

Q 3. How do you identify and address common baler malfunctions?

Common baler malfunctions often manifest as reduced compaction, slow cycle times, or complete machine stoppage. Identifying the cause requires systematic troubleshooting:

- Slow Cycle Times or Poor Compaction: This could indicate issues with the hydraulic system (low oil, leaks), worn ram seals, or a problem with the bale chamber.

- Jammed Baler: This is often due to improper material feeding, foreign objects in the chamber, or a malfunctioning tying mechanism.

- Hydraulic Leaks: Check hydraulic lines and fittings for leaks. Low hydraulic fluid level often points to a leak somewhere in the system.

- Electrical Problems: Issues with motors, switches, or control circuits can cause malfunctions. Check for blown fuses or tripped breakers.

- Wire/Twine Issues (Self-Tied Balers): Inspect the wire/twine supply, the tying mechanism, and ensure the correct type of wire or twine is being used.

Addressing these malfunctions often requires specific knowledge of the baler’s design and components. Regular maintenance significantly reduces the likelihood of these issues.

Q 4. Explain the process of troubleshooting a jammed baler.

Troubleshooting a jammed baler requires a methodical approach, prioritizing safety:

- Shut Down the Baler: Immediately shut down and lockout/tagout the baler before attempting any troubleshooting.

- Assess the Situation: Carefully inspect the baler to identify the location of the jam. Look for any visible obstructions.

- Clear the Jam: Use appropriate tools to carefully remove the obstruction. Avoid using sharp objects that could damage the baler.

- Check for Damage: After clearing the jam, inspect the baler for any damage caused by the blockage.

- Restart the Baler: Once the jam is cleared and any damage is addressed, restart the baler and monitor its operation.

In some cases, a complex jam might require professional assistance. Attempting to force the jam could damage the baler further.

Q 5. What are the different types of baling materials?

The range of materials suitable for baling is extensive, varying based on the baler’s design and capacity:

- Paper and Cardboard: This is a very common material for baling, particularly in recycling facilities.

- Plastics: Various types of plastics can be baled, although sorting is often necessary to ensure material compatibility.

- Textiles: Used clothing, rags, and other textile waste are frequently baled.

- Aluminum Cans: These are often baled for recycling, requiring a baler designed for metallic materials.

- Steel and Ferrous Metals: These heavier metals require robust balers capable of handling their weight and density.

- Non-ferrous Metals: Some balers are designed for handling non-ferrous metals such as copper and brass. These require careful separation to avoid contamination.

The specific materials suitable for baling are greatly influenced by the baler’s construction and the intended application. Mixing incompatible materials can lead to inefficient baling and potentially damage the machine.

Q 6. How do you ensure the baler produces high-quality bales?

Producing high-quality bales involves a combination of factors:

- Proper Material Preparation: Ensure the material is properly sorted and free of contaminants. Consistent size and density of the feedstock is key to uniform bales.

- Regular Maintenance: Regular maintenance keeps the baler operating efficiently, producing consistently dense bales.

- Correct Baler Settings: Adjusting bale density settings appropriately for the material being processed is crucial.

- Proper Tying: Ensure the bale is securely tied to maintain its shape and prevent it from unraveling.

- Appropriate Baler Selection: Selecting the right type of baler for the specific material improves bale quality.

High-quality bales are denser, easier to handle, and more valuable, especially in the recycling industry. Consider factors like bale weight, shape consistency, and the presence of contaminants when evaluating bale quality.

Q 7. What are the daily maintenance checks for a baler?

Daily maintenance is essential for ensuring the baler’s longevity and reliable operation. Checks should include:

- Hydraulic Fluid Level: Check and top off the hydraulic fluid as needed.

- Hydraulic System Leaks: Inspect the hydraulic lines and fittings for any leaks.

- Wire/Twine Supply (Self-Tied Balers): Ensure there’s an adequate supply of wire or twine.

- Bale Chamber: Clear out any loose material or debris from the bale chamber.

- Electrical Connections: Inspect electrical connections for any loose wires or damage.

- Moving Parts: Check for any unusual noises or binding in moving parts.

- Safety Features: Verify the functionality of safety devices such as emergency stop buttons and safety guards.

Thorough daily maintenance will significantly reduce the risk of breakdowns, improve bale quality and extend the lifespan of the baler. Regular documentation of these checks can also be beneficial for tracking maintenance history.

Q 8. How do you perform preventative maintenance on a baler?

Preventative maintenance on a baler is crucial for maximizing its lifespan and minimizing downtime. Think of it like regular check-ups for your car – you wouldn’t ignore oil changes, right? A comprehensive preventative maintenance program involves a combination of daily, weekly, and monthly checks.

- Daily Checks: Inspect the bale chamber for any blockages, check the tension on the belts and chains, and lubricate moving parts according to the manufacturer’s recommendations. Pay close attention to the knotter mechanism, ensuring it’s operating smoothly. A simple visual check can often prevent major problems down the line.

- Weekly Checks: This involves a more thorough inspection of the baler’s components. Check for wear and tear on the pickup teeth, the feed rolls, and the knotter. Tighten any loose bolts or connections you find. Clean out accumulated debris from the bale chamber and around the machine.

- Monthly Checks: During the monthly maintenance, you should do a more thorough examination of critical components such as bearings, hydraulic systems (if applicable), and the drive system. You might need to use specialized tools for some of these inspections, and consult your baler’s manual for specific procedures. Consider professional servicing at this level to ensure everything is aligned and operating correctly.

Regular maintenance not only extends the life of your baler but also ensures consistent bale quality and prevents costly repairs later on. For instance, regularly lubricating the moving parts prevents friction-induced damage, saving you from potentially needing a major overhaul.

Q 9. What are the signs of a worn-out baler component?

Recognizing signs of worn-out components is essential for timely repairs and avoiding catastrophic failures. Think of it as noticing a persistent cough – it’s a sign something is not right and needs attention.

- Excessive Vibration: Unusual vibrations often indicate worn bearings, loose belts, or other mechanical issues within the baler’s drive system.

- Uneven Bale Shape: Inconsistent bale size and shape can point towards problems with the bale chamber, knotter, or feed mechanism.

- Bale Breakage: Frequently breaking bales suggests issues with knotting, twine/wire tension, or insufficient bale density.

- Leaks (Hydraulic Systems): For balers with hydraulic systems, leaking fluid is a clear sign of damaged hoses, seals, or cylinders. This needs immediate attention.

- Slow Operation: A significant decrease in baling speed could indicate worn belts, chain problems, or issues within the drive system.

- Unusual Noises: Grinding, squealing, or knocking sounds are usually a warning sign of serious wear or damage somewhere in the machine.

Ignoring these signs can lead to more extensive damage and significantly increase repair costs. It’s always better to address minor issues before they escalate into major problems.

Q 10. How do you handle different bale sizes and types?

Handling different bale sizes and types requires adjusting the baler’s settings and potentially changing components. Different materials require different densities and sizes to optimise storage and handling.

- Size Adjustments: Most modern balers allow for adjustments to bale size through settings on the control panel. These adjustments will alter the bale chamber dimensions, leading to larger or smaller bales.

- Material Considerations: The density setting must be adjusted depending on the material being baled. Hay, for example, requires a different density than straw or plastic. Overly dense bales could lead to uneven compression and increased power usage, while overly loose bales may not be stable for transport and storage.

- Type of Bale: Some balers produce square bales, while others produce round bales. The baler’s configuration must be optimized for the chosen type. Switching between types might involve changing components or settings, so you must carefully consult the manufacturer’s instructions.

Properly adjusting the baler for the type of material and desired bale size is essential for efficient operation and optimal bale quality. Inconsistent settings can result in damaged equipment or sub-standard bales.

Q 11. What are the proper procedures for changing baler wire or twine?

Changing baler wire or twine is a routine task that demands careful attention to safety and procedure. Always disconnect the power source before any maintenance. Safety is paramount.

- Preparation: Gather the necessary materials: new wire or twine, wire cutters (for wire), and any specialized tools recommended in your baler’s manual. Ensure you have a clear workspace.

- Removal: Carefully remove the old wire or twine, being mindful of sharp edges. Dispose of old wire responsibly, avoiding injury or environmental hazards.

- Installation: Follow your baler’s manual precisely regarding the threading of new wire or twine through the various guides and mechanisms of the knotter. Incorrect threading will result in poor knotting and bale failure.

- Testing: After installation, test the knotter mechanism to ensure the new wire or twine is feeding and knotting correctly before resuming baling operations.

Proper wire and twine replacement ensures consistent bale quality and prevents costly breakdowns. Using improper techniques or damaged materials could damage your knotter and compromise bale integrity. Always follow the manufacturer’s recommendations.

Q 12. Explain the importance of bale density and its impact on efficiency.

Bale density is a critical factor influencing baler efficiency and the quality of the final product. Imagine squeezing a sponge – the tighter you squeeze, the less space it takes. This is similar to how bale density affects storage and transport.

- Efficiency: Higher bale density means fewer bales are required to store the same amount of material, reducing storage space needs and transportation costs. This directly impacts fuel consumption and labor costs.

- Storage and Transportation: Denser bales are easier to stack and transport, minimizing the risk of damage during handling and storage.

- Quality: Proper density protects the baled material from spoilage or deterioration, thus maintaining its quality for a longer time.

- Impact on Equipment: Maintaining a consistent, appropriate density prevents overworking the baler, leading to reduced wear and tear, and fewer breakdowns.

Optimizing bale density requires a good understanding of the baler’s capabilities and the material being processed. Incorrect settings can result in under-compressed or over-compressed bales, leading to inefficiencies and quality issues.

Q 13. How do you ensure the safe disposal of baler waste?

Safe disposal of baler waste is crucial for environmental protection and worker safety. Baler waste can include broken twine, damaged wire, and other debris.

- Proper Containment: Collect waste in designated containers to prevent accidental injuries or environmental contamination.

- Recycling Options: Explore recycling options for recyclable materials such as metal wire. This is an environmentally friendly approach.

- Disposal Regulations: Comply with all local regulations and guidelines for the disposal of baler waste. This might include specific requirements for hazardous materials.

- Regular Cleaning: Regularly cleaning the baler’s workspace helps to avoid the accumulation of large amounts of waste, making disposal more manageable.

Following safe disposal procedures minimizes environmental impact and prevents workplace accidents. Ignoring these guidelines can result in fines, environmental damage, and potential harm to workers.

Q 14. What are the environmental considerations when operating a baler?

Environmental considerations are paramount when operating a baler. The impact extends beyond just the disposal of waste.

- Fuel Consumption: Choose balers with fuel-efficient engines to minimize greenhouse gas emissions. Proper maintenance helps optimize fuel efficiency.

- Noise Pollution: Minimize noise pollution by adhering to recommended operating procedures and employing noise-reduction measures when necessary.

- Waste Management: Implement an efficient waste management plan to reduce landfill waste and promote recycling.

- Material Choice: Use biodegradable twine and wire where possible to reduce the environmental impact of waste materials.

Operating a baler responsibly minimizes its environmental footprint. Ignoring these factors can lead to environmental damage and potential legal repercussions.

Q 15. How do you calculate the production rate of a baler?

Calculating a baler’s production rate involves determining the amount of material processed within a specific timeframe. It’s usually expressed in bales per hour or tons per hour. The exact calculation depends on the type of baler and the material being processed.

Simple Calculation: Production Rate = Total Number of Bales Produced / Total Time (in hours)

Example: If a baler produces 10 bales in 2 hours, its production rate is 10 bales / 2 hours = 5 bales per hour.

More Complex Scenarios: For more accuracy, consider factors like downtime for maintenance, wire changes, or material feed inconsistencies. You might track production in shorter intervals (e.g., bales per shift) and then average these to get a more reliable overall rate. Advanced balers might have built-in systems that automatically track and report production data.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the key performance indicators (KPIs) for a baler operator?

Key Performance Indicators (KPIs) for a baler operator focus on both efficiency and safety. Here are some critical metrics:

- Bales per hour/shift: Measures the operator’s speed and efficiency.

- Downtime percentage: Indicates the proportion of time the baler is not producing due to malfunctions or other reasons. A low percentage is desirable.

- Material waste: Tracking material loss due to spillage or improper baling techniques is crucial for cost efficiency.

- Wire usage: Monitoring wire consumption helps optimize costs and identify potential inefficiencies.

- Safety record: Absence of accidents and adherence to safety protocols are paramount.

- Maintenance compliance: Regularly performing preventative maintenance tasks as scheduled helps reduce unexpected downtime.

Regular monitoring of these KPIs allows for identifying areas for improvement and optimizing the baling process.

Q 17. Describe the process of cleaning and sanitizing a baler.

Cleaning and sanitizing a baler is crucial for maintaining hygiene, preventing cross-contamination (especially important in food processing or recycling facilities), and ensuring smooth operation. The process varies depending on the type of baler and the materials handled, but generally involves these steps:

- Power Down and Lockout/Tagout (LOTO): This is the most critical step – ensure the baler is completely powered off and locked to prevent accidental startup.

- Remove Waste Material: Clear all loose material from the chamber, feed area, and surrounding areas.

- Clean the Chamber: Use appropriate tools and cleaning agents to remove any compacted material, debris, or residue. Compressed air can be helpful, but always wear appropriate safety glasses and hearing protection.

- Sanitize (if necessary): For food processing or applications requiring sanitation, use food-grade sanitizing agents following the manufacturer’s instructions. Allow sufficient contact time.

- Check for Leaks or Damage: Inspect hydraulic lines, seals, and other components for any leaks or damage that might need attention.

- Lubricate Moving Parts: Lubricate moving parts according to the manufacturer’s maintenance schedule.

- Dispose of Waste Properly: Dispose of cleaning solutions and waste materials according to local regulations.

Regular cleaning and sanitization extend the baler’s lifespan and improve its operational efficiency.

Q 18. How do you identify and report safety hazards related to baler operation?

Identifying and reporting safety hazards related to baler operation is essential for preventing accidents. Hazard identification requires regular inspections and awareness.

- Regular Inspections: Check for loose parts, damaged hydraulic lines, frayed wires, and any signs of wear and tear.

- Guards and Safety Devices: Ensure all safety guards are in place and functioning correctly. Report any missing or malfunctioning guards immediately.

- Emergency Stops: Verify that emergency stop buttons are easily accessible and function properly.

- Personal Protective Equipment (PPE): Always use appropriate PPE, including safety glasses, gloves, and hearing protection.

- Proper Training: Ensure all operators have received adequate training on safe operating procedures.

- Reporting: Report all hazards, incidents, and near misses using the company’s established reporting system. This could involve filling out an incident report form or notifying a supervisor.

Maintaining a safe working environment is a shared responsibility. Prompt reporting of hazards is crucial for preventing accidents.

Q 19. What are the emergency procedures in case of a baler malfunction?

Emergency procedures for baler malfunctions prioritize safety and minimizing damage. Actions should always be taken in a calm and controlled manner.

- Immediate Stop: Hit the emergency stop button immediately.

- Power Off: If necessary, follow lockout/tagout (LOTO) procedures to completely isolate the power supply.

- Assess the Situation: Identify the nature of the malfunction and the level of risk it presents.

- Evacuate the Area: Clear the immediate area around the baler to prevent injury.

- Report the Malfunction: Contact maintenance personnel or a supervisor to report the problem. Clearly describe the situation and any observed damage.

- Do Not Attempt Repairs: Unless trained to do so, do not attempt to repair the baler yourself.

- Follow Company Protocols: Adhere to the company’s established emergency procedures for equipment malfunctions.

Regular maintenance and training significantly reduce the likelihood of malfunctions and ensure effective responses in emergencies.

Q 20. How do you handle different types of baling wire?

Baler wire comes in various types, each with its properties and applications. Proper handling is crucial for efficient baling and operator safety.

- Steel Wire: The most common type, offering high tensile strength and durability. Different gauges (thicknesses) are available, selected based on the material being baled and the baler’s capacity.

- Plastic Wire: Used in some applications, particularly for lighter materials or those that might be susceptible to damage from steel wire. It’s generally less durable than steel wire.

- Recycled Wire: Environmentally friendly option made from recycled steel, offering similar properties to standard steel wire.

Handling Procedures:

- Storage: Store wire coils neatly and safely to prevent tangling or damage.

- Feeding: Use the baler’s wire feeding mechanism correctly to avoid jams or kinks.

- Disposal: Dispose of used wire responsibly, following local regulations and recycling guidelines.

- Safety: Always wear appropriate gloves to prevent cuts and abrasions when handling baling wire.

Understanding the properties of different wire types and implementing correct handling procedures maximizes efficiency and safety.

Q 21. What are the different types of hydraulic systems used in balers?

Hydraulic systems are essential for the operation of most balers, providing the power for compressing materials. Different types offer varying levels of efficiency and complexity.

- Open-Center Hydraulic Systems: The most common type in smaller balers. The pump runs continuously, and hydraulic fluid flows back to the tank when not needed. It’s simpler and less expensive but may be less efficient than closed-center systems.

- Closed-Center Hydraulic Systems: Used in larger, more advanced balers. The pump only runs when hydraulic power is needed, making them more efficient. They offer more precise control and responsiveness.

- Load-Sensing Hydraulic Systems: Sophisticated systems that adjust pump output based on the load, maximizing efficiency by only supplying the required hydraulic power.

The choice of hydraulic system depends on the size, complexity, and required performance of the baler. Regular maintenance of the hydraulic system, including oil changes and filter replacements, is essential for preventing malfunctions and ensuring optimal baler performance.

Q 22. How do you interpret the baler’s control panel and gauges?

Interpreting a baler’s control panel and gauges is crucial for safe and efficient operation. Think of it like the cockpit of an airplane – all the vital information is displayed there. Different balers will have varying layouts, but common elements include:

Power indicators: Lights indicating power is on and operational status.

Pressure gauges: Showing the pressure within the baling chamber. This is critical; low pressure might indicate a leak, while excessively high pressure suggests a potential blockage or malfunction.

RPM indicators: Display the speed of the ram or flywheel, vital for monitoring the baling process. Too slow, and you’ll have inefficient compaction. Too fast, and you risk damage.

Warning lights: These alert you to potential problems, such as overheating, low oil, or other malfunctions. Never ignore these.

Operational switches/buttons: These control the baling cycle (start, stop, reverse, etc.). Familiarity is key to preventing accidents.

For example, if the pressure gauge suddenly drops while the baler is running, I would immediately stop the machine and investigate for leaks or blockages, because that indicates a serious problem.

Q 23. How do you properly store and handle baling materials?

Proper storage and handling of baling materials are paramount for safety and efficiency. Think of it like organizing a well-stocked pantry – everything needs its place to prevent chaos. Here’s my approach:

Material segregation: Separate materials by type (cardboard, plastic, etc.) to prevent contamination and optimize the baling process. Mixing materials can lead to poorly formed bales.

Moisture control: Excessive moisture can damage the baler’s components and lead to inefficient compaction. Store materials in a dry, well-ventilated area.

Proper stacking: Stack materials neatly to prevent collapse and ensure easy access for feeding the baler. Don’t overload stacks.

Material preparation: Break down oversized items to prevent jams. Remove any foreign objects (metal, etc.) that could damage the baler.

For instance, if I’m working with cardboard, I would ensure it’s dry and relatively flat, preventing jams and improving bale density. Similarly, plastic films should be handled carefully to avoid tangling and ensure consistent feeding.

Q 24. What is your experience with different brands of balers?

My experience encompasses several leading baler brands, including Vermeer, Case IH, and Hesston. Each brand offers unique features and advantages. For example, Vermeer balers are often praised for their robust construction and reliability. Case IH models, on the other hand, might excel in a specific application due to their advanced features. Hesston is known for its innovative designs.

I’ve worked extensively with their different models, from smaller, self-tied balers ideal for smaller operations, to large, high-capacity round balers suitable for vast agricultural lands. This breadth of experience gives me a broad understanding of varying functionalities and potential maintenance issues for each model.

Ultimately, understanding the nuances of each brand’s operating manuals, preventive maintenance schedules, and troubleshooting guides has allowed me to become proficient in identifying specific needs and addressing issues effectively and efficiently.

Q 25. What are the potential hazards associated with baler operation?

Baler operation presents several potential hazards, making safety a top priority. It’s like working with any heavy machinery; understanding the risks is essential to mitigating them. Key hazards include:

Pinch points: Areas where body parts can be trapped between moving parts. These require careful attention and adherence to safety protocols.

Rotating parts: Flywheels, belts, and other rotating components can cause serious injuries if contacted. Guards and safety interlocks are crucial.

Hydraulic systems: High-pressure hydraulic lines can rupture, causing injury from escaping fluid or the force of the rupture. Regular inspections are critical here.

Material handling: Lifting, moving, and stacking bales can cause back injuries or crush hazards. Proper lifting techniques are crucial.

Electrical hazards: Malfunctioning electrical components can lead to shocks or fires. Proper grounding and regular inspections are vital.

I always emphasize using personal protective equipment (PPE), like safety glasses, gloves, and hearing protection, and conducting regular safety inspections to ensure that the machine is not operating with any obvious risks. A thorough understanding of the equipment’s limitations is paramount for injury prevention.

Q 26. Describe your experience with preventative maintenance programs.

Preventative maintenance is the cornerstone of reliable baler operation. Think of it as regular car maintenance – it prevents major breakdowns down the line. My experience with preventative maintenance programs includes:

Scheduled inspections: Following a manufacturer’s recommended schedule for inspections, checking fluid levels, greasing components, tightening bolts, and checking for wear and tear.

Lubrication: Regular lubrication is crucial for reducing friction and extending the lifespan of moving parts. I use the appropriate lubricants and follow manufacturer guidelines.

Component replacement: Replacing worn or damaged components promptly, based on wear indicators or manufacturer recommendations, to prevent catastrophic failures.

Record keeping: Maintaining detailed records of all maintenance activities, including dates, work performed, and parts replaced. This helps in tracking maintenance trends and predicting future needs.

For instance, I’ve implemented a system where we schedule routine inspections every 50 bales, or once a week, whichever comes first, to ensure that small problems are identified and addressed promptly, before they become large maintenance issues. This approach has significantly improved uptime and reduced costly repairs.

Q 27. How do you prioritize maintenance tasks to ensure efficient baler operation?

Prioritizing maintenance tasks for efficient baler operation requires a strategic approach. I use a combination of factors to determine the order of tasks:

Criticality: Tasks that directly impact safety or the baler’s ability to function are prioritized first (e.g., hydraulic leaks, electrical faults).

Urgency: Tasks that need immediate attention to prevent further damage or downtime are given higher priority (e.g., a broken belt).

Preventative nature: Regular maintenance tasks, such as lubrication and inspections, are scheduled to prevent future problems. This is crucial for long term operability.

Cost-benefit analysis: Some tasks might be more costly than others. A balanced approach needs to be used, prioritizing repairs that prevent significant downtime or damage.

For example, if I detect a minor hydraulic leak, I’d prioritize its repair over a less critical task like repainting the baler, even if repainting is part of the routine maintenance. The leak could lead to a significant loss of hydraulic pressure and affect operation, resulting in far greater cost and downtime than the painting job.

Q 28. Explain your understanding of lockout/tagout procedures for baler maintenance.

Lockout/tagout (LOTO) procedures are fundamental for baler maintenance safety. Think of it as a safety ritual before performing surgery – preventing accidental operation while the machine is being serviced. The process involves:

Turning off the power: Disconnecting the main power source to the baler. This is crucial for preventing accidental startup.

Applying a lockout device: A lockable device that prevents the activation of the power source. This ensures that only authorized personnel can restore power.

Applying a tagout device: A warning tag clearly stating that the baler is under maintenance and should not be operated. This acts as an additional visual warning.

Verification: After the LOTO devices have been applied, verifying that the equipment is inactive and that no residual energy can reactivate it is critical for preventing accidents.

Removal of LOTO devices: Only the person who applied the LOTO devices can remove them once maintenance is complete.

Failure to follow LOTO procedures can result in serious injury or death. It’s not a step that should ever be skipped. I always ensure everyone on the maintenance team fully understands the LOTO process and its importance for everyone’s well-being.

Key Topics to Learn for Balers Operation Interview

- Balers Mechanics: Understanding the various types of balers (horizontal, vertical, etc.), their components (e.g., rams, conveyors, tying systems), and their operational principles. Consider the differences in functionality and maintenance requirements.

- Safety Procedures and Regulations: Mastering lockout/tagout procedures, proper personal protective equipment (PPE) usage, and recognizing and addressing potential hazards (e.g., pinch points, entanglement risks). Familiarize yourself with relevant OSHA or industry-specific safety standards.

- Troubleshooting and Maintenance: Developing a systematic approach to diagnosing malfunctions (e.g., using diagnostic tools, identifying common points of failure). Understanding preventative maintenance schedules and procedures, including lubrication, cleaning, and component replacement.

- Material Handling and Processing: Knowledge of different materials processed by balers (e.g., paper, plastic, textiles) and how material characteristics impact baling operations (e.g., density, moisture content). Understanding bale size optimization and efficiency.

- Performance Monitoring and Optimization: Understanding key performance indicators (KPIs) such as bales per hour, downtime, and material yield. Knowing methods to improve efficiency and reduce waste.

- Data Interpretation and Reporting: Ability to interpret data from baler monitoring systems to identify trends, diagnose issues, and report on performance. Proficiency with data logging and reporting procedures.

Next Steps

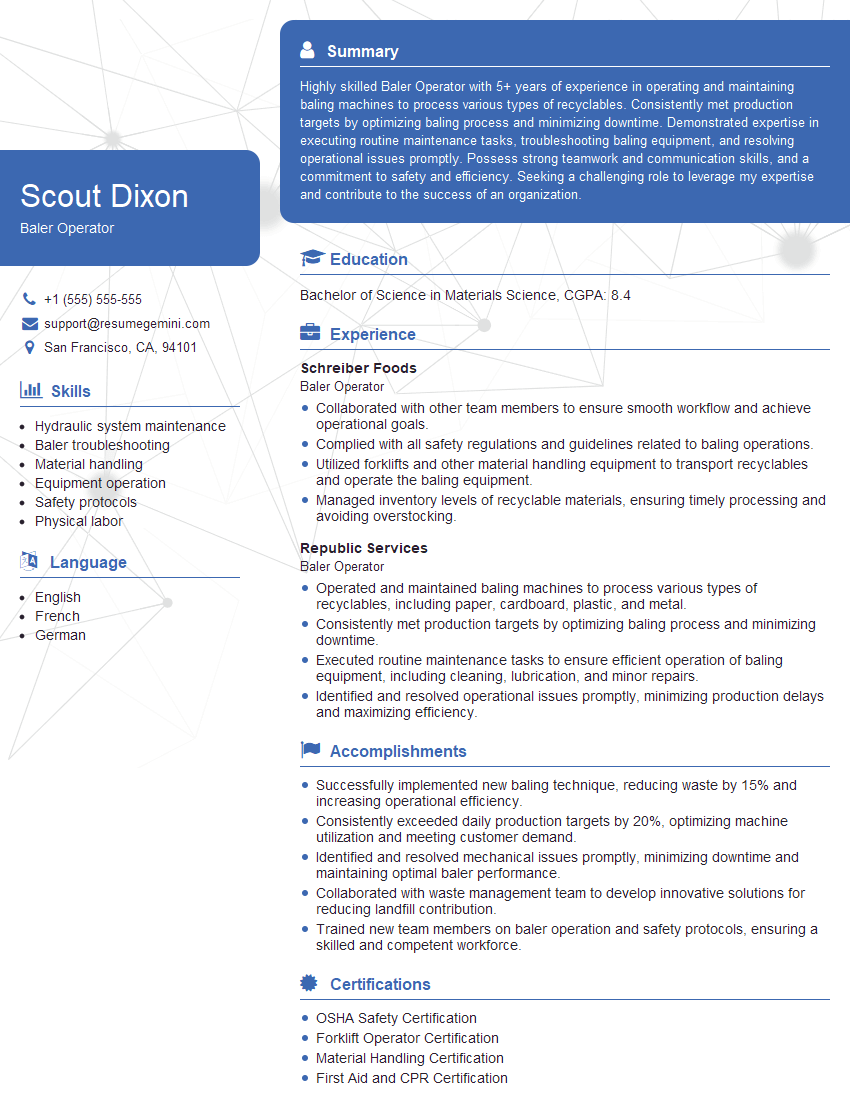

Mastering Balers Operation opens doors to rewarding careers in manufacturing, recycling, and waste management, offering opportunities for advancement and specialization. To maximize your job prospects, creating an ATS-friendly resume is crucial. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your skills and experience effectively. Examples of resumes tailored to Balers Operation are available to guide you, ensuring your application stands out.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good