Cracking a skill-specific interview, like one for Bleed Creation, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Bleed Creation Interview

Q 1. What is bleed in print design and why is it necessary?

Bleed in print design refers to extending the important elements of your design, like images and colors, beyond the final trim size of your printed piece. Think of it as a safety margin. It’s necessary because the printing process isn’t perfectly precise; during trimming, the edges of the paper might be slightly uneven, resulting in a visible white border if your design stops exactly at the trim line. Bleed ensures that even with slight trimming inconsistencies, no white space will show up, resulting in a clean, professional finish.

Imagine you’re printing a postcard with a vibrant photograph extending to all edges. Without bleed, the slightest misalignment during trimming would reveal unsightly white edges, ruining the intended look. Bleed prevents this, ensuring a perfect, clean edge every time.

Q 2. Explain the standard bleed margins for various print sizes (e.g., letter, A4).

Standard bleed margins are typically 1/8 inch (3.175 mm) or 0.125 inches on all sides (top, bottom, left, right) for most print sizes. This applies to common formats like Letter (8.5 x 11 inches) and A4 (210 x 297 mm). However, always confirm the specific bleed requirements with your printer. Some printers might require more or less, depending on their equipment. It’s crucial to adhere to their specifications to avoid unexpected results. Larger print sizes often require a larger bleed, but the standard 1/8 inch remains a common starting point for accurate and safe bleed design.

Q 3. How does bleed differ between offset and digital printing?

While the concept of bleed remains the same for both offset and digital printing—to prevent white edges—the implementation can differ slightly. In offset printing, due to the use of larger sheets and multiple printing plates, the need for precise bleed is more critical. Digital printing, on the other hand, tends to be more precise because it prints directly onto the smaller paper sheets. However, even with digital printing, bleed is still highly recommended to account for slight variations in the cutting process and ensure consistent results. The amount of bleed may be the same (1/8 inch), but the tolerance for inaccuracies might be slightly higher with digital printing. Always confirm the bleed requirement for your specific printing method to guarantee a clean, professional finish.

Q 4. Describe the process of setting up bleed in Adobe Illustrator or InDesign.

Setting up bleed in Adobe Illustrator or InDesign involves defining the bleed area beyond the trim size of your document. In Illustrator, you create the artboard with the bleed included. After designing, ensure the design elements extend at least 1/8 inch (or as specified by the printer) beyond the trim size. In InDesign, you set the bleed in the document setup dialogue; it automatically adds the extra space to your document, ensuring you are designing within the bleed margins. Both programs allow for visual confirmation of your bleed area; make sure you can see the additional area beyond your trim size to prevent any errors.

Example (Illustrative): Let’s say you’re designing an 8.5 x 11 inch flyer. In InDesign, you would set your document size to 8.75 x 11.25 inches (adding 0.25 inches or 1/8 inch bleed on each side). Then, ensure your design elements extend to all edges of the 8.75 x 11.25-inch artboard.

Q 5. How do you ensure proper bleed when working with different file formats (e.g., PDF, PSD, AI)?

Ensuring proper bleed across different file formats requires careful attention to detail. When saving as a PDF, use the ‘press quality’ or ‘high resolution’ settings and ensure the bleed is included in the document’s settings (usually within the ‘Export’ or ‘Save As’ options). For PSD (Photoshop) files, make sure the bleed area is present in the canvas dimensions. Likewise, in AI (Illustrator), make sure the artwork extends into the bleed area. Regardless of the format, always check your file carefully before sending it to the printer; a visual inspection is crucial for identifying any potential issues with the bleed. If using PDF/X, it can help to ensure that the bleed is correctly embedded and the appropriate color profiles are included.

Q 6. What are the consequences of insufficient bleed?

Insufficient bleed leads to unsightly white borders around your printed piece, especially if the trimming process is slightly off. This makes your design look unprofessional and unfinished, undermining the overall quality of your project. It can also lead to disappointment among clients if the final product doesn’t match expectations. Imagine a business card with text that’s too close to the edge – a slightly uneven cut could chop off important information! Insufficient bleed is a common reason for costly reprints.

Q 7. What are the potential problems caused by excessive bleed?

Excessive bleed, while less common, can also cause problems. It can lead to extra printing costs if the excess bleed material is cut off during the trimming process, essentially wasting ink and paper. In rare cases, excess bleed might cause unwanted marks or blurring at the edges during the printing and cutting process. It’s important to strike a balance; follow the printer’s specifications for bleed, which is typically 1/8 inch. Anything more would usually be considered excessive and unnecessary.

Q 8. How do you handle bleed when working with images that have complex shapes or rounded corners?

Handling bleed with complex shapes or rounded corners requires meticulous attention to detail. The key is to ensure that the crucial design elements extend beyond the trim line by the specified bleed amount (typically ⅛ inch or 3mm), even in areas with curves. Think of it like painting a wall – you need to go slightly beyond the edges to ensure complete coverage after trimming.

I typically use vector-based software like Adobe Illustrator or CorelDRAW for this. These programs allow for precise control over shapes and paths, ensuring the bleed extends evenly around even the most complex curves. For raster images (like JPEGs or PNGs), I’ll often add a transparent layer with the bleed extension in the vector software before exporting the final file for print.

For example, imagine a logo with rounded corners. Instead of stopping the design at the trim line, I extend the logo’s background color and elements at least ⅛ inch beyond the trim marks. This way, even if there’s a slight shift during the printing and cutting process, the final product will show the complete logo without any white margins.

Q 9. What is the role of color management in bleed creation?

Color management is paramount in bleed creation to ensure color consistency across the entire printed piece. Without proper color management, you could experience unexpected color shifts between the bleed area and the final trimmed product. This is particularly crucial when using spot colors or complex color profiles like Pantone.

I always work in a consistent color space, usually CMYK for print, and ensure my software is properly calibrated. I utilize color profiles that match the printer’s capabilities. Any discrepancies in color profiles can lead to noticeable variations, especially near the trim line where the bleed meets the final print. A good workflow involves creating a proof using the same color space and settings as the final print, thereby checking the bleed’s color accuracy before sending the files to print.

Think of it like mixing paint – you need to use the same color palette and formulas throughout to ensure a seamless and consistent finish. Any variation in the palette can result in noticeable color differences.

Q 10. How do you prepare files for different printing methods regarding bleed?

Preparing files for different printing methods requires understanding the specific bleed requirements of each method. Offset printing typically requires a larger bleed than digital printing due to the mechanical processes involved. Large-format printing might have even more generous bleed allowances.

- Offset Printing: Typically requires a bleed of ⅛ inch (3mm) or more, depending on the printer’s specifications.

- Digital Printing: Often requires a smaller bleed, sometimes as little as 1/16 inch (1.5mm), or may not require bleed at all, depending on the printer and finishing processes. Always check with your printer.

- Large Format Printing: Can require significantly larger bleeds, sometimes up to ½ inch (12mm), due to the larger print size and potential for minor misalignment.

I always confirm the exact bleed requirements with the printer before starting the design process. This avoids costly rework and ensures a smooth printing process. Each printer has its own specifications, and using the wrong settings could result in the trimmed piece lacking important design elements.

Q 11. Explain the difference between trim and bleed.

The trim and bleed areas are distinct but closely related. The trim size represents the final dimensions of your printed piece after it’s cut. The bleed is the extra area added to the design beyond the trim size, allowing for slight shifts during cutting and printing. Think of it like adding extra fabric to a garment’s edges before cutting; it ensures a clean finish even with slight variations in cutting.

For example, if your final printed piece needs to be 8.5 x 11 inches, that’s the trim size. If you need a ¼ inch bleed, your design file should be 8.75 x 11.25 inches. This extra ¼ inch on all sides is the bleed, providing a buffer for the trimming process. The bleed area typically mirrors the design elements at the edge of the trim area to prevent unsightly white borders.

Q 12. How do you communicate bleed requirements to clients?

Communicating bleed requirements to clients requires clear and concise communication. I provide them with a simple, easy-to-understand document outlining the necessary bleed dimensions and the file format requirements. Visual aids like a template or diagram showing the trim area and bleed area greatly assist in understanding.

I often use a visual guide that shows the design area, the trim marks, and the bleed area clearly labeled. This eliminates any confusion and makes the process transparent. I also explicitly mention the file format (e.g., PDF/X-1a) and the required resolution to prevent any compatibility issues. Clear communication is key to avoid potential issues and ensure the final product matches their expectations.

Q 13. What are some common bleed-related issues you’ve encountered and how did you resolve them?

One common issue is clients providing files without enough bleed or with incorrect bleed settings. This often requires going back and forth, potentially delaying the printing process. To resolve this, I carefully review the provided files before proceeding and inform the client immediately if there are any issues. I’ll provide detailed instructions, sometimes even a template, to ensure they provide the correctly prepared files next time.

Another challenge involves mismatched color profiles leading to unexpected color shifts in the print. To address this, I emphasize using consistent color spaces and profiles throughout the design and printing process. Proofs are also crucial for verifying that the colors look accurate before proceeding with the printing process.

Occasionally, improper imposition (arrangement of pages on the printing sheet) can lead to problems. To prevent this, I utilize design software features for proper imposition and double-check each step of the process.

Q 14. How do you handle bleed in variable data printing?

Handling bleed in variable data printing (VDP) requires a slightly different approach. Since each piece in a VDP job might have unique content, the bleed needs to be dynamically managed. It’s not a simple case of adding a fixed bleed amount to a static design.

I ensure that the template for each data record includes the necessary bleed area. The variable data elements within the template should be carefully positioned to avoid cutting into essential design features. This often involves using a dedicated software that allows the bleed to be automatically applied to every data record, maintaining consistency while still allowing for variable content.

Careful planning and template design are crucial to ensure all variable elements stay within the safety zone, avoiding any cut-off elements and ensuring each printed piece has the necessary bleed, regardless of the data content.

Q 15. Explain the importance of creating crop marks and registration marks.

Crop marks and registration marks are crucial for accurate printing, especially when dealing with bleed. Think of them as guides for the printer. Crop marks indicate where the printed sheet should be trimmed to the final size, ensuring your design’s edges are precisely where you intended. Registration marks, on the other hand, are small, precisely placed marks that help align multiple colors or elements during the printing process. Without these, slight misalignments can lead to noticeable imperfections, especially in multi-color projects.

- Crop Marks: These are usually small cross-shaped marks printed outside the trim area, acting as a visual cue for the printer’s cutting machine. They guarantee a clean, accurate cut.

- Registration Marks: These small, precisely positioned marks are vital for aligning multiple colors perfectly. Imagine printing a vibrant logo; the registration marks ensure that each color layer (cyan, magenta, yellow, black) falls exactly where it should, preventing blurry or misaligned elements.

For example, consider a business card. The design might extend to the very edge, requiring bleed. Crop marks show where the cutter needs to trim, while registration marks guarantee that the front and back of the card align seamlessly.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you verify that bleed is correctly applied before sending files to print?

Verifying bleed before sending files is critical to avoid costly reprints. My process involves several steps:

- Proofing the PDF: I always create a high-resolution PDF proof including the bleed area. I zoom in at 100% and meticulously check if the design elements extend beyond the trim marks by the specified bleed amount (usually 3mm or 1/8 inch).

- Soft Proofing: I utilize the soft proofing capabilities of my design software (Adobe Acrobat Pro, for example) to simulate the printed output. This allows me to review the color accuracy and bleed extent accurately without physically printing a test copy.

- Measuring Bleed: I use the measuring tools within my software to double-check the precise dimensions of the bleed area and ensure consistent bleed around all sides of the document.

- Client Approval: I send the finalized proof to the client for final review and approval before sending it to the printer. This last step eliminates any last-minute surprises and ensures satisfaction.

Missing this step can result in unsightly white borders around your design after trimming, wasting time and money.

Q 17. What software tools are you proficient in for bleed creation and management?

My expertise spans various software essential for bleed creation and management. I’m highly proficient in:

- Adobe InDesign: My go-to for creating and managing complex layouts, especially for brochures, magazines, and multi-page documents. It offers excellent control over bleed settings and facilitates accurate crop and registration mark placement.

- Adobe Photoshop: I utilize Photoshop for image manipulation and ensuring images extend adequately into the bleed area, especially for photographic elements with important details at the edges.

- Adobe Illustrator: Ideal for vector-based designs where precise lines and shapes are crucial, ensuring clean bleed extension without any pixelation or quality loss.

- Adobe Acrobat Pro: Used for creating press-ready PDFs with accurate bleed settings, embedding color profiles and ensuring compatibility with various printing processes.

I also have experience with other software such as CorelDRAW and QuarkXPress, depending on project requirements.

Q 18. How do you handle bleed for folded brochures or leaflets?

Handling bleed for folded brochures or leaflets requires careful planning to ensure consistent bleed across all panels after folding. It’s not simply adding bleed to each panel individually.

The key is to visualize the final folded piece. The bleed area needs to be accounted for across panels that will meet after folding. For instance, if you have a tri-fold brochure, the bleed area should be considered such that when the panels are folded, there’s no visible gap or white space in the final folded product. This involves extending the design elements across the panels to accommodate the fold lines and the final trim size.

Software like InDesign helps manage this effectively by allowing pre-flight checks and visual confirmation before printing.

Q 19. What are the considerations for bleed in die-cutting?

Die-cutting introduces an additional layer of complexity to bleed management. Die-cutting uses a sharp die to cut shapes or outlines from the printed sheet. The key here is to add extra bleed beyond the intended cut line to avoid any visible white edges. This excess bleed is later removed during the die-cutting process.

The amount of extra bleed required depends on the intricacy of the die-cut shape and the type of material. The more intricate the cut, the more bleed you need to ensure a clean cut and prevent any unwanted white areas. Accurate die-line placement is crucial, often requiring vector-based artwork.

Failing to account for this can leave you with a finished product that looks unprofessional and shows incomplete shapes.

Q 20. How do you manage bleed for oversized prints or banners?

Oversized prints and banners present unique challenges because of their size and the potential for discrepancies during printing and installation. The key is meticulous planning and the use of high-resolution files. Bleed requirements might be increased to account for stretching and potential inaccuracies during the mounting process. Careful consideration of the printing method and materials used is necessary to avoid issues with color variations, alignment, and overall quality.

For very large banners, it might be necessary to divide the design into multiple sections for printing and then carefully assemble them on-site, demanding accurate bleed and registration marks on each section to ensure seamless joining.

Q 21. Explain your process for creating and managing print-ready files with bleed.

My process for creating and managing print-ready files with bleed is a systematic approach focusing on accuracy and efficiency:

- Design & Layout: I start by creating the design, ensuring all important elements extend beyond the final trim line by the specified bleed amount (typically 3mm or 1/8 inch).

- Crop & Registration Marks: I then add crop and registration marks using my chosen software’s features, ensuring they are precisely positioned and accurately reflect the intended trim area.

- Color Management: I create the file using a consistent color profile and verify the color accuracy throughout the process. This ensures the final printed product matches the on-screen preview.

- File Format: I save the file as a high-resolution PDF (usually PDF/X-1a) compliant with industry standards and optimized for printing.

- Proofing & Verification: Before final submission, I meticulously review the PDF at 100% zoom and utilize soft-proofing tools to check the bleed, registration marks, and overall accuracy. This ensures there are no last-minute surprises.

- Client Review & Approval: The final PDF is reviewed and approved by the client before it is sent to the printer.

This detailed approach minimizes the chances of errors and ensures the final printed piece meets the highest quality standards.

Q 22. Describe your experience with preflighting files for bleed accuracy.

Preflighting files for bleed accuracy is a crucial step in the print production process. It involves meticulously checking the artwork to ensure that elements extending beyond the trim edge (bleed) are present and meet the specified requirements. My process begins with verifying the document’s dimensions and the designated bleed area, typically 3mm or 1/8 inch on all sides. I use preflight software like Acrobat Pro or other dedicated tools to analyze the file for missing or insufficient bleed, color issues near the edges, and potential problems with image resolution. I check for any color or image clipping that may occur once the final product is trimmed to the desired size. I also review the color profile and ensure it aligns with the printer’s specifications to avoid unexpected color shifts during printing. For example, I would flag a design where text or important logos are too close to the edge, risking being cut off during trimming. A successful preflight check results in a clean report, confirming that the file is ready for printing without the risk of unsightly white edges.

Q 23. What are some industry best practices for bleed implementation?

Industry best practices for bleed implementation prioritize clear communication and consistent application. This includes:

- Clearly defined bleed specifications: Providing precise dimensions (e.g., 3mm bleed) in the design brief and artwork templates.

- Using templates: Providing pre-made templates with bleed guides integrated directly into the design. This ensures designers automatically build in the correct amount of bleed.

- Color management: Maintaining consistent color profiles throughout the design and print processes to prevent unexpected color variations, particularly near the edges.

- Regular preflight checks: Performing thorough preflight checks on every file before sending it to the printer or finishing house.

- Communication with printers: Consulting with the printer regarding their specific bleed requirements and any additional considerations. This is crucial because the printer’s trimming process may vary.

Following these best practices minimizes errors and ensures a professional finish.

Q 24. How do you ensure consistency in bleed across different projects?

Consistency in bleed across different projects is achieved through standardization and process management. I maintain a style guide that details the precise bleed requirements for various print products, such as business cards, brochures, posters, etc. This guide is shared with all designers involved in the project. I also use pre-defined templates that automatically incorporate the correct bleed areas, eliminating the possibility of manual errors. Furthermore, utilizing a centralized preflight checklist helps to identify and rectify potential bleed discrepancies early on in the workflow. Regularly reviewing the print files against these standards ensures that we maintain consistent quality across all our projects, regardless of the designer or the project’s complexity.

Q 25. Have you ever had to troubleshoot a problem with incorrect bleed? If so, describe the situation and your solution.

In one instance, a client submitted a brochure design with insufficient bleed. During the preflight process, I discovered that crucial imagery was too close to the trim line, risking a significant portion being cut off during the finishing process. I immediately contacted the client and explained the issue, providing visual examples highlighting the risk. We collaborated to find a solution: we either extended the relevant artwork to meet the required bleed specifications or slightly adjusted the layout to move critical elements further away from the edge. We opted for the latter to retain the design integrity. It was a timely intervention that prevented a costly reprint and satisfied the client by maintaining the visual appeal.

Q 26. Explain how you would explain the concept of bleed to a non-technical client.

Imagine you’re printing a photograph. The image you see is the part that will be visible after printing. However, the printing process requires the image to extend slightly beyond the final edge. This extra area is called ‘bleed’. It ensures that even after the excess is trimmed away, the final printed piece has no unsightly white borders, even if there’s a slight shift during trimming. It’s like adding a small border to your picture before you get it printed, but the border will be cut off in the end, leaving a clean, crisp edge. We add bleed to your design to make sure your final product looks perfect!

Q 27. What are the implications of ignoring bleed requirements?

Ignoring bleed requirements can have serious consequences. The most immediate impact is the appearance of unsightly white borders around the printed piece. This unprofessional look undermines the quality and impact of the design. In more severe cases, critical design elements like text or logos might get partially or entirely cut off, rendering the print unusable and requiring expensive reprints. Ignoring bleed can also lead to delays in the production timeline due to the need for corrections or reprint requests. Ultimately, it impacts the client’s satisfaction and damages the company’s reputation.

Q 28. Describe a time you had to adapt your approach to bleed creation due to a client’s specific requirements.

One client had specific requirements for a die-cut business card. Their design featured a complex shape that extended beyond the standard rectangular trim area, requiring a specialized bleed approach. While my standard process focused on rectangular bleeds, this project demanded a more intricate solution. I worked closely with the client and the print house to define a custom bleed template that reflected their unusual shape. This required additional steps and closer collaboration to ensure the die-cut would precisely follow the intended design, preventing any cutting issues. The outcome was a high-quality product that met the client’s unique vision and highlighted the adaptability of my approach.

Key Topics to Learn for Bleed Creation Interview

- Understanding Bleed: Define bleed and its importance in print design and digital media. Explore different types of bleeds and their applications.

- Practical Applications: Discuss how bleed affects the final printed or displayed output. Analyze scenarios requiring different bleed settings and their impact on the design.

- Software Proficiency: Demonstrate your knowledge of design software (e.g., Adobe InDesign, Photoshop, Illustrator) and how you utilize them to set up and manage bleeds effectively.

- File Preparation: Explain the process of preparing files for print with correct bleed settings, ensuring a professional and high-quality final product. Discuss file formats and resolution considerations.

- Troubleshooting Bleed Issues: Describe common problems encountered during bleed setup and how you would troubleshoot and solve them. This includes understanding and resolving discrepancies between design software and printing processes.

- Client Communication: Explain how you communicate technical aspects of bleed to clients, ensuring they understand the implications of their design choices.

- Color Management and Bleed: Discuss how color profiles and color spaces affect bleed and the final output. Explain your understanding of color management best practices in relation to bleed.

Next Steps

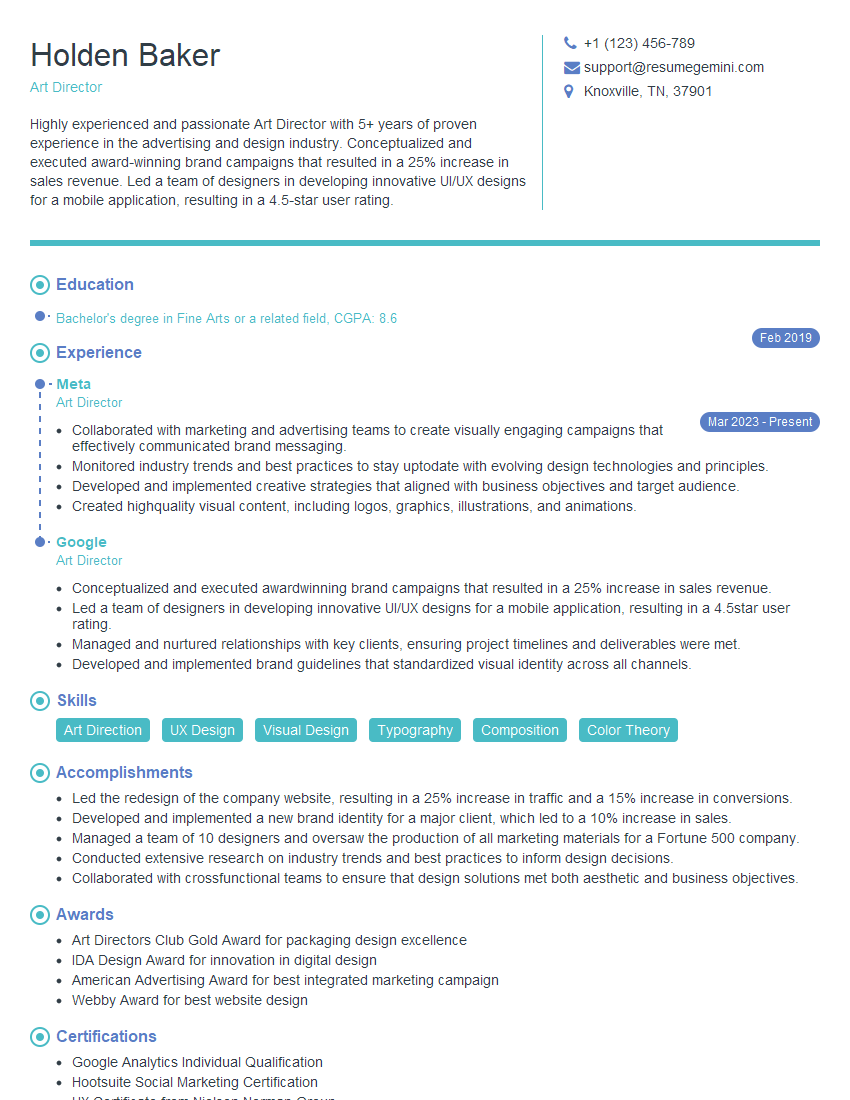

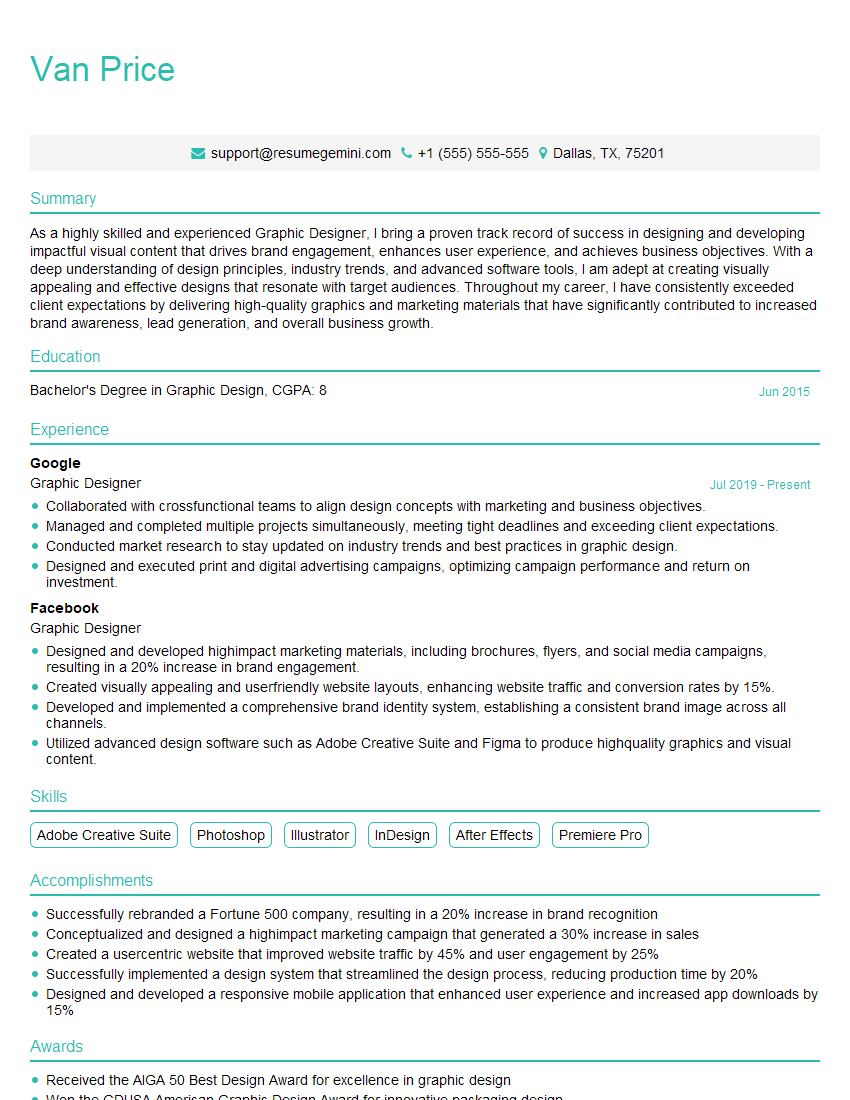

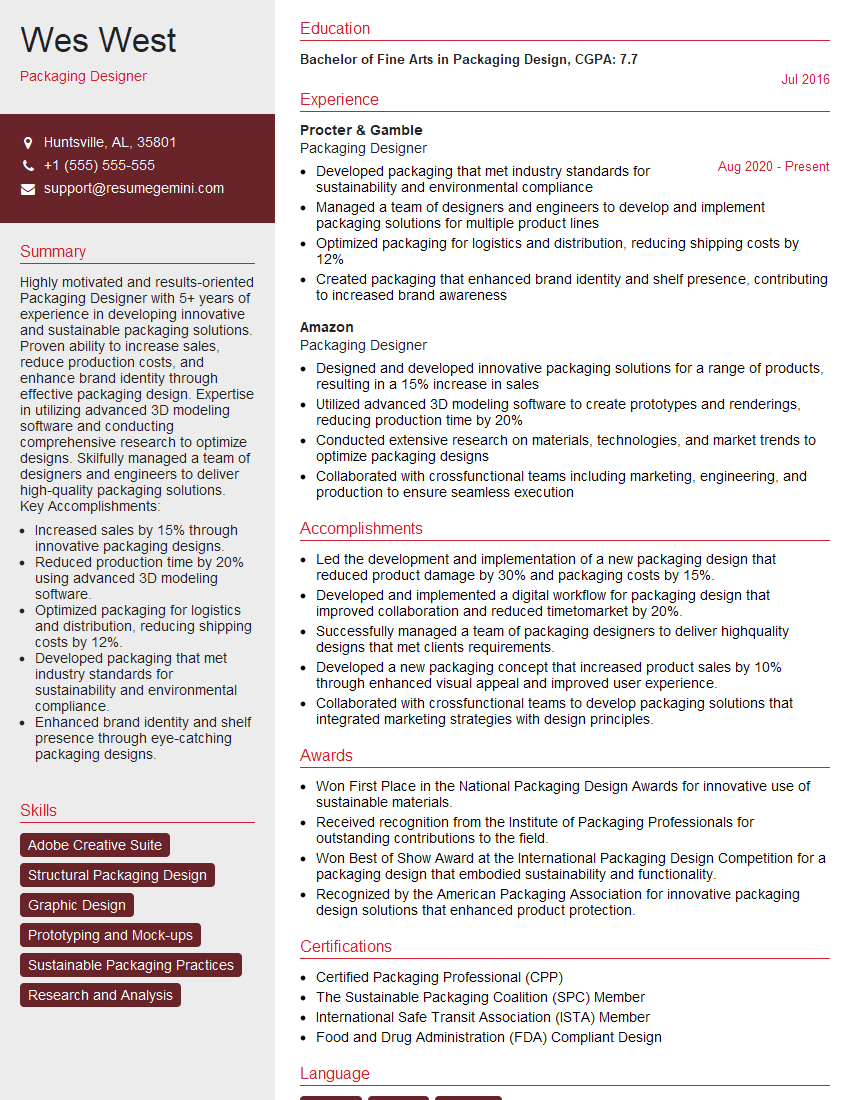

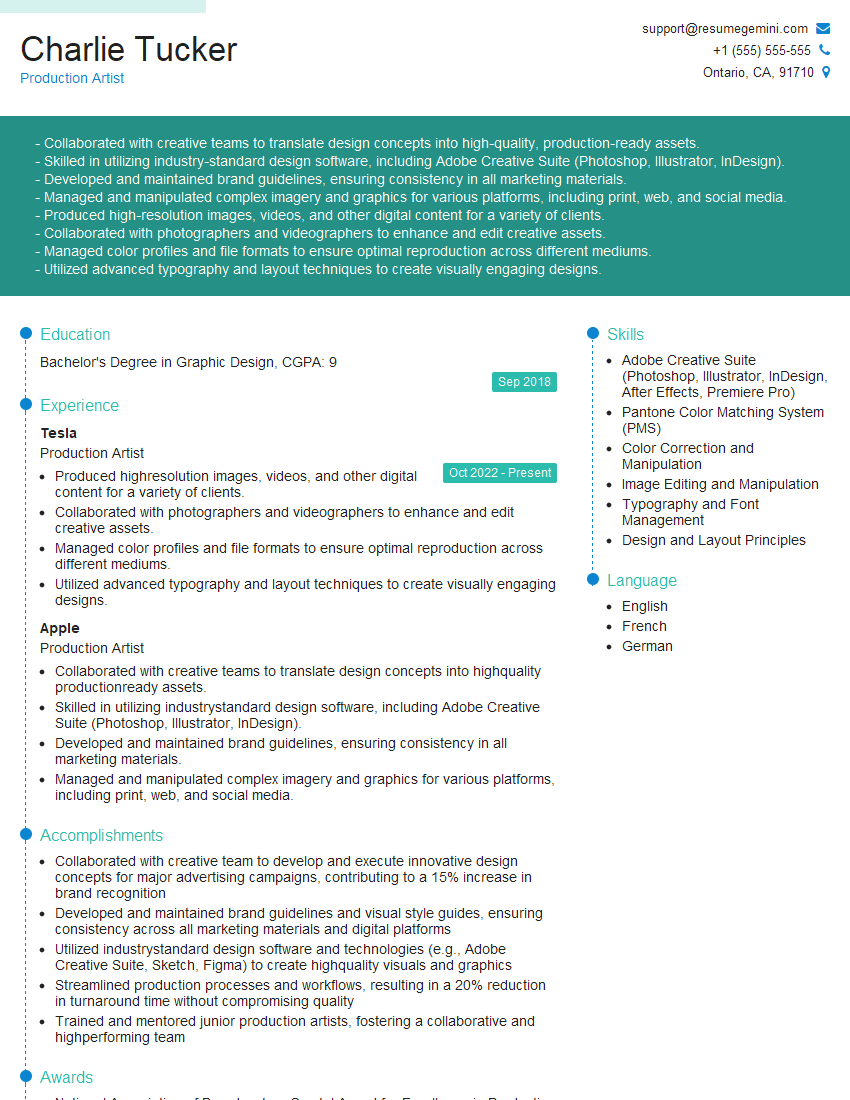

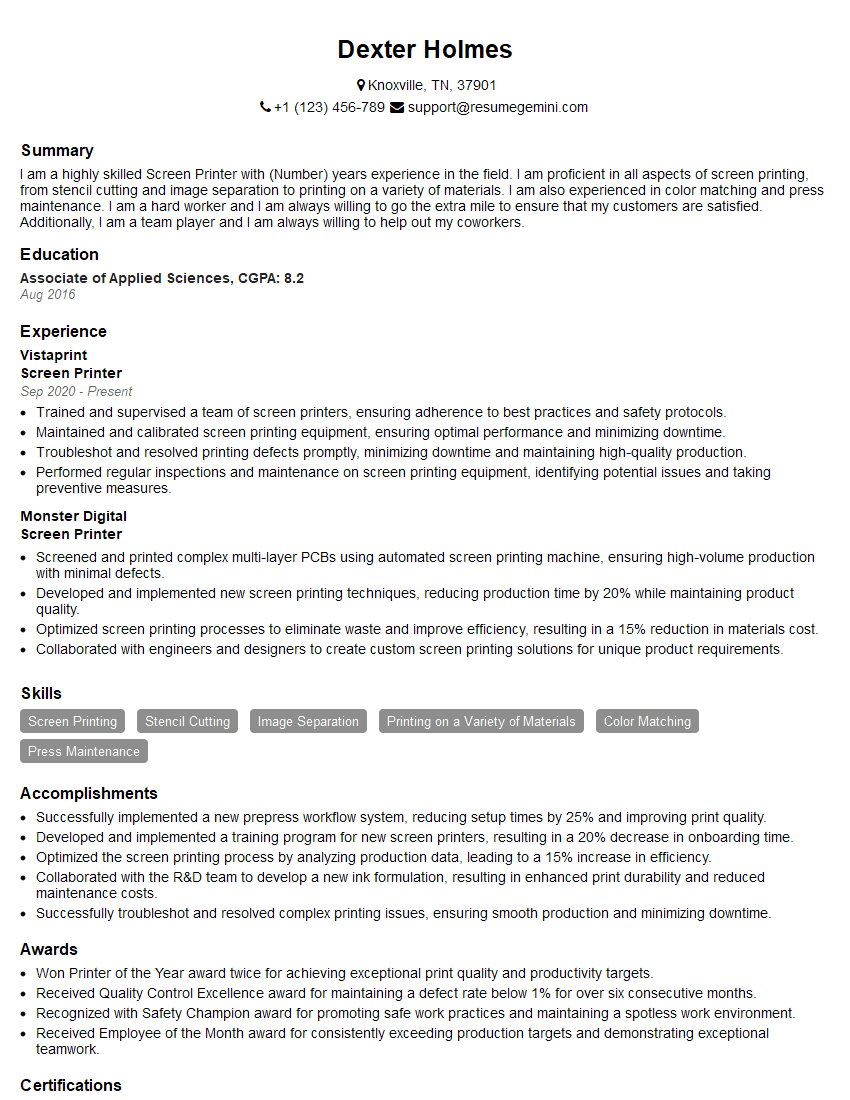

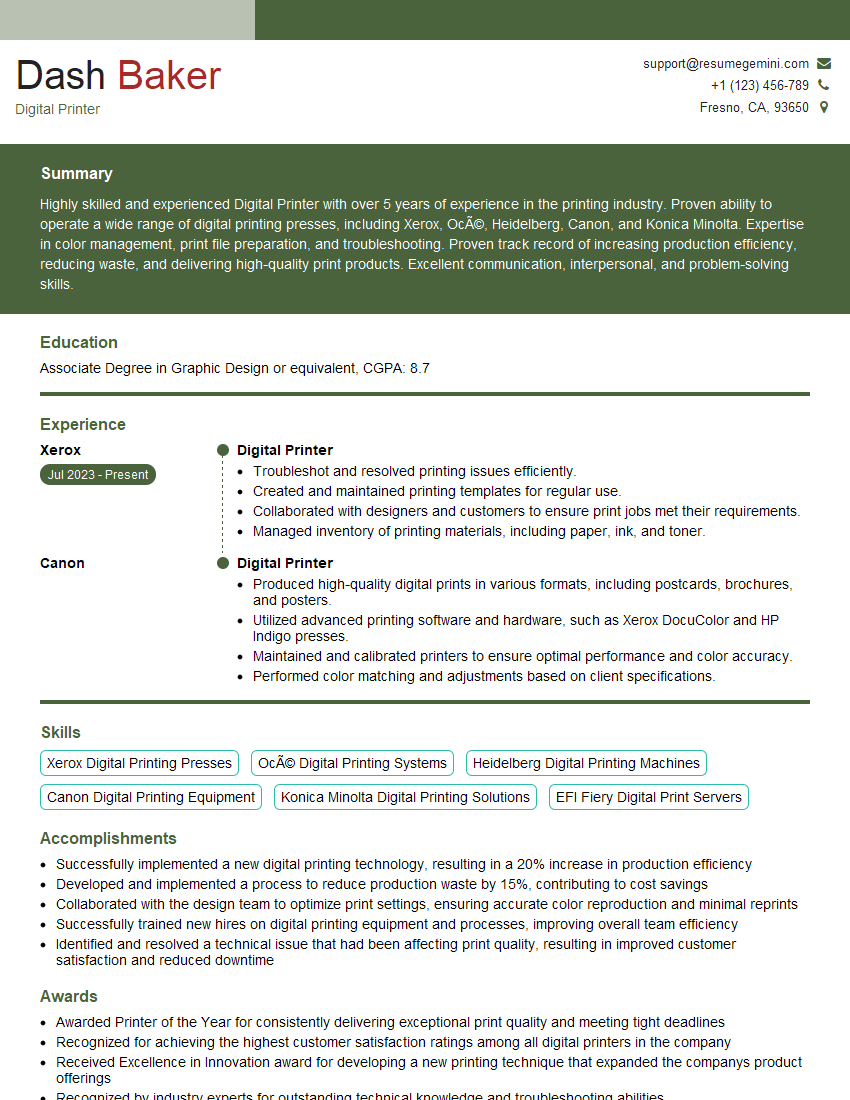

Mastering Bleed Creation is crucial for success in the graphic design and print production fields, opening doors to exciting career opportunities and higher earning potential. A strong understanding of bleed demonstrates attention to detail and technical proficiency – highly valued qualities in any creative role. To maximize your job prospects, creating an ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you build a professional and effective resume that highlights your skills and experience. Examples of resumes tailored to Bleed Creation are available to help guide you. Take the time to craft a compelling resume – it’s your first impression with potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good