Are you ready to stand out in your next interview? Understanding and preparing for Cable Engineering interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Cable Engineering Interview

Q 1. Explain the difference between coaxial and fiber optic cables.

Coaxial and fiber optic cables are both used for transmitting signals, but they differ significantly in their construction and how they carry data. Coaxial cables use a central conductor surrounded by an insulator, a conductive shield, and an outer jacket. They transmit signals as electrical currents. Think of it like a water pipe – the central conductor is the pipe, and the signal is the water flowing through it. Fiber optic cables, on the other hand, transmit data as pulses of light through a thin glass or plastic fiber. Imagine this as a fiber optic cable being like a super-efficient, high-speed light pipe, immune to many forms of interference.

The key differences lie in their bandwidth, immunity to electromagnetic interference (EMI), and distance capabilities. Coaxial cables are susceptible to EMI, limiting their bandwidth and transmission distance, particularly at higher frequencies. Fiber optic cables, however, are immune to EMI and offer significantly higher bandwidth and much longer transmission distances, making them ideal for long-haul communication and high-speed data transmission. For instance, coaxial cables are commonly used in cable television distribution networks for shorter distances, while fiber optics form the backbone of the internet, carrying vast amounts of data across continents.

Q 2. Describe the various types of cable terminations and their applications.

Cable terminations are crucial for ensuring signal integrity and preventing signal loss or reflection. Several types exist, each suited for specific applications:

- Crimp Connectors (e.g., BNC, F-type): These are commonly used for coaxial cables and involve crimping a connector onto the cable’s outer and inner conductors. They are easy to use but require precision to ensure a good connection. BNC connectors are often found in laboratory settings, while F-type connectors are prevalent in cable TV installations.

- Compression Connectors: These provide a more robust and reliable connection than crimp connectors, especially for outdoor applications. A compression tool is used to firmly clamp the connector onto the cable, ensuring a gas-tight seal, which is particularly important for waterproof connections.

- Splices: These join two cables together and can be mechanical or fusion splices. Mechanical splices involve using a connector to join the ends, suitable for both coaxial and fiber optic cables. Fusion splicing is a precise technique used for fiber optics, where the ends of two fibers are melted together, creating a seamless connection.

- Fiber Optic Connectors (e.g., SC, ST, LC): These precision connectors have ceramic ferrules at the end to ensure minimal light loss at the connection. SC, ST, and LC connectors are common in various fiber optic network applications and are carefully polished for optimal performance.

The choice of termination depends on factors such as cable type, application requirements (indoor vs. outdoor, high-frequency vs. low-frequency signals), and cost considerations.

Q 3. How do you troubleshoot a cable fault?

Troubleshooting a cable fault involves a systematic approach. First, I’d identify the symptoms – is there a complete signal loss, intermittent signal, or degraded signal quality? Then, I would use a combination of testing equipment and visual inspection to isolate the fault. This might involve:

- Visual Inspection: Checking for physical damage to the cable, such as cuts, bends, or water ingress. Look for poorly made connections or corrosion.

- Continuity Testing: Using a multimeter to check for continuity of the conductors, verifying that there’s an unbroken electrical path.

- Signal Tracing: Tracing the signal path to identify the point of failure. A signal tracer can help locate breaks or shorts in the cable.

- Time Domain Reflectometry (TDR): TDR is a sophisticated technique that can pinpoint the exact location of a fault within a cable. It sends a pulse down the cable and measures the time it takes for the reflection to return, allowing precise location of impedance mismatches, breaks, and shorts.

- Optical Time-Domain Reflectometer (OTDR): For fiber optics, an OTDR is used to detect faults, measure fiber length, and identify connection losses.

Once the fault is located, the appropriate repair or replacement can be undertaken. For instance, a simple cut might be repaired with a splice, while a severely damaged section of cable will require replacement.

Q 4. What are the safety precautions for working with high-voltage cables?

Working with high-voltage cables demands strict adherence to safety procedures to prevent electrical shock, arc flash, or other hazards. Crucial safety measures include:

- Lockout/Tagout Procedures: Always de-energize the cable and apply lockout/tagout devices to prevent accidental energization. This prevents accidental contact with live wires.

- Personal Protective Equipment (PPE): Wear appropriate PPE, including insulated gloves, safety glasses, and arc flash suits as needed. The level of PPE depends on the voltage level.

- Grounding and Bonding: Properly ground and bond the cable to prevent static buildup and protect against voltage surges. Grounding provides a safe path for electrical current to flow to earth.

- Proper Training and Supervision: Only qualified and trained personnel should handle high-voltage cables. Supervision is critical, especially for complex tasks.

- Emergency Procedures: Ensure that emergency procedures and rescue plans are in place in case of an accident. Knowing how to respond appropriately to an emergency is essential.

Failure to follow these procedures can lead to severe injuries or fatalities. Always prioritize safety when working with high-voltage systems.

Q 5. What are the different cable routing methods and when would you use each?

Cable routing methods aim to optimize cable performance, durability, and safety. Several methods exist:

- Direct Burial: Cables are directly buried underground, suitable for long distances and permanent installations. This protects the cables from environmental factors but requires careful consideration of soil conditions and potential damage from excavation.

- Aerial Installation: Cables are strung overhead on poles or towers. This is a cost-effective method for spanning distances where trenching is impractical, but requires attention to weather conditions and the risk of damage from trees or falling objects.

- Trenching: Cables are laid in trenches and then covered. This provides protection from environmental elements, but requires careful excavation and backfilling to prevent damage.

- Cable Trays and Conduits: Cables are run in cable trays or conduits for better organization and protection. This is a common method in buildings and industrial settings.

- Microducting: Small diameter tubes (micro-ducts) are installed and cables are pulled through these tubes, offering flexibility and ease of access for future additions or replacements.

The selection of the routing method depends on factors such as the cable type, the environment, cost, accessibility, and future expansion needs.

Q 6. Explain the concept of cable attenuation and its impact on signal quality.

Cable attenuation refers to the reduction in signal strength as it travels along a cable. It’s essentially a loss of signal power over distance. Think of it like a water flowing through a pipe – some water is lost due to friction with the pipe’s walls. This loss is expressed in decibels (dB) per unit length (e.g., dB/km). High attenuation means significant signal loss.

Attenuation is influenced by factors like cable type, frequency of the signal, and cable length. Higher frequencies generally experience greater attenuation. The impact on signal quality is significant. Excessive attenuation can lead to signal degradation, noise, data loss, and ultimately, system failure. To mitigate attenuation, engineers often use signal amplifiers or repeaters at intervals along the cable to boost the signal strength, maintaining acceptable signal quality.

Q 7. How do you calculate cable length and sag?

Calculating cable length is straightforward if the cable runs in a straight line; you simply measure the distance. However, for aerial installations, sag needs to be considered. Sag is the vertical distance between the highest point of a suspended cable and its lowest point. Accurate calculation is crucial to ensure proper cable tension and prevent excessive stress or breakage.

Several methods exist for calculating cable sag, ranging from simple empirical formulas to complex engineering models incorporating factors like cable weight, tension, and span length. Simple approximations are often sufficient for shorter spans, while more sophisticated methods are needed for longer spans. Software tools and engineering handbooks provide equations and calculators to assist in these calculations. For instance, catenary equations are used for a more accurate model accounting for cable weight distribution.

For example, a simplified formula for sag (s) in a parabolic approximation is: s = (wL^2)/(8T), where w is the cable weight per unit length, L is the span length, and T is the cable tension. However, this is a simplification and more rigorous calculations are needed for precise engineering.

Q 8. Describe different cable splicing techniques.

Cable splicing is the process of joining two or more cable sections together to create a continuous pathway for signal transmission. The technique used depends heavily on the cable type and application. Here are some common methods:

- Mechanical Splices: These utilize connectors or compression fittings that physically join the cable ends. They’re quick and relatively easy, ideal for coaxial cables in low-demand applications. Think of it like using a strong coupling to join two water pipes.

- Fusion Splicing: Primarily used for fiber optic cables, this technique melts the fiber ends together using heat and precise alignment. This creates a permanent, high-quality connection with minimal signal loss. It’s like welding two metal pieces together, creating a seamless bond.

- Thermal Splicing: This involves heating the cable jacket and insulation to create a melt that fuses the individual conductors together. It’s often used with solid copper conductors. The process needs precise temperature control to avoid damaging the conductor.

- Crimp Splicing: This uses a special crimping tool to press a connector onto the cable ends, ensuring a strong mechanical connection. It’s a common method for various types of cables, especially in field applications where soldering isn’t practical.

The choice of splicing technique depends on factors such as cable type, required signal integrity, environment, and budget. For instance, fusion splicing is preferred for high-bandwidth fiber optic networks where minimal signal loss is critical, while mechanical splicing might suffice for lower bandwidth applications.

Q 9. What are the different types of cable connectors and their applications?

Cable connectors are devices used to terminate or connect cables. The type used depends entirely on the cable type and application. Here are a few examples:

- BNC Connectors: Primarily used with coaxial cables for radio frequency (RF) applications, offering good impedance matching and shielding. Think of them as highly specialized connectors for transmitting radio signals efficiently.

- RJ45 Connectors: Used with twisted-pair cables for Ethernet networking, these connectors have eight pins to connect the individual wires. They’re ubiquitous in offices and homes for connecting devices to networks.

- SC Connectors: These are commonly used with fiber optic cables. They offer a simple push-pull connection mechanism.

- ST Connectors: Another common fiber optic connector type, they use a bayonet-type twist lock mechanism for secure connections.

- F Connectors: Used with coaxial cables for cable television and other RF applications. They are commonly used in cable TV setups.

Choosing the correct connector is crucial for signal integrity and compatibility. For example, using the wrong connector type on a fiber optic cable can lead to significant signal loss and system failure.

Q 10. How do you test cable integrity?

Testing cable integrity is critical to ensure reliable signal transmission. Several methods are used, depending on the cable type and the specific parameters to be tested.

- Continuity Testing: This verifies the electrical connection between the two ends of a cable. A simple multimeter can be used to check for continuity, indicating whether the cable is electrically complete.

- Resistance Measurement: Measures the electrical resistance of the cable conductors. High resistance can indicate problems such as corrosion or breaks in the conductors.

- Signal Attenuation Measurement: This measures the signal loss as it travels through the cable. High attenuation indicates signal degradation. Specialized test equipment is typically needed for this.

- Time Domain Reflectometry (TDR): This advanced technique uses pulses to identify reflections caused by impedance mismatches, faults, or breaks within the cable. It’s crucial for pinpointing the location of faults in long cables.

- Optical Time-Domain Reflectometry (OTDR): Specific to fiber optic cables, OTDR measures signal attenuation and reflection to identify breaks, splices, and other anomalies in the fiber.

A combination of these tests is often used to provide a comprehensive assessment of cable integrity. For instance, a simple continuity test might be sufficient for basic wiring, while TDR or OTDR is crucial for long fiber optic cables used in high-speed data transmission.

Q 11. What is impedance matching and why is it important?

Impedance matching refers to the condition where the impedance of a transmission line (the cable) is equal to the impedance of the source (e.g., a transmitter) and the load (e.g., a receiver). Think of it like matching the size of a water pipe to the size of the pump and the tap to ensure efficient water flow.

It is crucial because mismatched impedance causes reflections. These reflections result in signal loss, distortion, and can even damage equipment. A portion of the signal energy is reflected back to the source instead of being transmitted to the load. This is analogous to a sound wave bouncing off a wall instead of passing through it.

In practice, impedance matching is achieved through various techniques, such as using impedance matching transformers or terminators. For instance, 50-ohm coaxial cables are commonly used in RF systems because components designed for 50-ohm impedance are readily available, ensuring efficient signal transmission.

Q 12. Explain the concept of return loss and its significance in cable systems.

Return loss is a measure of the power reflected back from a load compared to the power incident on the load. It’s expressed in decibels (dB) and indicates the level of impedance mismatch in a transmission line. A higher return loss value means less reflected power and better impedance matching.

It’s significant because reflected power degrades signal quality and reduces efficiency. High return loss is desirable, ideally aiming for values above 20dB. A lower return loss indicates a significant impedance mismatch, leading to problems such as signal distortion, noise, and decreased data rate. Consider a scenario with a poorly terminated cable; a substantial part of the signal would be reflected back, leading to signal degradation and potential system instability.

Return loss measurements are crucial during cable system design, installation, and maintenance to identify and resolve impedance mismatches and ensure optimal signal transmission. This is particularly critical in high-speed data transmission systems where even small reflections can drastically affect performance.

Q 13. What are the common causes of signal degradation in cable systems?

Signal degradation in cable systems can stem from several sources:

- Attenuation: Signal loss as it travels along the cable, increasing with cable length and frequency. This is inherent to all transmission lines.

- Impedance Mismatch: As discussed earlier, mismatched impedance leads to signal reflections and loss.

- Noise: External electromagnetic interference (EMI) or radio frequency interference (RFI) can corrupt the signal. This is especially critical in environments with high electromagnetic noise.

- Cable Faults: Physical damage to the cable, such as kinks, cuts, or corrosion, can significantly disrupt signal transmission.

- Connector Problems: Poorly connected or damaged connectors introduce signal loss and reflection.

- Environmental Factors: Temperature extremes, moisture, and physical stress can degrade cable performance.

Understanding these causes is crucial for effective troubleshooting and preventative maintenance. For instance, using shielded cables can reduce EMI/RFI, while proper connector installation and regular cable inspections help prevent physical damage and maintain signal integrity. A thorough understanding of the system design and potential environmental factors is paramount in minimizing signal degradation.

Q 14. How do you design a cable infrastructure for a new building?

Designing a cable infrastructure for a new building requires careful planning and consideration of several factors.

- Needs Assessment: Determine the building’s requirements for data, voice, and video communication. Consider the number of users, the bandwidth requirements, and the types of devices to be connected.

- Cable Selection: Choose appropriate cable types based on the needs assessment (e.g., fiber optic for high bandwidth, twisted-pair for data networks, coaxial for video). Consider factors like distance, environmental conditions, and cost.

- Topology Design: Select a suitable network topology (e.g., star, ring, mesh) based on the building layout and communication requirements. Star topology is common for ease of management.

- Cable Routing: Plan the cable routes carefully, minimizing bends and ensuring proper cable management for easy maintenance and future expansion. Use cable trays, conduits, and other protection methods to prevent damage.

- Termination and Connection: Choose appropriate connectors and ensure proper termination to minimize signal loss and interference. Use standardized connectors for ease of maintenance and future upgrades.

- Testing and Documentation: Thoroughly test the cable infrastructure to ensure it meets the required specifications. Document the cable routes, connector locations, and test results for easy troubleshooting and future maintenance.

An example would be designing a modern office building requiring high-speed internet for all workstations and video conferencing capabilities. This would likely involve a fiber optic backbone for high bandwidth and twisted-pair cables for individual workstations, combined with a well-planned cable routing system to minimize signal loss and interference. Careful planning and the selection of appropriate materials are essential for a reliable, future-proof cable infrastructure.

Q 15. What are the environmental factors that affect cable performance?

Environmental factors significantly impact cable performance and lifespan. Think of it like this: a cable is like a delicate piece of electronic equipment exposed to the elements. Temperature extremes, both heat and cold, can affect the insulation’s dielectric strength, causing degradation and potentially failure. Excessive moisture can lead to corrosion of conductors and connectors, increasing resistance and signal attenuation. UV radiation from sunlight can degrade the outer jacket, making the cable brittle and susceptible to damage. Physical stress from bending, twisting, or crushing can also cause internal damage. Finally, chemical exposure, such as from solvents or acids, can weaken the cable materials.

- Temperature: Extreme temperatures can cause the cable’s insulation to expand or contract, potentially leading to cracking or short circuits. For instance, high temperatures in underground ducts can shorten a cable’s lifespan considerably.

- Moisture: Water ingress can cause corrosion of metal components, leading to signal loss and increased resistance. Proper sealing and water-resistant jackets are crucial.

- UV Radiation: Prolonged exposure to sunlight can degrade the outer jacket, making it brittle and prone to cracking. Using UV-resistant jackets is essential for outdoor installations.

- Physical Stress: Improper handling and installation can damage the cable’s internal structure, leading to signal degradation or failure. Following proper installation practices is paramount.

- Chemical Exposure: Contact with chemicals can weaken or dissolve the cable’s insulation or jacket materials. Using chemically resistant materials is crucial in harsh environments.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe the different types of cable shielding and their effectiveness.

Cable shielding protects the signal from external electromagnetic interference (EMI) and radio frequency interference (RFI). Think of it as a protective armor for the delicate signal traveling inside. Several types exist, each offering varying levels of protection:

- Braided Shielding: This is a woven mesh of conductive material, typically copper or aluminum. It offers good flexibility but has gaps that can allow some interference to penetrate. It’s effective against lower-frequency interference.

- Foil Shielding: A thin layer of conductive material, usually aluminum, offers excellent shielding at higher frequencies but is less flexible than braided shielding. Often used in conjunction with braided shielding for better protection.

- Spiral Shielding: A helical wrapping of conductive tape offers good shielding effectiveness and flexibility. It’s a cost-effective solution for moderate interference levels.

- Concentric Shielding: A solid, cylindrical conductive layer provides the best shielding effectiveness, offering nearly complete protection against EMI and RFI, but it is less flexible and often more expensive.

The effectiveness of shielding depends on factors like the type of shielding, the frequency of the interference, the quality of the shielding’s grounding, and the cable’s overall design. For instance, a coaxial cable with concentric shielding provides superior protection compared to a twisted pair cable with only braided shielding. A well-grounded shield is crucial for effective interference rejection.

Q 17. Explain the concept of NEXT and FEXT in cable systems.

NEXT (Near-End Crosstalk) and FEXT (Far-End Crosstalk) are crucial parameters in cable systems, representing the amount of unwanted signal leakage between adjacent conductors in a cable. Imagine two parallel water pipes; NEXT is like the leakage near the source, and FEXT is the leakage further down the line.

NEXT measures the interference experienced at the sending end of a cable caused by signals on adjacent pairs. High NEXT can significantly degrade signal quality close to the source.

FEXT measures the interference experienced at the receiving end of a cable due to signals on adjacent pairs. It’s often more problematic than NEXT, especially over longer cable runs, as the interference accumulates.

Both NEXT and FEXT are expressed in decibels (dB). Lower values indicate better performance (less crosstalk). These values are critical in high-speed data transmission, where even minor crosstalk can lead to significant data errors. For instance, in gigabit Ethernet networks, controlling NEXT and FEXT is vital for reliable data transfer. Cable specifications usually specify acceptable limits for NEXT and FEXT to ensure system performance.

Q 18. How do you manage cable inventory and documentation?

Effective cable inventory and documentation are crucial for efficient cable management. Think of it as a library for your cables, ensuring you always know what you have and where it is. I utilize a combination of physical and digital methods.

Physical Inventory: I maintain a well-organized cable storage area, clearly labeling each cable with identifiers such as type, length, date of installation, and location. Regular physical stock takes help verify the accuracy of the inventory.

Digital Documentation: I use a database system (often a spreadsheet or specialized cable management software) to track cable information digitally. This includes detailed specifications, cable routes (often with diagrams), connection points, and maintenance history. This allows for easy searching and reporting, simplifying tasks like troubleshooting and planning upgrades.

Barcode/RFID: Utilizing barcode or RFID tagging on cables streamlines the inventory process, allowing for quick and accurate scanning during stock takes and location tracking.

This integrated approach ensures accurate record keeping, efficient cable tracing, and reduces downtime caused by cable-related issues.

Q 19. What software or tools do you use for cable design and analysis?

I use several software tools for cable design and analysis, each serving a specific purpose. My choices depend on the project’s complexity and requirements.

- AutoCAD: For detailed cable routing diagrams and physical layout planning, particularly in larger infrastructure projects.

- Specialized Cable Design Software: Software like [mention specific software, e.g., specific cable design software] allows for detailed simulations and analysis of cable performance, including NEXT, FEXT, and attenuation calculations.

- Spreadsheet Software (Excel, Google Sheets): For managing cable inventories, creating BOMs (Bills of Materials), and performing basic cable length calculations.

- 3D Modeling Software (e.g., Revit): In complex projects involving integrated systems, 3D modeling software helps visualize cable routing and identify potential conflicts with other infrastructure elements.

The choice of software is driven by project scope; for simpler projects, spreadsheets may suffice, while complex projects necessitate sophisticated design and simulation software.

Q 20. Describe your experience with cable installation procedures.

My experience with cable installation spans various environments, from structured cabling in office buildings to outdoor fiber optic deployments. Safety is always my top priority.

Structured Cabling: I follow industry best practices, including using proper tools, ensuring correct termination techniques (e.g., crimping, punching down), and adhering to color-coding schemes for easy identification. Testing after installation is crucial, verifying connectivity and signal quality.

Outdoor Fiber Optic Installations: This involves careful handling of fiber optic cables to avoid damage and employing proper splicing and termination techniques. This demands specific safety measures, like using appropriate safety glasses to protect against potential laser damage. Proper grounding is essential in outdoor installations to protect against lightning strikes.

Underground Cable Installation: This requires detailed planning, understanding local regulations and utilizing specialized equipment to prevent damage to the cables during burial.

In all cases, meticulous record-keeping, including detailed as-built drawings, is vital for future maintenance and troubleshooting.

Q 21. How do you ensure compliance with industry standards and regulations?

Compliance with industry standards and regulations is paramount in cable engineering. Neglecting this can lead to safety hazards, signal quality issues, and legal repercussions. I ensure compliance through several methods.

- Adherence to Codes and Standards: I follow relevant codes and standards, such as TIA/EIA-568 for structured cabling and relevant national and international regulations concerning safety and environmental protection. This includes understanding regulations around cable burial depth and the use of specific cable types in hazardous environments.

- Regular Inspections and Testing: Performing regular inspections and testing, such as OTDR testing for fiber optic cables, ensure that the installed cables meet performance specifications and that there are no faults.

- Documentation and Record Keeping: Maintaining detailed documentation, including certifications of materials and test results, provides a clear audit trail demonstrating compliance. This includes keeping up-to-date records of any safety training and certifications obtained.

- Staying Updated: I actively participate in professional development activities and stay informed about the latest updates and revisions to relevant codes and standards.

Compliance isn’t just a checklist; it’s an ongoing commitment to ensuring the safety and reliability of the cable infrastructure.

Q 22. Explain your experience with different types of cable testing equipment.

My experience with cable testing equipment spans a wide range, encompassing both basic and advanced tools. I’m proficient in using Time Domain Reflectometers (TDRs) to pinpoint cable faults like shorts, opens, and impedance mismatches. Think of a TDR as a sophisticated sonar for cables – it sends a signal down the cable and analyzes the reflections to identify any irregularities. I’ve also extensively used Cable Certifiers to verify cable performance against industry standards, ensuring proper attenuation and return loss. These are crucial for ensuring data transmission quality, especially in high-speed networks. Beyond these, I’m familiar with Optical Time Domain Reflectometers (OTDRs) for fiber optic cables, which use light pulses instead of electrical signals to locate faults. For instance, I once used an OTDR to quickly identify a microbend in a fiber optic cable causing significant signal degradation in a critical data center connection, preventing a major service disruption. Finally, I have experience with various types of multimeters and signal generators, employed for basic continuity tests and signal level measurements.

- Time Domain Reflectometers (TDRs): Fault location in coaxial and twisted-pair cables.

- Cable Certifiers: Verification of cable performance against standards (e.g., TIA/EIA).

- Optical Time Domain Reflectometers (OTDRs): Fault location and performance testing in fiber optic cables.

- Multimeters and Signal Generators: Basic continuity and signal level measurements.

Q 23. Describe your problem-solving approach when dealing with complex cable issues.

My approach to solving complex cable issues is systematic and data-driven. I start by gathering all relevant information: cable specifications, network diagrams, fault reports, and environmental factors. Next, I use a process of elimination, starting with the most likely causes based on my experience. This might involve visually inspecting the cable for damage, performing continuity checks with a multimeter, or employing more sophisticated tools like a TDR or OTDR, depending on the suspected problem. For example, I recently diagnosed an intermittent network outage in a large building by systematically testing cables floor by floor, using a TDR to pinpoint a loose connection in a cable run within a specific section of the building. If the initial tests don’t identify the problem, I delve into more detailed analysis, such as spectrum analysis or protocol testing. Throughout the process, I meticulously document every step, ensuring that the solution is not only effective but also well-understood for future reference. Finally, after implementing the solution, I thoroughly test the system to ensure the problem is resolved and prevent future occurrences. This methodical approach allows for efficient troubleshooting and prevents unnecessary work.

Q 24. How do you prioritize tasks when working on multiple cable projects?

Prioritizing tasks across multiple cable projects involves a blend of urgency, impact, and resource allocation. I use a system that combines a project management tool (such as a Kanban board) with risk assessment. Projects are prioritized based on deadlines, potential impact (e.g., a critical data center outage versus a minor office network issue), and resource requirements (personnel, equipment). I typically use a weighted scoring system, considering each of these factors. Critical, time-sensitive projects with high impact naturally get top priority, even if they aren’t the biggest in terms of overall scope. For instance, a project to replace a damaged fiber optic cable affecting multiple critical servers would always take precedence over upgrading an older network segment with minimal impact on daily operations. Regular project reviews and communication with stakeholders are vital to ensure the priorities remain aligned with evolving business needs.

Q 25. What are your strengths and weaknesses in cable engineering?

My strengths lie in my analytical skills, problem-solving abilities, and deep understanding of cable technologies and standards. I’m comfortable working independently and as part of a team, and I thrive in fast-paced environments. I’m also a quick learner and adaptable to new technologies and challenges. A weakness I’ve identified is the occasional tendency to get bogged down in the details; however, I’m actively working on improving my ability to focus on the larger picture while maintaining attention to detail. To address this, I use time management techniques like the Pomodoro technique to improve my focus and efficiency.

Q 26. Describe your experience working with different cable materials.

My experience encompasses a range of cable materials, including copper (twisted-pair, coaxial), fiber optics (single-mode, multi-mode), and various shielding types. I understand the properties and limitations of each material, such as the bandwidth capabilities of different copper cable types or the attenuation characteristics of various fiber optic cables. For example, I’ve worked extensively with shielded twisted-pair cables in industrial settings to minimize electromagnetic interference. In contrast, I’ve selected single-mode fiber for long-haul data transmission due to its superior bandwidth and distance capabilities. This knowledge informs my material selection decisions, ensuring the cable type is appropriately matched to the application’s specific requirements. Knowledge of cable material properties is crucial for optimal system design and performance.

Q 27. How do you handle conflict resolution within a team setting?

Conflict resolution for me begins with open and honest communication. I believe in actively listening to all perspectives, ensuring everyone feels heard and understood. I strive to identify the root cause of the conflict, rather than focusing solely on the symptoms. This often involves separating the people from the problem. Once the core issue is understood, I work collaboratively with the team to develop solutions that address everyone’s concerns. Compromise and finding common ground are key. In situations where a compromise is not immediately possible, I facilitate a structured discussion to identify potential solutions and move forward constructively. Documentation and follow-up are also important for ensuring the resolution is implemented and to prevent similar conflicts in the future.

Q 28. Describe a time you had to adapt to a challenging cable engineering situation.

During a recent project, we encountered an unexpected problem with a new type of high-bandwidth cable that was experiencing significant signal attenuation over shorter distances than anticipated. The initial assumption was a manufacturing defect. However, after extensive testing, we discovered the issue stemmed from an incompatibility between the cable and the connectors being used. The cable’s unique impedance characteristics were not properly matched to the connectors. Adapting to this required quick problem-solving and collaboration with the vendor and the installation team. We tested various connector types and ultimately found one that provided a suitable impedance match, resolving the attenuation problem. This experience highlighted the importance of thoroughly understanding all aspects of a system – cables, connectors, and their interaction – before deployment and reinforced the value of collaboration when dealing with unforeseen challenges.

Key Topics to Learn for Cable Engineering Interview

- Fiber Optics: Understanding different fiber types (single-mode, multi-mode), transmission principles, and network architectures. Practical application: Designing a high-bandwidth fiber optic network for a large building or campus.

- Coaxial Cable Systems: Familiarize yourself with different coaxial cable types, impedance matching, signal attenuation, and amplification techniques. Practical application: Troubleshooting signal loss in a cable television network.

- Network Topologies: Mastering different network topologies (star, bus, ring, mesh) and their advantages and disadvantages in cable infrastructure. Practical application: Selecting the optimal topology for a specific cable network deployment.

- Cable Testing and Measurement: Understanding various testing methods (OTDR, TDR, spectrum analysis) and their applications in diagnosing cable faults. Practical application: Identifying and resolving a fault in an underground fiber optic cable.

- Signal Processing and Modulation Techniques: Gain a solid understanding of digital signal processing concepts and modulation techniques used in cable transmission systems. Practical application: Optimizing signal quality in a high-noise environment.

- Network Design and Planning: Learn the principles of network design, including capacity planning, routing, and network security considerations. Practical application: Designing a robust and scalable cable network for a new development.

- Safety Regulations and Best Practices: Understanding safety protocols and industry best practices for working with cable infrastructure. Practical application: Ensuring safe working practices during cable installation and maintenance.

Next Steps

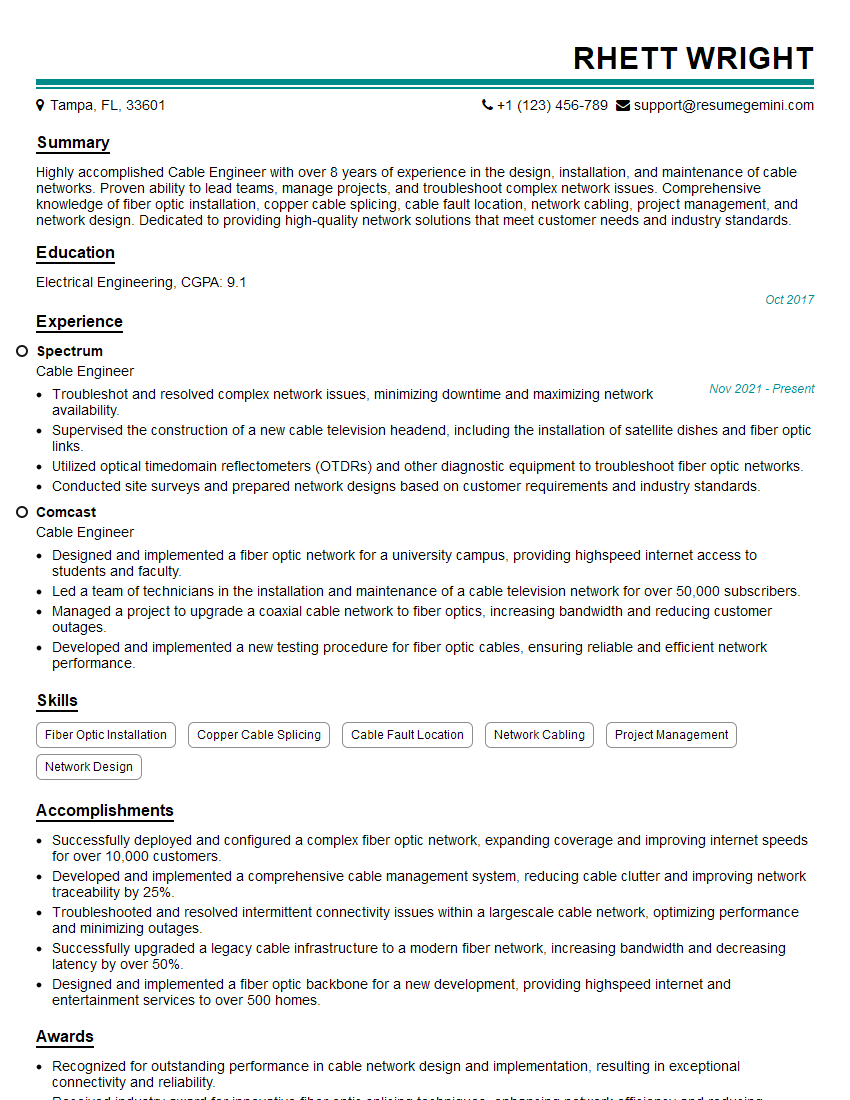

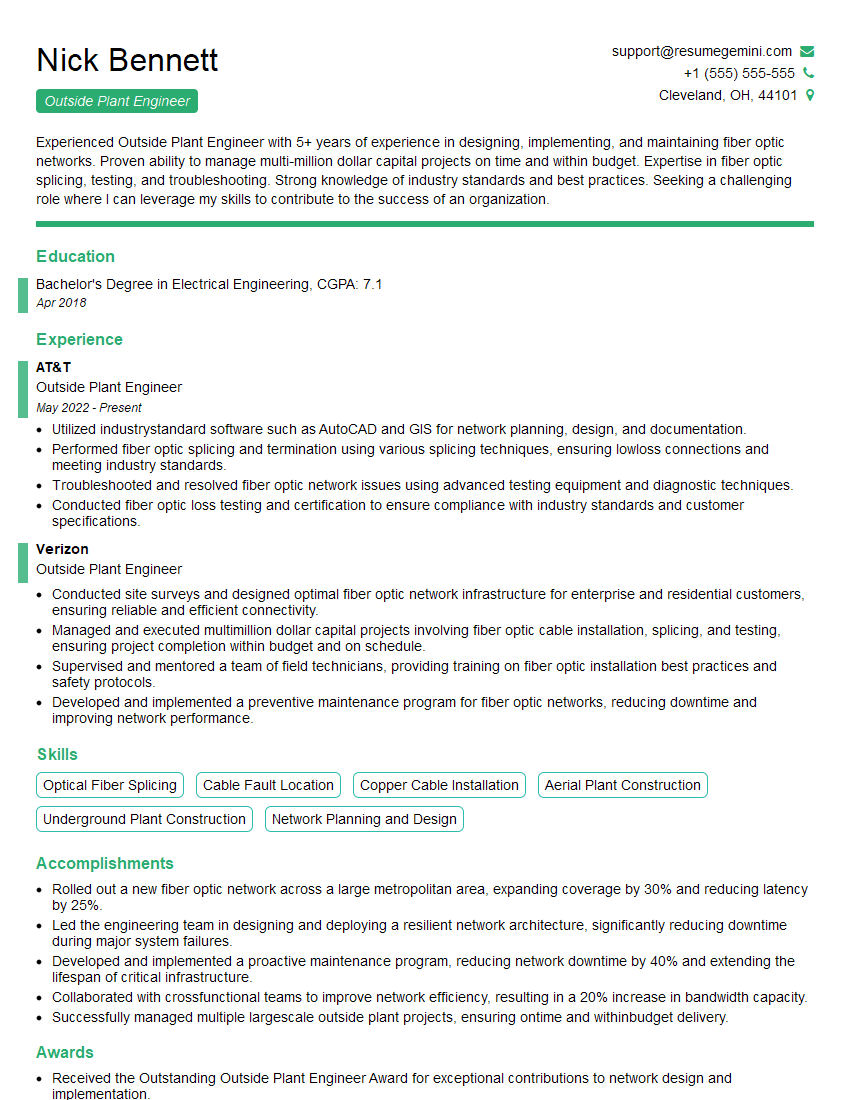

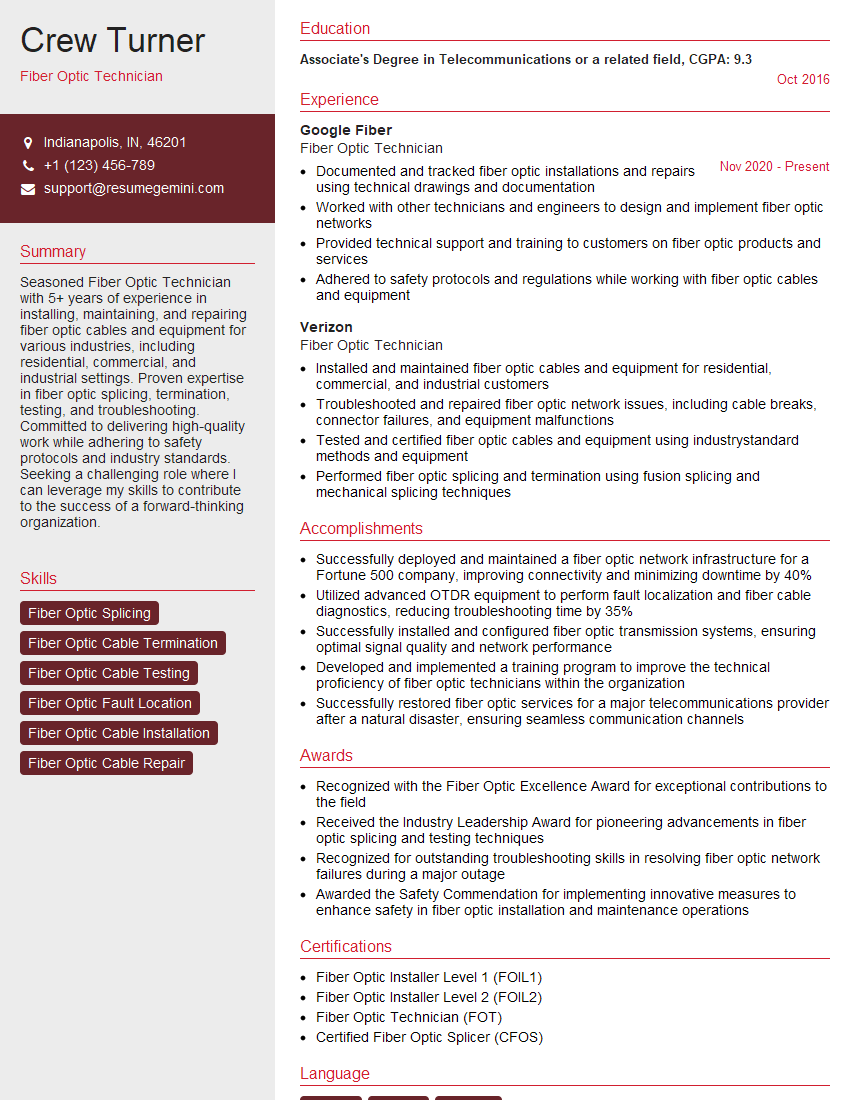

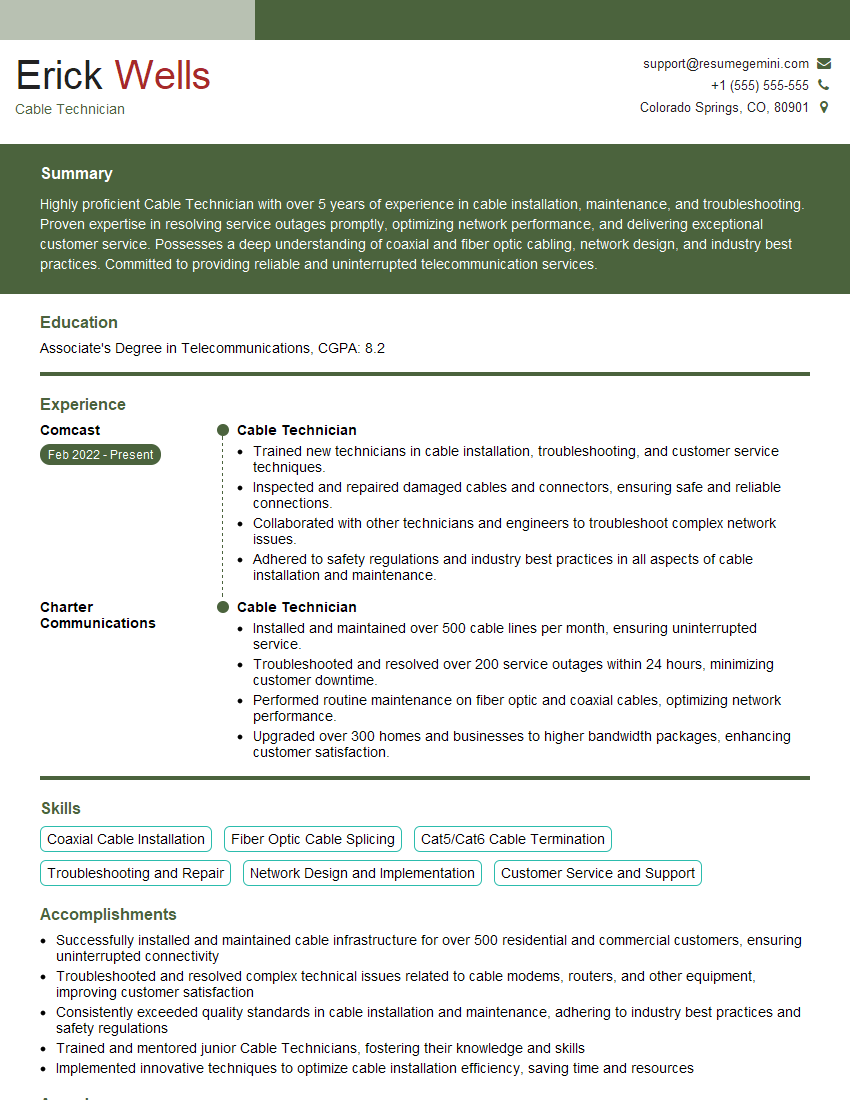

Mastering Cable Engineering opens doors to exciting and rewarding career opportunities in a rapidly evolving industry. To maximize your job prospects, a well-crafted, ATS-friendly resume is crucial. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your skills and experience effectively. We provide examples of resumes tailored to Cable Engineering to help guide you through the process. Invest time in crafting a strong resume – it’s your first impression with potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good