Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Brick Cutting interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Brick Cutting Interview

Q 1. What types of bricks are commonly used and how do their properties affect cutting techniques?

Brick types significantly impact cutting techniques. Common types include clay bricks (which can be further categorized by their strength and hardness), concrete bricks, and engineering bricks. Clay bricks, for instance, range from soft, easily-cut types to incredibly hard, fired bricks requiring specialized tools. Concrete bricks, due to their inherent strength and often the presence of aggregate, necessitate more robust cutting methods. Engineering bricks, designed for high-strength applications, pose even greater challenges and often demand diamond-tipped tools. The key is understanding the material’s hardness and potential for fracturing.

- Soft Clay Bricks: These are relatively easy to cut with hand tools like a brick hammer and bolster.

- Hard Clay Bricks: These often require angle grinders with diamond blades for efficient and clean cuts.

- Concrete Bricks: These are best cut with a masonry saw equipped with a diamond blade, due to their density and aggregate.

- Engineering Bricks: These typically need specialized diamond blades and possibly a wet saw to manage the heat and dust generated during cutting.

Q 2. Describe the different methods for cutting bricks (e.g., hand tools, power tools).

Brick cutting employs various methods, each suited to different brick types and project needs. Hand tools offer precision for smaller jobs, while power tools enhance speed and efficiency for larger-scale projects. Let’s explore some common methods:

- Hand Tools: A brick hammer and bolster are used for scoring and breaking bricks cleanly along a line. This method is best for soft bricks and precise cuts but is labor-intensive.

- Power Tools:

- Angle Grinder with Diamond Blade: A versatile tool for various brick types, providing quick cuts, but generating significant dust. A wet cutting system can mitigate dust.

- Masonry Saw (with diamond blade): Offers cleaner, more precise cuts, especially for hard bricks and intricate shapes. Wet cutting is often preferred to manage heat and dust.

- Brick Cutter (Handheld): A specialized tool offering some of the advantages of a masonry saw but smaller and more portable.

The choice depends on factors such as brick type, quantity, desired precision, and available resources. For example, a small DIY project might only need a hammer and bolster, while a large construction project necessitates efficient power tools.

Q 3. What safety precautions are crucial when cutting bricks?

Safety is paramount when cutting bricks. The potential for eye injury from flying debris, inhalation of dust, and cuts from sharp tools necessitates rigorous safety practices.

- Eye Protection: Always wear safety glasses or a full-face shield to protect against flying debris.

- Respiratory Protection: A dust mask is crucial, especially when using power tools. Consider a respirator for extended work or when cutting particularly dusty bricks.

- Hearing Protection: Power tools can be noisy; earplugs or earmuffs are essential for protecting your hearing.

- Hand Protection: Wear work gloves to prevent cuts and abrasions.

- Clothing: Wear long sleeves and sturdy work pants to protect your skin.

- Ventilation: Work in a well-ventilated area or use a dust extraction system to minimize dust inhalation. Wet cutting significantly reduces dust.

- Proper Tool Use: Always follow the manufacturer’s instructions for all power tools and ensure they are in good working order.

Q 4. How do you ensure accurate and precise cuts when working with bricks?

Accurate and precise brick cuts require careful planning and execution. The key is to establish a consistent cutting line and maintain control during the cutting process.

- Marking the Cut Line: Use a pencil or marker to clearly mark the desired cut line. A straight edge can ensure a clean, straight line.

- Stable Work Surface: Ensure the brick is securely positioned on a stable, flat surface to avoid accidental slippage.

- Controlled Cuts: Apply steady pressure when using hand tools or power tools. Avoid rushing the process to maintain accuracy.

- Using Guides: For intricate cuts, a guide can be used to ensure consistent and accurate cuts, especially when working with power tools. These can be homemade or purchased.

- Measuring Twice, Cutting Once: This old adage is particularly crucial with bricks; double-checking your measurements will avoid costly mistakes.

Practice makes perfect; with experience, you’ll develop a feel for applying the right amount of pressure and technique for achieving precise cuts.

Q 5. Explain the importance of selecting the right cutting tool for a specific brick type.

Choosing the right cutting tool is vital for efficiency and safety. Using the wrong tool can lead to broken bricks, damaged tools, and even injury. The hardness and type of brick dictate tool selection.

- Soft Clay Bricks: A brick hammer and bolster are ideal for precise cuts.

- Hard Clay Bricks: An angle grinder with a diamond blade is typically the best option.

- Concrete Bricks: A masonry saw with a diamond blade designed for concrete is necessary for clean cuts.

- Engineering Bricks: Specialized diamond blades and potentially a wet saw are often required due to their exceptional hardness.

Trying to cut a hard brick with a bolster will likely result in a shattered brick. Similarly, using a hand tool for a large-scale job is time-consuming and inefficient. Matching the tool to the task minimizes damage and maximizes safety and productivity.

Q 6. What are the common problems encountered during brick cutting and how are they resolved?

Common problems in brick cutting include chipped or broken bricks, inaccurate cuts, and excessive dust. Let’s look at how these issues are resolved:

- Chipped or Broken Bricks: This often results from incorrect tool selection, insufficient support during cutting, or excessive force. Selecting the appropriate tool for the brick type and applying gentle, controlled pressure will minimize this problem. Using a scoring method before cutting with a hammer and bolster can also reduce breakage.

- Inaccurate Cuts: This typically stems from poorly marked lines, uneven cutting pressure, or a dull blade. Double-checking measurements and using a straight edge for marking are essential. A sharp blade is critical for accurate cuts in power tools.

- Excessive Dust: This is inherent to dry cutting. Using a wet saw or wet cutting system significantly reduces dust. A good quality dust mask or respirator is also essential.

Addressing these problems requires a combination of proper planning, tool selection, and careful execution. Proper technique and preventive measures are key to a smooth brick-cutting process.

Q 7. How do you handle damaged or broken bricks during a project?

Damaged or broken bricks present a challenge in any project. The solution depends on the extent of the damage, the location of the brick, and the overall aesthetic requirements of the project.

- Minor Chips or Cracks: These can often be hidden with mortar, especially in areas less visible.

- Significant Damage: Severely damaged bricks should be replaced. This requires sourcing matching bricks. If exact matching is impossible, consider using bricks from a less visible area for replacement.

- Strategic Placement: Where feasible, damaged bricks can be strategically placed in areas where they are less noticeable.

Careful handling during transportation and storage minimizes damage. When replacement is necessary, ensuring a consistent mortar color and joint size helps blend the replacement brick seamlessly. Always prioritize safety during the handling and replacement process to prevent further injury.

Q 8. What are the different types of brick joints and how do you achieve them?

Bricklaying relies heavily on the type of joint used, influencing both aesthetics and structural integrity. Different joints are achieved through precise brick placement and tooling.

- Full Joint/Stretcher Bond: The most common, where bricks are laid end-to-end, creating a continuous horizontal line. Achieved by simply ensuring uniform mortar placement and consistent brick alignment.

- Header Bond: Bricks are laid with their ends facing outwards, adding strength and visual interest. Requires careful planning and precise cutting to fit headers into the stretcher bond pattern.

- English Bond: Alternates courses of headers and stretchers, providing both strength and visual appeal. This bond requires accurate cutting to ensure the headers fit perfectly between the stretchers.

- Flemish Bond: A more complex bond with alternating headers and stretchers in each course, creating a visually intricate pattern. This needs meticulous cutting and planning to maintain the pattern’s consistency.

- Raking Joint: The mortar is cut away at an angle to create a sloped effect, typically for aesthetic reasons. This involves skilled tooling after the mortar has slightly set.

Achieving each joint type correctly relies on consistent mortar application, accurate brick placement, and the appropriate tooling techniques. Using a jointing tool helps to create clean, consistent lines and a professional finish.

Q 9. How do you calculate the quantity of bricks needed for a given project?

Calculating brick quantity requires careful measurements and consideration of several factors. Think of it like baking a cake – you need the right ingredients in the correct proportions!

First, calculate the area to be bricked. Let’s say it’s a wall 10 feet long and 8 feet high. This gives us 80 square feet (10 x 8). Next, account for the size of your bricks. Standard bricks are typically around 8 inches long and 2 1/4 inches wide. This gives an area of about 0.625 square feet (8/12 x 2.25/12). Finally, we need to account for waste (around 5-10%, depending on complexity). Therefore, a simple calculation would be:

(Wall Area / Brick Area) * Waste Factor = Total Bricks NeededIn our example: (80 sq ft / 0.625 sq ft) * 1.05 (5% waste) ≈ 134.4 bricks. Always round up to the nearest whole brick to ensure you have enough. This simple formula needs adjustment for different brick sizes, wall types (e.g., cavity walls), and mortar joint thickness. Software or online calculators can be invaluable for more complex projects.

Q 10. Explain the process of preparing bricks for cutting (e.g., cleaning, soaking).

Preparing bricks for cutting is crucial for a clean and precise cut. Think of it like preparing a piece of wood for carving – the better the preparation, the better the result.

- Cleaning: Remove any loose debris, dirt, or mortar residue from the bricks using a wire brush or a pressure washer. This ensures a clean cutting surface and prevents damage to the cutting tool.

- Soaking (Optional): Soaking bricks, especially older, harder ones, for a few hours can soften them slightly, reducing the risk of chipping or cracking during cutting. This is especially useful for hand cutting.

- Marking: Use a pencil or marking tool to accurately mark the cutting lines on the bricks. Precision is key for accurate cuts.

The cleaning process is critical to avoid damaging your cutting tools. Removing loose material also ensures a clean cut, preventing any crumbling or uneven surfaces.

Q 11. Describe your experience with different types of brick saws and their applications.

My experience encompasses various brick saws, each suited to specific tasks and brick types.

- Hand Saw: Best for smaller cuts and intricate shaping on softer bricks. Requires skill and patience for accurate cuts. Great for fine detail work.

- Circular Saw with Diamond Blade: Ideal for straight cuts and mass production. Provides speed and precision, particularly for harder bricks. Requires safety precautions, like eye protection and dust masks.

- Angle Grinder with Diamond Blade: Extremely versatile for both straight and curved cuts, as well as shaping. Offers high speed and precision but demands significant skill and caution to prevent injury.

- Wet Saw: Ideal for cutting harder bricks or larger quantities. The water keeps the blade cool and reduces dust. This is a safer and more efficient option, especially for longer cuts.

The choice of saw depends on the project’s scale, the brick type, and the required level of precision. Each saw demands appropriate safety measures and proper operating techniques.

Q 12. How do you maintain and care for your brick cutting tools?

Maintaining brick cutting tools is crucial for their longevity and performance. Regular care prevents damage and ensures accuracy.

- Cleaning: After each use, clean the blades thoroughly to remove dust, mortar residue, and brick fragments. This will prevent clogging and damage.

- Lubrication: For some saws (e.g., circular saws), regular lubrication helps maintain smooth operation and reduces friction.

- Blade Sharpening: Dull blades lead to inaccurate cuts and increased effort. Diamond blades should be professionally sharpened, while hand saw blades may be sharpened using a sharpening stone.

- Storage: Store tools in a dry place, away from moisture and extreme temperatures, to protect against corrosion and damage.

Investing time in tool maintenance ensures accuracy, safety, and tool longevity, saving money in the long run.

Q 13. What are the common causes of inaccurate cuts and how can they be prevented?

Inaccurate cuts stem from various factors; addressing them prevents costly mistakes.

- Dull Blades: Dull blades result in jagged, uneven cuts. Regular sharpening is essential.

- Incorrect Marking: Inaccurate measurements and markings directly translate to inaccurate cuts. Using a ruler and a sharp pencil is critical.

- Improper Tool Use: Applying excessive pressure or using the wrong technique can cause inaccurate cuts or damage the brick. Practice and proper technique are paramount.

- Brick Quality: Cracks or inconsistencies in the brick itself can impact cutting accuracy. Inspect bricks before cutting.

- Vibration: Excessive vibration during the cutting process can lead to deviations from the cutting line. Ensure the saw is firmly supported.

By focusing on these potential issues and practicing proper techniques, you can reduce inaccuracy and ensure precision.

Q 14. How do you ensure the structural integrity of the brickwork after cutting?

Maintaining structural integrity post-cutting is paramount. It’s like ensuring the stability of a sculpture after carving.

- Clean Cuts: Precise cutting minimizes stress points and potential weaknesses.

- Proper Mortar Application: Using the right amount and type of mortar is crucial for filling any gaps and ensuring proper bonding.

- Support During Cutting: Avoiding excessive force during cutting minimizes chipping or cracking, crucial for structural integrity. A stable cutting surface helps here.

- Reinforcement (If Necessary): For critical structural elements, adding reinforcement, like steel wire mesh, might be necessary, especially with significant cuts.

- Inspection: Thoroughly inspecting the cut areas before laying the bricks prevents any compromises on the structure.

Careful attention to these steps ensures that the structural integrity of the brickwork remains uncompromised.

Q 15. Describe your experience with different types of mortars and their compatibility with bricks.

Mortar selection is crucial for successful bricklaying. The right mortar ensures strong adhesion, weather resistance, and longevity. My experience encompasses various types, each with its own strengths and weaknesses. For instance, Type N mortar is a general-purpose mix, suitable for most exterior and interior brickwork. It offers a good balance of strength and workability. Type S mortar, with its higher compressive strength, is ideal for projects requiring superior load-bearing capacity, like retaining walls or foundation work. Type M mortar is the strongest, often used in high-stress environments or areas susceptible to seismic activity. The choice depends heavily on the brick type; porous bricks might require a different mortar than dense, fired clay bricks. For example, highly porous bricks might benefit from a richer mortar mix to fill the voids and enhance bonding, while dense bricks can handle a leaner mix. Compatibility also involves considering the moisture content of the bricks and the surrounding environment to prevent efflorescence (salt deposits) and ensure long-term structural integrity.

Choosing the wrong mortar can lead to issues like cracking, crumbling, and reduced structural stability. Therefore, I always carefully assess the project’s requirements and the specific brick properties before making a mortar selection.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle intricate cuts and curves in brickwork?

Intricate cuts and curves demand precision and patience. I use a combination of techniques depending on the complexity of the design. For simple curves, I might employ a template made from sturdy material like plywood, accurately tracing the curve onto the brick before cutting with a brick saw. For more complex shapes, I often use a combination of scoring with a masonry chisel and carefully chipping away at the brick. A diamond blade angle grinder is invaluable for intricate cuts, offering speed and accuracy. However, it’s crucial to wear appropriate safety gear, like safety glasses and a dust mask, when using power tools. Sometimes, I even create smaller custom bricks by carefully cutting and piecing them together – a bit like working with a miniature jigsaw puzzle, to achieve very tight radiuses or unusual shapes. The key is meticulous planning and execution, ensuring a seamless blend between the cut bricks and the existing structure.

One time, I had to create a curved brick archway for a residential project. It involved dozens of custom cut bricks, each uniquely shaped to fit the overall curve perfectly. It was a challenging job, but the final result was stunning and demonstrated the value of careful planning and methodical execution.

Q 17. What is the proper way to dispose of brick waste?

Responsible disposal of brick waste is crucial for environmental compliance and responsible construction practices. My approach follows local regulations and prioritizes recycling and reuse whenever possible. Salvageable bricks, even those with minor chips, are often reused in less visible areas of the project or repurposed for landscaping features. Broken bricks can sometimes be crushed into aggregate for use in base materials or fill, reducing the environmental impact of sending them to a landfill. For waste that cannot be reused or recycled, I ensure it’s disposed of through registered and authorized waste removal services that comply with all relevant environmental regulations. This typically involves separating bricks from other construction waste for efficient processing and minimizes environmental harm.

Q 18. Describe your experience working with different brick sizes and formats.

My experience extends to a wide variety of brick sizes and formats, including standard modular bricks, oversized bricks, and thin bricks. Each type presents unique challenges and opportunities. Standard modular bricks offer ease of handling and predictable layout, while oversized bricks can expedite construction but require careful handling to prevent breakage. Thin bricks are becoming increasingly popular for their aesthetic appeal but necessitate precise cutting and installation. Understanding the different sizes and formats requires adaptability in cutting techniques and planning strategies. This often involves careful planning to minimize waste and to ensure correct alignment throughout the project. For instance, with oversized bricks, careful planning of cuts minimizes potential issues with weight and structural considerations. With thin bricks, precision becomes even more critical due to their fragility.

Q 19. How do you adapt your cutting techniques to varying weather conditions?

Weather conditions significantly impact brick cutting and installation. Extreme heat can cause the mortar to dry too quickly, affecting adhesion and potentially creating cracks. Cold temperatures can slow the drying process and make the mortar brittle. High humidity can lead to slower drying times and increased chances of efflorescence. To adapt, I adjust my techniques accordingly. In hot weather, I use a water spray to keep the bricks and mortar moist during application. In cold weather, I take extra care to protect the bricks and mortar from freezing temperatures, using covers or temporary heating where appropriate. For high humidity, I employ proper ventilation to expedite drying and prevent moisture buildup. Proper planning and selection of mortar, as discussed earlier, also plays a key role in mitigating weather-related challenges.

Q 20. Explain your knowledge of building codes and regulations related to brickwork.

Building codes and regulations regarding brickwork are paramount for safety and structural integrity. My understanding encompasses local, regional, and national regulations, including requirements for bond patterns, mortar specifications, structural calculations, and acceptable tolerances. I am well-versed in regulations concerning fire safety and the use of fire-resistant materials. I am also familiar with accessibility guidelines, ensuring that brickwork complies with regulations for disabled access. Prior to starting any project, I thoroughly review the relevant codes to ensure full compliance, creating designs and construction methods that meet or exceed all applicable standards. Staying updated on these regulations is an ongoing process and is fundamental to my professional practice.

Q 21. How do you measure and mark bricks for accurate cutting?

Accurate measurement and marking are essential for precise brick cutting. I typically use a combination of measuring tapes, speed squares, and marking pencils. For straight cuts, I measure the required length on the brick using a tape measure and mark it with a pencil. For angled cuts, I use a speed square to ensure accuracy. For curved cuts, I create templates as mentioned before. Precise measurement and marking prevent errors that can lead to misalignment, gaps, or the need for further cutting which wastes material. I always double-check my measurements before making any cuts to minimize errors and ensure efficient use of materials. I also use a chalk line for marking long straight cuts ensuring that the line is straight and crisp.

Q 22. What are the different types of brick finishes and how are they achieved?

Brick finishes significantly impact a building’s aesthetic appeal and durability. Achieving the desired finish requires careful planning and execution. Here are some common types:

- Rough/Natural Finish: This is the simplest finish, showcasing the natural texture of the brick. It’s achieved by simply laying the bricks with minimal tooling or alteration after laying.

- Smooth Finish: A smooth finish requires careful brick selection and laying techniques, with minimal mortar showing. Any excess mortar is removed, and the brick faces are often lightly brushed for a uniform look.

- Textured Finish: This involves adding texture to the brick’s surface. Techniques include brushing, scrubbing, or using specialized tools to create patterns or variations in the surface. This is often achieved during the brick-making process but can also be done on-site with certain techniques.

- Patterned Finish: This utilizes various brick sizes, colors, or laying patterns (like running bond, stack bond, or herringbone) to create a visually striking design. Careful planning and precise cutting are essential.

- Exposed Aggregate Finish: This unique finish involves partially exposing the aggregate within the brick, revealing the underlying stones or materials. This often involves careful cutting and potentially acid washing to achieve the desired visual effect.

The choice of finish depends on the architectural design, desired aesthetic, and budget. For example, a rustic building might benefit from a rough finish, while a modern building might call for a smooth or patterned finish.

Q 23. Describe your experience working from blueprints and specifications.

I’m highly proficient in interpreting blueprints and specifications. My experience includes working with various scales, detailing, and annotation methods. I’ve worked extensively with architectural drawings that specify brick types, layouts, cutting requirements, and mortar specifications. For example, on a recent project involving a Victorian-style building, the blueprints detailed intricate brickwork around arched windows requiring precise cutting and careful measurement to maintain symmetry and historical accuracy. I’ve always prioritized meticulous review of the plans before starting any cutting, confirming all dimensions and special requirements to avoid costly mistakes later on.

I routinely cross-check dimensions with on-site measurements to account for any minor discrepancies and to make sure my work aligns perfectly with the architect’s vision. This ensures that the finished product flawlessly matches the design intent.

Q 24. How do you ensure consistency in brick cutting throughout a project?

Maintaining consistency is paramount in brick cutting. I achieve this through several key strategies:

- Precise Measurement: Using accurate measuring tools such as a steel tape measure and a square to consistently get the required dimensions before cutting.

- Consistent Cutting Techniques: Employing the same cutting method (wet saw, grinder, chisel) and applying consistent pressure throughout the process to ensure uniform cuts.

- Regular Calibration: Periodically checking and calibrating cutting tools and equipment to maintain their accuracy and efficiency. A dull blade, for instance, can lead to inconsistent cuts.

- Sample Brick Testing: Before beginning large-scale cutting, I often cut a sample brick to test the technique and confirm it meets the desired specifications. This allows for adjustments before proceeding with the entire project.

- Clear Communication: Maintaining open communication with the team to ensure everyone understands the required standards, making corrections as needed throughout the process.

For instance, on a recent project involving a complex brick pattern, I created a detailed cutting schedule to ensure a uniform flow of work, preventing inconsistencies that might occur if cutting was done randomly.

Q 25. How do you deal with unexpected challenges during brick cutting?

Unexpected challenges are inevitable in brick cutting. My approach involves a combination of problem-solving skills, adaptability, and resourcefulness.

- Assessment: First, I carefully assess the nature of the challenge. Is it a material issue (damaged bricks), a design conflict, or a tooling problem?

- Problem Solving: Once identified, I find a solution. This might involve adjusting the cutting method, finding alternative materials, or consulting with the project manager or architect for guidance.

- Adaptability: I adjust my techniques and workflow as needed. This could mean modifying the cutting pattern or finding creative solutions to salvage damaged bricks.

- Documentation: I meticulously document any deviations from the original plan, ensuring a clear record of the issue, the solution implemented, and its impact on the project timeline or budget.

For example, I once encountered a batch of bricks with internal flaws that made them prone to cracking during cutting. I adapted by using a slower cutting speed and a more precise cutting technique to minimize damage and ensure the project wasn’t delayed.

Q 26. Explain your understanding of the importance of teamwork and communication in bricklaying.

Teamwork and communication are fundamental to successful bricklaying. Effective collaboration streamlines the workflow, ensures quality, and improves overall efficiency.

- Clear Communication: I believe in transparent communication with fellow bricklayers, supervisors, and other tradespeople to avoid misunderstandings and to proactively address potential issues.

- Collaboration: I actively participate in team discussions, sharing my expertise and offering assistance to colleagues when needed. This fosters a supportive working environment that helps maintain consistent quality and avoids errors.

- Coordination: I coordinate with other trades (e.g., masons, electricians) to ensure that my work complements theirs. Effective coordination is crucial, especially in complex projects.

- Mentorship: I’m also happy to mentor junior bricklayers, sharing my knowledge and skills to help them develop their expertise.

A recent project required a complex brick façade with intricate detailing. By working collaboratively, communicating effectively, and supporting each other, we completed the project on schedule and to a high standard.

Q 27. Describe your experience working on large-scale projects.

I have extensive experience working on large-scale projects, including multi-story buildings, commercial complexes, and historical renovations. These projects demanded precision, meticulous planning, and excellent teamwork. For instance, I worked on a high-rise apartment building that required over 100,000 bricks. Managing material flow, maintaining consistency in cutting, and coordinating with numerous other trades was critical to project success.

My experience working on large-scale projects has honed my skills in project management, material handling, and coordinating with large teams to meet tight deadlines and demanding specifications. This included effectively managing the logistics of material procurement, storage, and efficient deployment across different project phases.

Q 28. What are your salary expectations for this position?

My salary expectations are commensurate with my experience and skills, and aligned with the industry standards for experienced brick cutters in this region. I am open to discussing a competitive compensation package that reflects my contributions and value to your company. I’m confident my skills and experience make me a valuable asset and I am eager to discuss specifics further.

Key Topics to Learn for Brick Cutting Interview

- Understanding Brick Types and Properties: Learn about different brick types (clay, concrete, etc.), their strengths, weaknesses, and suitability for various projects. This includes understanding factors like compressive strength, water absorption, and frost resistance.

- Cutting Techniques and Tools: Master various brick cutting methods, including scoring and snapping, using a variety of tools such as brick saws (wet and dry), chisels, and hammers. Practice safe and efficient techniques.

- Precision and Accuracy: Develop skills in achieving precise cuts to meet project specifications. Understand the importance of accurate measurements and minimizing waste.

- Health and Safety Regulations: Familiarize yourself with relevant safety regulations and procedures for handling cutting tools and working with bricks. This includes proper use of personal protective equipment (PPE).

- Troubleshooting Common Issues: Learn to identify and resolve common problems encountered during brick cutting, such as chipped bricks, uneven cuts, and tool malfunctions. Develop problem-solving skills to ensure efficient workflow.

- Estimating Material Needs: Develop skills in calculating the required number of bricks and cutting patterns for a given project, minimizing waste and optimizing material usage.

- Understanding Project Blueprints and Specifications: Learn to interpret architectural drawings and specifications to understand the required brick cuts and patterns for a specific project.

Next Steps

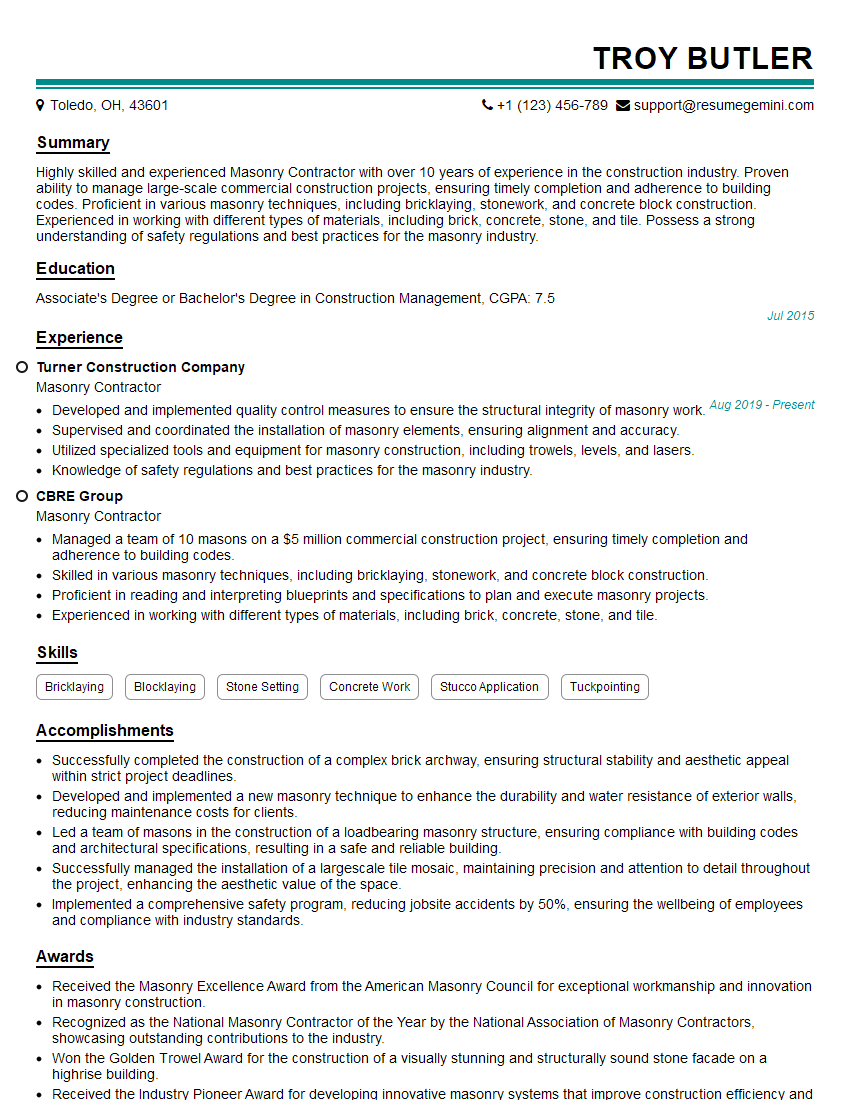

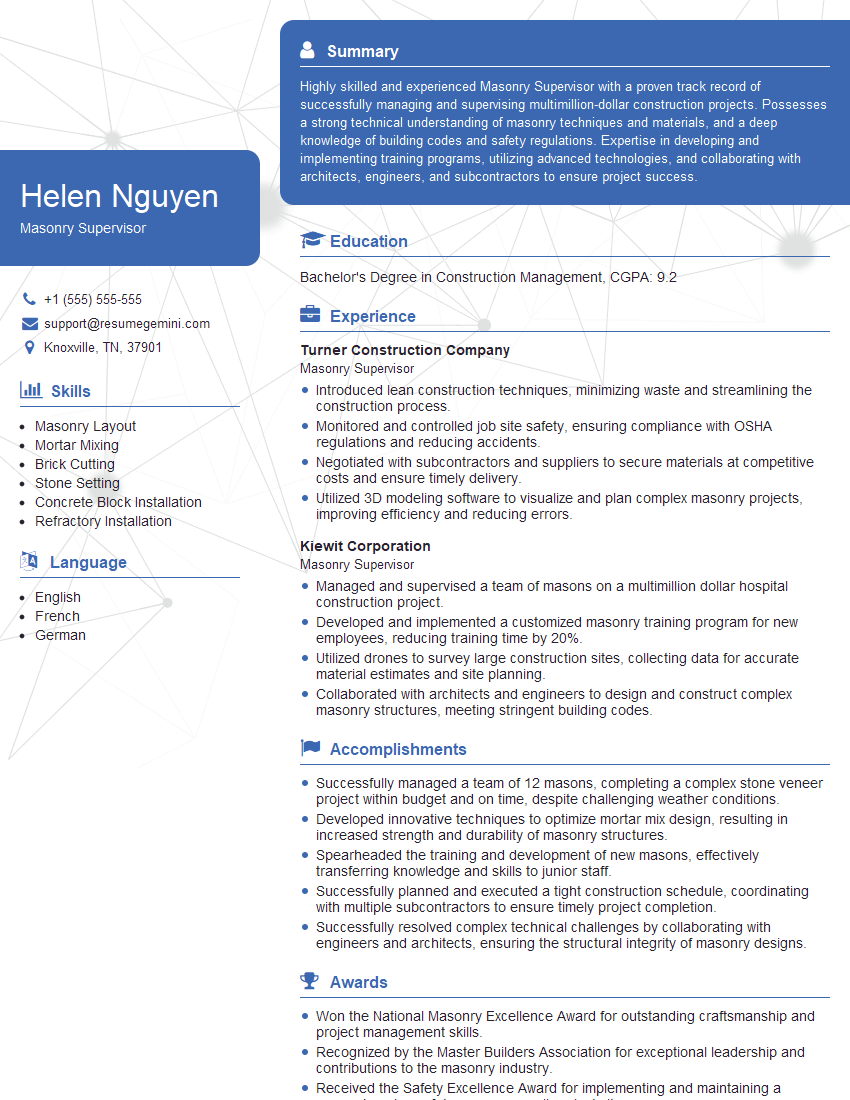

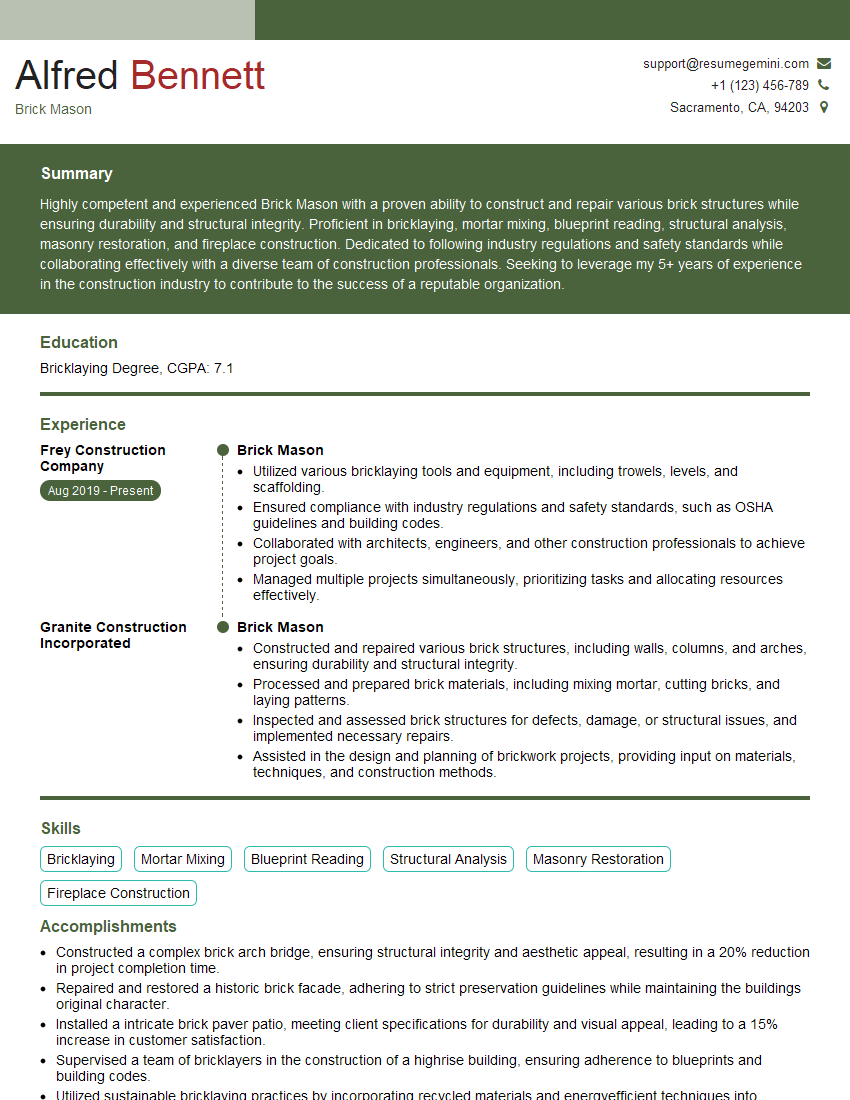

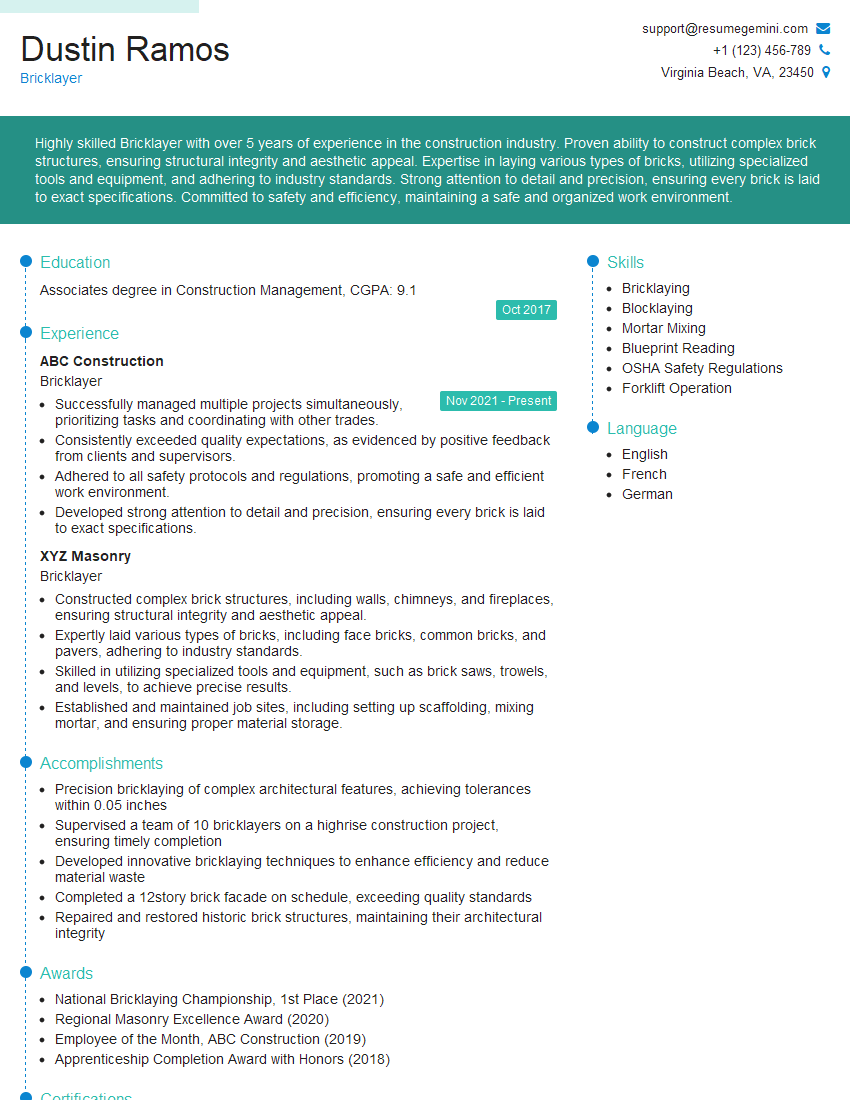

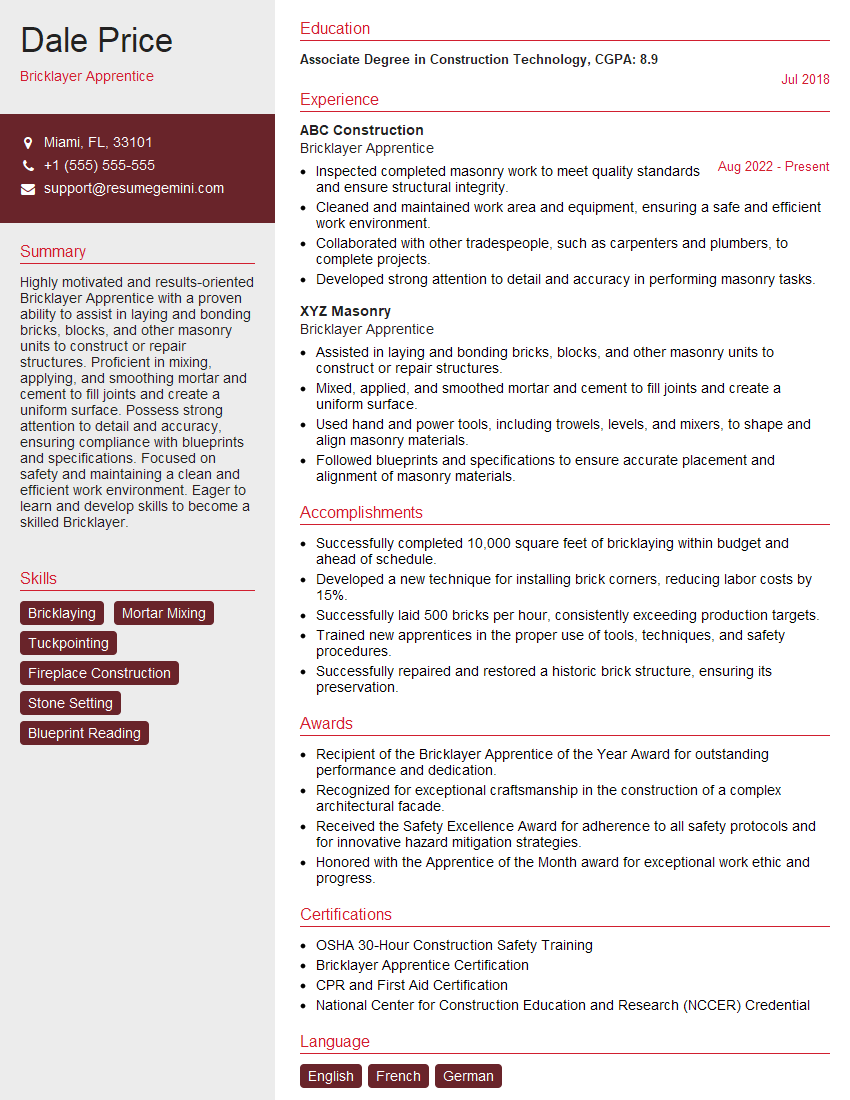

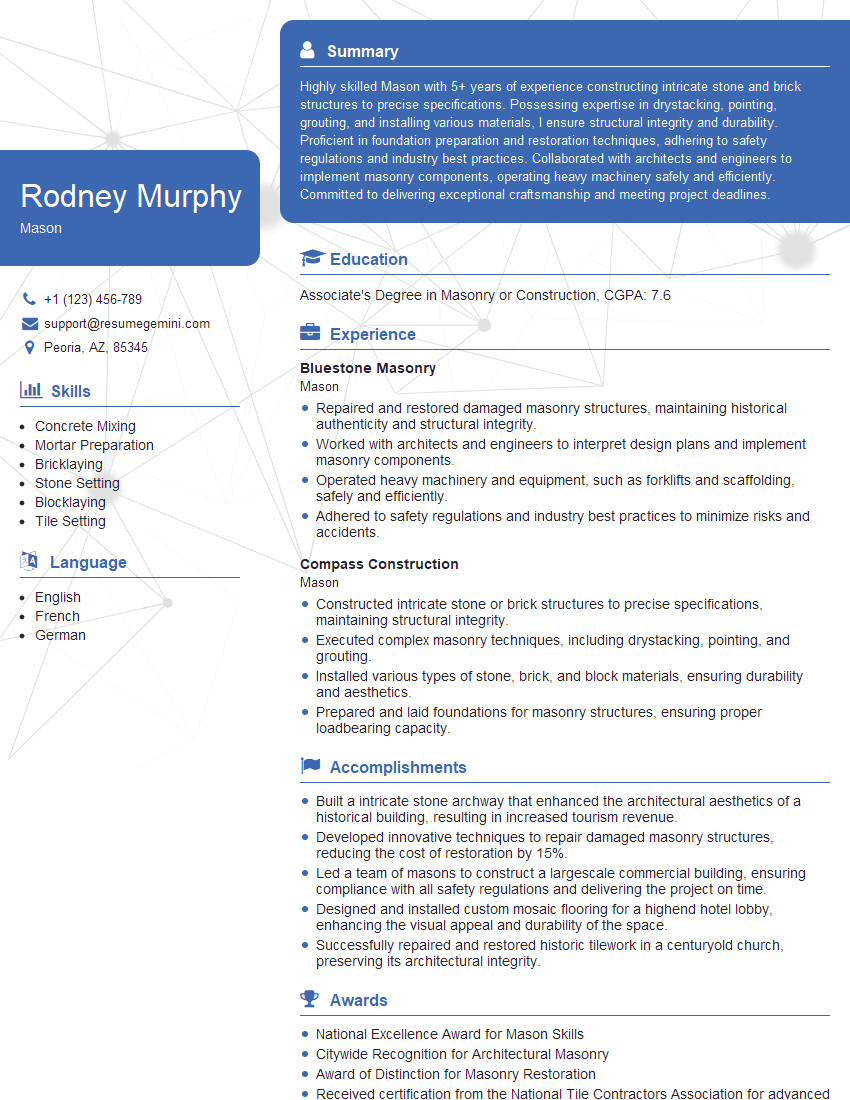

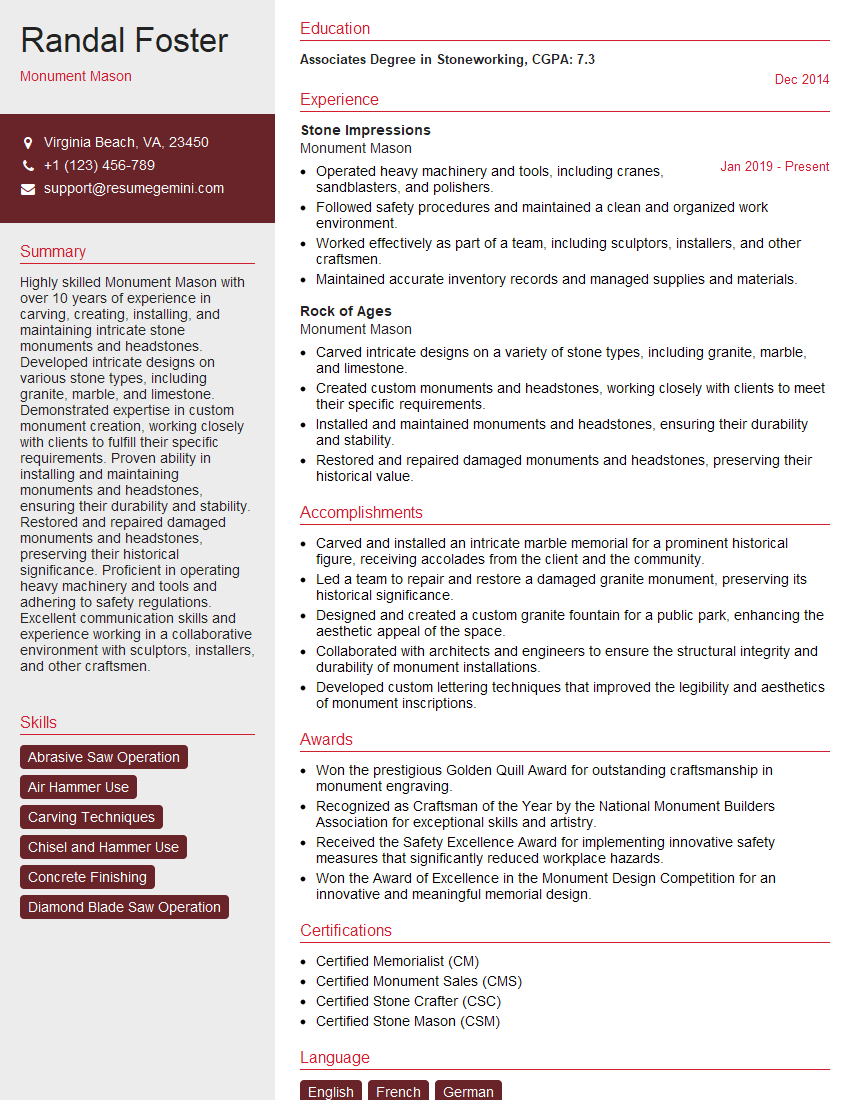

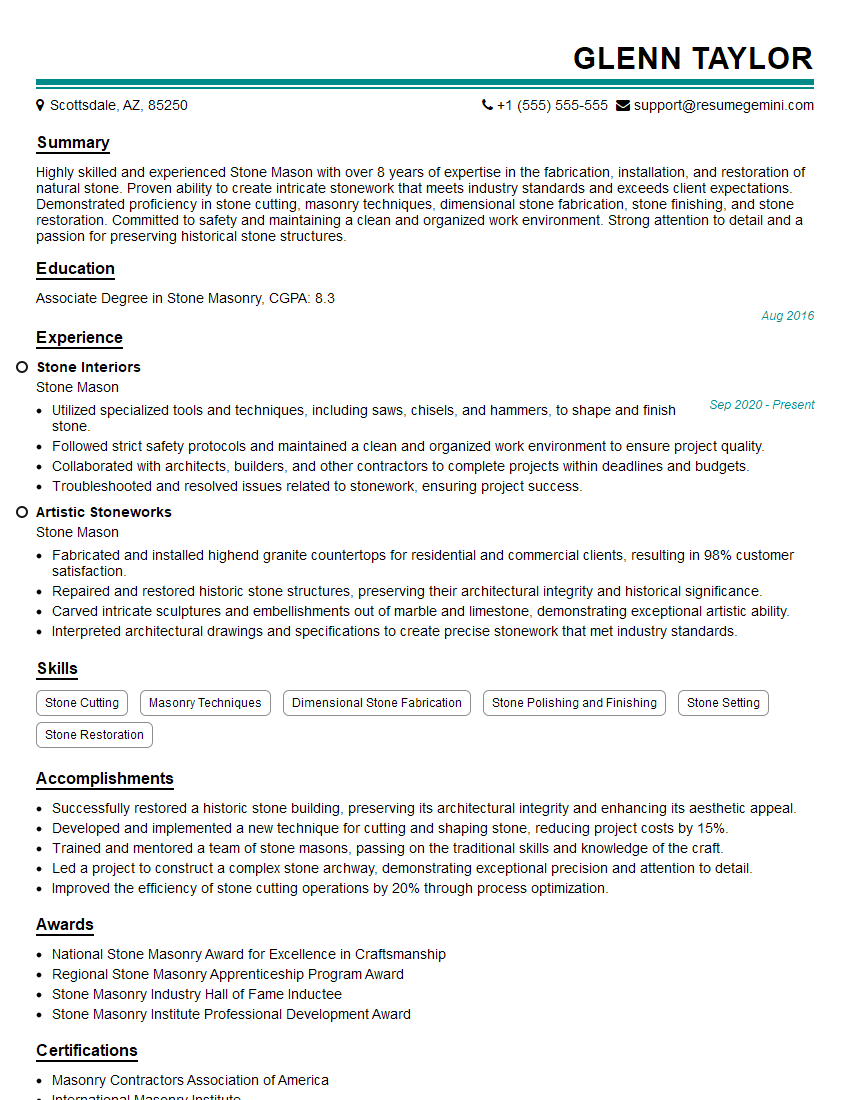

Mastering brick cutting opens doors to diverse and rewarding careers in construction, masonry, and related fields. A strong understanding of these techniques is crucial for career advancement and securing higher-paying positions. To significantly increase your job prospects, creating an ATS-friendly resume is paramount. ResumeGemini is a trusted resource that can help you build a professional and effective resume that highlights your skills and experience. Examples of resumes tailored to the Brick Cutting field are available through ResumeGemini to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good