Are you ready to stand out in your next interview? Understanding and preparing for Binding Operation interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Binding Operation Interview

Q 1. Explain the difference between perfect binding and saddle stitching.

Perfect binding and saddle stitching are two common methods for binding documents, but they differ significantly in their approach and the resulting product. Perfect binding is ideal for books with a larger page count and softer covers, while saddle stitching is best suited for smaller publications like brochures or magazines.

Perfect Binding: Imagine a paperback novel. The pages are glued together along the spine’s edge, creating a smooth, flat spine. Then, a cover is wrapped around the glued block of pages. This method allows for a larger page count and thicker documents. The spine is often flexible and allows for the book to lay flat easily.

Saddle Stitching: Think of a magazine. Pages are folded in half and then stapled through the fold in the center. This is a much simpler and faster process, suitable for publications with a lower page count (typically under 64 pages) and a relatively thin booklet. The resulting spine is noticeably thicker than perfect binding due to the staples.

- Perfect Binding Pros: Lay-flat design, higher page counts, professional look.

- Perfect Binding Cons: More expensive, less durable spine for high-use documents.

- Saddle Stitching Pros: Inexpensive, quick, durable for low-page count documents.

- Saddle Stitching Cons: Limited page count, spine cannot lay completely flat.

Q 2. Describe the process of three-hole drilling.

Three-hole drilling is a crucial step in preparing documents for binding, particularly using a three-ring binder. It involves precisely punching three equally spaced holes along the spine of the document to allow for easy insertion into the binder mechanism.

The process typically uses a specialized drilling machine, often electrically powered. The machine is set to the correct hole spacing and depth. The document stack is then carefully aligned and fed through the machine. The machine’s punches create precisely aligned holes. Incorrect alignment will lead to difficulty or inability to use the binder rings.

Process Steps:

- Setup: Adjust the machine to the correct hole spacing and depth, ensuring proper alignment.

- Alignment: Carefully align the document stack, ensuring all pages are neatly stacked.

- Drilling: Feed the stack through the machine, applying steady and even pressure.

- Inspection: Inspect the drilled holes for proper alignment and evenness. Incorrectly aligned or punched holes should be noted and addressed.

Three-hole drilling ensures consistent hole placement, which is essential for smooth and efficient insertion into a binder, preventing tearing or damage to the pages.

Q 3. What are the common types of binding glues used and their applications?

Several types of binding glues are used, each with specific properties tailored to different applications. The choice of glue significantly impacts the final product’s quality, durability, and aesthetics.

- PUR (Polyurethane Reactive): This is a strong, flexible adhesive that offers excellent adhesion and durability. It’s commonly used in perfect binding for its ability to create a robust and long-lasting bond, even on porous materials. PUR glue also provides a strong, flexible spine that can lay flat for improved readability.

- EVA (Ethylene Vinyl Acetate): EVA hot melt adhesive is a more cost-effective option than PUR, suitable for less demanding applications. It’s commonly used for case binding and other binding methods where high flexibility isn’t crucial.

- Hot Melt: This type of adhesive is applied in a molten state and quickly cools to create a strong bond. It’s widely used in various binding applications due to its speed and efficiency but may not be as flexible or durable as PUR.

The selection of glue depends on factors like the binding method, material type, required bond strength, and budget. For high-quality books requiring a durable and flexible bond, PUR is usually preferred. For simpler applications, EVA or hot melt may suffice.

Q 4. How do you troubleshoot a jammed collator?

A jammed collator can be frustrating, but systematic troubleshooting can quickly resolve the issue. Collators feed and organize printed sheets into sets, and jams can result from paper misfeeds, misaligned trays, or sensor malfunctions.

Troubleshooting Steps:

- Power Down and Safety Check: Always turn off the collator and unplug it before any maintenance or troubleshooting.

- Visual Inspection: Look for any obvious obstructions like crumpled paper, staples, or foreign objects in the paper path.

- Paper Path Check: Carefully examine the entire paper path, checking for any misaligned trays or rollers. Clean any dust or debris that may be causing friction.

- Sensor Check: Some collators have sensors that detect paper jams. Check for any error messages displayed and consult the machine’s manual for guidance. Sensors may need cleaning or adjustment.

- Tray Alignment: Ensure that the input and output trays are properly aligned and not causing paper jams.

- Paper Quality: Use high-quality paper recommended for the collator; low-quality paper may wrinkle and jam easily.

- Restart: After clearing obstructions and checking alignment, restart the collator and monitor its operation.

If the problem persists after these steps, consult the machine’s manual or contact a service technician.

Q 5. What safety precautions are crucial when operating binding machinery?

Safety is paramount when operating binding machinery. These machines have moving parts and sharp mechanisms, posing risks of injury if proper precautions are not followed.

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including safety glasses to protect eyes from flying debris, gloves to protect hands, and potentially hearing protection for noisy machines.

- Machine Guards: Ensure that all machine guards are in place and functioning correctly. Never operate a machine with missing or damaged guards.

- Proper Training: Receive thorough training on the safe operation and maintenance of the equipment before using it independently. Understand the machine’s controls and emergency stop mechanisms.

- Clear Workspace: Maintain a clean and organized workspace, free of clutter that could cause trips or falls. Keep the area around the machine free of loose papers or objects that could get caught in moving parts.

- Emergency Procedures: Familiarize yourself with the emergency procedures and know how to quickly shut down the machine in case of a malfunction or emergency.

- Regular Maintenance: Regular maintenance, as specified by the manufacturer, is essential to prevent malfunctions and ensure safe operation. Check for wear and tear, and report any issues immediately.

Q 6. Explain the importance of quality control in binding operations.

Quality control in binding operations is vital for ensuring a professional and marketable final product. It safeguards the reputation of the print shop, avoids costly reprints, and satisfies customers.

Quality control encompasses all stages, from checking the accuracy of page counts during gathering to inspecting the final bound product for imperfections. This involves visual inspections for misaligned pages, uneven glue application, or damage to the cover. Testing the durability of the binding itself is also crucial.

Benefits of robust quality control:

- Improved Customer Satisfaction: High-quality binding ensures customer satisfaction, leading to repeat business and positive referrals.

- Reduced Waste and Costs: Identifying and correcting errors early in the process prevents costly reprints and waste.

- Enhanced Brand Reputation: Consistent high quality enhances the brand’s reputation for professionalism and reliability.

- Process Improvement: Regular quality control helps identify areas for process improvement, leading to efficiency gains.

Implementing a systematic quality control system, including regular inspections and documentation, is essential for ensuring consistent quality in binding operations.

Q 7. How do you handle a discrepancy in the number of pages during gathering?

Discovering a page count discrepancy during gathering is a common problem that needs careful handling to avoid errors and reprinting. The first step is accurate identification of the error’s location and cause.

Handling Discrepancies:

- Verify the Count: Carefully recount the pages in the affected sections to confirm the discrepancy. Double-checking is critical to rule out simple counting errors.

- Identify the Source: Determine if the missing or extra pages are consistent throughout the gathering or are isolated incidents. This helps pinpoint whether the issue lies in the printing, collating, or gathering stages.

- Investigate the Printing Process: If the issue is related to page counts in the print job itself, review the printing specifications and check for any errors in the original document.

- Review the Gathering Process: Examine the gathering process. If pages are missing, it might be due to misfeeds during the gathering process. If there are extra pages, this may be a result of repeated pages.

- Correct the Issue: If the problem is minor, manual correction may be possible. If the error is significant, the affected sections might need to be reprinted. Accurate identification of the issue is paramount to a correct and swift solution.

- Documentation: Document all findings and corrective actions for future reference and process improvement.

Preventing such discrepancies is crucial; implementing thorough checks during printing and gathering helps mitigate these problems. Training and proper equipment maintenance also plays a key role.

Q 8. What are the different types of covers used in bookbinding?

Bookbinding covers are chosen based on factors like durability, aesthetics, and budget. There’s a wide variety, each suited to different projects and binding methods.

- Case Binding: Often uses cloth-covered boards (think hardcover books). The cloth can be linen, buckram, or other durable fabrics. These boards provide structural support and protection.

- Perfect Binding: Typically uses a paper cover, sometimes laminated for added durability. Think of paperback books or magazines.

- Saddle Stitch Binding: No cover is strictly required, as the pages are folded and stapled directly together. However, covers can be added for enhanced presentation, usually printed on heavier paper stock.

- Spiral Binding: The pages are punched and bound using a plastic or metal comb. These rarely have separate covers, unless it’s a more sophisticated version with a protective cover sheet.

- Wire-O Binding: Similar to spiral binding, but uses double-loop wire for a more professional and durable finish. Again, while no cover is strictly required, they can be added.

The choice of cover material greatly impacts the book’s lifespan and overall impression. For instance, a linen-covered case-bound book suggests high quality and longevity, whereas a simple paper cover might be ideal for a short-term project.

Q 9. Describe your experience with different types of binding equipment.

My experience encompasses a range of binding equipment, from manual to automated systems. I’m proficient with:

- Casemaking machines: These automate the creation of the cover boards for case binding, including gluing, pressing, and trimming.

- Perfect binding machines: These machines glue the edges of the book block (the gathered pages) and then attach the cover. I’m familiar with both smaller, tabletop models and larger, high-speed production lines.

- Saddle stitchers: I have experience operating various models, from simple manual stitchers to sophisticated automated ones that can handle high volumes.

- Spiral and Wire-O binding machines: I’m adept at using different sizes and types of these machines to produce professional results.

- Guillotine trimmers: Precise and safe operation of guillotines for trimming book blocks and covers is crucial for a clean, professional finish.

I understand the nuances of each machine’s operation, maintenance, and troubleshooting. For example, I’ve successfully resolved issues with paper jams on a perfect binding machine by adjusting the feeder rollers and cleaning the glue system.

Q 10. How do you ensure the proper alignment of pages before binding?

Ensuring proper page alignment is crucial for a professional-looking and easily readable book. This is achieved through several steps:

- Careful Gathering: The pages are gathered in the correct sequence, paying close attention to the order. Any discrepancies are easily spotted by flipping through the gathered pages and checking the page numbers.

- Folding (if applicable): For saddle stitch and some other methods, accurately folding the pages is crucial for alignment.

- Sewing (if applicable): For case binding, precise sewing techniques maintain proper alignment and create a durable spine.

- Pressing: After sewing or gathering, the book block is pressed to ensure flatness and proper alignment before trimming and binding.

- Trimming: Using a guillotine trimmer, the rough edges are removed to create a precise, aligned book block.

A slight misalignment can ruin the overall appearance, and, in case of significant issues, may impact the binding process. Regular checks during each stage are crucial to maintaining accuracy.

Q 11. What are the signs of a poorly bound book?

Poorly bound books exhibit several telltale signs:

- Pages falling out: This is a clear indication of insufficient glue or inadequate binding technique.

- Uneven spine: A crooked or bumpy spine suggests improper pressing or alignment issues.

- Crooked pages or cover: Alignment problems during the binding process can cause pages or the cover to be skewed.

- Weak spine: The spine may crack or break easily if the binding isn’t strong enough.

- Loose cover: The cover might detach or be loosely attached to the book block.

- Visible glue stains: Excess glue can be unattractive and detract from the overall quality.

These issues not only affect the book’s appearance but also its durability and functionality. Identifying these signs helps determine the cause and implement corrective measures for future projects.

Q 12. How do you calculate the cost of binding a specific project?

Calculating binding costs requires a detailed breakdown of several factors:

- Binding method: Different methods have different labor and material costs. Case binding, for example, is significantly more expensive than saddle stitching.

- Materials: The cost of paper, cover stock, thread, glue, and any other materials used varies greatly.

- Quantity: The number of books to be bound directly affects the overall cost; larger quantities often have lower per-unit costs due to economies of scale.

- Labor: This includes the time spent on pre-binding preparation, the binding process itself, and post-binding finishing.

- Equipment: Amortization of equipment costs might be factored into the pricing, especially for larger-scale operations.

A typical cost estimation would involve summing these costs. For example: Material cost + Labor cost + Equipment cost / Number of books = Cost per book. Detailed quotes usually include a clear breakdown of each component for transparency.

Q 13. What is your experience with different types of paper and their suitability for various binding methods?

Paper choice significantly impacts binding success. Different papers have varying thicknesses, weights, and textures, affecting their suitability for different binding methods.

- Case Binding: This method usually requires heavier, more durable paper stocks to support the weight of the cover boards.

- Perfect Binding: Papers with slightly rougher edges tend to hold the glue better, crucial for strong binding.

- Saddle Stitch Binding: Thinner papers are typically suitable for saddle stitch binding as the pages are simply folded and stapled.

- Spiral and Wire-O Binding: Paper weight and thickness are important for avoiding damage to the pages during punching.

For instance, using thin, lightweight paper for case binding would result in a weak and flimsy book. Conversely, using thick cardstock for saddle stitching would create a bulky, difficult-to-handle product. I have extensive experience selecting the optimal paper type for each project to ensure a durable and aesthetically pleasing end product.

Q 14. How do you maintain and troubleshoot binding equipment?

Regular maintenance and prompt troubleshooting are essential for keeping binding equipment in optimal condition. This involves:

- Regular cleaning: Removing dust, paper scraps, and glue residue prevents jams and malfunctions.

- Lubrication: Regular lubrication of moving parts ensures smooth operation and extends the equipment’s lifespan.

- Blade sharpening (for trimmers): Sharp blades are crucial for clean, accurate cuts, preventing damage to the book blocks.

- Glue system maintenance: Perfect binding machines require regular cleaning and maintenance of the glue system to ensure proper adhesion.

- Troubleshooting: This requires understanding the specific machine’s operation, recognizing common problems, and identifying solutions.

For example, a recurring paper jam in a perfect binding machine could indicate issues with the feeder rollers, necessitating adjustment or replacement. Proactive maintenance prevents costly downtime and ensures consistent, high-quality output. Keeping detailed maintenance logs is also vital for tracking the health and efficiency of each machine.

Q 15. Describe your experience with different types of finishing processes (e.g., cutting, trimming).

My experience encompasses a wide range of finishing processes crucial in bookbinding. Cutting, for instance, involves precision to ensure accurate page sizes and straight edges. I’m proficient in using both guillotine cutters for large volumes and smaller, more precise cutters for intricate jobs. Trimming is equally important, removing excess material after stitching or folding to achieve a clean, professional finish. I’ve worked with various types of trimming equipment, from automated trimmers for high-speed production to manual trimmers for delicate projects. I understand the importance of blade sharpness and correct adjustments for optimal results and minimal waste. For example, I’ve had to troubleshoot issues with skewed cuts by adjusting the blade alignment on a guillotine cutter and even worked on resolving jams caused by paper misfeeds. This required a detailed understanding of the machine’s mechanisms and the ability to quickly identify and correct the problem to minimize production downtime.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you manage workflow and prioritize tasks in a busy bindery environment?

Managing workflow in a busy bindery requires a structured approach. I utilize a combination of techniques. First, I prioritize tasks based on deadlines and project urgency, using tools like Kanban boards to visualize the workflow and identify bottlenecks. Secondly, I meticulously track production progress, ensuring materials are available and machinery is functioning optimally. This includes scheduling machine maintenance proactively. Thirdly, I communicate effectively with the team, ensuring everyone understands their roles and responsibilities, especially during peak times. We often hold short daily stand-up meetings to discuss potential roadblocks and coordinate efforts. For example, when faced with a tight deadline on a large order, I would create a detailed schedule, delegate tasks efficiently, and closely monitor progress to ensure timely completion without compromising quality. This often involves making informed decisions on resource allocation and prioritizing tasks strategically to mitigate risks and meet the deadline successfully.

Q 17. What are the common causes of binding failures?

Binding failures can stem from various sources. Common causes include incorrect folding, resulting in uneven stacks or pages not aligning properly. Problems with stitching, such as inconsistent tension or broken threads, can lead to pages falling out. Inadequate adhesive application in perfect binding can cause the spine to break or pages to detach. Poor quality materials, such as weak paper or substandard adhesives, also contribute. Incorrect machine settings, especially in automated binding lines, can cause misalignment or damage to the book. Finally, human error, such as incorrectly loading materials or operating equipment, can cause a wide array of problems. Identifying the root cause often requires a systematic approach involving careful examination of the failed binding, a review of the binding process and material specifications, and perhaps even testing alternative materials or machine settings. For instance, if pages were falling out of saddle-stitched booklets, I’d systematically check thread tension, needle alignment, and the paper type to pinpoint the exact cause.

Q 18. How do you ensure the consistent quality of binding across multiple projects?

Maintaining consistent quality across multiple projects relies on several key strategies. First, rigorous quality checks are performed at each stage of the binding process, using standardized checklists and quality control procedures. Second, regular calibration and maintenance of all binding equipment ensure optimal performance and prevent inconsistencies. Third, we employ thorough training for all bindery staff to ensure everyone understands and consistently applies the correct procedures. Fourth, the use of standardized materials and adhering to precise specifications for each project is essential. Finally, the documentation of processes and results helps track performance and identify areas for improvement. For instance, by regularly calibrating the spine thickness settings on our perfect binder and using a consistent adhesive application rate, we consistently produce high-quality books, ensuring that the binding is strong, visually appealing, and meets customer specifications across different projects.

Q 19. Describe your experience with different types of stitching methods.

My experience includes various stitching methods, each suited for different applications. Saddle stitching is common for magazines and booklets, involving folding sheets and stapling them through the fold line. Perfect binding uses adhesive to secure pages bound along the spine, ideal for softcover books. Wire-O binding uses double-loop wire to create a durable, lay-flat binding for calendars or notebooks. Case binding involves sewing pages together within a cover, usually found in high-quality hardcover books. I’ve worked extensively with each method, understanding the strengths and limitations of each one in terms of cost, production speed, durability, and aesthetic appeal. For example, I know that saddle stitching is quick and cost-effective but limits the number of pages that can be bound, while case binding, although more time-consuming, offers superior durability and a more luxurious feel.

Q 20. What are the advantages and disadvantages of different binding methods?

The choice of binding method depends on several factors. Saddle stitching is fast and economical but limited in page count and durability. Perfect binding is suitable for larger page counts and offers a cost-effective solution for softcover books, but the spine can be susceptible to cracking. Wire-O binding provides durability and allows for a lay-flat design, ideal for products needing frequent use, but it’s often more expensive. Case binding is the most durable and visually appealing option, but also the most expensive and time-consuming. The decision usually involves balancing cost, durability requirements, aesthetic preferences, and the number of pages. For instance, a short-run marketing brochure might use saddle stitching, while a high-quality textbook would likely benefit from case binding.

Q 21. How do you handle large-volume binding projects?

Handling large-volume binding projects requires careful planning and efficient execution. This involves a meticulous scheduling of tasks, potentially dividing the project into smaller, more manageable batches to streamline the process. Resource allocation is key, ensuring sufficient personnel, materials, and equipment to meet deadlines without compromising quality. Automated equipment plays a crucial role in high-volume projects, maximizing efficiency and minimizing production time. Regular quality checks throughout the process, coupled with prompt identification and correction of any issues, are critical for maintaining standards. For instance, when working on a large book printing and binding job, we might use a high-speed perfect binder to bind the books in batches and establish a robust quality control system to ensure each batch maintains a consistent quality and meets the order requirements. It involves coordination with our team to ensure the smooth flow of the workflow.

Q 22. Describe your experience with automated binding systems.

My experience with automated binding systems spans over ten years, encompassing various technologies from saddle-stitching machines to perfect binding lines and even more specialized equipment like case-making machines. I’ve worked extensively with both high-volume production systems and smaller, more flexible automated systems suitable for shorter runs and customized projects.

For instance, I’ve managed the setup and operation of a Muller Martini perfect binder, a high-speed machine requiring precise adjustments for different paper stocks and cover thicknesses. My role included programming the machine to achieve optimal binding quality, troubleshooting malfunctions, and performing preventative maintenance to minimize downtime. Another example involves using a Horizon Stitchliner system, proficiently handling different saddle-stitching jobs, from brochures to magazines, ensuring accurate folding and stapling.

- Proficiency: Muller Martini Perfect Binder, Horizon Stitchliner, Heidelberg Stitchmaster

- Skills: Machine setup, programming, troubleshooting, preventative maintenance, quality control

Q 23. How do you deal with client requests or specifications that are unusual or challenging?

Unusual client requests are often the most stimulating part of the job! When faced with a challenging specification, my approach is systematic. First, I thoroughly understand the client’s needs and the desired outcome. I then analyze the feasibility of the request, considering the available resources, technology, and timelines. If the request presents a technical hurdle, I’ll research solutions, potentially consulting with binding equipment manufacturers or industry experts.

For example, a client once requested a unique binding method using a combination of wire-o and a custom-designed cover. This wasn’t a standard process. I collaborated with our engineering team and the client to design a feasible solution that involved modifying a standard wire-o machine and creating a custom die for the cover. We completed the project successfully, exceeding client expectations and gaining valuable knowledge that we could apply to future projects. This illustrates my ability to tackle challenges creatively and collaboratively.

Q 24. How do you address problems or errors that occur during the binding process?

Addressing problems during the binding process requires a methodical approach. My first step is to identify the exact nature of the error. Is it a mechanical issue with the equipment, a problem with the materials, or an error in the setup? I use a combination of diagnostic tools and my experience to pinpoint the root cause.

For example, if a perfect binding line is producing books with uneven glue application, I might first check the glue tank level and viscosity. If that’s not the problem, I’ll inspect the glue rollers and nozzles for clogs or wear. I might also analyze the paper stock for moisture content, as this can affect glue adhesion. I believe in a proactive approach, frequently performing preventative maintenance to mitigate potential issues.

- Identify the error: Detailed observation and diagnostics.

- Isolate the cause: Check equipment, materials, and setup.

- Implement solution: Repair, adjust, or replace components as needed.

- Prevent recurrence: Implement preventative maintenance and adjust processes.

Q 25. What is your experience working with different types of materials (e.g., cardstock, paperboard)?

My experience encompasses a wide range of materials, including various types of paper (coated, uncoated, textured), cardstock in different weights and finishes, and paperboard for cover applications. I’m familiar with the unique properties of each material and how they affect the binding process. For instance, thicker cardstock may require adjustments to the pressure settings on a perfect binding machine to ensure proper adhesion. Similarly, coated paper might require a different type of adhesive to achieve optimal results.

Understanding material properties is crucial for selecting the appropriate binding method and ensuring quality. I regularly work with material specifications, ensuring that they meet the project requirements and are compatible with our equipment. Dealing with materials that have unusual textures or thicknesses often requires experimentation to determine the best binding solutions.

Q 26. What are your skills in using measuring tools and other equipment?

Precision is paramount in binding. I’m highly proficient in using various measuring tools including rulers, calipers, micrometers, and digital scales to ensure accuracy in cutting, folding, and assembling materials. I regularly use these tools to verify dimensions, measure thicknesses, and weigh materials, all crucial steps in ensuring consistent quality.

Additionally, I’m skilled in operating and maintaining various bindery equipment, including cutting machines, folding machines, collators, and stitching/binding machines. Understanding the technical specifications and operational parameters of these machines is essential for optimal performance and safety.

Q 27. How do you ensure the safety of yourself and others in the bindery environment?

Safety is my top priority. The bindery environment involves heavy machinery and sharp tools, demanding strict adherence to safety protocols. I meticulously follow all safety guidelines, using appropriate personal protective equipment (PPE) such as safety glasses, gloves, and hearing protection. I regularly inspect equipment for any potential hazards and report any malfunctions immediately.

Beyond personal safety, I also play a key role in ensuring the safety of my colleagues. I actively participate in safety training and promote a culture of safety awareness among my team. This includes providing guidance to new employees on safe operating procedures and encouraging them to report any safety concerns without hesitation. A safe work environment is not just a regulation; it’s a responsibility.

Key Topics to Learn for Binding Operation Interview

- Types of Binding: Understand the various binding methods (e.g., perfect binding, saddle stitch, wire-o, case binding) and their applications. Consider the advantages and disadvantages of each.

- Pre-Press Preparation: Learn about the crucial steps involved in preparing documents for binding, including imposition, folding, and gathering. Familiarize yourself with common pre-press challenges and solutions.

- Equipment and Machinery: Gain knowledge of the different machines used in a binding operation, such as collators, folders, and binding machines. Understand their functionality and maintenance requirements.

- Quality Control: Explore techniques for ensuring high-quality bound documents. This includes understanding common binding defects and how to prevent them.

- Materials and Supplies: Become familiar with the different types of paper, cover stock, adhesives, and other materials used in binding. Understand their properties and how they impact the final product.

- Production Processes and Workflow: Learn about optimizing workflow efficiency within a binding operation, including job scheduling, material handling, and team coordination. Consider potential bottlenecks and solutions.

- Safety Procedures: Understand and be prepared to discuss the safety protocols and best practices associated with operating binding machinery and handling materials.

- Troubleshooting: Be ready to discuss common problems encountered in binding operations and how to effectively troubleshoot and resolve them.

Next Steps

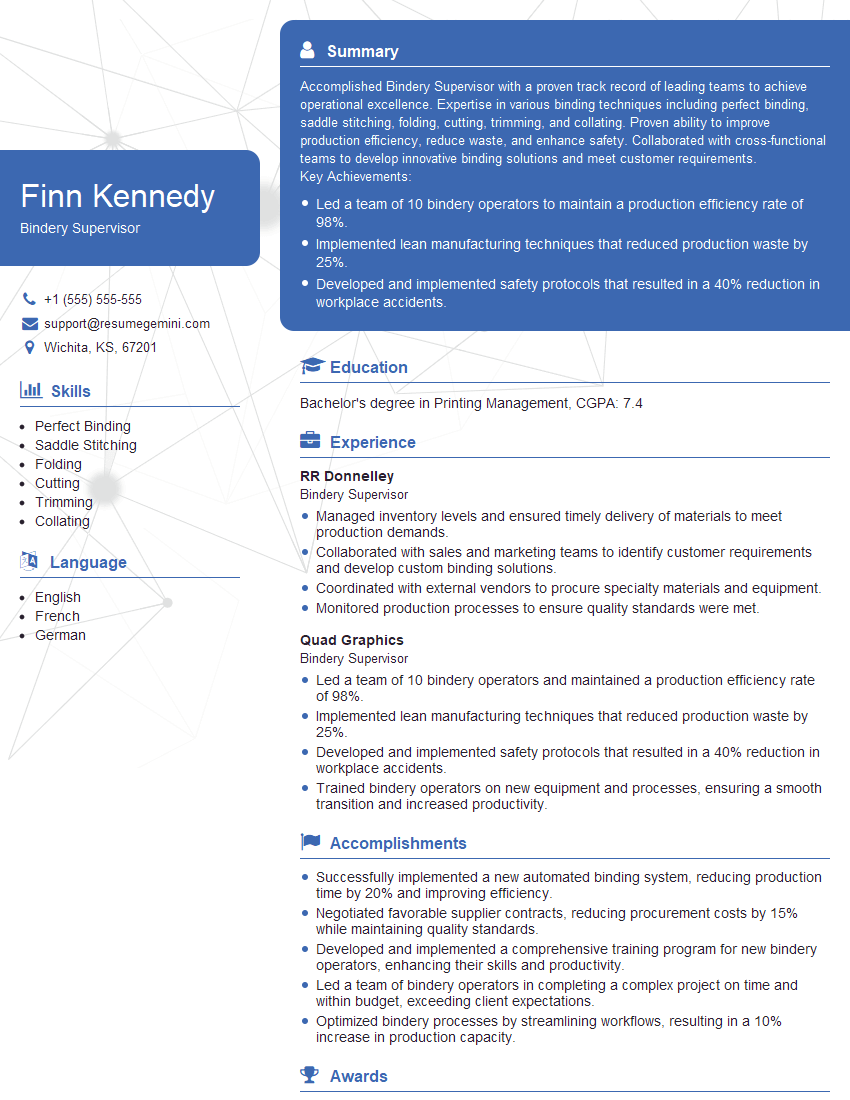

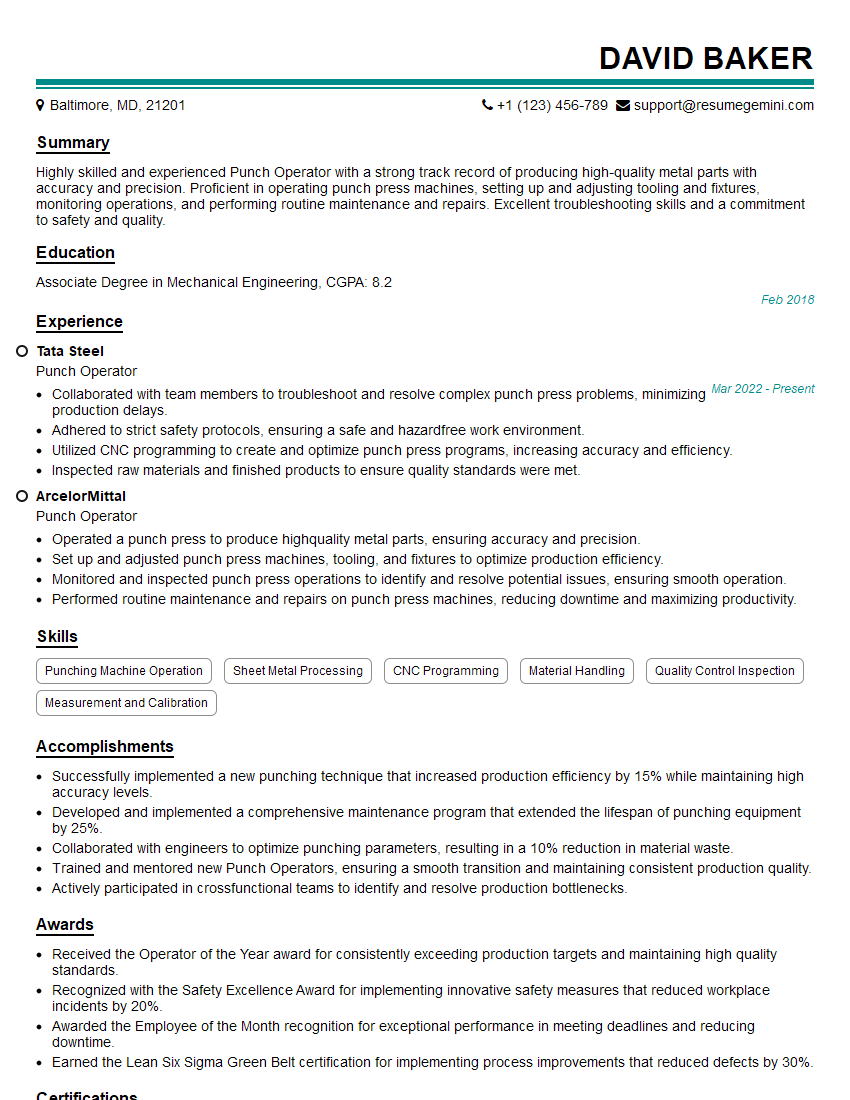

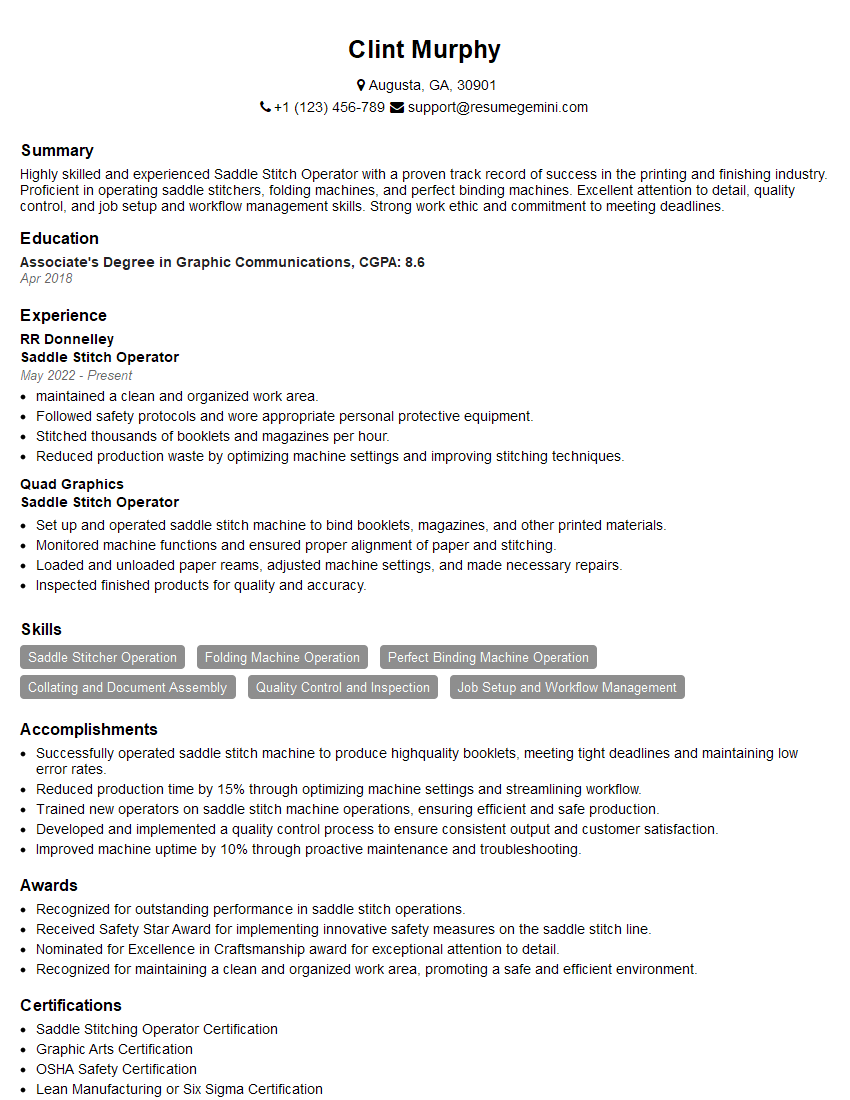

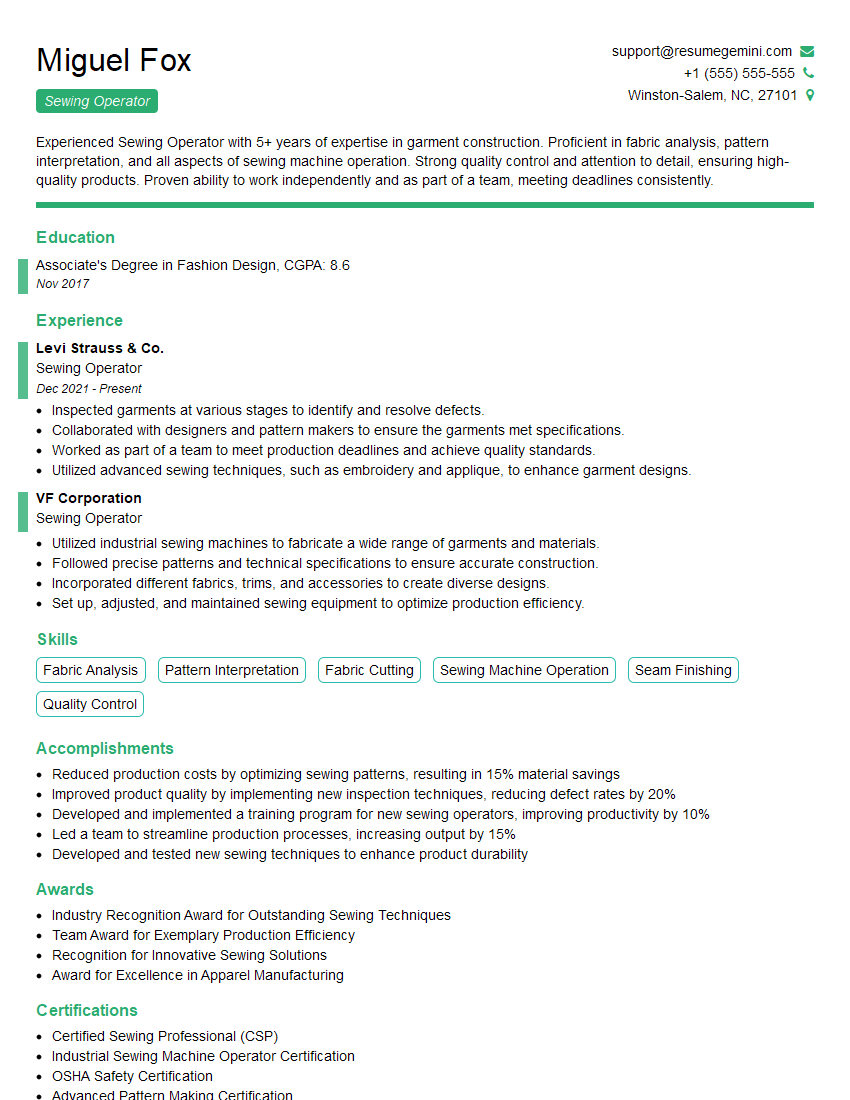

Mastering Binding Operation skills opens doors to diverse and rewarding career opportunities within the printing and publishing industries. A strong understanding of these processes is highly valued by employers. To significantly boost your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. We highly recommend using ResumeGemini to build a professional and impactful resume. ResumeGemini provides tools and resources to craft a compelling narrative and offers examples of resumes tailored to Binding Operation roles, helping you showcase your qualifications in the best possible light.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good