The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Bioreactor Modeling interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Bioreactor Modeling Interview

Q 1. Explain the different types of bioreactor models (e.g., mechanistic, empirical).

Bioreactor models are broadly categorized into mechanistic and empirical models. Mechanistic models, also known as physiologically based models, are built upon fundamental principles of biology, chemistry, and physics. They describe the underlying processes within the bioreactor, such as cell growth, substrate consumption, product formation, and mass transfer, using differential equations that represent these processes. In contrast, empirical models rely on experimental data and statistical analysis to establish correlations between input and output variables. They are essentially curve-fitting exercises that predict system behavior without explicitly describing the underlying mechanisms.

- Mechanistic Models: These models offer a deeper understanding of the bioreactor’s inner workings. For example, a mechanistic model for a cell culture bioreactor might incorporate equations describing Monod kinetics (relating growth rate to substrate concentration), mass balances for nutrients and metabolites, and heat transfer equations. They are generally more complex to develop but provide greater predictive power and allow for better process optimization.

- Empirical Models: These are simpler to develop and require less detailed information about the system. A simple example might be a linear regression model relating cell density to a specific nutrient concentration based on experimental data. However, they lack the predictive capacity of mechanistic models, especially when operating conditions move outside the range of the original experimental data. They are essentially a ‘black box’ approach.

Q 2. Describe the limitations of using empirical models in bioreactor design.

Empirical models, while easier to develop, suffer from several significant limitations in bioreactor design. Primarily, they lack the ability to extrapolate beyond the experimental conditions under which they were developed. A model trained on data from a small-scale bioreactor might not accurately predict the behavior of a large-scale production bioreactor due to changes in factors such as mixing, oxygen transfer, and heat dissipation. Furthermore, they cannot readily explain the why behind a particular observation, only the what. This makes it difficult to troubleshoot problems or design novel bioreactor configurations.

For example, imagine an empirical model predicting cell growth based only on nutrient concentration. If a process issue introduces a hidden variable, like unexpected pH changes affecting cell growth, the empirical model won’t capture this effect, leading to inaccurate predictions and potentially failed production runs. Mechanistic models, however, offer the potential to identify and incorporate such influences for improved predictive power.

Q 3. What are the key parameters to consider when developing a mechanistic model for a specific bioreactor?

Developing a mechanistic model for a bioreactor requires careful consideration of several key parameters. The specific parameters depend on the bioprocess, but generally include:

- Cell Growth Kinetics: This includes the selection of an appropriate growth model (e.g., Monod, Logistic, or more complex models incorporating inhibition effects). The model must accurately reflect the relationship between cell growth rate and nutrient availability, pH, temperature, and other relevant factors.

- Stoichiometry: This defines the quantitative relationships between substrates consumed, cells produced, and metabolites formed. Accurate stoichiometric coefficients are essential for accurate mass balances within the model.

- Mass Transfer Coefficients: These quantify the rates of transfer of oxygen, nutrients, and metabolites between the gas phase (for oxygen), liquid phase, and cells. They are highly dependent on bioreactor design and operating conditions.

- Bioreactor Geometry and Hydrodynamics: The design and operational parameters (mixing speed, aeration rate, impeller type) greatly influence mixing and mass transfer. CFD simulations often assist in characterizing these aspects.

- Physicochemical Properties: Temperature, pH, and dissolved oxygen concentrations are critical parameters influencing cell growth and product formation. Accurate models must incorporate their effect on the system.

For example, in designing a model for a mammalian cell culture bioreactor producing a therapeutic protein, we’d carefully consider parameters like glucose and lactate dynamics (substrate consumption and byproduct formation), glutamine metabolism, and the effect of dissolved oxygen on cell viability and productivity.

Q 4. How do you validate a bioreactor model?

Model validation is crucial to ensure a bioreactor model’s reliability and predictive power. This process involves comparing the model’s predictions with experimental data obtained under various operating conditions. It’s usually a multi-step process:

- Parameter Estimation: The model parameters are adjusted to best fit the experimental data. Methods include least squares fitting, maximum likelihood estimation, or more advanced techniques.

- Model Fitting: The ability of the model to accurately represent the experimental data within the design space is assessed using statistical measures like R-squared and residual analysis. A good fit indicates the model adequately captures the system behavior.

- Model Prediction: The model is used to predict the system’s behavior under conditions not included in the initial parameter estimation. This assesses the model’s predictive capacity beyond the training data.

- Sensitivity Analysis: This evaluates the influence of each model parameter on the overall model predictions. It helps identify parameters that require more accurate determination or control.

For example, a successful validation might involve comparing predicted cell density and product concentration over time against data from a separate set of experiments run under different nutrient feed rates. Significant discrepancies indicate that the model needs refinement or that critical parameters are missing.

Q 5. Discuss the use of computational fluid dynamics (CFD) in bioreactor design and optimization.

Computational Fluid Dynamics (CFD) plays a significant role in bioreactor design and optimization. CFD uses numerical methods to solve the Navier-Stokes equations, predicting fluid flow patterns, mixing characteristics, and mass transfer within the bioreactor. This information is invaluable for optimizing bioreactor design and operating conditions.

Specifically, CFD can help:

- Improve Mixing: CFD simulations can be used to optimize impeller design and placement to ensure uniform mixing and avoid dead zones where cells may experience nutrient limitation or product accumulation.

- Enhance Mass Transfer: CFD simulations can be used to predict the distribution of dissolved oxygen and other nutrients, helping optimize aeration strategies and improve oxygen transfer rates.

- Reduce Shear Stress: High shear stress can damage sensitive cells. CFD can identify regions of high shear and inform the design of bioreactors with better cell protection.

- Optimize Scale-up: CFD simulations can facilitate scale-up from smaller laboratory bioreactors to larger production bioreactors by identifying scaling factors and avoiding unexpected behavior in larger vessels.

In practice, CFD results are often integrated into mechanistic models to provide a more complete and accurate representation of the bioreactor system. For instance, CFD-derived mass transfer coefficients can be directly incorporated into the equations describing nutrient uptake and product formation.

Q 6. Explain how mass transfer limitations influence bioreactor performance.

Mass transfer limitations significantly impact bioreactor performance. These limitations arise when the rate at which nutrients (e.g., oxygen, glucose) are transported to cells or products are transported away from cells is slower than the rate at which the cells consume nutrients or produce products. This can lead to reduced cell growth, reduced product yield, and the accumulation of inhibitory byproducts.

For example, in a high-density cell culture, oxygen transfer limitations can occur if the oxygen supply from the gas phase cannot keep up with the cells’ demand. This can result in oxygen depletion in the culture broth, leading to reduced cell growth and even cell death. Similarly, limitations in the removal of metabolic byproducts like lactic acid can lead to a decrease in pH, further inhibiting cell growth.

Strategies to mitigate mass transfer limitations include improving aeration and agitation, employing oxygen carriers, using optimized bioreactor designs, and controlling the cell density to maintain sufficient nutrient supply.

Q 7. How do you account for cell growth kinetics in bioreactor models?

Cell growth kinetics are incorporated into bioreactor models through mathematical equations that describe the rate of cell growth as a function of various factors. The choice of kinetic model depends on the type of cells and the specific bioprocess.

- Monod Kinetics: This is a widely used model for microbial growth, describing the growth rate as a function of the limiting substrate concentration (e.g., glucose):

μ = μmax * S / (Ks + S), where μ is the specific growth rate, μmax is the maximum specific growth rate, S is the substrate concentration, and Ks is the half-saturation constant. - Logistic Growth: This model accounts for the finite carrying capacity of the bioreactor:

dX/dt = μmax * X * (1 - X/Xmax), where X is the cell concentration and Xmax is the maximum cell concentration. - More Complex Models: For more sophisticated modeling, models can incorporate inhibitory effects of substrates or products, diauxic growth (growth on multiple substrates sequentially), or other regulatory mechanisms. These often involve more parameters and require advanced techniques for estimation.

Incorporating these growth kinetics into the mass balance equations for cells and substrates allows for a dynamic simulation of cell growth and substrate consumption over time, which is crucial for predicting bioreactor performance and optimizing operational strategies.

Q 8. Describe different strategies for model parameter estimation.

Model parameter estimation is crucial for creating accurate bioreactor models. It involves determining the values of model parameters (e.g., kinetic parameters like maximum specific growth rate (µmax), substrate affinity constant (Ks), yield coefficients) that best describe the observed experimental data. Several strategies exist:

Least Squares Method: This classic approach minimizes the sum of squared differences between the model predictions and experimental measurements. It’s relatively simple but can be sensitive to outliers.

Maximum Likelihood Estimation (MLE): MLE finds the parameter values that maximize the likelihood of observing the experimental data given the model. It’s statistically robust and handles different types of experimental errors effectively.

Bayesian Estimation: This approach incorporates prior knowledge about parameter values, making it particularly useful when data is scarce or noisy. It provides a probability distribution for the parameters, reflecting the uncertainty in their estimation. Markov Chain Monte Carlo (MCMC) methods are often used for Bayesian estimation in complex models.

Evolutionary Algorithms: These optimization techniques, such as genetic algorithms, are suitable for complex, non-linear models with many parameters. They are less sensitive to local optima compared to gradient-based methods.

The choice of method depends on factors such as the complexity of the model, the amount and quality of data, and the level of uncertainty that needs to be addressed. For example, in a simple model of bacterial growth, the least squares method might suffice. However, for a more complex model incorporating multiple substrates and product formation, Bayesian estimation might be more appropriate.

Q 9. Explain the concept of model sensitivity analysis and its importance in bioreactor modeling.

Model sensitivity analysis assesses the impact of parameter variations on model outputs. It is crucial in bioreactor modeling because it helps identify which parameters most significantly influence the process and therefore require precise estimation or control. This analysis helps us understand the model’s robustness and potential limitations. Several methods exist, including:

Local Sensitivity Analysis: Examines the sensitivity of model outputs to small changes in individual parameters, typically using partial derivatives. This approach is efficient but assumes linearity within the investigated range.

Global Sensitivity Analysis: Explores the sensitivity of outputs to variations across the entire parameter space, considering potential interactions between parameters. Methods like variance-based methods (Sobol indices) quantify the contribution of each parameter to the total output variance. This is important because parameters can interact in complex ways.

In practice, sensitivity analysis guides experimental design by prioritizing the accurate measurement of critical parameters. For example, if sensitivity analysis reveals that oxygen transfer rate is highly influential on cell growth, more resources should be devoted to accurately measuring and controlling this parameter in the bioreactor. Ignoring sensitive parameters can lead to inaccurate predictions and suboptimal bioreactor operation.

Q 10. How do you handle model uncertainty in bioreactor design and operation?

Model uncertainty arises from various sources: imperfect model structure, noisy experimental data, and uncertainty in parameter estimates. Handling this uncertainty is crucial for reliable bioreactor design and operation. Strategies include:

Robust Design: Designing the bioreactor operation to be less sensitive to parameter variations identified through sensitivity analysis. This reduces the impact of uncertainty on the overall process.

Probabilistic Modeling: Incorporating uncertainty directly into the model using probability distributions for parameters or inputs. This leads to a range of possible outcomes, providing a more realistic representation of the process uncertainty.

Monte Carlo Simulation: Repeatedly simulating the model with randomly sampled parameter values from their probability distributions. This generates a distribution of predicted outputs, quantifying the uncertainty in the predictions.

Adaptive Model Predictive Control (MPC): Employing control strategies that adapt to changing conditions and model uncertainties by using real-time measurements and continuously updating the model predictions.

For instance, during scale-up, uncertainty in the oxygen transfer rate is common. Using probabilistic modeling and Monte Carlo simulation would allow for a prediction of the range of possible oxygen transfer rates and thus inform design choices, leading to a more robust bioreactor design less susceptible to failures due to oxygen limitation.

Q 11. Compare and contrast different bioreactor types (e.g., stirred tank, airlift, photobioreactor).

Different bioreactor types cater to various cell cultivation needs. Key distinctions lie in mixing, oxygen transfer, and scalability:

Stirred Tank Bioreactor (STR): Widely used, offering excellent mixing and oxygen transfer. They are relatively easy to scale up but can cause shear stress to sensitive cells.

Airlift Bioreactor: Uses air bubbles for mixing and oxygen transfer, reducing shear stress. Simpler design than STRs but can have lower oxygen transfer rates and less uniform mixing.

Photobioreactor: Designed for photosynthetic organisms, allowing for controlled light exposure. Designs vary greatly, from tubular to flat-panel systems, each with its own advantages and disadvantages in terms of light penetration and scalability.

The choice depends on the specific application. For example, mammalian cell cultures often prefer low-shear airlift bioreactors to minimize cell damage. Algae cultivation in photobioreactors requires careful design to optimize light penetration and gas exchange. STRs are generally versatile for a range of microorganisms and processes.

Q 12. How would you design experiments to validate a bioreactor model?

Validating a bioreactor model involves systematically comparing model predictions with experimental data under various conditions. A well-designed validation strategy includes:

Defining Validation Criteria: Establishing clear metrics to quantify the agreement between model and experiment, such as root mean square error (RMSE) or R-squared.

Experimental Design: Designing experiments covering a broad range of operating conditions (e.g., varying substrate concentrations, temperature, pH) to thoroughly test the model’s predictive capabilities under various scenarios. This includes testing at conditions beyond the range used for parameter estimation.

Data Acquisition: Ensuring accurate and reliable data collection. Careful attention should be paid to experimental techniques, data logging, and error analysis.

Statistical Analysis: Using appropriate statistical methods to assess the goodness of fit, identifying potential biases, and checking the model’s predictive power. Statistical tests should include tests for model adequacy.

Sensitivity Analysis on Model Parameters: Ensure that model sensitivity is well-characterized to ensure accurate predictions of output under varied conditions.

For example, if modeling bacterial growth, experiments might involve varying nutrient concentrations and measuring cell density, biomass, and metabolite concentrations over time. The model predictions are then compared to these experimental results using statistical tests to determine if the model adequately represents the system.

Q 13. Describe your experience with software used for bioreactor modeling and simulation (e.g., Aspen Plus, COMSOL).

My experience encompasses several software packages commonly used for bioreactor modeling and simulation. I’ve extensively used:

MATLAB with Simulink: This platform excels in creating custom models, implementing advanced algorithms (e.g., for optimization or control), and visualizing results. I’ve used it to build dynamic models of various bioreactor types, including STRs and airlift bioreactors, incorporating mass and energy balances and metabolic networks.

%Example MATLAB code snippet (Illustrative):% Define parametersmu_max = 0.5; % Maximum specific growth rateKs = 0.1; % Substrate affinity constant% ...rest of the model code...COMSOL Multiphysics: A powerful tool for solving coupled partial differential equations (PDEs), particularly useful for modeling transport phenomena (mass transfer, heat transfer) within the bioreactor. I’ve used it to simulate the fluid dynamics and oxygen transfer in different bioreactor configurations.

Aspen Plus: Suitable for large-scale bioprocess simulation, integrating unit operations and process control aspects. I’ve used it for designing and analyzing complete bioprocess trains, including downstream processing.

The choice of software often depends on the complexity of the model and the specific aspects to be analyzed. For simple models, MATLAB might suffice. For complex, multiphysics problems involving fluid dynamics and transport phenomena, COMSOL is a preferred choice. Aspen Plus is ideal for integrating bioreactors within a larger process flowsheet.

Q 14. Explain the challenges of scaling up a bioreactor process from lab-scale to industrial scale.

Scaling up a bioreactor process from lab-scale to industrial scale presents several challenges:

Geometric Similarity: Maintaining similar ratios of reactor dimensions is crucial, but not always achievable due to physical limitations.

Oxygen Transfer: Oxygen transfer becomes increasingly challenging at larger scales due to the decreased surface-to-volume ratio. Specialized equipment like sparger design and impeller configuration might be required to ensure adequate oxygen supply.

Mixing: Ensuring homogenous mixing becomes more difficult as the scale increases. Dead zones can develop, leading to localized variations in substrate concentration and cell density.

Heat Transfer: Managing heat generated by cell metabolism can be difficult at larger scales. Efficient cooling systems are crucial to maintain optimal temperature.

Scale-Dependent Phenomena: Certain phenomena, such as cell aggregation, may be more pronounced at larger scales. This needs to be accounted for during model development and scale-up strategy.

Process Control: Sophisticated control systems are often required to maintain consistent operation at the larger scale, particularly to address the challenges mentioned above.

To address these challenges, a combination of experimental data, computational fluid dynamics (CFD) simulations, and scale-down studies are often employed. A well-defined scale-up strategy, guided by accurate modeling and thorough understanding of the key process parameters, is critical for successful scale-up.

Q 15. How do you address model discrepancies between experimental data and simulation results?

Discrepancies between experimental data and simulation results in bioreactor modeling are common and often highlight limitations in our understanding of the system. Addressing these discrepancies is crucial for model refinement and reliable prediction. My approach involves a systematic investigation, starting with a thorough review of the experimental setup and data quality. This includes checking for errors in data acquisition, processing, and handling.

Next, I meticulously examine the model structure itself. Are the assumptions valid? Have I included all relevant factors? Often, simplifying assumptions made for model tractability lead to deviations. For example, neglecting cell-to-cell variability or assuming homogeneous mixing within the bioreactor can significantly affect results. I refine the model by incorporating more complex biological processes or by relaxing simplifying assumptions where possible.

Parameter estimation is another critical aspect. I use robust statistical methods like Bayesian inference or maximum likelihood estimation to refine the model parameters. I’d also explore different parameterization strategies; for example, using more detailed kinetic models instead of simpler Monod kinetics. Furthermore, model calibration techniques such as sensitivity analysis can help identify parameters that strongly influence the model output and guide refinement efforts. If discrepancies persist after these steps, I might consider expanding the model to include additional factors or investigate potential unmeasured variables influencing the process, like trace contaminants or subtle environmental changes.

Finally, if significant unexplained discrepancies remain, it might be necessary to re-evaluate the experimental design and conduct further experiments to address the identified gaps in the model understanding. It’s an iterative process: model building, validation, refinement, and potentially redesign of experiments—a continuous cycle toward increased accuracy.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Discuss the role of oxygen transfer rate (OTR) and carbon dioxide evolution rate (CER) in bioreactor modeling.

Oxygen transfer rate (OTR) and carbon dioxide evolution rate (CER) are crucial parameters in bioreactor modeling, directly reflecting the metabolic activity of the cells and the efficiency of gas exchange within the bioreactor. OTR represents the rate at which oxygen is transferred from the gas phase to the liquid phase, where it’s available for cellular respiration. CER, conversely, signifies the rate at which carbon dioxide, a byproduct of cellular metabolism, is released from the liquid phase into the gas phase.

In modeling, accurate OTR and CER estimations are essential for predicting cell growth and product formation. Oxygen limitation, for example, can significantly inhibit cell growth and shift metabolic pathways, resulting in reduced product yields. Similarly, high CO2 levels can also negatively impact cell growth and product quality. I commonly incorporate OTR and CER into bioreactor models using mass balance equations, considering factors like gas flow rates, agitation speed, dissolved oxygen concentration, and the specific metabolic characteristics of the cells.

For instance, the OTR can be modeled using the following equation:

OTR = KLa (C* - C)where KLa is the overall volumetric mass transfer coefficient, C* is the oxygen concentration at saturation, and C is the dissolved oxygen concentration.

CER is similarly modeled, often using stoichiometric relationships derived from the cellular metabolism or from experimental data relating CER to substrate consumption or cell growth rate. The interplay between OTR and CER and their impact on cellular physiology are vital in designing robust and efficient bioprocesses and optimizing bioreactor operation.

Q 17. Explain how you would model the effect of temperature on cell growth and product formation.

Modeling the effect of temperature on cell growth and product formation is crucial as temperature significantly influences enzymatic activity and cellular processes. I typically incorporate temperature effects through Arrhenius-type equations for growth rate and product formation rate.

The Arrhenius equation describes the relationship between reaction rate and temperature:

k = A * exp(-Ea / (R * T))where k is the rate constant, A is the pre-exponential factor, Ea is the activation energy, R is the ideal gas constant, and T is the absolute temperature. We can adapt this equation to describe the temperature dependence of the maximum specific growth rate (µmax) and product formation rate. In the models, µmax and the product formation rate are not constant but become functions of temperature (T).

For example, we might model the temperature dependence of µmax as:

µmax(T) = A_µ * exp(-Ea_µ / (R * T))Similarly, the product formation rate (qp) could be modeled as a function of temperature.

However, it’s important to consider that at very high or very low temperatures, the cell growth can be inhibited even if the kinetic equation shows an increase in the growth rate, so we’d include additional factors or adjustments to our equations to reflect this. I also incorporate the effects of temperature on other bioreactor parameters, such as oxygen solubility and viscosity of the culture broth, to create a comprehensive model.

The choice of parameters in these equations is determined by experimental data, using techniques like curve fitting or statistical modeling to find the best fit to experimental data obtained across a range of temperatures.

Q 18. How do you integrate process monitoring data into bioreactor models for real-time optimization?

Integrating process monitoring data into bioreactor models for real-time optimization is a key aspect of advanced bioprocess control. This involves using sensors to measure various parameters such as dissolved oxygen, pH, temperature, substrate concentration, cell density, and product concentration. This real-time data is then used to update and refine the bioreactor model, allowing for more accurate predictions and better control of the process.

There are several ways to integrate the data. A common approach is using a state observer or Kalman filter. This helps estimate unmeasured states (like cell concentration or intracellular metabolites) based on the measurements, improving the model accuracy. Another common approach is the use of data-driven methods. Here, algorithms analyze the large sets of process data to generate empirical models that can then be integrated into the simulation. These methods include machine learning techniques, which can discover complex patterns and relationships within the data that might be missed in more mechanistic models.

For example, a recurrent neural network (RNN) could be trained on historical data to predict future states of the bioreactor, which would then be used to guide real-time adjustments to process parameters. This allows for a more dynamic and responsive control strategy, optimizing the process based on the most up-to-date information. The output from the model is compared to the sensor data and any difference is used to correct the model or to trigger changes in the control strategy to maintain optimal process conditions.

This close coupling of data and model ensures the model reflects the current state of the bioreactor and improves both prediction accuracy and control efficiency, ultimately increasing product yield and quality.

Q 19. Describe your experience with different control strategies for bioreactors.

My experience encompasses a wide range of bioreactor control strategies, from simple Proportional-Integral-Derivative (PID) controllers to more advanced model predictive control (MPC) systems. PID controllers are widely used for regulating parameters like pH, temperature, and dissolved oxygen. They’re relatively simple to implement and effective for maintaining setpoints but can struggle with complex, nonlinear processes.

For more intricate bioprocesses, advanced control strategies are necessary. I’ve worked extensively with cascade control systems, where multiple controllers are linked to achieve precise control of several interdependent variables. For instance, a cascade controller might regulate the airflow to maintain dissolved oxygen by manipulating agitation speed, which is independently controlled using a second PID loop. I also have experience with feedforward control which anticipates process disturbances. This is particularly useful in fed-batch operations where the nutrient feed rate is adjusted based on predicted cell growth and substrate consumption rates.

Furthermore, I’ve implemented fuzzy logic controllers which are particularly useful when dealing with ambiguous data or when precise process models aren’t available. This allows for more robust control in the presence of uncertainty.

Finally, I am well-versed in the implementation of model predictive control techniques, which are used in more advanced bioreactor optimization processes. The choice of controller depends heavily on the specifics of the process, the level of available process understanding, and the complexity of the bioreactor system.

Q 20. Discuss the importance of model predictive control (MPC) in bioreactor operation.

Model Predictive Control (MPC) is a powerful technique that uses a process model to predict the future behavior of the bioreactor and optimize control actions accordingly. This offers significant advantages over traditional control methods in bioreactor operation.

Unlike PID controllers which only react to current errors, MPC takes into account future dynamics. By using a model to predict the system’s response to different control actions, MPC anticipates potential issues and actively prevents deviations from optimal setpoints, even in the presence of disturbances like fluctuating nutrient feeds or changes in environmental conditions. This results in tighter control and improved process performance.

MPC also allows for the incorporation of constraints. For example, it can maintain the dissolved oxygen above a certain level while keeping the agitation speed within acceptable mechanical limits. This feature is crucial in bioprocessing, where many parameters have operational constraints to ensure optimal cell growth and product quality. It enables the optimization of multiple process variables simultaneously. For instance, an MPC controller can optimize both biomass production and product yield by balancing nutrient feed rate, temperature, and pH. The result is a more efficient and robust bioprocess.

Moreover, MPC can handle complex nonlinear systems more effectively than PID controllers and adapts to changing process conditions more dynamically. Its predictive capabilities make it ideal for handling disturbances and improving robustness.

Q 21. Explain how you would design a fed-batch bioreactor strategy using modeling techniques.

Designing a fed-batch bioreactor strategy using modeling techniques involves developing a dynamic model that accurately reflects the bioreactor’s behavior over time. The strategy aims to optimize substrate feeding to maximize cell growth, product yield, or both. The key is to develop an accurate model and use it to predict the optimal feeding profile.

The process begins with defining the objective, such as maximizing product concentration or minimizing production time. The next step is the development of a dynamic model, which could incorporate models for cell growth, substrate utilization, and product formation kinetics. It’s important to choose an appropriate model structure, incorporating the relevant biological and physical processes. Parameters in the model are typically estimated using experimental data. For example, I could employ techniques such as nonlinear least squares regression or Bayesian inference to estimate the kinetic parameters.

After model validation, optimization techniques are applied to determine the optimal feeding profile. A common approach involves using numerical optimization algorithms to find the substrate feeding strategy that maximizes the defined objective function, while accounting for operational constraints such as maximum bioreactor volume. These could involve model predictive control (MPC) algorithms or nonlinear programming techniques.

For example, a simple model might employ Monod kinetics for cell growth and a linear relationship for product formation. The optimization would then determine the optimal feeding rate as a function of time to maximize the final product concentration, while adhering to constraints on the maximum bioreactor volume and the concentration of the feeding substrate. The optimal feeding strategy would then be implemented and verified experimentally. Further refinement of the model and feeding strategy is usually conducted through feedback from the experimental results. This iterative design process is critical for achieving a high-performing and robust fed-batch process.

Q 22. How do you incorporate nutrient limitations into your bioreactor models?

Nutrient limitations are crucial aspects of bioreactor modeling because they directly impact cell growth and product formation. We incorporate these limitations through various mathematical models, most commonly by employing Monod kinetics or its modifications. Monod kinetics describes the relationship between substrate concentration and specific growth rate. It assumes that the growth rate increases with substrate concentration, reaching a maximum value at high substrate levels, and asymptotically approaches this maximum.

Example: A typical Monod equation is: μ = μmax * S / (Ks + S) where μ is the specific growth rate, μmax is the maximum specific growth rate, S is the substrate concentration, and Ks is the half-saturation constant (the substrate concentration at which the growth rate is half of the maximum). In a model, we would integrate this equation into a system of differential equations that also describe cell growth and product formation, allowing us to simulate how nutrient limitation affects these factors.

Furthermore, more complex models might incorporate multiple substrates and competitive or synergistic interactions between them. For instance, we could have separate Monod terms for glucose and ammonium if both are limiting factors in our system. The choice of the model depends on the specific system and the available experimental data.

Q 23. What are some common challenges encountered during bioreactor model development and implementation?

Developing and implementing bioreactor models presents several challenges. One common issue is the complexity of biological systems. Cells are incredibly intricate, and their behaviour can be affected by numerous factors, many of which are difficult to measure or quantify precisely. For instance, cell-to-cell variability, and unanticipated metabolic shifts can lead to discrepancies between model predictions and experimental results.

Another challenge is obtaining high-quality, reliable data for model calibration and validation. Bioreactor experiments can be expensive and time-consuming, and the data generated may be noisy or incomplete. This necessitates careful experimental design and rigorous data analysis techniques.

- Parameter estimation: Determining the values of model parameters (e.g.,

μmax,Ks) can be challenging. Methods like nonlinear regression and Bayesian inference are commonly used, but they can be computationally intensive and sensitive to initial parameter guesses. - Model validation: Verifying that the model accurately reflects the real system is crucial. This often involves comparing model predictions to independent experimental data sets, which may not always be available.

- Model scalability: A model developed for one bioreactor configuration might not be easily transferable to another with different design parameters or operating conditions.

Finally, it’s important to remember that models are simplifications of reality. They can never perfectly capture the full complexity of biological systems, and it’s crucial to acknowledge the inherent limitations of any modeling approach.

Q 24. Describe your experience with using statistical methods for analyzing bioreactor data.

Statistical methods are indispensable for analyzing bioreactor data. I have extensive experience using various techniques to extract meaningful insights from experimental results and improve model accuracy. This includes:

- Regression analysis: To quantify relationships between independent and dependent variables. For example, I’ve used linear and nonlinear regression to estimate model parameters based on experimental data on cell growth, substrate consumption, and product formation.

- Statistical process control (SPC): To monitor and detect deviations from normal operating conditions. Control charts help identify potential problems in bioreactor operation, allowing for timely interventions.

- Design of experiments (DOE): To plan efficient and informative experiments that minimize the number of runs needed to optimize bioreactor operation. DOE helps identify the most significant factors influencing the process and their interactions.

- Principal component analysis (PCA): To reduce the dimensionality of complex datasets and identify patterns and trends in high-dimensional data.

For instance, in a recent project, I employed PCA to analyze a large dataset from a mammalian cell culture bioreactor. PCA effectively reduced the dimensionality of the data, revealing hidden relationships between different process parameters and cell behavior, leading to improvements in process control.

Q 25. How would you use bioreactor modeling to optimize product yield and quality?

Bioreactor modeling is a powerful tool for optimizing product yield and quality. By simulating the effects of different operating parameters, we can identify optimal conditions that maximize product output and meet desired quality specifications. For example, by simulating the impact of different feeding strategies, temperatures, or pH values on cell growth, productivity, and product quality attributes, we can determine the optimal process parameters and operational strategy for any given bioprocess.

Example: Let’s say we’re producing a therapeutic protein. We can use a bioreactor model to simulate the effects of different nutrient feeding strategies on protein yield and glycosylation patterns (which influences efficacy and safety). By running various simulations, we can identify the feeding strategy that yields the highest amount of protein with the desired glycosylation profile. This eliminates the need for extensive and costly experimental trials and allows for process optimization in a more efficient manner.

Sensitivity analysis is another useful technique to identify parameters having the largest impact on product yield and quality. This helps prioritize efforts to improve measurement and control of those key parameters. Optimization algorithms can further streamline the search for optimal process conditions.

Q 26. Explain your understanding of metabolic pathway modeling and its applications in bioreactor design.

Metabolic pathway modeling is crucial for understanding and improving bioreactor design. It involves creating a mathematical representation of the complex network of biochemical reactions within a cell. This allows us to predict how changes in environmental conditions or genetic modifications will affect cellular metabolism and product formation.

Metabolic pathway models, such as those built using Flux Balance Analysis (FBA) or constraint-based reconstruction and analysis (COBRA), can predict intracellular fluxes, providing insights into the efficiency of various metabolic pathways involved in product synthesis. This information can then be used to design bioreactor operating conditions that maximize flux through the desired pathways and minimize flux through competing pathways. Furthermore, these models enable us to predict how genetic modifications, such as overexpressing enzymes in a pathway, would impact the productivity of the cell.

Application: In designing a bioreactor for producing a particular metabolite, a metabolic model can be used to identify potential bottlenecks in the metabolic pathways leading to the desired product. Then, we can develop strategies to overcome these bottlenecks, such as optimizing nutrient feeding, or even implementing genetic modifications to enhance the activity of specific enzymes. These models can significantly improve the efficiency and yield of the bioreactor.

Q 27. How would you address issues related to cell viability and apoptosis in your bioreactor model?

Cell viability and apoptosis are critical parameters to include in bioreactor models because they directly affect product yield and quality. We typically incorporate these factors by including differential equations that describe the dynamics of viable cells, apoptotic cells, and potentially other cell populations (like necrotic cells). The model will account for factors that influence cell death, such as nutrient limitations, toxic byproducts, or shear stress from the bioreactor’s mixing.

Example: A simple model might include equations that describe the growth rate of viable cells and the rate of apoptosis (cell death). These rates could depend on factors like nutrient availability, oxygen concentration, and the concentration of toxic byproducts. For example, the rate of apoptosis might increase as the concentration of a toxic byproduct increases. We can introduce functions that represent these dependencies in our model equations.

By incorporating these parameters, we can predict how different operating conditions will affect cell viability and ultimately, the overall productivity of the bioreactor. This allows for strategies that minimize cell death and maximize product formation. We can also use the model to explore potential interventions, such as adding protective agents to the culture medium, to improve cell viability.

Q 28. Describe your approach to troubleshooting bioreactor process deviations using model-based analysis.

Model-based analysis is invaluable for troubleshooting bioreactor process deviations. When a deviation occurs, instead of resorting to trial and error, we use the model to diagnose the root cause. This involves comparing the model’s predictions to the observed data to identify discrepancies. These discrepancies indicate potential problems in the bioreactor.

Example: If the model predicts a higher cell density than observed experimentally, it might suggest nutrient limitations, problems with oxygen transfer, or the presence of inhibitory compounds. Similarly, if the model predicts a higher product concentration than what is experimentally observed, it might indicate product degradation or problems with downstream processing. A systematic analysis that evaluates the sensitivity of model outputs to different parameters could be particularly helpful.

A step-by-step approach might include:

- Data analysis: Carefully analyze the experimental data to identify the nature and extent of the deviation.

- Model comparison: Compare the model’s predictions to the observed data, identifying discrepancies.

- Sensitivity analysis: Determine which model parameters significantly affect the outcome.

- Root cause identification: Based on the analysis, determine the most likely root cause of the deviation.

- Corrective action: Implement corrective actions to address the identified problem.

- Model update: Refine the model parameters or structure based on the new insights gained from troubleshooting.

This model-based approach allows for a more efficient and effective troubleshooting process, minimizing downtime and optimizing bioreactor operation.

Key Topics to Learn for Bioreactor Modeling Interview

- Mass Balances: Understanding and applying mass balance principles to different components within a bioreactor (substrate, product, biomass). Practical application includes predicting substrate consumption rates and product formation.

- Kinetic Models: Exploring various kinetic models (e.g., Monod, Michaelis-Menten) to describe microbial growth and product formation. Practical application involves parameter estimation and model validation using experimental data.

- Stoichiometry: Determining the stoichiometric relationships between substrates, biomass, and products. Practical application: optimizing bioreactor operation for maximum yield.

- Bioreactor Types & Operation: Familiarizing yourself with different bioreactor types (e.g., stirred tank, airlift, photobioreactors) and their operational strategies (e.g., fed-batch, continuous). Practical application: choosing the appropriate bioreactor for a specific application.

- Model Calibration & Validation: Understanding techniques for calibrating and validating bioreactor models using experimental data. Practical application: ensuring model accuracy and reliability for process optimization.

- Software & Simulation: Gaining experience with relevant software packages for bioreactor modeling and simulation (e.g., MATLAB, Aspen Plus). Practical application: designing and optimizing bioprocesses using simulation tools.

- Process Control & Optimization: Exploring strategies for controlling and optimizing bioreactor performance, including feedback control loops and model predictive control. Practical application: maintaining optimal conditions for efficient production.

- Scale-up & Scale-down: Understanding the challenges and strategies involved in scaling bioprocesses up or down. Practical application: translating laboratory-scale results to industrial-scale production.

Next Steps

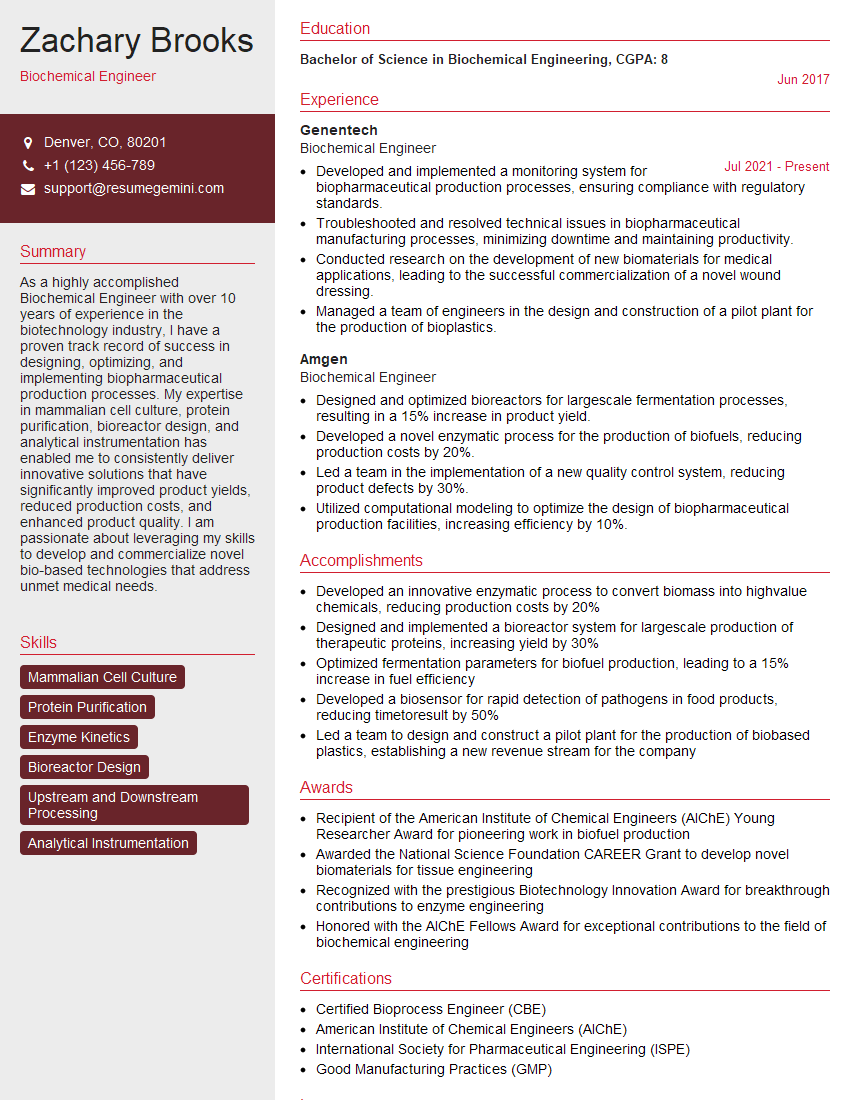

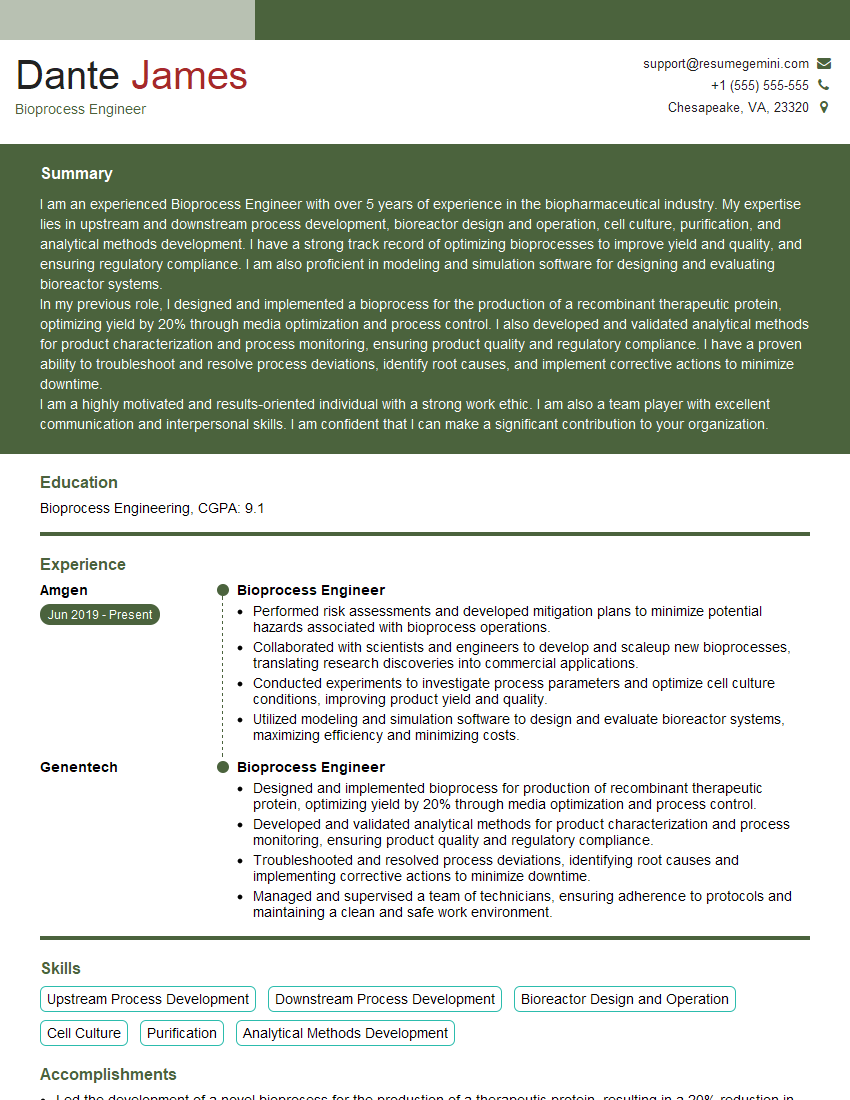

Mastering bioreactor modeling is crucial for a successful career in biotechnology, opening doors to exciting roles in process development, research, and optimization. A strong, ATS-friendly resume is your key to unlocking these opportunities. To ensure your resume effectively showcases your skills and experience, we recommend leveraging ResumeGemini, a trusted resource for creating professional and impactful resumes. ResumeGemini provides examples of resumes tailored specifically to Bioreactor Modeling, giving you a head start in crafting your application materials.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good