Preparation is the key to success in any interview. In this post, we’ll explore crucial Bioprocess Optimization interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Bioprocess Optimization Interview

Q 1. Explain the principles of Design of Experiments (DOE) in bioprocess optimization.

Design of Experiments (DOE) is a powerful statistical methodology used to efficiently explore the impact of multiple factors on a bioprocess outcome. Instead of changing one variable at a time (a much slower and less efficient approach), DOE allows us to systematically vary several factors simultaneously, enabling us to understand not only the individual effects but also their interactions. This is crucial because in bioprocesses, the interplay between factors like temperature, pH, nutrient concentration, and dissolved oxygen can be complex and unexpected.

The most common DOE approaches in bioprocess optimization include:

- Factorial Designs: These designs systematically test all combinations of factors at different levels (e.g., high, low, medium). Full factorial designs examine every possible combination, while fractional factorial designs efficiently select a subset of combinations, especially useful when dealing with many factors.

- Response Surface Methodology (RSM): RSM builds upon factorial designs by fitting a mathematical model (often a polynomial) to the experimental data. This allows us to visualize the response surface (e.g., product yield) and identify optimal operating conditions. Common RSM designs include central composite designs and Box-Behnken designs.

- Mixture Designs: These are used when the factors are components of a mixture (e.g., different nutrient sources in a cell culture media), where the sum of the components is constrained (100%).

For example, in optimizing a monoclonal antibody production process, we might use a factorial design to assess the impact of glucose concentration, pH, and temperature on antibody titer. By analyzing the results, we can identify the optimal combination of these parameters to maximize yield and reduce production costs.

Q 2. Describe your experience with statistical software (e.g., JMP, Design Expert) in analyzing bioprocess data.

I have extensive experience using JMP and Design Expert for bioprocess data analysis. These statistical software packages offer powerful tools for DOE design, data analysis, and model fitting. I’m proficient in designing experiments, analyzing variance (ANOVA), fitting regression models (linear and non-linear), and visualizing response surfaces.

In a recent project, we used JMP to optimize the fermentation conditions for a bacterial protein. We employed a central composite design to study the effects of temperature, agitation rate, and inoculum size on protein yield. JMP’s ANOVA capabilities allowed us to determine which factors significantly impacted yield, while the response surface plots helped us identify the optimal operating parameters. The generated model allowed us to predict the protein yield for various combinations of the input parameters, guiding further process development. Design Expert provided similar functionality and robust model validation metrics, proving equally valuable in other projects focusing on mammalian cell culture optimization.

Q 3. How do you optimize cell culture media for maximum cell density and productivity?

Optimizing cell culture media involves a systematic approach focusing on providing the cells with optimal nutrients while minimizing inhibitory substances. This usually involves a combination of experimental design (as discussed previously) and a deep understanding of cell metabolism.

The process typically involves:

- Identifying key nutrients: Different cell lines have unique nutrient requirements. We need to determine which nutrients are limiting cell growth and/or productivity.

- Screening different media components: This might involve testing different carbon sources (glucose, galactose), nitrogen sources (amino acids, peptides), vitamins, and growth factors.

- Optimizing concentrations: Once key nutrients are identified, we use DOE to optimize their concentrations for maximum cell density and productivity. This is where statistical software such as JMP or Design Expert become extremely valuable.

- Removing inhibitory factors: Certain components of the media, even at low concentrations, can inhibit cell growth. We might systematically remove or reduce the concentration of potentially inhibitory components to improve performance.

- Feed strategies: Designing efficient feeding strategies (e.g., fed-batch culture) that supply nutrients gradually to maintain optimal growth without creating inhibitory byproduct accumulation.

For example, in optimizing a CHO cell line producing a therapeutic protein, we might start with a base medium and systematically test different concentrations of glucose, glutamine, and various amino acids. We’d use a DOE approach, like a central composite design, to analyze the data and find the optimal combination that yields the highest cell density and desired protein titer. We might also investigate adding growth factors to enhance performance or use perfusion systems to remove waste products and improve long-term cell viability.

Q 4. Explain the challenges associated with scale-up of a bioprocess from lab to manufacturing scale.

Scaling up a bioprocess from the lab (e.g., shake flasks, small bioreactors) to manufacturing scale (large-scale bioreactors) presents significant challenges because several factors change dramatically with scale. These challenges include:

- Mass and heat transfer limitations: In larger reactors, the surface area-to-volume ratio decreases. This can lead to oxygen limitation, uneven mixing, and difficulties in controlling temperature. Efficient mixing and oxygen transfer become much more critical.

- Shear stress: Higher shear forces in larger reactors can damage cells, particularly sensitive mammalian cells. Careful design of impeller and baffles is necessary to minimize shear stress.

- Process control: Maintaining consistent process parameters (pH, temperature, dissolved oxygen) across large volumes becomes more challenging. Advanced process control systems and monitoring are crucial.

- Contamination risk: The larger the scale, the greater the risk of contamination. Stricter aseptic techniques and robust process design are critical.

- Instrumentation and automation: Large-scale bioreactors require complex instrumentation and automation systems to monitor and control process parameters effectively.

To address these challenges, a well-defined scale-up strategy is essential. This often involves using scale-down models and computational fluid dynamics (CFD) to predict the behavior of larger reactors. Careful consideration of mass and heat transfer coefficients, and the potential for shear stress damage are critical in successful scale-up.

Q 5. Describe different strategies for improving the productivity of a bioreactor.

Improving bioreactor productivity involves several strategies that focus on enhancing cell growth, product formation, or both. These strategies can be categorized as follows:

- Media Optimization: As discussed earlier, optimizing the nutrient composition of the culture media is crucial for achieving high cell density and product yield.

- Process Parameter Optimization: Fine-tuning parameters such as temperature, pH, dissolved oxygen, and agitation rate can significantly impact cell growth and productivity. DOE techniques are invaluable in this step.

- Cell Line Engineering: Genetic engineering techniques can be used to enhance cell growth, product yield, or product quality. This can involve overexpressing genes involved in nutrient uptake or product synthesis or knocking out genes that are detrimental to productivity.

- Bioreactor Design and Operation: Using advanced bioreactor designs (e.g., perfusion bioreactors, hollow fiber bioreactors) that improve mass transfer, nutrient delivery, and waste removal can dramatically increase productivity.

- Improved Harvest and Purification: Optimizing downstream processing steps can significantly improve overall product yield and reduce costs.

For example, in a microbial fermentation, we might explore using a fed-batch strategy to provide a controlled supply of substrate, minimizing substrate inhibition and maximizing product formation. In mammalian cell culture, we might utilize perfusion systems to maintain a high cell density for an extended period, leading to higher overall product yield. The choice of strategy depends heavily on the specific cell line and product being produced.

Q 6. What are the key performance indicators (KPIs) you monitor in a bioprocess?

The key performance indicators (KPIs) monitored in a bioprocess vary depending on the specific process and product, but some common examples include:

- Cell density (viable cell count): Measures the number of viable cells in the culture.

- Cell viability: Indicates the percentage of live cells in the culture.

- Product titer (concentration): Measures the concentration of the desired product in the culture broth.

- Specific productivity (qP): Indicates the amount of product produced per cell per unit time (e.g., pg/cell/day). This is a valuable metric for comparing different cell lines or culture conditions.

- Substrate consumption rate: Measures the rate at which essential nutrients are being consumed.

- Byproduct formation rate: Monitors the production of potentially inhibitory byproducts.

- Dissolved oxygen (DO): Essential for aerobic processes.

- pH: Must be maintained within an optimal range for cell growth and product formation.

- Temperature: A critical process parameter.

Regular monitoring of these KPIs is crucial for effective process control, troubleshooting, and optimization. Data logging and real-time monitoring systems are essential for capturing this information and detecting any deviations from the expected values.

Q 7. How do you troubleshoot deviations in a bioprocess?

Troubleshooting deviations in a bioprocess requires a systematic and analytical approach. This generally involves:

- Identifying the deviation: Carefully review the process data (KPIs) to pinpoint the specific deviation and its timing.

- Analyzing the data: Examine trends and patterns in the data to determine if the deviation is related to specific process parameters or environmental factors.

- Investigating potential causes: Based on the data analysis, develop a list of potential causes for the deviation. This might involve reviewing process parameters, media composition, cell line characteristics, or equipment malfunction.

- Implementing corrective actions: Based on the potential causes, develop and implement corrective actions. This might involve adjusting process parameters, changing the media composition, replacing equipment, or investigating the cell line for potential instability.

- Documenting the process: Maintain detailed records of the deviation, its causes, the corrective actions taken, and the effectiveness of the actions.

For instance, if we observe a sudden drop in dissolved oxygen in a bioreactor, we would first check the airflow rate, the aeration system, and the impeller speed. If these parameters are within the acceptable range, we might suspect a problem with the oxygen transfer efficiency. This could be caused by foam formation or a change in the broth viscosity. We’d then investigate the foam and viscosity and implement corrective actions such as adding an anti-foaming agent or adjusting the agitation rate to improve mixing and oxygen transfer.

Q 8. Explain your experience with various cell lines (e.g., CHO, HEK293) and their culture conditions.

My experience spans several commonly used mammalian cell lines, primarily CHO (Chinese Hamster Ovary) and HEK293 (Human Embryonic Kidney) cells. These are workhorses in biopharmaceutical production due to their ability to produce complex proteins. CHO cells are known for their high productivity and glycosylation capabilities, making them ideal for therapeutic antibodies. HEK293 cells, on the other hand, are often favored for producing viral vectors and other proteins requiring specific post-translational modifications.

Culture conditions are meticulously optimized for each cell line to maximize growth and product yield. This includes careful control of parameters such as:

- Media Formulation: The choice of basal media, supplements (e.g., growth factors, hormones), and feeding strategies significantly impacts cell growth and protein production. For example, I’ve worked with chemically defined media to minimize the risk of contamination and ensure batch-to-batch consistency. In some cases, we’ve used serum-free media to avoid potential problems associated with animal-derived components.

- Temperature and pH: Maintaining optimal temperature (typically 37°C for mammalian cells) and pH (usually around 7.0 – 7.4) is critical for cell health and viability. I have experience using sophisticated bioreactors with automated control systems to ensure these parameters remain stable throughout the cultivation process.

- Dissolved Oxygen (DO) and CO2: Adequate oxygen supply is crucial for cell metabolism. We utilize online sensors and gas blending systems to maintain appropriate DO levels. Similarly, CO2 levels are carefully controlled to maintain the desired pH.

- Cell Density and Viability: Monitoring cell growth and viability is essential for optimizing harvest time and maximizing product yield. I have experience with various techniques such as cell counting using automated cell counters and flow cytometry to ensure optimal cell culture conditions.

For instance, in one project involving CHO cells producing a monoclonal antibody, we optimized the feeding strategy by implementing a fed-batch process with a customized nutrient feed profile. This led to a 30% increase in antibody titer compared to the initial batch process. In another project with HEK293 cells producing a viral vector, we optimized the transfection conditions, resulting in a significant improvement in vector yield and infectivity.

Q 9. Describe your experience with different chromatography techniques used in downstream processing.

My experience encompasses a range of chromatographic techniques crucial for downstream processing, which aims to purify the target protein from the complex mixture of cellular components. The choice of technique depends on factors such as the target protein’s properties, scale of production, and desired purity.

- Protein A Chromatography: This is a widely used affinity chromatography technique for purifying monoclonal antibodies. Protein A, a bacterial protein, binds specifically to the Fc region of antibodies, allowing for efficient capture and purification. I have extensive experience optimizing Protein A chromatography processes for both batch and continuous operations, focusing on maximizing binding capacity and minimizing protein loss.

- Ion Exchange Chromatography (IEC): This technique separates proteins based on their net charge. I have used both anion exchange (for negatively charged proteins) and cation exchange (for positively charged proteins) chromatography to purify various biomolecules. Method development typically involves optimizing the salt gradient and pH to achieve optimal resolution and purity.

- Hydrophobic Interaction Chromatography (HIC): This separates proteins based on their hydrophobicity. HIC is often used as a polishing step to further improve the purity of the target protein. My experience includes optimizing the salt concentration and buffer conditions to achieve high recovery and purity.

- Size Exclusion Chromatography (SEC): Also known as gel filtration chromatography, this technique separates proteins based on their size and shape. SEC is commonly used as a final polishing step to remove aggregates and other impurities. I’ve utilized SEC to ensure the homogeneity and stability of the final product.

I am also familiar with process scale-up of these techniques, transitioning from small-scale laboratory experiments to large-scale bioreactors using chromatographic columns with varying sizes and capacities. For example, I was involved in a project where we successfully scaled up a Protein A chromatography process from a 50ml column to a 500L column while maintaining high purity and yield.

Q 10. Explain the concept of critical quality attributes (CQAs) in biopharmaceutical manufacturing.

Critical Quality Attributes (CQAs) are the physical, chemical, biological, or microbiological properties of a biopharmaceutical product that should be within an acceptable range to ensure safety and efficacy. These attributes are critical because they directly impact the product’s quality, performance, and patient safety. Think of them as the key indicators of whether your drug will work as intended and be safe for the patient.

Examples of CQAs might include:

- Purity: The percentage of the desired protein in the final product. Impurities can include host cell proteins, DNA, and other contaminants.

- Potency: The biological activity of the drug substance. This is often measured using in vitro or in vivo assays.

- Molecular Weight: The correct molecular weight ensures the proper function of the protein.

- Glycosylation Profile: For many therapeutic proteins, the type and extent of glycosylation can significantly impact their efficacy and safety.

- Aggregation: The presence of protein aggregates can affect efficacy and potentially trigger adverse immune responses.

Defining and monitoring CQAs throughout the biomanufacturing process is essential for ensuring consistent product quality and meeting regulatory requirements. We utilize various analytical techniques like HPLC, mass spectrometry, and capillary electrophoresis to measure CQAs and ensure they meet pre-defined specifications.

Q 11. How do you ensure the sterility of a bioprocess?

Ensuring sterility in a bioprocess is paramount to prevent contamination, which can compromise product quality and safety. This is achieved through a combination of strategies:

- Aseptic Techniques: Strict adherence to aseptic techniques during all stages of the process is crucial. This includes proper gowning and cleaning procedures, use of sterile equipment and materials, and working in laminar flow hoods or cleanrooms to minimize exposure to microorganisms.

- Sterilization of Equipment and Media: Equipment like bioreactors, filters, and tubing is typically sterilized using autoclaving (steam sterilization) or dry heat sterilization. Media and buffers are sterilized by filtration using 0.22 µm filters, which remove bacteria and other microorganisms.

- Environmental Monitoring: Regular monitoring of the environment (air, surfaces) for microbial contamination is vital. This helps to identify potential sources of contamination and take appropriate corrective actions.

- Process Validation: Validation studies are performed to demonstrate the effectiveness of the sterilization methods and aseptic techniques used in the bioprocess. This ensures that the process reliably produces sterile products.

- Sterility Testing: After production, sterility testing is performed to verify the absence of microorganisms in the final product. This involves incubating samples of the product under specific conditions and monitoring for microbial growth.

For example, in one project, we identified a recurring contamination issue during media preparation. Through rigorous investigation, we pinpointed the source to a faulty filter. Replacing the filter with a validated one immediately resolved the contamination issue, demonstrating the importance of regular maintenance and validation of equipment and processes.

Q 12. Describe different methods used for protein purification.

Protein purification involves a series of steps to isolate and purify the target protein from a complex mixture. The specific methods used depend on the protein’s properties and the desired level of purity. Common methods include:

- Centrifugation: Used to remove cells and cell debris from the culture supernatant.

- Filtration: Removes larger particles and contaminants using depth filters or membrane filters.

- Precipitation: Selective precipitation of the target protein using salts (e.g., ammonium sulfate) or organic solvents.

- Chromatography (as discussed above): A powerful technique for separating proteins based on their properties, such as size, charge, hydrophobicity, or affinity.

- Crystallization: A high-resolution purification technique used for obtaining highly pure and stable protein crystals, often for structural studies.

Often, a combination of these methods is used to achieve the desired purity. For instance, a typical purification scheme might involve initial centrifugation and filtration, followed by several chromatographic steps (e.g., Protein A chromatography, ion exchange, and size exclusion) to obtain a highly pure product.

Q 13. Explain your experience with process analytical technology (PAT) tools.

Process Analytical Technology (PAT) tools are advanced technologies that provide real-time, in-line or at-line measurements of critical process parameters and attributes. They enable better process understanding and control, leading to improved product quality, reduced variability, and faster development times. My experience with PAT tools includes:

- Spectroscopy (UV-Vis, NIR): Used to monitor various parameters such as cell density, substrate concentration, and product titer in real time. This enables rapid adjustments to process parameters to optimize the bioprocess.

- Raman Spectroscopy: Provides information on the protein structure, aggregation state, and other critical quality attributes.

- Flow Cytometry: Used to monitor cell viability, size, and other properties relevant to bioprocess optimization.

- In-line Particle Size Analyzers: Used to monitor the formation of aggregates during cell culture and downstream processing.

Implementing PAT significantly enhances our ability to achieve consistent and high-quality biopharmaceutical products. For instance, in one project, the use of real-time monitoring of cell density and nutrient levels via spectroscopy allowed for more effective fed-batch control, significantly increasing the antibody titer. This minimized process variability and improved overall process efficiency.

Q 14. How do you validate a bioprocess?

Bioprocess validation is a crucial step in demonstrating that a manufacturing process consistently produces a product that meets predefined quality attributes and specifications. It involves a comprehensive set of activities designed to prove the process’s reliability and reproducibility. Validation ensures that the process is robust and can be controlled consistently over time.

Key aspects of bioprocess validation include:

- Process Development: Thorough development of the process, including optimization of all critical parameters, is a crucial first step.

- Design Qualification (DQ): Verification that the process design is suitable for its intended purpose.

- Installation Qualification (IQ): Verification that the equipment is installed correctly and operates as intended.

- Operational Qualification (OQ): Demonstration that the equipment and process operate within pre-defined limits.

- Performance Qualification (PQ): Production of multiple batches under routine operating conditions to demonstrate consistent product quality and compliance with specifications. This includes the assessment of critical quality attributes and the use of statistical analysis to establish process capability.

Documentation is crucial throughout the entire validation process. The validation report must be comprehensive and meet regulatory requirements. Successful validation ensures that the bioprocess is reliable, consistent, and produces a safe and effective product, giving confidence to regulatory agencies and patients.

Q 15. Describe your experience with single-use technologies in bioprocessing.

Single-use technologies (SUTs) have revolutionized bioprocessing by replacing traditional stainless steel systems with disposable components like bags, tubing, and sensors. My experience encompasses the full spectrum, from upstream processing (cell culture in single-use bioreactors) to downstream processing (filtration and purification using single-use systems). I’ve worked with various SUTs, including those from various manufacturers, for both mammalian and microbial cell cultures. For instance, I’ve extensively used single-use bioreactors for clinical-scale production of monoclonal antibodies, optimizing parameters like agitation, aeration, and temperature to maximize cell growth and product yield while minimizing risks associated with cross-contamination and cleaning validation.

Specifically, I’ve compared the performance of different single-use bioreactor systems for a particular cell line, analyzing factors such as scalability, oxygen transfer rate (OTR), and mixing efficiency. In one project, we successfully transitioned from a traditional stainless steel system to a single-use bioreactor, resulting in a 20% increase in productivity and a significant reduction in operational costs. We meticulously evaluated different bag materials and their impact on cell growth and product quality to select the most optimal system.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your understanding of GMP (Good Manufacturing Practices) guidelines in bioprocessing.

Good Manufacturing Practices (GMP) are a set of guidelines that ensure the consistent production of high-quality medicines and biologics. My understanding of GMP in bioprocessing extends to all phases, from raw material sourcing and equipment qualification to process validation and final product release. I’m intimately familiar with regulatory requirements, including documentation, change control, deviation management, and quality assurance protocols. For example, I’ve participated in numerous GMP audits and have successfully implemented corrective actions to address identified gaps.

Compliance with GMP necessitates meticulous record-keeping, detailed standard operating procedures (SOPs), and rigorous training for all personnel involved. In my previous role, I was responsible for developing and implementing SOPs for critical bioprocessing steps, ensuring that all procedures were aligned with GMP requirements. I understand the importance of maintaining a cleanroom environment, validating equipment performance, and carefully managing process deviations. Non-compliance can result in costly delays, product recalls, and reputational damage, underscoring the importance of a proactive, comprehensive approach to GMP.

Q 17. How do you handle data inconsistencies in bioprocess optimization experiments?

Data inconsistencies in bioprocess optimization experiments are a common challenge. My approach involves a multi-step process starting with careful data review and validation. I begin by visually inspecting the data for outliers or obvious errors. This might involve checking sensor calibration logs or reviewing process parameters for anomalies.

Next, I employ statistical tools like Grubbs’ test or other outlier detection methods to identify statistically significant outliers. If outliers are deemed genuine experimental errors, they are removed. However, it’s crucial to investigate the root cause before discarding the data. For example, a sudden drop in pH might indicate a malfunctioning sensor or a problem with the media. Addressing the root cause prevents similar issues in future experiments.

After outlier removal, I might use robust statistical methods less sensitive to outliers, like median instead of mean, for data analysis. Finally, I thoroughly document all data handling decisions, including justifications for outlier removal. This transparency ensures data integrity and reproducibility.

Q 18. Describe your experience with bioreactor control systems.

I possess extensive experience with various bioreactor control systems, ranging from simple PLC-based systems to sophisticated SCADA (Supervisory Control and Data Acquisition) systems. My expertise includes programming, troubleshooting, and optimization of these systems. I’m familiar with the various sensors and actuators used to control parameters such as pH, dissolved oxygen (DO), temperature, agitation speed, and feed rate. I can interpret data from these systems, identify trends, and make informed decisions to optimize the bioprocess.

For instance, I have experience programming PID controllers to maintain stable parameters within narrow ranges. I’ve also worked with advanced control strategies, such as feedforward control and model predictive control (MPC), to improve process efficiency and reduce variability. My skills extend to integrating bioreactor data with other laboratory information management systems (LIMS) for streamlined data management and analysis.

In one project, we implemented an MPC system to optimize the feeding strategy in a cell culture bioreactor. This resulted in a 15% increase in product titer and a reduction in process variability. I’m also proficient in using software packages for data analysis and visualization, enabling effective interpretation of bioreactor data for optimization purposes.

Q 19. Explain your approach to risk assessment in bioprocess development.

Risk assessment in bioprocess development is critical for ensuring product safety and quality. My approach follows a structured framework, typically incorporating a HAZOP (Hazard and Operability Study) or FMEA (Failure Mode and Effects Analysis). I begin by identifying potential hazards and vulnerabilities across the entire bioprocess, from upstream to downstream processing.

This involves considering factors such as equipment failures, contamination risks, operator errors, and raw material variability. For each identified hazard, I determine its likelihood and potential consequences. This analysis leads to the prioritization of risks based on their severity and probability, allowing for focused mitigation efforts. Mitigation strategies might include implementing redundant systems, improving operator training, enhancing process controls, or modifying the process itself to eliminate or minimize the risk.

Following risk mitigation, a residual risk assessment is conducted to evaluate the effectiveness of implemented controls. This iterative process ensures that the bioprocess is as safe and robust as possible, minimizing the potential for deviations or failures. Documentation of the entire risk assessment process is crucial for regulatory compliance and continuous improvement.

Q 20. How do you ensure the robustness of a bioprocess?

Robustness in a bioprocess ensures consistent product quality and yield despite variations in process parameters or environmental conditions. Achieving robustness requires a multi-pronged approach starting with thorough process characterization. This involves designing experiments (like Design of Experiments or DOE) to identify the critical process parameters (CPPs) that significantly impact product quality and yield. Then, a process understanding is developed through mathematical models that encapsulate how the CPPs affect the process outcome.

Once CPPs are identified, robust process design utilizes tools like Design of Experiments (DOE) to determine optimal operating ranges for these parameters that allow for variations whilst still ensuring a consistent outcome. This strategy minimizes the sensitivity of the process to minor fluctuations. Process analytical technology (PAT) plays a vital role in monitoring critical process parameters and providing real-time feedback for control and adjustment. Finally, continuous monitoring and data analysis helps detect and address any emerging deviations before they significantly affect product quality.

For example, I have experience implementing Quality by Design (QbD) principles in bioprocess development to create a robust process for manufacturing a therapeutic protein. QbD principles emphasize process understanding and control, leading to higher confidence in consistency and reliability.

Q 21. What are the advantages and disadvantages of different types of bioreactors?

Various bioreactor types exist, each with its advantages and disadvantages. The choice depends on the specific application and cell type. Here’s a comparison:

- Stirred-tank bioreactors (STRs): These are versatile and widely used, offering good mixing and oxygen transfer. However, they can cause shear stress damage to sensitive cells.

- Airlift bioreactors: These provide gentler mixing and reduced shear stress, suitable for shear-sensitive cells. However, they might have lower oxygen transfer rates than STRs.

- Photobioreactors: Designed for photosynthetic organisms, they offer precise light control but can be challenging to scale up.

- Fixed-bed bioreactors: Used for immobilized cells, they offer high cell density but can be difficult to clean and sterilize.

- Fluidized-bed bioreactors: Similar to fixed-bed but with better mixing, suited for high cell density applications but more complex to operate.

The selection of an appropriate bioreactor often involves trade-offs. For instance, a high-shear STR might be chosen for robust cells needing high oxygen transfer, whereas an airlift bioreactor is preferred for shear-sensitive cells even if oxygen transfer might require optimization.

Q 22. Describe your experience with process modeling and simulation software.

My experience with process modeling and simulation software is extensive. I’m proficient in using tools like Aspen Plus, gPROMS, and specialized bioprocess simulators like CellDesigner and COPASI. These tools are invaluable for predicting process behavior, optimizing parameters, and reducing the need for extensive experimental trials. For instance, in a recent project involving monoclonal antibody production, I used Aspen Plus to model the chromatography purification steps, allowing us to optimize resin bed height and flow rate to maximize product yield and purity while minimizing processing time. This significantly reduced the time and cost associated with experimental optimization.

Beyond the basic simulations, I am skilled in applying advanced techniques like model predictive control (MPC) to dynamically adjust bioreactor parameters (e.g., pH, temperature, dissolved oxygen) based on real-time data. This ensures optimal process operation even under fluctuating conditions, leading to improved product quality and consistency. My proficiency also extends to integrating experimental data with simulation models to validate and refine our predictions, ensuring a robust and accurate representation of the bioprocess.

Q 23. How do you develop a process flow diagram (PFD) for a bioprocess?

Developing a Process Flow Diagram (PFD) for a bioprocess is a systematic procedure. It’s like creating a blueprint for a factory, outlining the entire production sequence. I begin by clearly defining the overall objective: What product are we making, and what are the desired specifications? This guides the subsequent steps.

Next, I meticulously chart out each unit operation, from upstream processing (cell culture, media preparation) to downstream processing (purification, formulation). This involves using standardized symbols and clearly labeling all streams (inputs, outputs, waste). I carefully consider the sequence of operations, taking into account factors like sterility maintenance, critical process parameters (CPPs), and potential bottlenecks. For instance, a typical PFD for a mammalian cell culture process would show the media preparation unit, bioreactor, harvest tank, clarification steps, chromatography columns, and finally, the formulation and filling stages. Each step is connected by flow lines, indicating the flow of materials.

Finally, the PFD is reviewed by the project team for accuracy and completeness. This ensures that all aspects of the bioprocess are accounted for and that any potential issues are identified early on. The final PFD serves as a valuable communication tool for the entire team and a crucial guide during the design, construction, and operational phases of the bioprocess.

Q 24. Explain your understanding of regulatory requirements for biopharmaceutical manufacturing.

My understanding of regulatory requirements for biopharmaceutical manufacturing is thorough. I’m intimately familiar with the guidelines issued by agencies like the FDA (in the US), EMA (in Europe), and PMDA (in Japan). These regulations are critical for ensuring the safety and efficacy of biopharmaceuticals.

This involves strict adherence to Good Manufacturing Practices (GMP), which covers all aspects from facility design and equipment qualification to process validation and quality control testing. We must meticulously document every step of the process, ensuring traceability and reproducibility. Critical process parameters (CPPs) and critical quality attributes (CQAs) must be carefully monitored and controlled throughout the manufacturing process. Deviation management and change control procedures are essential for maintaining compliance. Additionally, the regulations cover areas such as risk assessment, process analytical technology (PAT) implementation, and the handling of deviations and out-of-specification results.

Understanding and adhering to these regulations is not just a matter of compliance; it’s crucial for ensuring patient safety and building public trust in our products. Failure to comply can lead to severe penalties, including product recalls and regulatory actions.

Q 25. How do you manage time constraints and competing priorities in bioprocess development projects?

Managing time constraints and competing priorities in bioprocess development projects demands a structured approach. I typically employ project management techniques like critical path analysis to identify tasks critical to the project timeline. This allows prioritization of tasks and allocation of resources accordingly.

Effective communication is vital. Regular team meetings, clear reporting, and transparent updates keep everyone informed and aligned. Risk management is proactively integrated. Identifying potential delays and developing mitigation strategies early on significantly reduces the impact of unforeseen challenges. Flexibility is key; I’m adept at adapting plans to accommodate unexpected changes while still meeting deadlines. For example, if a critical piece of equipment fails, alternative strategies are readily implemented to minimize delays.

Finally, efficient delegation and utilization of available resources, whether human or technological, are crucial for staying on schedule. Prioritizing tasks based on their impact on the project’s overall goals ensures efficient resource allocation, allowing us to navigate competing priorities effectively.

Q 26. Describe a situation where you had to troubleshoot a complex bioprocess problem. What was your approach?

During a large-scale production run of a therapeutic protein, we experienced a significant drop in cell viability in our bioreactors. The initial hypothesis was contamination, but thorough sterility tests were negative. My approach involved a systematic troubleshooting methodology.

First, we meticulously reviewed all operational parameters, comparing them to previous successful runs. This included checking parameters like temperature, pH, dissolved oxygen levels, and nutrient feed rates. We then conducted a detailed analysis of the cell culture media, looking for inconsistencies or degradation. Parallel experiments were run to test different hypotheses. One team focused on evaluating the impact of media components while another team investigated potential shear stress effects.

Eventually, we discovered that a batch of the cell culture media contained an unexpected level of a trace metal impurity that proved cytotoxic. This was confirmed through a rigorous investigation of the supplier’s manufacturing process and further experiments involving purified media. The problem was resolved by switching to a new media supplier and implementing stricter quality control checks.

This experience highlighted the importance of meticulous record-keeping, a systematic troubleshooting process, and strong collaboration within the team. It also underscored the critical role of supplier quality control in biopharmaceutical manufacturing.

Q 27. Explain your understanding of different types of cell death and their impact on bioprocess performance.

Understanding different types of cell death and their impact on bioprocess performance is fundamental in bioprocessing. Cell death, or cell lysis, can significantly reduce product yield, alter product quality, and complicate downstream processing. There are several key mechanisms:

- Apoptosis (programmed cell death): This is a regulated process involving cell shrinkage, DNA fragmentation, and apoptotic body formation. In bioprocesses, apoptosis can be triggered by various factors such as nutrient deprivation, stress, or viral infection. It can lead to reduced cell density and product yield.

- Necrosis (unprogrammed cell death): This is a passive process resulting from cell injury. It leads to cell swelling, membrane rupture, and release of intracellular contents. Necrosis is often associated with sudden changes in environmental conditions (e.g., extreme temperature, pH shifts). It results in decreased product quality due to the release of contaminants.

- Autophagy: This is a cellular self-degradation process that can be either beneficial or detrimental depending on context. Under stress, cells activate autophagy to recycle cellular components. However, excessive autophagy can lead to cell death.

The impact of cell death on bioprocess performance depends on the type and extent of cell death. For example, apoptosis might lead to lower productivity but minimal contamination, whereas necrosis would cause a significant reduction in product quality due to released intracellular material. Monitoring cell viability, morphology, and the release of intracellular components are crucial for identifying and mitigating cell death in bioprocesses. Strategies include optimizing cell culture conditions, controlling environmental stressors, and incorporating cell death inhibitors when appropriate.

Key Topics to Learn for Bioprocess Optimization Interview

- Upstream Process Optimization: Understanding and optimizing cell culture conditions (media formulation, temperature, pH, dissolved oxygen) for maximal productivity and product quality. Practical application: Designing experiments to identify optimal feeding strategies for high-density cell cultures.

- Downstream Process Optimization: Mastering purification techniques (chromatography, filtration) to achieve high yield, purity, and stability of the target biomolecule. Practical application: Analyzing and improving the efficiency of a purification train through process analytical technology (PAT).

- Statistical Design of Experiments (DoE): Applying experimental design principles (e.g., factorial designs, response surface methodology) to efficiently screen and optimize multiple process parameters simultaneously. Practical application: Using DoE to identify the optimal combination of temperature and pH for maximizing enzyme activity.

- Process Modeling and Simulation: Developing and utilizing mathematical models to predict and optimize bioprocess performance. Practical application: Creating a dynamic model to simulate the effects of different feeding strategies on cell growth and product formation.

- Process Analytical Technology (PAT): Implementing real-time monitoring and control strategies to ensure consistent product quality and reduce variability. Practical application: Utilizing in-line sensors to monitor critical process parameters and implement automated control loops.

- Bioreactor Design and Operation: Understanding the principles of different bioreactor types (stirred tank, airlift, perfusion) and their suitability for different applications. Practical application: Selecting the appropriate bioreactor and operating parameters for a specific cell line and product.

- Scale-up and Scale-down: Successfully translating optimized processes from lab-scale to pilot-scale and manufacturing scale. Practical application: Addressing challenges related to mixing, oxygen transfer, and heat removal during scale-up.

- Quality by Design (QbD): Implementing a systematic approach to ensure consistent product quality and reduce process variability. Practical application: Designing experiments to understand critical process parameters and their impact on product quality attributes.

Next Steps

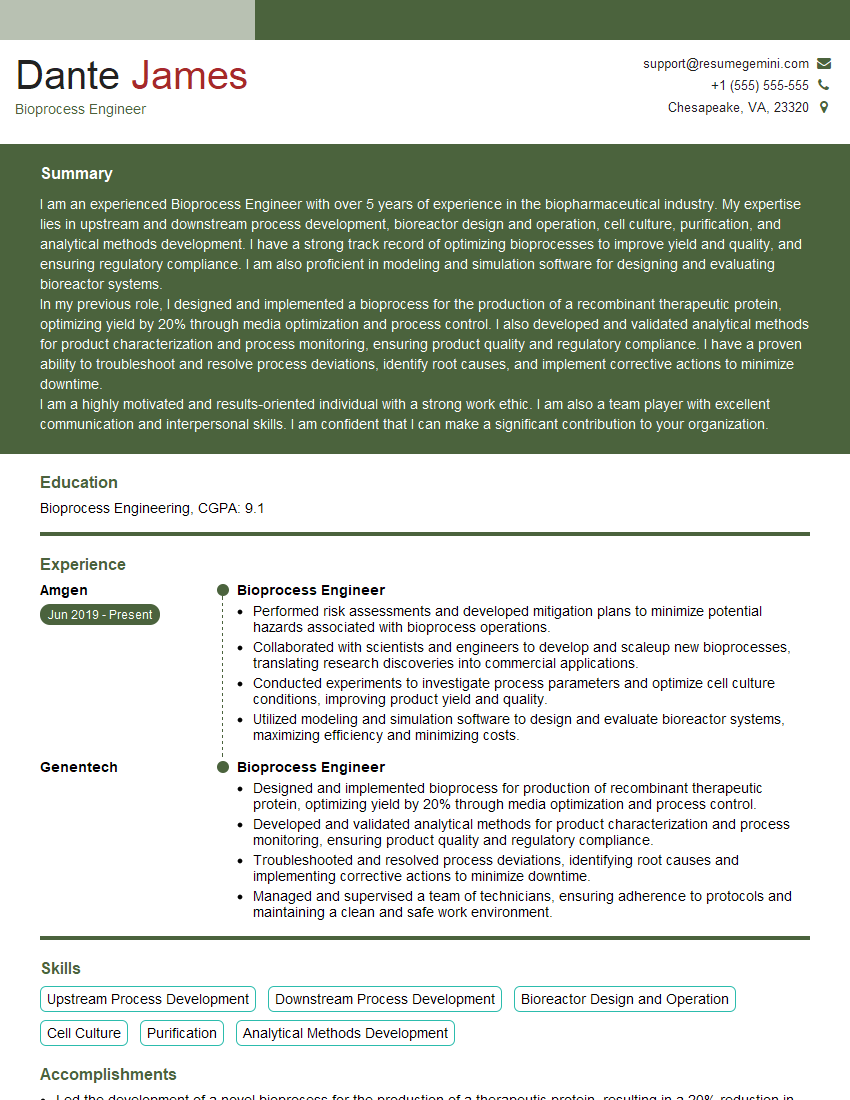

Mastering Bioprocess Optimization is crucial for career advancement in the biopharmaceutical industry, opening doors to leadership roles and high-impact projects. An ATS-friendly resume is essential for maximizing your job prospects. To create a compelling and effective resume that highlights your skills and experience in Bioprocess Optimization, we highly recommend using ResumeGemini. ResumeGemini provides a powerful platform for building professional resumes, and we offer examples of resumes tailored specifically to Bioprocess Optimization to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good