Cracking a skill-specific interview, like one for Borehole Deviation Analysis, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Borehole Deviation Analysis Interview

Q 1. Explain the different types of borehole deviation and their causes.

Borehole deviation refers to the unplanned or intentional departure of a wellbore from its planned vertical trajectory. Several types exist, primarily categorized by their shape and cause.

- Dogleg Severity: This describes the abrupt change in direction, often measured as the angle between two consecutive survey points. A high dogleg severity can cause difficulties in drilling and completion operations. Causes include sudden changes in formation properties, drill string buckling, or equipment malfunction.

- Build-up: A gradual increase in the inclination angle of the wellbore. This is often planned, but can be unintentional due to factors like formation anisotropy or uneven bit wear.

- Drop-off: The opposite of build-up, where the inclination angle decreases. This can be caused by changes in formation strength, bit balling, or improper weight on the bit.

- Spiral Deviation: A twisting or helical path of the wellbore. This is often caused by the torque on the drill string, which can twist the drill bit and cause the hole to deviate in a spiral pattern. This can result from insufficient directional control, uneven formation resistance, or problems with the bottom hole assembly (BHA).

The causes are multifaceted and often interconnected. They range from geological factors (formation dip, faults, fractures) to drilling parameters (weight on bit, rotary speed, torque), equipment issues (bit wear, BHA design), and even human error.

Imagine trying to dig a straight hole in soft sand versus solid rock – the consistency of the material directly impacts the ease of maintaining a straight path, mirroring how formation properties affect borehole deviation.

Q 2. Describe the principles of Measurement While Drilling (MWD) and Logging While Drilling (LWD) in relation to borehole deviation.

Measurement While Drilling (MWD) and Logging While Drilling (LWD) are crucial technologies for real-time monitoring of borehole deviation. Both involve sensors placed within the drill string that collect data during the drilling operation.

MWD primarily focuses on surveying the wellbore’s position and orientation. It uses tools like gyroscopes and accelerometers to measure inclination, azimuth, and toolface. This data is then transmitted to the surface in real-time, allowing for immediate adjustments to the drilling direction. Think of it as providing a continuous GPS for the drill bit.

LWD expands on MWD by incorporating various sensors for measuring formation properties (e.g., porosity, permeability, resistivity). While these formation measurements aren’t directly used for deviation calculations, they provide valuable context to understand the geological factors that might be contributing to borehole deviation. For example, encountering a soft, unconsolidated formation could explain an unexpected increase in deviation.

Both MWD and LWD data are critical for accurate borehole deviation analysis and control, enabling proactive adjustments to maintain the planned trajectory.

Q 3. How do you interpret MWD/LWD data to determine borehole deviation?

Interpreting MWD/LWD data to determine borehole deviation involves several steps. The raw data, typically inclination, azimuth, and measured depth, is processed to calculate the wellbore trajectory.

- Data Acquisition: MWD/LWD tools collect data at regular intervals during drilling.

- Data Cleaning: Raw data often contains noise and errors; therefore, it needs to be cleaned and corrected to improve accuracy.

- Survey Calculation: Specialized software uses the cleaned data and sophisticated algorithms to calculate the wellbore trajectory, including inclination, azimuth, and dogleg severity at each survey station. This often involves applying minimum curvature methods for higher accuracy.

- Trajectory Visualization: The processed data is typically displayed graphically using profiles and 3D plots which allows engineers to visualize the well path and assess the deviation.

- Deviation Analysis: Engineers compare the measured trajectory to the planned trajectory to identify any deviations and analyze their causes. They examine dogleg severity, build-up, drop-off, and other deviations in detail.

This process relies heavily on sophisticated software packages that can handle large datasets and perform complex calculations. The outcome is a detailed understanding of the wellbore path allowing informed decisions on corrective actions or future well planning.

Q 4. What are the limitations of MWD and LWD technologies in measuring borehole deviation?

While MWD and LWD technologies are powerful, they have limitations in measuring borehole deviation:

- Tool Accuracy: The accuracy of MWD/LWD measurements is affected by various factors, including tool drift, sensor calibration, and environmental conditions (e.g., temperature, pressure). This can lead to uncertainties in deviation measurements.

- Survey Interval: Measurements are taken at discrete intervals; therefore, deviations that occur between these intervals might not be fully captured. The shorter the interval, the higher the accuracy, but this comes at increased cost and complexity.

- Environmental Factors: Magnetic interference from the drilling equipment, formation magnetic anomalies, and even the earth’s magnetic field can influence the accuracy of azimuth measurements.

- Data Transmission Issues: In some cases, communication between the downhole tools and the surface can be interrupted, resulting in data loss or incomplete surveys.

- Cost: MWD and LWD are costly technologies which can make them inaccessible for smaller or lower-budget operations.

It’s crucial to understand these limitations when interpreting data and planning drilling operations. Multiple independent measurements and continuous data quality checks are important to mitigate these issues.

Q 5. Explain the concept of wellbore trajectory planning and its importance.

Wellbore trajectory planning is the process of designing the optimal path for a wellbore before drilling begins. It involves specifying the planned inclination, azimuth, and depth at various points along the well path. It’s not just about reaching the target, it is about the most efficient and safe method to do so.

Its importance is immense, as it directly impacts several aspects of drilling:

- Safety: A well-planned trajectory reduces the risk of wellbore instability, stuck pipe, and other drilling hazards. It minimizes the likelihood of encountering unwanted geological formations.

- Efficiency: Optimal trajectory planning minimizes the drilling time and cost by reducing the distance to the target and avoiding complex well geometries. It optimizes drilling parameters.

- Productivity: It allows for better reservoir access by precisely placing the well to intersect the productive zones at optimal angles. It also allows for effective use of horizontal drilling technology.

- Completion and Production: A well-designed trajectory ensures ease of running casing, setting production tubing, and completing the well. It maximizes hydrocarbon recovery.

Imagine building a road – you wouldn’t start digging without a plan. The same applies to wellbore trajectory planning. A careful plan ensures the project is completed safely, efficiently, and to the desired specifications.

Q 6. How do you use directional drilling tools to control borehole deviation?

Directional drilling tools are used to control borehole deviation and steer the wellbore along the planned trajectory. These tools are incorporated into the Bottom Hole Assembly (BHA) and include:

- Bent Sub: A simple tool that introduces a pre-defined angle to the drill string, causing the bit to deviate in a specific direction. It can only cause a gradual change in wellbore direction.

- Adjustable Bent Sub: Allows for on-site adjustments to the bending angle which provides greater control.

- Positive Displacement Motors (PDM): These motors rotate the bit independently of the drill string, allowing the drill string to be oriented and control the bit’s direction for greater control and precision.

- Rotary Steerable Systems (RSS): The most advanced systems, using sophisticated mechanisms to change the bit’s orientation and direction dynamically based on real-time MWD data. They provide a high degree of accuracy and flexibility. They use specialized tools to measure the direction of the drill bit and provide feedback that allows adjustments to be made as the drilling progresses.

The selection of the appropriate directional drilling tool depends on the required level of control, the wellbore geometry, and the geological conditions. Experienced drilling engineers choose tools based on a trade-off between cost and accuracy. For example, a simple bent sub is less expensive than an RSS but less precise.

Q 7. What are the factors influencing borehole deviation during drilling operations?

Numerous factors influence borehole deviation during drilling operations. These can be broadly categorized into geological factors, drilling parameters, and equipment-related factors.

- Geological Factors:

- Formation Dip: The inclination of the rock layers. Layers that dip significantly can cause the wellbore to deviate along the dip direction.

- Formation Strength and Anisotropy: Variations in rock strength lead to uneven bit penetration, resulting in deviations. Anisotropy (directional variation in rock properties) can cause preferential drilling along certain directions.

- Faults and Fractures: These geological discontinuities can cause unexpected changes in wellbore direction, even leading to lost circulation.

- Stress State: In-situ stress fields can induce forces on the drill string that may cause deviations.

- Drilling Parameters:

- Weight on Bit (WOB): Excessive WOB can cause the bit to become embedded in the formation, leading to deviations. Insufficient WOB may cause poor penetration rate, especially in hard formations.

- Rotary Speed: Improper rotary speed can contribute to bit balling and uneven wear, leading to deviations.

- Torque: High torque can cause the drill string to twist and deviate, leading to spiral deviation.

- Mud Properties: The properties of the drilling fluid affect friction and hole cleaning, influencing deviation.

- Equipment-Related Factors:

- Bit Wear: Worn bits may cause irregular penetration and deviations.

- BHA Design: The design of the BHA influences the drill string stability and its response to the drilling environment.

- Drill String Condition: Bending, buckling, or other defects in the drill string contribute to deviation.

Understanding and managing these factors is crucial for successful wellbore trajectory control. Careful planning and real-time monitoring using MWD/LWD are essential to mitigate the impact of these factors and maintain the desired wellbore path.

Q 8. Describe different methods used to correct borehole deviation.

Correcting borehole deviation involves techniques aimed at steering the drill string back towards the planned trajectory. The methods employed depend on the severity of the deviation and the drilling environment. Common techniques include:

- Weight on Bit (WOB) adjustments: Increasing or decreasing the weight applied to the drill bit can influence the direction of drilling. Higher WOB can help steer the bit, while lower WOB can reduce the tendency to deviate.

- Rotary Steerable Systems (RSS): These sophisticated tools use downhole motors and sensors to actively control the direction of the drill bit. They are highly effective for precise steering and correcting significant deviations. Think of it like having a remote control for the drill bit.

- Mud Motor Steering: Mud motors use the flow of drilling mud to rotate the drill bit, allowing for directional control. This method is particularly useful in challenging formations.

- Bent Sub Assemblies: These specialized drill collars are designed with a pre-determined bend, causing the bit to steer in a specific direction. They’re less precise than RSS but simpler and often used for smaller corrections.

- Combination of Methods: Often, a combination of these methods is used for optimal results. For instance, an RSS might be used for major corrections, followed by WOB adjustments for fine-tuning.

The choice of method depends on several factors including the type of drilling rig, the formation properties, and the severity of the deviation. A small deviation might be corrected simply by adjusting WOB, while a large deviation would likely require an RSS.

Q 9. How do geological formations affect borehole deviation?

Geological formations significantly impact borehole deviation. Different rock types exhibit varying strengths, weaknesses, and anisotropies (directional variations in properties), leading to unpredictable drilling paths.

- Hard, Competent Rocks: These formations tend to provide more stability and less deviation. Think of drilling through solid granite – it’s less likely to veer off course.

- Soft, Unconsolidated Formations: These formations are easily eroded and can cause significant deviation. Imagine drilling through loose sand; the drill bit is more likely to wander.

- Anisotropic Formations: Formations with directional variations in strength (like layered sedimentary rocks) can cause the drill bit to preferentially deviate along planes of weakness. Picture drilling through layered shale – the bit might tend to follow along the layers.

- Faults and Fractures: The presence of faults and fractures creates pathways for the drill bit to follow, leading to unexpected deviations. It’s like the drill bit finding an easier path along a pre-existing crack.

- In-situ Stresses: The direction and magnitude of earth stresses can also influence deviation. High horizontal stresses can force the borehole to deviate horizontally.

Understanding the geological formations is crucial for predicting and mitigating borehole deviation. Geotechnical data, including well logs and geological surveys, are essential for planning the drilling trajectory and selecting appropriate steering techniques.

Q 10. What is the role of a Borehole Deviation Analyst in a drilling project?

A Borehole Deviation Analyst plays a vital role in ensuring the success of a drilling project. They are responsible for monitoring, analyzing, and interpreting borehole deviation data to guide drilling operations and prevent costly complications. Their responsibilities include:

- Pre-Drilling Planning: Analyzing geological data and designing the optimal well trajectory to minimize potential deviations.

- Real-time Monitoring: Tracking the wellbore’s path during drilling and identifying any deviations from the planned trajectory.

- Deviation Analysis: Interpreting the deviation data to determine the causes of any deviations and recommending corrective actions.

- Reporting and Communication: Providing regular reports to the drilling team and other stakeholders on the borehole’s progress and any potential issues.

- Problem Solving: Identifying and recommending solutions to address significant deviations or unforeseen geological challenges.

Essentially, they are the navigators of the drilling process, ensuring the well is drilled safely and efficiently to its intended target.

Q 11. Explain the significance of real-time monitoring of borehole deviation.

Real-time monitoring of borehole deviation is incredibly significant because it allows for immediate corrective actions, reducing the likelihood of severe deviations and costly remedial work. Think of it as using GPS for drilling.

- Early Detection of Problems: Real-time monitoring allows for the immediate identification of any deviations, enabling prompt intervention before they escalate.

- Optimized Drilling Strategy: The data allows for adjustments to the drilling parameters (WOB, drilling fluid properties, etc.) in real-time to correct the deviation and maintain the planned trajectory.

- Cost Savings: Early detection and correction prevents the need for costly sidetracking or re-drilling operations.

- Improved Safety: Real-time monitoring enhances safety by allowing for early detection of potential hazards associated with extreme deviations.

- Increased Efficiency: By proactively addressing deviations, drilling time is reduced and the overall efficiency of the operation is improved.

Without real-time monitoring, a significant deviation might only be discovered after the drill string is pulled out of the well, necessitating costly and time-consuming remedial actions.

Q 12. How do you analyze borehole deviation data to identify potential problems?

Analyzing borehole deviation data involves a systematic approach to identify potential problems. This typically involves:

- Data Acquisition and Quality Control: Ensuring the accuracy and reliability of the deviation data obtained from downhole tools (e.g., gyroscopic, magnetic, or inclinometry surveys).

- Data Visualization: Plotting the deviation data to create a visual representation of the borehole trajectory (typically using specialized software).

- Deviation Rate Analysis: Calculating the rate of deviation to identify sections of the borehole with rapid changes in direction.

- Comparison with Planned Trajectory: Comparing the actual borehole path with the planned trajectory to identify deviations and assess their severity.

- Correlation with Geological Data: Correlating the deviation patterns with geological information (e.g., well logs, geological maps) to identify potential causative factors (e.g., formation type, stress, fractures).

- Statistical Analysis: Using statistical methods to identify trends and patterns in the deviation data, which might indicate underlying issues.

By combining visual inspection with quantitative analysis, potential problems such as excessive deviation, dog-legging, or unexpected changes in direction can be quickly identified and addressed.

Q 13. What software or tools are you familiar with for borehole deviation analysis?

I am familiar with several software packages and tools used for borehole deviation analysis. These include:

- Petrel (Schlumberger): A comprehensive reservoir simulation and modeling software that includes robust modules for borehole trajectory analysis and planning.

- Landmark DecisionSpace (Halliburton): Another powerful suite of software for planning, drilling, and analyzing wells, providing tools for visualizing and analyzing deviation data.

- Roxar RMS (Emerson): A suite of reservoir modeling and management software that offers tools for analyzing and managing wellbore trajectories.

- Dedicated Deviation Analysis Software: Specialized software packages exist for dedicated borehole deviation analysis, providing tools for detailed analysis, reporting, and visualization.

In addition to commercial software, I am also proficient in using data analysis tools such as Python with libraries like NumPy and Matplotlib for data manipulation, visualization, and custom analysis scripts.

Q 14. How do you ensure accurate data acquisition and processing in borehole deviation analysis?

Ensuring accurate data acquisition and processing is crucial for reliable borehole deviation analysis. This requires meticulous attention to detail throughout the entire process:

- Calibration and Maintenance of Downhole Tools: Regularly calibrating and maintaining downhole measurement tools (e.g., gyroscopic, magnetic, inclinometers) to ensure accurate data acquisition.

- Proper Survey Techniques: Using appropriate survey techniques and following standardized procedures for data acquisition to minimize errors.

- Data Validation and Quality Control: Implementing robust quality control checks at each stage of the process to identify and correct any data anomalies or inconsistencies.

- Error Propagation Analysis: Considering potential sources of error throughout the process and analyzing their impact on the results.

- Cross-Validation of Data: Using multiple data sources (where possible) to cross-validate the findings and improve accuracy.

- Appropriate Data Processing Techniques: Applying appropriate filtering and smoothing techniques to the data to reduce noise and highlight underlying trends.

By adhering to strict quality control measures and best practices, we can maximize data accuracy and ensure the reliability of the resulting deviation analysis.

Q 15. Describe a situation where you had to troubleshoot a borehole deviation problem.

During a geothermal drilling project, we encountered unexpected and severe borehole deviation. Initially, the well was tracking as planned, but after reaching a certain depth, the inclination increased dramatically. This was causing significant concern because it threatened to deviate from the targeted geothermal reservoir.

Troubleshooting involved a multi-step process. First, we reviewed the drilling parameters and logging data to pinpoint the depth and potential causes of the deviation. We analyzed the formation characteristics at that depth – including the presence of soft, unconsolidated formations or potential geological faults – as these can influence borehole stability and contribute to deviation. Secondly, we employed advanced measurement while drilling (MWD) tools to obtain real-time data on the wellbore trajectory. This helped us understand the rate and direction of the deviation. Finally, we implemented corrective measures. This included adjusting the drilling parameters, such as weight on bit (WOB) and rotary speed, and utilizing steerable motor technology to correct the wellbore trajectory, bringing it back towards the target. Regular measurement while drilling (MWD) checks were carried out to monitor progress and ensure the correction was successful.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you communicate complex technical information about borehole deviation to non-technical audiences?

Communicating complex technical information about borehole deviation to a non-technical audience requires simplification and the use of visual aids. Instead of using jargon like ‘inclination’ or ‘azimuth’, I would describe them as the ‘angle of the hole’ and the ‘direction the hole is pointing’, respectively. I use analogies to make it easier to understand. For example, I’d explain borehole deviation as similar to a garden hose that bends while watering a lawn; the hose represents the borehole and the bending represents deviation.

I rely heavily on visual aids such as diagrams and 3D models showing the well’s path, clearly highlighting the deviation from the planned trajectory. Explaining the cost implications – potential delays, increased drilling time, and increased expenses – helps illustrate the importance of controlled deviation. Simple charts showing the well’s path compared to the planned path, along with the corresponding cost implications, are highly effective.

Q 17. What are the safety considerations related to borehole deviation control?

Safety is paramount in borehole deviation control. Uncontrolled deviation can lead to several hazards. One significant risk is the potential for wellbore instability, resulting in wellbore collapses or stuck pipe. This poses risks to personnel on site and can lead to significant equipment damage.

Another critical safety consideration is the potential for kicks and blowouts. If a deviated wellbore intersects a high-pressure formation unexpectedly, the sudden influx of formation fluids could lead to a blowout. To prevent this, rigorous well control procedures are crucial. Preventing stuck pipe is a major safety concern since retrieving a stuck drill string in a highly deviated wellbore is exceptionally challenging and time-consuming, increasing the risk of accidents. Regular monitoring of the wellbore’s trajectory, adherence to established drilling practices, and proper well control protocols are essential to mitigate these risks. Training personnel on safety procedures and emergency response plans is also crucial.

Q 18. Explain the difference between build rate, turn rate, and inclination.

These three terms are fundamental to understanding borehole deviation:

- Inclination: This is the angle of the borehole from the vertical. It’s measured in degrees, with 0° being perfectly vertical and 90° being perfectly horizontal. Imagine a plumb line hanging straight down; the angle the borehole makes with that line is the inclination.

- Build Rate: This is the rate at which the inclination of the borehole changes over a given distance. It’s typically measured in degrees per unit of length (e.g., degrees per 30 meters). Think of it as how quickly the borehole is bending.

- Turn Rate: This refers to the rate of change in the azimuth (direction) of the borehole. Azimuth is measured as a compass bearing. The turn rate indicates how rapidly the wellbore is changing its direction within a given distance. It is also usually measured in degrees per unit of length (e.g., degrees per 30 meters).

For example, a build rate of 2°/30m means the inclination increases by 2 degrees for every 30 meters drilled. A turn rate of 3°/30m signifies that the borehole’s direction shifts by 3 degrees for every 30 meters drilled.

Q 19. What are the economic consequences of uncontrolled borehole deviation?

Uncontrolled borehole deviation has significant economic consequences. The most direct impact is increased drilling time and costs. A deviated well may require additional drilling to reach the target zone, leading to extended operational time and increased fuel and labor costs. The potential for stuck pipe adds substantially to these costs, involving expensive and time-consuming fishing operations.

Furthermore, uncontrolled deviation can cause complications during well completion. If the well is not accurately positioned within the reservoir, it may compromise the effectiveness of the completion operations, reducing production and requiring remedial work, leading to further economic losses. In extreme cases, the well might have to be abandoned, incurring complete loss of investment. Accurate borehole deviation control is a crucial factor for minimizing such risks.

Q 20. How does borehole deviation impact well completion operations?

Borehole deviation significantly impacts well completion operations. Accurate knowledge of the well’s trajectory is crucial for designing and implementing a successful completion strategy. If the well deviates excessively from the planned path, it can cause difficulties in setting casing and perforating the reservoir. For example, running casing in a highly deviated wellbore increases the risk of buckling and getting stuck, necessitating expensive remedial operations. Moreover, inaccurate positioning may mean that perforations do not intersect the reservoir optimally, reducing the productivity of the well.

Deviation also impacts the placement of downhole equipment such as packers, gravel packs, and production tubing. In horizontal wells, accurate trajectory control is critical for maximizing reservoir contact and production. Misaligned perforations in a horizontal well can seriously impair productivity, leading to inefficient exploitation of the reservoir. Precise control of the wellbore trajectory is, therefore, crucial for optimal well completion and reduced costs.

Q 21. How does borehole deviation affect reservoir access and production?

Borehole deviation directly affects reservoir access and production. Ideally, wells should be positioned to intersect the reservoir at the most productive zones. Uncontrolled deviation can cause the wellbore to miss these zones completely or to intersect them at an inefficient angle. This reduces the well’s productivity and recovery rates, as the well may not adequately contact the hydrocarbon-bearing formations.

In horizontal wells, maintaining the desired trajectory is particularly critical to maximizing contact with the reservoir. Deviation that results in a less than optimal horizontal section length reduces the effective reservoir drainage area, impacting overall production. In addition, uncontrolled deviation can lead to the wellbore intersecting unwanted zones, like water or gas, affecting the flow and potentially reducing the quality of the produced fluids. Precise control of borehole deviation is crucial for maximizing reservoir access and ensuring efficient hydrocarbon production.

Q 22. Describe the process of generating a well trajectory plan.

Generating a well trajectory plan is a crucial initial step in directional drilling. It involves meticulously designing the path the borehole will follow underground, considering various geological and operational factors. This isn’t simply a straight line; it’s a carefully planned 3D route optimized for reaching the target reservoir while avoiding obstacles and minimizing risks.

The process typically starts with defining the target location and its subsurface coordinates. Then, using specialized software, engineers design the planned trajectory, considering factors like:

- Target depth and location: The precise coordinates of the reservoir.

- Surface location: The point where drilling begins.

- Kicks and build-up rates: The planned changes in the wellbore inclination and azimuth.

- Dog legs: Sharp bends in the wellbore (we’ll discuss this further in a later answer).

- Geological formations: Anticipating potential challenges like fault zones or high-pressure zones.

- Operational constraints: Equipment limitations, drilling time, and cost.

The software generates a detailed plan showing the planned trajectory in a 3D view, including inclination and azimuth profiles against depth. This plan serves as a roadmap for the drilling crew, allowing them to monitor progress and make necessary adjustments during the drilling operation. For example, if we are drilling a horizontal well to maximize contact with a shale gas reservoir, the plan would include a long build-up section to reach the target depth, followed by a long hold section to maximize horizontal reach. The plan is constantly reviewed and updated throughout the drilling process, adapting to unforeseen geological changes.

Q 23. What are some common challenges encountered in borehole deviation analysis?

Borehole deviation analysis, while crucial, presents several challenges. One major issue is the inherent uncertainty in subsurface conditions. Unexpected geological formations, such as faults or unexpected changes in rock strength, can significantly impact the well trajectory. Accurate prediction is difficult and necessitates constant monitoring and adjustments.

Another challenge lies in the accuracy of measurement tools. While technology has advanced, there are still limitations in obtaining precise measurements, particularly in challenging geological environments. Tool failures or poor signal quality can lead to inaccurate data. Furthermore, the accumulation of errors across the entire borehole length can magnify the overall deviation.

Finally, complex well trajectories, such as those in highly deviated or horizontal wells, pose significant analytical challenges. The interplay of various factors affecting the wellbore path increases the complexity, making precise analysis and prediction more difficult. A further challenge is the management and interpretation of data from multiple sources, ensuring consistency and accuracy throughout the drilling process.

Q 24. How do you validate the accuracy of borehole deviation measurements?

Validating the accuracy of borehole deviation measurements is crucial for ensuring the well reaches its target and meets operational requirements. This process involves multiple steps and techniques.

One primary method is comparison with independent measurements. This might involve using different types of measurement tools – for example, comparing measurements from a gyro-surveying tool with those from an electromagnetic tool. Discrepancies between these readings can highlight potential errors and prompt further investigation. Another method is to conduct periodic checks with wireline logging tools; these tools provide independent confirmation of the well’s position. Furthermore, comparing the measured deviation with the planned trajectory, and analyzing any discrepancies, allows identification of potential issues during drilling and subsequent adjustments to the planned trajectory.

Additionally, continuous monitoring of drilling parameters, such as weight on bit (WOB) and rotational speed, alongside the deviation data, can help identify potential causes of unexpected deviations and improve future planning. For instance, consistently high WOB might be indicative of a harder formation, leading to increased deviation. Finally, post-drill analysis, where the actual well path is compared to the plan using comprehensive data, helps refine future well planning and improve the accuracy of deviation predictions.

Q 25. Explain the concept of a dog-leg severity.

Dog-leg severity (DLS) quantifies the sharpness of a bend in a wellbore. Imagine bending a piece of wire; the sharper the bend, the higher the DLS. In directional drilling, a high DLS can cause problems, including increased torque and drag on the drill string, potential damage to the drill string or downhole tools, and difficulties in running casing.

DLS is typically measured in degrees per 100 feet (or degrees per 30 meters). A low DLS indicates a gradual bend, while a high DLS signifies a sharp bend. The calculation is based on the change in inclination and azimuth over a specific interval. While the exact formula varies slightly depending on the software or method used, the core principle remains the same: measuring the change in direction over a short distance. For instance, a DLS of 5 degrees per 100 feet implies a gentle curve, whereas a DLS of 15 degrees per 100 feet represents a sharper bend.

Controlling DLS is essential for efficient and safe drilling operations. Excessively high DLS necessitates adjustments in drilling parameters or re-planning of the trajectory. Experienced directional drillers utilize DLS as a key performance indicator (KPI) to monitor wellbore quality and drilling efficiency.

Q 26. How do you use borehole deviation data to optimize drilling parameters?

Borehole deviation data is invaluable for optimizing drilling parameters. By analyzing the actual well path in comparison to the planned trajectory, we can identify factors contributing to deviations and adjust drilling strategies accordingly. For example, if the well is deviating more than planned to one side, it could indicate a directional drilling motor is not working efficiently or issues with tool face orientation.

Real-time analysis of deviation data allows for immediate adjustments to parameters such as:

- Weight on bit (WOB): Increasing or decreasing WOB can influence the rate of penetration and hence the deviation. Higher WOB can result in increased bending.

- Rotary speed: Adjusting rotational speed can impact the drilling rate and the tendency for the wellbore to deviate.

- Drill string inclination and azimuth: These are actively controlled parameters using directional drilling equipment like mud motors and steerable systems, influencing the rate and direction of deviation.

- Mud properties: The rheological properties of the drilling mud can also affect wellbore stability and deviation, therefore influencing the wellbore’s trajectory.

Let’s say a well is consistently deviating to the left of the planned trajectory. Analysis of the deviation data might reveal a correlation with higher-than-expected weight on bit in a specific geological formation. By reducing the WOB, the tendency to deviate can be mitigated, keeping the well closer to the planned trajectory, thus optimizing drilling parameters and maintaining wellbore stability and drilling efficiency.

Q 27. What are the latest advancements in borehole deviation measurement and control technologies?

Recent advancements in borehole deviation measurement and control technologies have significantly enhanced accuracy and efficiency. One key development is the integration of advanced sensor technologies within measurement-while-drilling (MWD) and logging-while-drilling (LWD) tools. These tools now provide higher-resolution data, including more precise inclination and azimuth measurements, as well as improved data transmission capabilities, allowing for real-time monitoring and adjustment.

The use of advanced algorithms and sophisticated software for trajectory prediction and control has also improved significantly. These systems can integrate various data sources (geological information, drilling parameters, real-time deviation measurements) to predict the well path with greater accuracy and provide recommendations for optimized drilling strategies. Furthermore, the development of improved directional drilling motors with enhanced steering capabilities allows for greater precision in controlling wellbore trajectories, particularly in challenging geological formations.

Additionally, advancements in automation and robotics are playing a crucial role. Automation is improving the accuracy and repeatability of drilling operations, while robotic systems enhance remote control and monitoring, allowing for safer and more efficient directional drilling. The use of artificial intelligence and machine learning in analysing deviation data and predicting wellbore trajectories promises to improve the accuracy and efficiency even further.

Q 28. Describe your experience with different types of directional drilling motors.

My experience encompasses a wide range of directional drilling motors, each with its own strengths and weaknesses. I’ve worked extensively with positive displacement motors (PDM), which are commonly used for building inclination and maintaining directional control. These motors use a positive displacement mechanism to rotate the drill string and achieve directional changes through the orientation of a bent sub.

I’m also familiar with turbine motors, which are generally preferred for maintaining direction in long horizontal sections of a well due to their high torque capacity and ability to operate at higher RPM. The choice of motor heavily depends on the planned trajectory, the geological formation, and the available power at the surface.

Furthermore, I have experience using steerable motors, which offer more flexibility and precision in controlling the wellbore trajectory. These motors allow for real-time adjustments to inclination and azimuth during drilling, making them particularly valuable in complex well designs. The selection of a specific motor type is based on a detailed analysis of the planned trajectory and the anticipated geological conditions, taking into account factors such as torque and drag, rate of penetration and the desired accuracy in achieving the final target depth and location.

Key Topics to Learn for Borehole Deviation Analysis Interview

- Fundamentals of Borehole Deviation: Understanding the causes of deviation (e.g., tool face, formation properties, drilling parameters), and the different types of deviation (e.g., dog legs, helical deviation).

- Measurement Techniques: Familiarity with various tools and methods used to measure borehole deviation, including inclinometers, gyro-surveying, and magnetic surveys. Understanding the limitations and accuracies of each method.

- Deviation Modeling and Prediction: Knowledge of software and techniques used to model and predict borehole trajectory, including the use of directional drilling parameters and geological models. This includes understanding the impact of various factors on trajectory.

- Compensation Techniques: Exploring methods used to control and correct borehole deviation, including techniques like directional drilling and steerable drilling systems. Understanding the practical application of these techniques.

- Data Analysis and Interpretation: Ability to interpret deviation survey data, identify potential issues, and make informed decisions based on the analysis. Proficiency in interpreting graphical representations of borehole trajectories.

- Safety and Risk Mitigation: Understanding safety protocols and risk mitigation strategies related to borehole deviation control and management. This includes awareness of potential hazards and best practices for preventing them.

- Advanced Concepts: Exploring advanced topics such as real-time drilling optimization, advanced surveying techniques, and the use of automation in deviation control.

Next Steps

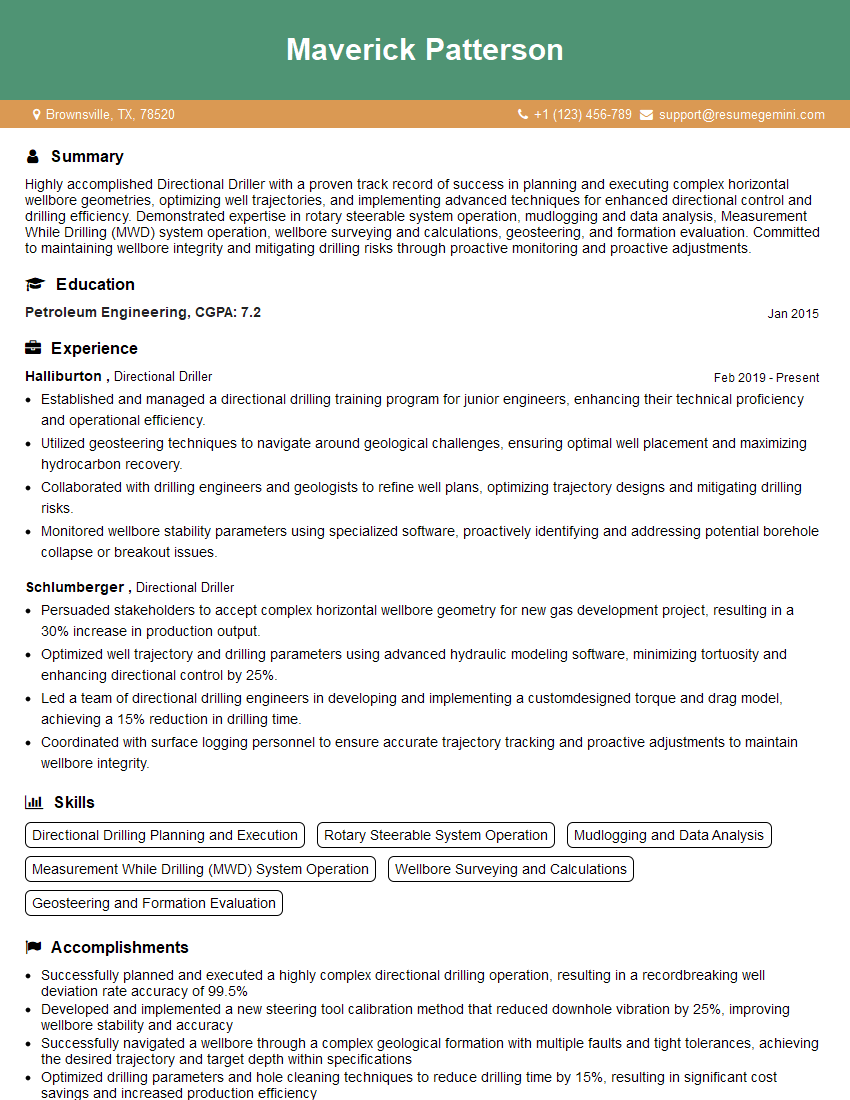

Mastering Borehole Deviation Analysis opens doors to exciting career opportunities in the energy and geological sectors, offering significant growth potential and specialized roles. To maximize your chances of landing your dream job, crafting a compelling and ATS-friendly resume is crucial. ResumeGemini can help you build a professional resume that highlights your skills and experience effectively. We provide examples of resumes tailored to Borehole Deviation Analysis to give you a head start. Invest the time to build a strong application – it’s an investment in your future success.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good