The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Cable Fault Locating interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Cable Fault Locating Interview

Q 1. Explain the principles of Time Domain Reflectometry (TDR).

Time Domain Reflectometry (TDR) is a powerful technique used to locate faults in electrical cables. It works by sending a short electrical pulse down the cable and then analyzing the reflections of that pulse. Think of it like shouting into a canyon and listening for the echoes – the timing and strength of the echoes tell you about the obstacles (faults) in the canyon (cable).

The principle lies in the fact that when a pulse encounters an impedance mismatch – a change in the electrical characteristics of the cable, such as a break, short circuit, or connector problem – a portion of the pulse reflects back to the source. The time it takes for the reflection to return is directly proportional to the distance of the fault from the TDR unit. The amplitude of the reflected pulse indicates the severity of the fault.

For example, a complete break in the cable will produce a large, abrupt reflection, while a partial short might cause a smaller, less defined reflection.

Q 2. Describe the operation of an OTDR (Optical Time Domain Reflectometer).

An Optical Time Domain Reflectometer (OTDR) is similar to a TDR, but instead of electrical pulses, it uses light pulses. These pulses are launched into an optical fiber, and any reflections are detected and analyzed. OTDRs are crucial for maintaining and troubleshooting optical fiber networks.

The OTDR transmits a short pulse of light into the fiber. As this light travels, a portion is scattered back towards the OTDR at each point of discontinuity (like a connector or fault). A sensitive receiver in the OTDR measures the time it takes for these reflections to return, translating it into distance, and the power of the returned signal gives an indication of the severity of the reflection event (fault, splice, or connector).

Unlike TDR which requires direct connection to the cable, OTDRs can test long stretches of fiber without interrupting service, making them ideal for long-haul telecom and data center applications. The trace generated by an OTDR shows the loss of power along the fiber and highlights locations of events which can be analyzed to determine the nature and location of faults.

Q 3. What are the differences between TDR and OTDR?

The key difference between TDR and OTDR lies in the type of signal they use and the type of cable they test.

- TDR uses electrical pulses and tests metallic cables (coaxial, twisted-pair).

- OTDR uses optical pulses and tests optical fibers.

Other differences include the range, with OTDRs typically being used for much longer distances than TDRs. Additionally, OTDRs provide a visual representation of the entire fiber link, whereas TDRs provide measurements for specific points based on the reflections received. Both are invaluable tools for fault location but in different applications.

Q 4. How do you interpret a TDR trace?

Interpreting a TDR trace involves analyzing the time and amplitude of the reflected pulses. The horizontal axis represents the distance along the cable, and the vertical axis represents the amplitude of the reflected signal. A sharp downward spike usually indicates an open circuit; whereas a sharp upward spike might indicate a short circuit.

For instance, a reflection occurring at 500 meters with a large negative amplitude strongly suggests a break in the cable at that location. A smaller reflection could indicate a poor connection or a partial short. The specific interpretation depends on the cable type, the impedance of the cable, and the settings of the TDR.

Experience is crucial in properly interpreting TDR traces; knowing the characteristics of the cable being tested allows for more accurate analysis.

Q 5. How do you interpret an OTDR trace?

An OTDR trace displays the optical power loss along an optical fiber as a function of distance. The horizontal axis represents distance along the fiber, while the vertical axis represents the power level (usually in dB). The trace shows a decreasing power level as the light travels down the fiber, due to attenuation.

Events such as connectors, splices, and faults appear as distinct dips or reflections on the trace. A sharp downward spike usually indicates a fault or break in the fiber, while a less pronounced dip might represent a connector or splice. The amount of attenuation can be measured between these events which gives an indication of the quality of the fiber.

Just like with TDR, analyzing OTDR traces requires experience and an understanding of the fiber optic link components. Knowing the characteristics of the fiber allows for more precise evaluation of the trace and accurate fault identification.

Q 6. What are the common causes of cable faults?

Common causes of cable faults are diverse and depend heavily on the cable type and environmental factors. Here are some examples:

- Physical damage: Cuts, crushes, kinks, and rodent damage are common in both metallic and fiber cables.

- Water ingress: Water can cause shorts, corrosion, and signal attenuation.

- Connector issues: Loose, corroded, or damaged connectors are frequent culprits.

- Ground faults: Metallic cables can develop ground faults due to insulation breakdown or environmental factors.

- Manufacturing defects: Flaws introduced during the cable’s manufacturing process.

- Overloads and surges: Excessive power or voltage surges can damage cables.

In optical fibers, microbends, poor splices, and contamination within the fiber are also major causes of signal degradation and attenuation.

Q 7. How do you troubleshoot a fault in a coaxial cable?

Troubleshooting a coaxial cable fault involves a systematic approach:

- Visual inspection: Carefully examine the cable for any visible damage like cuts, kinks, or exposed conductors.

- Continuity test: Use a multimeter to check the continuity of the inner and outer conductors. A break in continuity indicates a cable break.

- TDR testing: Utilize a TDR to pinpoint the location of the fault. The TDR trace will identify the distance to the fault, giving a specific location.

- Signal tracing: If the fault is not easily accessible, signal tracing techniques can be used to track the signal strength along the cable and locate the fault area.

- Connector inspection: Inspect all connectors and terminations for damage, corrosion, or poor connections. Re-terminate if needed.

- Replacement: If the fault is severe or in an inaccessible location, replacing a section of cable might be necessary.

Remember to always disconnect power before working on any electrical cables. Safety should be the top priority.

Q 8. How do you troubleshoot a fault in a fiber optic cable?

Troubleshooting fiber optic cable faults differs significantly from metallic cable troubleshooting because light signals, not electrical current, transmit data. The process often involves specialized equipment and techniques. We begin with visual inspection for physical damage like cuts or bends. Then, we utilize an Optical Time-Domain Reflectometer (OTDR). This device sends a light pulse down the fiber and measures the time it takes for reflections to return. These reflections indicate breaks, splices, or other imperfections. The OTDR provides a visual representation of the fiber’s condition, showing the distance to faults. For example, a sharp drop in signal power on the OTDR trace indicates a break. Finally, once a fault is located, we use a fusion splicer or other appropriate technique to repair the fiber.

Imagine an OTDR trace as a map of your fiber optic cable. Any dips, peaks, or sudden stops in the line signify potential problems. The device helps pinpoint their exact location along the cable’s length, making repairs more efficient.

Q 9. Explain the process of cable fault localization using a clamp meter.

A clamp meter measures the current flowing in a cable. To localize a fault using a clamp meter, we need a known good point and a suspected faulty point. We first clamp the meter around the cable at the known good point to establish a baseline current reading. Then, we systematically move the clamp meter along the cable towards the suspected fault area, measuring current at intervals. A significant decrease or increase in current compared to the baseline indicates the presence of a fault. The location where the change is most pronounced is the approximate location of the fault. This method is primarily useful for locating shorts or opens where a noticeable change in current is expected.

For instance, if a short circuit occurs, the current reading will abruptly increase as you approach the fault location. Conversely, an open circuit will show a drastic drop in current. Remember, accuracy depends on the quality of the readings and the meter’s precision.

Q 10. Describe different types of cable faults (opens, shorts, grounds).

Cable faults can be categorized broadly into opens, shorts, and grounds. An open is a break in the conductor, completely interrupting the circuit. Imagine a broken wire; there’s no longer a continuous path for current to flow. A short circuit, or simply a short, occurs when two conductors touch unintentionally, creating an unintended low-resistance path. This can lead to excessive current and even overheating. Think of two wires accidentally twisted together. Finally, a ground fault happens when a conductor makes contact with the earth or a grounding system. This can create a dangerous situation, potentially causing shocks and equipment damage. It’s like a wire touching a metal pipe grounded to the earth.

Understanding these fault types is crucial because different diagnostic techniques are better suited for each. For example, a clamp meter is excellent for detecting shorts and some grounds, while an OTDR is necessary for fiber optic cable faults.

Q 11. What safety precautions are necessary when performing cable fault location?

Safety is paramount during cable fault location. Always treat all cables as potentially live, even if they appear de-energized. This requires following several key safety precautions:

- Lockout/Tagout (LOTO): Before working on any cable, ensure it’s properly de-energized and locked out using a LOTO procedure. This prevents accidental re-energization.

- Personal Protective Equipment (PPE): Wear appropriate PPE, including safety glasses, insulated gloves, and safety shoes. The specific PPE will depend on the voltage level of the cable and the work environment.

- Awareness of Surroundings: Be aware of your surroundings, especially overhead power lines and other potential hazards.

- Follow Safety Procedures: Adhere strictly to the company’s safety procedures and regulations. This is non-negotiable.

- Proper Training: Only trained and qualified personnel should perform cable fault location.

A single lapse in safety can lead to serious injury or fatality. Prioritizing safety isn’t optional; it’s the foundation of responsible cable fault locating.

Q 12. How do you identify the location of an underground cable fault?

Locating an underground cable fault often requires specialized equipment because you can’t directly see the cable. Common methods include:

- Cable Tracing Equipment: These devices emit a signal into the cable, and a receiver traces the signal along the route, aiding in identifying the cable’s path and potential breaks.

- Ground-penetrating radar (GPR): GPR uses radar pulses to create an image of the subsurface, revealing the location of buried cables and potential damage.

- Time Domain Reflectometry (TDR): Similar to OTDR for fiber, TDR sends electrical signals down the cable. Reflections from faults are analyzed to pinpoint their location.

- Fault location equipment with tracing capability: This equipment will measure the electrical signals and trace the path of the cable, thus allowing you to pinpoint the cable fault location.

Often, a combination of these techniques is used for increased accuracy. For example, we might use cable tracing equipment to pinpoint the general area of the fault, followed by GPR for precise location. This phased approach greatly improves the efficiency of the repair process.

Q 13. How do you identify the location of an overhead cable fault?

Locating an overhead cable fault is generally easier than an underground fault because the cable is visible. However, safety remains a paramount concern. Visual inspection is the initial step. We check for obvious damage like broken wires, damaged insulators, or tree contact. If no visual fault is identified, we might use a high-voltage tester to determine the insulation’s integrity. Specialized tools, such as a line tester, can pinpoint specific locations of damage along the line. Additionally, thermal imaging cameras can be used to detect hotspots, indicating potential faults due to high resistance or current leakage.

Working on overhead cables requires specific safety training and harnesses to prevent falls. Always remember that working at height presents unique risks that need careful management.

Q 14. Explain the use of different cable testing equipment.

Numerous cable testing equipment types exist, each suited to different situations. We already discussed the OTDR for fiber and the clamp meter for current measurements. Other important equipment includes:

- Time Domain Reflectometers (TDR): Used for metallic cables, as mentioned before.

- High-Voltage Testers: Check the insulation integrity of cables by applying high voltage and checking for breakdowns.

- Cable Fault Locators: These devices combine multiple testing techniques, often including TDR, to provide precise fault location.

- Bridge Testers: Used to measure the resistance of individual conductors, helping identify opens and shorts.

- Multimeters: General-purpose instruments for measuring voltage, current, and resistance. Helpful for basic diagnostics.

- Thermal Imaging Cameras: Detect heat signatures that might indicate faulty connections or overloaded cables.

The choice of equipment depends on the specific type of cable, the suspected fault type, and the environment. Often, using several types of equipment improves accuracy and confidence in the fault identification process.

Q 15. What is the significance of impedance in cable fault location?

Impedance is crucial in cable fault location because it represents the opposition to the flow of electrical current within the cable. Think of it like friction in a pipe – higher impedance means more resistance. In cable fault locating, we use impedance measurements to identify discontinuities or changes in the cable’s electrical characteristics. These changes often indicate a fault, such as a break, short circuit, or water ingress. For instance, a break in the cable will show a significantly higher impedance compared to a healthy section. By comparing impedance values along the cable’s length, we can pinpoint the fault’s location. Different fault types (e.g., open circuit, short circuit) will manifest with distinct impedance signatures, which experienced technicians can interpret to determine the nature of the fault.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is the role of attenuation in cable fault location?

Attenuation, or signal loss, is the weakening of a signal as it travels along the cable. This is an unavoidable phenomenon, much like sound diminishing as it travels further. In cable fault location, attenuation significantly affects the accuracy of measurements, particularly with Time Domain Reflectometry (TDR). A strong signal is needed for accurate reflection analysis. High attenuation means the signal weakens rapidly, making it difficult to detect reflections from small faults or faults located far away. Therefore, understanding and compensating for attenuation is crucial for accurate fault location. Techniques like using higher-power signals or specialized equipment that can deal with high attenuation are essential for overcoming this challenge.

Q 17. How do you use a bridge to locate cable faults?

A bridge, in the context of cable fault location, is a type of electrical circuit used to measure impedance. It compares the impedance of a known section of the cable with an unknown section (where the fault might be). The process typically involves balancing the bridge circuit until a null point is reached, indicating equal impedance on both sides. The location of the fault is then calculated based on the known length of the cable and the impedance values. This method is particularly effective for locating faults that exhibit a clear impedance change, like short circuits. Imagine a seesaw: the bridge balances when the impedance on both sides is equal. When unbalanced, the difference points to the location of the impedance mismatch – the fault.

Q 18. What are the limitations of TDR and OTDR?

Time Domain Reflectometry (TDR) and Optical Time Domain Reflectometry (OTDR) are powerful tools, but they have limitations. TDR’s limitations include: difficulty in locating faults in very long cables due to signal attenuation; inaccuracy in locating faults that don’t produce strong reflections; and susceptibility to interference from other electrical signals. OTDR, while excellent for fiber optic cables, is limited to fiber optic applications only. Its limitations include high cost, inability to detect very small faults, and issues with high-attenuation fibers.

Q 19. How do you deal with difficult-to-locate cable faults?

Dealing with difficult-to-locate faults requires a systematic approach. First, a thorough understanding of the cable’s history and the nature of the problem is essential. This may involve reviewing past maintenance records. Next, multiple fault location techniques should be employed, combining TDR, OTDR, bridge measurements, and even manual tracing. Advanced techniques like narrow-pulse TDR or using specialized probes may be necessary. If the fault remains elusive, it might be necessary to excavate a section of the cable for visual inspection. The process often involves meticulous record-keeping and analysis of data collected from different methods to triangulate the fault’s position.

Q 20. What are the different types of cable connectors and their applications?

Cable connectors are vital for establishing reliable connections. Common types include: BNC connectors (used for coaxial cables in radio frequency applications); RJ45 connectors (used for Ethernet cables in computer networks); ST connectors (used for fiber optic cables); and SC connectors (another type of fiber optic connector). The choice depends on the cable type, application, and required performance. Incorrect connector usage can degrade signal quality and lead to signal loss or even damage to equipment. For example, using a BNC connector on a fiber optic cable would be incorrect and ineffective.

Q 21. Explain the importance of proper grounding and shielding in cable systems.

Proper grounding and shielding are critical for reliable cable system performance and safety. Grounding provides a path for unwanted electrical currents (like surges or lightning strikes) to safely flow to the earth, preventing damage to equipment and ensuring personnel safety. Shielding protects the cable from external electromagnetic interference (EMI), which can corrupt signals and cause errors. Think of shielding as a protective barrier against unwanted electrical noise. Without proper grounding and shielding, signals can be degraded, leading to inaccurate readings in fault location and potentially hazardous situations. This is especially important in high-voltage or high-noise environments.

Q 22. How do you document your findings after locating a cable fault?

Thorough documentation is crucial for efficient cable fault repair and future troubleshooting. My documentation process involves several key steps. First, I create a detailed report including the date, time, location, and nature of the fault. This includes specifics like the type of cable, its length and gauge, and the exact location of the fault along its length (e.g., 1.2km from the main junction). Next, I document the testing methods used – for example, Time Domain Reflectometry (TDR), Optical Time Domain Reflectometry (OTDR), or other techniques. The report includes the readings obtained, any diagrams or schematics illustrating the cable route and the fault location, and photos of the damaged area, if applicable. Finally, I outline the repair method used, the materials required, and the steps taken to rectify the fault. All documentation is digitally stored in a secure and accessible database for easy retrieval and future reference. For example, a recent fiber optic cable fault was documented with OTDR traces showing the exact location of the break, which allowed the repair crew to target the precise area instead of digging indiscriminately. Clear documentation ensured the repair was fast and minimized disruption.

Q 23. Describe your experience working with different types of cable.

My experience spans a wide range of cable types, including copper coaxial cables (used in traditional cable TV networks), fiber optic cables (critical for high-speed data transmission), and various types of power cables (used for electrical distribution). I’m proficient in using different testing methods suitable for each cable type. For example, with copper coaxial cables, I use TDR to precisely locate short circuits or open circuits. For fiber optic cables, OTDR is essential for identifying breaks, macrobends, and other attenuations. I’ve worked extensively with different cable sheathing materials—from polyethylene to steel armored cables—understanding their properties and how to handle them appropriately during fault location. Working on a large-scale project involving both aerial and underground fiber optic cables taught me the nuances of different cable installations and the challenges each presents. For instance, pinpointing faults in underground cables requires a different approach and more specialized equipment compared to aerial cables.

Q 24. What software or applications are you familiar with for analyzing cable fault data?

I’m proficient in several software applications used for analyzing cable fault data. These include specialized software packages that integrate with my TDR and OTDR equipment, allowing me to analyze waveforms and pinpoint fault locations with high precision. I’m also familiar with Geographical Information Systems (GIS) software for visualizing cable routes and integrating fault location data into existing network maps. For example, I use software that allows me to export OTDR trace data and generate reports with detailed visual representations of signal loss, aiding in clearer communication with engineers and technicians. Data analysis software helps determine the severity of a fault, identify potential patterns (like recurring faults in a specific section), and contribute towards proactive maintenance planning.

Q 25. How do you handle conflicts or disagreements with colleagues during a cable fault locating job?

Handling disagreements is a critical aspect of teamwork. I believe in fostering open communication and a collaborative environment. If a conflict arises, I initiate a discussion focusing on objective facts and the data. I present my findings clearly, highlighting the evidence supporting my assessment. If disagreements persist, I propose alternative solutions, and invite further analysis or a second opinion from a senior colleague or supervisor. The goal is to reach a consensus based on the available evidence, ensuring the most efficient and accurate resolution. For instance, during a recent project, a colleague and I had differing interpretations of TDR readings. We compared our methods and found a minor calibration issue in one of the devices, resolving the discrepancy and leading to a shared conclusion.

Q 26. Explain your experience working under pressure and meeting deadlines on cable fault location projects.

I thrive under pressure and am accustomed to working to tight deadlines. In my previous role, I consistently met tight deadlines during emergency cable repairs, often working extended hours to restore services. For example, during a major storm, a critical fiber optic cable was damaged, leading to service outages for multiple communities. Working under considerable pressure and coordinating with multiple teams, I successfully located the fault within the critical timeframe, enabling the speedy restoration of services, minimizing downtime and inconvenience.

Q 27. Describe your experience with preventative maintenance of cable systems.

Preventative maintenance is crucial for minimizing cable faults and ensuring network reliability. My experience includes performing regular inspections of cable systems, looking for signs of wear, damage, or degradation. I’m familiar with using specialized tools to check cable parameters, such as insulation resistance and signal attenuation. Regular testing helps identify potential problems before they cause major disruptions. This can include using OTDR to monitor fiber optic cable health or performing thermal imaging to detect potential hotspots in power cables. Proactive maintenance also involves updating cable system documentation and creating a preventative maintenance schedule tailored to the specific cable system. For example, a preventative maintenance program I implemented resulted in a 20% reduction in cable faults over a six-month period.

Q 28. What are your salary expectations for this role?

My salary expectations are in line with the market rate for experienced cable fault location specialists with my skills and experience. Considering my qualifications, the responsibilities of this role, and my proven track record of success, I’m seeking a competitive compensation package that reflects my contributions.

Key Topics to Learn for Cable Fault Locating Interview

- Fundamentals of Cable Construction: Understanding different cable types (coaxial, fiber optic, twisted pair), their construction, and common failure points is crucial. This forms the basis for effective troubleshooting.

- Fault Location Techniques: Mastering various techniques like Time Domain Reflectometry (TDR), Optical Time Domain Reflectometry (OTDR), and Bridge Wiring methods is essential. Be prepared to discuss their principles and practical applications.

- Signal Analysis and Interpretation: Interpreting readings from fault locators, understanding signal attenuation, and identifying noise are key skills. Practice analyzing different types of readings to build your diagnostic abilities.

- Troubleshooting Strategies: Develop a structured approach to troubleshooting. Discuss your problem-solving methodology, including systematic testing, data analysis, and prioritization of repair strategies.

- Safety Procedures and Regulations: Demonstrate a strong understanding of relevant safety regulations and procedures for working with high-voltage cables and equipment. This is critical for any cable technician.

- Testing Equipment: Familiarize yourself with different types of testing equipment used in cable fault locating, including their capabilities and limitations. Be ready to discuss their operation and maintenance.

- Data Analysis and Reporting: Know how to effectively document your findings, create clear reports, and communicate technical information to both technical and non-technical audiences.

Next Steps

Mastering Cable Fault Locating opens doors to rewarding and stable careers in telecommunications, utilities, and other crucial infrastructure sectors. A strong understanding of these techniques is highly valued, and directly translates to higher earning potential and increased career opportunities.

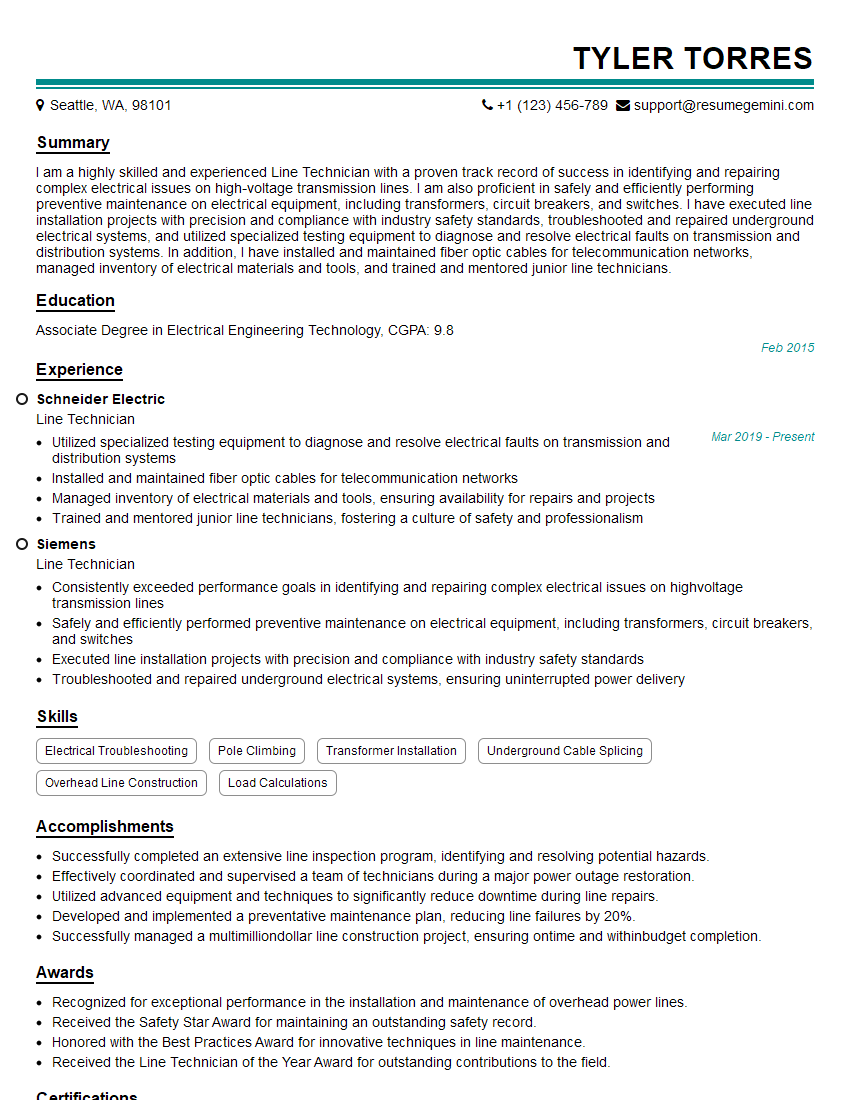

To maximize your job prospects, creating a compelling and ATS-friendly resume is paramount. ResumeGemini is a trusted resource to help you build a professional resume that highlights your skills and experience effectively. ResumeGemini offers examples of resumes tailored to the Cable Fault Locating field, providing you with templates and guidance to showcase your abilities to potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good