The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Basic Maintenance skills interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Basic Maintenance skills Interview

Q 1. Explain the importance of preventative maintenance.

Preventative maintenance is like regular check-ups at the doctor – it’s far better to address small issues before they become major problems. It focuses on proactively identifying and addressing potential equipment or system failures before they occur, minimizing downtime, extending the lifespan of assets, and ultimately saving significant costs in the long run. Think of it as an ounce of prevention being worth a pound of cure.

- Reduced Downtime: By catching minor issues early, you avoid costly production halts or service disruptions.

- Extended Equipment Lifespan: Regular maintenance prevents wear and tear from escalating into major repairs or complete replacements.

- Cost Savings: Addressing small problems early is significantly cheaper than fixing major breakdowns later. This includes labor, parts, and potential lost revenue.

- Improved Safety: Regular inspections identify potential safety hazards before they can cause accidents or injuries.

For example, regularly lubricating moving parts in machinery prevents friction and wear, avoiding costly repairs or complete failure down the line. Similarly, checking electrical connections and tightening loose wires prevents potential fires or power outages.

Q 2. Describe your experience with troubleshooting basic electrical issues.

Troubleshooting basic electrical issues requires a systematic approach, starting with safety. I always begin by turning off the power at the breaker box before working on any electrical component. My experience involves identifying problems such as faulty switches, tripped breakers, loose wiring, and malfunctioning outlets.

For instance, I once encountered a situation where several lights in a building stopped working. By systematically checking each circuit breaker and individual lights, I identified a faulty breaker that was tripping. Replacing the breaker resolved the issue. Another time, I found a loose wire connection behind an outlet causing intermittent power failures. Securing the connection with appropriate connectors permanently fixed the problem.

I’m comfortable using multimeters to check voltage, amperage, and continuity to diagnose issues accurately and safely. I also understand basic wiring diagrams and can trace circuits to isolate problems.

Q 3. How do you prioritize maintenance tasks?

Prioritizing maintenance tasks requires a blend of urgency and impact. I typically use a system that combines criticality, frequency, and cost. I employ a matrix that looks at:

- Criticality: How vital is this system or piece of equipment to overall operations? A critical system with high potential for disruption needs immediate attention.

- Frequency: How often does this equipment require maintenance? Regular tasks like filter changes have a set schedule.

- Cost: What is the potential cost of failure? A small, inexpensive component with a high likelihood of failure should be addressed before a larger, more expensive one.

For example, a broken HVAC system in the middle of summer is obviously critical and needs immediate attention. Regularly scheduled tasks like lubricating machinery would be prioritized based on the manufacturer’s recommendations. A minor leak in a non-critical water pipe might be scheduled for a later date.

Q 4. What safety precautions do you follow when performing maintenance?

Safety is paramount in all maintenance tasks. My safety protocols are unwavering and include:

- Lockout/Tagout Procedures: Always de-energize equipment before working on it, using appropriate lockout/tagout procedures to prevent accidental re-energization.

- Personal Protective Equipment (PPE): I always wear appropriate PPE based on the task, including safety glasses, gloves, hearing protection, and steel-toe boots.

- Proper Lifting Techniques: Using proper lifting techniques to avoid injuries, especially when handling heavy equipment or materials.

- Awareness of Surroundings: Maintaining situational awareness to avoid hazards and to prevent accidents, such as tripping over cords or objects.

- Following Manufacturer’s Instructions: Always adhering to the manufacturer’s instructions and safety guidelines for all equipment and tools.

A concrete example is always disconnecting the power supply before working on electrical circuits. Never assume power is off; always verify with a multimeter. Similarly, always use appropriate lifting equipment for heavy objects to prevent back injuries.

Q 5. Describe your experience with basic plumbing repairs.

My experience with basic plumbing repairs covers tasks such as unclogging drains, repairing leaky faucets, replacing toilet flappers, and fixing minor leaks in pipes. I’m familiar with various plumbing tools, including pipe wrenches, basin wrenches, plungers, and drain snakes.

For instance, I’ve successfully unclogged several drains using a combination of plungers and drain snakes. I’ve also replaced several leaky faucets by identifying the specific cause of the leak – whether a worn-out O-ring, a faulty cartridge, or a corroded valve – and replacing the faulty part. I understand the importance of water shut-off valves and always utilize them to minimize water waste and potential flooding during repairs.

Q 6. How do you handle unexpected maintenance emergencies?

Handling unexpected maintenance emergencies requires quick thinking and decisive action. My approach involves:

- Assessment: Quickly assess the situation to determine the severity of the problem and its potential impact.

- Prioritization: Prioritize the most critical issues and address them first.

- Containment: Take immediate steps to contain the problem and prevent further damage. For example, if there is a water leak, turn off the water main to prevent flooding.

- Communication: Communicate the emergency to relevant parties, such as supervisors or clients, providing regular updates.

- Temporary Fixes: Implement temporary fixes to mitigate the problem until a permanent solution can be implemented.

For example, if a significant water leak occurs outside of business hours, I would shut off the water main, contact emergency services if necessary, and arrange for a plumber to perform repairs as soon as possible. Temporary containment solutions like placing buckets to catch dripping water would minimize immediate damage. Documenting everything meticulously is crucial for any insurance claims or for future reference.

Q 7. What tools and equipment are you proficient with?

I’m proficient with a wide range of tools and equipment commonly used in basic maintenance, including:

- Hand Tools: Screwdrivers (Phillips and flathead), wrenches (adjustable and socket), pliers (needle-nose and slip-joint), hammers, utility knives, measuring tapes.

- Power Tools: Drills, impact drivers, reciprocating saws, circular saws (with appropriate safety measures).

- Plumbing Tools: Pipe wrenches, basin wrenches, plungers, drain snakes.

- Electrical Tools: Multimeters, wire strippers, voltage testers.

- Other Equipment: Ladders, safety glasses, gloves, hearing protection.

My experience includes using these tools in various settings to carry out tasks effectively and safely. I am constantly updating my skills and knowledge to keep pace with new technologies and techniques.

Q 8. Explain your experience with HVAC system maintenance.

My HVAC system maintenance experience spans over five years, encompassing both preventative and reactive maintenance. Preventative maintenance includes tasks like changing air filters, cleaning condenser coils, checking refrigerant levels, and lubricating moving parts. This is crucial for optimal efficiency and preventing costly breakdowns. For example, I once identified a slightly loose connection in a condenser fan motor during a routine check, preventing a potential overheating issue and a subsequent expensive repair. Reactive maintenance involves troubleshooting and repairing malfunctions. I’ve diagnosed and fixed issues such as compressor failures, refrigerant leaks (using leak detection equipment), and problems with blower motors. I’m proficient in using diagnostic tools to identify the root cause of the problem, not just treating symptoms. I also have experience with various HVAC system types, including split systems, heat pumps, and packaged units.

Q 9. Describe your experience with carpentry repairs.

My carpentry repair experience includes a wide range of tasks, from simple repairs like fixing loose door handles and patching drywall to more complex projects such as building custom shelving units and repairing damaged framing. I’m skilled in using various woodworking tools, both hand and power tools, and I understand the importance of precision and safety. For instance, I once repaired a structurally compromised section of a staircase by carefully removing the damaged parts, reinforcing the framing using appropriate techniques, and then replacing the damaged treads and risers. I also have experience with different types of wood and understand how to select the appropriate materials for specific applications. My work emphasizes both functionality and aesthetics, ensuring a seamless blend with the existing structure.

Q 10. How do you document completed maintenance tasks?

I meticulously document completed maintenance tasks using a combination of digital and physical methods. For digital documentation, I utilize a mobile app specifically designed for maintenance tracking, allowing me to log the date, time, location, task performed, materials used, and any relevant notes or photos. This app generates a comprehensive report that’s easily searchable and shareable. For physical documentation, I use well-organized work orders and checklists. I always sign and date the work order and the homeowner signs as well. This ensures traceability and accountability. For example, if a specific part was replaced, I’ll note the part number and manufacturer for future reference. A clear, consistent record-keeping system is vital for efficiency and to maintain a transparent history of performed work.

Q 11. What is your experience with reading and interpreting blueprints or schematics?

I’m comfortable reading and interpreting blueprints and schematics. My experience includes working with both architectural and mechanical drawings. I understand symbols, dimensions, notations, and how to translate them into practical, on-site work. I’ve used blueprints to locate specific systems within a building, understand the layout of electrical circuits, and plan the execution of repair or maintenance tasks. Understanding blueprints helps me prevent errors and ensure that work is done efficiently and accurately. For example, when working on a plumbing repair, I used the building’s plumbing schematic to trace the pipe’s route and identify the exact location of the valve, allowing me to avoid unnecessary demolition and reduce the overall repair time.

Q 12. Describe your experience with using a multimeter.

I’m highly proficient in using a multimeter for various electrical testing tasks. I’m experienced in measuring voltage, current, and resistance, and understanding the implications of these readings. I use a multimeter to troubleshoot electrical circuits, identify short circuits, test continuity, and verify the proper operation of electrical components. For instance, I recently used a multimeter to identify a faulty outlet in a kitchen. By measuring the voltage at the outlet, I quickly determined there was no power reaching the outlet, and further testing pinpointed the break in the wiring. This prevented potential electrical hazards and minimized downtime.

Q 13. How do you identify and address potential safety hazards?

Identifying and addressing potential safety hazards is paramount in my work. My approach involves a proactive risk assessment before starting any task. This includes checking for things like exposed wires, unstable structures, hazardous materials, and ensuring proper personal protective equipment (PPE) is used – such as safety glasses, gloves, and hearing protection. During the work itself, I consistently maintain a safe working environment by properly securing tools, materials, and work areas. If an unexpected hazard arises, I know how to safely shut down operations, assess the situation, and take appropriate corrective actions before resuming. For instance, if I encounter asbestos during a demolition, I immediately stop work and contact the appropriate authorities for safe removal. Safety is non-negotiable; my priority is always to complete the work safely and without incident.

Q 14. What is your experience with using hand and power tools?

I have extensive experience using both hand and power tools. My hand tool proficiency includes saws (hacksaws, hand saws), screwdrivers, hammers, chisels, pliers, wrenches, and measuring tools. With power tools, I’m adept at using drills, saws (circular, reciprocating, jigsaw), sanders, and grinders. I understand the importance of proper tool maintenance and safety procedures. Before using any power tool, I carefully inspect it to ensure it’s in good working order and I always use appropriate safety equipment. For example, when using a circular saw, I always use a safety guard and push stick to minimize the risk of injury. Knowing how to properly use and maintain both hand and power tools is essential for completing tasks effectively, safely, and with a high-quality outcome.

Q 15. Explain your understanding of preventative maintenance schedules.

Preventative maintenance schedules are the backbone of any successful maintenance program. They’re essentially a roadmap outlining regular inspections, cleaning, and minor repairs designed to prevent major equipment failures and extend the lifespan of assets. Think of it like regular check-ups for your car – far better to change the oil regularly than to wait for the engine to seize.

- Frequency: Schedules vary depending on the equipment, its usage intensity, and manufacturer recommendations. Some tasks might be daily (e.g., sweeping a warehouse floor), weekly (e.g., checking lubrication levels), monthly (e.g., inspecting HVAC filters), or annually (e.g., boiler inspections).

- Tasks: Specific tasks listed in the schedule include lubrication, cleaning, visual inspections for wear and tear, tightening bolts, and replacing worn parts. The detail will be specific to the equipment; for instance, a preventative maintenance schedule for a photocopier would differ vastly from one for a large industrial oven.

- Documentation: Crucially, preventative maintenance schedules require meticulous record-keeping. This includes dates of service, tasks performed, any identified issues, and the signatures of the personnel who carried out the work. This documentation is vital for tracking performance, identifying trends, and demonstrating compliance with safety regulations.

For example, a preventative maintenance schedule for a small office might include weekly vacuuming, monthly dusting of electronics, and quarterly deep cleaning of carpets. A larger factory floor might involve daily inspections of conveyor belts, weekly lubrication of machinery, and monthly inspections of electrical systems. The key is tailoring the schedule to the specific environment and the equipment in use.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you troubleshoot and resolve basic mechanical issues?

Troubleshooting mechanical issues involves a systematic approach. It’s not about randomly trying things; it’s about using logic and observation to pinpoint the problem’s root cause. I typically follow these steps:

- Identify the problem: What exactly is malfunctioning? Describe it clearly and specifically.

- Gather information: When did the problem start? Has anything changed recently (new equipment, new procedures)? Are there any error codes or warning lights?

- Visual inspection: Carefully examine the equipment for any obvious issues – loose connections, broken parts, leaks, unusual sounds, or excessive vibrations.

- Testing and measurements: Use appropriate tools (multimeters, pressure gauges, etc.) to take readings and check the equipment’s performance against specifications.

- Isolate the problem: Through testing and deduction, identify the specific component causing the malfunction.

- Repair or replacement: Once the problem is identified, carry out the necessary repair or replace faulty components. This might involve simple fixes like tightening a screw or more complex repairs requiring specialized tools and knowledge.

- Testing and verification: After repair, test the equipment to verify that the problem has been solved and the equipment functions correctly.

For example, if a pump isn’t working, I might first check the power supply, then the inlet and outlet valves, and finally, check for clogs or internal damage. The process is similar regardless of the equipment type.

Q 17. Describe your experience with cleaning and maintaining equipment.

Cleaning and maintaining equipment is not just about aesthetics; it’s crucial for safety, efficiency, and longevity. Proper cleaning prevents the build-up of dirt, grease, and debris which can lead to malfunctions, safety hazards, and reduced performance.

- Types of cleaning: This ranges from simple wiping and dusting to more intensive cleaning involving specialized solvents and equipment. It includes the removal of dust from computer components, the thorough cleaning of kitchen appliances, or washing and sanitizing equipment in food processing environments.

- Maintenance practices: Beyond cleaning, maintenance includes lubricating moving parts, inspecting for wear and tear, replacing filters, and ensuring proper ventilation. Regular maintenance prevents small issues from escalating into significant problems. For example, regularly cleaning and lubricating a conveyor belt will prevent premature wear and tear and costly replacements.

- Safety procedures: This includes using appropriate personal protective equipment (PPE) such as gloves, safety glasses, and respirators, particularly when working with hazardous materials or chemicals. Also, understanding lock-out/tag-out procedures for safe equipment shutdown before cleaning and maintenance is critical.

For example, during my previous role, I developed a cleaning schedule for all kitchen equipment, including specific procedures for each appliance. This significantly reduced downtime and improved hygiene standards.

Q 18. How familiar are you with different types of building materials?

Familiarity with building materials is essential for effective maintenance. This knowledge helps in identifying potential problems, selecting appropriate repair materials, and understanding the implications of different materials on maintenance procedures.

- Wood: I understand different types of wood, their strengths and weaknesses, and appropriate treatment methods. I know how to repair minor damage such as scratches and cracks and how to protect wood from moisture and rot.

- Concrete: I’m knowledgeable about different concrete mixes and their applications, as well as methods for repairing cracks and spalling, sealing, and protecting it from weathering.

- Metals: My experience includes working with various metals, understanding their properties (corrosion resistance, strength, etc.), and how to repair or replace metal components. This includes identifying corrosion and addressing issues with different types of metal such as steel, aluminum, and stainless steel.

- Plastics: I’m aware of different types of plastics and their suitability for specific applications. I understand the limitations of different plastic materials and how to approach their maintenance and repair.

Understanding the properties of building materials enables me to make informed decisions during maintenance and repair. For example, choosing the right sealant for a particular type of masonry is crucial to preventing further damage.

Q 19. What is your experience with using a level or other measuring tools?

I’m proficient in using a variety of measuring tools, including levels, tape measures, calipers, and digital measuring devices. Accuracy is critical in many maintenance tasks.

- Levels: I use levels to ensure surfaces are perfectly horizontal or vertical, essential for installing cabinets, hanging pictures, or laying flooring. I understand the different types of levels (torpedo, box, etc.) and their applications.

- Tape measures: These are indispensable for accurate measurements of lengths, widths, and heights. I am skilled at taking precise measurements for cutting materials, checking dimensions, and verifying installations.

- Calipers: I use calipers to measure precise dimensions of components and ensure proper fit during repairs or replacements. This is crucial in tasks requiring precise tolerances.

- Digital measuring tools: My experience includes using digital multimeters to measure electrical parameters, digital thermometers for temperature checks, and laser distance meters for accurate long-distance measurements.

For instance, when installing new shelving, I use a level to ensure it’s perfectly horizontal and a tape measure to ensure the correct spacing between shelves.

Q 20. How do you effectively communicate maintenance issues to supervisors?

Effective communication is paramount in maintenance. I ensure that my reports to supervisors are clear, concise, and actionable.

- Clear and concise reporting: I use clear and unambiguous language, avoiding jargon. My reports describe the issue, its severity, and any immediate actions taken or needed. I always avoid ambiguity.

- Documentation: I meticulously document all maintenance issues, including photographs, measurements, and test results. This provides clear visual evidence of the problem.

- Prioritization: I clearly prioritize reported issues based on their urgency and potential impact. This allows supervisors to focus on critical issues promptly.

- Proposing solutions: I don’t just report problems; I proactively suggest solutions and provide estimates for time and resources required for repairs.

For example, instead of simply saying ‘the pump is broken,’ I would report: ‘The main pump in the south wing has stopped working. Visual inspection reveals a broken impeller. I have already shut off the power and propose replacing the impeller as soon as possible; this will require approximately one hour and the cost of a new impeller.’ This ensures the supervisor has all the information they need to make informed decisions.

Q 21. Describe a time you had to solve a challenging maintenance problem.

One of the most challenging maintenance problems I encountered was a sudden drop in water pressure across an entire building. Initial checks suggested a main pipe burst, but after an extensive search, I found no visible signs of damage or leaks. This indicated a more subtle issue.

My approach was methodical: I systematically checked pressure gauges at different points in the system, isolating sections to pinpoint the problem area. After hours of investigation, I discovered a small, almost invisible crack in a hidden section of pipe deep within a wall. Because the pipe was aged and encased in concrete, a standard visual inspection was ineffective. I used a thermal imaging camera, which revealed a temperature differential at the crack, confirming its location. This allowed me to precisely target the repair, minimizing disruption and preventing further damage.

This experience highlighted the importance of systematic troubleshooting, the use of advanced diagnostic tools, and patience in problem-solving. It also underscored the significance of accurate documentation to aid future maintenance and repairs in similar scenarios.

Q 22. What are your strengths and weaknesses in relation to maintenance skills?

My greatest strength lies in my proactive and preventative approach to maintenance. I believe in identifying potential issues before they become major problems, saving time and resources in the long run. For example, during my time at [Previous Company Name], I noticed a recurring issue with a specific piece of equipment. By implementing a simple lubrication schedule, I prevented a costly breakdown and significant downtime. My weakness, however, is sometimes getting overly involved in details, leading to minor delays. I’m actively working on improving my time management skills to mitigate this by prioritizing tasks effectively using techniques like Eisenhower Matrix.

Another strength is my versatility. I’m comfortable handling a wide range of maintenance tasks, from basic plumbing and electrical work to more complex mechanical repairs. I’m adept at troubleshooting and diagnosing problems efficiently. My weakness would be limited experience with specialized equipment or systems that may be highly sophisticated. To address this, I dedicate time to researching new technologies and seek opportunities for training and certification when they arise.

Q 23. How do you stay up-to-date on the latest maintenance techniques?

Staying current in maintenance is crucial. I utilize several strategies to keep my skills sharp. Firstly, I subscribe to relevant trade magazines and online journals, such as [Mention specific journals/magazines]. These publications provide updates on new technologies, best practices, and industry regulations. Secondly, I actively participate in online forums and professional organizations like [Mention organizations], engaging with other professionals and sharing knowledge. Finally, I regularly attend workshops and training sessions offered by equipment manufacturers and industry leaders, ensuring my expertise remains aligned with industry standards and advancements.

Q 24. Describe your experience with working independently versus in a team.

I’m equally comfortable working independently and as part of a team. When working independently, I’m highly self-motivated and can manage my time effectively to meet deadlines. For instance, during a recent project at [Previous Company Name], I was solely responsible for maintaining the HVAC system of a small building. I planned, executed, and completed all maintenance tasks autonomously, ensuring the system remained functional. However, teamwork is essential for complex projects, I thrive in collaborative environments, where I can share my expertise and learn from others. In previous team projects, I successfully collaborated with electricians, plumbers, and other maintenance personnel to resolve significant building issues, leveraging each team member’s unique skills for efficient and effective solutions. My communication and problem-solving skills contribute to a strong collaborative working environment.

Q 25. How do you handle stressful situations during maintenance tasks?

Stressful situations during maintenance are inevitable. My approach is methodical and prioritized. Firstly, I assess the situation calmly, identifying the root cause of the problem. Secondly, I prioritize tasks based on urgency and impact. I focus on immediate critical issues first to mitigate risks and then address other issues systematically. For example, when a major power outage occurred at [Previous Company Name], I quickly assessed the situation, prioritizing restoring essential services before addressing secondary issues. This ensured minimal disruption and ensured safety of building occupants. Finally, I communicate effectively with all relevant parties, keeping them updated on progress and any potential delays. Clear and consistent communication helps prevent further stress and maintain trust.

Q 26. What is your experience with using computerized maintenance management systems (CMMS)?

I have significant experience using CMMS (Computerized Maintenance Management Systems). In my previous role at [Previous Company Name], I used [Specific CMMS software, e.g., Fiix, UpKeep, etc.] to manage work orders, track maintenance activities, schedule preventive maintenance, and generate reports. My skills include entering work orders, tracking inventory, scheduling preventative maintenance, managing assets, and generating reports to support budgeting and decision-making. I am proficient in using CMMS software to optimize maintenance operations, improve efficiency, and reduce downtime. I am comfortable learning new CMMS software as needed; adaptability is a key aspect of my approach to technology.

Q 27. Describe your experience with maintaining grounds and landscaping.

My experience with grounds and landscaping maintenance includes [Describe specific tasks, e.g., mowing lawns, trimming hedges, planting flowers, removing snow, etc.]. I understand the importance of regular maintenance to keep grounds looking presentable and functional. I am familiar with various tools and equipment commonly used in landscaping, and I prioritize safety when working with power tools and machinery. At [Previous Company Name], I was responsible for maintaining the grounds of a large office complex, which included coordinating with a small team to ensure that the grounds were well-maintained and met the company’s aesthetic standards. This included tasks such as planning seasonal plantings, ensuring proper lawn care, and addressing any urgent issues.

Q 28. What is your understanding of building codes and regulations related to maintenance?

I have a good understanding of building codes and regulations related to maintenance. I am familiar with [Mention specific codes and regulations relevant to your area of expertise, e.g., OSHA regulations, local fire codes, electrical codes]. My understanding of these regulations ensures I perform maintenance tasks safely and in compliance with all relevant laws and standards. Before undertaking any maintenance task, I always review the applicable codes and regulations to ensure that my work meets all safety and legal requirements. I know that neglecting building codes can lead to serious consequences, such as fines, legal actions, and safety hazards. My commitment to safety and legal compliance guides all my work.

Key Topics to Learn for Basic Maintenance Skills Interview

- Preventive Maintenance: Understanding the importance of scheduled maintenance to prevent equipment failure. This includes knowing how to create and follow maintenance schedules and logs.

- Corrective Maintenance: Diagnosing and repairing malfunctioning equipment. Practical application includes troubleshooting common issues and utilizing appropriate tools and safety procedures.

- Safety Procedures and Regulations: Demonstrating knowledge of relevant safety protocols, including lockout/tagout procedures, proper use of personal protective equipment (PPE), and hazard identification.

- Basic Hand Tools and Equipment: Familiarity with common hand tools (screwdrivers, wrenches, pliers) and power tools (drills, saws). Understanding their proper use and maintenance is crucial.

- Basic Electrical Knowledge (if applicable): Understanding basic electrical concepts such as voltage, amperage, and circuits. This might include safe practices around electrical equipment.

- Record Keeping and Documentation: Maintaining accurate records of maintenance activities, repairs, and parts used. This demonstrates accountability and helps track equipment history.

- Problem-Solving and Troubleshooting: Explaining your approach to identifying the root cause of equipment malfunctions and implementing effective solutions. This often involves a systematic approach and logical reasoning.

- Understanding Work Orders and Procedures: Following instructions accurately and efficiently. This includes interpreting technical manuals and diagrams.

Next Steps

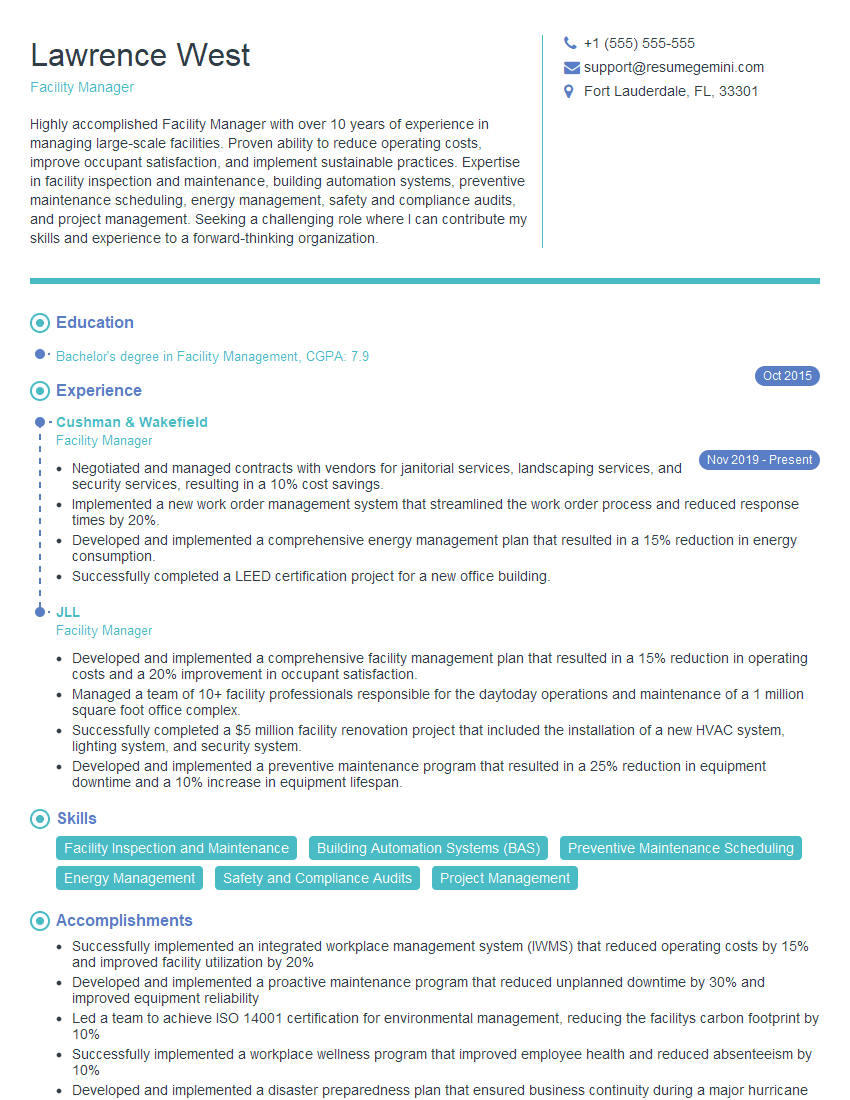

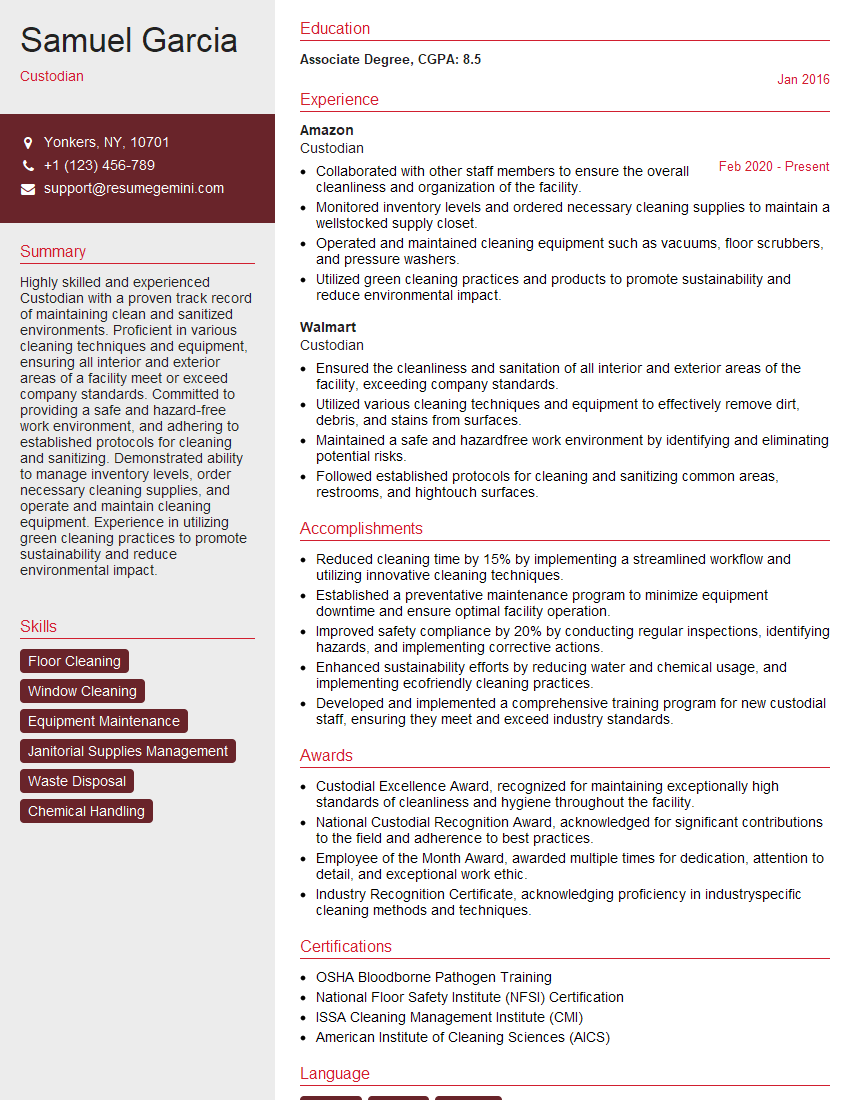

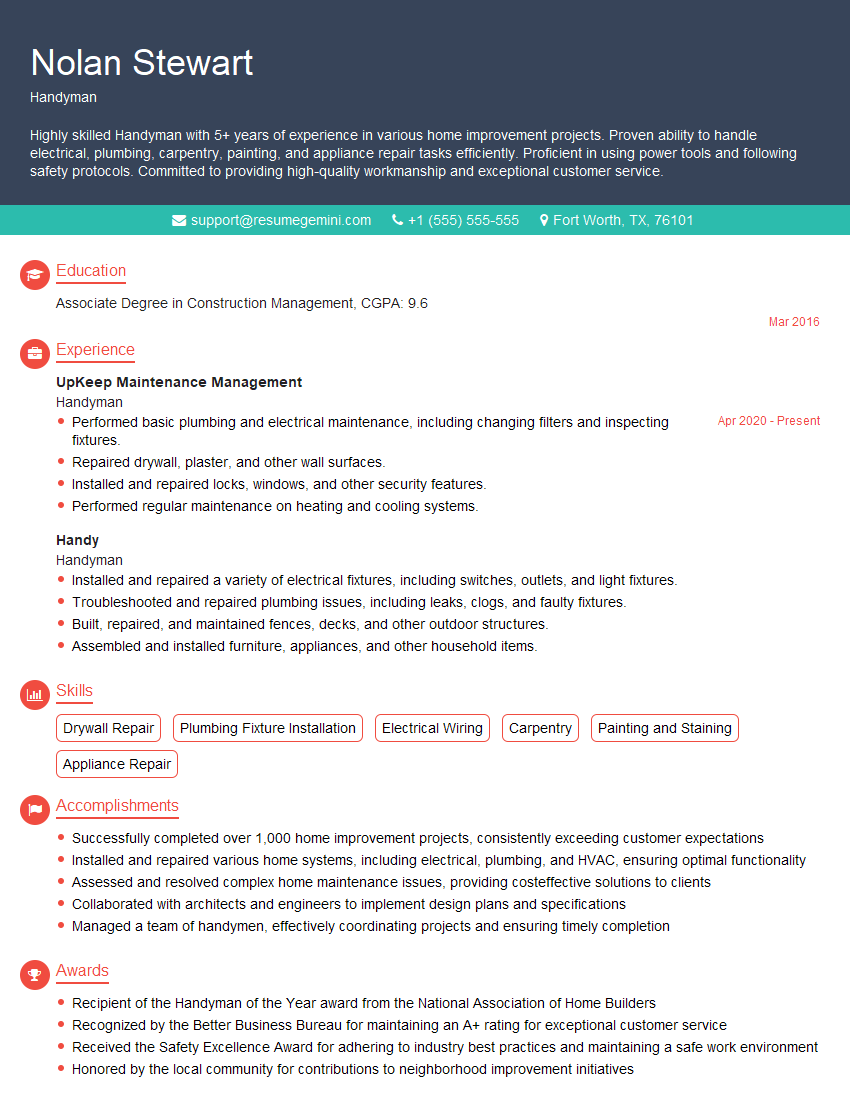

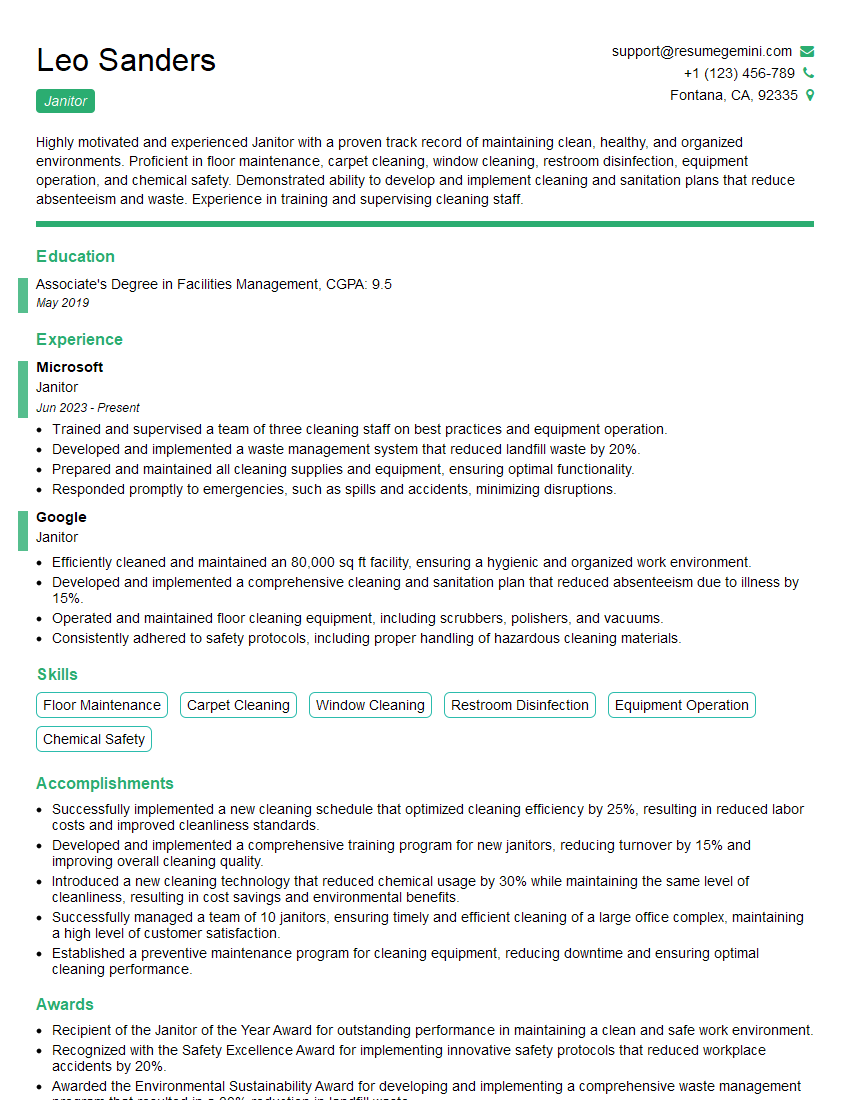

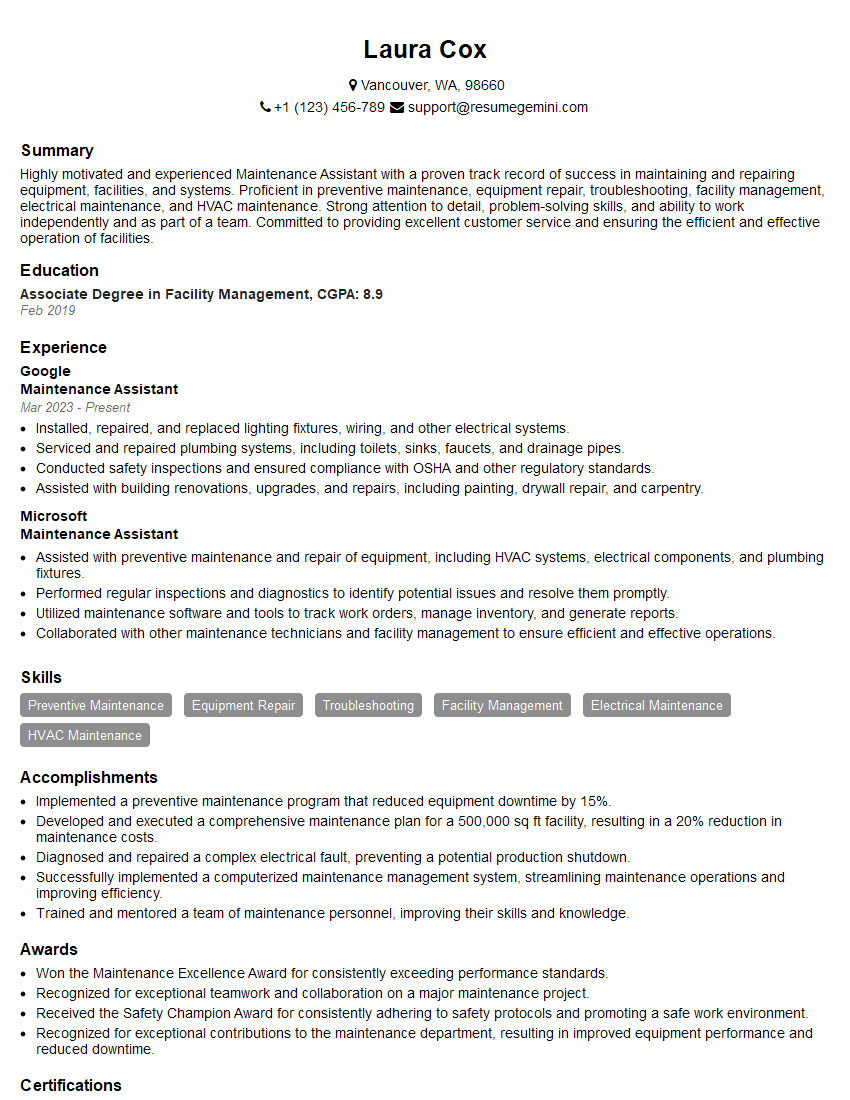

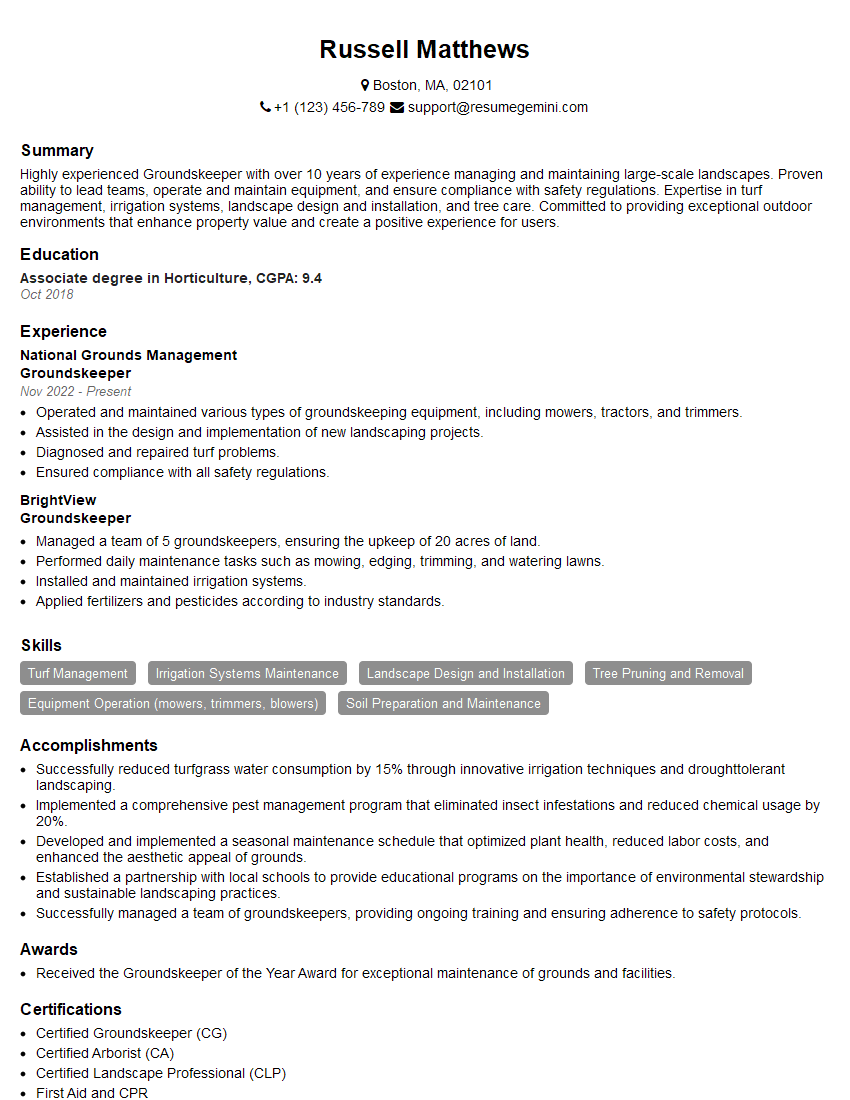

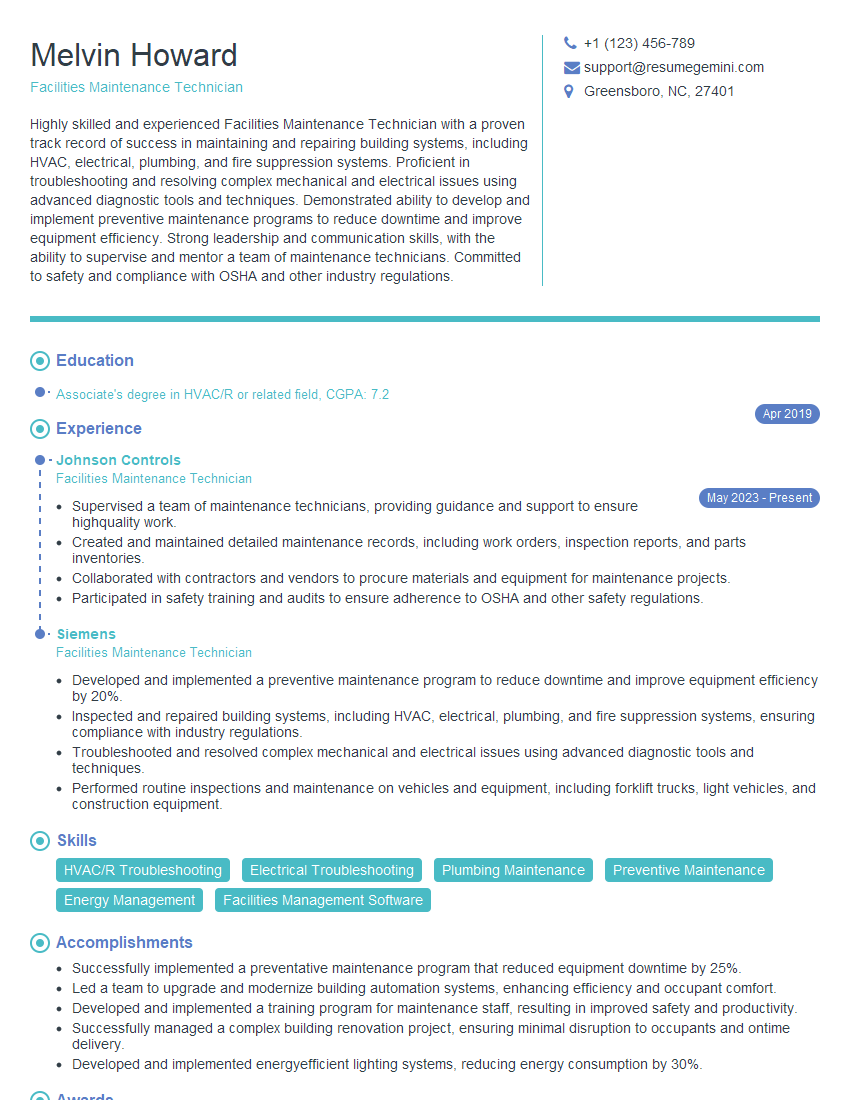

Mastering Basic Maintenance skills opens doors to diverse and rewarding career opportunities, offering stability and the chance for professional growth within various industries. A strong resume is your key to unlocking these opportunities. Building an ATS-friendly resume is essential to ensure your application gets noticed by potential employers. ResumeGemini is a trusted resource to help you craft a compelling and effective resume that highlights your skills and experience. Examples of resumes tailored to Basic Maintenance skills are available to guide you, helping you present yourself in the best possible light to prospective employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good