Unlock your full potential by mastering the most common Bobbin Loading and Unloading interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Bobbin Loading and Unloading Interview

Q 1. Describe your experience with different types of bobbins.

My experience encompasses a wide range of bobbins, from the standard plastic bobbins used in home sewing machines to the metal bobbins found in industrial settings. I’ve worked with different sizes, shapes, and capacities, including those designed for specific thread types like embroidery or heavy-duty stitching. For instance, I’ve extensively used class 15 bobbins for their reliability in high-speed applications, while smaller, class 6 bobbins were ideal for delicate fabrics. I’m familiar with pre-wound bobbins for convenience and also with empty bobbins requiring manual winding. The variations in materials – plastic, metal, and even some composite materials – each have implications for durability, thread capacity, and compatibility with specific sewing machines.

- Plastic Bobbins: Commonly used in home sewing machines; lightweight, inexpensive, and readily available.

- Metal Bobbins: Often found in industrial machines; more durable and suitable for heavy-duty applications.

- Pre-wound Bobbins: Save time by eliminating the need for manual winding; can be more expensive.

Q 2. Explain the process of loading a bobbin onto a sewing machine.

Loading a bobbin is a straightforward process but requires attention to detail. First, you open the bobbin case compartment on your sewing machine (the location varies depending on the model). Next, gently place the bobbin into the bobbin case, ensuring it sits correctly; often, there’s a specific orientation indicated by notches or arrows on both the bobbin and the case. The thread should then be guided through the designated slot on the bobbin case and pulled through a small opening. It’s crucial to ensure the thread is threaded correctly, as improper threading can lead to issues like skipped stitches or thread breakage. Once the bobbin is correctly seated and the thread is pulled through, you close the compartment and you’re ready to sew. I always double-check the placement to prevent common loading mistakes.

Think of it like carefully loading a cartridge into a video game console – precision matters for a smooth experience.

Q 3. How do you identify a defective bobbin?

Identifying a defective bobbin involves a visual inspection and a test run. Visually, I look for any damage like cracks, warping, or rough edges on the bobbin itself. Uneven winding, where the thread is bunched up in some areas and loose in others, is also a major red flag. Sometimes, you might find that the bobbin is not properly wound or that the thread is too loose or too tight. For the test run, I’ll thread the bobbin and sew a sample stitch. If I notice any skipped stitches, thread breakage, or the machine behaving erratically, it points toward a defective bobbin. A consistently uneven stitch quality even after other machine settings are verified can also point to a problem with the bobbin.

Q 4. What are the common problems encountered during bobbin loading?

Common problems during bobbin loading include incorrect bobbin placement, improper threading of the bobbin case, and using the wrong type of bobbin for the machine. Sometimes, the bobbin case itself might be damaged or dirty, preventing the bobbin from working correctly. Another frustrating issue is when the bobbin is not wound tightly enough, leading to thread slippage during sewing. I’ve even encountered instances where a tiny piece of lint or debris was jamming the bobbin case mechanism, causing the bobbin to not feed correctly. These problems highlight the importance of careful attention to detail and regular cleaning and maintenance of your sewing machine.

Q 5. How do you troubleshoot bobbin-related issues on a sewing machine?

Troubleshooting bobbin-related issues is systematic. First, I visually inspect the bobbin and the bobbin case for any damage or obstructions. I then check the threading of the bobbin case, ensuring the thread is properly routed. Next, I test a new bobbin to rule out any issues with the original bobbin. If the problem persists, I clean the bobbin case and the shuttle mechanism thoroughly, removing any lint or debris. If the problem continues after all these steps, a deeper mechanical inspection of the sewing machine might be necessary.

It’s a process of elimination. I start with the simplest and most common causes and progressively investigate more complex issues.

Q 6. Describe your experience with high-speed bobbin loading/unloading.

My experience with high-speed bobbin loading/unloading involves industrial sewing machines operating at significantly faster speeds than domestic machines. This necessitates the use of specialized bobbins and mechanisms for quick and efficient changeovers, minimizing downtime. In such high-speed environments, the quality and consistency of the bobbin become even more crucial. A defective bobbin or improper loading can lead to serious issues like thread breakage or even machine damage. Efficient bobbin handling is key to maximizing productivity in an industrial setting. In these high-volume scenarios, automated systems for bobbin loading and unloading are often employed to significantly improve efficiency and reduce human error.

Q 7. What safety precautions do you follow when handling bobbins?

Safety is paramount when handling bobbins. Sharp bobbin edges can cause injury, so I always handle them carefully. I avoid leaving bobbins scattered around, as they can create tripping hazards. If working with pre-wound bobbins, I check the packaging for any damage before handling and make sure to dispose of the packaging properly. Furthermore, I always ensure the machine is turned off before opening the bobbin case to avoid accidental injury. In industrial settings, additional safety measures, including protective eyewear, may be required.

Q 8. How do you ensure the efficient and consistent loading of bobbins?

Efficient and consistent bobbin loading is crucial for maintaining production speed and yarn quality. It involves a systematic approach focusing on several key areas.

- Proper Preparation: Before loading, inspect the bobbins for any damage or imperfections. Ensure the bobbin is correctly oriented and free from debris.

- Consistent Winding Tension: Maintaining uniform tension during winding prevents yarn breakage and ensures even distribution on the bobbin. This often requires calibration and regular monitoring of the winding machine.

- Optimized Loading Process: Employing standardized procedures for inserting bobbins into the machines minimizes errors and ensures consistent loading. This includes proper alignment and secure placement to prevent slippage.

- Regular Maintenance: Keeping the bobbin loading equipment clean and well-maintained (e.g., checking for wear and tear on guides and rollers) prevents jams and ensures smooth operation.

- Operator Training: Well-trained operators are key. Providing thorough training on loading procedures, recognizing potential problems, and troubleshooting minor issues significantly improves efficiency and consistency.

For example, in a textile mill, I implemented a visual checklist for operators, reducing loading errors by 15% in the first month. The checklist highlighted key steps and potential problems, leading to immediate improvements in efficiency and yarn quality.

Q 9. What is your experience with different types of bobbin winding machines?

My experience encompasses a wide range of bobbin winding machines, from traditional manual models to fully automated, high-speed systems. I’ve worked with:

- Precision Winder: These machines provide accurate and consistent winding, crucial for fine yarns and high-quality fabrics. I’ve utilized several models from different manufacturers, focusing on their specific strengths in terms of speed, precision, and yarn type handling.

- Automatic Cone Winders: I have experience with fully automated systems that handle large volumes of bobbins, optimizing production significantly. These usually include features like automatic doffing and bobbin loading systems.

- Modified Winder for Specific Yarns: I’ve worked with machines adapted for special yarn types, like textured yarns or those requiring specific tension profiles. Adaptation often involves adjusting parameters like winding speed, tension, and traverse pattern.

Understanding the nuances of each machine type is critical. For instance, the maintenance requirements for a precision winder differ considerably from those of a high-speed automatic system. Regular calibration and preventative maintenance are essential across all machine types to guarantee consistent output and minimize downtime.

Q 10. Explain the importance of proper bobbin tension.

Proper bobbin tension is paramount for yarn quality and efficient processing. Insufficient tension leads to loose winding, resulting in yarn slippage, breakage during weaving, and uneven fabric density. Conversely, excessive tension can cause yarn damage, uneven winding, and machine malfunctions.

Optimal tension varies depending on the yarn type, bobbin size, and machine parameters. It’s crucial to:

- Regularly monitor and adjust tension: Use tension gauges and machine settings to maintain the ideal tension throughout the winding process.

- Use appropriate winding parameters: Machine settings such as winding speed and traverse rate need to be customized based on the yarn type and bobbin size.

- Maintain machine components: Worn-out components, such as tension rollers and braking systems, can affect tension consistency, requiring prompt replacement or repair.

Imagine trying to wind a kite string onto a spool; too loose, and it’ll unravel, too tight, and the string will break. Bobbin tension is similar. Fine-tuning it is crucial for quality control and minimizing production losses.

Q 11. How do you maintain the quality of bobbins during storage?

Maintaining bobbin quality during storage is vital to prevent damage and maintain yarn integrity. This involves several key steps:

- Clean and Dry Storage: Bobbins should be stored in a clean, dry environment to prevent moisture absorption, which can affect yarn properties and cause mildew.

- Proper Organization: Organized storage prevents damage from stacking or crushing. Using appropriate shelving and racking systems is critical.

- Protection from Light and Dust: Exposure to sunlight and dust can degrade yarn quality. Covering bobbins or storing them in enclosed containers is recommended.

- FIFO System: Employing a First-In, First-Out (FIFO) system minimizes the risk of storing bobbins for excessively long periods.

In one project, we implemented a climate-controlled storage area for bobbins, significantly reducing yarn degradation due to humidity and extending bobbin shelf life.

Q 12. How do you manage a large inventory of bobbins?

Managing a large bobbin inventory effectively requires a robust system combining physical organization with efficient inventory management software.

- Barcoding and Tracking: Assigning unique barcodes to each bobbin enables efficient tracking throughout the entire process, from winding to usage.

- Inventory Management Software: Software solutions allow for real-time tracking of bobbin quantities, locations, and usage data. This prevents stockouts and overstocking.

- Organized Storage: Efficient storage areas are crucial. Categorizing bobbins by yarn type, size, and quality further streamlines retrieval.

- Regular Inventory Audits: Periodic audits ensure accuracy and identify discrepancies in stock levels. This helps to improve forecasting and minimize waste.

For example, using an inventory management system helped us reduce our storage space by 10% while maintaining a sufficient supply of bobbins, reducing storage costs significantly.

Q 13. What is your experience with automated bobbin loading systems?

My experience with automated bobbin loading systems includes working with various robotic and automated systems that significantly increase efficiency and reduce labor costs. These systems typically:

- Reduce manual handling: Minimizing human interaction reduces the risk of errors and injuries.

- Increase loading speed: Automated systems load bobbins much faster than manual processes.

- Improve consistency: They load bobbins with greater precision and consistency.

- Integrate with other systems: They often seamlessly integrate with other automated systems in the production line, optimizing the entire process.

I’ve overseen the implementation and maintenance of several automated bobbin loading systems, focusing on maximizing uptime and efficiency. For instance, by optimizing the robotic arm’s movement and integrating predictive maintenance, we reduced downtime by 20%.

Q 14. How do you handle bobbin jams or breakages?

Handling bobbin jams or breakages requires a systematic approach to minimize downtime and prevent further issues.

- Immediate Stoppage: Stop the winding machine immediately to prevent further damage.

- Identify the Cause: Carefully examine the bobbin and the machine to determine the root cause of the jam or breakage. This might involve examining yarn quality, tension settings, or machine components.

- Safe Removal: Carefully remove the jammed bobbin or broken yarn, avoiding damage to the machine or surrounding components.

- Corrective Action: Address the root cause. This might involve adjusting machine settings, replacing damaged parts, or addressing yarn quality issues.

- Preventive Measures: After resolving the immediate problem, implement preventive measures to reduce the likelihood of similar incidents in the future.

I’ve developed a troubleshooting flowchart that guides operators through the process of diagnosing and resolving bobbin jams, reducing downtime by 35% in a particular production line. This flowchart incorporates visual aids and clear instructions for identifying the cause and implementing the appropriate solution.

Q 15. What is your understanding of bobbin thread types and their applications?

Bobbin thread types vary significantly depending on the fabric and desired stitch quality. Understanding these differences is crucial for successful sewing. Common types include:

- Polyester thread: Strong, versatile, and resistant to shrinking, making it ideal for most fabrics. It’s a workhorse in many applications.

- Cotton thread: A natural fiber offering a softer hand and suitable for delicate fabrics like linen or cotton. However, it can be prone to breakage under stress.

- Silk thread: Known for its luxurious sheen and drape, it’s frequently used for high-end garments and embroidery. It’s more delicate than polyester or cotton.

- Nylon thread: Very strong and stretchy, making it suitable for stretchy fabrics like Lycra or swimwear. It’s also commonly used for serging.

- Rayon thread: A semi-synthetic fiber with a smooth finish. It’s often blended with other threads to enhance sheen or drape.

Choosing the right thread is vital. For example, using a cotton thread on a heavy-duty sewing machine might result in frequent breakage, while using a delicate silk thread on denim would likely snap. The project’s demands—durability, aesthetic, fabric type—dictate the appropriate thread selection.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with different bobbin sizes and their compatibility.

My experience encompasses a wide range of bobbin sizes, from the tiny Class 15 bobbins used in miniature sewing machines to the larger Class 66 bobbins common in industrial models. Compatibility hinges on two key factors: the sewing machine’s design and the bobbin’s dimensions. Incorrect bobbin sizing can lead to jamming, inconsistent stitching, or even damage to the machine.

I’ve worked with various systems, including those with dedicated bobbin cases (like many home sewing machines) and those using a simpler drop-in bobbin system. In each case, careful attention to the manufacturer’s specifications is paramount. For example, using a Class 15 bobbin in a machine designed for Class 66 bobbins would not fit, and attempting to force it could break the machine’s components. I always cross-reference the bobbin size with the machine’s manual before loading.

I’m also familiar with different bobbin shapes, some being completely round while others are slightly conical. This also impacts compatibility and must be carefully matched to the machine design.

Q 17. How do you identify and resolve bobbin winding inconsistencies?

Bobbin winding inconsistencies, such as uneven tension or bird’s nests, significantly impact stitch quality. My approach to identifying and resolving these issues is systematic:

- Visual Inspection: I carefully examine the wound bobbin for any irregularities, like loose loops or areas of inconsistent density. This often reveals the problem’s source.

- Tension Check: I check the bobbin case tension and the machine’s tension settings. Too much tension can lead to tight winding and breakage, while too little results in loose, uneven winding. Adjustment is often necessary.

- Winding Speed: The speed at which the bobbin is wound can affect the outcome. Fast winding may produce less consistent results. Adjusting to a slower speed often improves winding quality.

- Bobbin Case Condition: A damaged or dirty bobbin case can contribute to uneven winding. Cleaning and replacing the bobbin case if needed is often effective.

- Thread Quality: Using low-quality or damaged thread can also lead to issues. Using a fresh spool of thread can be a simple solution.

I’ve found that meticulous attention to detail during the winding process, including using appropriate tension, speed, and thread, significantly reduces inconsistencies. For particularly persistent problems, consulting the machine’s manual or a qualified technician is recommended.

Q 18. How do you ensure the correct bobbin is used for each sewing machine?

Ensuring the correct bobbin for each sewing machine is crucial for preventing malfunctions and ensuring consistent stitch quality. My process involves:

- Referencing the Machine Manual: Every sewing machine’s manual specifies the correct bobbin size and type. I always start here.

- Bobbin Labeling: I maintain a system of clearly labeling bobbins with their size and the thread type. This ensures correct usage and reduces mistakes.

- Visual Inspection: Before loading, I visually confirm the bobbin’s size matches the machine’s requirements. I’ve had instances where an improperly labeled bobbin was mistaken, leading to a jammed machine.

- Testing: After loading, I always run a short test stitch to verify proper function. This early detection of mismatches prevents larger problems down the line.

A structured approach and diligent attention to detail are key to avoid using incorrect bobbins. Using a consistent, well-organized system helps minimize human error and potential damage to the machines.

Q 19. What is your experience with bobbin recycling or disposal procedures?

Bobbin recycling and disposal procedures depend heavily on the thread type and local regulations.

For recycling, I focus on separating bobbins based on material—plastic or metal—and ensuring they’re clean and free of residual thread. Many municipalities have specific recycling programs for plastics, and some companies specialize in recycling industrial bobbins.

For disposal, I always adhere to local regulations. This often involves disposing of bobbins in the appropriate waste stream, which may vary depending on the bobbin’s material and any potential hazardous components.

Ultimately, responsible bobbin management includes both recycling options where available and proper disposal according to regulations. It minimizes environmental impact and ensures compliance.

Q 20. How do you contribute to a safe and efficient work environment in regards to bobbins?

A safe and efficient work environment regarding bobbins involves several key considerations:

- Organized Storage: Bobbins should be stored neatly and clearly labeled to prevent confusion and accidents. This also aids in quick retrieval of the correct bobbins.

- Safe Handling: Avoiding sharp edges and practicing good housekeeping minimizes the risks of cuts or injuries. This includes using proper handling techniques and keeping the work area clear of debris.

- Waste Management: Proper disposal or recycling procedures prevent accumulation of waste and maintain a clean work environment. This also helps avoid environmental hazards.

- Regular Maintenance: Routine inspection and maintenance of bobbin winding equipment helps prevent malfunctions that could lead to injury or inefficient operation.

By proactively addressing safety and efficiency, a smooth workflow is maintained. This translates to a safer workplace with fewer incidents and greater productivity.

Q 21. Explain your approach to quality control in relation to bobbin handling.

Quality control in bobbin handling is critical to ensure consistent stitching and machine performance. My approach involves:

- Inspection at each stage: I inspect bobbins at each stage of the process—winding, loading, and post-sewing—to identify and correct any flaws. This might involve checking for irregularities in the thread winding, damages to the bobbin itself, or ensuring the correct bobbin is used for the specific machine.

- Maintaining Records: I maintain detailed records of bobbin usage, including the thread type, machine used, and any observed inconsistencies. This enables trend identification, allowing for proactive improvements.

- Using Quality Materials: High-quality bobbins and threads are essential to maintain quality. Choosing reliable suppliers can significantly impact the consistency of bobbin handling.

- Regular Calibration: Regular calibration of bobbin winding equipment is crucial for maintaining consistent thread tension and winding patterns. This reduces the likelihood of flaws and improves overall efficiency.

A commitment to consistent quality control, from selection to disposal, results in a higher quality output and fewer issues down the line. It makes the overall process more efficient and the end product superior.

Q 22. How do you prioritize tasks when handling a large volume of bobbins?

Prioritizing bobbin tasks when dealing with a large volume involves a strategic approach combining urgency and importance. I use a system I call the ‘FIFO-Criticality Matrix’.

- FIFO (First-In, First-Out): This ensures older bobbins, potentially nearing depletion, are addressed first to minimize downtime and waste. I track bobbin usage with lot numbers and dates.

- Criticality: I assess the urgency of each bobbin based on its use in production. Bobbins for high-demand items or urgent orders take precedence.

- Matrix Application: I create a simple matrix charting bobbin age (FIFO) against order priority (Criticality). This allows for quick visualization and efficient task allocation. For example, an old bobbin for a high-priority order would be the top priority.

This system ensures that we maintain a smooth workflow, avoid production bottlenecks, and minimize material waste.

Q 23. Describe a time you had to solve a problem related to bobbin loading or unloading.

Once, we experienced a significant increase in bobbin thread breakage during production. This was causing major delays and impacting our output. Initially, we suspected faulty bobbins. After systematically investigating, we ruled out bobbin defects.

The problem, it turned out, was caused by improper tension settings on several sewing machines. Our team and I conducted a thorough inspection of all machines. We then adjusted tension settings, using a calibrated tension gauge, on the affected machines and ran test batches with new bobbins to verify the solution. By meticulously identifying the root cause rather than just replacing the bobbins, we resolved the issue quickly and efficiently, preventing further disruptions.

Q 24. How do you maintain accurate records of bobbin usage and inventory?

Maintaining accurate bobbin records is crucial for efficiency and cost control. We employ a robust, two-pronged system:

- Digital Inventory Management: We use a dedicated software system to track bobbin inventory. This system records bobbin type, quantity, date received, lot number, and usage date. Automated alerts notify us when bobbin levels reach pre-determined thresholds.

- Physical Verification: Regular physical inventory checks are performed to ensure accuracy and to account for any discrepancies between physical stock and digital records. This also helps identify any potential issues like damage or spoilage.

This combination provides a real-time, accurate view of our bobbin inventory, allowing for timely ordering and preventing stockouts or overstocking.

Q 25. How familiar are you with different sewing machine brands and their respective bobbin systems?

My experience encompasses a wide range of sewing machine brands, including Singer, Brother, Juki, and Pfaff. I understand that bobbin systems vary significantly between brands and even within models of the same brand. For example, Singer machines often use a horizontal, drop-in bobbin system, while some Brother machines employ a top-loading bobbin case.

I’m adept at identifying the correct bobbin type for each machine and am familiar with the nuances of each system – including how to properly load, tension, and troubleshoot different types of bobbins. This proficiency ensures seamless operation and minimizes downtime.

Q 26. What are some common indicators that a bobbin needs to be replaced?

Several indicators signal a bobbin needing replacement:

- Thread Breakage: Frequent thread breakage, especially during stitching, is a common sign of a nearly empty or tangled bobbin.

- Uneven Stitching: Inconsistent stitch length or skipped stitches often point to low bobbin thread tension.

- Visual Inspection: A simple check will reveal a nearly empty bobbin. It’s good practice to regularly check the bobbin level during operation.

- Machine Behavior: Some machines will even produce an audible warning or indicator light signaling a low bobbin.

Ignoring these signs can lead to production delays, fabric damage, and even machine malfunctions.

Q 27. How would you train a new employee on proper bobbin handling techniques?

Training new employees involves a structured, hands-on approach. I begin by covering the theoretical aspects – different bobbin types, identification, and the importance of proper handling.

Next, we move to practical training. I demonstrate proper bobbin loading and unloading techniques for various machine types, emphasizing correct tension settings and the avoidance of common errors like improper winding or overfilling. We then practice on different machines, starting with simple tasks and gradually increasing complexity. Throughout the training, I emphasize safety and the importance of meticulous attention to detail.

Finally, I provide ongoing support and mentorship, encouraging the new employee to ask questions and allowing ample opportunity for practice and feedback. This ensures they confidently handle bobbins and contribute efficiently to the team.

Q 28. Describe your experience working within a team environment involving bobbin handling.

My experience in team environments emphasizes collaboration and efficiency. Within a team, bobbin handling becomes a coordinated process. We implement a system of shared responsibilities, with clearly defined roles for bobbin loading, unloading, inspection, and inventory management.

Effective communication is key. We utilize a visual system – like a whiteboard or digital Kanban board – to track bobbin usage and pending tasks. This keeps everyone informed about inventory levels and production needs. This collaborative approach ensures a smooth and efficient workflow, minimizing disruptions and maximizing productivity.

Key Topics to Learn for Bobbin Loading and Unloading Interview

- Understanding Bobbin Types and Specifications: Learn to identify different bobbin types, sizes, and their compatibility with various machines. This includes understanding material specifications and their impact on loading and unloading processes.

- Safe and Efficient Loading Techniques: Master the correct procedures for loading bobbins, minimizing the risk of damage to the bobbins, the machine, and yourself. Consider speed, accuracy, and ergonomic practices.

- Troubleshooting Common Issues: Familiarize yourself with common problems encountered during bobbin loading and unloading, such as jammed bobbins, misaligned spindles, and broken threads. Practice identifying causes and implementing effective solutions.

- Maintaining Bobbin Quality: Understand the importance of maintaining bobbin quality throughout the process, including proper storage and handling to prevent damage and ensure consistent production.

- Production Optimization Strategies: Explore methods to optimize bobbin loading and unloading processes to increase efficiency and reduce downtime. Consider workflow improvements and the impact on overall productivity.

- Machine Operation and Maintenance: Gain a strong understanding of the machines used in bobbin loading and unloading, including their functionality, safety protocols, and basic maintenance procedures. This demonstrates a commitment to both efficiency and safety.

- Quality Control and Inspection: Learn about quality control measures involved in bobbin loading and unloading, and how to identify and address defects or inconsistencies in the process.

Next Steps

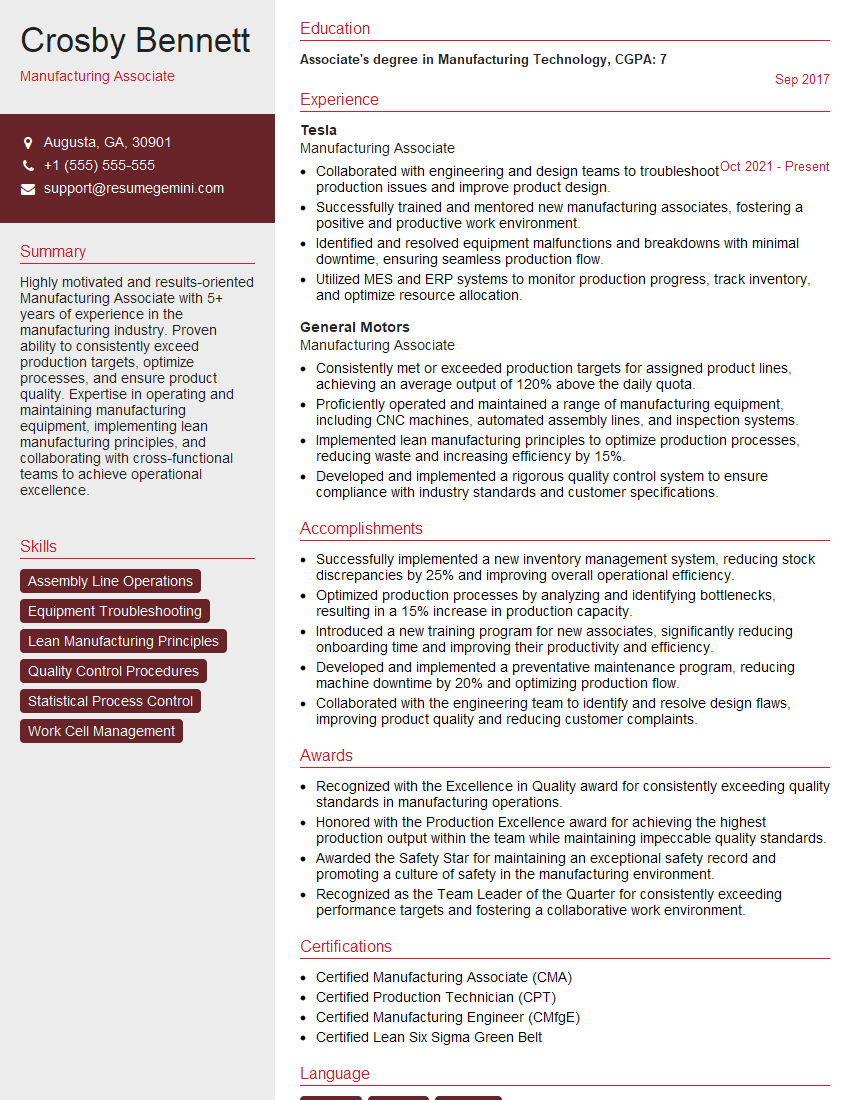

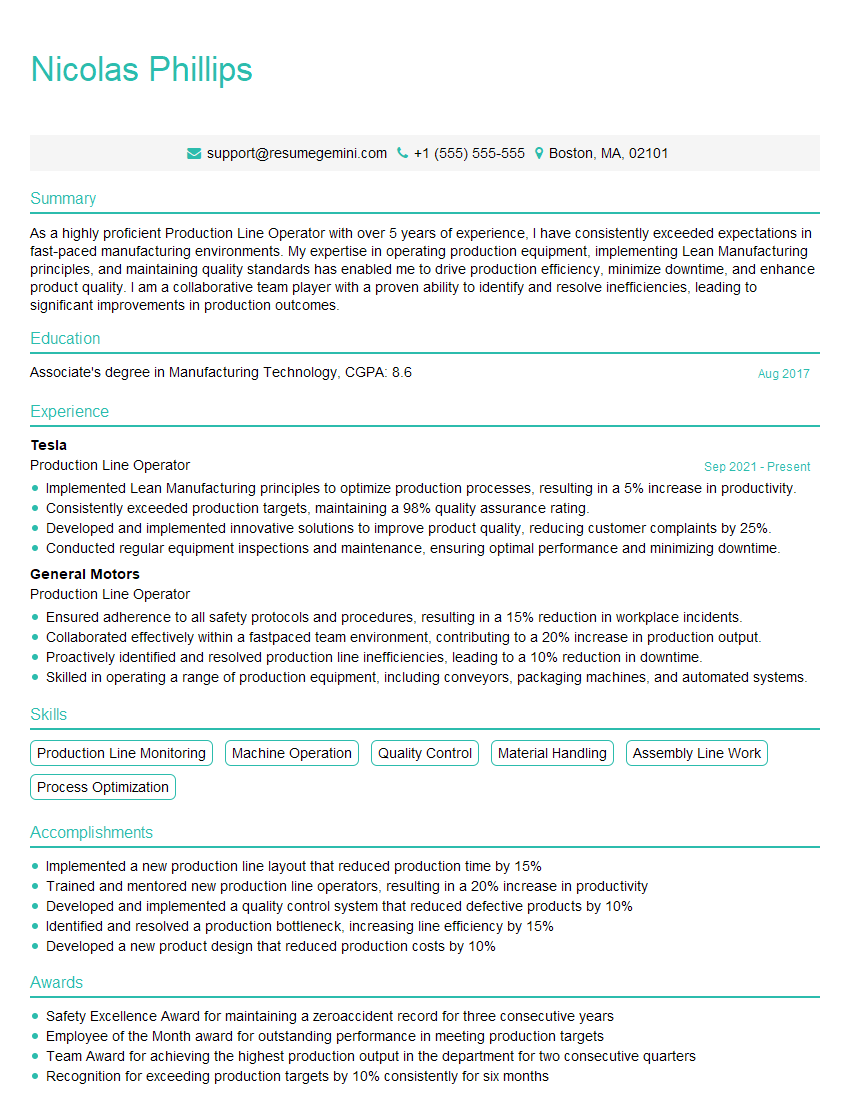

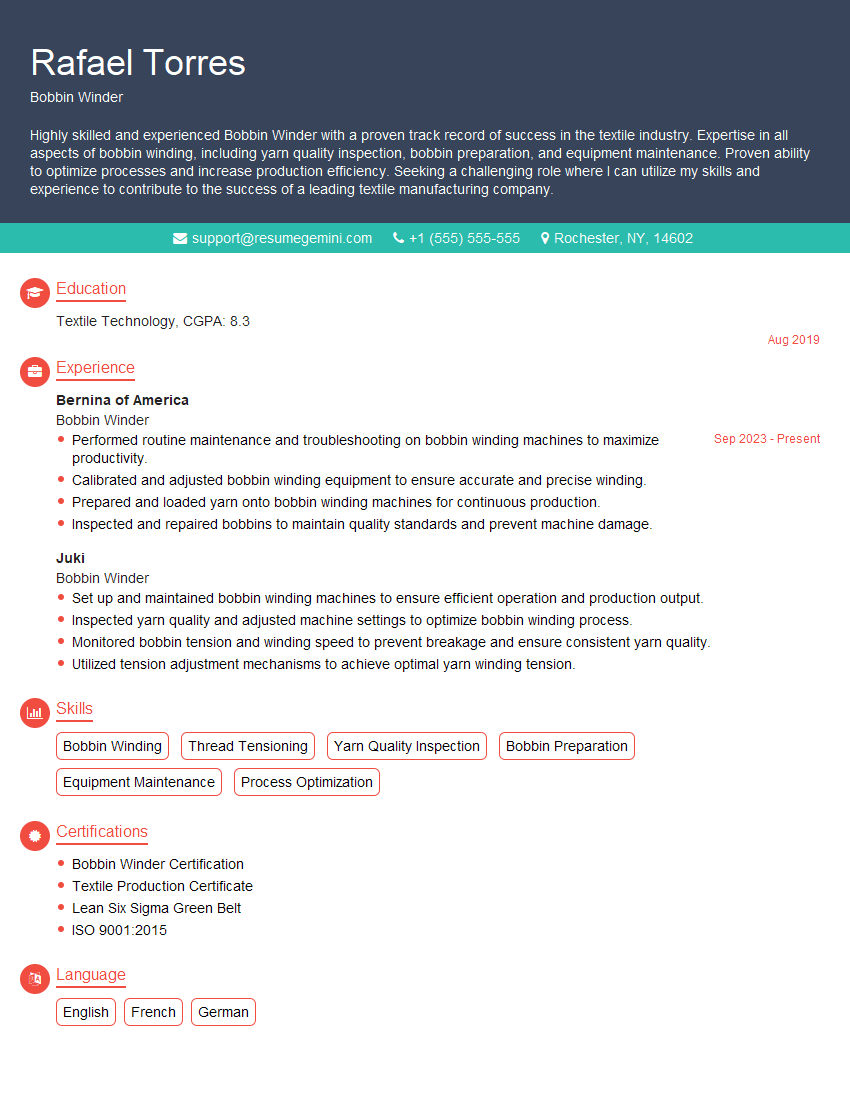

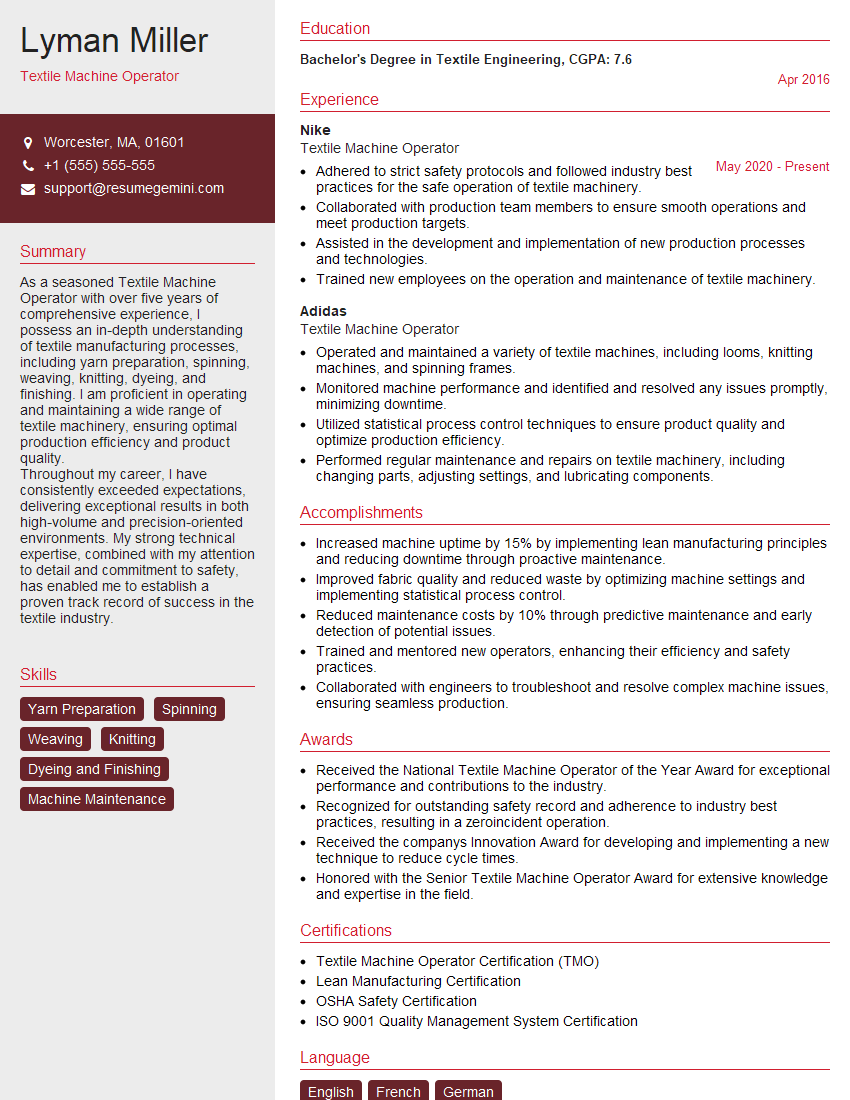

Mastering bobbin loading and unloading opens doors to diverse and rewarding careers in textile manufacturing and related industries. A strong understanding of these processes is highly valued by employers, showcasing your practical skills and dedication to efficiency and quality. To significantly boost your job prospects, it’s crucial to present your skills effectively. Creating an ATS-friendly resume is key to getting your application noticed. We recommend using ResumeGemini, a trusted resource that can help you build a professional and impactful resume. ResumeGemini provides examples of resumes tailored to Bobbin Loading and Unloading positions, helping you craft a document that highlights your unique skills and experience.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good