Cracking a skill-specific interview, like one for Cable Inspection, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Cable Inspection Interview

Q 1. Describe your experience with different types of cable inspection equipment.

My experience with cable inspection equipment spans a wide range, encompassing both optical and electrical testing methodologies. I’ve extensively used Optical Time-Domain Reflectometers (OTDRs) for fiber optic cable testing, Time-Domain Reflectometers (TDRs) for copper cable testing, and various other tools. This includes cable fault locators, which pinpoint the precise location of a fault along the cable’s length, and visual inspection tools such as microscopes for detailed examination of connectors and fiber end-faces. I’m also proficient with network analyzers, which assess signal quality and attenuation, helping identify problems within the cable system. For example, I recently used an OTDR to diagnose a fault on a long-haul fiber optic link, pinpointing a microbend causing significant signal loss, which was then successfully repaired.

Beyond these core tools, I’m comfortable using specialized equipment like capacitance bridges for testing the integrity of coaxial cables and various signal generators and analyzers for checking signal strength and clarity across different cable types. The specific tools used depend greatly on the type of cable being tested (fiber, copper, coaxial) and the suspected nature of the problem.

Q 2. Explain the process of identifying and locating cable faults.

Identifying and locating cable faults is a systematic process. It begins with a thorough understanding of the reported problem: slow speeds, complete signal loss, intermittent connectivity, etc. Then, I employ a combination of techniques. Visual inspection is always the first step, checking for obvious physical damage like cuts, kinks, or water ingress.

If visual inspection doesn’t reveal the issue, I’ll use specialized test equipment. For fiber optics, an OTDR creates a visual representation of the fiber’s reflectivity, highlighting any discontinuities or attenuation. For copper cables, a TDR uses similar principles, but with electrical pulses, to detect reflections from impedance mismatches signifying shorts, opens, or other faults. Cable fault locators, often using TDR technology, help pinpoint the geographical location of the fault. In practice, I might use an OTDR to find a break in a fiber optic line, and then a fault locator to precisely determine its location along the cable route. This allows for targeted repair, minimizing downtime.

Finally, the process includes detailed documentation, creating reports that record the testing procedures, findings, and any corrective actions taken.

Q 3. How do you interpret test results from OTDR, TDR, or other cable testing equipment?

Interpreting test results from OTDR, TDR, and other cable testing equipment requires a strong understanding of the underlying principles and the ability to recognize different patterns indicative of specific fault types. An OTDR trace, for instance, displays signal attenuation and reflections as a function of distance. A sharp drop in signal power suggests a break or a very significant loss event. Reflections can be caused by splices, connectors, or actual faults. I’ve found learning to differentiate between these is critical. For example, a gradual signal attenuation might be caused by a slow deterioration of the fiber over time, whereas a sudden drop indicates a more abrupt damage.

Similarly, a TDR trace will show reflections indicating short circuits, opens, or impedance mismatches within the copper cable. Other test equipment might show signal-to-noise ratios, return loss, or other metrics, all of which need to be interpreted within the context of the cable’s specifications and the expected performance. Experience is vital; recognizing anomalies and making accurate interpretations based on the data comes with practice and a solid understanding of the equipment and the physics behind the testing methods.

Q 4. What are the common causes of cable failures?

Cable failures have numerous causes, broadly categorized as environmental, mechanical, and manufacturing defects. Environmental factors include water ingress, which can corrode conductors and cause short circuits; extreme temperatures, which can cause material degradation and cracking; and rodent damage, which can chew through insulation and compromise the cable’s integrity.

Mechanically, cable failures can result from bending beyond the allowable radius, crushing, improper handling during installation (such as over-tensioning), and physical damage from construction or other external forces. Manufacturing defects can include flaws in the cable’s insulation, weak connectors, or inconsistencies in the manufacturing process itself. For instance, a cable running alongside a poorly installed underground power line may suffer voltage-induced damage.

Accurate identification of the root cause is crucial for preventative maintenance and to avoid recurring faults.

Q 5. How do you differentiate between different types of cable damage?

Differentiating between various cable damage types relies heavily on the type of test used and the nature of the observed results. For example, a break in a fiber optic cable will produce a clear reflection on an OTDR trace, while a gradual degradation might show as attenuation along the fiber. A crack in the outer jacket of a fiber optic cable, not affecting the fiber itself, might not be detected by an OTDR but would be obvious through visual inspection.

With copper cables, a TDR might show a short circuit as a sharp reflection at a specific point, whereas an open circuit will be indicated by the absence of a signal beyond a specific point. Corrosion will often show as an increase in attenuation or impedance mismatch. A physical kink might be identified through visual inspection or a mechanical continuity test. Understanding the subtle differences between these various indicators requires experience and attention to detail.

Q 6. Explain your experience with fiber optic cable inspection.

My fiber optic cable inspection experience is extensive. I routinely use OTDRs to locate faults, assess attenuation, and measure optical return loss. I’m adept at interpreting OTDR traces to identify breaks, macrobends, microbends, splices, connectors, and other anomalies. This involves recognizing characteristic patterns in the trace to pinpoint the nature and location of faults. Additionally, I have considerable experience using fiber optic microscopes to visually inspect connectors and fiber end-faces for cleanliness, damage, or other issues affecting signal quality. For example, I recently helped troubleshoot a network outage that was eventually traced to a poorly cleaved fiber end-face causing excessive back reflection.

Beyond locating and identifying faults, I’m also proficient in performing optical loss testing to verify signal strength and attenuation levels across the entire fiber optic link. My work has involved single-mode and multi-mode fibers, with various connector types.

Q 7. Describe your experience with coaxial cable inspection.

My experience with coaxial cable inspection involves a combination of visual inspection, signal testing, and impedance measurements. Visual inspection is crucial for identifying physical damage such as crushing, kinking, or cuts in the outer jacket or shielding. I’ve used TDRs to detect shorts, opens, or impedance mismatches within the coaxial cable, and network analyzers to assess the signal quality and attenuation.

In practice, this has involved diagnosing signal loss on cable television networks, troubleshooting issues with antenna installations, and inspecting the integrity of in-building coaxial distribution systems. One memorable example was a case where a series of intermittent outages on a cable television network were ultimately traced to a series of poorly crimped connectors causing high impedance mismatch leading to signal degradation. The application of proper testing procedures allowed us to accurately identify and resolve these failures.

Q 8. How do you ensure the safety of yourself and others during cable inspection?

Safety is paramount in cable inspection. It’s not just about following procedures; it’s about a mindset. Before any inspection, I conduct a thorough site survey to identify potential hazards – things like overhead power lines, underground utilities, and uneven terrain. I always use appropriate personal protective equipment (PPE), including safety helmets, high-visibility clothing, safety glasses, and insulated gloves. When working near energized cables, I follow strict lockout/tagout procedures to ensure the power is completely de-energized. I also work with a buddy system whenever possible, ensuring someone is always aware of my location and can assist in case of an emergency. For inspections in confined spaces, I utilize gas detection equipment and follow confined space entry procedures. Communication is key; I make sure everyone on the site is aware of my activities and potential hazards.

Think of it like this: You wouldn’t climb a ladder without checking its stability first. The same principle applies to cable inspection. A systematic approach to safety prevents accidents and protects both myself and my colleagues.

Q 9. What are the industry standards and regulations you follow during cable inspections?

Cable inspections adhere to a range of industry standards and regulations, varying depending on the location and type of cable. These often include national electrical codes (like the NEC in the US), relevant OSHA standards (for workplace safety), and industry-specific best practices. For example, when inspecting telecommunications cables, I follow TIA standards. For power cables, I follow IEEE and IEC standards which detail inspection methodologies, testing procedures, and documentation requirements. These standards often specify acceptable levels of damage, degradation, and testing parameters. Compliance is meticulously documented, and all work is conducted in line with the relevant permits and licenses.

Imagine a building’s structural integrity – you wouldn’t just visually inspect it; specific tests and standards are followed to ensure safety. The same meticulous approach is vital for cable inspections to ensure reliability and safety.

Q 10. How do you document your findings from a cable inspection?

Thorough documentation is essential for accurate record-keeping and future reference. My documentation includes a detailed report containing the date, time, location, and purpose of the inspection. I use checklists to ensure consistency and avoid overlooking key aspects. Findings are meticulously recorded, including photos and video evidence of any damage, defects, or anomalies. I employ standardized forms with sections for cable specifications, test results (e.g., insulation resistance, attenuation), and a summary of conclusions and recommendations. All documentation is digitally stored and readily accessible, often utilizing specialized software for cable management and reporting.

Consider it like a doctor’s examination – a detailed record of the patient’s condition is vital for effective treatment and ongoing care. Similarly, thorough documentation enables effective cable maintenance and repair.

Q 11. Describe a time you had to troubleshoot a complex cable fault.

During a recent inspection of a high-voltage submarine cable, we experienced intermittent signal loss. Initial visual inspections revealed no obvious damage. Using a Time Domain Reflectometer (TDR), we identified a significant impedance mismatch approximately halfway along the cable’s length. This suggested a possible break or water ingress. We then deployed a remotely operated vehicle (ROV) equipped with an underwater camera and sonar to inspect the cable’s seabed section. The ROV revealed a small but critical section of the outer sheath had been compromised due to seabed erosion, allowing water ingress and causing the intermittent signal loss. The precise location allowed for targeted repairs, minimizing downtime and costly cable replacement.

This highlighted the power of using multiple diagnostic tools and a systematic approach to pinpoint the problem. It’s like solving a complex puzzle – each piece of information leads you closer to the solution.

Q 12. What is your experience with underground cable inspection techniques?

My experience with underground cable inspection techniques is extensive. I’m proficient in using various methods, including: Ground Penetrating Radar (GPR) to locate cable routes and identify potential damage; cable tracing equipment to pinpoint cable paths and identify breaks; and specialized cameras, often with pan and tilt capabilities, inserted into access points to inspect cable condition within conduits. I also have experience with traditional methods like excavation to expose sections of the cable for visual inspection, although this is a less preferred method due to the disruption it can cause. For high-voltage cables, I utilize specialized testing equipment to assess insulation integrity and detect potential faults before excavation is considered.

Imagine searching for a buried treasure. Underground cable inspection requires similar skill and careful utilization of specialized tools to locate and assess the condition of the cable without unnecessary disruption.

Q 13. How do you handle unexpected challenges during a cable inspection?

Unexpected challenges are a regular part of cable inspection. My approach is to remain calm, assess the situation systematically, and prioritize safety. If equipment malfunctions, I have backup equipment or alternative techniques ready. If I encounter unforeseen environmental conditions (e.g., severe weather), I will immediately halt the inspection and reassess the safety of proceeding. If a problem is beyond my expertise, I don’t hesitate to consult with colleagues or specialists. Open communication with all stakeholders is crucial; I keep them informed of any issues and their potential impact on the project timeline and budget.

Dealing with unexpected challenges is like navigating an unfamiliar road; flexibility, adaptability, and a well-thought-out plan are essential for reaching your destination safely and efficiently.

Q 14. Explain your understanding of cable splicing and termination techniques.

Cable splicing and termination are crucial for extending or connecting cables. I have extensive knowledge of both techniques. Splicing involves joining two cables of the same type, while termination involves preparing the cable end for connection to equipment. The process involves careful preparation, including stripping the insulation and jacket, cleaning the conductors, and correctly applying protective materials. The specific techniques vary widely depending on the cable type (e.g., coaxial, fiber optic, power), voltage level, and environmental conditions. For power cables, proper insulation and grounding are crucial to ensure safety and reliability. For fiber optic cables, precision alignment and proper fusion splicing or mechanical splicing are essential to maintain signal integrity. I always adhere to manufacturer’s specifications and industry best practices to ensure successful and reliable connections.

Imagine sewing two pieces of fabric together – the stitching must be precise and strong for a lasting result. The same level of care and precision is crucial for successful cable splicing and termination.

Q 15. How do you prioritize multiple cable inspection tasks?

Prioritizing cable inspection tasks requires a strategic approach balancing urgency, criticality, and resource availability. I typically employ a risk-based prioritization matrix. This involves assessing each task based on factors like the potential impact of a cable failure (e.g., network downtime, safety hazard), the likelihood of failure, and the cost of repair or replacement.

For instance, a high-voltage power cable supplying a critical hospital system would rank higher than a low-voltage data cable in a less critical building. I also consider the age of the cable, the environmental conditions it’s exposed to (e.g., underground, aerial, marine), and the history of previous maintenance. This matrix helps me to objectively rank and schedule inspections, ensuring that the most critical cables receive attention first, even with limited resources.

- High Priority: Critical infrastructure, aging cables, known issues.

- Medium Priority: Routine inspections, cables in moderately challenging environments.

- Low Priority: Newly installed cables, cables in benign environments, routine checks.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with different types of cable materials and their properties.

My experience encompasses a wide range of cable materials, each with distinct properties affecting their lifespan and performance. For example, copper is a common conductor due to its high conductivity, but it’s susceptible to corrosion. Aluminum, while lighter and cheaper, has higher resistance and is prone to oxidation. Fiber optic cables, on the other hand, offer high bandwidth and are immune to electromagnetic interference, but are sensitive to physical damage.

I’ve worked with various insulating materials as well, including polyethylene (PE), cross-linked polyethylene (XLPE), and ethylene propylene rubber (EPR). PE is cost-effective but less resistant to heat compared to XLPE or EPR, which are used in higher-temperature applications. Understanding these properties is vital for predicting cable lifespan and determining appropriate inspection intervals. For instance, cables installed in high-humidity environments might require more frequent inspections to check for corrosion.

Q 17. What is your understanding of cable attenuation and its significance?

Cable attenuation refers to the reduction in signal strength as it travels along the cable. It’s a crucial factor in communication and power systems. Attenuation is measured in decibels (dB) per unit length (e.g., dB/km). Several factors contribute to attenuation, including the cable’s material, frequency of the signal, and the cable’s physical condition. For example, water ingress in a coaxial cable can significantly increase attenuation, leading to signal loss and poor performance.

The significance of understanding attenuation lies in ensuring reliable signal transmission. Excessive attenuation necessitates amplification or signal regeneration, adding cost and complexity. During inspections, I measure attenuation levels using specialized equipment (e.g., OTDRs for fiber optics, TDRs for copper cables) to identify potential problems before they lead to complete signal failure. If attenuation exceeds acceptable thresholds, it signals the need for repair or cable replacement.

Q 18. How do you maintain accurate records of cable inspection data?

Maintaining accurate cable inspection records is paramount for efficient management and future planning. I use a combination of digital and physical methods. Each inspection is meticulously documented using a standardized format that includes the cable’s identification number, location, date of inspection, testing methods used, results (including images and videos), and any identified defects.

I utilize a dedicated database system, often linked to a Geographic Information System (GIS), to store all data. This allows for easy retrieval and analysis of information. Physical records, such as inspection reports and test results, are stored securely for audit trail and archival purposes. The digital system allows for quick searches and generates reports facilitating informed decision-making concerning maintenance schedules and potential upgrades. It is crucial to ensure data integrity and version control for future reference.

Q 19. What are the common signs of cable degradation?

Recognizing signs of cable degradation is crucial for preventative maintenance. Common signs include:

- Physical Damage: Cuts, abrasions, crushing, or excessive bending.

- Corrosion: Rust, pitting, or discoloration on metallic cables, indicating moisture ingress or chemical reactions.

- Deterioration of Insulation: Cracks, brittleness, or softening of the insulation material, often a result of age, heat exposure, or chemical attack.

- Excessive Attenuation: Significant signal loss, indicating internal damage or degradation of the cable’s conductive material.

- Unusual Heat: Excessively warm cables can point towards internal short circuits or excessive current flow.

- Water Ingress: Presence of moisture inside the cable, often accompanied by corrosion or insulation damage.

Observing these signs warrants further investigation, potentially requiring specialized testing to assess the cable’s condition and plan necessary interventions.

Q 20. How do you use cable maps and drawings during inspection?

Cable maps and drawings are essential tools during cable inspections. They provide a visual representation of the cable network’s layout, including the cable’s routing, termination points, and identifying markers. Before starting an inspection, I carefully review these documents to understand the cable’s path and anticipate potential challenges or access limitations.

For example, if the drawings indicate that a section of cable runs beneath a busy roadway, I would plan for appropriate safety measures. During the inspection, I use the maps to navigate to specific locations, confirming that the physical cable layout matches the design. Any discrepancies between the maps and the physical infrastructure are carefully noted and documented as this may indicate undocumented changes or inaccuracies in the original documentation which could be critical for future repairs or upgrades.

Q 21. Describe your experience with using GIS systems for cable management.

Geographic Information Systems (GIS) are invaluable for managing and visualizing cable networks. My experience involves using GIS to create and maintain accurate maps of cable infrastructure, including their location, type, and attributes. This allows for efficient planning and execution of inspections, maintenance, and repairs.

GIS also aids in identifying potential conflicts, such as planned construction projects or underground utilities, that could impact cable infrastructure. By integrating data from various sources (e.g., cable databases, utility maps), GIS provides a comprehensive view of the network, facilitating better decision-making regarding network expansion, upgrades, and troubleshooting. For example, locating a fault in an underground cable is significantly streamlined using GIS, and allows for informed excavation planning, preventing unnecessary damage to other utility lines.

Q 22. How familiar are you with various cable testing standards (e.g., TIA, IEC)?

My familiarity with cable testing standards is extensive. I’m proficient in both TIA (Telecommunications Industry Association) and IEC (International Electrotechnical Commission) standards, understanding their nuances and applications. TIA standards, such as TIA-568, are crucial for structured cabling systems in commercial buildings, focusing on aspects like cabling topology, testing procedures, and performance requirements. IEC standards, on the other hand, provide a broader international perspective, encompassing various cable types and applications, including power cables and fiber optics. I regularly consult both sets of standards to ensure my inspections adhere to the highest industry benchmarks and meet specific client requirements. For instance, I’ve utilized TIA-568 to troubleshoot connectivity issues in a large office complex, and employed IEC 60332-1-2 for fire resistance testing of power cables in an industrial setting. Understanding the differences between these standards allows me to select the most appropriate tests and interpret the results accurately.

Q 23. What are the safety precautions for working with high-voltage cables?

Safety is paramount when working with high-voltage cables. My approach always begins with a thorough risk assessment, identifying potential hazards specific to the cable type, voltage level, and the environment. This includes checking for proper lockout/tagout procedures to prevent accidental energization. Personal Protective Equipment (PPE) is critical, and this goes beyond just gloves. We use arc flash suits for high-voltage work, safety glasses, and insulated tools rated for the voltage level involved. Before commencing any work, I always verify the cable is de-energized using appropriate testing equipment and ensure the absence of residual voltage. Furthermore, I strictly follow all relevant safety regulations and company procedures, including regular training on safe work practices. Think of it like this: treating high-voltage cables with anything less than the utmost caution is like playing with fire—the consequences can be severe.

Q 24. Explain your experience with preventative cable maintenance.

Preventative cable maintenance is key to avoiding costly downtime and safety incidents. My experience involves a multi-pronged approach. This includes regular visual inspections to identify potential issues like physical damage, corrosion, or signs of overheating. I also utilize advanced testing equipment, such as Time Domain Reflectometers (TDRs) and Optical Time Domain Reflectometers (OTDRs), to detect faults that may not be visible to the naked eye. These technologies help pinpoint cable breaks, shorts, and other anomalies that could lead to failure. For example, during a preventative maintenance program for a telecommunications company, I identified a potential fault in an underground fiber optic cable using an OTDR, averting a costly service disruption. Beyond testing, I advise on best practices for cable routing, proper termination techniques, and environmental protection to extend the lifespan of the cables. It’s a proactive strategy – like regularly servicing a car to prevent major breakdowns.

Q 25. How do you communicate effectively with colleagues and clients during an inspection?

Effective communication is essential throughout the inspection process. With colleagues, I emphasize clear, concise reporting, using plain language and avoiding technical jargon unless absolutely necessary. Before starting an inspection, I clearly outline the scope of work and the expected timeline. During the inspection, I maintain open communication, updating colleagues on progress and any unexpected findings. With clients, I tailor my communication to their level of technical understanding. I present findings in a clear, understandable manner, using visuals like diagrams and photographs when helpful. Crucially, I prioritize active listening, allowing clients to express their concerns and ensuring they understand the implications of my findings. For example, I once had to explain complex TDR results to a non-technical client by using an analogy of a traffic jam on a highway to illustrate cable signal disruptions. Transparency and clear communication build trust and foster strong working relationships.

Q 26. How do you stay updated on the latest advancements in cable inspection technology?

Staying current in this field requires continuous learning. I actively participate in industry conferences and workshops, attending seminars on new technologies and best practices. I subscribe to relevant industry journals and online publications, keeping abreast of advancements in cable inspection methodologies and equipment. I also actively engage in online forums and professional networks to learn from and collaborate with other experts in the field. This constant pursuit of knowledge allows me to adopt new technologies and techniques, optimizing my inspection efficiency and accuracy. For instance, I recently completed training on using a new type of fiber optic inspection camera that offers significantly improved image quality, allowing me to identify defects more quickly and easily.

Q 27. Describe your experience working in diverse environmental conditions (e.g., extreme temperatures, wet conditions).

I have extensive experience working in diverse and challenging environments. This ranges from working in extreme heat and humidity, requiring careful management of equipment and personal hydration, to working in sub-zero temperatures where equipment needs protection from freezing and workers need appropriate thermal protection. I’ve navigated wet and muddy conditions, employing measures to protect equipment from water damage and ensuring personal safety. Safety precautions are always adjusted depending on the specific environmental factors, and proper planning is crucial to ensure the safety and success of the inspection. For example, while inspecting cables in a flooded underground conduit, I implemented specific safety measures including using waterproof equipment and ensuring that all personnel wore protective gear to guard against electric shock and exposure to hazardous materials.

Q 28. How do you ensure the accuracy and reliability of your cable inspection reports?

Ensuring the accuracy and reliability of my reports is a top priority. This starts with meticulous data collection, double-checking readings and ensuring all equipment is calibrated and functioning correctly. I meticulously document every step of the inspection process, including the equipment used, testing methods applied, and observed conditions. All data is recorded in a standardized format, reducing the risk of error and facilitating easy analysis. The report itself is structured logically, presenting findings in a clear, concise manner with supporting evidence – photographs, diagrams, and raw data. Furthermore, I conduct a thorough review of the report before submission, ensuring accuracy and consistency. This meticulous approach allows clients to confidently rely on the findings and make informed decisions based on my assessment. It’s similar to a scientific experiment; thorough documentation and rigorous analysis are essential to ensure the reliability of the results.

Key Topics to Learn for Cable Inspection Interview

- Cable Types and Properties: Understanding different cable types (coaxial, fiber optic, etc.), their construction, and their respective strengths and weaknesses. This includes knowledge of materials used and their impact on signal transmission.

- Testing and Measurement Techniques: Familiarize yourself with various testing methods used in cable inspection, including OTDR (Optical Time Domain Reflectometry), TDR (Time Domain Reflectometry), and signal level testing. Understand how to interpret the results and identify potential faults.

- Fault Identification and Troubleshooting: Develop your skills in diagnosing common cable faults such as breaks, shorts, attenuation, and signal interference. Practice problem-solving approaches to identify the root cause of issues and propose effective solutions.

- Safety Procedures and Regulations: Demonstrate knowledge of relevant safety standards and regulations concerning cable inspection, including working at heights, handling specialized equipment, and adhering to industry best practices.

- Reporting and Documentation: Understand the importance of clear and accurate reporting. Practice documenting your findings using industry-standard formats and providing concise, well-supported conclusions.

- Network Topologies and Protocols: A basic understanding of network architectures (e.g., star, ring, mesh) and relevant protocols will demonstrate a broader understanding of the cable’s role within a larger system.

Next Steps

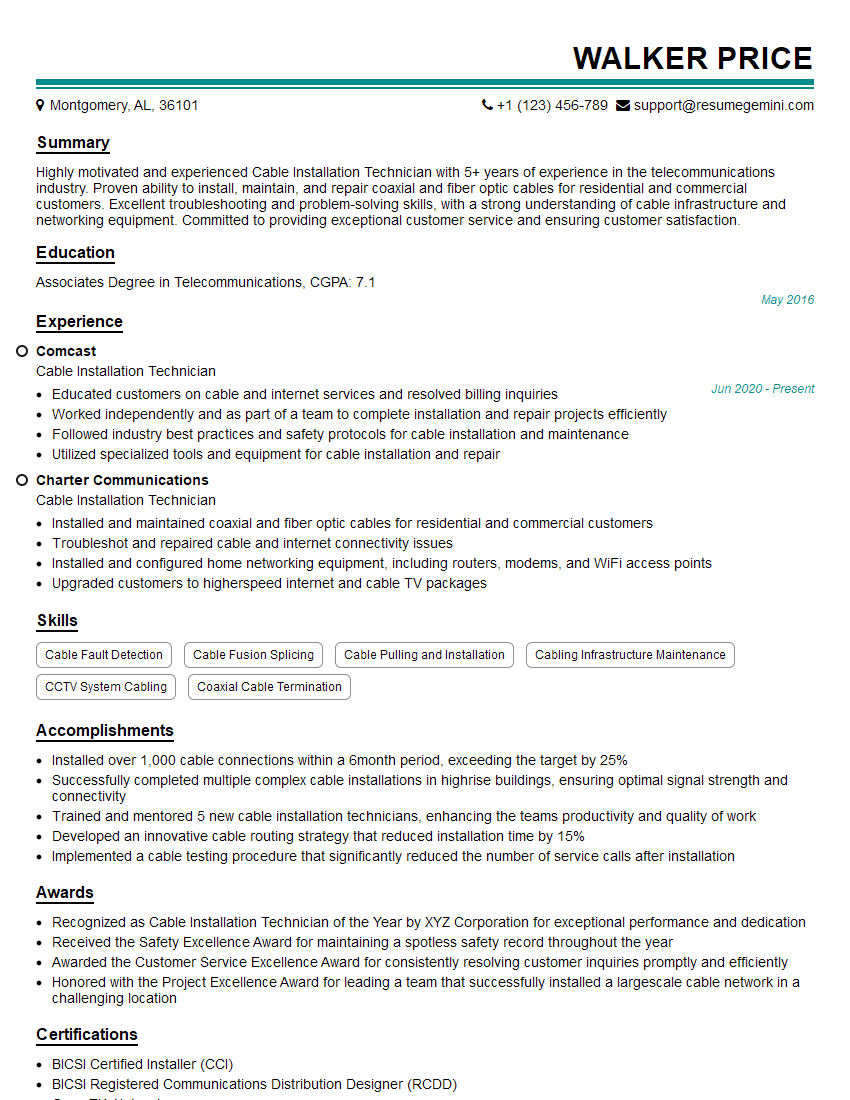

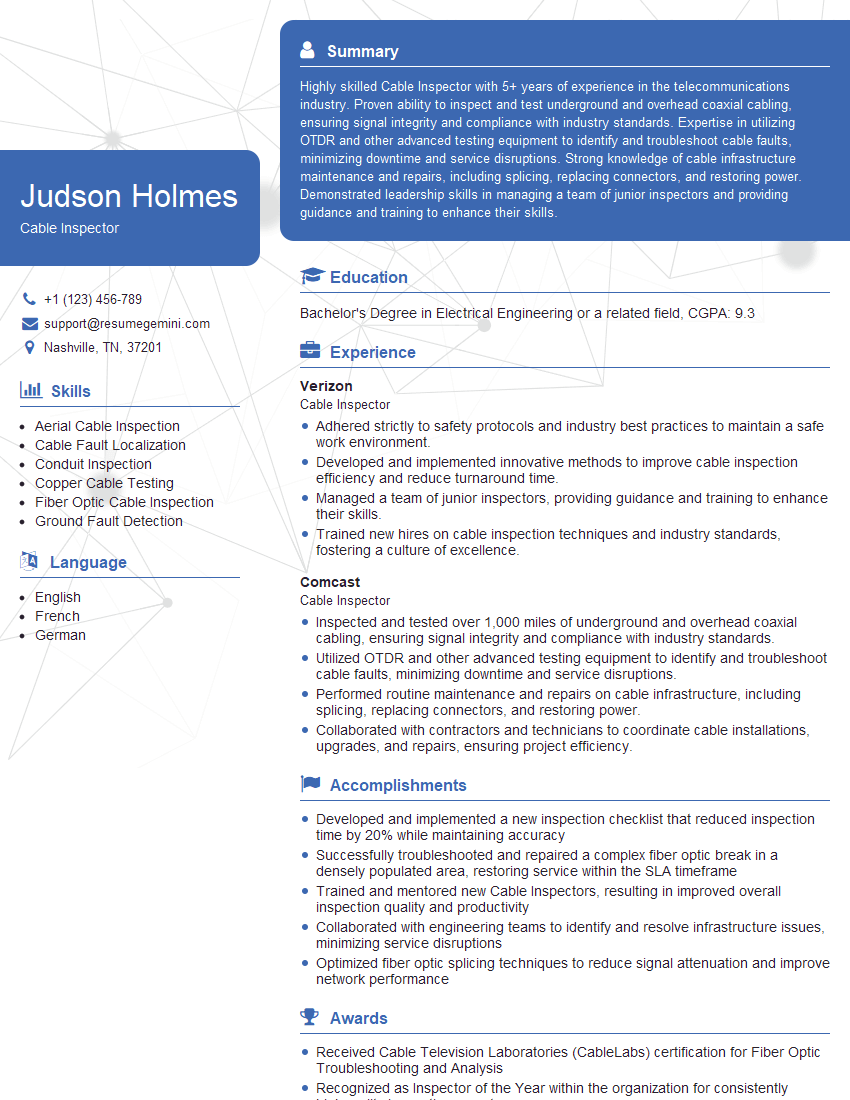

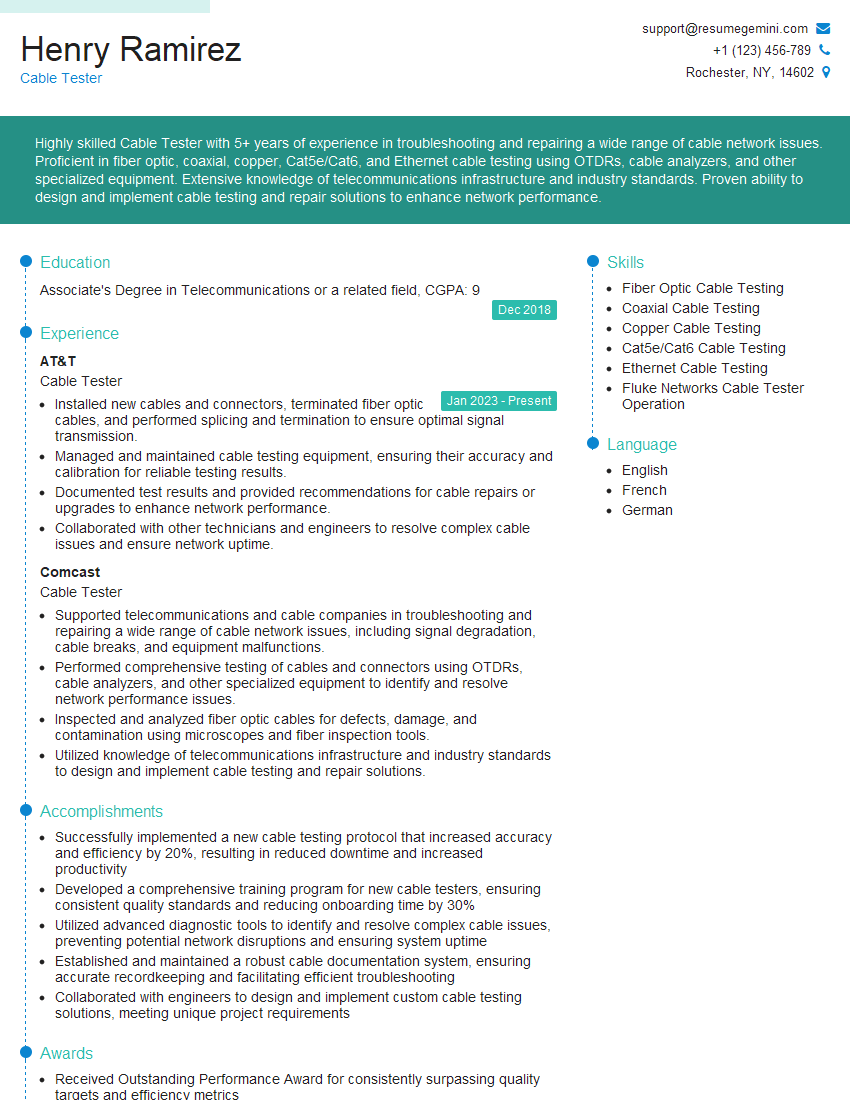

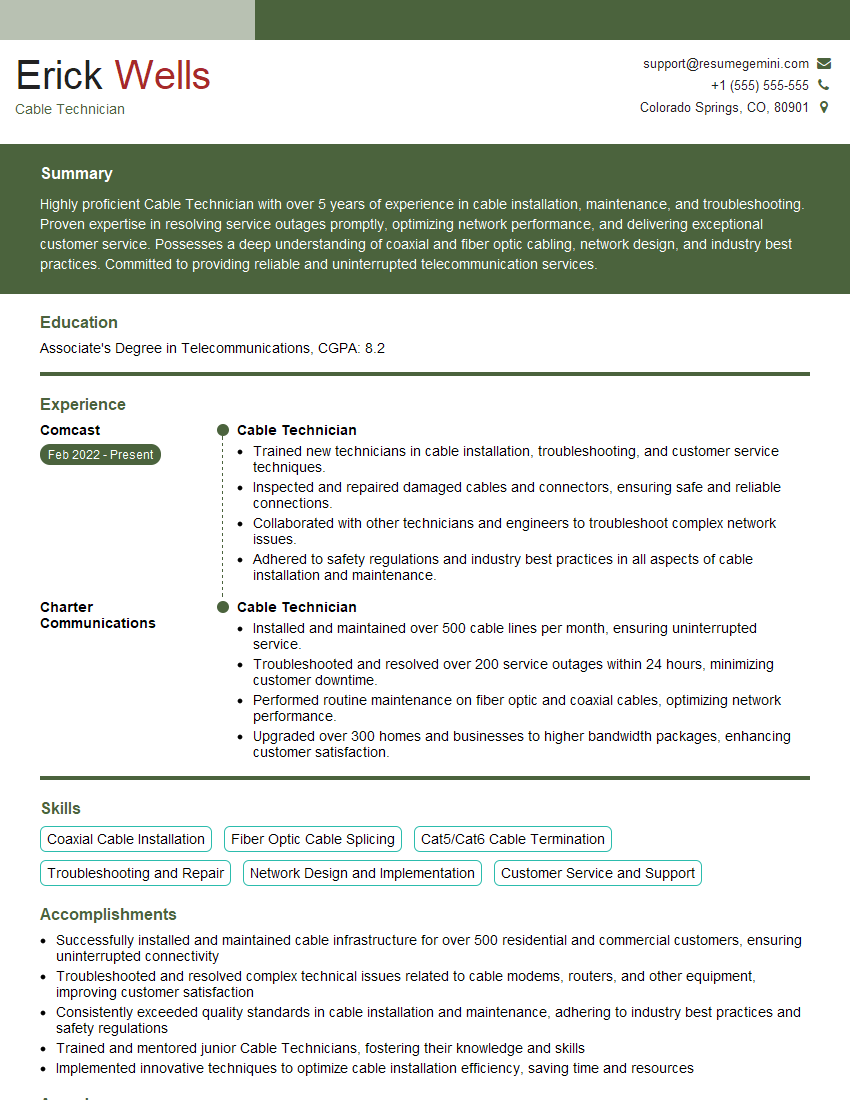

Mastering cable inspection opens doors to a rewarding career with excellent growth potential in the telecommunications and infrastructure sectors. To maximize your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume that stands out from the competition. We provide examples of resumes tailored to Cable Inspection to help you get started. Invest the time in crafting a strong resume – it’s your first impression with potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good