Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Bulb Storage and Handling Techniques interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Bulb Storage and Handling Techniques Interview

Q 1. Explain the importance of proper bulb ventilation during storage.

Proper bulb ventilation is crucial for preventing the development of diseases and maintaining bulb quality during storage. Think of it like this: bulbs, much like us, need to breathe. They respire, releasing heat and moisture. Poor ventilation traps this heat and moisture, creating a damp, warm environment that’s ideal for fungal and bacterial growth, leading to rot and spoilage.

Adequate airflow removes excess moisture and carbon dioxide, preventing condensation and maintaining a cool, dry environment that inhibits microbial activity. This extends the shelf life of bulbs and ensures they remain healthy and viable for planting.

- Example: Storing bulbs in airtight containers without adequate ventilation will quickly lead to rot and decay.

- Practical Application: Using mesh bags or well-ventilated crates instead of sealed plastic bags is essential for successful bulb storage.

Q 2. Describe different methods for preventing bulb diseases during storage.

Preventing bulb diseases during storage is paramount for successful cultivation. It involves a multi-pronged approach focusing on pre-storage practices and the storage environment itself.

- Pre-storage treatment: This involves carefully inspecting bulbs before storage, discarding any damaged or diseased ones. Treating healthy bulbs with fungicides before storage can significantly reduce the risk of fungal infections. Proper curing (drying) after harvesting is also critical for reducing moisture content, making bulbs less susceptible to disease.

- Storage environment: Maintaining optimal temperature and humidity (as discussed later) is crucial. Ensuring good air circulation to prevent humidity buildup is essential. Regular inspection of stored bulbs for any signs of disease is necessary to quickly address potential issues.

- Specific Disease Prevention: Different diseases require specific strategies. For instance, controlling soilborne pathogens before planting is vital to avoid problems later during storage. In some cases, treating with systemic fungicides post-harvest might be necessary, but always follow label instructions carefully.

Example: A farmer successfully prevented a widespread fungal infection by carefully culling diseased bulbs before storage and employing proper ventilation in the storage facility.

Q 3. What are the optimal temperature and humidity levels for storing different types of bulbs?

Optimal storage conditions vary significantly depending on the type of bulb. There’s no one-size-fits-all approach.

- Temperature: Generally, a cool, but not freezing, temperature is ideal. Many bulbs store well between 35°F and 45°F (2°C and 7°C). However, some bulbs, like tulips, benefit from a slightly warmer temperature of around 50°F (10°C).

- Humidity: Moderate humidity is usually best, aiming for around 60-70%. Too high humidity promotes rot, while too low humidity can cause desiccation.

Examples:

- Tulips: 50°F (10°C), 60-70% humidity

- Daffodils: 40°F (4°C), 60-70% humidity

- Lilies: 35-40°F (2-4°C), 70% humidity

Knowing the specific needs of the bulb type is crucial for successful storage. Always refer to specific guidelines for each type of bulb.

Q 4. How do you identify and address common bulb storage problems like rot or sprouting?

Identifying and addressing rot or sprouting is key to minimizing losses during storage. Regular inspection is essential.

- Rot Identification: Look for soft, mushy areas, discoloration, and foul odors. Affected bulbs often show signs of fungal growth.

- Sprouting Identification: Bulbs beginning to sprout are using their stored energy and will lose viability quickly. This is especially common if storage temperatures are too high.

- Addressing Rot: Remove and discard all affected bulbs immediately to prevent spread. Treat surrounding bulbs with a fungicide if necessary, and improve ventilation in the storage area.

- Addressing Sprouting: Lower the storage temperature if possible, although it might already be too late for many bulbs. Sprouting bulbs may still be able to be planted but their yield and quality will likely be reduced.

Example: During a routine check, a storage worker noticed several bulbs showing signs of soft rot. Prompt removal and treatment of the surrounding bulbs prevented further spread.

Q 5. Explain the process of bulb grading and its importance.

Bulb grading is the process of sorting bulbs based on size, shape, and quality. This is crucial for determining planting density, ensuring uniformity in growth, and maximizing market value.

- Size Grading: Bulbs are categorized into different size classes (e.g., large, medium, small) based on their circumference or diameter. Larger bulbs generally produce larger, more vigorous plants.

- Shape Grading: Bulbs with a uniform, well-formed shape are preferred. Deformed or misshapen bulbs are typically graded lower.

- Quality Grading: This assesses the overall health and soundness of the bulbs. Bulbs with any signs of disease, damage, or pest infestation are downgraded or rejected.

Importance: Consistent grading ensures that bulbs are priced appropriately, allowing for effective inventory management. It simplifies the planting process and results in more uniform flowering, which is important for both commercial growers and home gardeners.

Example: A nursery sorts daffodil bulbs into three size categories—large, medium, and small—to ensure appropriate pricing and efficient planting in different garden beds.

Q 6. Describe various bulb packaging techniques and their suitability for different types of bulbs.

Bulb packaging techniques are chosen based on the type of bulb, intended storage duration, and transportation needs.

- Mesh Bags: Provide good ventilation, suitable for bulbs that require good air circulation and are relatively robust. Best for short-term storage and transport.

- Paper Bags: Offer some protection and cushioning, useful for more delicate bulbs. However, ventilation may be limited, so they’re often best for short-term storage.

- Wooden Crates: Excellent for protecting bulbs during transit, providing cushioning and better stackability than bags. Best for larger quantities and longer transportation.

- Cardboard Boxes: These offer good protection and can be customized to fit various bulb sizes. Suitable for both storage and shipping but require additional measures for ventilation.

Suitability: Delicate bulbs like lilies might benefit from soft cushioning within a crate or box, while hardy bulbs like daffodils might store adequately in mesh bags. Always consider the specific needs of the bulb type when choosing packaging.

Example: A commercial grower uses wooden crates for shipping large quantities of tulips over long distances, while a home gardener uses paper bags for storing smaller numbers of lilies for a shorter period.

Q 7. What are the key considerations for transporting bulbs to maintain quality?

Transporting bulbs requires careful consideration to maintain quality and minimize damage. Key considerations include:

- Temperature Control: Maintaining the optimal temperature during transport is crucial. Refrigerated trucks or containers are often necessary for longer distances to prevent spoilage.

- Proper Packaging: Adequate packaging protects bulbs from physical damage and ensures proper ventilation to prevent moisture buildup. Use appropriate cushioning materials.

- Handling: Avoid rough handling that can bruise or damage bulbs. Gentle loading and unloading are essential. Proper stacking techniques are crucial to prevent crushing.

- Transit Time: Minimizing transit time is beneficial as prolonged transport increases the risk of damage and deterioration. Choose the most efficient route possible.

Example: A grower ships a large order of daffodil bulbs across the country using a refrigerated truck equipped with climate control, ensuring the bulbs arrive in perfect condition.

Practical Application: Clear labeling is essential, indicating temperature requirements and ‘handle with care’ instructions to help maintain quality during transit.

Q 8. How do you ensure the traceability of bulbs throughout the storage and handling process?

Traceability in bulb storage and handling is crucial for quality control and efficient inventory management. Think of it like a detective following a trail of clues. We achieve this by using a robust tracking system, often involving barcodes or RFID tags attached to each bulb container or batch. These tags are scanned at every stage, from harvesting and grading to storage and eventual shipment. This data is then logged into a central database, allowing us to pinpoint the location and history of any given bulb batch at any time. For example, if a problem arises with a specific batch, we can quickly trace its origins, identify any potential points of failure, and prevent similar issues in the future.

This system not only ensures accountability but also aids in recall procedures if necessary and helps in optimizing storage strategies. We can analyze data to identify trends like optimal storage durations for specific varieties, leading to reduced waste and improved quality.

Q 9. Explain different methods for controlling pests and diseases in bulb storage facilities.

Controlling pests and diseases in bulb storage is paramount to maintaining quality and preventing significant losses. We employ a multi-pronged approach:

- Pre-storage treatment: Bulbs are carefully inspected and treated before storage. This might involve fungicides or other treatments to eliminate surface pathogens.

- Controlled environment: Storage facilities maintain specific temperature and humidity levels to inhibit fungal growth and pest activity. Low temperatures slow down metabolic processes in the bulbs, extending their shelf life and reducing susceptibility to disease.

- Regular monitoring: Facilities are routinely inspected for signs of pest infestation or disease outbreaks. Early detection enables prompt intervention to prevent widespread damage.

- Bio-control agents: In some instances, we introduce beneficial insects or microbes to control pest populations without resorting to harmful chemicals.

- Proper ventilation: Adequate ventilation helps maintain appropriate humidity levels and prevents the build-up of gases that can encourage fungal growth or suffocate the bulbs.

Imagine trying to store apples without proper refrigeration; they would quickly rot. Similarly, controlling the environment within bulb storage facilities is critical to their longevity and quality.

Q 10. What are the best practices for maintaining accurate inventory records for bulbs?

Maintaining accurate inventory records is essential for efficient operations and profitability. We typically use specialized inventory management software that integrates with our tracking system. This software allows us to record all incoming and outgoing bulb batches, track their location within the facility, and monitor stock levels in real-time.

The software facilitates periodic inventory counts, reconciling physical counts with the digital record. Any discrepancies are investigated and addressed promptly. We often use barcodes or RFID technology to automate the tracking process, reducing manual entry errors. Data generated from the software provides valuable insights into sales trends and helps optimize ordering strategies. Regular audits ensure the accuracy and reliability of the entire system. Thinking of this as a well-organized library catalog – always up-to-date and readily accessible – is a helpful analogy.

Q 11. Describe the importance of proper sanitation and hygiene in bulb handling.

Sanitation and hygiene are fundamental to preventing the spread of diseases and maintaining bulb quality. Imagine preparing food in an unclean kitchen – the result would be disastrous. The same principle applies to bulb handling. We enforce strict hygiene protocols at every stage:

- Clean storage facilities: Regular cleaning and disinfection of storage areas, including floors, walls, and equipment, are crucial.

- Hand hygiene: Workers are required to wash their hands frequently and wear clean gloves.

- Pest control: Regular pest control measures prevent contamination.

- Equipment cleaning: All equipment used in handling bulbs is thoroughly cleaned and disinfected between uses.

- Proper waste disposal: Infected or damaged bulbs are disposed of safely and properly.

These measures minimize the risk of disease transmission, thus improving bulb health and quality and reducing economic losses.

Q 12. How do you adapt storage techniques for different bulb sizes and varieties?

Adapting storage techniques to accommodate different bulb sizes and varieties is key to optimizing storage space and maintaining bulb quality. Smaller bulbs might be stored in trays or boxes, while larger bulbs might require different shelving or racking systems. We also consider the specific needs of each bulb variety. Some varieties require specific temperature and humidity levels, or may need to be stored in a dark environment to prevent premature sprouting. Different types of containers or packaging – for example, mesh bags versus solid containers – might also be utilized depending on the bulbs’ characteristics and the need for ventilation. For example, delicate tulip bulbs might require more cushioned packaging compared to more robust daffodil bulbs. Proper spacing within containers is equally crucial to allow for air circulation and prevent damage from crushing.

Q 13. What are the health and safety regulations surrounding bulb handling and storage?

Health and safety regulations surrounding bulb handling and storage are stringent and vary by location but generally focus on worker safety and environmental protection. These regulations encompass:

- Personal Protective Equipment (PPE): Workers must use appropriate PPE, such as gloves, safety glasses, and respiratory protection when handling certain chemicals or dealing with potentially hazardous materials.

- Ergonomics: Work practices must be designed to minimize physical strain on workers, using appropriate lifting techniques and equipment.

- Chemical safety: Proper handling, storage, and disposal of pesticides and other chemicals are mandatory, adhering to local regulations.

- Fire safety: Storage facilities must have appropriate fire detection and suppression systems.

- Emergency response plans: Plans should be in place to handle various emergencies, such as power outages or chemical spills.

Compliance with these regulations is essential to ensure a safe working environment and minimize risks.

Q 14. How do you manage and respond to potential emergencies, like power outages, in a bulb storage facility?

Managing emergencies, like power outages, is critical in bulb storage. We have contingency plans in place to mitigate the impact on bulb quality. These plans typically include:

- Backup power generators: These ensure that critical systems, such as refrigeration and ventilation, remain operational during power outages.

- Emergency lighting: Adequate lighting is essential for safe evacuation and continued monitoring of the facility.

- Temperature monitoring: Continuous temperature monitoring helps us assess the impact of the outage on the stored bulbs.

- Communication systems: Reliable communication systems enable us to alert relevant personnel and coordinate responses.

- Post-outage procedures: These procedures guide the inspection of bulbs to assess damage and implement any necessary corrective measures.

Regular drills and training ensure that our staff is prepared to respond effectively to such situations. A well-rehearsed emergency response plan is crucial to minimize losses during unforeseen circumstances.

Q 15. Explain the use of different types of storage containers for bulbs.

Choosing the right storage container for bulbs is crucial for maintaining their quality and preventing damage. The ideal container protects bulbs from physical damage, excessive moisture, and pests. Several types are commonly used, each with its advantages and disadvantages.

Mesh Bags: These offer good ventilation, preventing fungal growth and promoting proper airflow. They’re ideal for bulbs that need to breathe during storage, but offer less protection from physical impacts. Think of storing delicate tulip bulbs – mesh bags allow for air circulation while safeguarding them from bruising.

Wooden Crates: These provide excellent protection and are often used for larger bulbs or during transport. However, they can be heavier and more expensive than other options, and require careful handling to avoid damage to the bulbs.

Cardboard Boxes: Cost-effective and readily available, cardboard boxes are suitable for shorter-term storage, but they offer less protection against moisture and pests. You’d use these for bulbs that are going to be planted relatively soon.

Plastic Containers: These offer good protection against moisture and pests, but adequate ventilation is crucial to prevent fungal growth. Make sure they have sufficient drainage holes. These are a good all-around option for many bulb types.

The choice of container depends on the type of bulb, storage duration, and the overall storage environment.

Career Expert Tips:

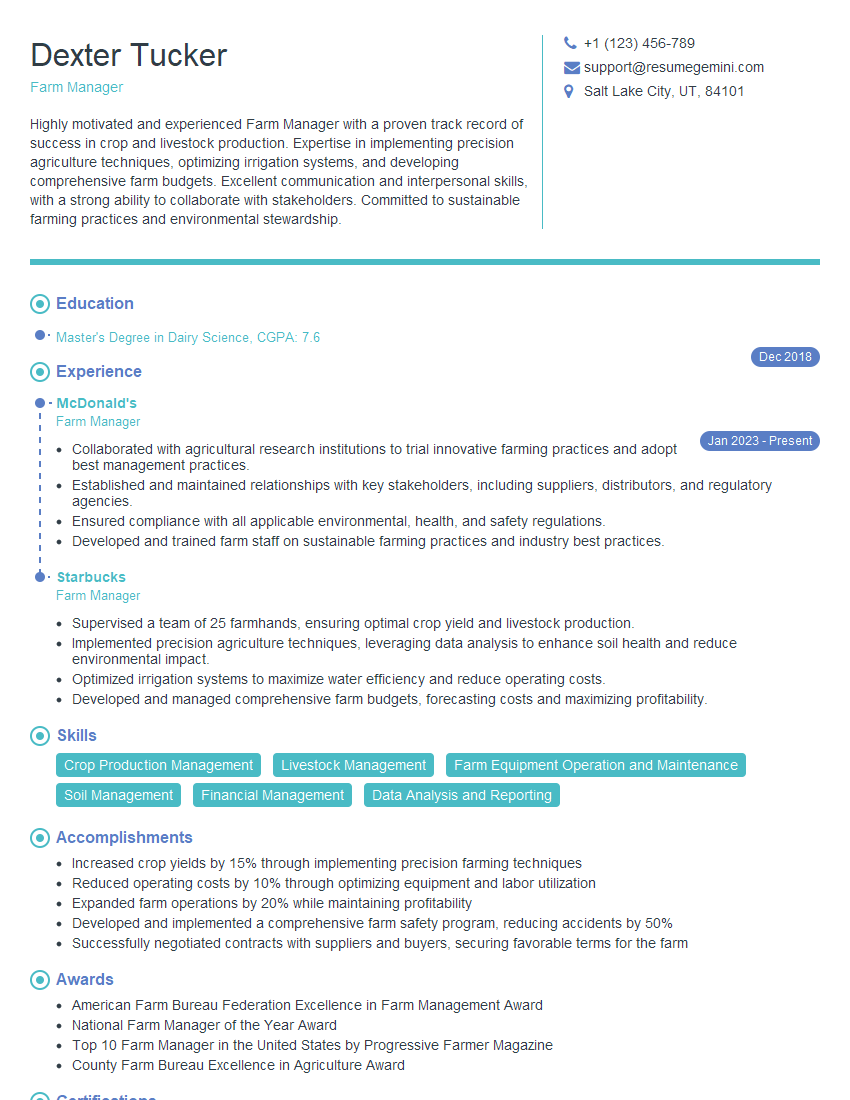

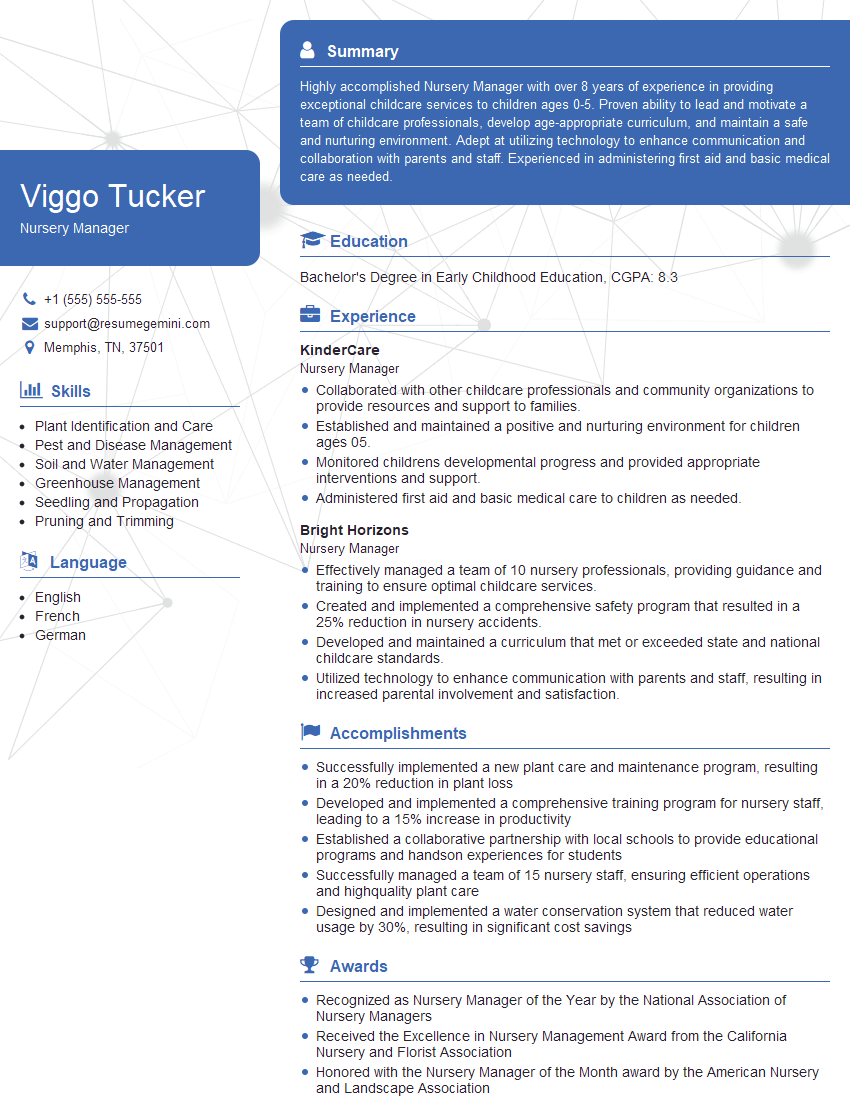

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the economic implications of improper bulb storage and handling?

Improper bulb storage and handling can lead to significant economic losses for growers, distributors, and retailers. Imagine a large shipment of daffodil bulbs arriving with significant rot due to improper curing and storage. The losses are multifaceted:

Reduced Yield: Damaged or diseased bulbs result in fewer flowers or smaller blooms, directly impacting the quantity and quality of the final product, resulting in reduced sales and revenue.

Increased Waste: Spoiled bulbs must be discarded, leading to direct financial losses. This is particularly damaging on a large scale, as in commercial flower production.

Reputational Damage: Delivering low-quality bulbs can damage a company’s reputation, making it difficult to secure future contracts or sales.

Increased Costs: The need for replanting or sourcing replacements adds to the overall cost, impacting profitability.

Disease Spread: Improper storage can facilitate the spread of diseases to healthy bulbs, further exacerbating losses.

Therefore, investing in proper storage and handling techniques is a crucial aspect of ensuring profitability and maintaining a good business reputation in the bulb industry.

Q 17. Describe different methods of bulb pre-cooling.

Pre-cooling bulbs before storage is essential for extending their shelf life and minimizing physiological disorders. Several methods exist:

Forced-Air Cooling: This involves circulating cool, dry air over the bulbs. It’s a rapid and efficient method, often used commercially with sophisticated temperature and humidity control systems. Think large-scale bulb storage facilities.

Hydrocooling: Bulbs are immersed in chilled water for a specific time. This method is effective but requires careful monitoring to prevent water damage. This is more suited for smaller-scale operations where precise temperature control is still vital.

Vacuum Cooling: This method utilizes vacuum pressure to evaporate moisture from the bulbs’ surface, resulting in rapid cooling. It’s effective but requires specialized equipment, making it more common in larger operations.

The choice of pre-cooling method depends on factors such as the scale of operation, the type of bulb, and available resources.

Q 18. What are the benefits of using controlled atmosphere storage for bulbs?

Controlled atmosphere (CA) storage modifies the gaseous environment surrounding the bulbs to slow down respiration and reduce physiological deterioration. This translates to several key benefits:

Extended Shelf Life: Reduced respiration rates dramatically extend the storage life of bulbs, allowing for longer-term storage and flexibility in market timing.

Improved Quality: Maintaining optimal conditions prevents sprouting, shriveling, and other quality issues, leading to a higher-quality product upon planting or sale.

Reduced Disease Risk: The controlled environment can suppress the growth of many fungal and bacterial pathogens, reducing disease incidence and associated losses.

Enhanced Market Value: The ability to store bulbs longer allows for strategic release to market, potentially commanding higher prices during peak demand periods.

While CA storage requires specialized facilities and expertise, the investment can significantly enhance profitability for commercial bulb operations.

Q 19. How do you assess the quality of stored bulbs?

Assessing the quality of stored bulbs requires a multi-faceted approach that combines visual inspection with other techniques.

Visual Examination: Look for signs of disease, damage, or sprouting. Healthy bulbs should be firm, free from blemishes, and have a characteristic color for their species. Look for any signs of rot, mold, or pests.

Firmness Test: Gently squeeze the bulbs. Firm bulbs indicate good quality, while soft or shriveled bulbs indicate potential problems. A soft bulb may mean dehydration or the beginnings of rot.

Weight Checks: Monitoring the weight of a sample can help detect moisture loss or other problems. Significant weight loss may be due to dehydration.

Germination Testing: A small sample of bulbs can be tested for germination rate to assess their viability. This gives a reliable prediction of the success rate of planting.

Regular monitoring and quality assessments are crucial for identifying problems early and minimizing losses.

Q 20. Explain different methods for chilling bulbs.

Chilling bulbs is a crucial step in promoting flowering and preventing premature sprouting. Different methods exist, varying in their effectiveness and cost:

Cold Storage: This involves storing bulbs at low, but non-freezing temperatures (typically 1-5°C or 34-41°F). This is the most common method, readily applicable across different scales of operation.

Stratification: This technique mimics natural winter conditions, involving a period of cold, moist storage, often used for bulbs that require a period of chilling before flowering. This is often done by layering bulbs in moist peat moss or vermiculite.

Refrigeration: Commercial operations often use refrigerated storage rooms or walk-in coolers to achieve controlled chilling. This ensures consistent temperature and humidity control, crucial for large quantities of bulbs.

The specific chilling requirements vary depending on the bulb species. Improper chilling can lead to poor flowering or even failure to bloom.

Q 21. Describe the process of bulb curing.

Bulb curing is a post-harvest process that allows bulbs to heal after harvest and improves their storage life. This is critical to prevent fungal infections and other post-harvest issues.

The process generally involves:

Initial Drying: Newly harvested bulbs are allowed to dry under well-ventilated conditions to reduce moisture content. This reduces the risk of fungal diseases that thrive in moist conditions.

Temperature Control: The curing environment is maintained at a temperature that allows for healing without promoting premature sprouting. Optimal temperatures vary depending on the species.

Duration: The duration of curing varies, depending on the bulb type and climate conditions. A well-defined curing protocol specific to the bulb species is paramount.

Monitoring: Regular monitoring for moisture content, temperature, and disease symptoms is important to ensure the effectiveness of the process.

Proper curing is a crucial step in ensuring the high quality and longevity of stored bulbs.

Q 22. What are the signs of improper bulb storage?

Improper bulb storage manifests in several ways, often indicating that the bulbs haven’t been kept under ideal conditions. Think of it like leaving a delicate fruit out in the sun – it’ll show signs of distress.

- Shriveling or wrinkling: This is a classic sign of dehydration, showing the bulbs are losing moisture. You’ll see the outer layers become less plump and firm.

- Mold or rot: The appearance of fuzzy patches, discoloration, or soft, mushy areas points to fungal growth, often caused by excessive moisture or poor air circulation.

- Sprouting prematurely: Bulbs beginning to sprout before the intended planting time indicates a disruption in their dormancy period, possibly due to exposure to warmer-than-ideal temperatures or inappropriate light levels.

- Loss of firmness: Healthy bulbs should feel firm to the touch. If they’re soft or spongy, this could indicate internal decay or damage.

- Discoloration: Changes in color from the usual (e.g., browning, yellowing) can signal stress or disease.

For instance, imagine storing tulip bulbs in a warm, humid basement. You’ll likely find them sprouting prematurely and possibly rotting due to the lack of proper ventilation and temperature control.

Q 23. How do you prevent bulb dehydration during storage?

Preventing bulb dehydration is crucial for ensuring their viability and successful planting. Think of it as keeping your skin hydrated on a hot day – you need the right conditions to maintain its health.

- Proper curing: After harvesting, allow bulbs to dry gently in a well-ventilated area for several weeks. This allows the outer layers to toughen and helps prevent moisture loss.

- Maintaining optimal humidity: High humidity promotes dehydration. Aim for moderate humidity levels during storage. Storing bulbs in a humid environment can actually encourage rot, counterintuitively.

- Appropriate temperature: Temperatures that are too warm will speed up respiration and dehydration. Cold, but not freezing, temperatures are best for most bulbs.

- Storage containers: Use breathable containers such as mesh bags or open-weave baskets, rather than airtight plastic bags which trap moisture. Think of it like putting apples in a paper bag versus a sealed plastic container.

- Pre-storage treatment: Some pre-planting treatments, like applying a protective coating or dipping in fungicide, can prevent moisture loss and protect against rot.

For example, storing daffodil bulbs in a well-ventilated crate in a cool, dry cellar is a common practice. This ensures the bulbs don’t lose moisture while remaining free from mold or rot.

Q 24. Explain the role of ethylene in bulb storage.

Ethylene, a natural plant hormone, plays a significant role in bulb storage, often negatively. It’s like a ripening agent, but for bulbs, it can be detrimental.

Ethylene accelerates senescence (aging) in bulbs, promoting sprouting, and potentially causing decay. It can also trigger the production of undesirable odors. High concentrations of ethylene can lead to rapid deterioration and significant yield losses. This is why controlling ethylene levels is crucial. Imagine placing a ripe banana near your bulbs – that banana releases ethylene, and it would affect the bulbs negatively.

To minimize ethylene’s effects:

- Proper ventilation: Ensures the dissipation of ethylene produced by the bulbs themselves or from other sources.

- Low temperatures: Slows down the production of ethylene and reduces its impact.

- Use of ethylene absorbents: Certain commercial products can absorb ethylene from the air within the storage facility.

Q 25. How do you maintain optimal bulb dormancy during storage?

Maintaining optimal bulb dormancy is key to successful storage; it’s about keeping them ‘asleep’ until planting time. Dormancy ensures the bulbs conserve energy and don’t prematurely sprout. Think of it as hibernation for plants.

To achieve optimal dormancy:

- Cool temperatures: This is a primary factor. Most bulbs require temperatures between 33°F and 41°F (0°C and 5°C) for successful dormancy.

- Darkness: Exposure to light can break dormancy prematurely. Keep the storage area dark or dimly lit.

- Dry conditions: Excess moisture can lead to rot and premature sprouting, disrupting dormancy.

- Proper ventilation: Allows for sufficient air circulation, preventing the buildup of moisture or gases (like ethylene) that can break dormancy.

For instance, storing potatoes in a cool, dark place is an analogy; similar principles apply to bulb storage, promoting dormancy and preventing sprouting.

Q 26. What are the environmental factors that affect bulb storage?

Several environmental factors significantly influence bulb storage success. Think of them as essential elements for a successful hibernation.

- Temperature: Too warm temperatures will break dormancy, and too cold temperatures can cause freezing damage. The ideal temperature range varies depending on the bulb type.

- Humidity: High humidity increases the risk of fungal diseases and rot. Low humidity leads to dehydration.

- Light: Light exposure can stimulate sprouting before planting time. Darkness is crucial for maintaining dormancy.

- Air circulation: Poor ventilation can lead to the buildup of moisture, ethylene gas, and other harmful substances.

- Oxygen levels: Sufficient oxygen is needed for respiration, though excessive oxygen can increase respiration rates, leading to faster depletion of energy reserves.

For example, a poorly ventilated storage area with fluctuating temperatures and high humidity will lead to rapid deterioration and increased risk of disease in the stored bulbs. Conversely, a cool, dark, and well-ventilated area will help maintain ideal conditions for dormancy.

Q 27. Describe the advantages and disadvantages of different bulb storage systems.

Various bulb storage systems offer different advantages and disadvantages. Choosing the right system depends on factors like the volume of bulbs, available space, and budget. Think of it like choosing the right tool for a job.

- Cold storage facilities (refrigerated):

- Advantages: Precise temperature and humidity control, minimizing risks of sprouting and rotting, suitable for large-scale commercial operations.

- Disadvantages: High initial investment cost, energy consumption, need for specialized equipment and expertise.

- Root cellars or basements:

- Advantages: Low cost, readily available for small-scale storage.

- Disadvantages: Difficult to maintain consistent temperatures and humidity, greater risk of temperature fluctuations and pest infestations.

- Mesh bags or open-weave baskets:

- Advantages: Good air circulation, prevents moisture buildup, relatively low cost.

- Disadvantages: Not suitable for long-term storage, may require additional protection from pests.

- Controlled Atmosphere Storage (CAS):

- Advantages: Allows for precise control of oxygen, carbon dioxide, and ethylene levels, significantly extending storage life.

- Disadvantages: High initial investment, requires sophisticated technology and monitoring equipment, suitable only for commercial settings.

For example, a small-scale grower might use a root cellar, while a large commercial operation might utilize a cold storage facility. The choice depends on individual needs and resources.

Key Topics to Learn for Bulb Storage and Handling Techniques Interview

- Bulb Physiology and Storage Requirements: Understanding the biological needs of different bulb types (e.g., tulips, daffodils, lilies) to determine optimal storage conditions.

- Environmental Control: Mastering the practical application of temperature, humidity, and ventilation control within storage facilities to prevent spoilage and maintain bulb quality.

- Pre-storage Handling: Learning best practices for harvesting, cleaning, and curing bulbs before storage to minimize disease and extend shelf life. This includes understanding the impact of different handling techniques on bulb health.

- Storage Structures and Technologies: Familiarizing yourself with various storage structures (e.g., cold storage rooms, ventilated containers) and technologies (e.g., controlled atmosphere storage) used in bulb preservation. Be prepared to discuss their advantages and disadvantages.

- Pest and Disease Management: Understanding common pests and diseases affecting bulbs in storage and implementing effective preventative and control measures. This also includes recognizing the signs and symptoms of various issues.

- Post-storage Handling and Preparation for Planting: Knowing the procedures for preparing bulbs for planting after storage, including inspection, grading, and treatment to ensure successful growth.

- Quality Assessment and Control: Developing a strong understanding of methods for assessing bulb quality throughout the storage and handling process, from initial harvest to final planting. This includes quantitative and qualitative assessment techniques.

- Safety Procedures and Regulations: Familiarity with relevant health and safety regulations and best practices related to bulb handling and storage to prevent workplace accidents.

- Inventory Management and Tracking: Understanding the importance of accurate record-keeping and inventory management systems to ensure efficient bulb storage and distribution.

- Troubleshooting Common Storage Issues: Developing problem-solving skills to identify and address common challenges encountered during bulb storage, such as rot, sprouting, or pest infestations.

Next Steps

Mastering Bulb Storage and Handling Techniques is crucial for career advancement in horticulture, agriculture, and related fields. It demonstrates a deep understanding of plant biology, practical skills, and problem-solving abilities highly valued by employers. To maximize your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. Examples of resumes tailored to Bulb Storage and Handling Techniques are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good