Unlock your full potential by mastering the most common Bobbin Threading interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Bobbin Threading Interview

Q 1. Describe the process of threading a bobbin on a standard sewing machine.

Threading a bobbin is fundamental to sewing. It involves carefully guiding the thread onto the bobbin, creating a neat and even spool ready for use in your sewing machine. Different machines have slightly varying bobbin cases and mechanisms, but the general process remains consistent.

- Obtain your bobbin: Ensure it’s the correct type for your machine.

- Prepare your thread: Pull a length of thread, several feet long, from your spool. This allows for easier threading and prevents breakage.

- Insert the bobbin into the bobbin winder: This is usually located on the top or side of the sewing machine. Engage the bobbin winder by pushing it slightly.

- Begin winding: Hold the thread tail lightly and depress the foot pedal. The bobbin will begin to wind. Watch carefully for even winding. If the thread winds unevenly, stop, adjust the thread tension (there’s often a small screw on the winder), and restart.

- Stop winding: Once the bobbin is full, disengage the bobbin winder. Cut the thread and remove the full bobbin.

- Install the bobbin into the bobbin case: Each sewing machine is different, consult your machine’s manual for detailed instructions. This usually involves sliding the bobbin into the case and gently pulling the thread through a small slot.

Think of it like carefully winding a small yarn ball – you want it neat and tight to avoid tangles later.

Q 2. Explain the difference between a class 15 bobbin and a class 66 bobbin.

Class 15 and Class 66 bobbins are standard classifications referring to the bobbin’s dimensions and size. They’re not interchangeable, and using the wrong bobbin can lead to issues with your machine.

- Class 15 bobbins are smaller and more commonly found in older or smaller sewing machines. They often have a more delicate build.

- Class 66 bobbins are larger and more commonly used in newer and industrial machines. They’re generally more robust.

Think of it like trying to fit a square peg into a round hole. Using the wrong bobbin class will likely result in the bobbin not fitting properly into the bobbin case or causing malfunctions.

Q 3. How do you identify a properly wound bobbin?

A properly wound bobbin is crucial for smooth sewing. You can identify a properly wound bobbin through observation and a few simple checks.

- Even Winding: The thread should be wound neatly and tightly, without gaps or loose areas. The layers should be evenly distributed across the bobbin’s surface, like a perfectly organized cake.

- Firmness: A properly wound bobbin will feel firm to the touch, not loose or wobbly.

- No Loose Threads:There shouldn’t be any loose or hanging threads on the bobbin’s surface, that could snag and cause issues.

- Correct Tension: The thread should be snug but not overly compressed – it should unwind smoothly without being overly tight or loose.

Imagine it like a well-packed suitcase – everything should be organized, nothing hanging out, ensuring a smooth journey. Any imperfections in the bobbin winding can directly impact the quality and consistency of your stitching.

Q 4. What are the common causes of a bobbin that won’t feed correctly?

Several factors can cause a bobbin to fail to feed correctly. Diagnosing the problem requires a systematic approach.

- Improper Bobbin Winding: Loosely wound bobbins or those with uneven thread distribution are major culprits. The thread can bunch up, causing feeding problems.

- Incorrect Bobbin Placement: If the bobbin is not inserted correctly into the bobbin case, it won’t feed properly. Check your machine’s manual for precise instructions.

- Full Bobbin: A completely full bobbin might not have enough room to unwind smoothly, leading to jamming.

- Lint Buildup: Lint and debris can accumulate in the bobbin area, hindering the bobbin’s movement and causing jams.

- Bobbin Case Issues: A damaged or dirty bobbin case can also cause feeding problems. Inspect the case for any damage or obstructions.

- Tension Issues: Incorrect bobbin tension, either too tight or too loose, can prevent the bobbin from feeding correctly.

Troubleshooting this issue involves carefully inspecting each component and following a process of elimination. Remember that a clean and well-maintained machine is key to success.

Q 5. How do you troubleshoot a tangled bobbin?

A tangled bobbin is frustrating, but usually fixable. Here’s how to approach it:

- Remove the bobbin case: Carefully remove the bobbin case from your sewing machine.

- Unwind the tangle: Gently try to unwind the tangle. Use a small needle or pin to help separate the threads. Be patient and avoid yanking to prevent thread breakage.

- Inspect the bobbin case: Make sure nothing is obstructing the bobbin’s smooth movement within the case. Clean out any lint or debris that might be causing the tangle.

- Rewind the bobbin (if necessary): If the tangle is severe, it might be easier to rewind the bobbin correctly. Otherwise, carefully reinsert the bobbin into the case ensuring proper alignment.

- Check the thread path: After re-inserting the bobbin, double-check the entire thread path for any kinks, obstructions, or tension issues.

Think of it like untangling a pair of earphones. Gentle, deliberate actions are key to success. If it’s too tangled, start fresh with a new bobbin to save time.

Q 6. Explain the importance of proper bobbin tension.

Proper bobbin tension is essential for achieving balanced and even stitching. It’s the delicate balance between the tension of the upper thread and the lower thread (from the bobbin). If the balance is incorrect, it shows in the stitches.

The bobbin tension controls the amount of resistance the bobbin thread encounters when being pulled up by the needle. Too much or too little tension leads to problems. Think of it like a tug-of-war: the upper and lower threads should pull equally to create a perfect stitch.

Q 7. How does incorrect bobbin tension affect the stitching?

Incorrect bobbin tension significantly impacts stitch quality and the overall look of your sewing project. Here’s how:

- Too tight bobbin tension: Results in stitches that are pulled to the bottom of the fabric. The top thread is dominant, and the bobbin thread is tightly compressed, resulting in puckering or a tight, bunched look.

- Too loose bobbin tension: Leads to loops of the bobbin thread appearing on the top of the fabric. The stitches appear loose, and the bobbin thread doesn’t interact properly with the top thread causing inconsistent stitching.

- Broken Threads: Incorrect bobbin tension can put strain on the threads, leading to frequent breakage.

Finding the perfect balance requires experimentation with the tension adjustment dial on your sewing machine. A well-balanced tension creates a beautiful, uniform stitch where both the top and bottom threads are interwoven perfectly, creating a strong and aesthetically pleasing seam.

Q 8. Describe how to adjust bobbin tension.

Adjusting bobbin tension is crucial for achieving balanced stitching. Too much tension leads to puckering and thread breakage, while too little results in loose stitches and skipped stitches. Most sewing machines have a small dial or screw located near the bobbin case that controls this tension.

- Identifying the Tension Dial/Screw: Consult your machine’s manual to locate the precise tension adjustment mechanism. It’s usually marked with numbers or symbols indicating tension levels (e.g., 1-9).

- Making Adjustments: Start by making small incremental adjustments. Turn the dial or screw slightly clockwise to increase tension, or counterclockwise to decrease it. Test the stitching after each adjustment until you achieve a balanced stitch with both the needle and bobbin threads interwoven neatly.

- Testing and Fine-Tuning: Sew a test seam on a scrap fabric. If the stitches are too tight, loosen the tension. If they are too loose, tighten the tension. Repeat the process until you achieve the desired stitch quality.

Think of it like this: the bobbin thread and the needle thread are in a tug-of-war. You need to find the perfect balance so neither one wins completely.

Q 9. How do you prevent bobbin breakage?

Bobbin breakage is a common sewing frustration, but it’s often preventable. Several factors contribute, including incorrect tension, poor bobbin winding, and using damaged bobbins.

- Proper Bobbin Winding: Ensure the bobbin is wound evenly and tightly. Loosely wound bobbins are prone to breakage.

- Correct Tension: As previously discussed, balanced tension is crucial. Too much tension on either the needle or bobbin thread will strain the thread, increasing the risk of breakage.

- Using High-Quality Thread: Opt for good-quality thread that’s appropriate for your machine and fabric. Damaged or weak threads break easily.

- Inspecting Bobbins: Before using a bobbin, inspect it for any imperfections, damage, or lint buildup, which might impede its smooth rotation.

- Regular Maintenance: Keep your sewing machine clean and lubricated. Dust and lint buildup can interfere with bobbin rotation and contribute to breakage.

Imagine a tightly wound ball of yarn versus a loosely tangled one. The tightly wound one is much stronger and less prone to breaking.

Q 10. What types of bobbins are used in industrial sewing machines?

Industrial sewing machines use a variety of bobbins, often tailored to the specific machine model and application. Some common types include:

- Metal Bobbins: Durable and reliable, often found in heavy-duty industrial machines.

- Plastic Bobbins: Lighter and less expensive than metal, but may not be as durable for high-speed, heavy-duty applications.

- Class 15 Bobbins: A widely used standard size for various industrial machines.

- Class 66 Bobbins: Another common size used in numerous industrial machines.

The choice of bobbin depends on factors such as the machine’s speed, the type of fabric being sewn, and the thread type.

Q 11. How do you load a top-loading bobbin?

Top-loading bobbins are loaded from the top of the bobbin case. The process varies slightly depending on the machine model but generally involves these steps:

- Open the Bobbin Case Cover: Locate and open the compartment containing the bobbin case.

- Insert the Bobbin: Place the bobbin into the bobbin case, ensuring it’s oriented correctly (the thread should typically be drawn from the bottom or side, consult your machine’s manual).

- Guide the Thread: Route the thread through the guide on the bobbin case (if applicable), ensuring it’s taut but not overly stretched.

- Close the Cover: Carefully close the bobbin case cover.

- Pull Up the Bobbin Thread: This is crucial. There will be a small space or hook to draw the bobbin thread up and through. This ensures the bobbin thread is engaged with the needle thread. Often, there is a small slot for the thread to be pulled through.

Think of it as carefully placing a spool into a container. The key is to make sure the thread is correctly positioned to ensure smooth stitching.

Q 12. How do you load a front-loading bobbin?

Front-loading bobbins are loaded from the front of the sewing machine. Again, precise steps vary by machine model.

- Open the Bobbin Access Door: Open the access door on the front of the machine.

- Insert the Bobbin: Gently slide the bobbin into the designated slot, ensuring it’s oriented correctly.

- Route the Thread: Guide the thread through the designated path, typically following the guide grooves on the machine.

- Close the Access Door: Close the access door firmly, ensuring it latches securely.

- Pull Up the Bobbin Thread: Carefully pull up the bobbin thread to ensure it’s engaged with the needle thread. The method often involves a small notch or slot on the front of the machine.

It is like loading a cassette into a player – each machine has a specific method to load the bobbin, but the goal is always smooth and secure insertion.

Q 13. What is the significance of using the correct type of bobbin for a particular machine?

Using the correct bobbin type is essential for several reasons:

- Proper Fit and Function: Incorrect bobbin sizes or types can lead to improper functioning, such as jamming, inconsistent stitching, and breakage.

- Machine Longevity: Using the wrong bobbin can damage the internal components of your sewing machine over time.

- Stitch Quality: The correct bobbin ensures that the needle thread and bobbin thread intertwine effectively, resulting in high-quality, consistent stitching.

- Safety: In industrial settings, using an incorrect bobbin might cause machine failure, potentially creating a safety hazard.

Think of it like using the correct size bolt for a specific nut; using the wrong one results in improper fitting and potential damage.

Q 14. Explain the steps to remove and replace a bobbin.

Removing and replacing a bobbin is a routine maintenance task. The procedure varies slightly depending on whether the machine is top-loading or front-loading but shares fundamental steps:

- Open the Bobbin Compartment: Access the compartment housing the bobbin (top or front depending on the machine).

- Remove the Bobbin Case: Carefully remove the bobbin case.

- Remove the Bobbin: Take out the old bobbin from the case.

- Insert New Bobbin: Place a new, correctly wound bobbin into the case.

- Reinstall the Bobbin Case: Carefully replace the bobbin case back into its slot.

- Pull Up the Bobbin Thread: Ensure the bobbin thread is properly engaged with the needle thread, as described in the previous sections.

Similar to changing a lightbulb – it’s a simple process but requires careful attention to avoid any mishaps.

Q 15. How do you clean and maintain a bobbin case?

Cleaning your bobbin case regularly is crucial for preventing thread jams and ensuring smooth sewing. Think of it like cleaning the engine of your sewing machine – it keeps everything running smoothly.

- Gentle Brushing: First, use a soft brush, like a small paintbrush or even an old toothbrush, to remove loose lint and dust from the case. Pay close attention to the areas around the shuttle hook and spring.

- Compressed Air: A can of compressed air can help dislodge stubborn lint particles that the brush might miss. Hold the can upright and use short bursts to avoid damaging delicate components.

- Lubrication (Optional): Some sewing machine experts recommend a drop of high-quality sewing machine oil on the moving parts of the bobbin case, specifically the shuttle hook. However, be mindful of applying only a tiny amount; too much oil can attract more lint.

- Inspection: After cleaning, carefully examine the bobbin case for any damage, such as bent parts or scratches. A damaged bobbin case can lead to inconsistent stitching or thread breakage.

Regular cleaning, even after every few sewing projects, will significantly prolong the life of your bobbin case and improve your sewing experience. It’s a small task with a big impact!

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are some common bobbin-related maintenance tasks?

Bobbin-related maintenance goes beyond just cleaning the case. It’s a comprehensive approach to keeping your sewing machine running smoothly.

- Bobbin Case Cleaning: As detailed previously, regularly cleaning the bobbin case is paramount. Lint and dust build-up are major culprits of bobbin problems.

- Bobbin Winding: Make sure you wind bobbins correctly, avoiding loose or unevenly wound thread. This is crucial for preventing thread breakage and jams. A poorly wound bobbin is like a poorly stacked tower – unstable and prone to collapse.

- Bobbin Tension Adjustment: The tension on your bobbin thread needs to be balanced with the upper thread tension. Incorrect tension leads to uneven stitching. Use your machine’s tension dial to fine-tune this adjustment. Think of it as finding the perfect balance between two equally important forces.

- Bobbin Case Alignment: The bobbin case needs to be correctly seated and aligned in your machine. Improper alignment is a frequent cause of skipped stitches or broken threads.

- Regular Inspection: Periodically inspect your bobbins for damage, such as nicks or cracks, or for excessive wear. Damaged bobbins should be replaced to prevent sewing problems.

Q 17. Describe the signs of a worn-out bobbin case.

A worn-out bobbin case will often show subtle signs that indicate it’s time for a replacement.

- Scratches and Dents: Deep scratches or dents on the metal casing can hinder smooth thread movement, leading to thread breakage or skipped stitches. It’s like a rough road for the thread.

- Difficulty in Threading: If you consistently struggle to thread the bobbin case or the thread keeps slipping off, it’s a clear indicator of wear and tear.

- Consistent Thread Breakage: Despite proper tension settings, persistent thread breakage, particularly on the bobbin thread, suggests a problem with the bobbin case’s functionality.

- Uneven Stitching: Irregular stitch formation, characterized by skipped stitches or inconsistent stitch length, is a strong sign of a worn-out bobbin case or other related mechanical problems.

- Rough Edges: Noticeably rough edges on the bobbin race or shuttle hook indicate wear that impairs the smooth movement of the bobbin.

Ignoring these signs can lead to more significant sewing problems and potentially damage your machine. It’s always better to replace a worn-out bobbin case than to risk extensive repairs.

Q 18. How would you handle a situation where you consistently experience bobbin problems?

Persistent bobbin problems require a systematic approach to troubleshooting. Don’t jump to conclusions; examine the situation step-by-step.

- Re-evaluate Threading: Begin by carefully checking if you’ve correctly threaded the bobbin and the machine. Many bobbin issues stem from simple threading errors.

- Check Bobbin Tension: Verify that the bobbin tension is appropriately adjusted and balanced with the upper thread tension. Use the tension dial on your machine to adjust accordingly.

- Inspect the Bobbin Case: Clean and thoroughly inspect the bobbin case for damage, dirt, or obstructions. Replace if necessary.

- Examine the Bobbin: Check the bobbin itself for uneven winding or damage. Replace if needed. A poorly wound bobbin is a common culprit.

- Check Needle: A bent or damaged needle can also contribute to bobbin problems, so check its condition. Replace as needed.

- Consult Manual: If you’ve completed the above steps and continue to experience problems, refer to your sewing machine’s manual for specific troubleshooting guidelines. Many machines have diagrams and detailed instructions.

- Professional Help: If all else fails, it’s time to seek assistance from a qualified sewing machine technician. They can diagnose more complex issues that may be beyond your scope of troubleshooting.

Q 19. How do you determine the correct bobbin thread type for a particular fabric?

Selecting the right bobbin thread is crucial for achieving high-quality sewing results. The fabric type dictates the appropriate thread weight and fiber content.

- Lightweight Fabrics: Delicate fabrics like silk, chiffon, or voile require fine-weight threads (e.g., 60 wt or 80 wt) to prevent puckering or damage. Imagine trying to sew heavy-duty thread on a fine silk – it’s a recipe for disaster!

- Medium-Weight Fabrics: Cotton, linen, or light wool generally work well with medium-weight threads (e.g., 40 wt or 50 wt). These threads offer a good balance of strength and fineness.

- Heavyweight Fabrics: Thick fabrics like denim, canvas, or upholstery usually need heavier-weight threads (e.g., 20 wt or 30 wt) for durability. These threads provide the strength needed for sturdy seams.

- Fiber Content: The fiber content of the thread should also be considered. For example, polyester thread is often a good all-purpose choice due to its strength and durability, while cotton thread offers a more natural feel.

Matching thread weight and type to your fabric type is essential for achieving even and durable seams. It’s an often-overlooked detail, yet it’s critical for the overall success of your sewing project. Remember, the wrong thread can lead to puckering, breakage, or uneven seams.

Q 20. What are the implications of using the wrong thread type on a bobbin?

Using the incorrect thread type in your bobbin has several undesirable consequences.

- Thread Breakage: Using a thread too fine for the fabric can lead to frequent breakage due to insufficient strength. Conversely, a thread that’s too heavy can also cause breakage due to excessive tension and friction.

- Uneven Stitches: A mismatch in thread weight between the bobbin and the top thread can lead to inconsistent stitch length and an overall uneven appearance. It’s like trying to build a wall with bricks of different sizes.

- Puckering: Using a thread that’s too heavy on a lightweight fabric can cause puckering and distortion of the fabric. It can ruin the entire project.

- Weakened Seams: If the bobbin thread is too weak for the fabric and the top thread, the resulting seam will lack the necessary strength. This can lead to seam failure under stress.

- Damage to the Sewing Machine: In extreme cases, using the wrong thread, especially a thread too heavy for the machine, can put undue strain on the machine’s internal mechanisms, potentially leading to damage or breakage.

Choosing the correct thread is a fundamental aspect of successful sewing. Don’t underestimate its importance; the right thread makes all the difference!

Q 21. How do you know when to replace a bobbin?

Knowing when to replace a bobbin is important for maintaining sewing quality and avoiding problems.

- Visible Damage: If the bobbin is cracked, chipped, or significantly worn down, it needs replacing. A damaged bobbin can cause thread breakage and inconsistent stitching. Think of it as a cracked foundation – it won’t support your project.

- Uneven Winding: If the thread on the bobbin is unevenly wound or excessively loose, it can cause tension problems and thread jams. A well-wound bobbin is key for smooth sewing.

- Excessive Lint Buildup: Accumulated lint on the bobbin can interfere with its smooth rotation, causing tension issues and thread breakage.

- Consistent Problems: If you consistently experience bobbin-related problems, such as frequent thread breakage or skipped stitches, even after troubleshooting other potential causes, consider replacing the bobbin.

- Frequent Use: Even without visible damage, it is good practice to replace your bobbin after frequent use. Bobbins are consumables, and their performance naturally deteriorates over time.

It’s better to be proactive and replace a bobbin before it causes major sewing problems than to wait until it’s a disaster.

Q 22. What are some preventative measures to avoid bobbin issues?

Preventing bobbin issues starts with proactive maintenance and careful handling. Think of your bobbin like a tiny, vital engine part – if it’s not properly cared for, the whole sewing process suffers.

- Use the correct bobbin type: Always use the bobbin type specifically recommended for your sewing machine model. Using the wrong bobbin can lead to poor winding, tension issues, and even damage to your machine.

- Keep bobbins clean and free of lint: Lint and dust can interfere with the smooth movement of the bobbin and cause inconsistent stitching. Regularly clean your bobbin case and bobbins with a soft brush.

- Properly wind your bobbins: This is crucial. Improperly wound bobbins, with loose or unevenly distributed thread, are a major source of problems. Use the machine’s bobbin winder correctly and ensure the thread is wound neatly without gaps or overlaps.

- Check bobbin tension: Before sewing, ensure your bobbin tension is correctly adjusted. Too loose or too tight, and your stitches will be uneven or break.

- Store bobbins properly: Protect your bobbins from dust and damage by storing them in a clean, dry place. Consider using a bobbin storage case.

By diligently following these steps, you can significantly reduce the chances of encountering bobbin-related problems and enjoy smoother, more consistent sewing.

Q 23. Can you describe the different ways a bobbin can malfunction?

Bobbin malfunctions can manifest in several frustrating ways, often impacting stitching quality or causing the machine to jam. Imagine a tiny car engine – problems can be subtle or catastrophic.

- Uneven winding: A poorly wound bobbin, with loose or tight spots in the thread, will lead to inconsistent stitch length and tension.

- Broken thread: A broken bobbin thread will cause the machine to stop stitching completely. This can be due to poor quality thread, a tangled bobbin, or incorrect tension.

- Tangled thread: A tangled bobbin will prevent it from rotating properly, leading to skipped stitches, broken threads, or even machine damage.

- Incorrect tension: If the bobbin tension is too tight or too loose, you’ll get loops on the top or bottom of your fabric, or the thread might break repeatedly.

- Full bobbin: A completely full bobbin can make it difficult for the machine to pull the thread through, resulting in missed stitches.

- Damaged bobbin: A cracked or otherwise damaged bobbin can malfunction and interfere with the smooth rotation needed for consistent stitching.

Identifying the specific type of malfunction is key to quickly resolving the issue and getting back to sewing.

Q 24. How do you ensure consistent stitching when using bobbins?

Consistent stitching with bobbins relies on a harmonious balance of several factors. Think of it as a perfectly tuned orchestra – every section plays its part.

- Proper bobbin winding: As mentioned earlier, a neatly and evenly wound bobbin is the foundation of consistent stitching.

- Correct bobbin tension: The bobbin tension must be correctly adjusted to create a balance with the top thread tension. This is usually a dial or screw on your machine.

- Clean bobbin case: A clean bobbin case ensures that the bobbin spins freely without resistance.

- High-quality thread: Using a good quality thread in both the top and bobbin reduces the chances of thread breakage and inconsistent stitching. A smooth, even thread is key.

- Needle type and size: The correct needle type and size for your fabric and thread will also help prevent skipped stitches and improve consistency. Using the wrong needle is a common mistake.

By paying attention to these details, you will greatly increase your chances of achieving perfect, even stitches every time.

Q 25. Explain the relationship between bobbin winding and stitching quality.

Bobbin winding and stitching quality are inextricably linked. A poorly wound bobbin is like building a house on a shaky foundation – the results won’t be pretty.

A bobbin wound too tightly can create tension issues, leading to broken threads and skipped stitches. Conversely, a loosely wound bobbin can cause the thread to bunch up, resulting in uneven stitches and poor fabric quality. An unevenly wound bobbin can cause the machine to skip stitches or pull the fabric, resulting in puckers and inconsistent seam lines. The goal is a smooth, evenly distributed thread on the bobbin that feeds consistently.

Imagine winding a ball of yarn – a perfectly wound ball will unravel smoothly. A poorly wound ball, however, will have loose ends and knots that cause problems during use. The same principle applies to your bobbin.

Q 26. Describe the process of winding a bobbin on a sewing machine.

Winding a bobbin is a straightforward process, but precision is key. Here’s a step-by-step guide:

- Place the empty bobbin on the bobbin winder spindle: Ensure it’s securely seated.

- Thread the bobbin: Feed the thread through the designated guide on the bobbin winder and then onto the bobbin itself, tucking the end under the threads already wound (a small amount to start).

- Engage the bobbin winder: There will be a lever or mechanism on your sewing machine to activate the winder.

- Start the machine: The bobbin will start to wind. Avoid pulling the thread during winding.

- Monitor the process: Make sure the thread is winding evenly. If it’s not, adjust the bobbin tension accordingly.

- Stop the machine once the bobbin is full: Do not overfill the bobbin.

- Disengage the bobbin winder: Turn off the machine and carefully remove the full bobbin.

Practice makes perfect! With a little experience, you’ll be able to wind perfect bobbins every time.

Q 27. What are the safety precautions when working with bobbins and sewing machines?

Safety is paramount when working with sewing machines and bobbins. Always treat them with respect. Remember, a sewing machine is a powerful piece of machinery.

- Keep fingers clear of moving parts: Never put your fingers near the needle or moving parts of the machine while it’s in operation. Use a bobbin case to avoid injuries while inserting the bobbin.

- Unplug the machine before cleaning or maintenance: Always unplug the machine before changing needles, cleaning the bobbin case, or performing any maintenance tasks.

- Use appropriate thread: Using the correct thread type and avoiding frayed or tangled threads helps prevent accidents. Good quality thread is safer.

- Be mindful of sharp objects: Needles are sharp; handle them with care. Dispose of broken needles safely.

- Supervise children: Never leave a sewing machine unattended, especially if children are present.

Following these simple guidelines will create a safe and productive sewing environment.

Q 28. Explain how to troubleshoot a bobbin that’s causing skipped stitches.

Skipped stitches caused by the bobbin usually point towards a tension or thread problem. Let’s troubleshoot step-by-step:

- Check the bobbin thread: Ensure the thread is not tangled, broken, or too thin. If it is, replace it with a new spool of high-quality thread.

- Inspect the bobbin case: Look for lint, dust, or any obstructions in the bobbin case. Clean it thoroughly with a brush or compressed air.

- Examine the bobbin tension: Adjust the bobbin tension dial or screw on your machine. You may need to experiment slightly to find the correct setting for your thread.

- Check the top thread tension: Sometimes, problems with the top thread tension can cause bobbin issues. Check the top thread and make sure the tension is adjusted appropriately.

- Inspect the needle: A bent, dull, or incorrect needle can also contribute to skipped stitches. Replace it if necessary.

- Try a new bobbin: A problem with the bobbin itself may exist, so testing with a new, properly wound bobbin helps isolate the issue.

By systematically checking each component, you’ll be able to pinpoint the cause and resolve the skipped stitch problem efficiently.

Key Topics to Learn for Bobbin Threading Interview

- Understanding Bobbin Types: Learn the different types of bobbins used in various sewing machines and their specific applications. This includes understanding their size, material, and capacity.

- Proper Bobbin Winding Techniques: Master the correct techniques for winding bobbins, including consistent tension and preventing bird’s nests. Practice on different machine types to showcase adaptability.

- Bobbin Insertion and Removal: Become proficient in smoothly inserting and removing bobbins from various sewing machine models. Understand the troubleshooting steps for common issues encountered during this process.

- Troubleshooting Bobbin Problems: Learn to diagnose and solve common bobbin-related issues such as skipped stitches, tangled thread, and uneven stitching. Develop a systematic approach to problem-solving.

- Bobbin Tension Adjustment: Understand how bobbin tension affects stitch quality and learn how to adjust it for different fabrics and thread types. Practice making fine adjustments for optimal results.

- Maintenance and Care of Bobbins: Learn how to properly clean and maintain bobbins to extend their lifespan and ensure optimal performance. Understand the importance of using the correct bobbin for your machine.

- Impact of Bobbin on Stitch Quality: Connect the theory of bobbin function to the practical impact on the final stitch quality. Be able to explain how bobbin issues manifest in the final product.

Next Steps

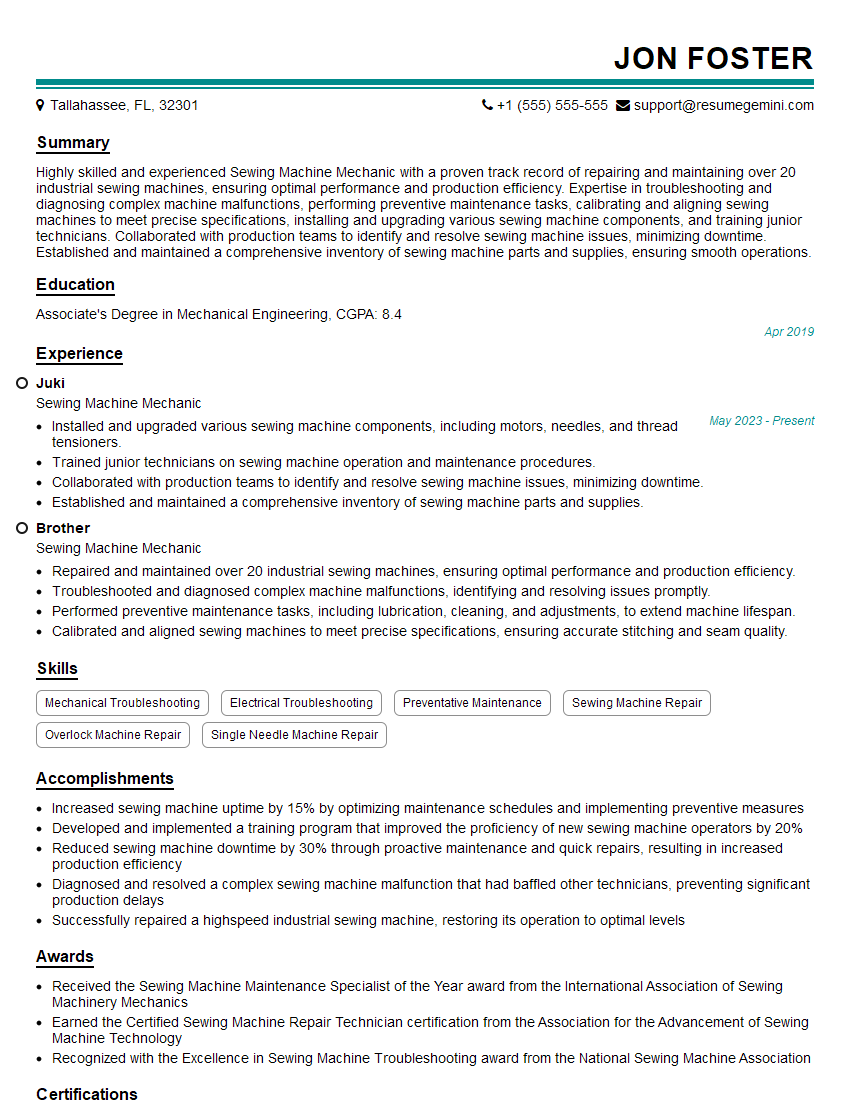

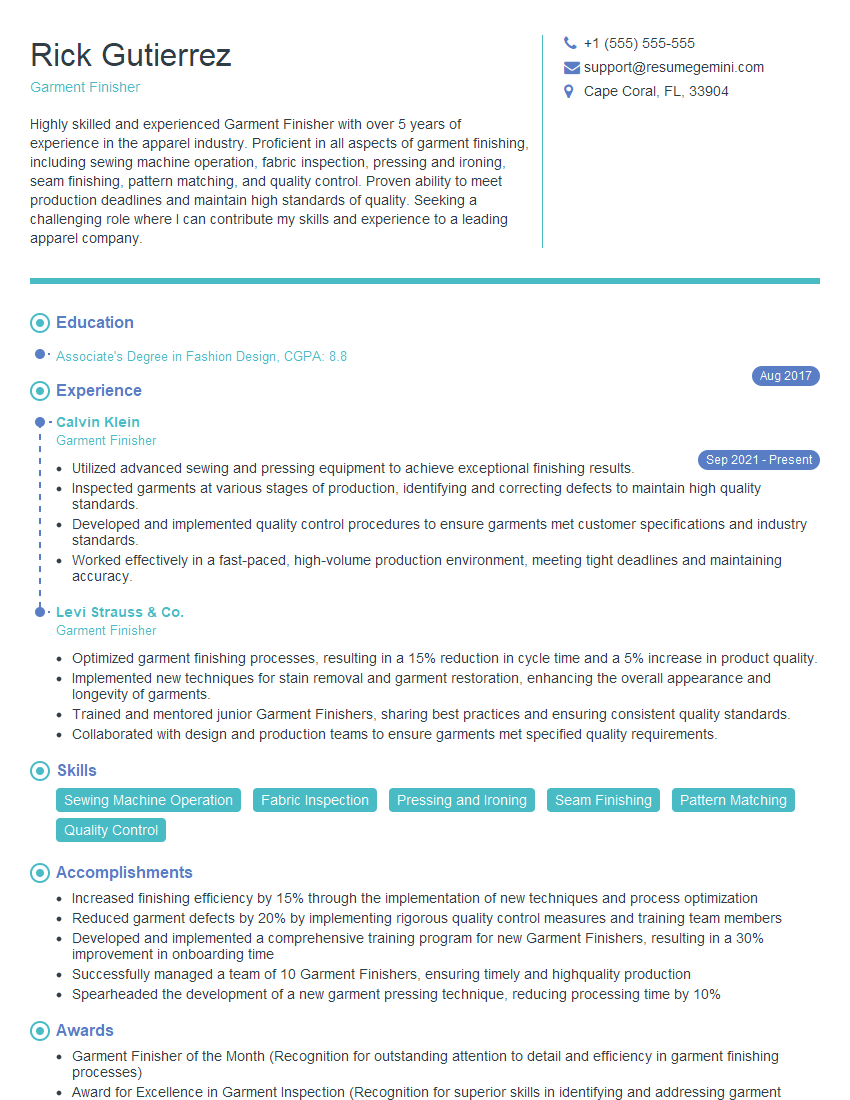

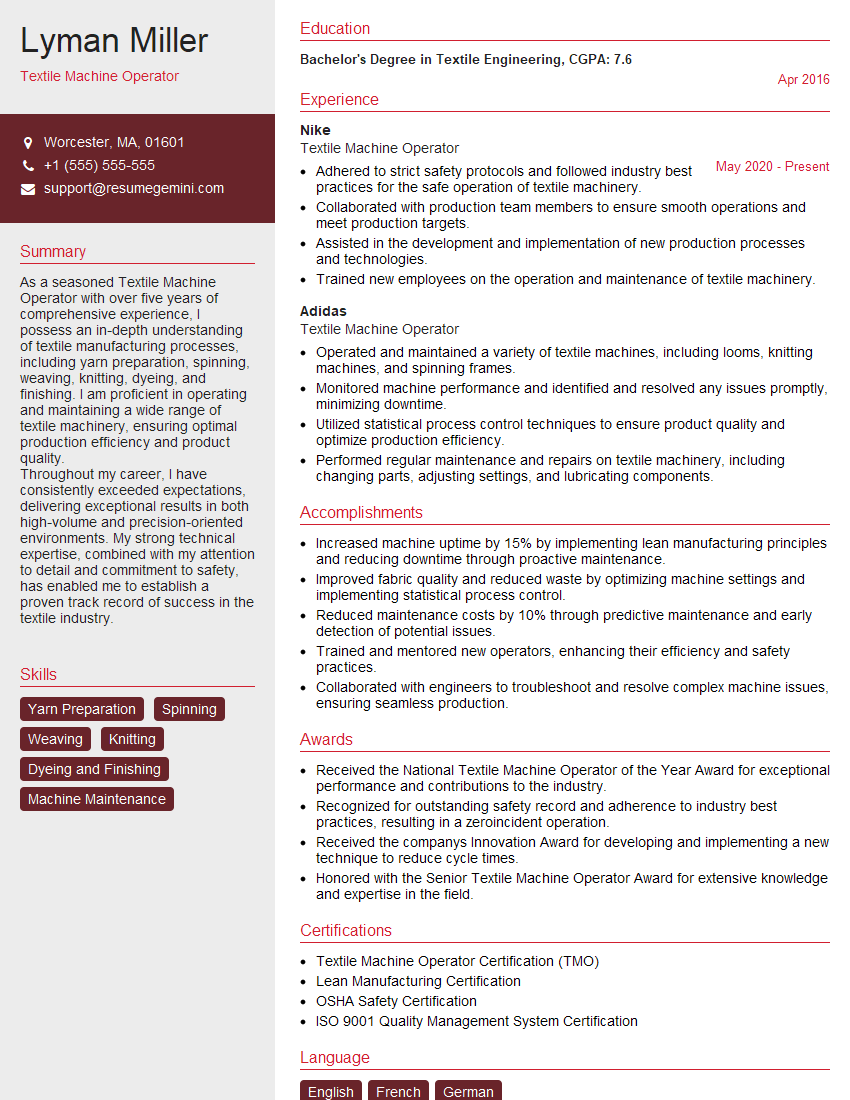

Mastering bobbin threading is crucial for success in many sewing and textile-related roles, showcasing your attention to detail and practical skills. A strong understanding of this fundamental skill will significantly improve your chances of landing your dream job. To maximize your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. Examples of resumes tailored to the Bobbin Threading field are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good