Unlock your full potential by mastering the most common Cable Terminating interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Cable Terminating Interview

Q 1. Explain the difference between TIA/EIA 568A and 568B wiring standards.

TIA/EIA 568A and 568B are wiring standards for twisted-pair cables, most commonly used in Ethernet networks. They define the color order of the wires within the cable, which is crucial for proper signal transmission. The difference lies in the arrangement of the orange and green pairs at the ends of the cable. Think of it like this: both standards use the same ingredients, but they arrange them differently in the recipe. This impacts how the cable transmits data, and using the wrong standard will result in connectivity issues.

- 568A: The order is: White/Green, Green, White/Orange, Blue, White/Blue, Orange, White/Brown, Brown.

- 568B: The order is: White/Orange, Orange, White/Green, Blue, White/Blue, Green, White/Brown, Brown.

Choosing between 568A and 568B is usually a matter of consistency. It’s critical to use the *same* standard at both ends of the cable. Mixing them will result in a non-functioning connection. In most installations, 568B is the more commonly used standard.

Q 2. Describe the process of terminating a CAT5e cable.

Terminating a CAT5e cable involves preparing the cable and connecting it to a keystone jack or punch-down block. It’s a precise process requiring care to avoid signal interference and ensure reliable connectivity. Improper termination leads to slow speeds or connection drops.

- Cut and Strip: Cut the cable to the desired length and carefully strip the outer sheath, exposing the twisted pairs. Be careful not to nick the wires.

- Untwist and Straighten: Untwist the pairs slightly, but only about ½ inch. Keep the pairs neatly arranged, this prevents crosstalk.

- Arrange the Wires: Arrange the wires according to your chosen standard (568A or 568B). Using a punch-down tool, carefully insert each wire into the appropriate slot of your jack or block, ensuring each wire is fully seated.

- Punch Down: Using the punch-down tool, firmly press each wire into its corresponding slot. This crimps the wire and creates a secure connection.

- Test and Verify: After terminating both ends of the cable, use a cable tester to verify continuity and proper wiring. This step is absolutely crucial to ensure your termination is successful.

Remember to always use the correct tool for the job! A poorly terminated cable can lead to signal loss and significant networking problems.

Q 3. What tools are required for terminating a fiber optic cable?

Terminating fiber optic cables is a more delicate process than copper cable termination, requiring specialized tools to avoid damage to the fiber. Improper termination can lead to significant signal loss and network outages.

- Fiber Optic Cleaver: Creates a precise, perpendicular cut on the fiber optic cable end. A poorly cleaved end will result in signal degradation.

- Fiber Optic Splice Kit (for splicing): Includes tools for precisely aligning and fusing two fiber optic cables together.

- Fiber Optic Connectors (SC, ST, LC, etc.): These connectors are used to terminate the cable ends. Each connector type requires specific tools and procedures.

- Fiber Optic Polishing Kit: Used to polish the connector end to ensure proper coupling. Imperfect polishing will increase signal loss.

- Optical Power Meter: Used to measure the strength of the optical signal passing through the cable.

- Fiber Optic Identifier: Used to identify the type of fiber and to test the cable.

It’s essential to use extreme caution when handling fiber optic cables. Always wear appropriate safety glasses, as the glass fibers can cause serious eye injuries.

Q 4. How do you test cable continuity and identify shorts?

Testing cable continuity and identifying shorts involves using a cable tester. These testers send a signal through the cable and measure the return signal to identify any breaks, shorts, or miswiring.

A simple cable tester will show you a visual indication of continuity (typically lights or beeps). More advanced testers can pinpoint the exact location of faults. For example, a short will show up as a failure of continuity between certain pairs in the cable, while an open circuit will not show any signal at all.

Identifying shorts often requires a visual inspection of the wiring along with the cable tester results. You might find a wire touching another wire unexpectedly.

Think of it like testing electrical wiring in your house. A continuity tester verifies that the wire is continuous and unbroken, while detecting shorts identifies areas where the circuit is unintentionally completed.

Q 5. Explain the importance of proper cable management.

Proper cable management is crucial for a number of reasons: it prevents signal interference, enhances network performance, reduces the risk of damage, and improves overall organization. A messy cable installation is a nightmare to troubleshoot and maintain.

- Improved Network Performance: Properly managed cables minimize crosstalk and signal attenuation, ensuring optimal data transmission speeds.

- Reduced Risk of Damage: Organized cables are less likely to be tripped over, damaged, or accidentally disconnected.

- Easier Troubleshooting: Well-organized cables make troubleshooting much simpler and faster. Finding a specific cable in a well-managed system is a breeze compared to searching through a tangled mess.

- Enhanced Safety: Properly managed cables reduce the risk of tripping hazards and electrical shocks.

- Improved Aesthetics: A neat and organized cable installation presents a more professional and visually appealing appearance.

In a data center environment, proper cable management is critical. It’s not just about aesthetics; it’s about ensuring uptime and preventing costly downtime. A well-managed cable system reduces the risk of failures and makes maintenance easier.

Q 6. What are the common causes of cable termination failures?

Cable termination failures can stem from several sources, often due to human error during the termination process. Here are some common causes:

- Incorrect Wire Order: Using the wrong wiring standard (568A vs. 568B) or incorrect wire placement in the jack or block.

- Improper Crimping: Insufficient crimp pressure, resulting in a loose connection and signal loss.

- Damaged Wires: Nicked or broken wires during the stripping process. This can lead to intermittent connections or complete failure.

- Poorly Cleaved Fiber (for fiber optic cables): An improperly cleaved fiber end will lead to significant signal loss.

- Dirty or Damaged Connectors: Dust, debris, or physical damage to connectors will impede signal transmission.

- Excessive Bending Radius: Bending the cable too sharply can damage the internal wires and cause signal loss.

Careful attention to detail and the use of the appropriate tools will minimize the chances of termination failures. Always double-check your work!

Q 7. How do you troubleshoot a faulty network connection?

Troubleshooting a faulty network connection requires a systematic approach. Start with the most obvious and work your way down to more complex issues.

- Check the Physical Connection: Ensure that the cable is securely plugged into both ends and that there is no physical damage to the cable or connectors.

- Test the Cable: Use a cable tester to verify continuity and identify shorts or open circuits.

- Check the Devices: Ensure that the devices at both ends of the connection (e.g., computers, switches, routers) are powered on and functioning correctly.

- Examine Network Configuration: Verify the IP address, subnet mask, and default gateway settings on the devices involved. Check for any conflicting IP addresses.

- Test with a Different Cable and Device: Try substituting a known good cable and device to isolate the problem.

- Consult Network Documentation: Review network diagrams and documentation to identify potential problems within the network infrastructure.

- Use Network Monitoring Tools: Use network monitoring tools to diagnose network traffic, latency, and other performance metrics.

Troubleshooting network issues often involves a mix of physical inspection, testing, and configuring network settings. A methodical approach will save time and help you efficiently solve the problem.

Q 8. Describe your experience with different types of connectors (e.g., RJ45, SC, ST).

My experience encompasses a wide range of connectors used in various cabling systems. I’m proficient with RJ45 connectors, the ubiquitous standard for Ethernet networks. I understand the importance of proper termination, including the T568A and T568B wiring standards, to ensure reliable data transmission. Beyond RJ45, I’ve worked extensively with fiber optic connectors like SC and ST. These connectors, used in high-bandwidth applications, require precision and cleanliness during termination to avoid signal loss. I understand the differences between single-mode and multi-mode fiber and the specific termination techniques for each. My experience also includes working with other connector types such as BNC connectors for coaxial cables used in video and RF applications. Each connector type demands a unique approach to ensure proper connection and signal integrity. For example, with SC and ST connectors, the cleanliness of the fiber end faces is critical for a proper connection, and the use of cleaning tools and procedures are essential. With RJ45, ensuring the correct wire placement is key to maintain network speed and avoid connectivity issues.

Q 9. What are the safety precautions you take when working with cables?

Safety is paramount in cable termination. Before starting any work, I always ensure the power is disconnected from the equipment to prevent electrical shock. I use appropriate personal protective equipment (PPE), including safety glasses to protect my eyes from flying debris during crimping, and gloves to protect my hands from cuts and abrasions. When working with fiber optic cables, I take extra precautions, using safety glasses specifically designed to protect against laser light, especially during testing and cleaning, and avoid looking directly into the fiber end faces. Proper grounding techniques are essential to prevent static electricity discharge that could damage sensitive equipment. Finally, I always maintain a clean and organized workspace to prevent tripping hazards and improve overall safety.

Q 10. How do you identify different types of cables (e.g., coaxial, fiber optic, twisted pair)?

Identifying different cable types involves examining several characteristics. Coaxial cables, often used for video and RF signals, are identified by their characteristic round shape with a central conductor surrounded by an insulating layer, a braided shield, and an outer jacket. Fiber optic cables are typically thinner and have a protective outer sheath that hides glass or plastic fibers. Twisted pair cables are recognized by their multiple pairs of insulated wires twisted together to reduce electromagnetic interference (EMI). Each type might have color-coding or markings on the jacket, indicating the cable’s gauge, application and manufacturer, for easier identification. For example, I would differentiate between Cat5e, Cat6, and Cat6a twisted-pair cables based on the printed markings on their outer jackets and their performance characteristics. Understanding these visual cues and knowing the applications of each cable type is essential for quick and accurate identification.

Q 11. Explain the concept of impedance matching in cable termination.

Impedance matching is crucial for efficient signal transmission. It’s the process of ensuring the characteristic impedance of the cable is matched to the impedance of the source and load. Mismatched impedance leads to signal reflections, reducing signal strength, and potentially causing signal distortion. This means that if a cable has a characteristic impedance of 50 ohms (common in coaxial cables), the equipment at both ends should also have a 50-ohm impedance to prevent signal loss. For example, if you’re connecting a 50-ohm antenna to a receiver with a 75-ohm input, you might see significant signal loss and distortion. Using proper terminators at the end of the cable that match the cable’s impedance is critical to avoid signal reflections.

Q 12. What is the significance of cable shielding and grounding?

Cable shielding and grounding are critical for minimizing electromagnetic interference (EMI) and radio frequency interference (RFI). Shielding, usually a braided metal layer or foil, surrounds the cable conductors to prevent external electromagnetic fields from affecting the signal. Grounding provides a low-impedance path for any stray currents, further reducing interference. Effective shielding and grounding ensure signal integrity and protect sensitive equipment from damage. Imagine a network cable running alongside a high-voltage power line; without proper shielding and grounding, the power line’s electromagnetic field could interfere with the network signal, resulting in data loss or connectivity issues.

Q 13. How do you handle different cable gauges?

Different cable gauges, indicated by AWG (American Wire Gauge) numbers, represent the thickness of the wire. Lower AWG numbers indicate thicker wires with lower resistance and higher current carrying capacity. Handling different gauges requires using appropriate tools and techniques. Thicker gauges require more force during crimping, while thinner gauges can be easily damaged with excessive force. Choosing the right crimping tool for each cable gauge is very important to prevent damage and ensure a secure connection. For example, I would use a different crimping tool for a 22 AWG cable (often used in electronics) than for a 12 AWG cable (used for high-current applications).

Q 14. Describe your experience with crimping tools and punch-down tools.

I’m experienced with various crimping tools and punch-down tools. Crimping tools are used to securely connect connectors to cables, ensuring a reliable electrical connection. Different types of crimping tools exist, each designed for specific connector types and cable sizes. Punch-down tools are used to terminate cables in modular jacks and patch panels. I understand the importance of using the right tool for each job and how to maintain these tools in good working condition, ensuring the blades stay sharp and accurate for clean, secure terminations. In my experience, proper tool maintenance is paramount for achieving consistent and reliable connections in any cable termination tasks. A dull blade can lead to poor connections and signal degradation.

Q 15. What is your experience with fiber optic splicing?

Fiber optic splicing is a crucial part of my work. It involves precisely joining two fiber optic cables to create a continuous optical path with minimal signal loss. My experience encompasses various splicing techniques, including fusion splicing and mechanical splicing. Fusion splicing, my preferred method, uses an electric arc to melt and fuse the fiber ends, creating a strong and precise connection. I’ve worked with numerous fiber types, including single-mode and multi-mode, and have consistently achieved splice losses well below industry standards. For example, on a recent project involving the installation of a new fiber optic network for a large data center, I successfully spliced over 200 fiber connections, all within the required loss budget. I’m proficient in using various fusion splicers and understand the importance of proper cleaving, alignment, and testing procedures to ensure high-quality splices.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you test fiber optic cable continuity and attenuation?

Testing fiber optic cable continuity and attenuation is critical to ensure network functionality. Continuity testing verifies a complete physical path exists. I typically use an Optical Time Domain Reflectometer (OTDR) for this. An OTDR sends a light pulse down the fiber and measures the time it takes for the light to return, revealing any breaks or significant discontinuities. Attenuation testing measures signal loss over the fiber’s length. This is also done with an OTDR, which analyzes the signal strength at various points along the fiber. High attenuation indicates problems like bending, poor connections, or fiber damage. For instance, if an OTDR shows a sudden drop in signal strength at a specific point, it suggests a break or a poorly made splice requiring repair. I’m experienced in interpreting OTDR results and troubleshooting problems based on their analysis.

Q 17. Explain the difference between single-mode and multi-mode fiber optic cables.

Single-mode and multi-mode fiber optic cables differ in their core size and the number of light paths they support. Single-mode fiber has a smaller core diameter (around 9 microns) and only allows a single light path to propagate. This allows for longer transmission distances with minimal signal degradation because of less modal dispersion. Think of it like a single-lane highway – all the traffic travels in one direction. Multi-mode fiber has a larger core diameter (50/125 microns or 62.5/125 microns) and supports multiple light paths, allowing more light to travel but leading to higher signal dispersion and thus shorter transmission distances. It’s like a multi-lane highway, with different paths leading to more signal scattering. Single-mode is ideal for long-haul networks and high-bandwidth applications, while multi-mode is often used in shorter-distance applications like local area networks.

Q 18. What are the common types of cable faults and how to repair them?

Common cable faults include breaks, poor splices, excessive bending, and connector issues. A break is indicated by a complete loss of signal, often detectable via an OTDR. A poor splice results in high attenuation at the splice point, again easily seen on an OTDR trace. Excessive bending can cause micro-bends that increase attenuation and signal degradation. Connector issues may manifest as high insertion loss or inconsistent connections. Repairing breaks usually involves splicing or replacing the damaged section. Poor splices are corrected by recleaving the fibers and re-splicing. Excessive bending needs to be rectified by careful cable routing. Connector issues are fixed through cleaning, re-termination, or replacing damaged connectors. For example, I once encountered a network outage due to a fiber break caused by rodent damage. Using my OTDR, I pinpointed the break, spliced the cables, and restored service quickly.

Q 19. Describe your experience with cable labeling and documentation.

Proper cable labeling and documentation are crucial for maintainability and troubleshooting. My experience includes using a variety of labeling methods, from heat-shrink labels to printed labels, ensuring clear and consistent information on each cable. I document everything meticulously, including cable paths, splice locations, connector types, and test results. This documentation often utilizes drawings, spreadsheets, and databases for easy reference. For instance, on a large-scale project, I used a specialized cable management software to map the entire network, ensuring traceability and ease of maintenance. Clear labeling and documentation ensure quick identification and prevent delays in troubleshooting.

Q 20. How do you ensure proper cable strain relief?

Proper cable strain relief is essential to prevent damage to the fiber cable and connectors. I utilize various techniques, including using strain relief clamps, properly secured cable ties, and managing cable bends. Over-bending or sharp bends can weaken the fiber and introduce micro-bends causing signal degradation and loss. At termination points, I ensure proper strain relief boots are installed. I’ve often seen issues resulting from inadequate strain relief, which can lead to costly repairs and service disruptions. My experience ensures that each installation includes appropriate strain relief measures to protect the cables’ integrity and prevent future problems.

Q 21. What is your experience with different types of cable testing equipment?

My experience encompasses a wide range of cable testing equipment. This includes OTDRs for testing continuity and attenuation, optical power meters for measuring optical signal strength, optical light sources for injecting light into the fiber, and visual fault locators (VFLs) for quickly locating breaks or problems in the fiber. I’m also proficient with various types of connector testers to ensure proper connector performance. For example, I’ve used OTDRs from different manufacturers, each with unique features, to troubleshoot complex network problems. Familiarity with a variety of equipment is important to adapt to different situations and provide effective solutions.

Q 22. How do you manage your time effectively during a cable termination project?

Effective time management in cable termination projects hinges on meticulous planning and execution. I begin by thoroughly reviewing the project specifications, identifying all necessary materials and tools, and creating a detailed schedule. This schedule isn’t just a list of tasks; it incorporates buffer time for unexpected delays – a crucial element given the intricacies of cable termination. I break down large tasks into smaller, manageable units, allowing for regular progress checks and adjustments as needed. For example, instead of simply listing ‘Terminate 100 fiber optic cables,’ I’d break it down into ‘Prepare 100 connectors,’ ‘Clean and inspect fibers,’ ‘Fuse connectors,’ ‘Test connections,’ and finally ‘Document and label.’ This granular approach enables better tracking and resource allocation. Utilizing project management tools, like Kanban boards or Gantt charts, further enhances visibility and allows for proactive problem-solving. Finally, consistent communication with the team and stakeholders ensures everyone is aligned and any potential roadblocks are addressed promptly.

Q 23. Describe a challenging cable termination project you’ve worked on and how you overcame it.

One particularly challenging project involved terminating high-density fiber optic cables in a live data center environment. The tight deadlines, limited space, and the critical nature of the operation presented significant hurdles. The initial challenge was navigating the existing infrastructure without disrupting ongoing operations. We mitigated this by working during off-peak hours and implementing strict safety protocols to prevent accidental disconnections or damage to live equipment. Another obstacle was the high density of the cables; it was a complex maze requiring precise planning and execution to avoid mistakes. To overcome this, we utilized advanced fiber optic management tools and techniques, such as pre-terminated cable assemblies where possible and color-coded labeling for clear identification. We also employed a rigorous quality control process, testing each connection individually with an optical time-domain reflectometer (OTDR) to ensure signal integrity. This methodical approach, coupled with excellent teamwork, allowed us to successfully complete the project on time and without any disruptions to the data center’s operations.

Q 24. Explain your understanding of network topologies and their impact on cable termination.

Understanding network topologies is fundamental to effective cable termination. Different topologies directly impact cable requirements, termination methods, and overall network performance. For instance, a star topology, common in Ethernet networks, requires a central hub or switch with numerous cables radiating outwards. Termination in this scenario focuses on connecting each individual device to the central point, requiring careful labeling and consistent standards to ensure easy troubleshooting. In contrast, a ring topology, often used in fiber optic networks, involves a closed loop of connections. This necessitates careful consideration of redundancy and the use of specialized termination techniques to minimize signal loss. A mesh topology, offering high redundancy, requires even more extensive cabling and termination, demanding a deep understanding of routing protocols. Incorrect cable termination in any topology can lead to signal degradation, network outages, or even data loss. The choice of cabling (e.g., twisted pair, coaxial, fiber optic) is also directly influenced by the topology and the network’s bandwidth requirements. Therefore, a thorough understanding of network topologies is essential for efficient and effective cable termination.

Q 25. How do you stay updated on the latest cable termination technologies and standards?

Staying updated in this rapidly evolving field requires a multi-faceted approach. I actively participate in professional organizations like BICSI (Building Industry Consulting Service International), attending conferences and webinars to learn about the latest standards and best practices. I subscribe to industry-leading publications and online resources that provide insights into new technologies and advancements. Moreover, I regularly review updated standards documents from organizations such as TIA (Telecommunications Industry Association) and ISO (International Organization for Standardization) to ensure compliance with current regulations. Hands-on experience through continued project work and exposure to diverse cabling systems also plays a vital role in maintaining my expertise.

Q 26. What are your strengths and weaknesses in cable termination?

My strengths lie in my meticulous attention to detail, my problem-solving abilities, and my proficiency in a wide range of cable termination techniques, encompassing copper and fiber optic systems. I’m adept at troubleshooting complex network issues and efficiently managing multiple projects simultaneously. However, my weakness, if I had to identify one, is perhaps my tendency to be overly thorough, which can sometimes lead to slightly longer completion times. I’m actively working to balance this thoroughness with optimized efficiency through improved project planning and time management strategies.

Q 27. Why are you interested in this cable termination position?

I’m highly interested in this cable termination position because it aligns perfectly with my skills and experience. I’m drawn to the opportunity to contribute to a team focused on delivering high-quality, reliable network infrastructure. I’m particularly enthusiastic about the prospect of working on [mention specific projects or technologies mentioned in the job description]. The company’s reputation for innovation and its commitment to best practices strongly resonate with my professional values. I believe my meticulous approach, problem-solving abilities, and commitment to continuous learning will make me a valuable asset to your team.

Q 28. What are your salary expectations?

My salary expectations are in the range of $[lower bound] to $[upper bound] annually, depending on the comprehensive benefits package and the specifics of the role. I’m confident that my skills and experience justify this range, and I’m open to discussing this further based on a more detailed understanding of the position and the company’s compensation structure.

Key Topics to Learn for Cable Terminating Interview

- Cable Types and Properties: Understanding different cable types (coaxial, fiber optic, twisted pair), their applications, and properties (impedance, attenuation, bandwidth) is crucial. Be prepared to discuss the advantages and disadvantages of each.

- Termination Techniques: Master various termination methods, including crimping, soldering, and connectorization. Practice explaining the steps involved in each technique and the importance of precision.

- Testing and Troubleshooting: Familiarize yourself with common testing equipment (e.g., OTDR, TDR) and troubleshooting techniques for identifying and resolving cable faults. Be ready to describe your problem-solving approach in a practical scenario.

- Safety Procedures: Demonstrate a thorough understanding of safety protocols related to cable handling, termination, and testing. This includes proper use of personal protective equipment (PPE) and adherence to industry standards.

- Industry Standards and Codes: Be aware of relevant industry standards and codes of practice that govern cable termination procedures. Understanding these ensures compliance and quality workmanship.

- Network Topologies and Cabling Systems: Show your understanding of different network topologies (star, ring, bus) and how cable termination fits within the overall cabling infrastructure.

- Documentation and Reporting: Understand the importance of accurate documentation and reporting procedures related to cable termination projects. This often involves maintaining detailed records of cable installations and testing results.

Next Steps

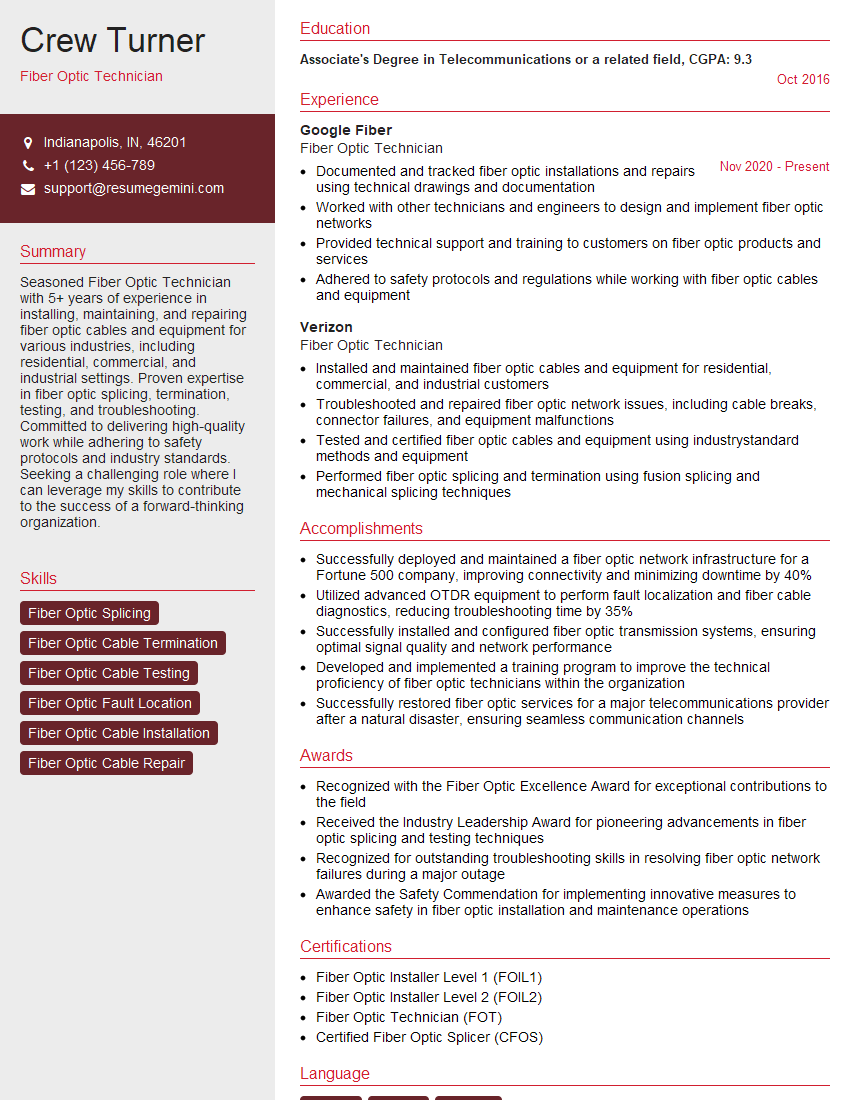

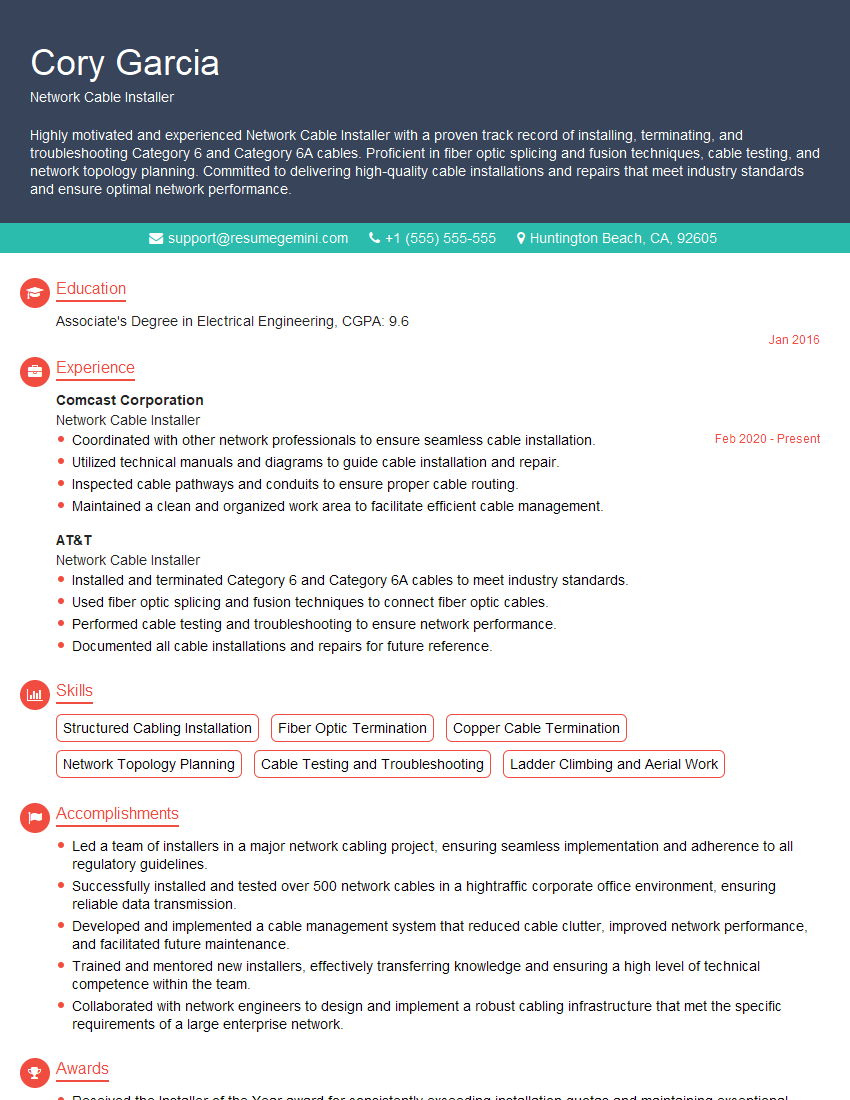

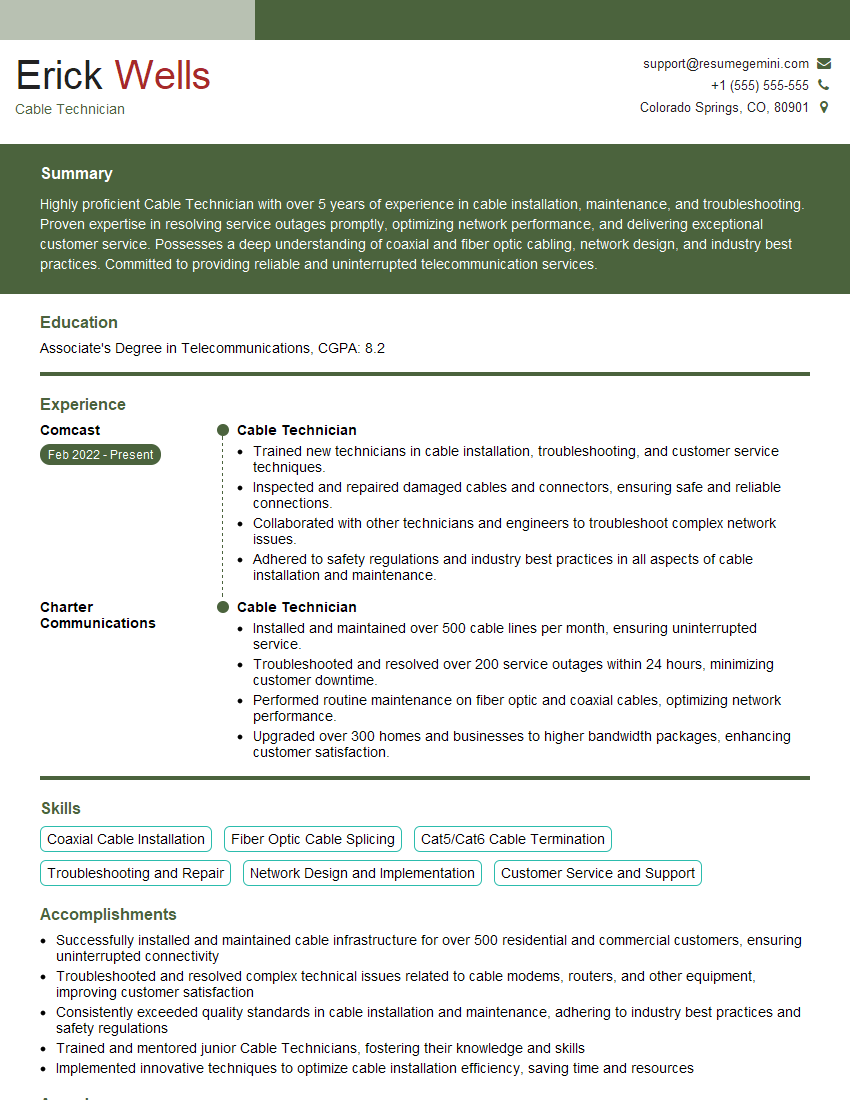

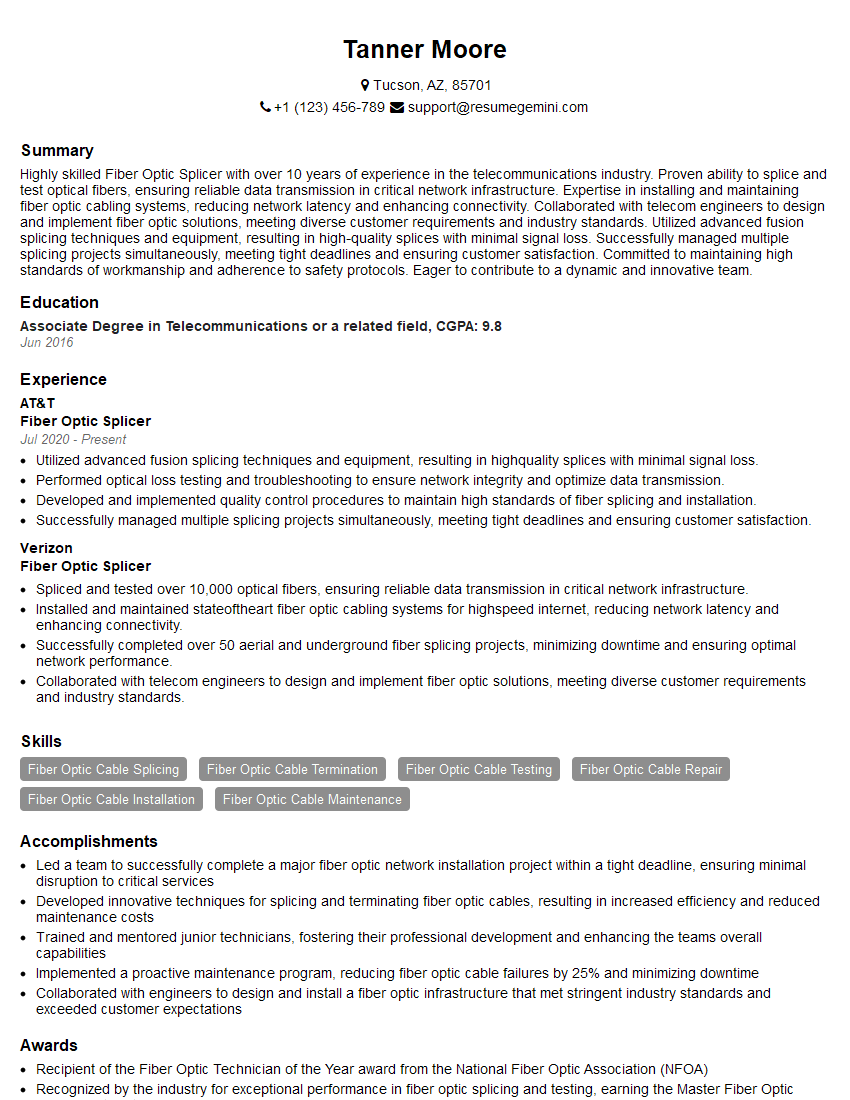

Mastering cable termination opens doors to exciting career opportunities in telecommunications, networking, and data center infrastructure. A strong foundation in this skillset is highly valued by employers. To maximize your job prospects, create a compelling and ATS-friendly resume that highlights your skills and experience. ResumeGemini is a trusted resource to help you build a professional resume that showcases your abilities effectively. Examples of resumes tailored to the Cable Terminating field are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good